Air bag catheter

A technology of balloon catheters and balloons, which is applied in the direction of balloon catheters, stents, etc., can solve problems such as bending and distortion of rigid transition parts, and achieve the effect of improving flexibility and supporting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

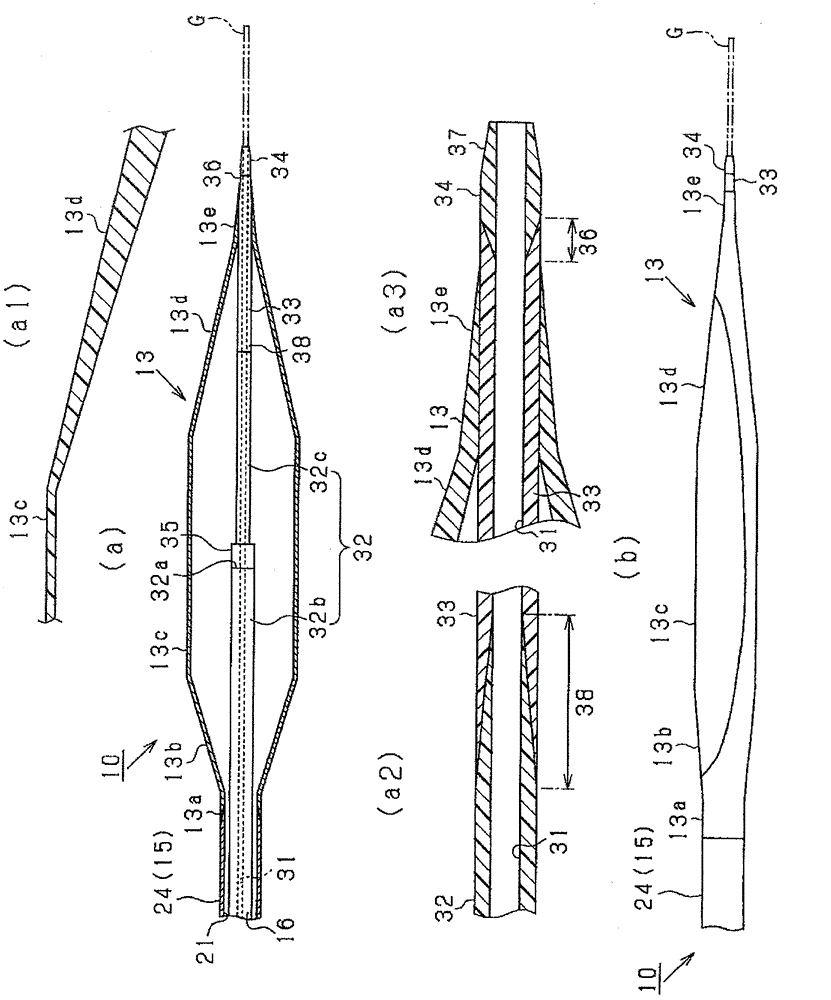

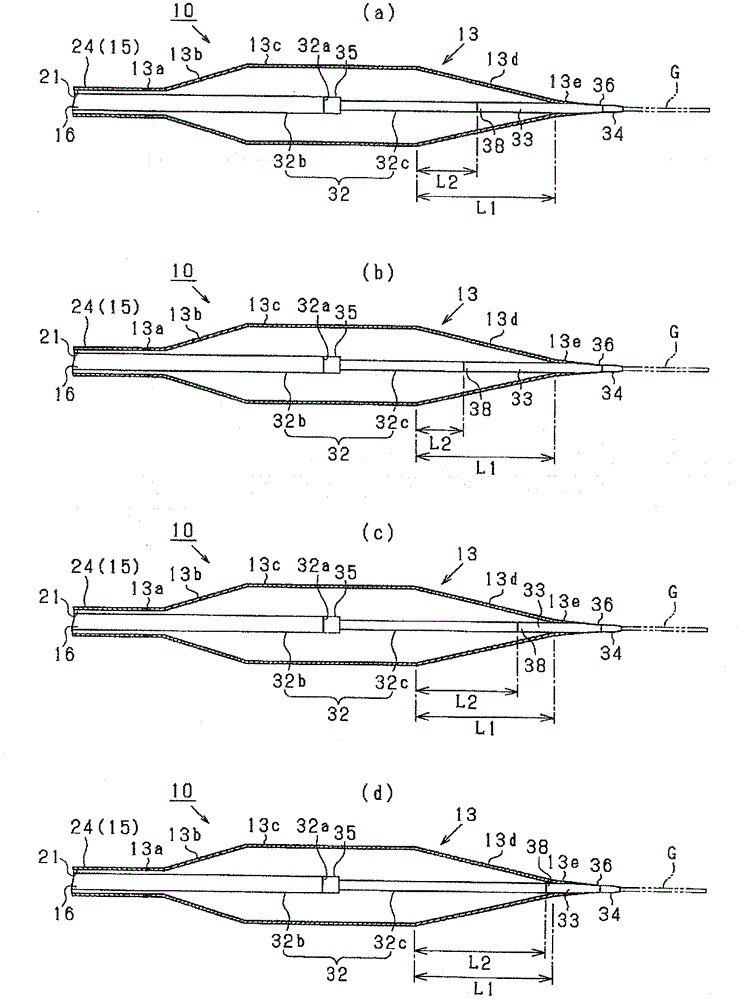

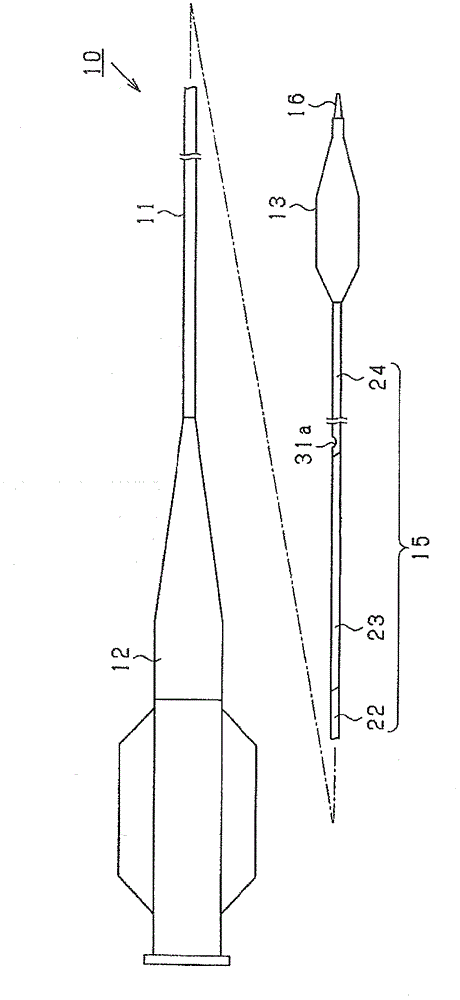

[0097] An inner layer with a thickness of 0.016 mm made of high-density polyethylene (Petrothene LR7340 from M.holland), a middle layer with a thickness of 0.004 mm made of low-density polyethylene (Plexar PX3080 from Equistar), and a polyamide elastic A hollow tube having an outer layer with a thickness of 0.06 mm, an inner diameter of 0.42 mm, an outer diameter of 0.58 mm, and a length of 300 mm formed of a body (Pebax7033 from ARKEMA Corporation).

[0098] A range of 10 mm from one end of the hollow tube was extended by passing an extending jig in which a circular hole with an inner diameter of 0.52 mm was formed with the mandrel for fixing the inner diameter inserted inward. Afterwards, the end portion of the extended side is cut off, thereby making the inner proximal region 32b having an inner diameter of 0.41 mm, an outer diameter of 0.55 mm, and a length of 290 mm, and a small diameter area 32 c of an inner diameter of 0.41 mm, an outer diameter of 0.52 mm, and a length ...

Embodiment 2

[0102] The inner tube 16 was produced in the same manner as in Example 1, except that the length from the above-mentioned stepped portion 32 a to the distal end of the above-mentioned inner proximal tube 32 was 10 mm.

Embodiment 3

[0104] The inner tube 16 was produced in the same manner as in Example 1, except that the length from the above-mentioned stepped portion 32 a to the distal end of the above-mentioned inner proximal tube 32 was 12 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com