Patents

Literature

117results about How to "Easy to weld and fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

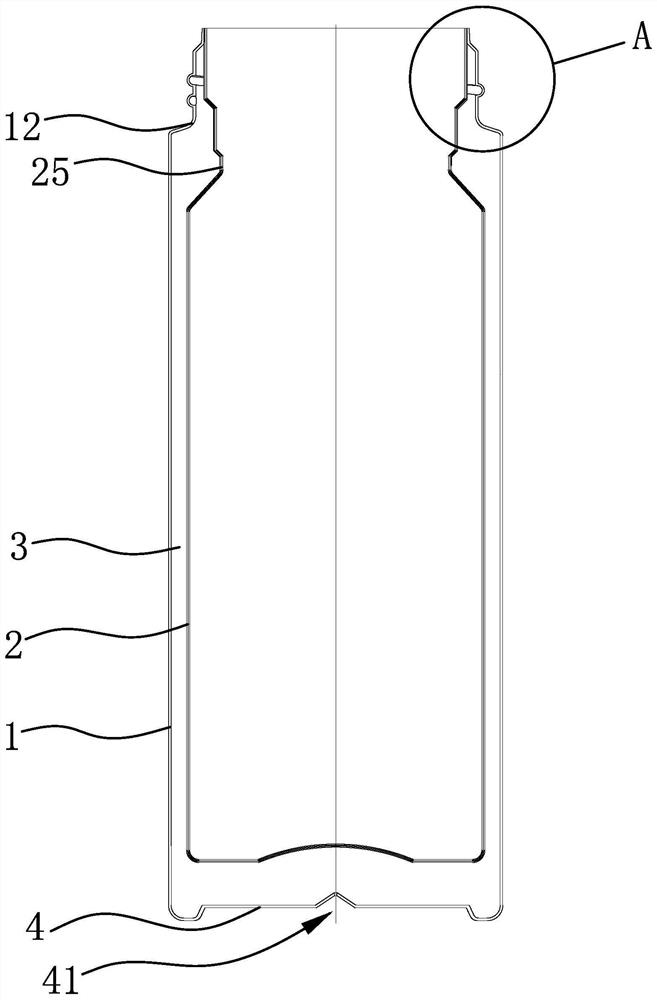

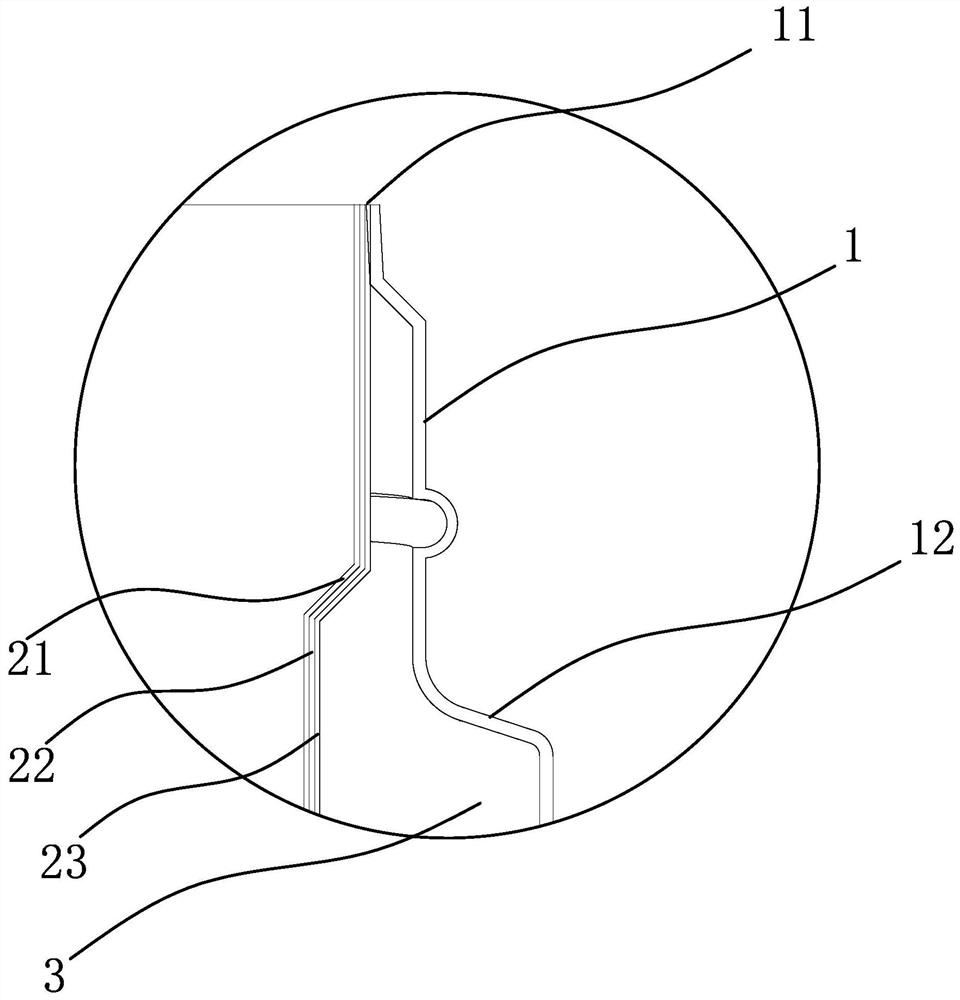

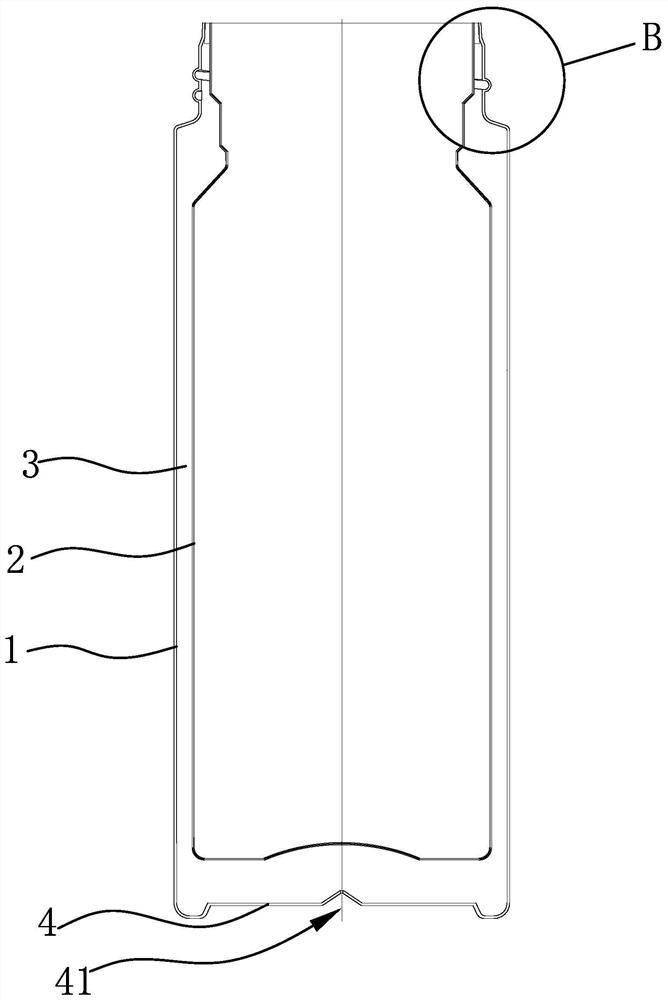

Composite vacuum cup and manufacturing process thereof

PendingCN112137371AManufacturing process advantagesImprove cleanlinessDrinking vesselsTitanium metalTitanium

The invention provides a composite vacuum cup and a manufacturing process thereof, and belongs to the technical field of vacuum cups. The technical problems that an existing vacuum cup is low in production efficiency, high in manufacturing cost and the like are solved. The composite vacuum cup comprises a shell and an inner container inserted into the shell, a vacuum layer is arranged between theshell and the inner container, and the inner layer of the inner container is made of titanium or titanium alloy. The inner container is provided with a middle layer made of copper metal or copper alloy or aluminum metal or aluminum alloy and an outer layer made of stainless steel materials, or the inner container is provided with an outer layer made of copper metal or copper alloy or aluminum metal or aluminum alloy, and a welding ring made of stainless steel materials is arranged on the outer surface of the upper end of the outer layer. The manufacturing process of the composite vacuum cup comprises the following steps: a, manufacturing a shell; b, manufacturing an inner container: manufacturing the inner container from a composite board through a plurality of stretching processes; and c,performing assembling. The machining efficiency is improved, and the manufacturing cost is saved.

Owner:亚钛军创(金华)控股有限公司

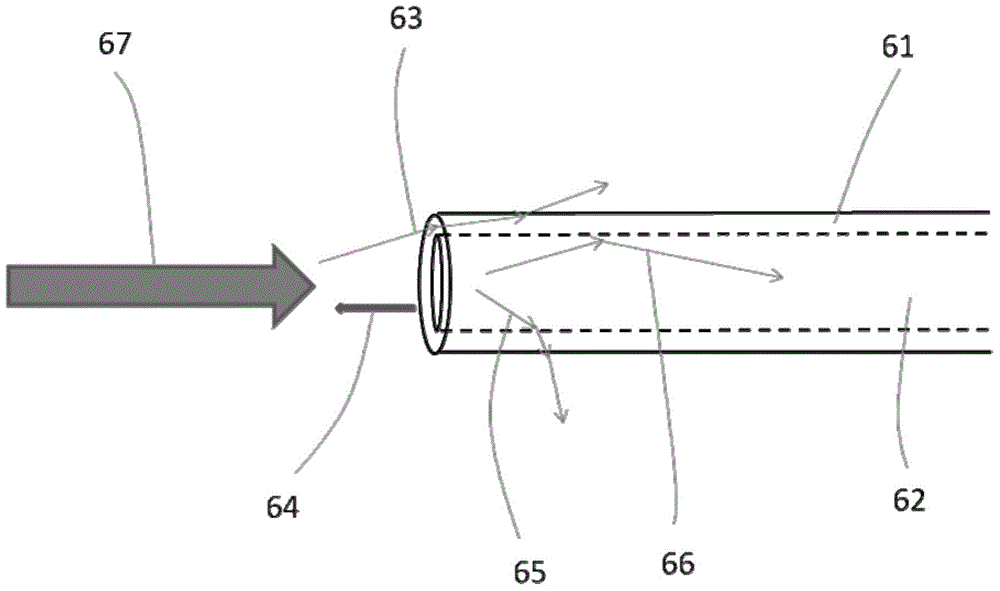

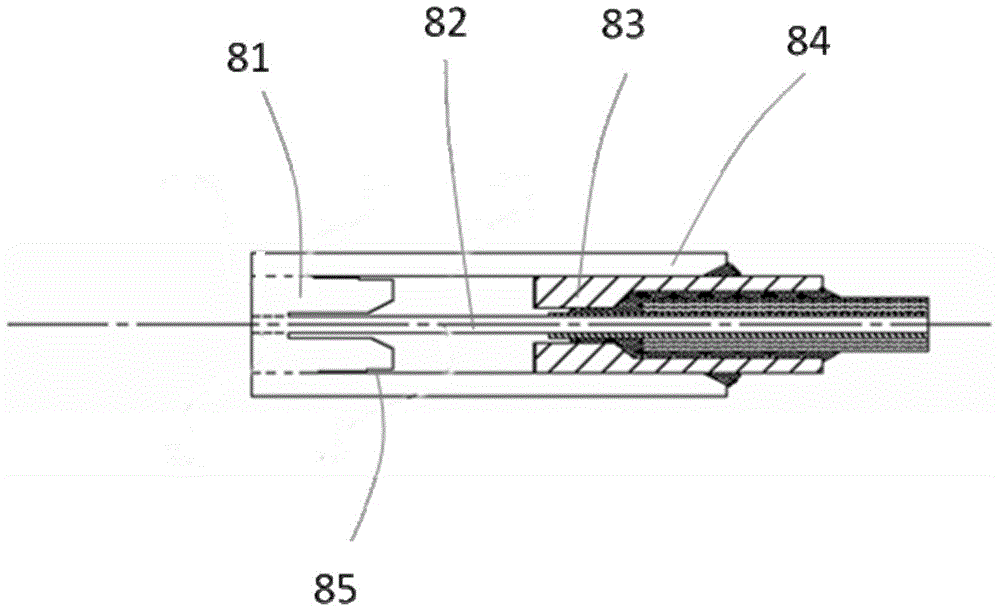

Optical fiber connector

ActiveCN103823277AGood wettabilityGood thermal conductivityCoupling light guidesOptical fiber connectorThermal conductivity

Disclosed in the invention is an optical fiber connector comprising a connector body and a segment of bare fiber penetrating the connector body. The connector body includes a metal sleeve, a first fiber fixed component fixed at one end of the metal sleeve, and a second fiber fixed component fixed at the other end of the metal sleeve. The bare fiber includes a first bare fiber passing through the first fiber fixed component and a second bare fiber passing through the second fiber fixed component. Because the metal sleeve and metal solder have good invasion, welding fixation of the optical fiber connector and a laser protection shell can be realized beneficially. Moreover, due to the good thermal conductivity of the metal, the heat can be transmitted to the air through the metal sleeve or be transmitted to the metal solder through the metal sleeve and then to the laser protection shell for dissipation, so that heat dissipation can be carried out beneficially.

Owner:天津凯普林光电科技有限公司

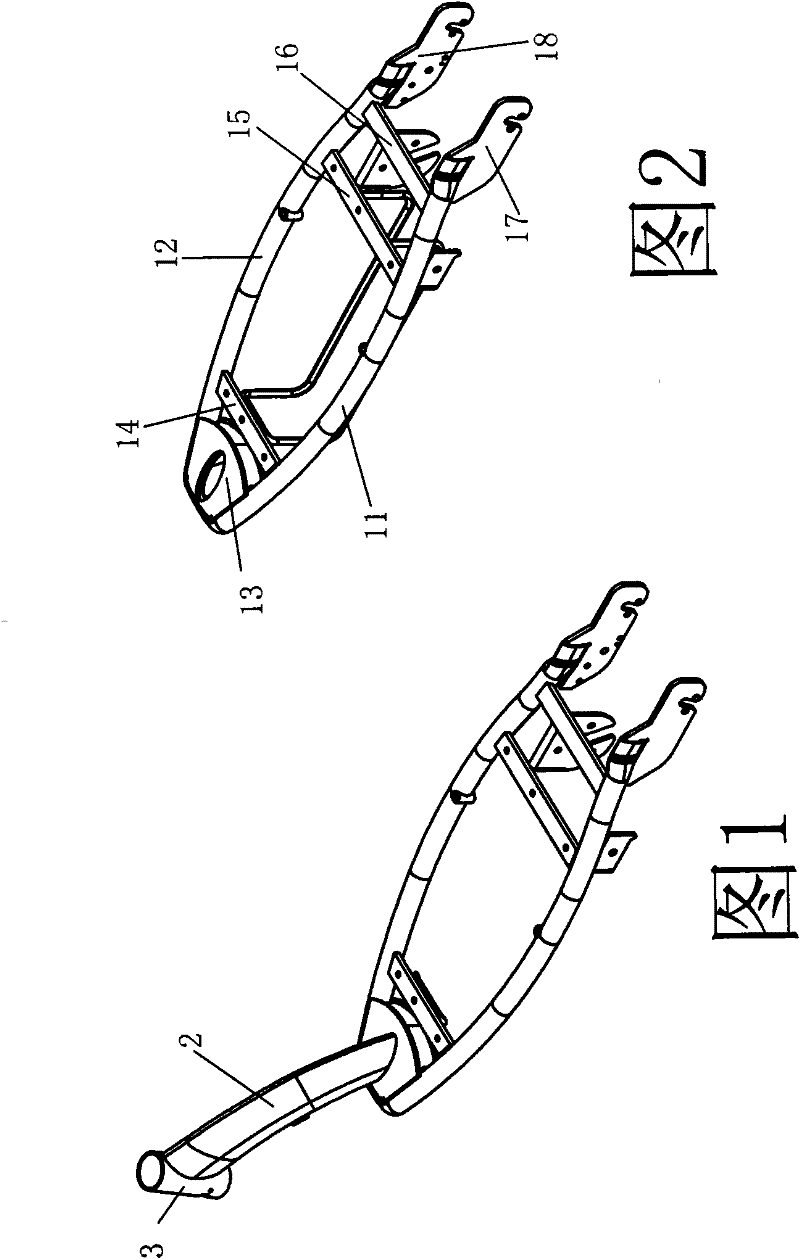

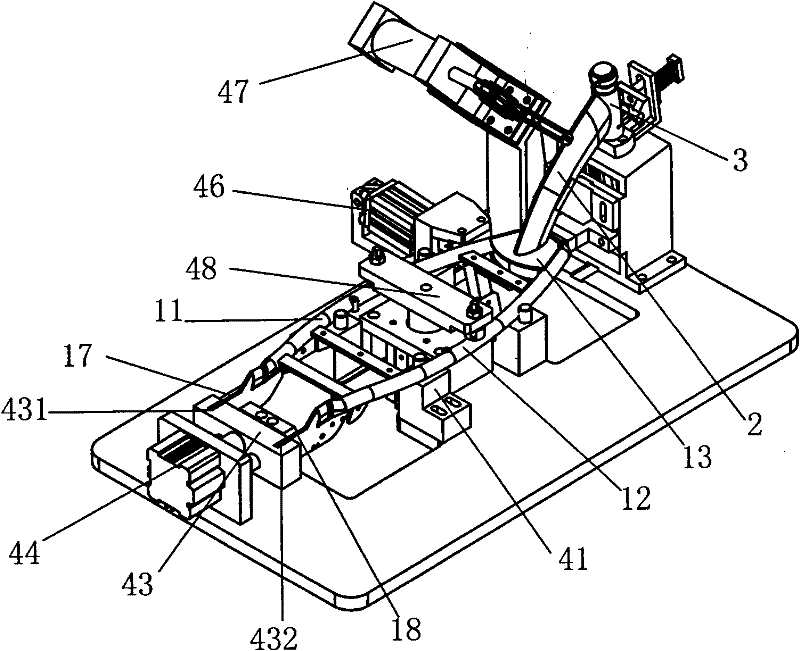

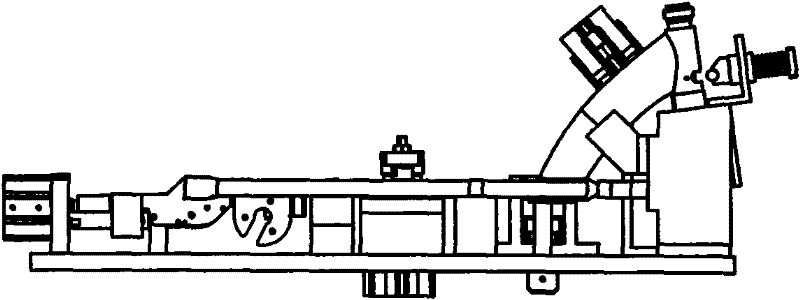

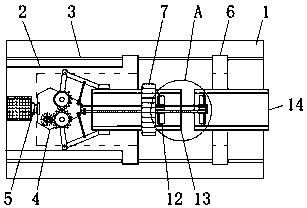

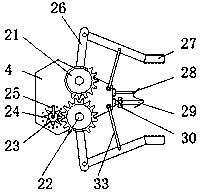

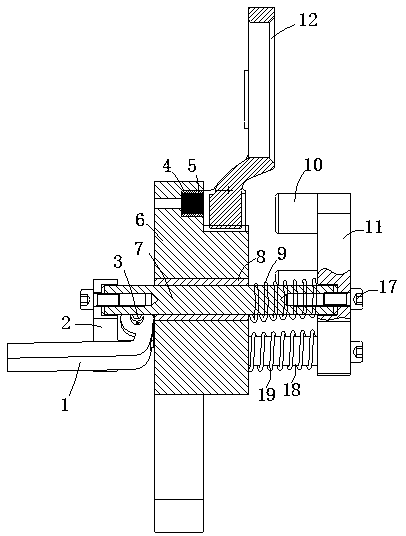

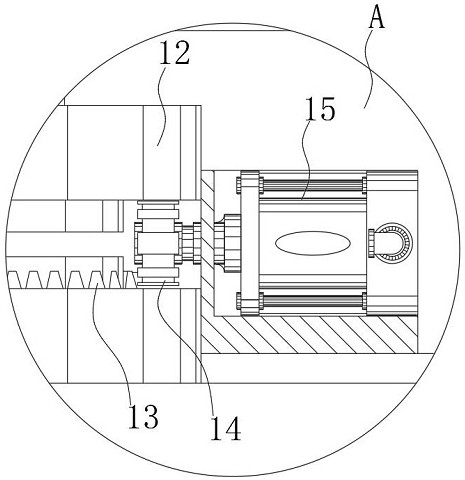

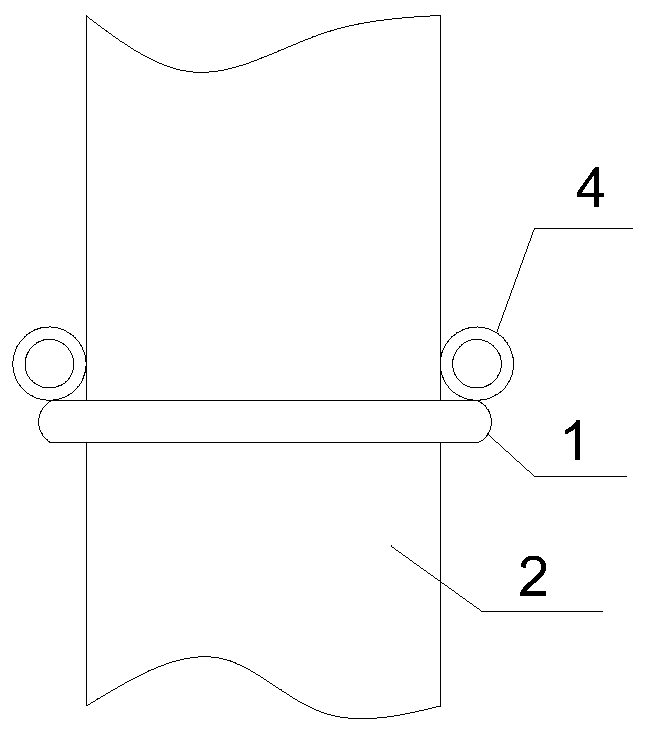

Scooter head assembly jig

InactiveCN102189365AEasy to weld and fixEasy to adjust welding positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a scooter head assembly jig, comprising a first clamping mechanism, a first locating mechanism, a second locating mechanism, a second clamping mechanism and a third clamping mechanism, wherein the first clamping mechanism comprises a frame fixing seat arranged below a pair of frame elbows and a first clamping cylinder used for fixing the frame elbows on the frame fixing seat; the first locating mechanism comprise a pressing block arranged at the end part of a pair of rear fork pieces and a first locating cylinder used for driving the pressing block to compact the rear fork pieces; the second locating mechanism comprises a locating module arranged below an upper sealing strip on the frame and a second locating cylinder used for driving the locating module to elevate; the second clamping mechanism comprises a quick release claw at the side part of a special pipe and a second clamping cylinder used for controlling the quick release claw to compact the special pipe; and the third clamping mechanism comprises a cylinder shaft which is sheathed with a front pipe in a penetrated mode and a third locating cylinder used for driving the cylinder shaft to locate, and the third clamping mechanism also comprises a piercing shaft sleeve which is sheathed at the upper end of the cylinder shaft and can be inserted into the front pipe and a scooter head pressing die fixed at the upper end part of the piercing shaft sleeve.

