Rated-voltage 6-35kV high-elasticity distortion-resistant wind power cable and manufacture method

A technology with rated voltage and high elasticity, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of lagging development of wind energy cables, achieve the effects of easy bending and winding, excellent elasticity, and improved twist resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

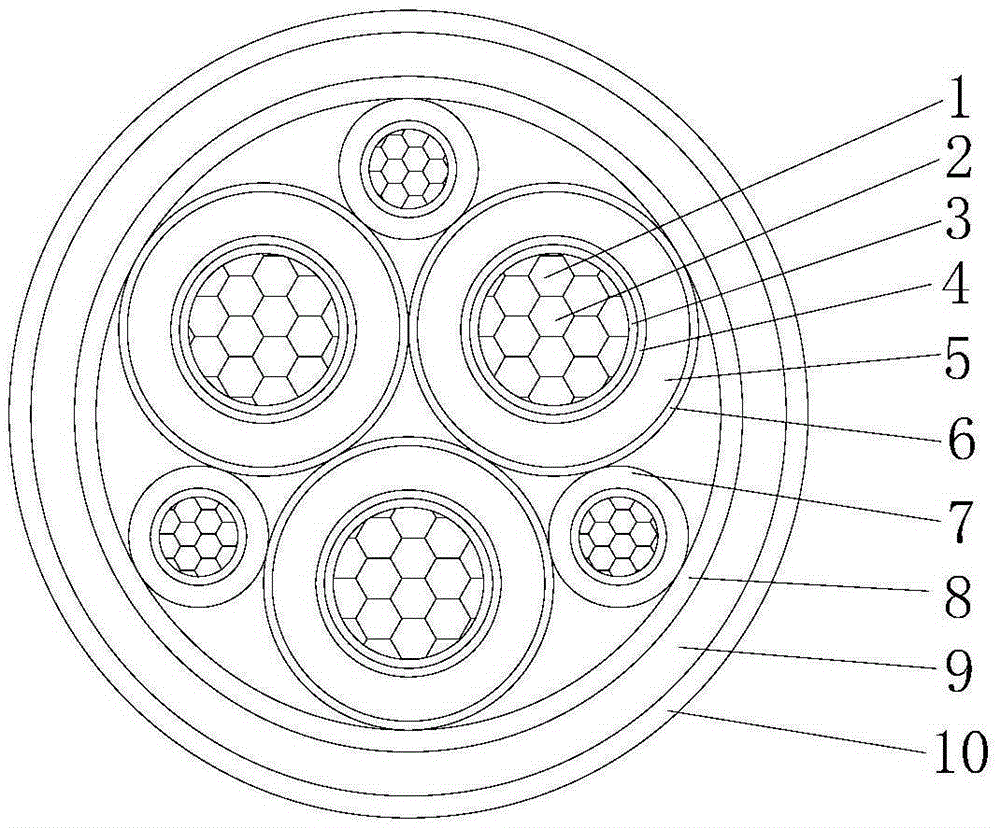

[0057] Embodiment: The rated voltage of the present invention is 6-35kV high elastic and twist-resistant wind energy cable, which consists of three power insulated wire cores and three grounded insulated wire cores twisted to form a cable core. The ribbon 8 is extruded with a thermoplastic elastomer outer sheath 9, and the outermost layer of the cable is a braided layer 10 composed of stainless steel wire and polyester synthetic fiber yarn;

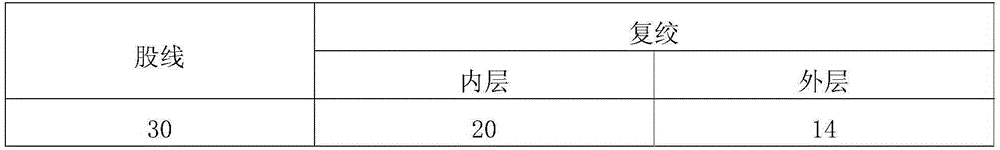

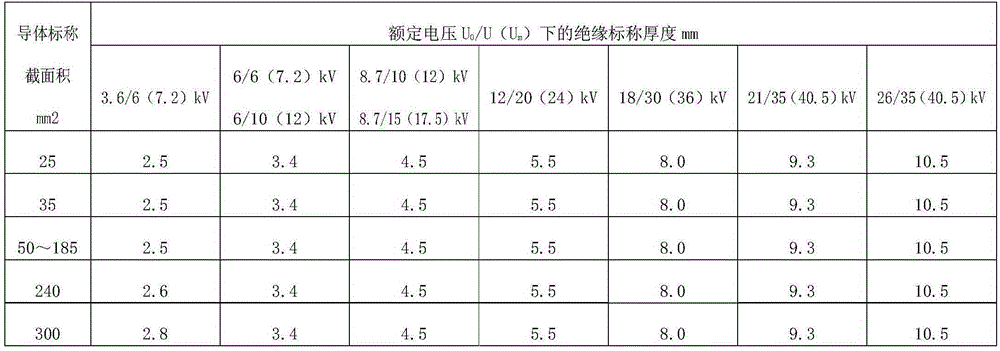

[0058] Each power insulated wire core is made of tinned oxygen-free copper wire 1 and stainless steel wire 2 twisted to form a conductor, and the conductor is overlapped and wrapped with a single-layer semi-conductive cotton tape wrapping layer 3, and the outer wrapping layer 3 is co-extruded with three layers There is a conductor shielding layer 4, an EPDM insulating layer 5 and an insulating shielding layer 6 to form a power insulating core;

[0059] Each grounding insulated wire core is made of tinned oxygen-free copper wire and stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com