Hardware strip bending device

A bending device and hardware technology, which is applied in the field of hardware processing, can solve the problems of inability to perform spiral bending and small damage rate, and achieve good results and ensure precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

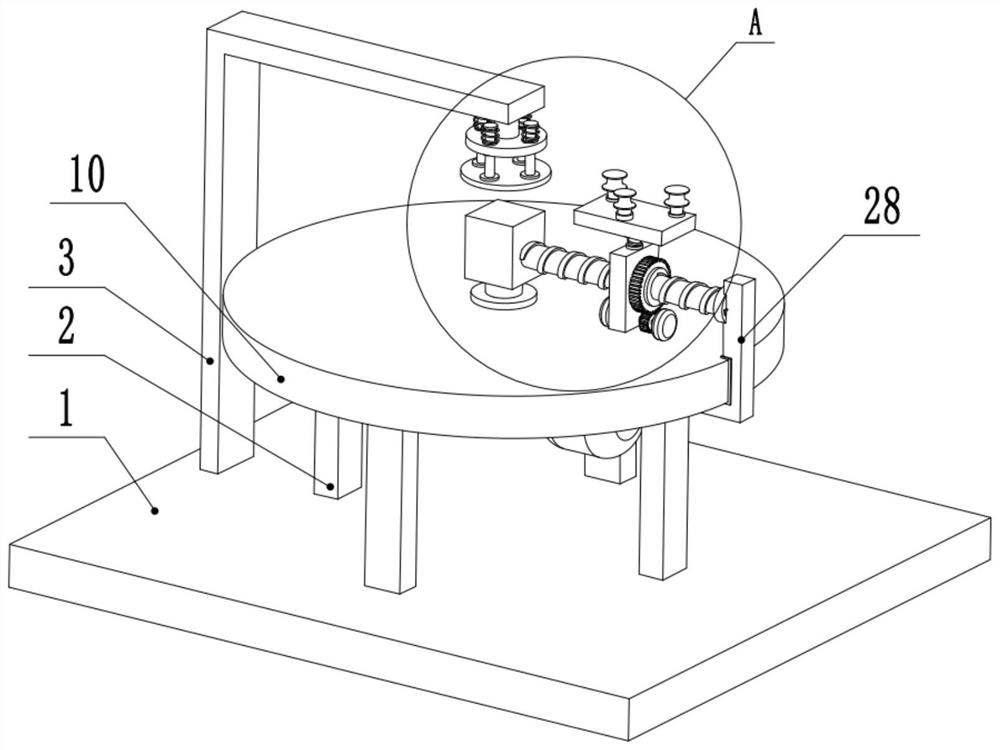

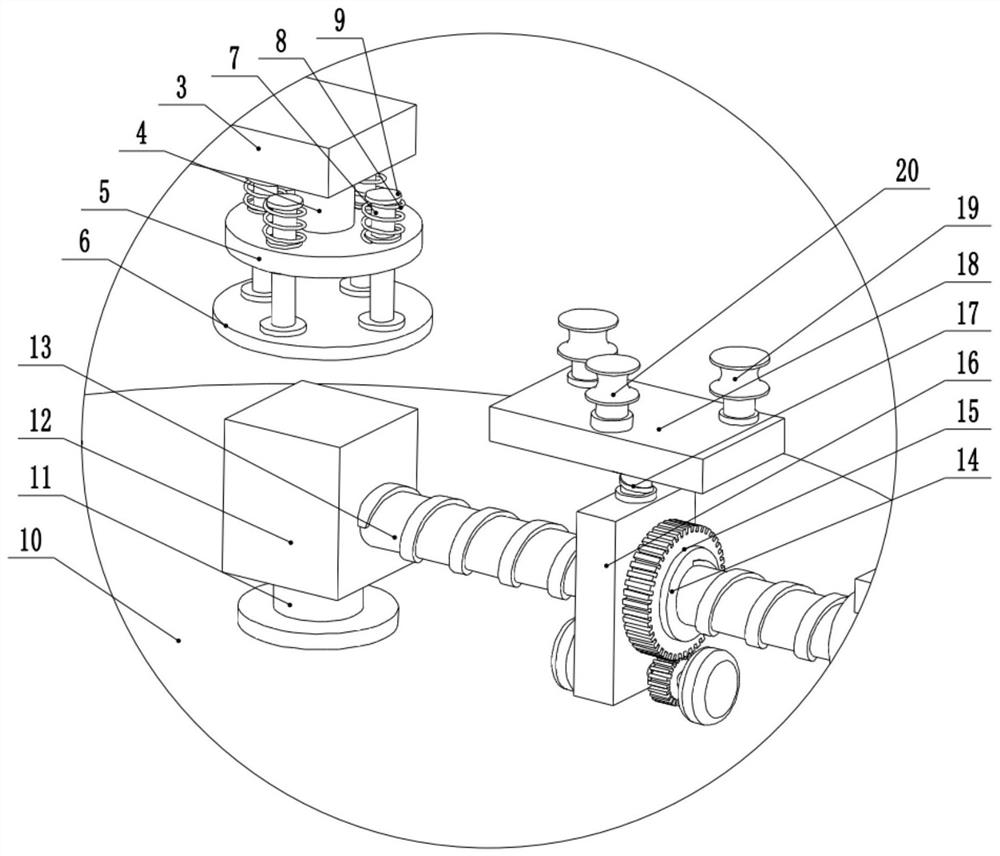

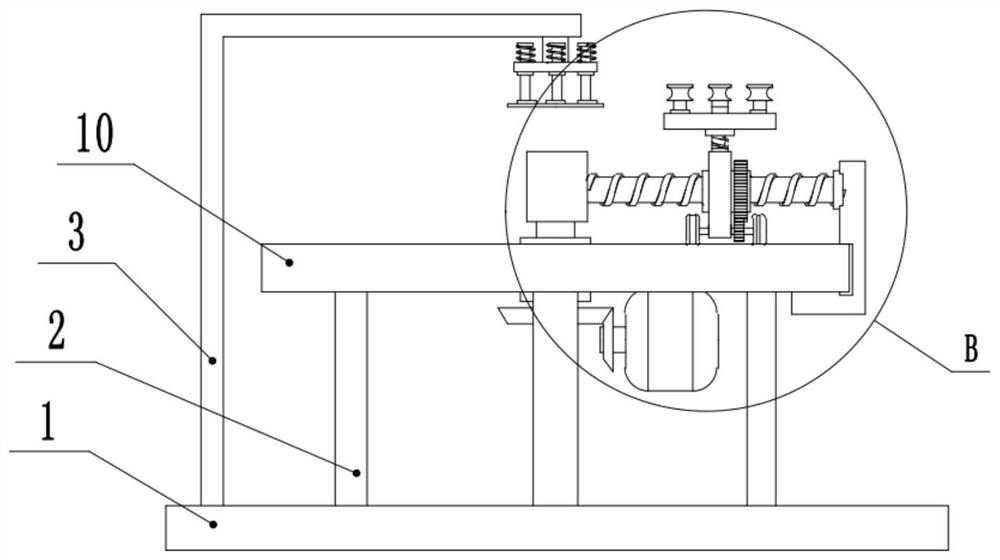

Embodiment 1

[0023] see Figure 1-4 , a metal bar bending device, comprising a base plate 1, a fixed frame 3 is provided on the left side of the upper surface of the base plate 1, a fixed rod 4 is provided at the right end of the fixed frame 3, and a fixed block 5 is provided at the bottom of the fixed rod 4, and the fixed block The outer side of 5 slides and connects guide rod 7, and the lower end of guide rod 7 is provided with movable plate 6, and the upper end of guide rod 7 is provided with stop block 9, is provided with spring 8 between stop block 9 and fixed block 5, and spring 8 sets On the outside of the guide rod 7, the spring 8 is limited by the guide rod 7. The right side of the upper surface of the base plate 1 is provided with a support column 2, and the upper end of the support column 2 is provided with a workbench 10 for working. The middle part of the table 10 is rotatably connected to the middle part of the rotating shaft 11, the top of the rotating shaft 11 is provided w...

Embodiment 2

[0026] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, except that the right end of the screw rod 13 is rotatably connected to the upper part of the block 28, and the lower part of the block 28 is slidably connected to the side of the workbench 10. In order to maintain the force balance of the screw mandrel 13, a block 28 is provided at the right end of the screw mandrel 13, and a part of the force of the screw mandrel 13 is transmitted to the workbench 10 through the block 28, thereby reducing the requirement for the rigidity of the screw mandrel 13. At the same time, the workbench 10 needs to be designed as a circle, and the friction between the block 20 and the workbench 10 needs to be reduced as much as possible. A bush is arranged between them, and the friction force is reduced through the bush, so that the screw rod 13 can better rotate around the rotating shaft 11 .

[0027]During the implementation of the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com