Owner:旭东机械(昆山)有限公司

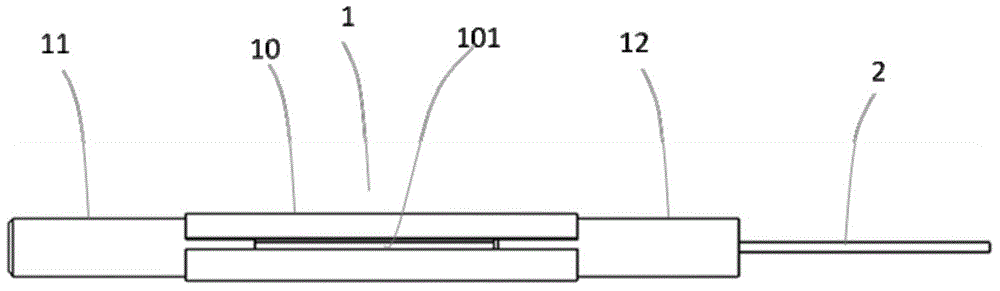

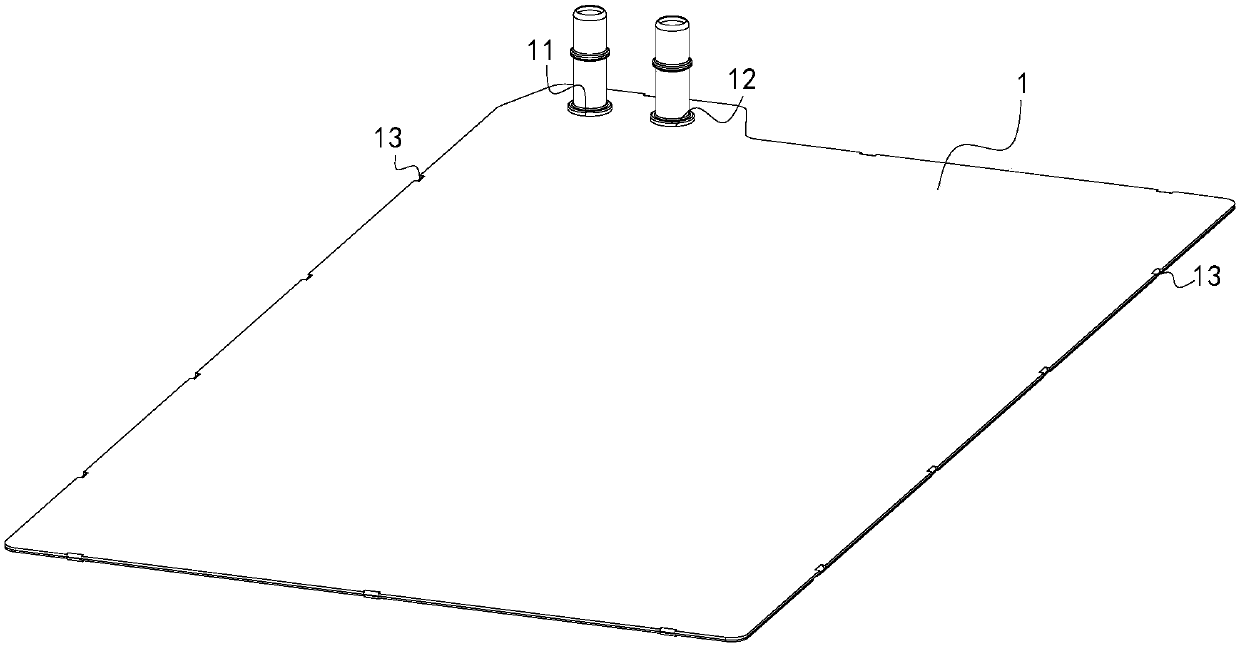

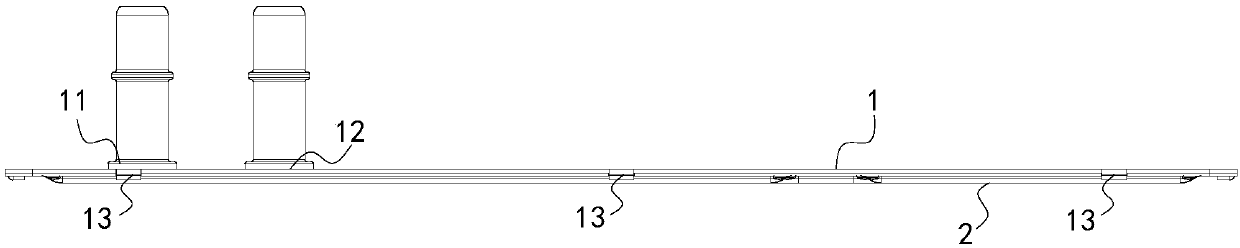

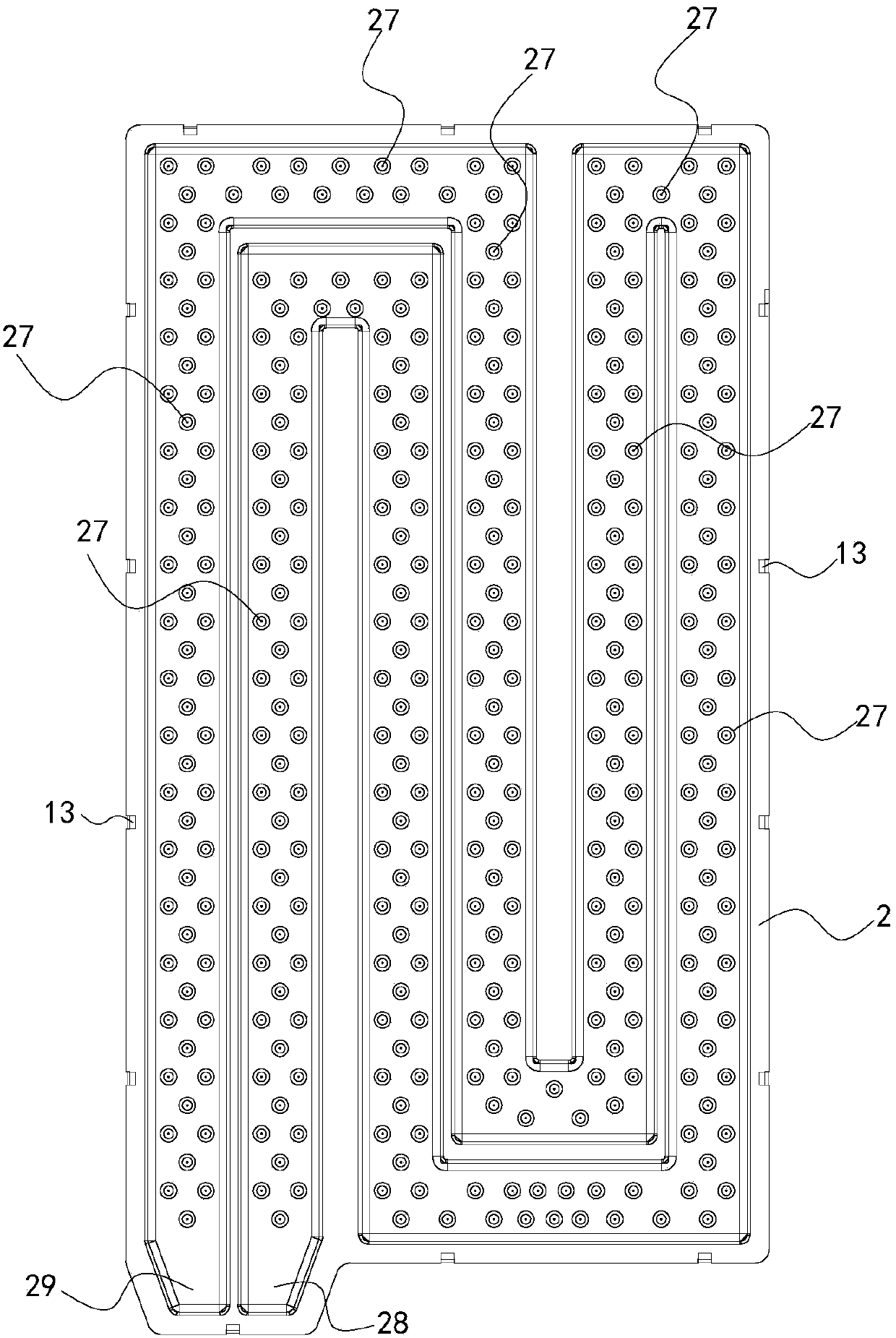

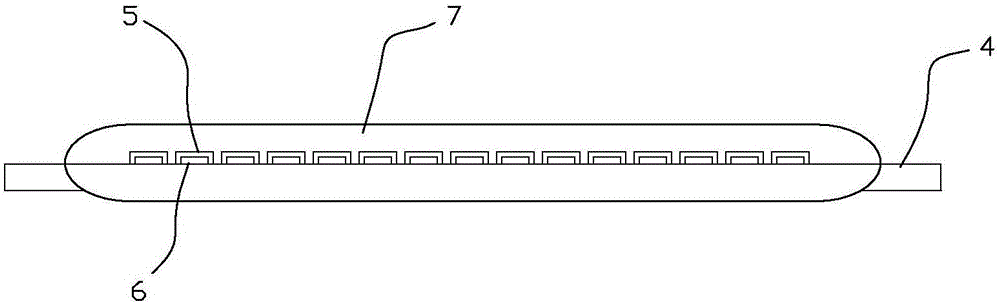

Power battery water-cooling plate for brazing

InactiveCN107863587ASimple structureImprove pressure resistanceSecondary cellsBatteriesPower batteryEngineering

The invention relates to a power battery water-cooling plate for brazing. The power battery water-cooling plate comprises an upper plate and a lower plate, wherein the upper plate is buckled with thelower plate, the upper plate and the lower plate are fixed by brazing, a runner is formed between the upper plate and the lower plate and is used for a cooling liquid to flow, the runner comprises a liquid inlet runner and a liquid return runner which are arranged in parallel, an inlet and an outlet of the runner are arranged in parallel, a liquid inlet is formed in a position, corresponding to the inlet, of the upper plate, and a liquid outlet is formed in a position, corresponding to the outlet, of the upper plate. The power battery water-cooling plate is formed by only combining the upper plate and the lower plate, is simple in structure, good in pressure resistance, light in weight and high in heat exchange efficiency and is difficult to leak; by arranging the liquid inlet runner and the liquid outlet runner in parallel, the thermal equalization performance of a battery module is greatly improved; and the upper plate and the lower plate are fixed by brazing, the production efficiency is high, the weight of a battery module water-cooling system is reduced, the heat exchange capability of the water-cooling plate is improved, good temperature uniformity is achieved, and the powerbattery water-cooling plate is suitable for rapid production on a large scale.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

