Aluminum thin-wall screw beverage bottle and manufacturing method thereof

A beverage bottle and aluminum technology, which is applied in the field of aluminum thin-walled screw mouth beverage bottle and its manufacturing field, can solve the problems of low pressure resistance and anti-twisting force of the bottleneck, poor shading performance, poor moisture resistance, waterproof and anti-counterfeiting, etc. Good sealing and quick drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

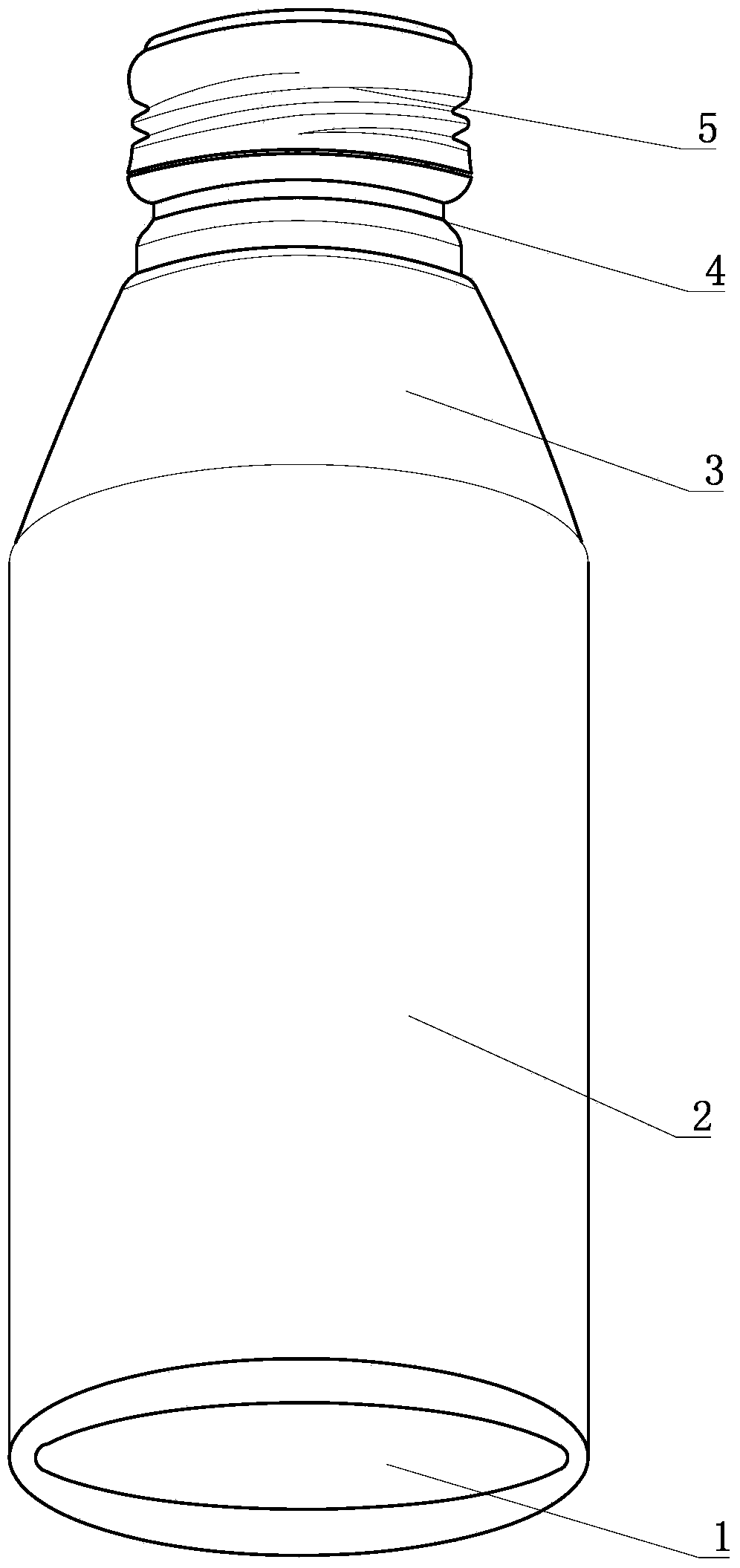

