Multi-joint spine and spine four-foot robot

A quadruped robot, multi-joint technology, applied in the field of robotics, can solve the problems of inability to bend the torso, limited movement speed and flexibility, and inconsistency with biological movement patterns, so as to increase operability and enrich the diversity of bending shapes. , the effect of increasing running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

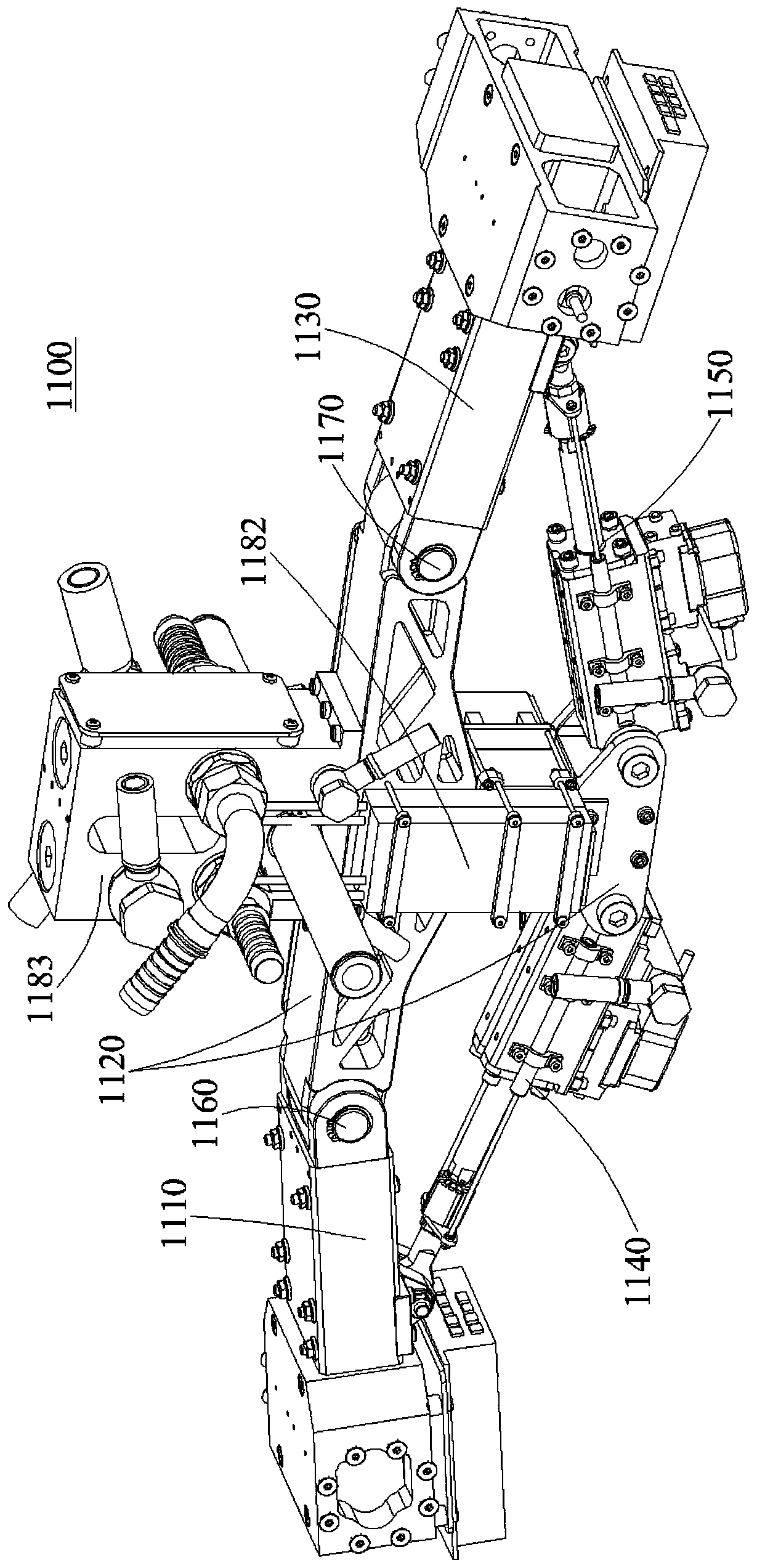

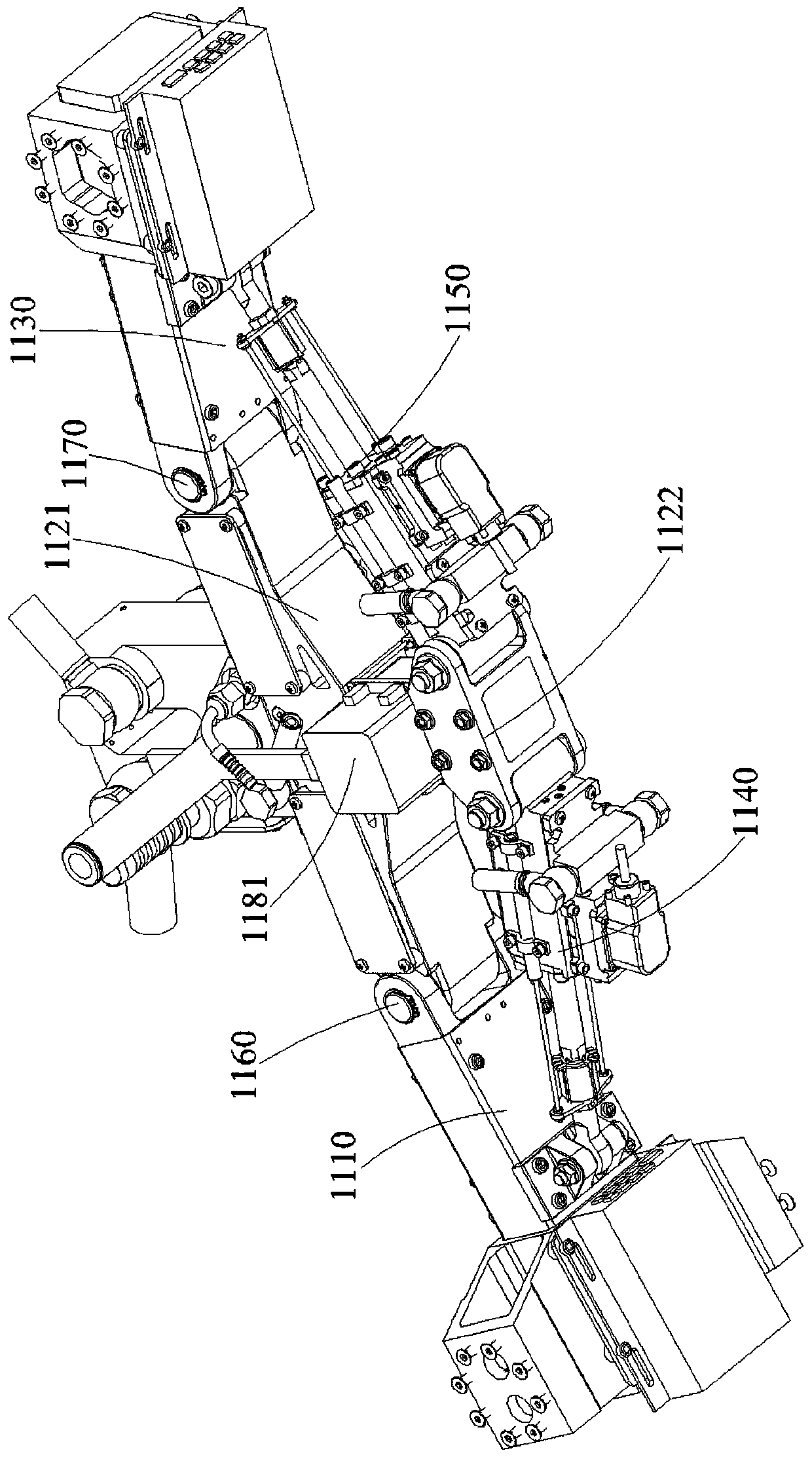

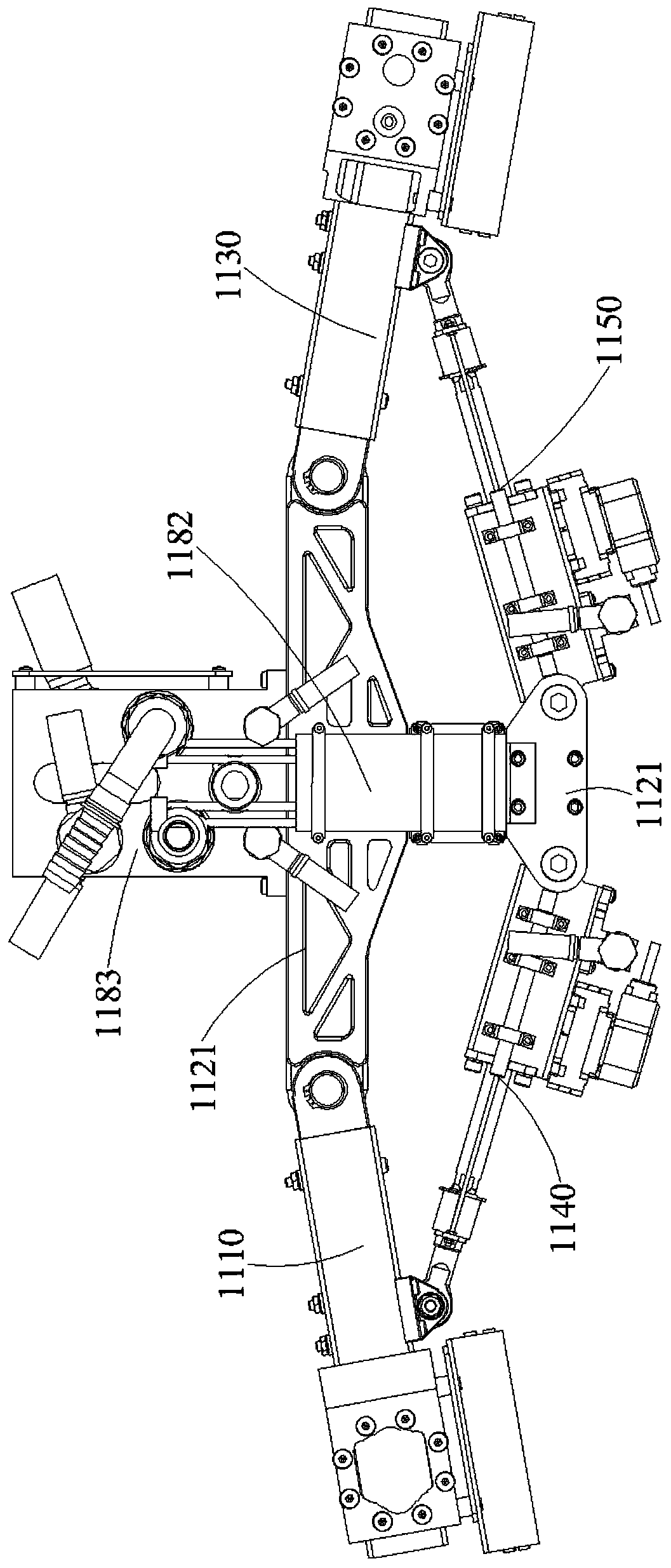

[0032] Please refer to Figure 1~3 This embodiment discloses a multi-joint spine 1100. The multi-joint spine 1100 includes a first spine 1110, a second spine 1120, and a third spine 1130 that are hinged in sequence to form a three-segment main body joint structure, thereby simulating four The spine bending movement of the foot creature improves the movement speed and movement flexibility of the quadruped robot.

