Wear-resistant waterproof rubber flexible cable of suspender

A technology of flexible cables and rubber sheaths, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of cable short circuit, wire core break, easy damage of cable sheath, etc., achieve good extrusion and friction performance, and prolong The effect of high service life and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

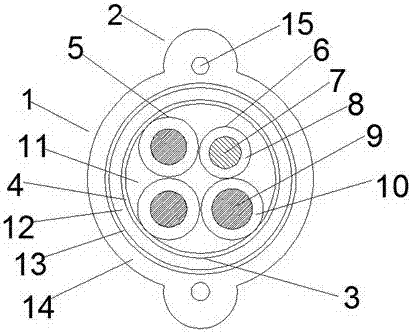

[0038] see figure 1 , the present invention provides a technical solution: a wear-resistant and waterproof suspender rubber-sheathed flexible cable, including a cable body 1, and protrusions 2 symmetrically arranged at the upper and lower ends of the cable body 1, and the cable body 1 is composed of a cable core 3, The inner sheath 12, the load-bearing reinforcing layer 13 and the outer sheath 14 are composed; the cable core 3 is composed of a water-blocking tape around the cladding 4 and the inner core; the inner core 3 is provided with three sets of power cores 5 and A set of ground cores 6; the ground core 6 is provided with a ground core conductor 7; the ground core conductor 7 is extruded with a layer of ground core insulation layer 8; the power core 5 is internally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com