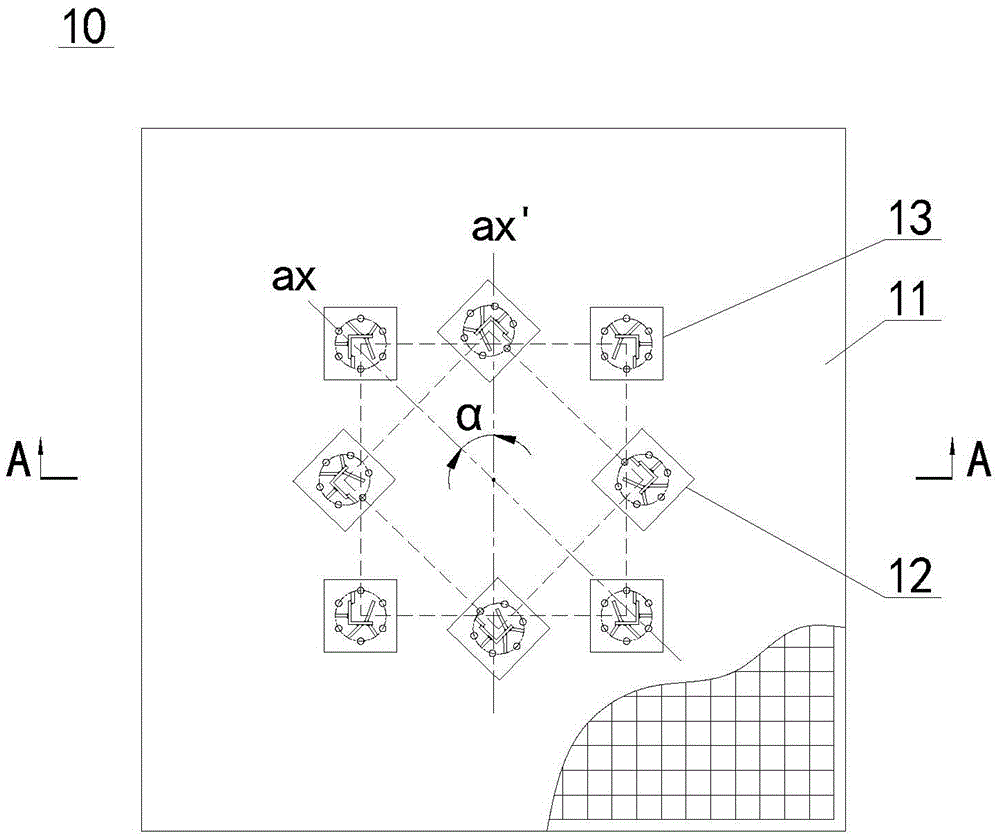

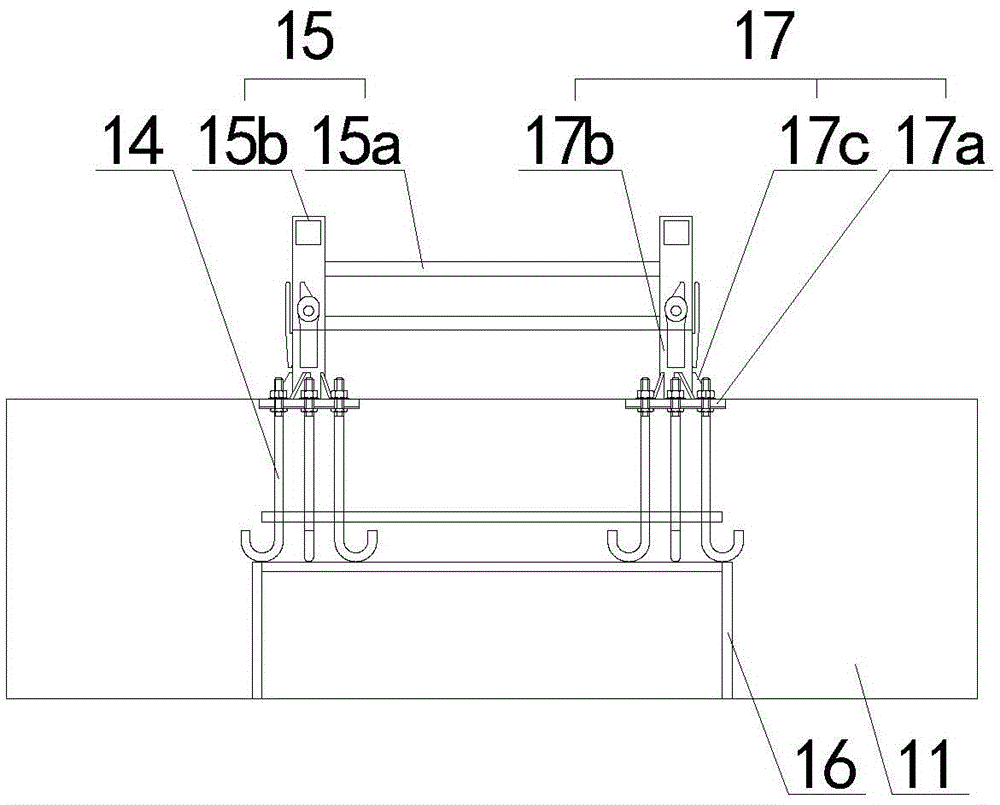

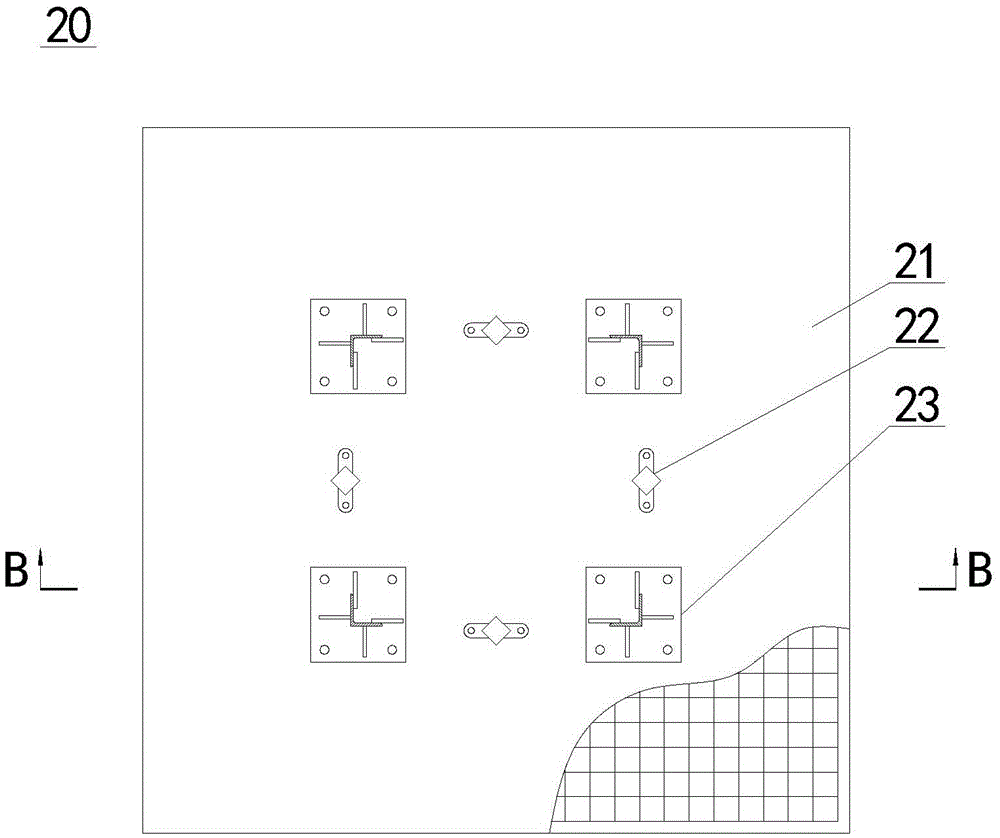

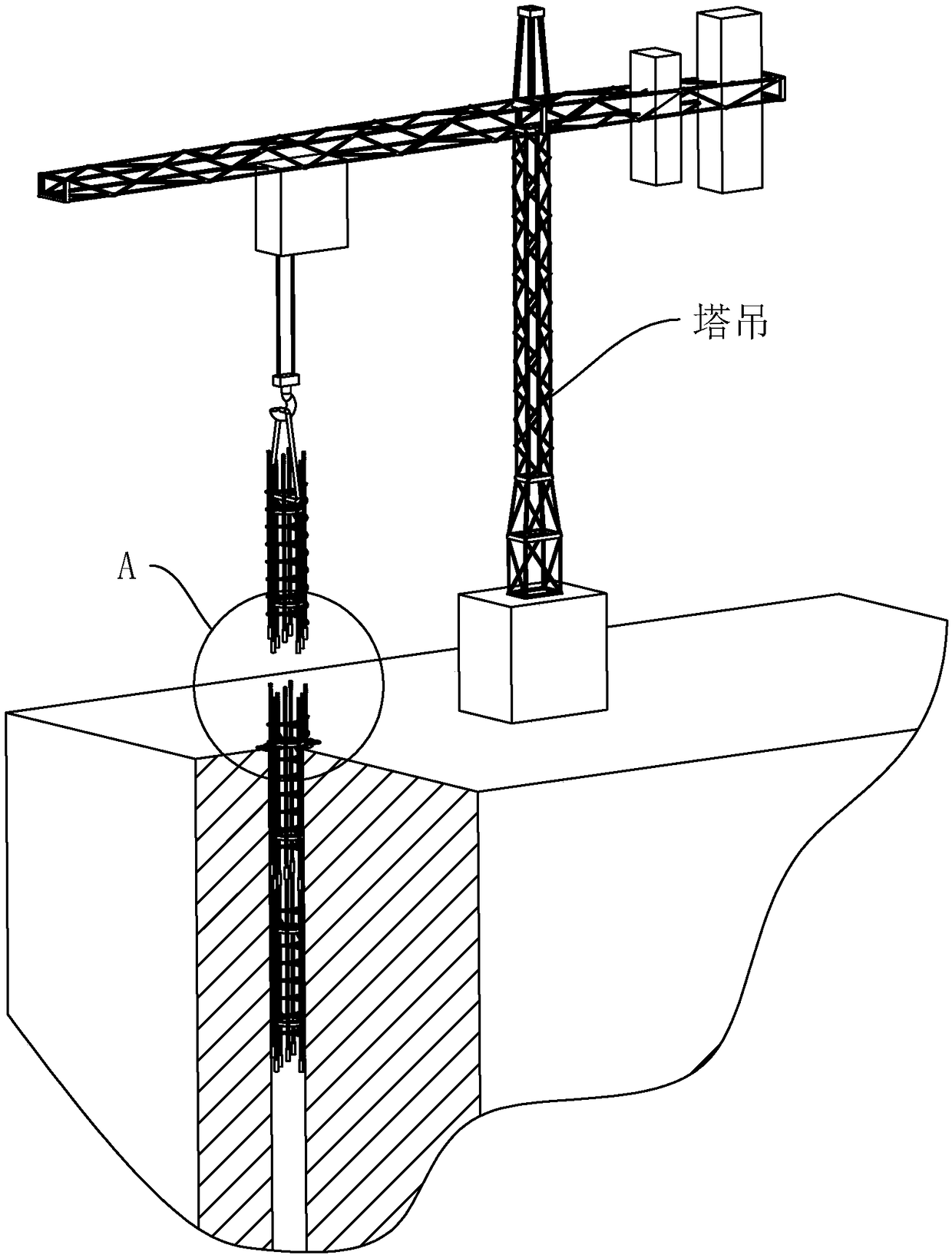

Combined tower crane foundation and construction method thereof

ActiveCN105544587AFlexible and convenient replacementReduce manufacturing costFoundation engineeringAssistive device/technologyRebar

The invention discloses a combined tower crane foundation and a construction method thereof, relates to the technical field of auxiliary equipment for fixing tower cranes, and aims at the problem that a certain limitation exists in tower crane selection during a construction process due to the fact that an existing tower crane foundation is capable of fixing tower cranes of only one type. The compound tower crane foundation comprises a concrete foundation and two sets of embedded assemblies, wherein the two sets of embedded assemblies are anchored in the concrete foundation, and are respectively an embedded assembly I corresponding to a tower crane I, and an embedded assembly corresponding to a tower crane II; each set of embedded assemblies comprises four embedded parts which can be connected with four supporting foot bolts of a tower body of the corresponding tower crane, and the embedded parts of the two sets of embedded assemblies are arranged in a staggered manner. The construction method comprises the following steps: erecting a reinforcement cage and a template in the concrete foundation to be poured, and mounting and fixedly connecting the embedded assembly I and embedded bolts in the reinforcement cage; connecting the four embedded parts of the embedded assembly II onto a planar positioning frame and placing the planar positioning frame into the reinforcement cage, and enabling the embedded parts of the two sets of embedded assemblies to be arranged in a staggered manner; pouring the concrete, and after the concrete reaches strength of the design requirement, dismantling the planar positioning frame.

Owner:SHANGHAI CONSTR NO 1 GRP

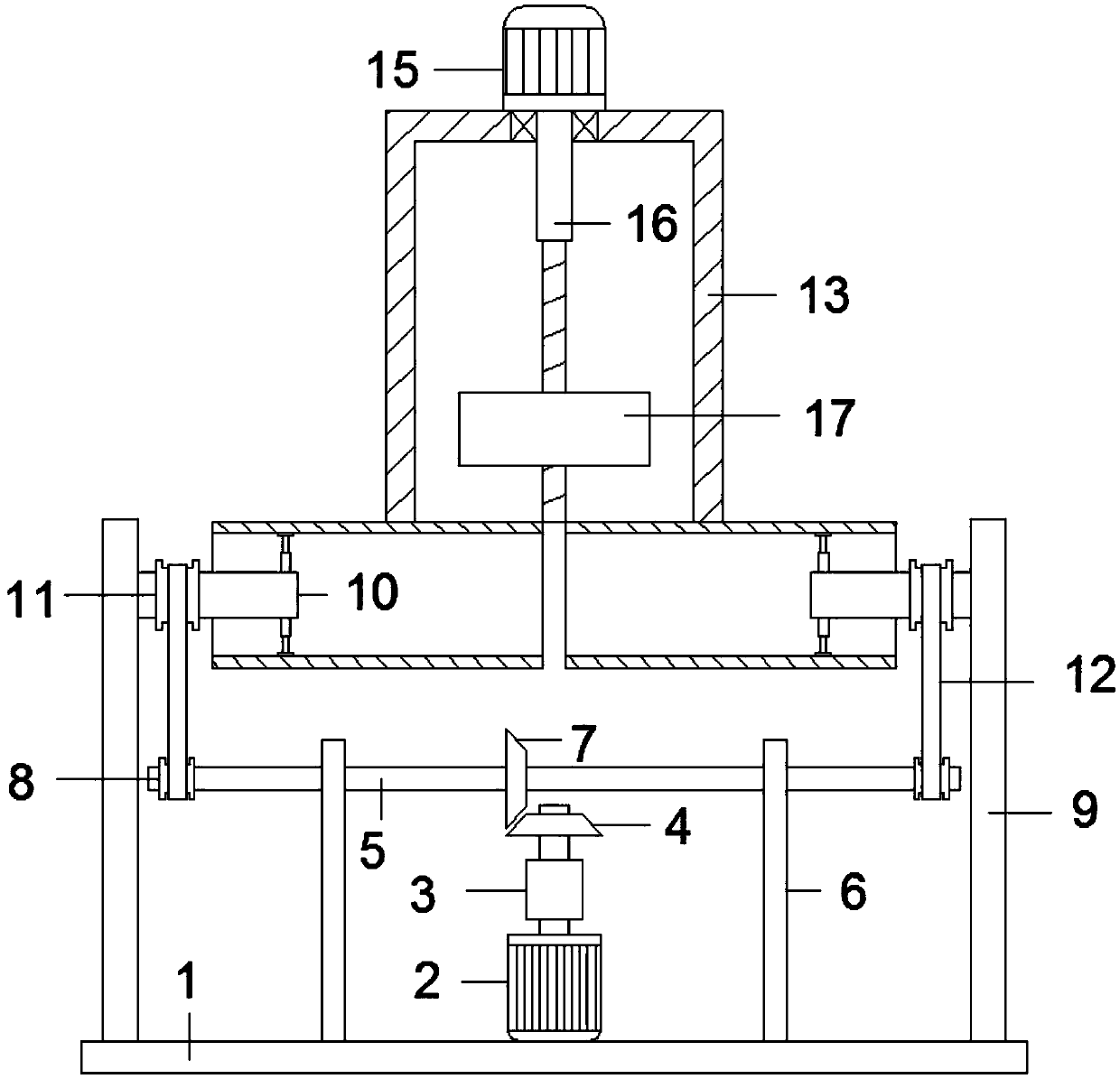

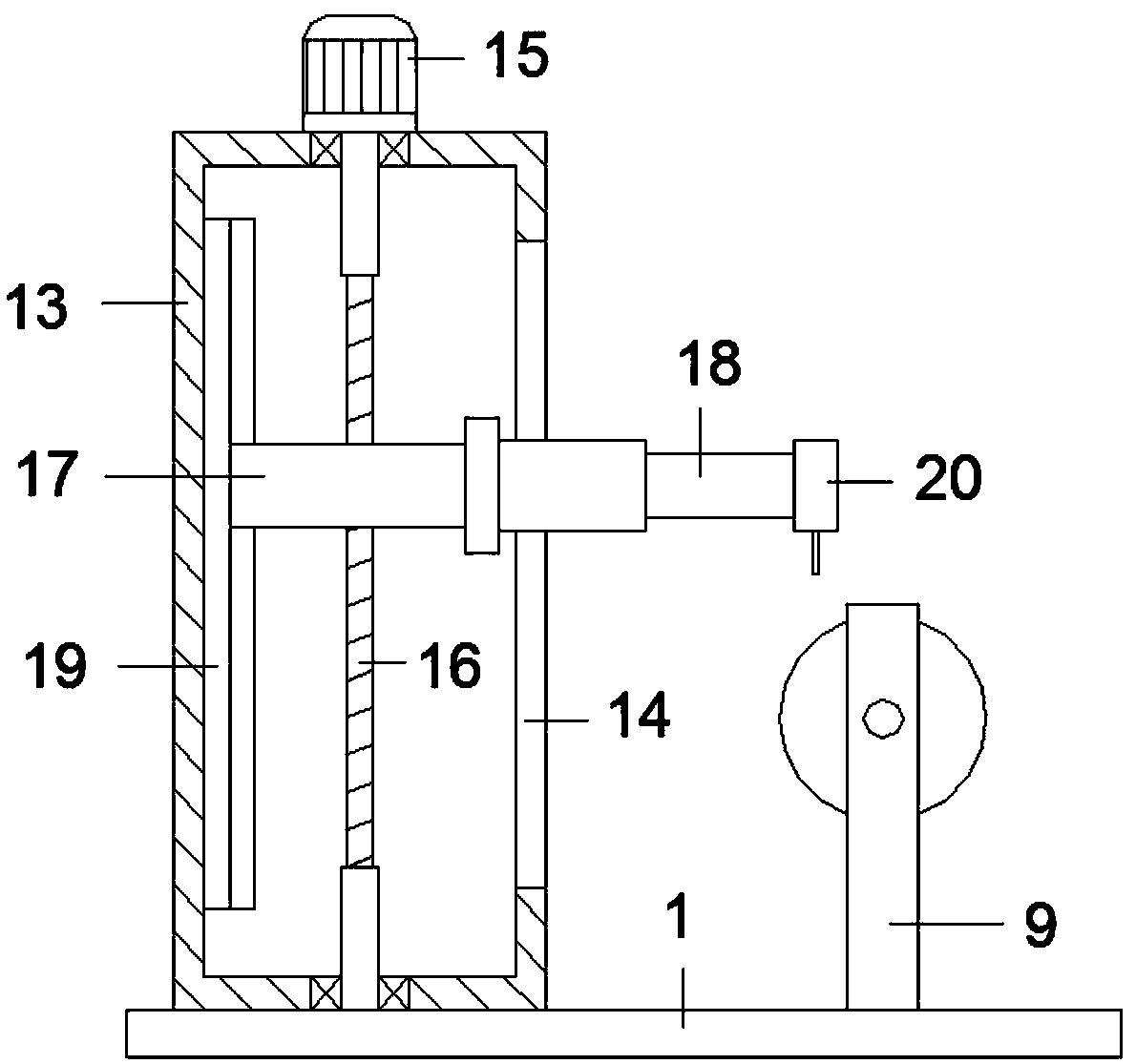

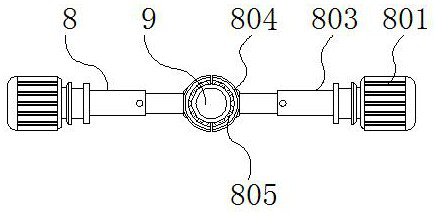

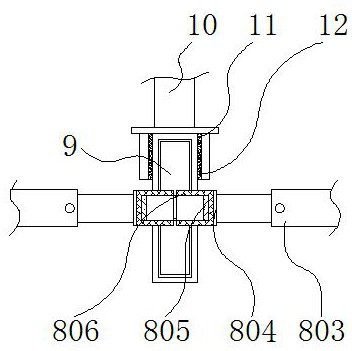

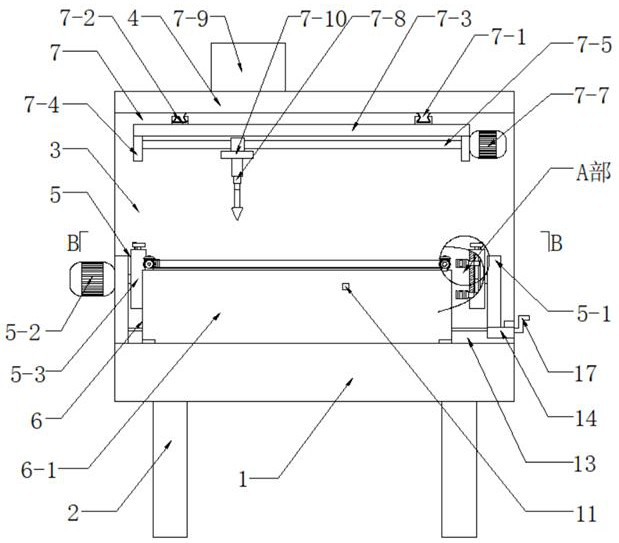

Positioning device beneficial for pipeline welding

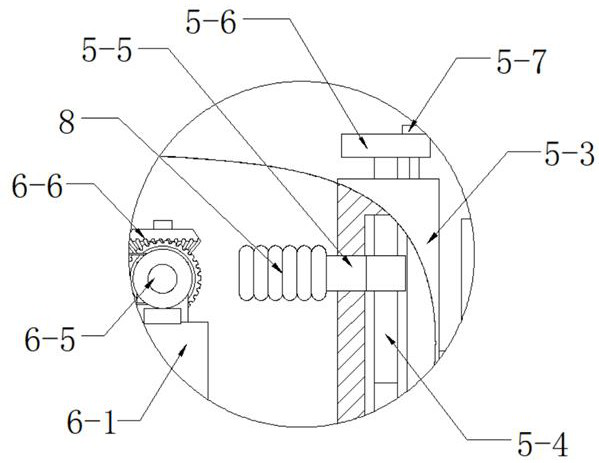

InactiveCN111375974AUniform weldingEasy to weld and fixWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelReduction drive

The invention discloses a positioning device beneficial for pipeline welding in the technical field of welding. The positioning device comprises a bottom plate. A first motor is installed at the center of the top of the bottom plate. The power output end of the top of the first motor is connected with a main bevel gear through a speed reducer. The top of the bottom plate is provided with a rotating rod. The circumferential outer side of the rotating rod is rotationally connected with two symmetrical inner supporting rods through bearings. The bottoms of the inner supporting rods are fixedly connected to the top of the bottom plate. The middle of the circumferential outer side of the rotating rod is fixedly connected with an auxiliary bevel gear. The auxiliary bevel gear meshes with the main bevel gear. The two sides of the rotating rod are fixedly connected with two symmetrical driving wheels. The top of the bottom plate is fixedly connected with two outer rods in left-right symmetry.The sides, close to each other, of the two outer rods are each rotationally connected with a support through a bearing. The circumferential outer side wall of the support is fixedly connected with a driven wheel. The driven wheel is connected with the driving wheels through a belt. Thus, the invention provides the positioning device for pipeline welding and beneficial for rotating pipelines.