[0033] Based on the articulation relationship, the first spine 1110 and the third spine 1130 can respectively rotate around the articulation axis of the second spine 1120 and itself to realize the bending motion of the multi-joint spine 1100. Under the aforementioned structure, the multi-joint spine 1100 has a three-stage basic configuration. The three-stage basic configuration has a wide bending angle, which can achieve large body bending, thereby effectively increasing the running distance. At the same time, the three-stage basic configuration of the spine motion law ...

Embodiment 2

[0046] See Figure 4 This embodiment discloses a spine-type quadruped robot 1000. The spine-type quadruped robot 1000 includes the multi-joint spine 1100 and the lower limb 1200 described in the first embodiment. As mentioned above, the lower limbs of the robot 1200 are respectively installed on the first spine 1110 and the third spine 1130, so that the robot has four limbs (which can be divided into fore and hind limbs).

[0047] Among them, the front and rear limbs of the robot can be formed by a linear array of the lower limbs 1200 of the robot, with the same orientation, forming, for example, " > "Shaped legs distribution and other structural forms. Or, the front and rear limbs of the robot have a symmetrical distribution relationship. Exemplarily, in the latter form, the lower limb 1200 of the robot located on the first spine 1110 and the lower limb 1200 of the robot located on the third spine 1130 It is symmetrical about the second spine 1120. In the symmetrical form, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com