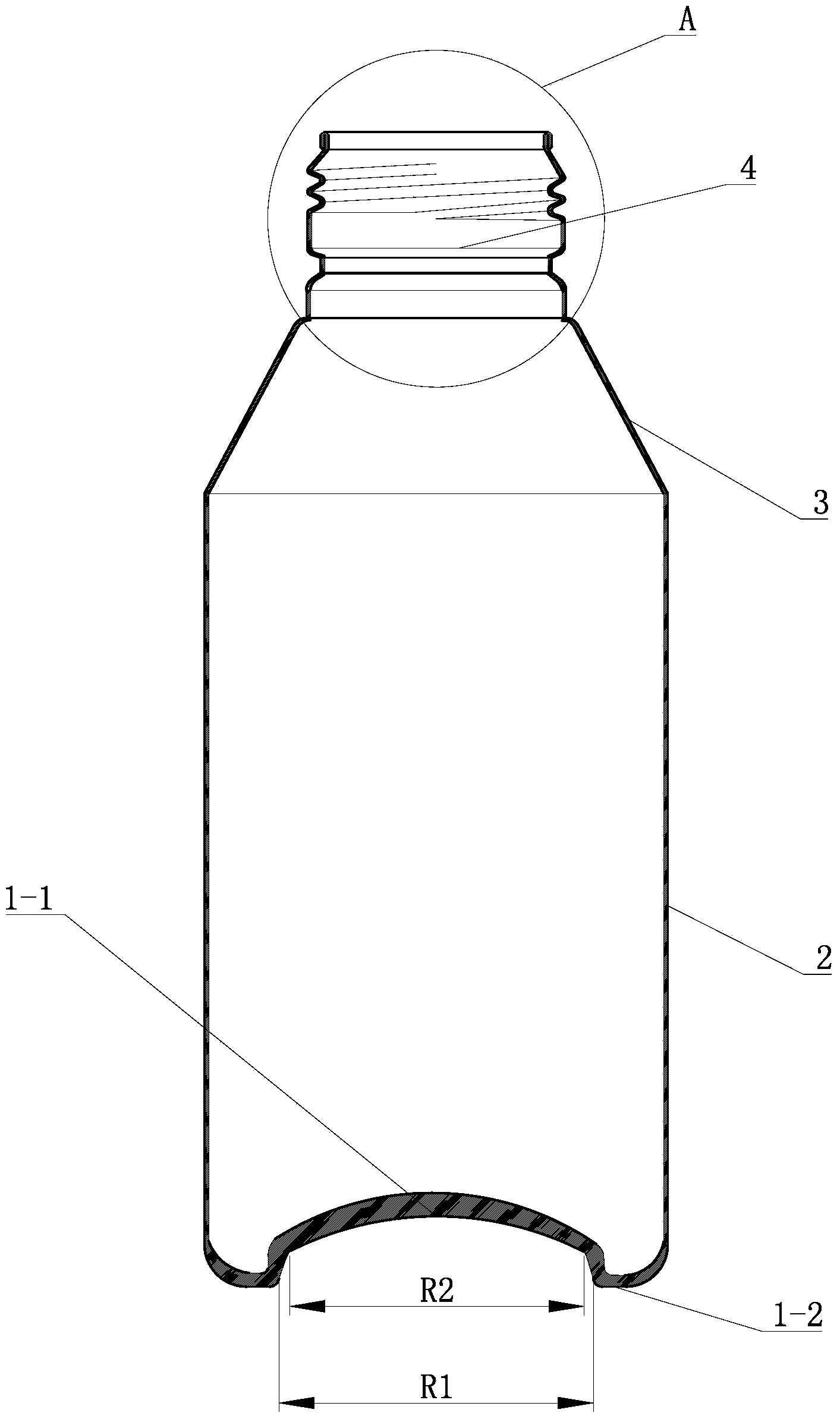

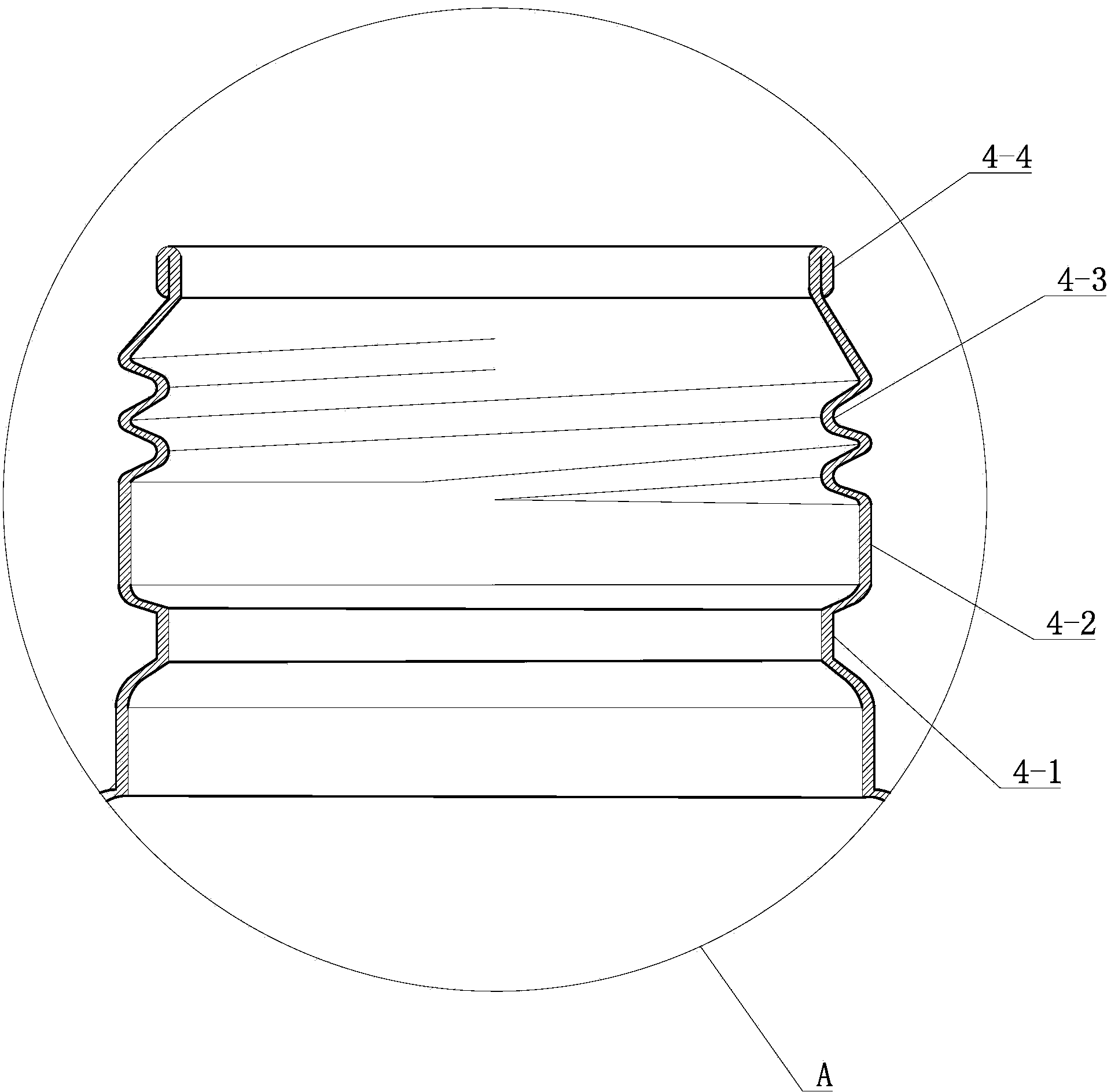

[0032] Such as figure 1 and figure 2 The shown aluminum thin-wall screw-top beverage bottle includes a bottle bottom 1, a bottle barrel 2, a can shoulder 3, a can neck 4 and a bottle cap 5. The bottom of the bottle 1 includes a recessed part 1-1 and a supporting part 1-2. The recessed part 1-1 is set in the middle of the bottle bottom 1 and is recessed into the bottle. The first diameter R1 of the recessed part 1-1 at the bottom is larger than that of the recessed part 1 ‐1 The second diameter R2 at the top is similar to a cone but the top is set in an arc shape. This structure enhances the overall bearing capacity and central axial pressure capacity of the bottle. The supporting part 1‐2 is in the shape of a ring, such that The support part 1-2 is more stable when supporting the entire bottle body, and this structure is not easily deformed so that the bottle will not be placed unstable. The thickness of the bottle bottom 1 is 0.25-0.70mm, and the thickness of the bottle bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com