Tool fixture for automobile accessory welding

A technology for tooling fixtures and auto parts, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problem of different shapes or the lack of fixed points of multiple pieces of accessories, and the inability to weld multiple pieces of accessories into one at a time. Fixing and other problems, to achieve the effect of firm and reliable connection, slow down the vibration amplitude, and facilitate welding and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

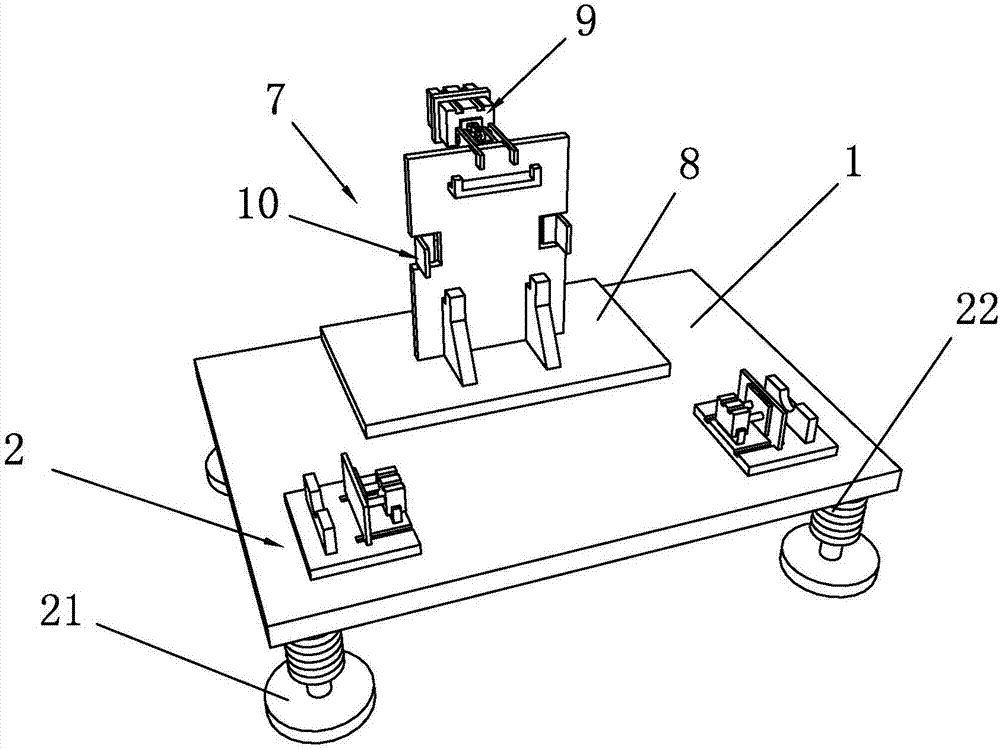

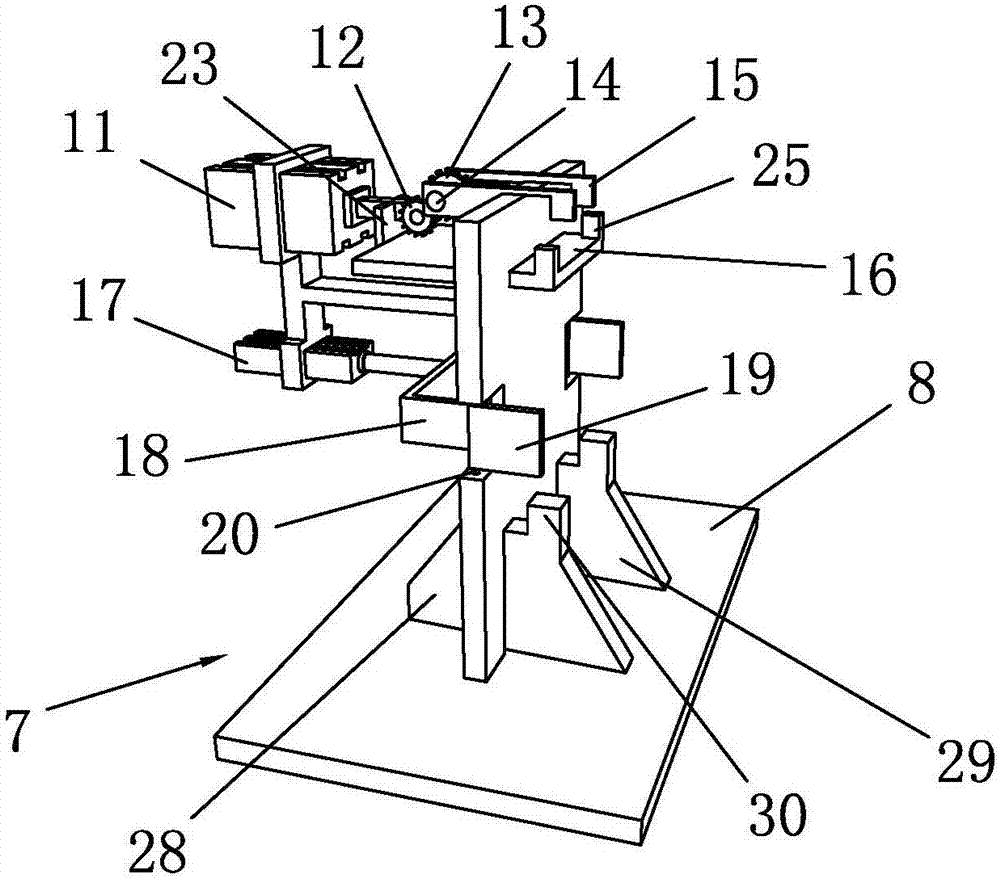

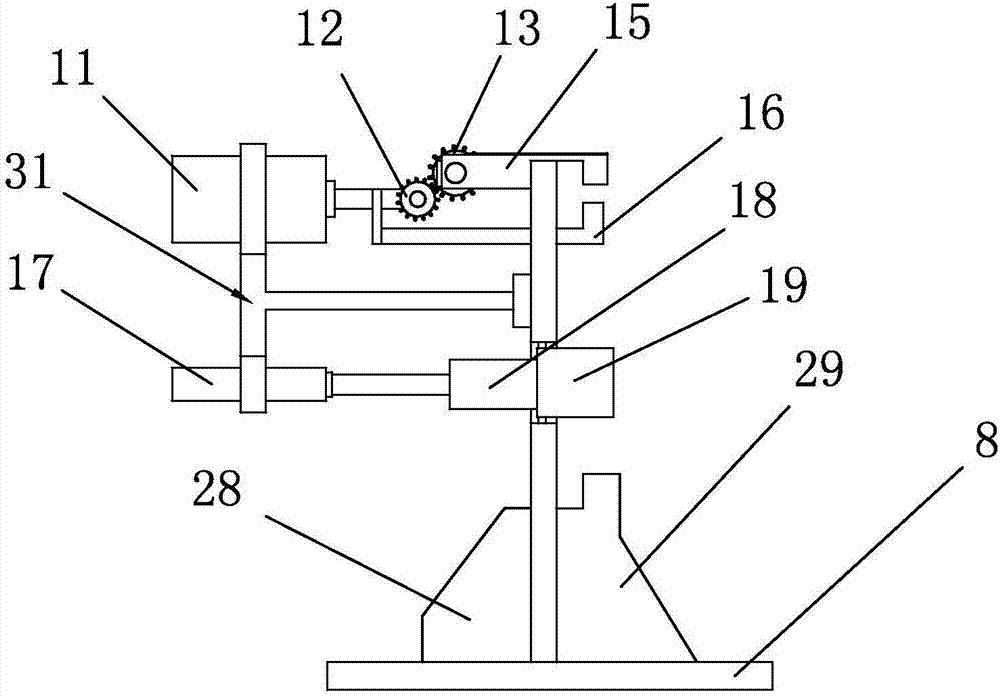

[0026] like Figure 1 to Figure 6 As shown, it is a frock and fixture for welding auto parts of the present invention, including a workbench 1, and support legs 21 are arranged on the four corners of the bottom surface of the workbench 1, and the upper ring of the support legs 21 is provided with a cushioning compression spring 22, and the support legs The design of 21 can make the structure of the workbench 1 firmer and improve the stability of the support. At the same time, the design of the buffer compression spring 22 can slow down the vibration amplitude during the welding process of the parts, which is more convenient for actual operation.

[0027] A left-right symmetrical auxiliary clamping part 2 is arranged on the workbench 1. The auxiliary clamping part 2 includes a fixed plate 3, a clamping cylinder 4, a clamping plate 5 and a limit plate 6, and the clamping cylinder 4, clamping plate 5 and The limiting plates 6 are all arranged on the fixed plate 3, the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com