Progressive centrifugal machine blade machining auxiliary equipment

A technology of auxiliary equipment and centrifuges, which is applied in the field of centrifuges, can solve the problems of affecting product quality, difficulty in adjusting the angle of centrifuge blades, and different degrees of bending, so as to achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

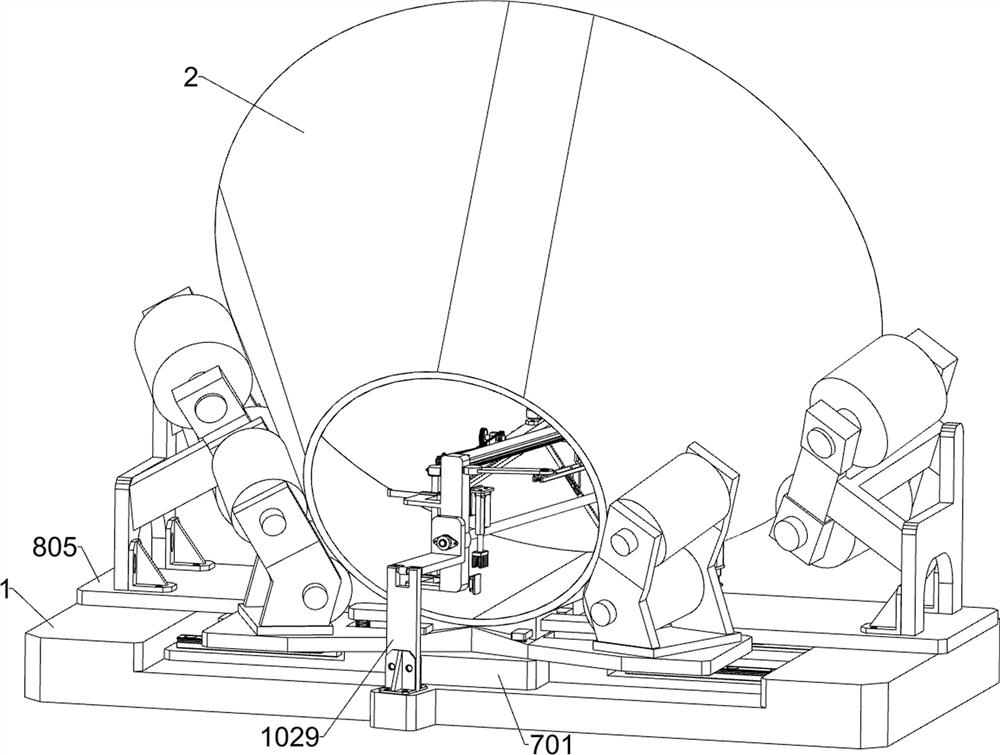

[0033] A progressive centrifuge blade processing auxiliary equipment such as Figure 1-3 As shown, it includes a U-shaped base 1, a limit cover 2, a bending mechanism, a transmission mechanism and an auxiliary mechanism; the upper part of the U-shaped base 1 is provided with a limit cover 2; the upper part of the U-shaped base 1 is equipped with a bending mechanism; the bending mechanism The right part is connected with a transmission mechanism; the lower side of the rear part of the bending mechanism is connected with an auxiliary mechanism; the transmission mechanism is connected with the auxiliary mechanism.

[0034] Working process: When working, place the U-shaped base 1 horizontally so that the high sides of the U-shaped base 1 are at the same level as the ground, then connect the external power supply, and the operator will transport the centrifuge blades into the bending mechanism and auxiliary mechanism, and pass the limit Cover 2, the bending mechanism and the auxili...