Owner:童卓超

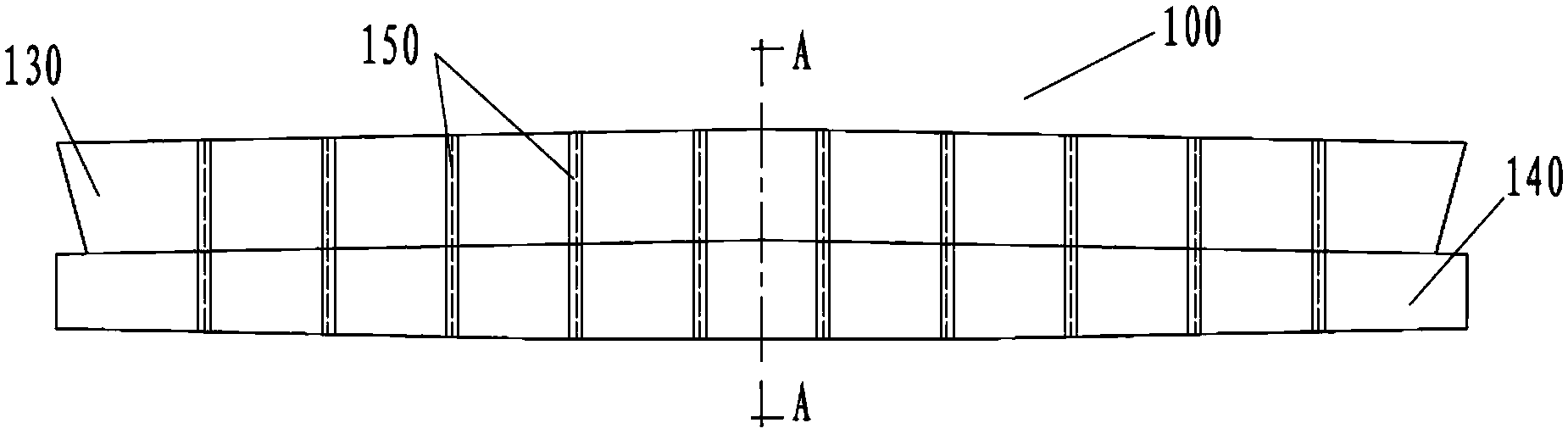

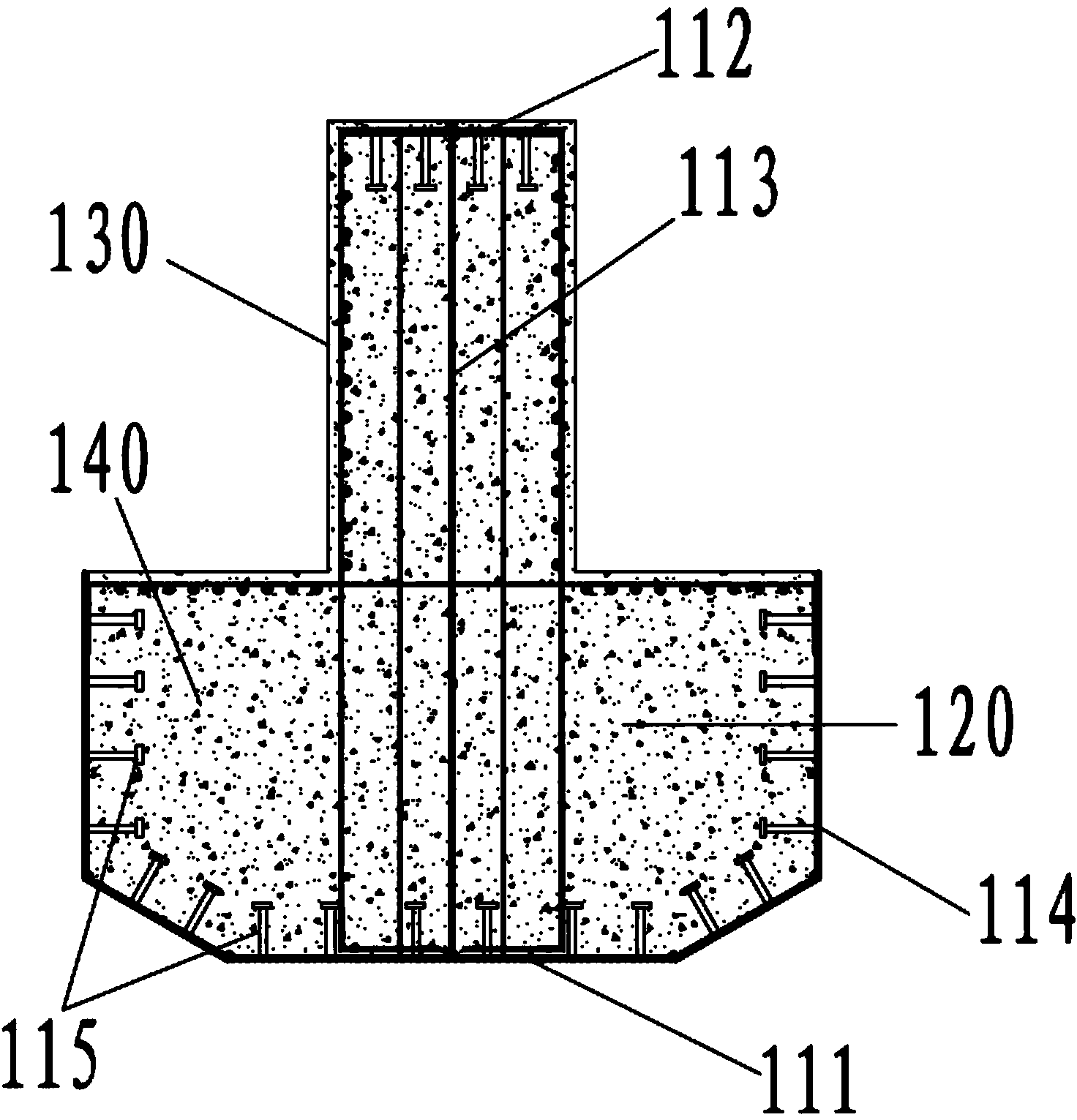

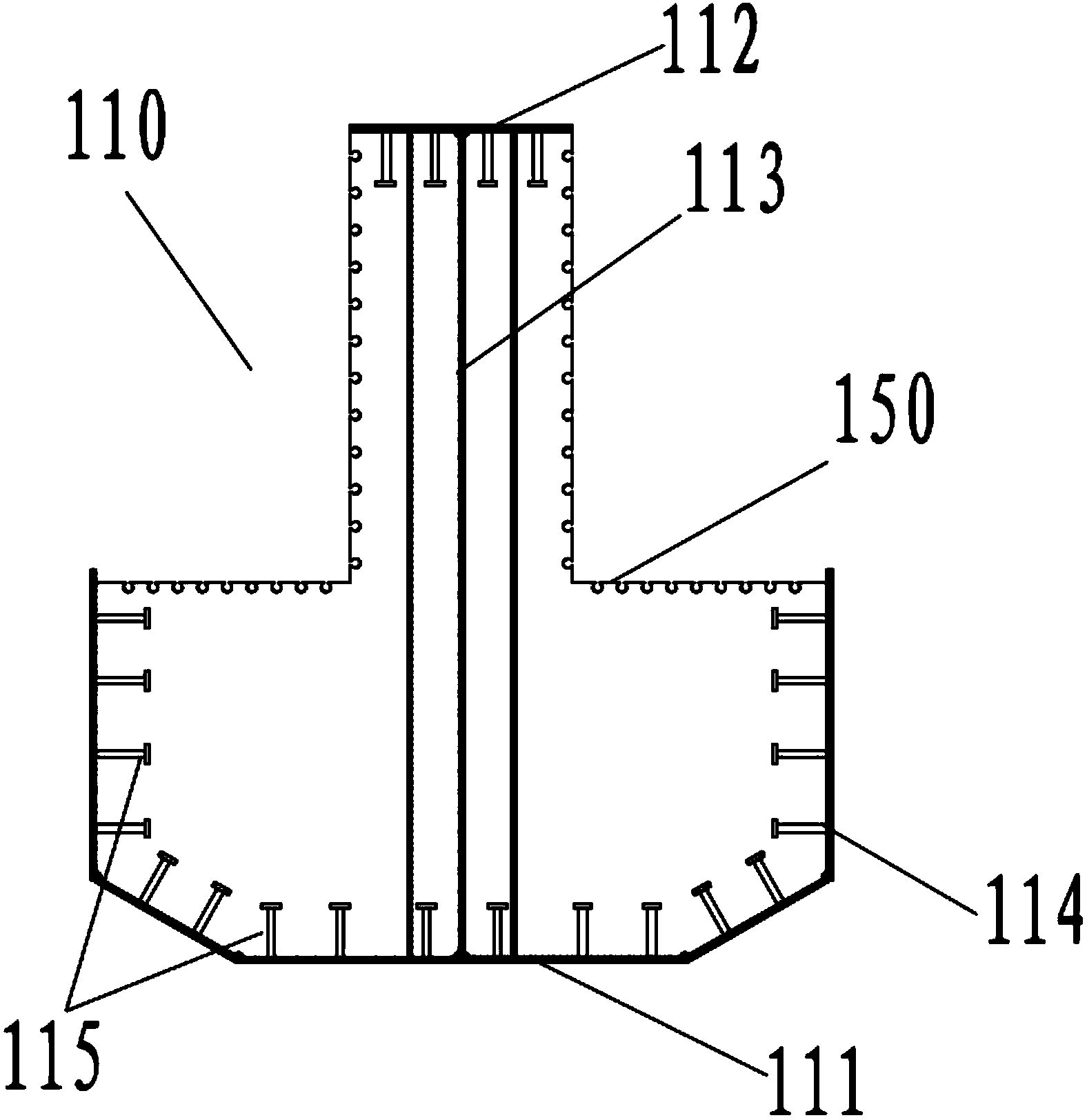

Cast-in-situ inverted-T-shaped bent cap and pier and pier construction process

ActiveCN103452039AImprove structural performanceIncrease stiffnessBridge structural detailsBridge erection/assemblyRebarInverted t

The invention discloses a cast-in-situ inverted-T-shaped bent cap and a pier as well as a pier construction process. The cast-in-situ inverted-T-shaped bent cap comprises a rigid skeleton and a concrete structure, wherein the concrete structure is cast in the rigid skeleton; the rigid skeleton comprises a lower baffle plate, an upper baffle plate, a connecting plate and two side baffle plates, and the lower baffle plate, the upper baffle plate and the connecting plate are connected to form an I-shaped steel structure; the side baffle plates are respectively arranged at the two side edges of the lower baffle plate and extend upwards. The pier comprises a stand column and the cast-in-situ inverted-T-shaped bent cap, wherein the cast-in-situ inverted-T-shaped bent cap is arranged on the stand column. The pier construction process comprises the following steps: because the rigid skeleton is prefabricated, and the stand column is built, the rigid skeleton is lifted on the stand column, and the anchoring steel bar on the stand column is inserted into the rigid skeleton; the rigid skeleton is used as a concrete casting template to cast the concrete structure, and finally the pier is formed. The cast-in-situ inverted-T-shaped bent cap and the pier as well as the pier construction process have the advantages that the construction is convenient, no support or a few supports can be arranged, and the interference on ground traffic is smaller.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

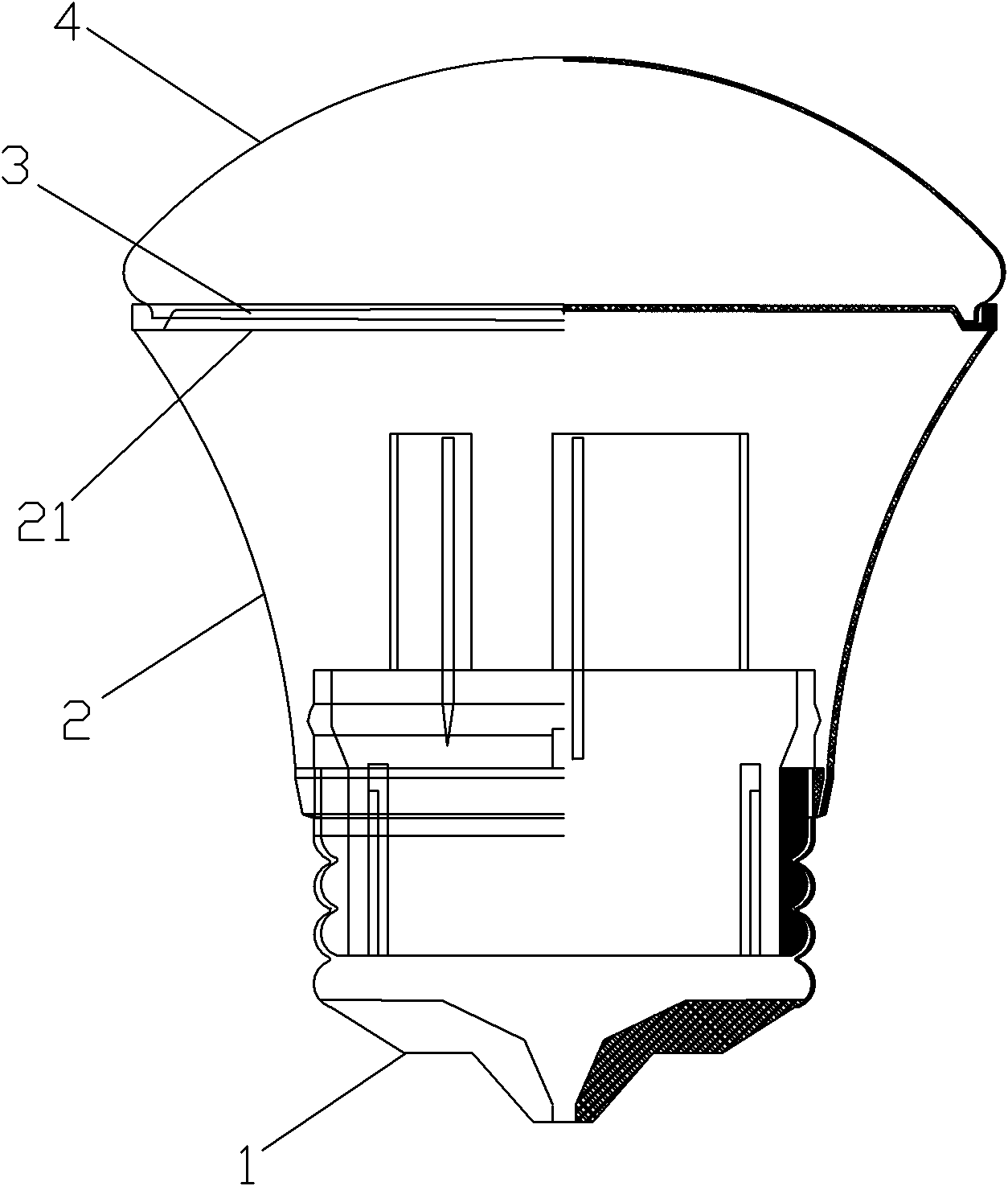

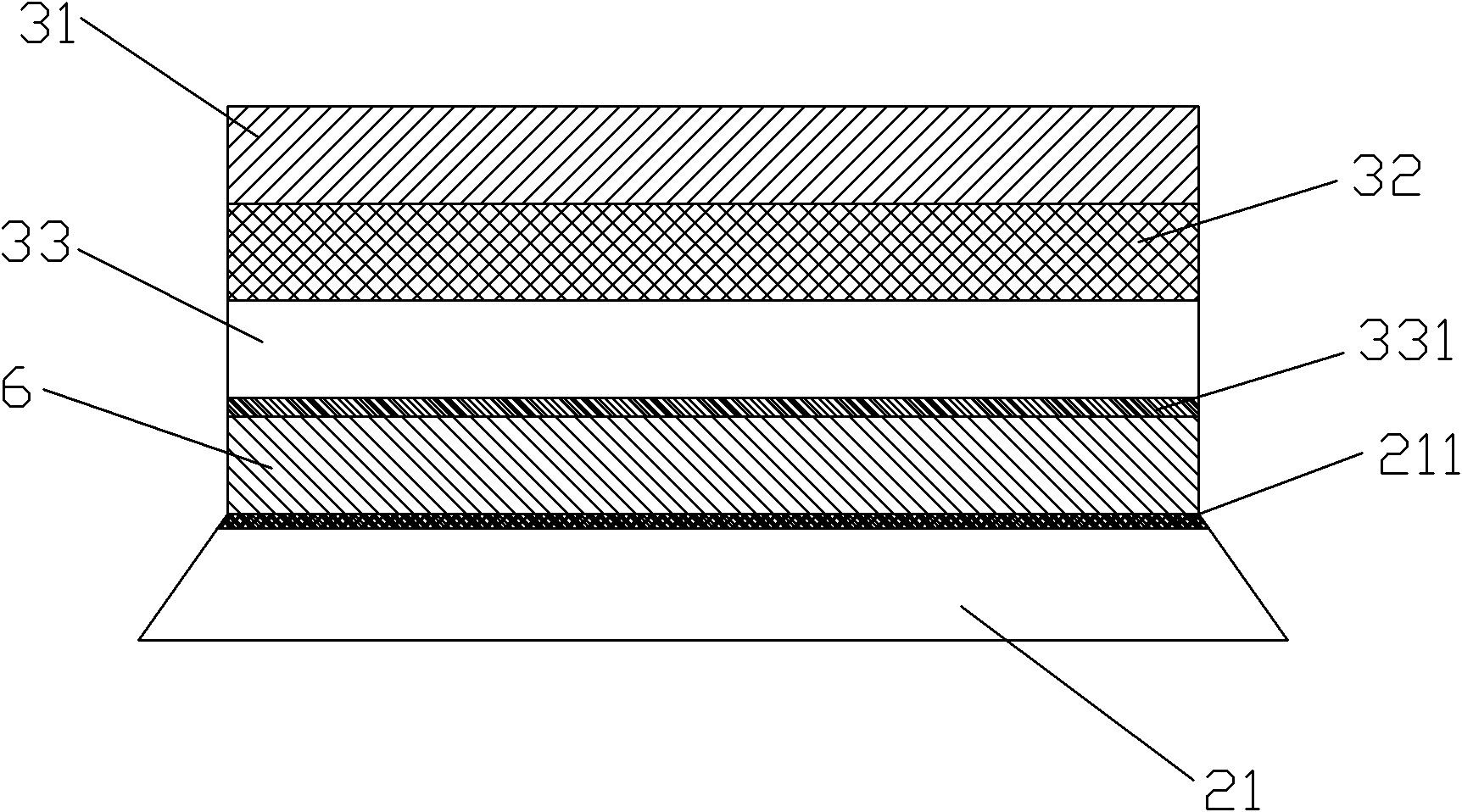

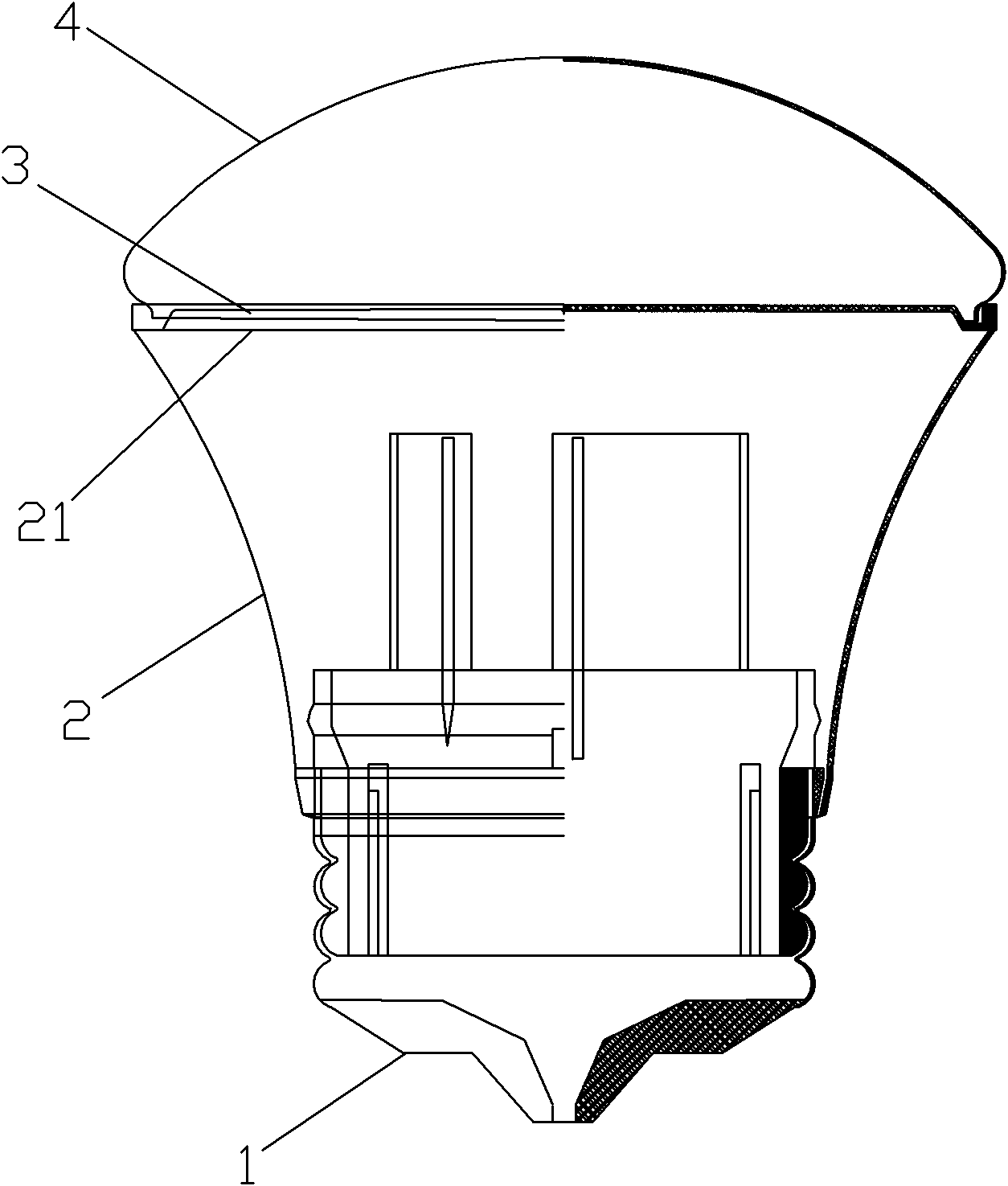

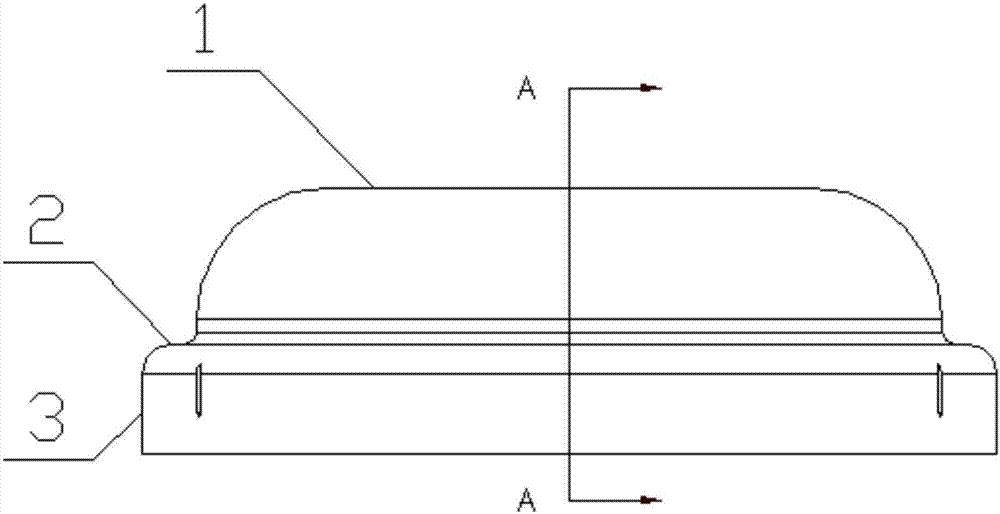

Completely-metal integrated illuminating and backlight LED heat radiating structural body

InactiveCN102012005AImprove solderabilityIncrease heat dissipation structurePoint-like light sourceLighting heating/cooling arrangementsMetal coatingEngineering

The invention discloses a completely-metal integrated illuminating and backlight LED heat radiating structural body which comprises a lamp holder, a lamp cup body, a circuit board provided with an LED, and a lamp shade, wherein the lamp holder is fixedly connected with one end of the lamp cup body through an insulation plastic shell, the lamp shade is fixedly connected with the other end of the lamp cup body, the circuit board is connected to the lamp cup body, the lamp cup body is an integrated structure made of an aluminum material; an aluminum foil or aluminum plate layer is arranged on one surface in the circuit board, which is connected with the lamp cup body, the outer side surface of the aluminum foil or aluminum plate layer is plated with a first metal coating; one surface in the lamp cup body, which is connected with the circuit board is provided with an aluminum installing surface, the outer side surface of the aluminum installing surface is plated with a second metal coating; and the first metal plating layer of the aluminum foil or aluminum plate layer of the circuit board is welded and fixed with the second metal coating of the lamp cup body. The invention realizes a completely-metal integrated structure, greatly improves the heat radiation of the LED lamp and ensures that the heating temperature of the LED lamp is effectively controlled.

