Pipeline fixing support

A technology for fixing brackets and pipelines, which is applied in the direction of circuits or fluid pipelines, transportation and packaging, vehicle parts, etc. It can solve the problems of fixed brackets and pipelines that cannot be buffered, so as to increase strength, reduce difficulty, and increase bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

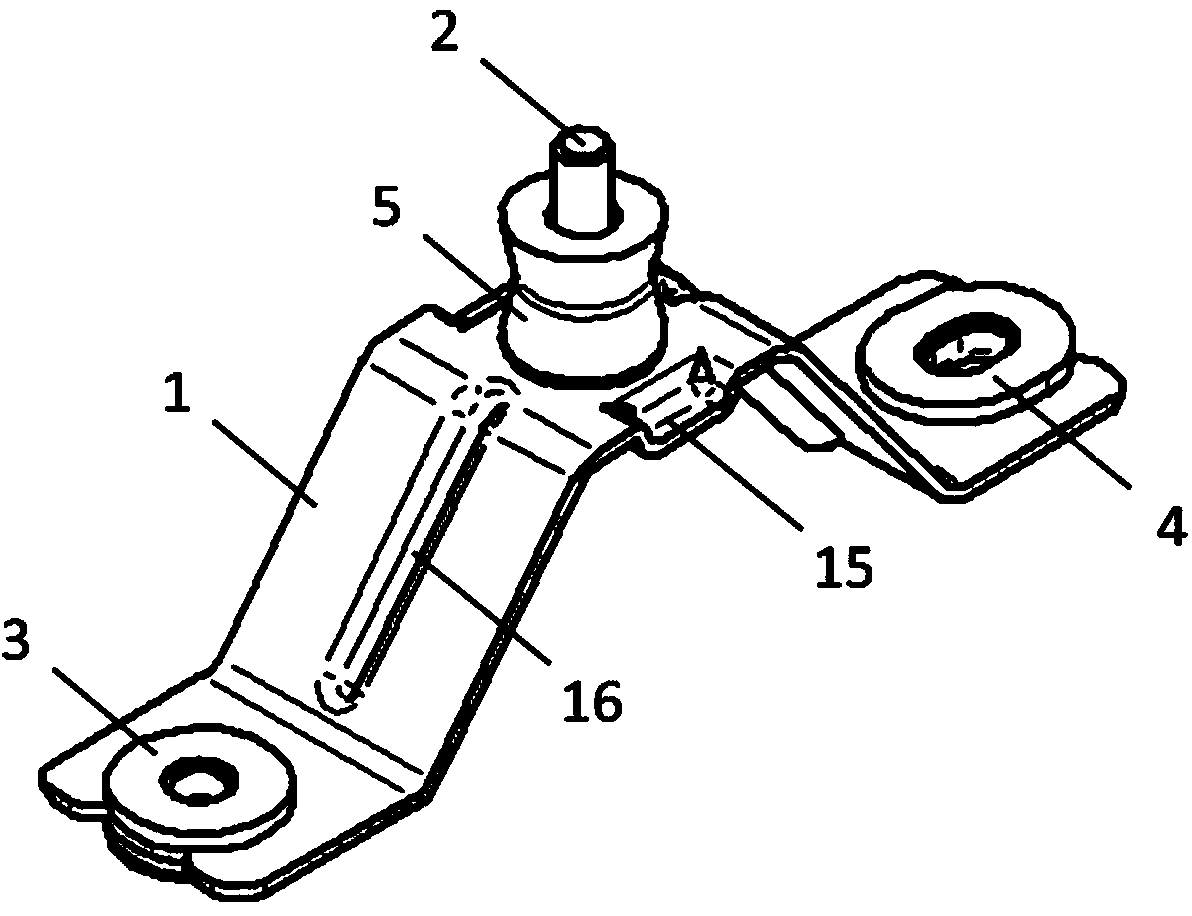

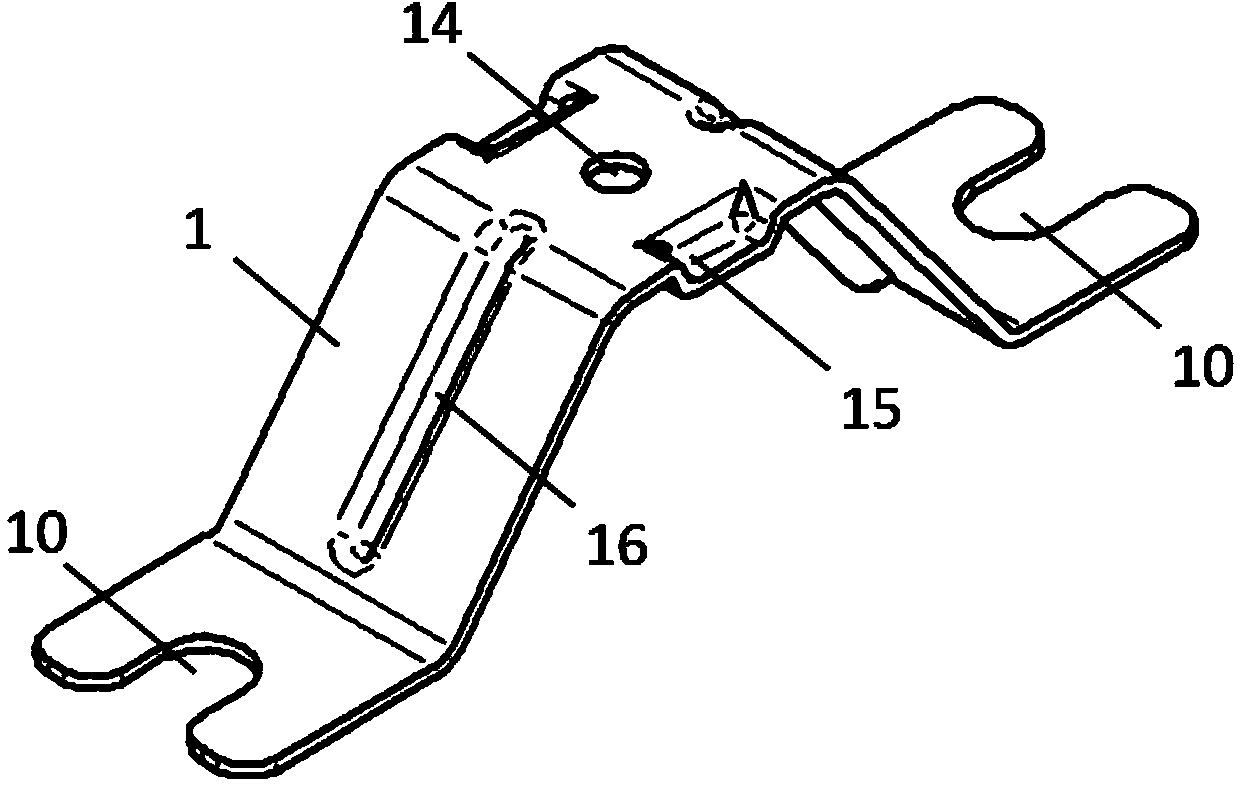

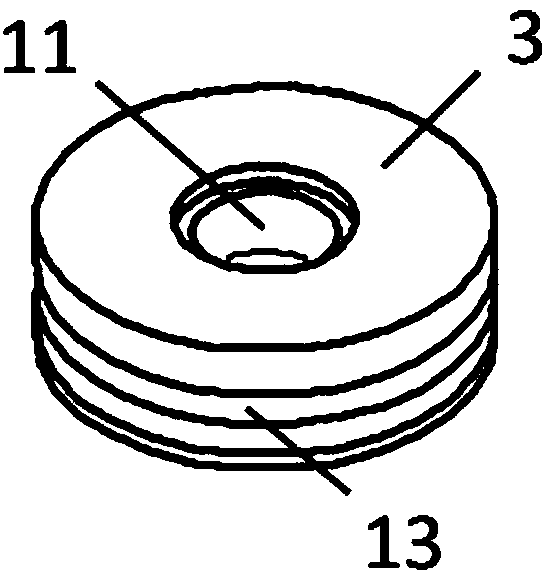

[0040] Such as figure 1 and Figure 6 As shown, the pipeline fixing bracket of the present invention includes a bracket body 1 and a bolt column 2 provided on the top surface of the bracket body 1; The second damping pad 4 is arranged on the side straight edge; the third damping pad 5 is arranged on the bolt post 2; This pipeline fixing bracket adds two layers of vibration-damping pads on the basis of the original fixing bracket, wherein the contraction structure 6 of the third vibration-damping pad 5 arranged on the upper layer of the bracket body 1 can play a role in reducing the vibration stress brought on the frame. And the vibration stress brought by the pipeline is concentrated in the middle of the third vibration-damping pad 5. By moving the vibration stress to the middle of the third vibration-damping pad 5, the vibration stress intensity brought by the two directions can be gradually dispersed to achieve the effect of flexible cushioning. Effect. Of course, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com