Modularized seat support for reactor pressure vessel

A pressure vessel, modular technology, applied in reactors, nuclear power generation, nuclear engineering, etc., to avoid interference and improve support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and specific embodiments.

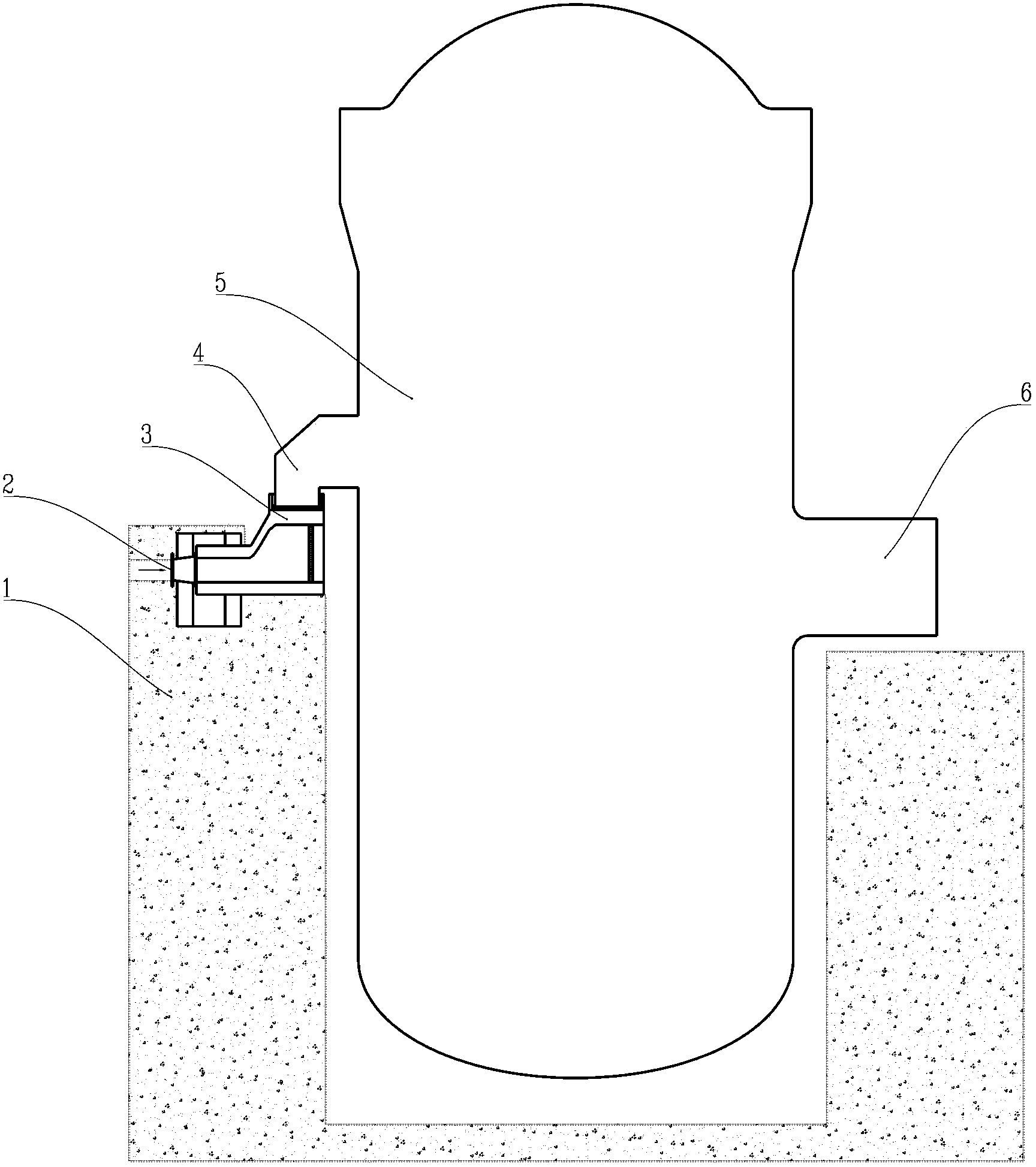

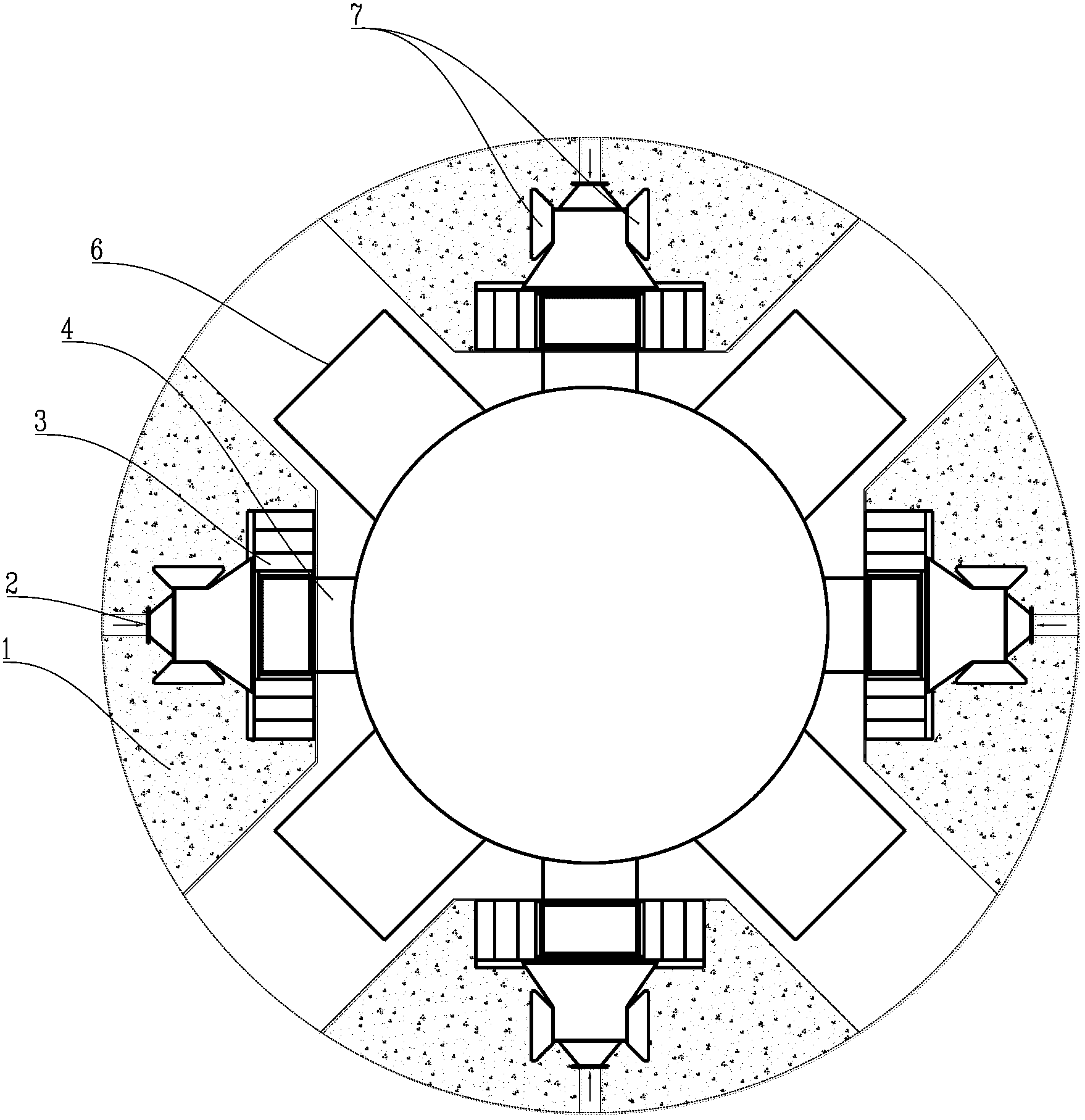

[0018] Such as figure 1 , figure 2 As shown, a modular support for a reactor pressure vessel includes 4 modular supports. A single modular support forms the final support structure through on-site installation. The modular structure simplifies the difficulty of manufacturing and is suitable for transportation and on-site installation. Provides convenience and saves layout space. They are evenly arranged around the reactor pressure vessel. The bottom of the support is fixed on the concrete foundation. The reactor pressure vessel is fixed on the central part of the support by the support pad 4 provided on the outer wall of the cylinder. , The main pipe of the pressure vessel is led out from the gap between the supports.