Owner:XIAMEN HUIGENG ELECTRONICS IND

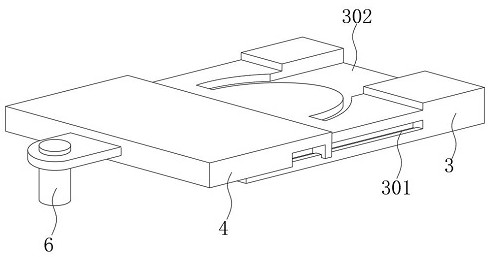

Assembling device with clamping and overturning structure for electronic part machining

InactiveCN112207501AEasy flipEasy to assembleWelding/cutting auxillary devicesAuxillary welding devicesRotational axisElectric machine

The invention discloses an assembling device with a clamping and overturning structure for electronic part machining, and relates to the technical field of electronic part machining. The assembling device comprises a workbench, a clamping and overturning mechanism and a welding and fixing mechanism, wherein machine frames are fixed on the two sides of the upper part of the workbench, a top plate is fixed on the upper sides of the machine frames, an air cylinder is arranged below the middle of the top plate, a piston rod is arranged on the lower side of the air cylinder, a lifting plate is arranged below the piston rod, and side plates are fixed on the two sides of the lower part of the lifting plate. The assembling device has the beneficial effects that the clamping and overturning mechanism is arranged, the positions of clamping plates can be conveniently adjusted in a telescopic mode through a hydraulic telescopic rod, so that the two sets of symmetrically-arranged clamping plates can clamp and fix an electronic part main body; and the hydraulic telescopic rod, the clamping plates and the electronic part main body can be conveniently driven to rotate through a rotating motor anda rotating shaft, so that the overturning of the electronic part main body is conveniently realized, and the upper side and the lower side of the electronic part main body can be conveniently assembled.

Owner:深圳市康瑞龙数控科技有限公司

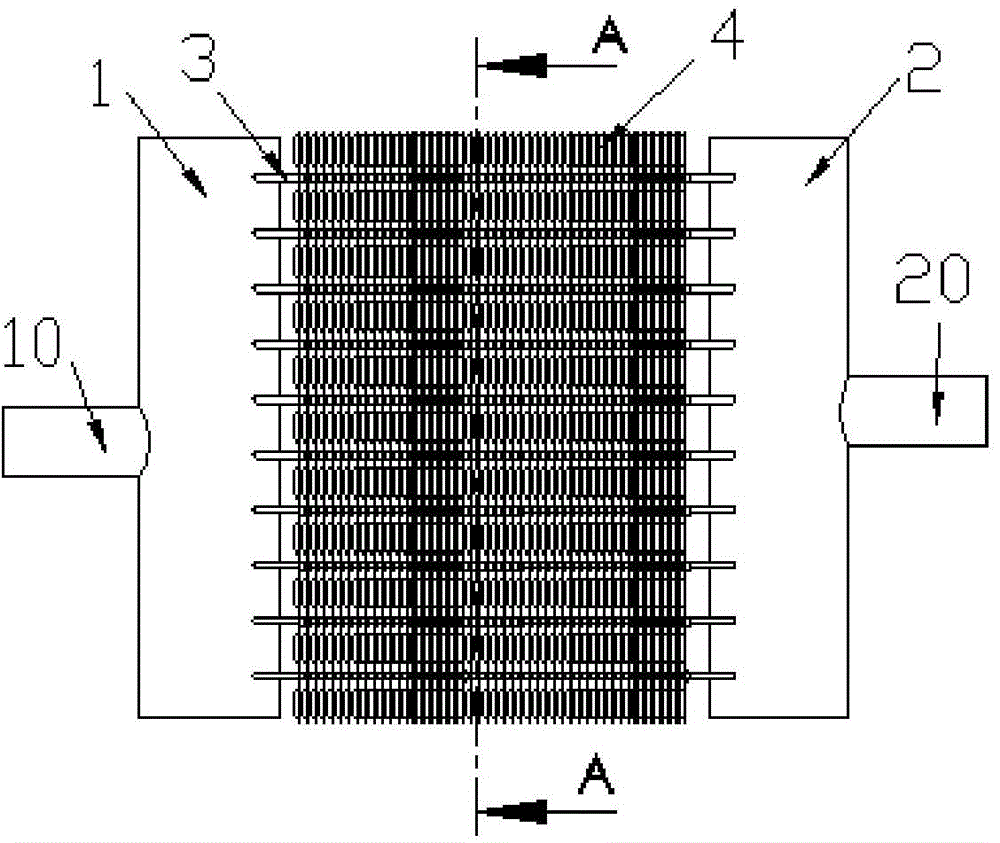

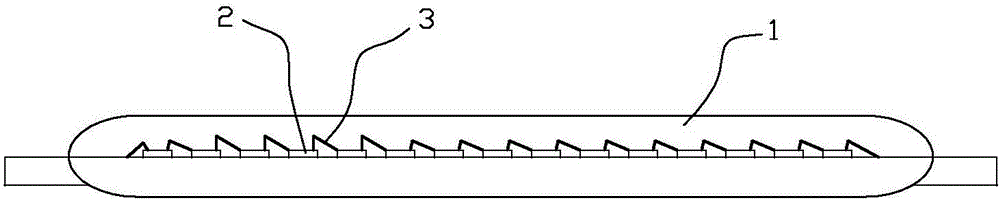

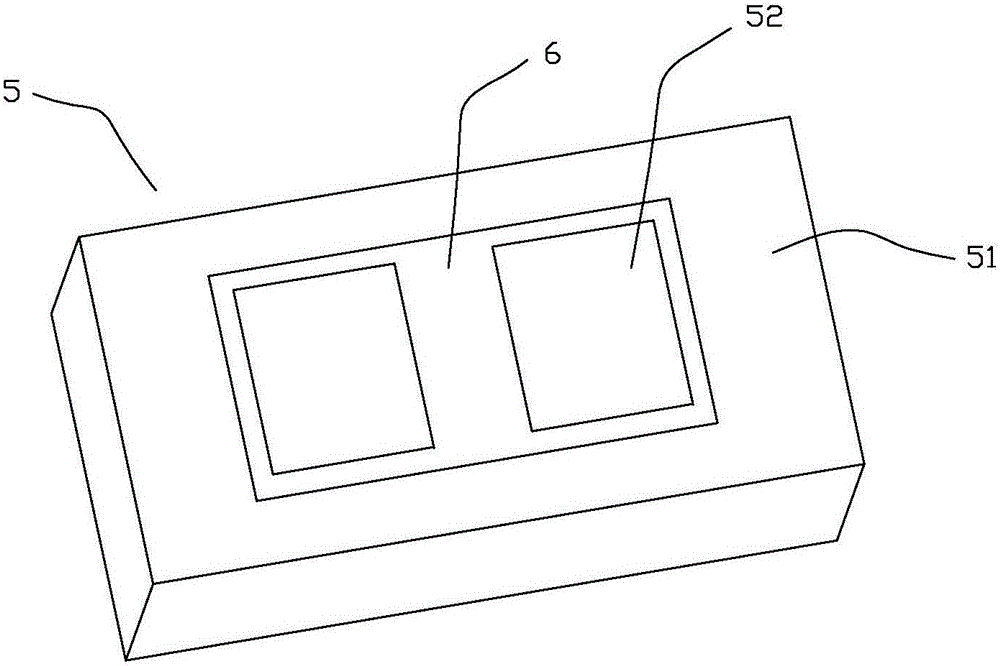

Heat pump type microchannel heat exchanger

InactiveCN104949395AEasy to installHigh strengthEvaporators/condensersTubular elementsDislocationEngineering

The invention discloses a heat pump type microchannel heat exchanger which comprises flat tubes and fins. A flat tube insertion hole is formed in each fin, the width dimension of each flat tube is H1, the width dimension H2 of each flat tube insertion hole is larger than the width dimension H1 of each flat tube, the flat tubes are clamped into the corresponding flat tube insertion holes and fixed in a welded mode, turned edges are arranged on each fin along the periphery of the corresponding flat tube insertion hole, an installation hole with the width larger than that of the corresponding flat tube is reserved at one end or at the two ends of each flat tube insertion hole. According to the technical scheme, the installation hole with the width larger than that of the corresponding flat tube is reserved at one end or at the two ends of each flat tube insertion hole to form a larger space or a cutting edge, and the space can be used for installing flat tube installation guide rails to fix the relative positions of the fins, so that dislocation of fins does not occur, and installation of the flat tubes is convenient.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

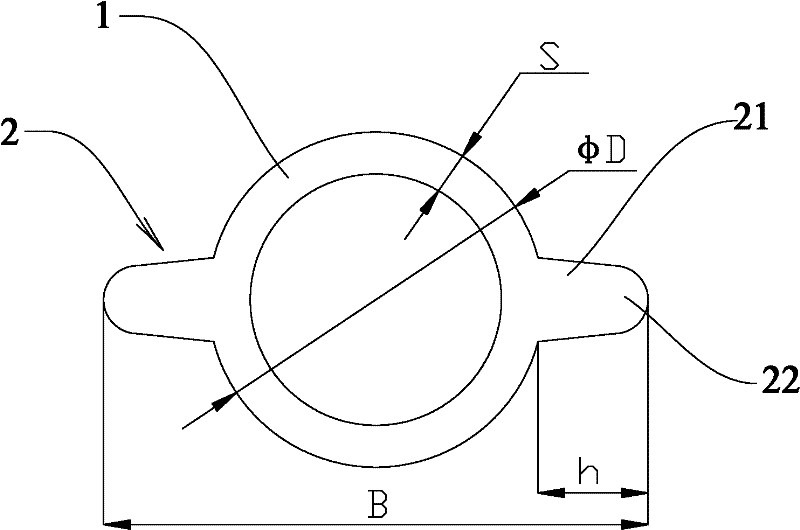

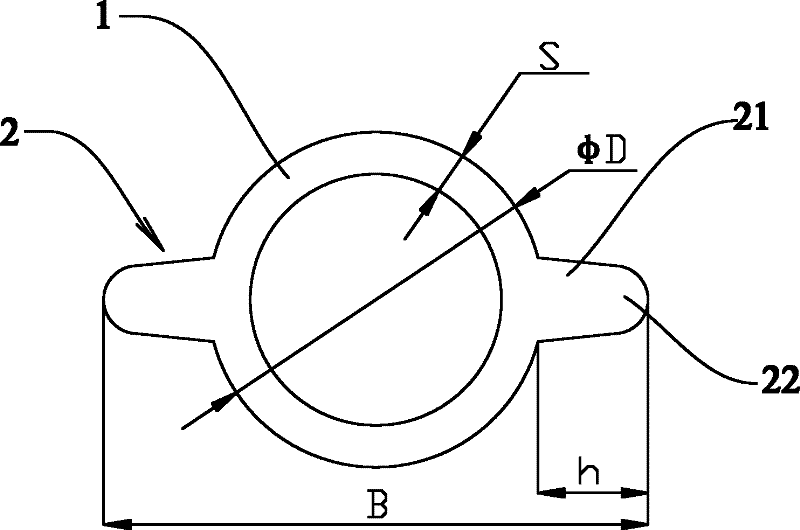

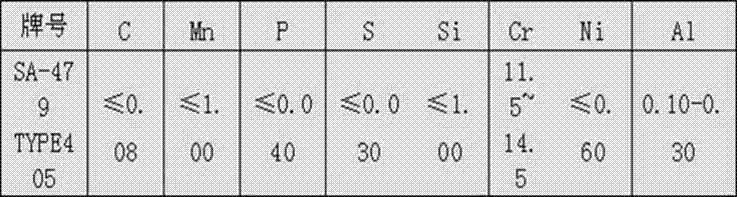

Special-shaped pipe for waste heat boiler and its processing method

InactiveCN102261640AEasy to fix and weldHigh strengthSteam boilersSteam boilers componentsLubricationProcess engineering

The invention provides a special-shaped pipe for waste heat boilers. The special-shaped pipe has an integral structure, which includes a cylindrical pipe body and a protrusion extending radially outward from the pipe body. The protrusion includes a The connection part and the outer end part, the connection part of the surface of the connection part and the outer end part is rounded; the present invention also provides a method for processing the special-shaped pipe for waste heat boiler, including the following steps: (a) hot rolling; (b ) cold drawing, pickling and lubrication, and intermediate heat treatment; repeat the steps of cold drawing, pickling and lubrication and heat treatment until the desired finished special-shaped pipe is obtained; (c) heat-treat and temper the obtained finished special-shaped pipe; (d) Quenching and tempering; (e) Carry out flaw detection on the quenched and tempered special-shaped pipe to detect water pressure and internal environment. The invention adopts the cold drawing method to process the special-shaped pipe for the waste heat boiler, which has low cost and good stability, and the processed seamless special-shaped pipe is more resistant to high pressure, and the rounded structure of the protruding part of the special-shaped pipe improves the welding performance of the pipe fitting.

Owner:常熟市异型钢管有限公司

Welding device with antirust effect for electrical engineering

ActiveCN109894796AAnti-rustEasy to weld and fixLiquid surface applicatorsWelding/cutting auxillary devicesFuel tankPetroleum engineering

The invention discloses a welding device with an antirust effect for electrical engineering. The device comprises a base, a first pipeline, a second pipeline and a welding machine. A first supportingtable is in sliding connection with the upper left side of the base, a second supporting table is in sliding connection with the upper right side of the base, a lower oil tooth disc is rotationally connected to the middle of the base, a gear disc is in engaged connection with the lower end of the lower oil tooth disc, oil tanks are fixedly installed on the inner walls of an upper oil tooth disc and the lower oil tooth disc, an adjusting rod is in through connection with the interior of the upper oil tooth disc, an upper transverse plate is fixedly connected to the upper end of a supporting rod, and the welding machine is fixedly connected with the lower end of a rack. The welding device with the antirust effect for electrical engineering can weld and fix pipelines with different sizes forelectrical engineering conveniently, the welding position can be conveniently protected against deformation, antirust protecting treatment can be carried out on the welding position conveniently, andthe problems that cracks are produced after long-time use and the service life is affected are avoided.

Owner:GUANGDONG OCEAN UNIVERSITY

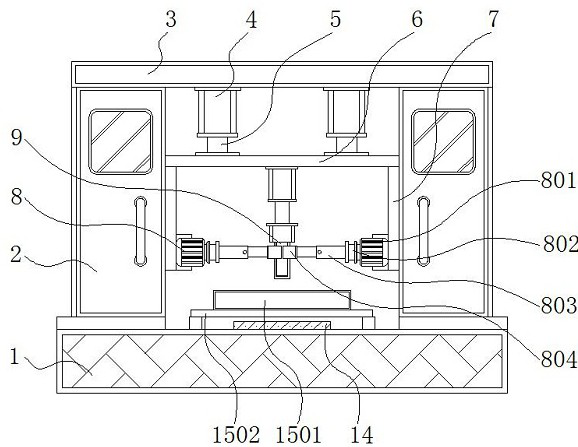

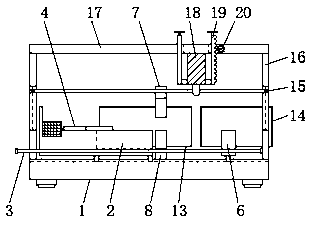

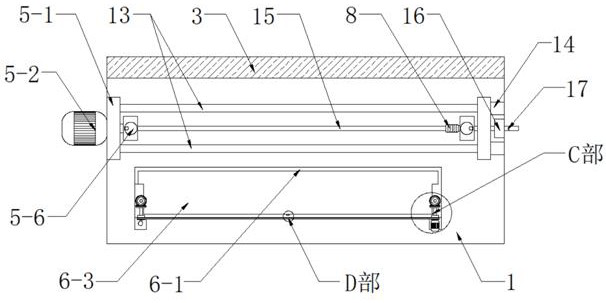

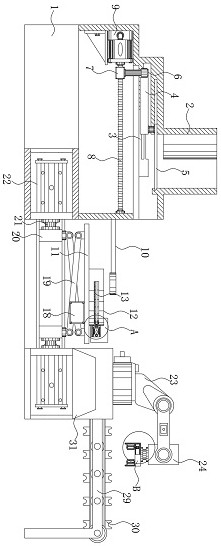

Automatic finned tube welding device convenient to fix

ActiveCN112171102AReduce laborEasy to weld and fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The invention discloses an automatic finned tube welding device convenient to fix, and relates to the technical field of finned tube welding. Supporting legs are fixed to the four corners of the lowersurface of a workbench, a supporting plate is fixed to the rear side of the upper surface of the workbench, and a top plate is fixed to the upper side of the front side wall of the supporting plate and suspended above the workbench. The device further comprises a fixing mechanism, a feeding mechanism and a welding mechanism, the fixing mechanism is arranged in the center of the upper surface of the workbench, fixing plates in the fixing mechanism are arranged on the left side and the right side of the upper surface of the workbench, the feeding mechanism is arranged on the front side of the upper surface of the workbench, a storage box in the feeding mechanism is arranged on the upper surface of the workbench, the welding mechanism is suspended above the feeding mechanism, and first sliding rails in the welding mechanism are fixed to the left side and the right side of the lower surface of the top plate correspondingly. In the welding process, automatic feeding can be achieved, manualsingle feeding is not needed, and therefore the labor amount of workers is reduced, the time-saving and labor-saving effects are achieved, and the automatic finned tube welding device has the advantages of being reasonable in arrangement, low in manufacturing cost and the like.

