Machining method of micropore catheter

A processing method and catheter technology, which is applied in the field of medical devices, can solve problems such as inability to accurately control the flow of liquid medicine, inability to process microporous catheters, and uneven hole sizes in microporous catheters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of processing method of microporous catheter

[0020] 1. Material preparation: Select the steel wire with the same pore size as the required micropore, and carry out siliconization treatment on the surface of the steel wire. The siliconization process is as follows: use medical-grade needle-point silicone oil, that is, medical-grade dimethyl silicone oil (Dow Corning, USA), and dilute it with After the agent HCFC141B is diluted to a concentration of 2%, it is directly filled into the spray tank and sprayed on the surface of the steel wire; or it is directly dipped and smeared for siliconization treatment; after completion, the steel wire is dried by a drying device at a drying temperature of 70°C , time 10S;

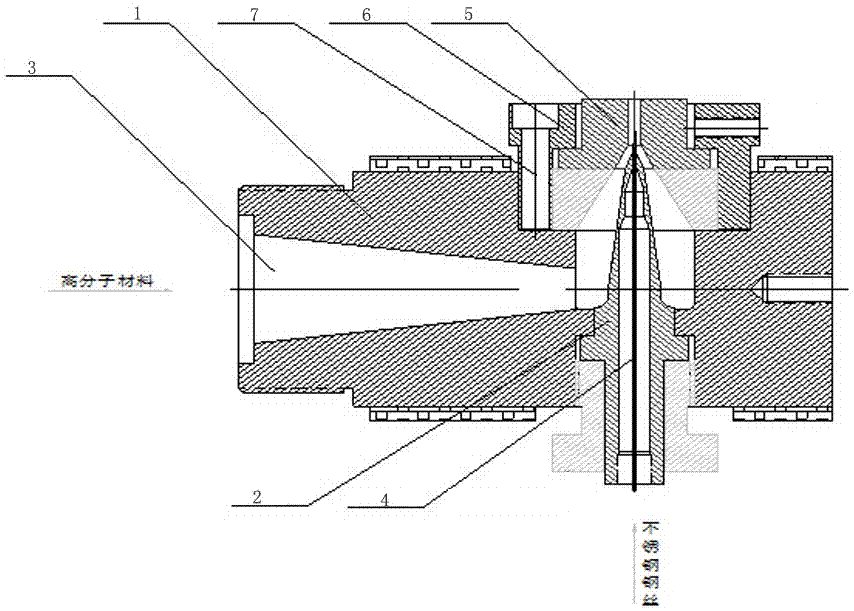

[0021] 2. Co-extrusion processing: the steel wire and polymer material after surface silicification are co-extruded, so that the surface of the steel wire is covered with polymer material, that is, the steel wire is implanted in the center of the catheter; ...

Embodiment 2

[0025] A kind of processing method of microporous catheter

[0026] 1. Material preparation: Select the steel wire with the same pore size as the required micropore, and carry out siliconization treatment on the surface of the steel wire. The siliconization process is as follows: use medical-grade needle-point silicone oil, that is, medical-grade dimethyl silicone oil (Dow Corning, USA), and dilute it with After the agent HCFC141B is diluted to a concentration of 20%, it is directly filled into the spray tank and sprayed on the surface of the steel wire; or it is directly dipped and smeared for siliconization treatment; after completion, the steel wire is dried by a drying device at a drying temperature of 100°C , time 5S;

[0027] 2. Co-extrusion processing: the steel wire and polymer material after surface silicification are co-extruded, so that the surface of the steel wire is covered with polymer material, that is, the steel wire is implanted in the center of the catheter;...

Embodiment 3

[0031] A kind of processing method of microporous catheter

[0032] 1. Material preparation: Select the steel wire with the same pore size as the required micropore, and carry out siliconization treatment on the surface of the steel wire. The siliconization process is as follows: use medical-grade needle-point silicone oil, that is, medical-grade dimethyl silicone oil (Dow Corning, USA), and dilute it with After the agent HCFC141B is diluted to a concentration of 5%, it is directly filled into the spray tank and sprayed onto the surface of the steel wire; or it is directly dipped and smeared for siliconization treatment; after completion, the steel wire is dried by a drying device at a drying temperature of 85°C , time 7S;

[0033] 2. Co-extrusion processing: the steel wire and polymer material after surface silicification are co-extruded, so that the surface of the steel wire is covered with polymer material, that is, the steel wire is implanted in the center of the catheter;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com