Improved tube bundle for tube bundle dryer

A tube bundle drying and tube bundle technology, which is used in dryers, drying solid materials, drying and other directions, can solve the problems of shortening the service life of the shovel angle iron, poor anti-distortion ability of the shovel angle iron, and economic losses of the manufacturer. To achieve the effect of reducing the frequency of tube bundle maintenance, prolonging the service life and improving the synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

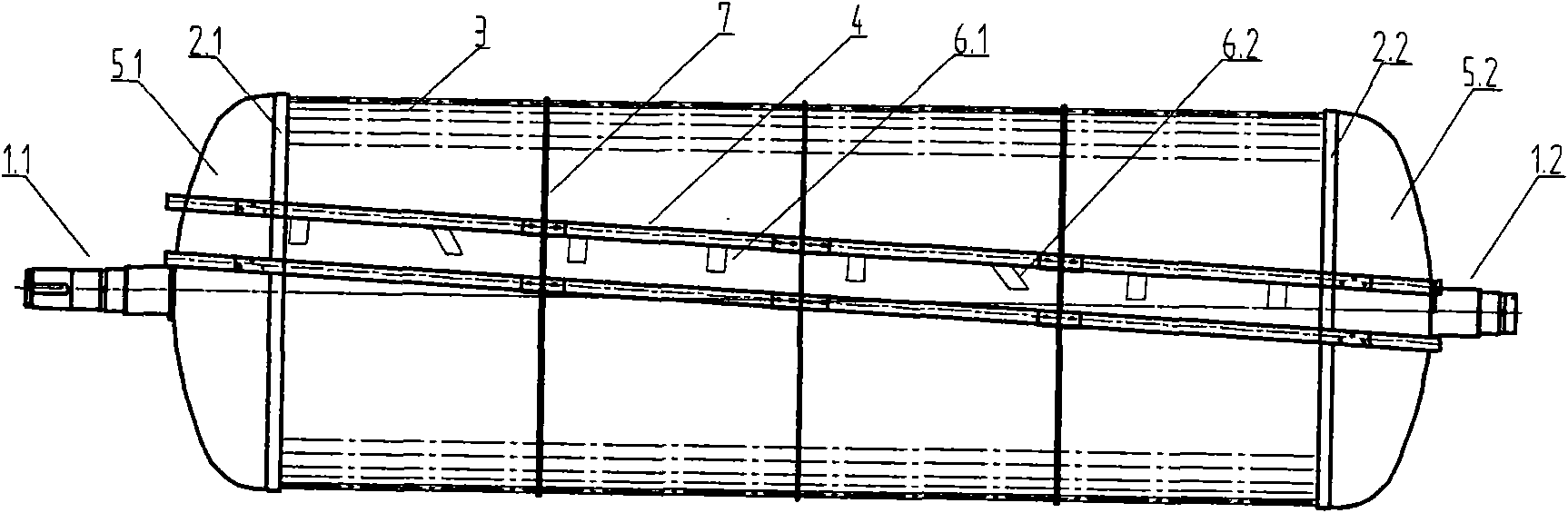

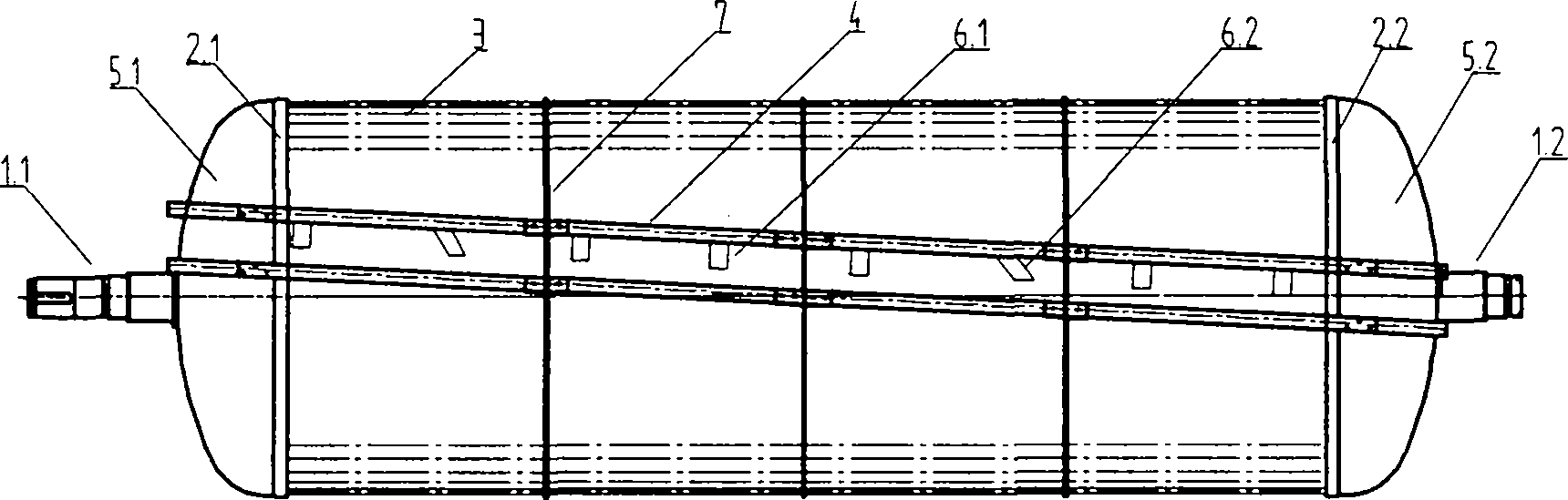

[0006] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0007] The tube bundle of the tube bundle dryer includes the transmission main shaft 1.1, the passive main shaft 1.2, the two ends of the head (the transmission end 5.1 and the passive end 5.2) and the two ends of the tube plate (the transmission end 2.1 and the passive end 2.2) are welded together, and the heating tube 3 It is connected with the tube sheets at both ends (the driving end 2.1 and the passive end 2.2), and there are several support tube sheets 7 in the middle of the heating tube 3, and the inclined shovels with straight shovel 6.1 and inclined shovel 6.2 are installed The angle iron 4 is welded and fixed on the circumference of the tube plate (the driving end 2.1, the driven end 2.2 and the support tube plate 7), and forms an inclination angle of 3-4° with the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com