Owner:江苏鼎翔节能科技有限公司

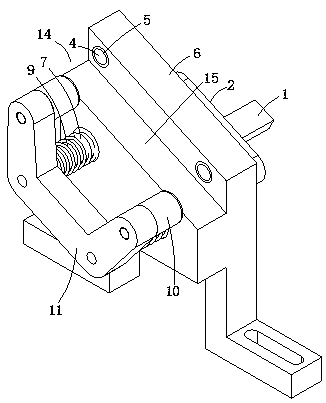

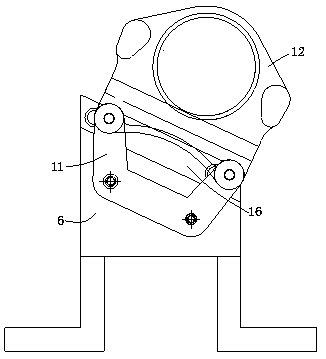

Clamping fixture used during brake caliper bracket welding

InactiveCN110666433ASolve the technical problem of blocking the girth weldEasy to weld and fixWelding/cutting auxillary devicesAuxillary welding devicesBrakeEngineering

The invention relates to a clamping fixture used during brake caliper bracket welding. The clamping fixture comprises a rear tension plate and a front pressing plate, wherein an angle positioning plate is arranged on one side of the front pressing plate, the rear tension plate and the front pressing plate are connected through a stretchable adjusting mechanism, and a clamping opening is formed between the angle positioning plate and the front pressing plate; a workpiece positioning assembly is arranged on the angle positioning plate and the front pressing plate, the workpiece positioning assembly comprises copper sleeves fixed to the two ends of the angle positioning plate, and magnets are arranged in the copper sleeves; and two pressing pins are arranged on one side of the front pressingplate, the pressing pins correspond to the magnets, point supporting, clamping and fixing on the a brake caliper bracket are facilitated through the magnets and the pressing pins, the front pressing plate is U-shaped and provided with an avoidance notch, the avoidance notch is in communication with the clamping opening, and the brake caliper bracket and a shaft head are welded and fixed conveniently through the avoidance notch. The welding is convenient, the technical problem that a ring weld joint is blocked due to the fact that the brake caliper bracket of the type is recessed towards the directions of the sleeves is solved, the production cost is reduced, and the quality is improved.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

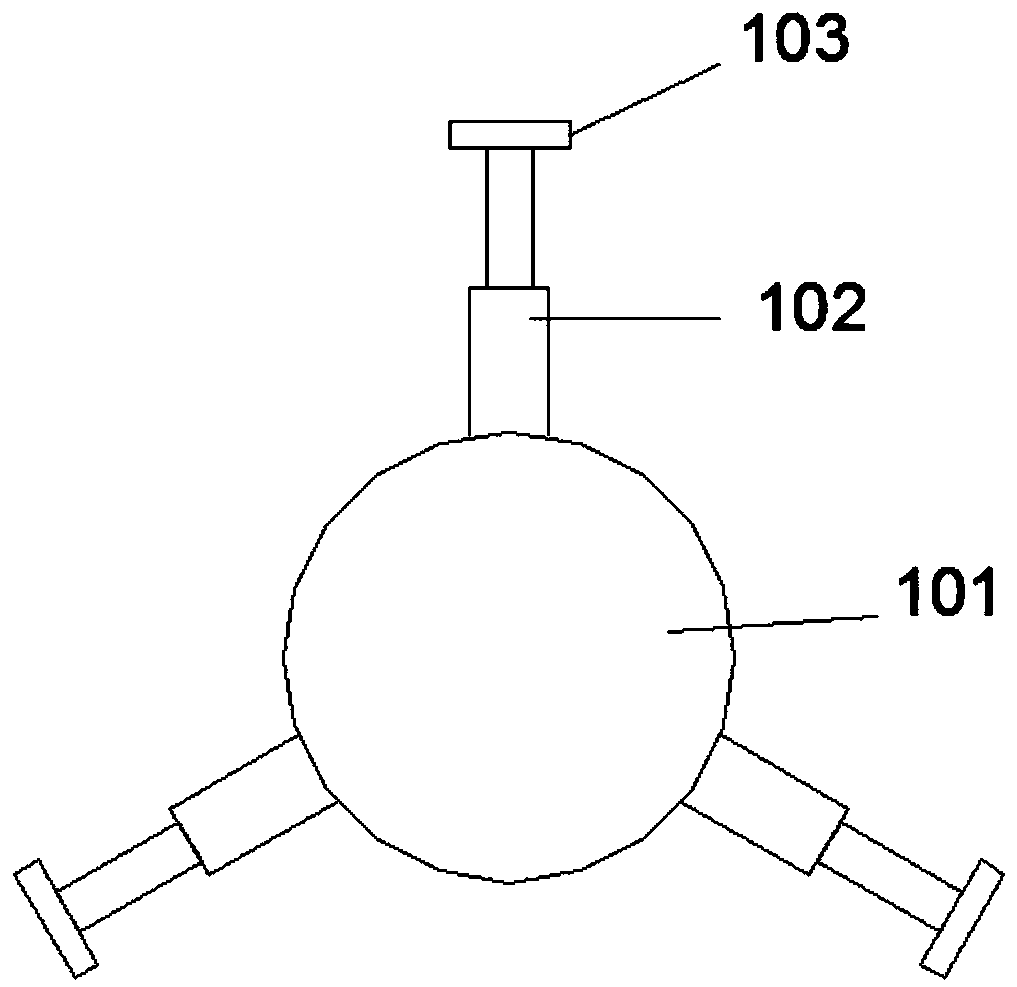

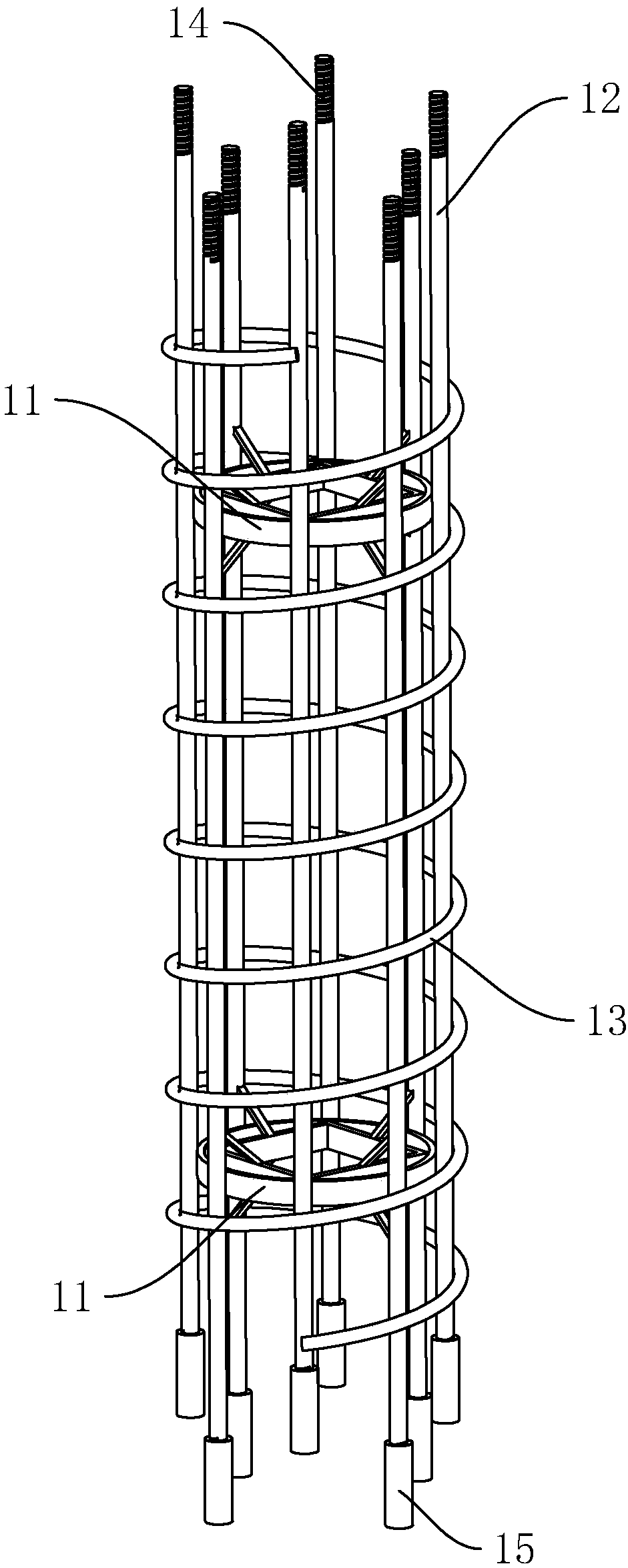

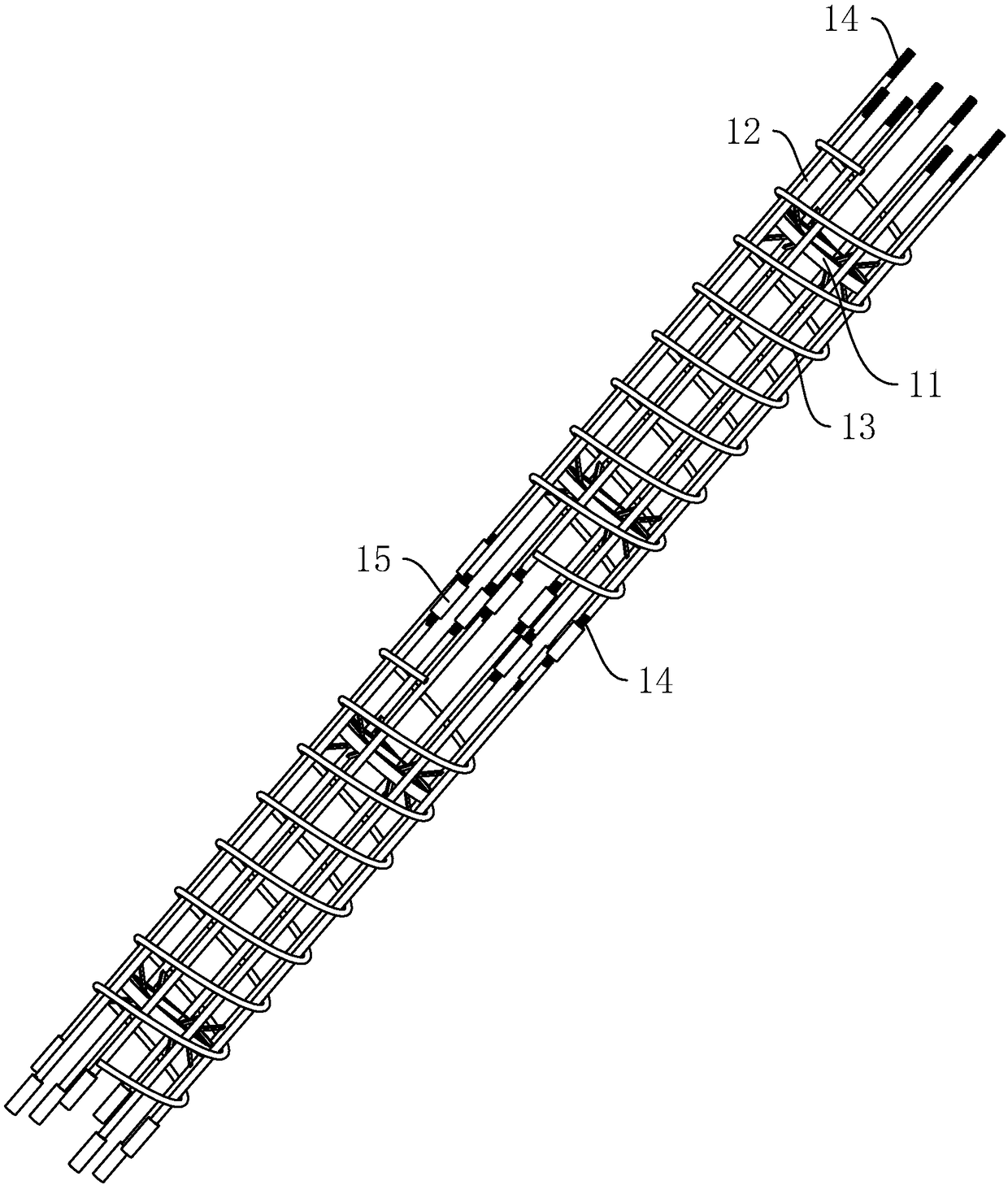

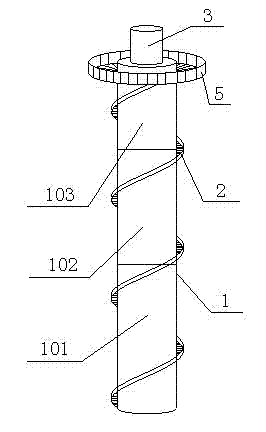

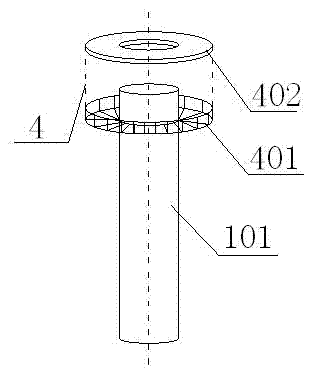

Reinforcement cage for drilled press-grouting piles and molding device thereof

ActiveCN108213282AImprove structural strengthSimple structureWire networkBulkheads/pilesEngineeringRebar

Owner:C KIS CONSTR CO LTD

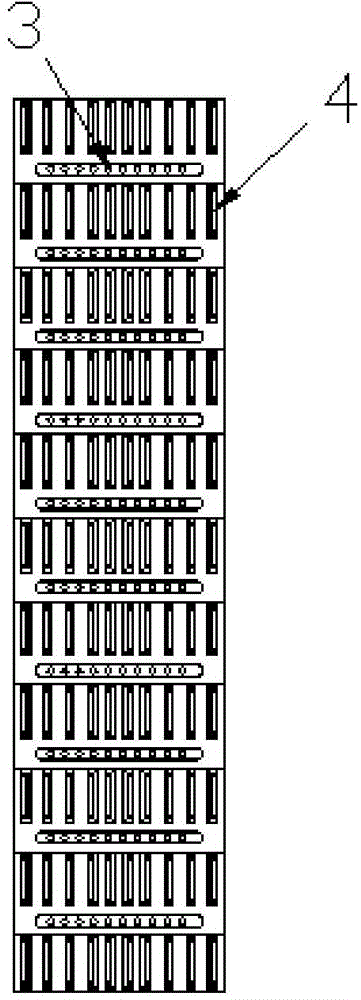

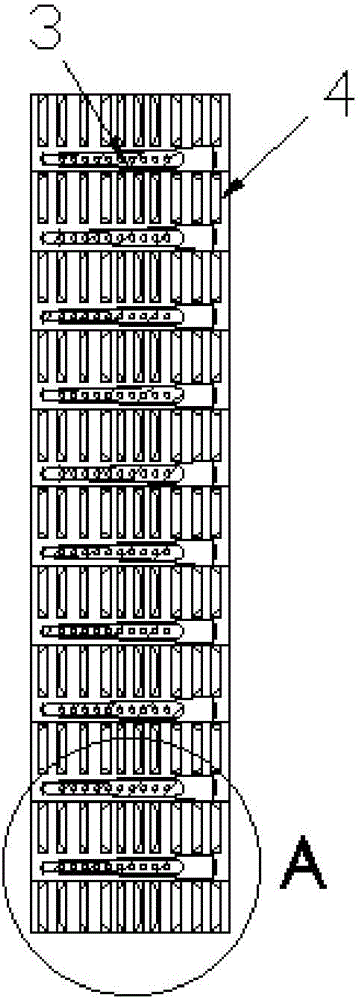

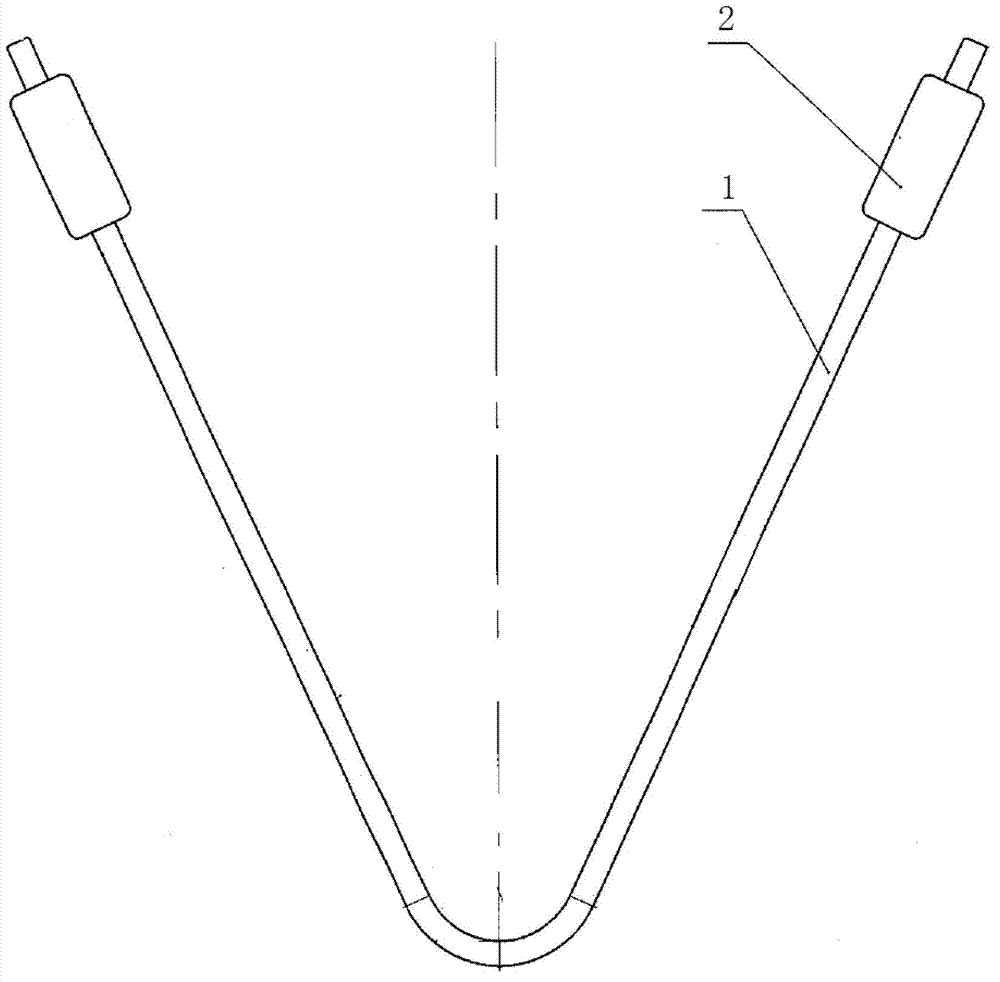

Method for producing vibration-resistant bar assembly of AP1000 nuclear power generating set steam generator

ActiveCN102764966AMeet the precision requirementsGuaranteed process requirementsNuclear engineeringNuclear power

Disclosed is a method for producing a vibration-resistant bar assembly of an AP1000 nuclear power generating set steam generator. The method comprises processes of production of vibration-resistant bars, production of end caps, bending molding, assembly of end caps, heading, detection, cleaning and packaging. The vibration-resistant bar assembly of the AP1000 nuclear power generating set steam generator has a simple structure, the quality of the vibration-resistant bar assembly meets accurate requirements of steam generators in a nuclear power plant for vibration-resistant bars and the vibration-resistant bar assembly is safe during usage. According to the method for producing the vibration-resistant bars, the production processes are strict, the technical requirements for the vibration-resistant bar assembly of the steam generator in the nuclear power plant are guaranteed, the quality is guaranteed and the safety is improved.

