Sealed curved line pipe bending technology

A closed curve and pipe bending technology, which is applied in the field of closed curve pipe bending technology, can solve the problems that the arc closed curve pipe cannot be bent, and cannot meet the needs of efficient and stable mass production of closed curve pipes, and achieve high production efficiency. The production process is stable and achieves the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The core of the present invention is to provide a closed curved pipe bending process, which can realize mass production of closed curved pipes efficiently and stably.

[0018] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

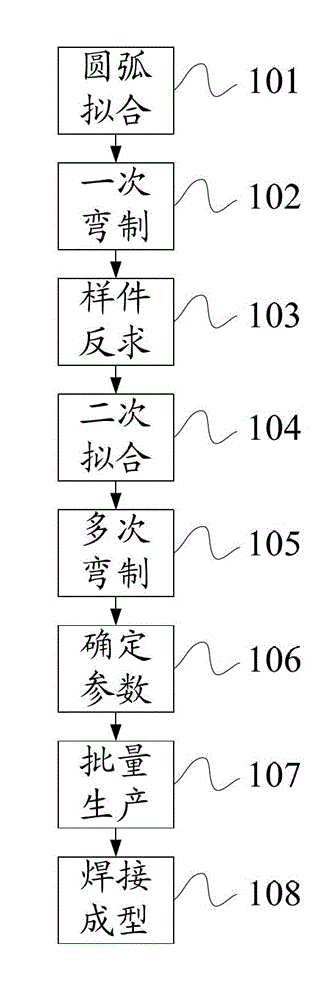

[0019] Please refer to figure 1 , figure 1 A flow chart of a closed curve pipe bending process provided by a specific embodiment of the present invention.

[0020] The closed curve pipe bending process provided by Embodiment 1 of the present invention includes:

[0021] Step 101: arc fitting;

[0022] The secondary design of the digital model of the door frame is done, and the contour is fitted with an arc, which meets the programming requirements of the CNC pipe bender.

[0023] Step 102: bending once;

[0024] The pipe is pushed and bent in multiple con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com