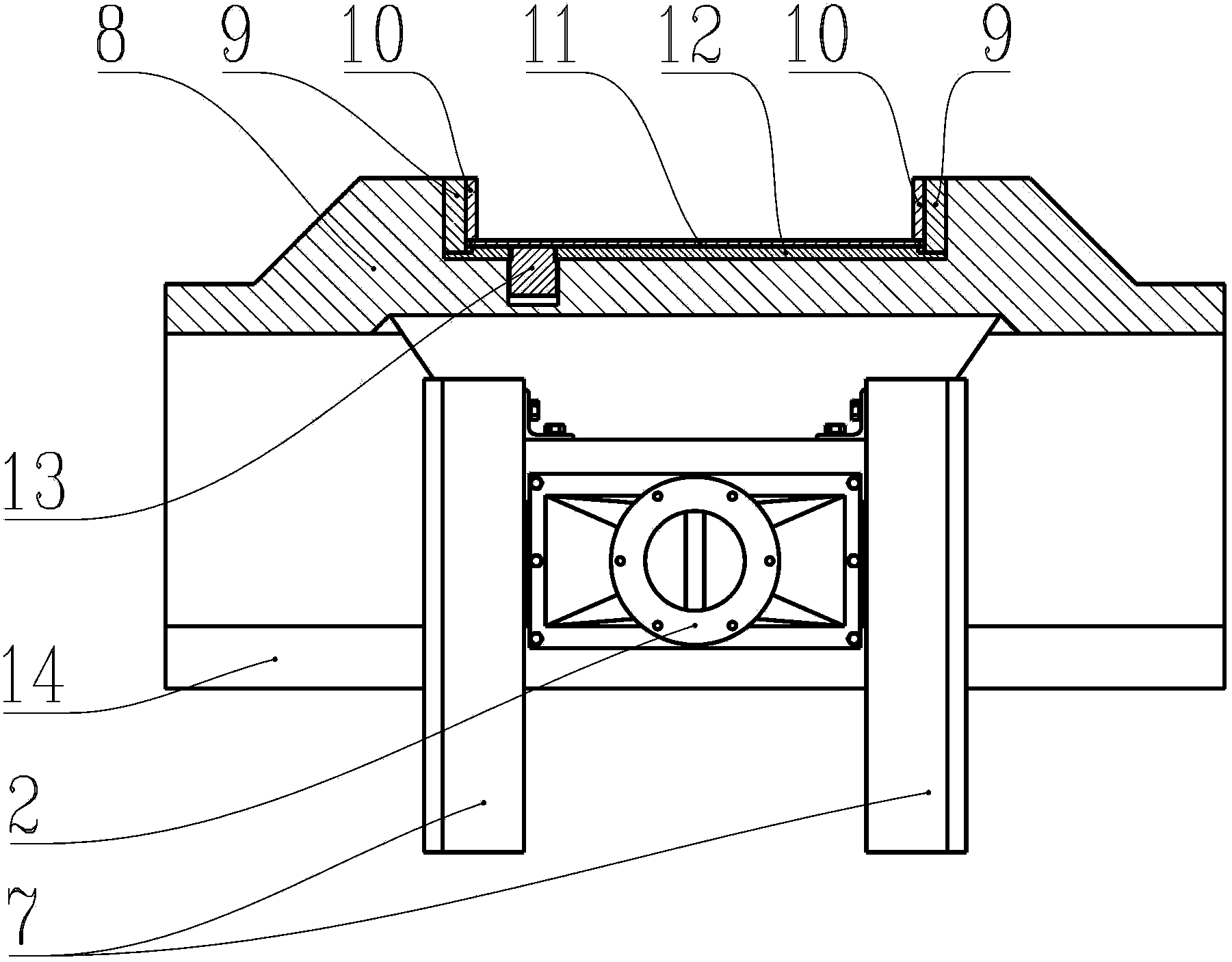

[0019] Such as image 3 , Figure 4 with Figure 5 As shown, the modular support includes a T-shaped support body 3, which includes an upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com