Owner:丹阳市龙鑫合金有限公司

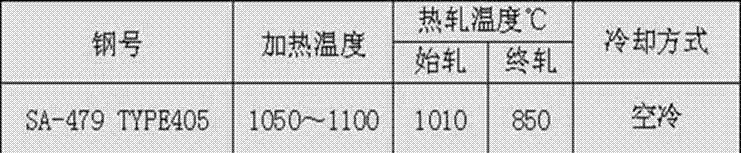

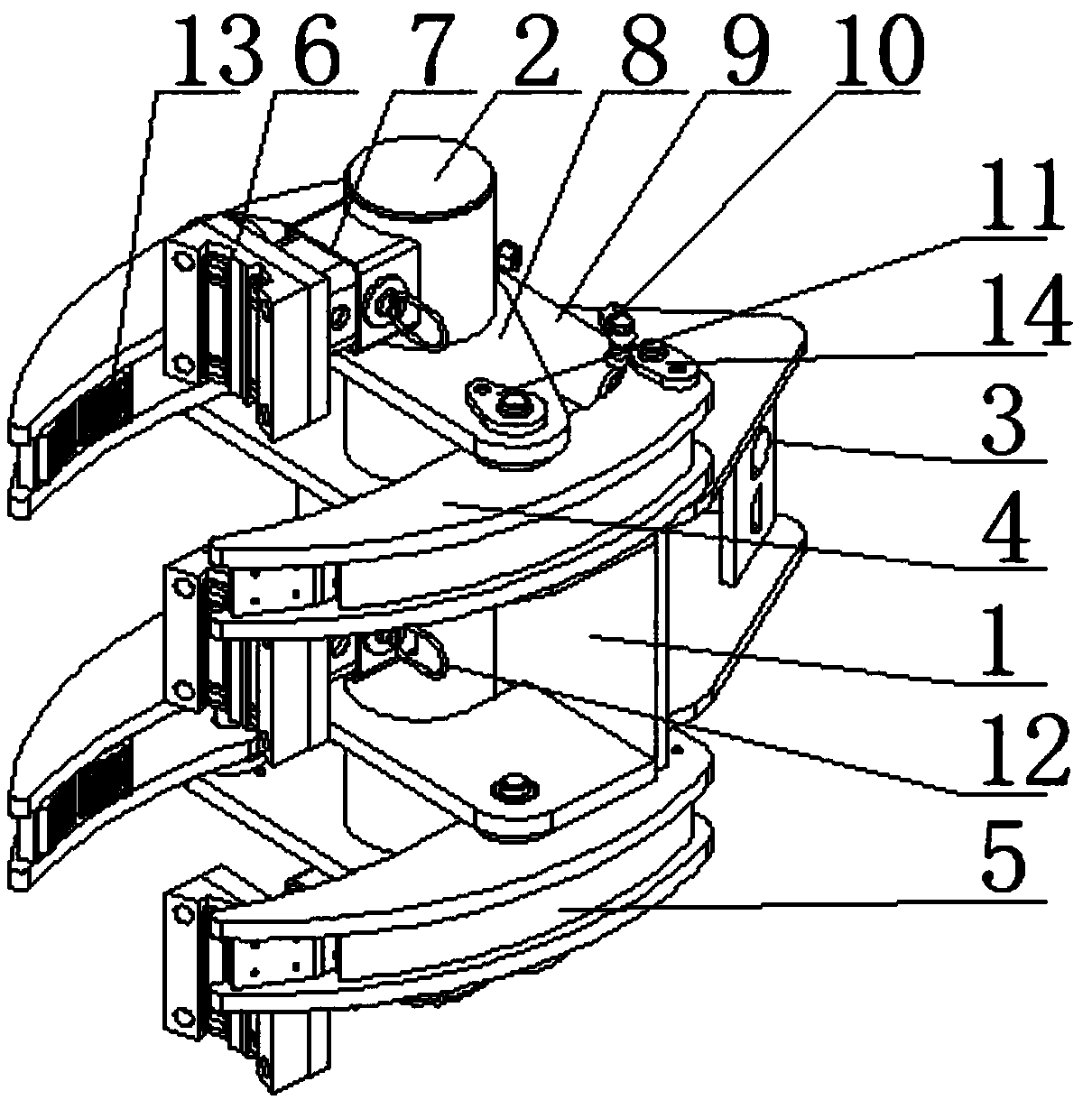

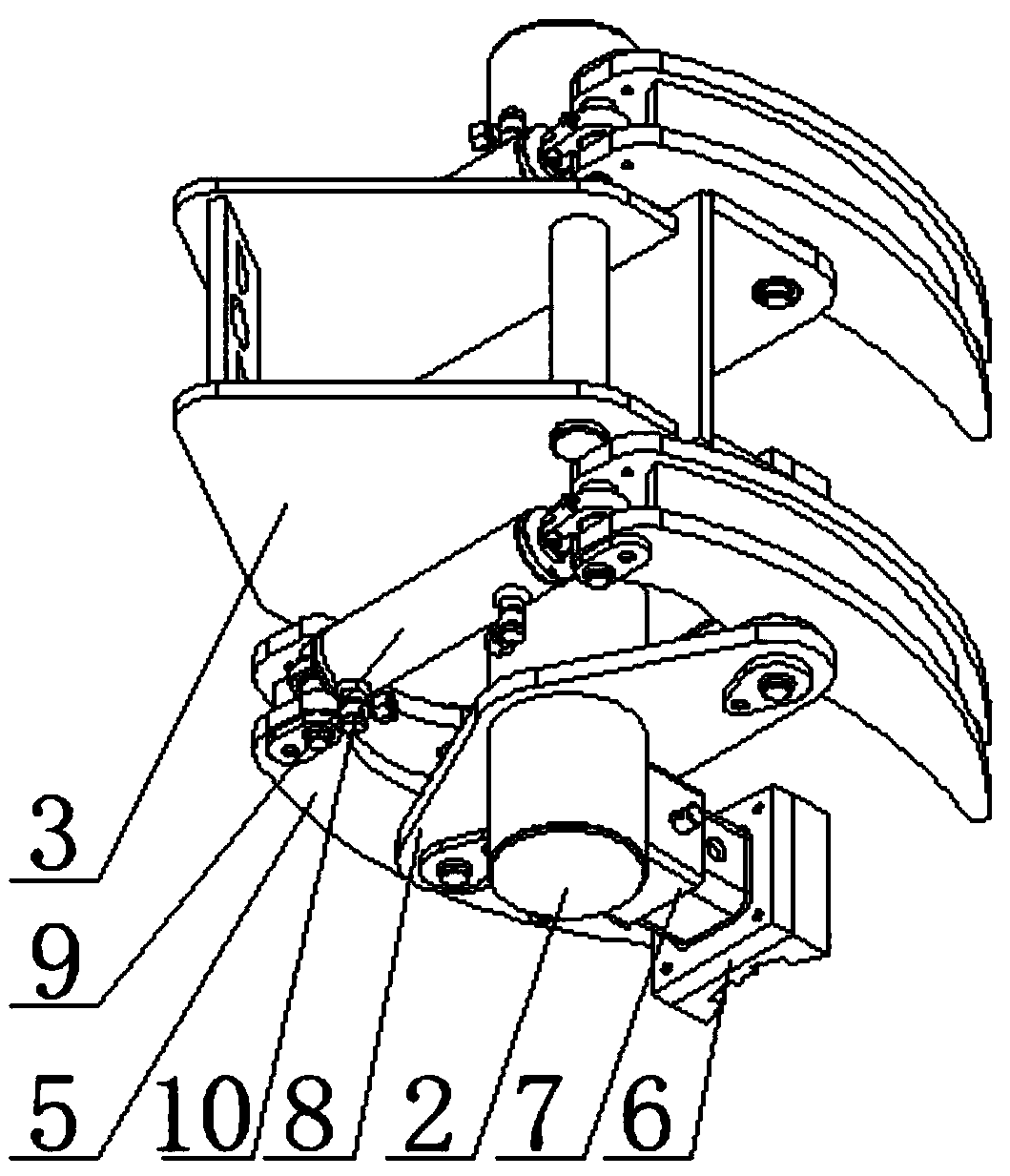

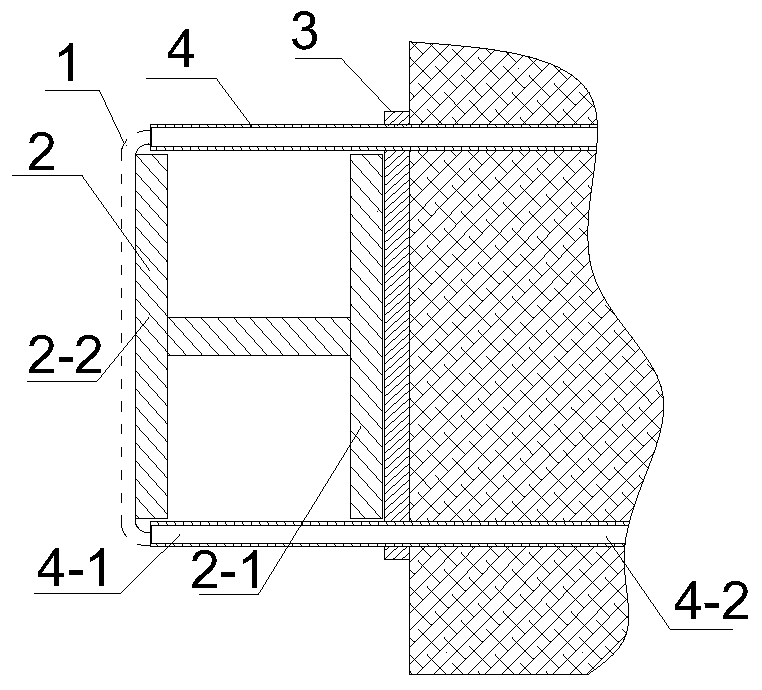

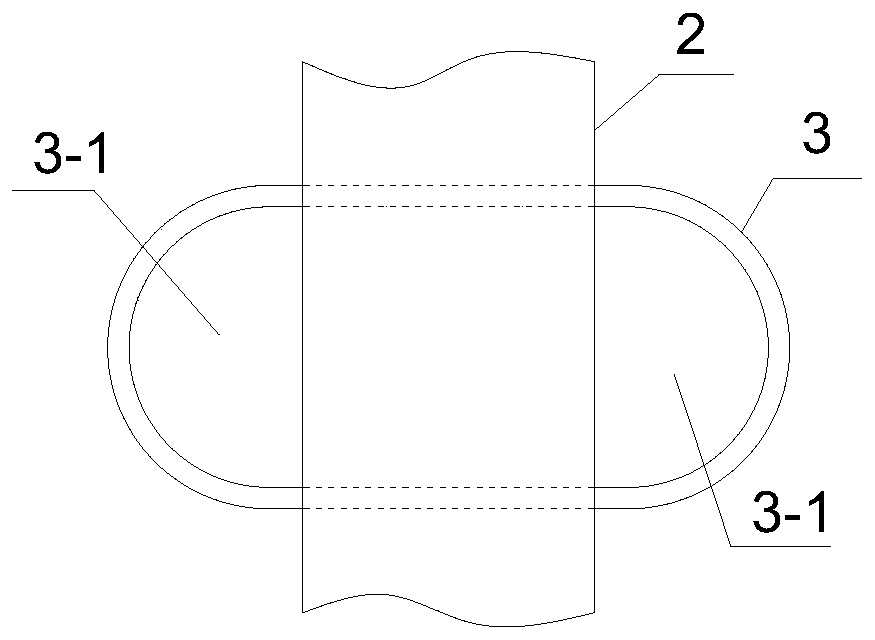

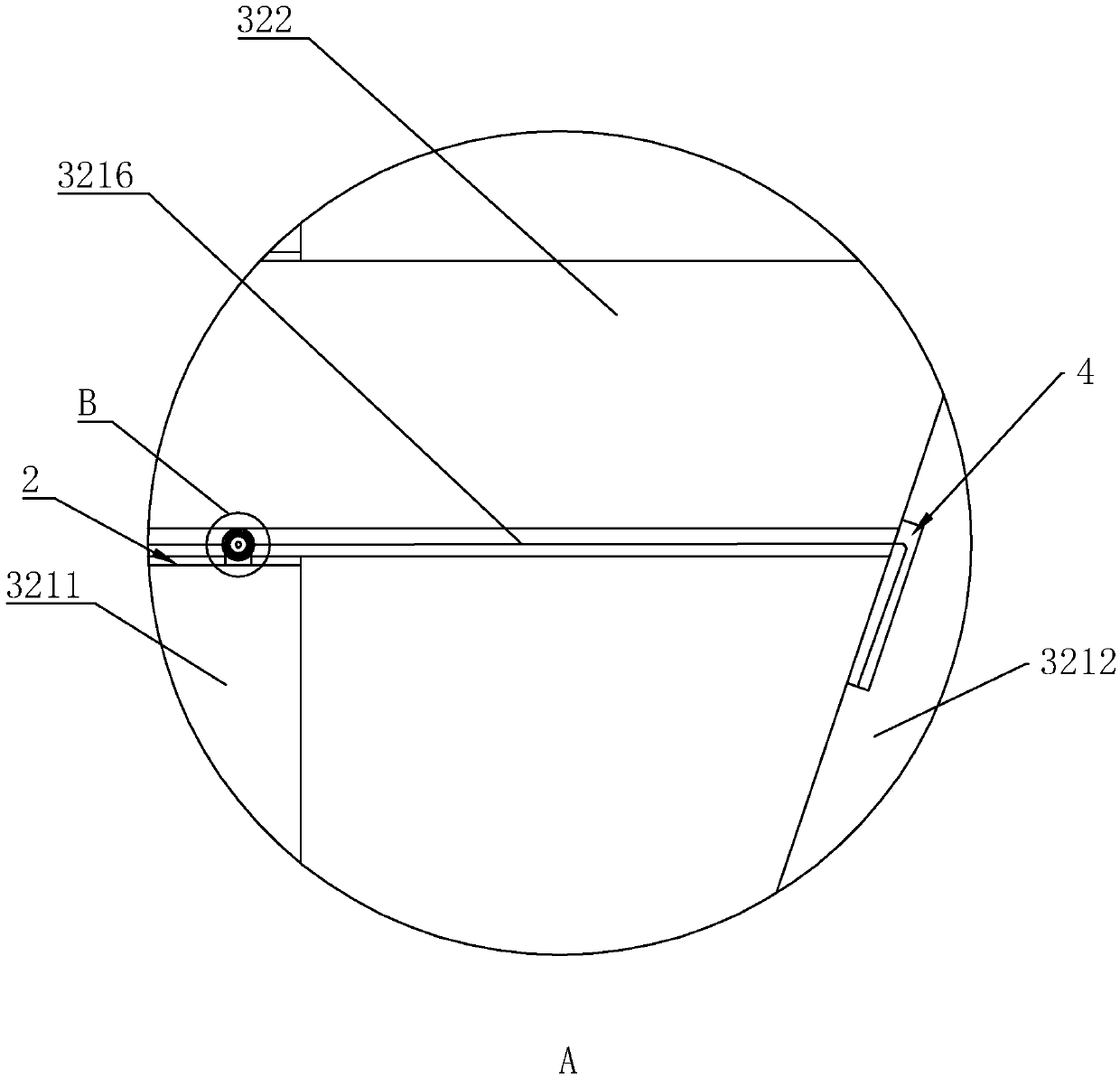

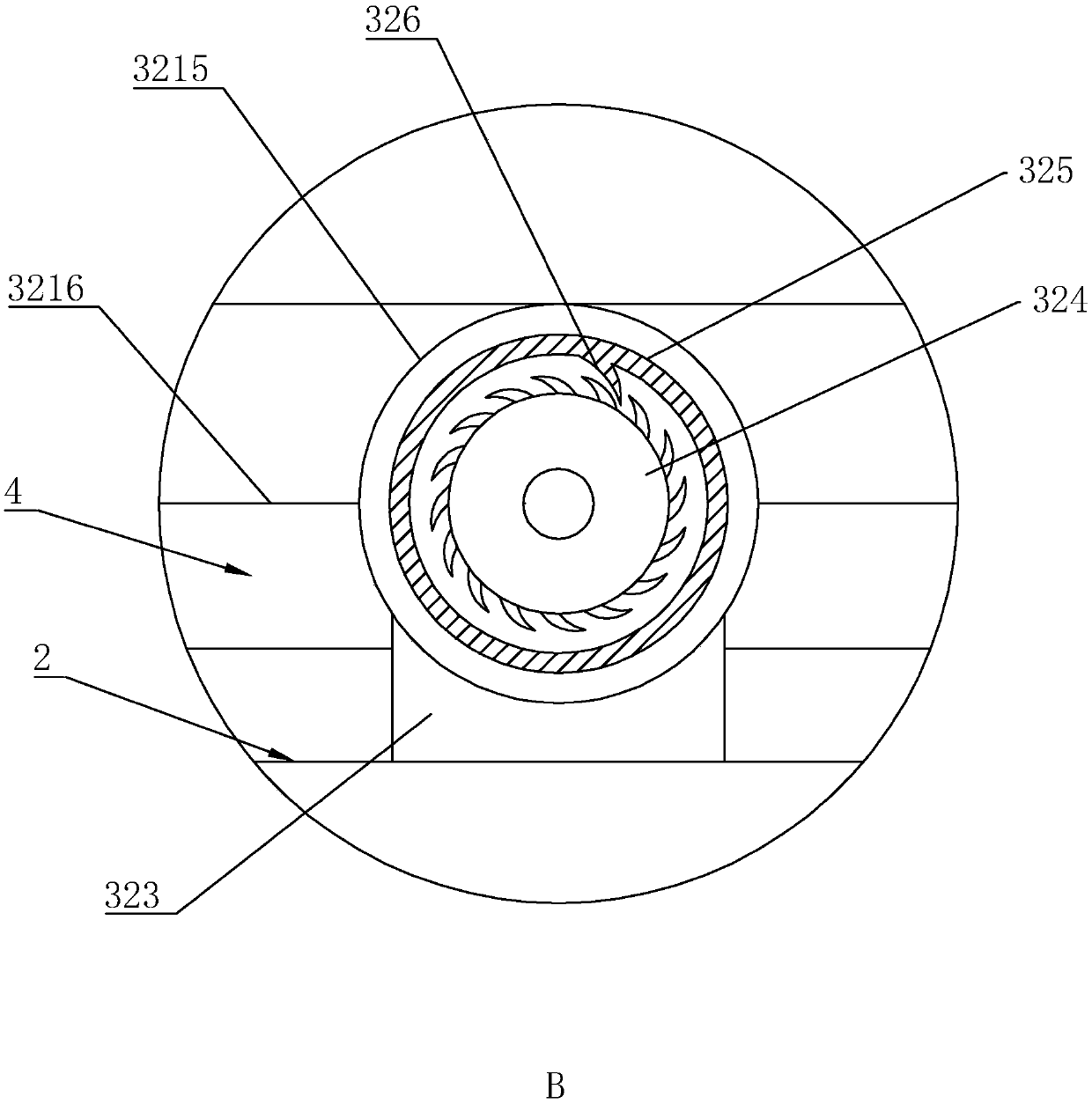

High-speed and high-load hub bearing unit and assembling method thereof

PendingCN112157429AImprove stabilityImprove carrying capacityAssembly machinesBearing componentsEngineeringStructural engineering

The invention discloses a high-speed high-load hub bearing unit and an assembling method thereof. The high-speed high-load hub bearing unit comprises a body, wherein the body is provided with a bearing sleeve, an inner flange plate arranged at the front end of the bearing sleeve, and a fixing plate fixedly connected to the outer side wall of the rear end of the bearing sleeve; positioning holes and mounting holes are distributed in the circumference of the inner flange plate at intervals; connecting screw rods are arranged in the mounting holes; the outer side of the bearing sleeve is sleevedwith a reinforcing sleeve; the reinforcing sleeve is located between the inner flange plate and the fixing plate; the fixing plate is provided with a clamping assembly; and the clamping assembly clamps the reinforcing sleeve, so that the reinforcing sleeve clamps the outer side wall of the bearing sleeve. The method comprises the following steps of a, preparing before assembling; b, clamping; c, assembling the reinforcing sleeve; d, assembling the clamping assembly; and e, completing assembling. According to the high-speed high-load hub bearing unit and the assembling method thereof provided by the invention, the stability and the bearing capacity of the bearing sleeve are improved, and deformation and cracks of the bearing sleeve are avoided, so that the service life of the hub bearing unit is greatly prolonged.