Embodiment 2

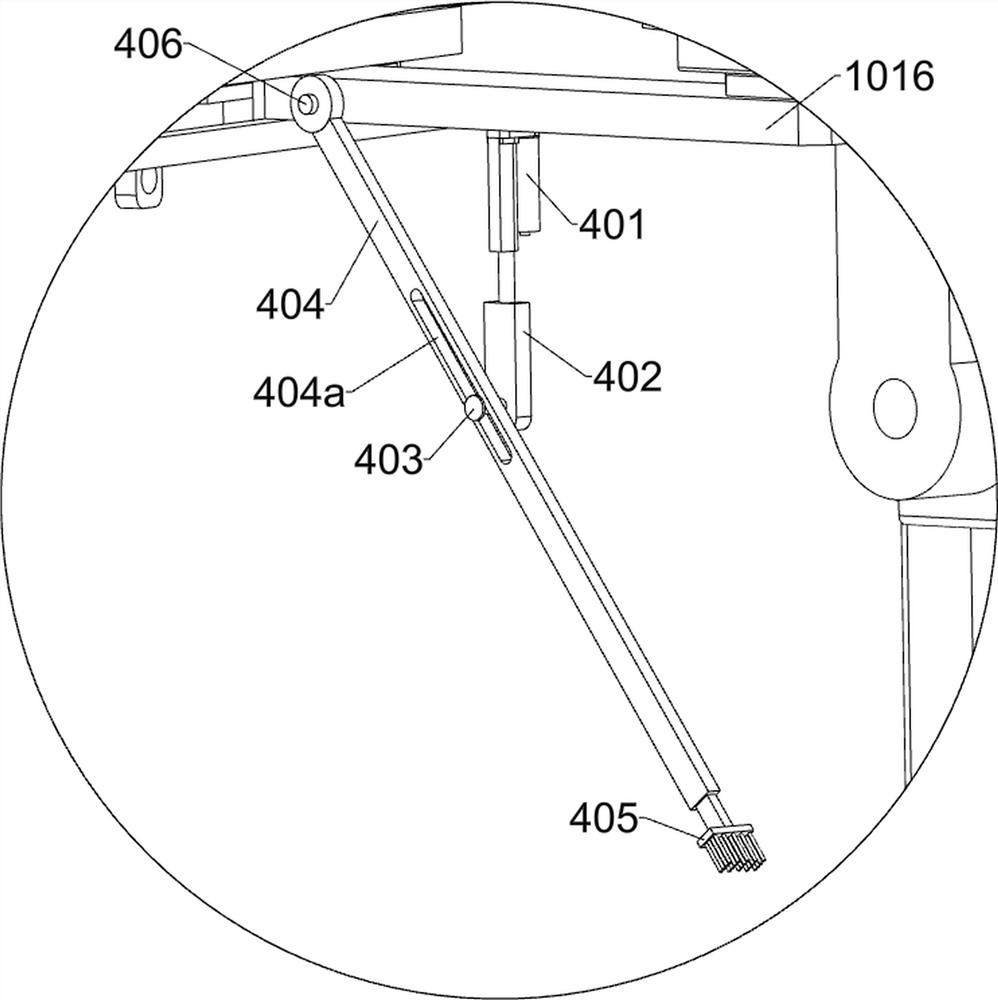

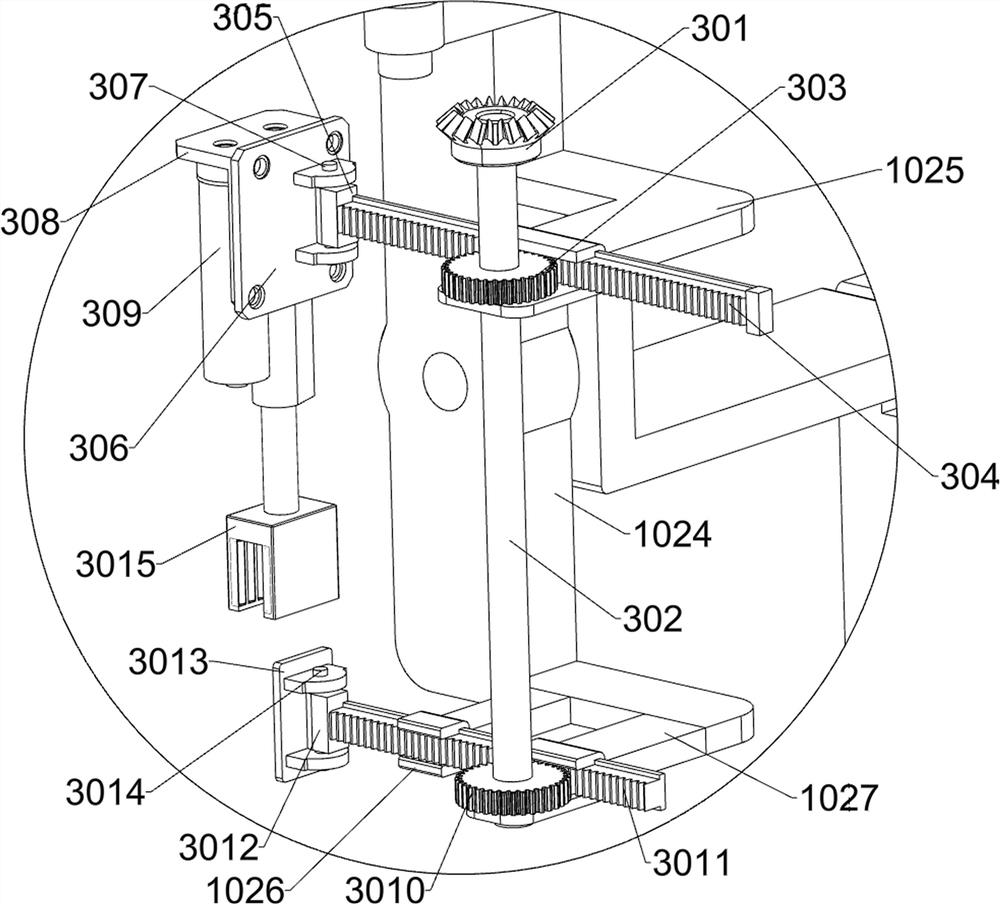

[0036] On the basis of Example 1, such as Figure 4-7 As shown, the bending mechanism includes a tripod wheel 101, a leg 102, a cross base 103, a handle 104, a driver 105, a first swing frame 106, a horizontal plate 107, a first bracket 108, a second bracket 109, a first electric slide Rail 1010, first electric slider 1011, first guide rail 1012, first moving block 1013, second guide rail 1014, second moving block 1015, first moving plate 1016, first electric push rod 1017, first U-shaped block 1018, the third guide rail 1019, the first mounting plate 10191, the second mounting plate 10192, the third mounting plate 10193, the first bidirectional rack 1020, the second bidirectional rack 1021, the third bidirectional rack 1022, the rotating rod 1023, The second swing frame 1024, the first bracket 1025, the second bracket 1026, the third bracket 1027, the rotating plate 1028, the riser 1029, the third support 1030, the fourth support 1031 and the third moving block 1032; U-shaped...

Embodiment 3

[0043] On the basis of Example 2, such as figure 1 and Figure 8-12 As shown, it also includes a lifting mechanism, the upper side of the U-shaped base 1 is connected with a lifting mechanism, and the lifting mechanism includes a fixed plate 701, a first elastic member 702, a first support plate 703, a first supporting plate 704, The second support plate 705, the second elastic member 706, the third elastic member 707, the third support plate 708, the second support plate 709, the fourth support plate 7010 and the fourth elastic member 7011; the upper middle part of the U-shaped base 1 The fixed plate 701 is welded; the upper side of the fixed plate 701 is connected with four first elastic members 702 distributed in a rectangular shape; each of the upper ends of the four first elastic members 702 is connected with a first support plate 703; A first supporting plate 704 is welded between the plates 703 and between the two first supporting plates 703 on the right; the two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com