Owner:新昌县林泉轴承有限公司

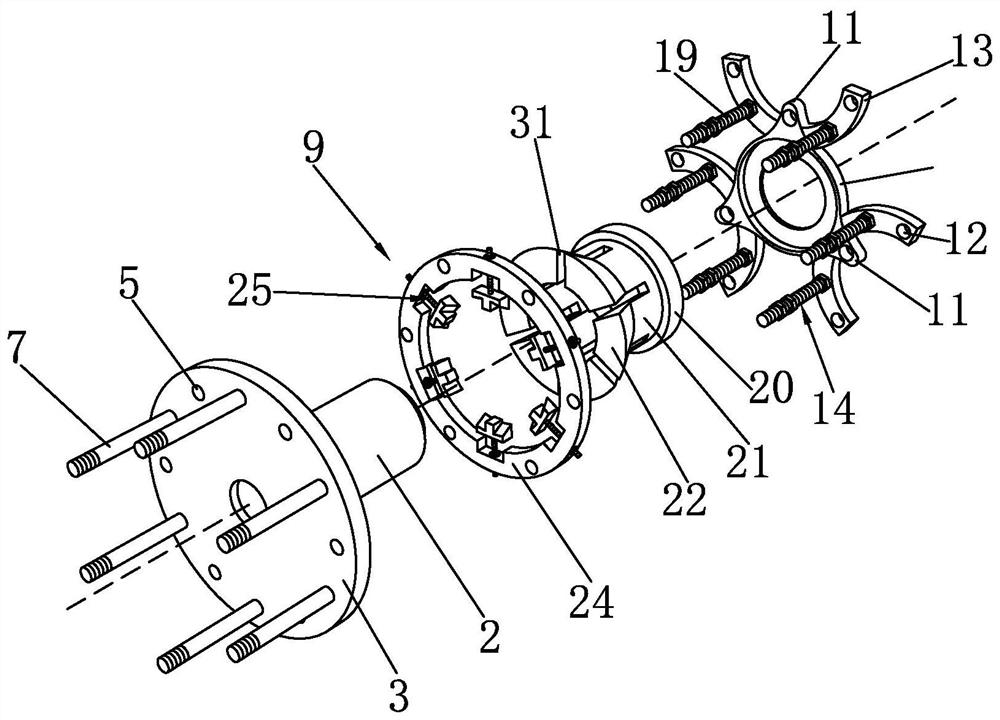

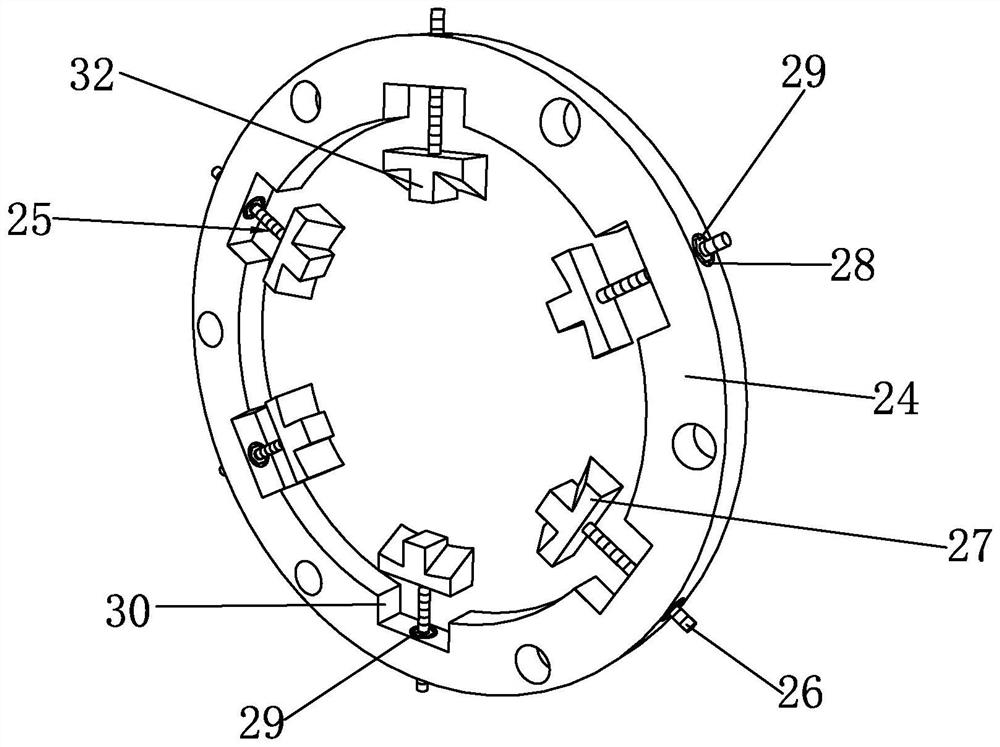

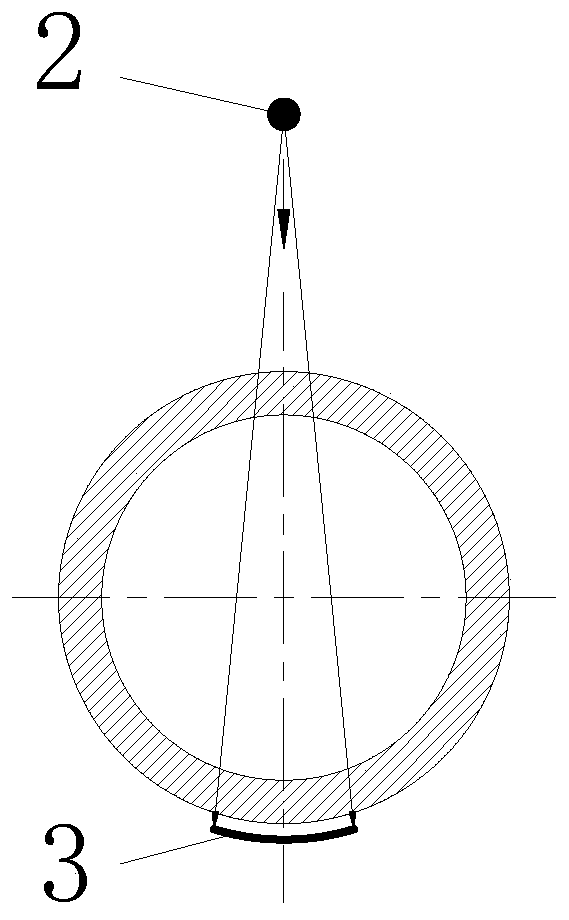

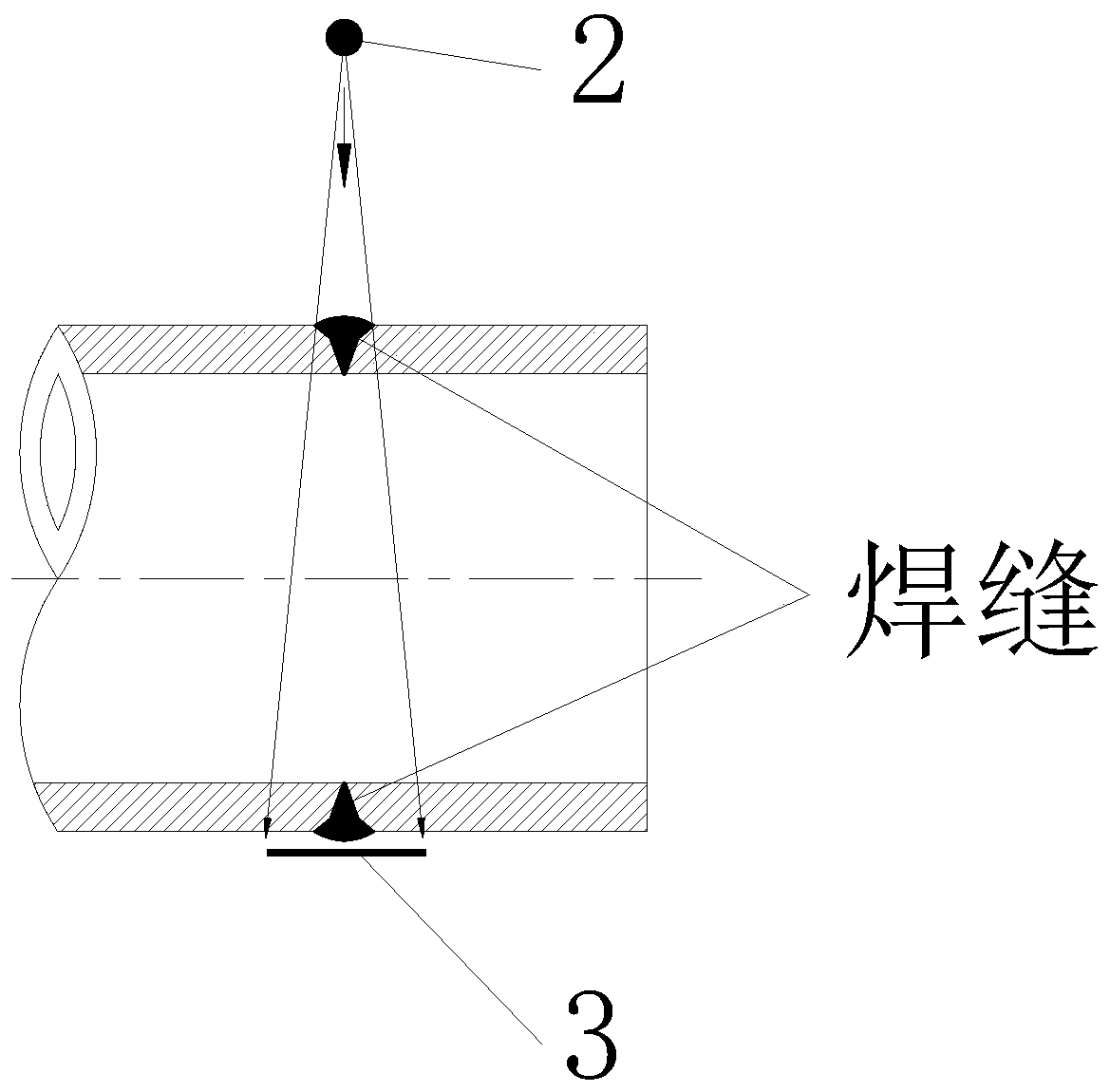

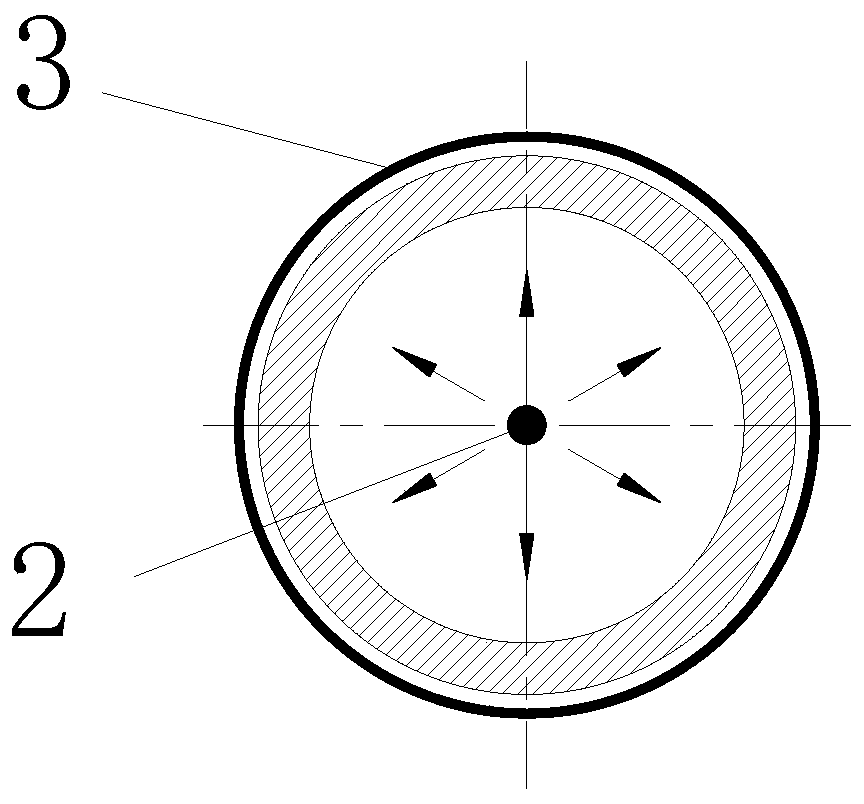

Nondestructive testing method for pipeline welding joint of thermal power plant and flow detection hole blocking piece

PendingCN110174420AEasy to reachAvoid long distancesEngine sealsMaterial analysis by transmitting radiationEngineeringNondestructive testing

The invention discloses a nondestructive testing method for a pipeline welding joint of a thermal power plant. The nondestructive testing method is used for nondestructive testing of the pipeline welding joint of the thermal power plant; a ray source is arranged at the circle center of the pipeline through a flaw detection hole formed in the pipeline, and a negative film coats the outer side of the welding joint; and circumferential exposure flaw detection is carried out, and the flaw detection hole is sealed by utilizing a flaw detection hole blocking piece after the flaw detection is finished. The invention further discloses a structure of the flaw detection hole blocking piece, so that the sealing of the flaw detection hole can be ensured, and the normal working performance of the pipeline is ensured not to be damaged. According to the testing method, it can be guaranteed that rays pass through a relatively thick tube wall smoothly, and the ray energy level and the illumination timeare greatly reduced; in addition, the imaging on the negative film corresponds to a specific position, overlapping is avoided, and the imaging accuracy is ensured. Meanwhile, according to the relation between the design temperature and the creep temperature of the pipeline, different flaw detection holes and flaw detection hole blocking piece structures are provided; and when the design temperature of the pipeline is within the creep temperature range, a threaded connection pipe seat can be used for ensuring that the flaw detection hole is effectively sealed.

Owner:CHINA HUADIAN ENG

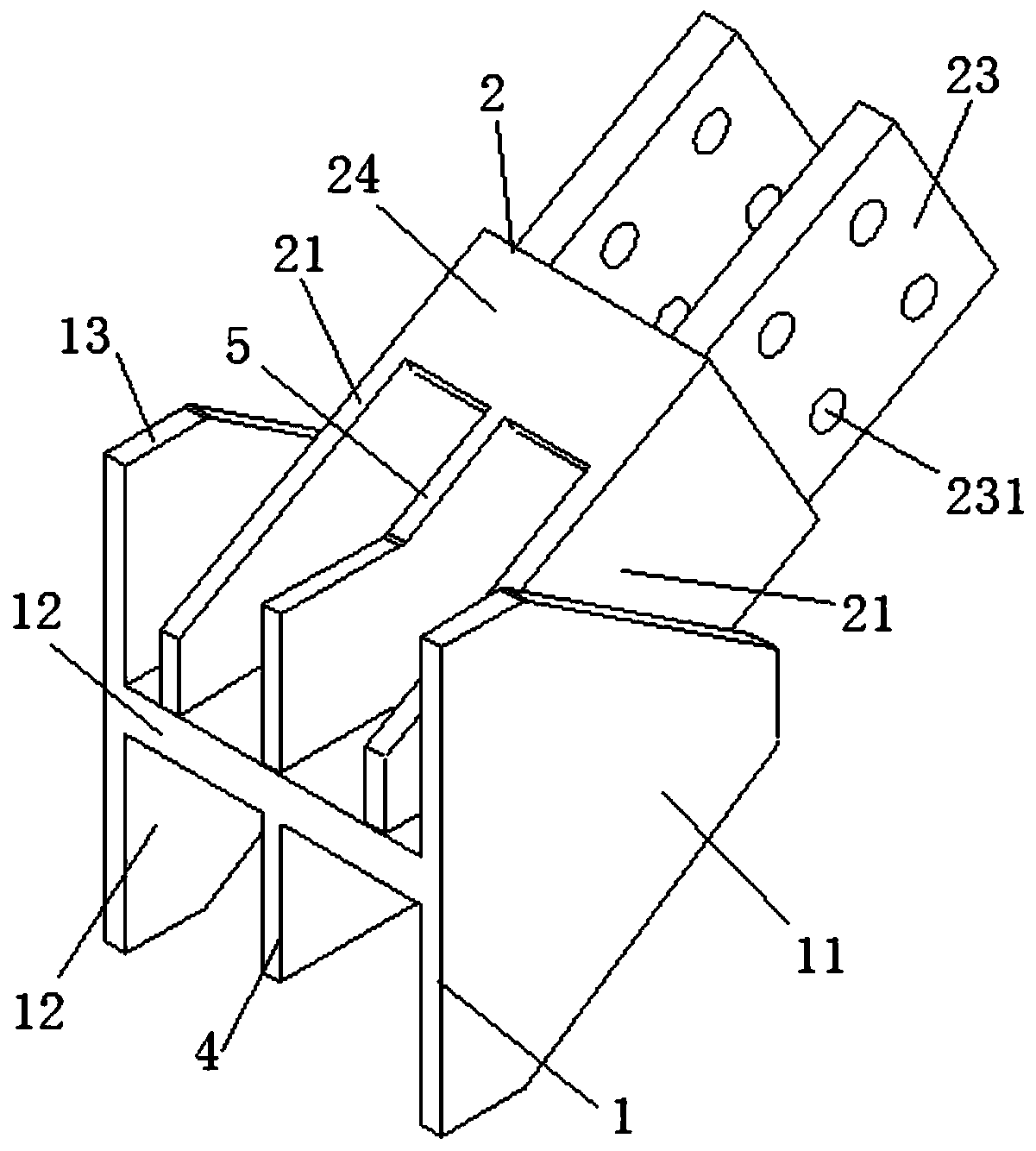

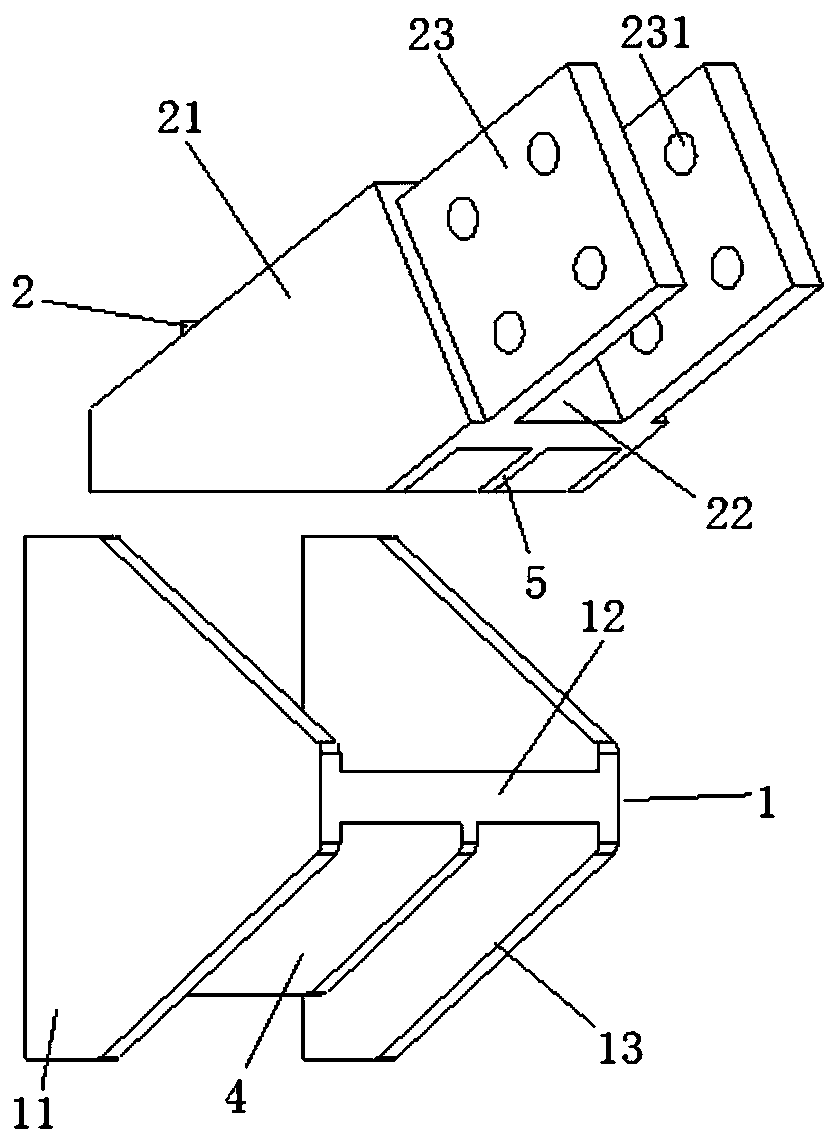

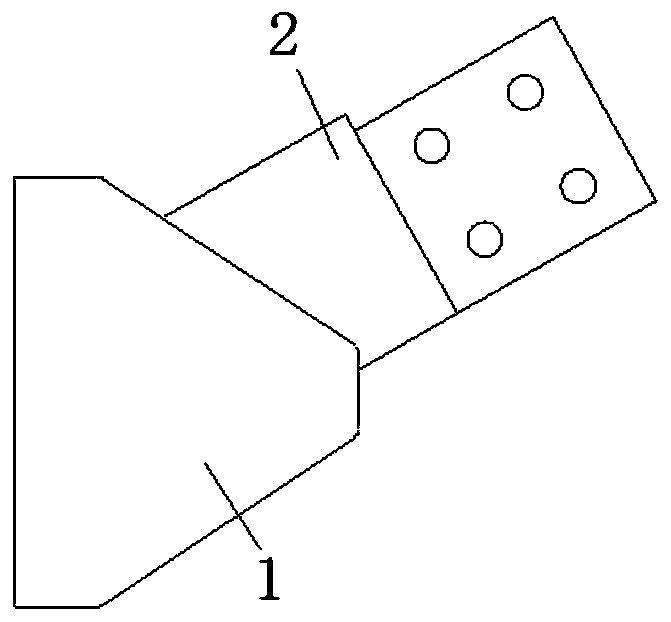

Fabricated steel frame structure supporting joint and connecting device thereof

PendingCN109914595ASimple structureEasy Field ReplacementBuilding constructionsPhotovoltaic energy generationAcute angleSteel frame

The invention discloses a fabricated steel frame structure supporting joint and a connecting device thereof. The fabricated steel frame structure supporting joint comprises a supporting base and a first supporting joint, the first supporting joint is fixedly installed on the supporting base, the supporting base is used for being connected with a frame column or a frame beam, and the first supporting joint is used for being connected with an inclined support; the supporting base comprises a first end plate, a rib plate and a second end plate, the first end plate and the second end plate are arranged in parallel oppositely, and the first end plate and the second end plate are fixedly connected through the rib plate; the first supporting joint comprises two side wing plates, a supporting plate and two connecting plates; the side wing plates are vertically arranged on one side of the supporting plate, the included angle between the axis of the side wing plates and the axis of the rib plateis an acute angle, and the connecting plates are vertically arranged on the other side of the supporting plate. The structure is simple, and the size of each component can be machined and manufactured in an industrialized mode according to needs, field replacement is facilitated, interchangeability is good, standardized production is facilitated, transportation and installation are facilitated, and the building construction efficiency can be improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for rapidly installing steelmaking diffusing tower in narrow area

The invention discloses a method for rapidly installing a steelmaking diffusing tower in a narrow area. The method includes the steps of dividing a main pipe into three branch pipes, arranging an operating platform at the upper end of each branch pipe, and independently installing the three branch pipes. The method has the advantages that the main pipe of the diffusion tower is divided into the three branch pipes to be respectively lifted, the lifting requirement for a crane is reduced, the length of the main pipe is shortened in a converted mode, and therefore the diffusion tower can be installed in the narrow area; the operating platforms are arranged below the connecting positions of the three branches, and therefore convenience is brought to welding fixation between the branch pipes.

Owner:CHINA MCC5 GROUP CORP

Production and processing equipment with automobile shifting fork welding assembly detection function

InactiveCN112296495AEasy to moveEasy to reinforceWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringElectric machinery

The invention discloses production and processing equipment with an automobile shifting fork welding assembly detection function. The production and processing equipment comprises a shifting fork feeding case, and a shifting fork feeding bin is fixedly welded on the right side of the upper surface of the top of the shifting fork feeding case; an arc-shaped sliding groove is fixedly welded on the right side of the surface of a control console; a motor controller is arranged at the bottom of a small arm of a rotary mechanical arm, and a second conveyor belt is arranged on the surface of the right side of the rotary mechanical arm; and a discharging port is formed in the bottom of the front side of the rotary mechanical arm. According to the production and processing equipment, the control console is arranged between the shifting fork feeding case and the rotary mechanical arm; single-column pneumatic cylinders are arranged at the bottoms of the shifting fork feeding case and the rotary mechanical arm separately, thereby facilitating pushing of a driven sliding block to enable a control console to rise upwards; meanwhile, through arrangement of the arc-shaped sliding groove, a weldinghead is easy to move along the arc-shaped sliding groove, and the problem of low precision during manual welding is solved; and thus, automatic welding is facilitated, and the welding precision is improved.

Owner:东莞市夯实科技有限公司

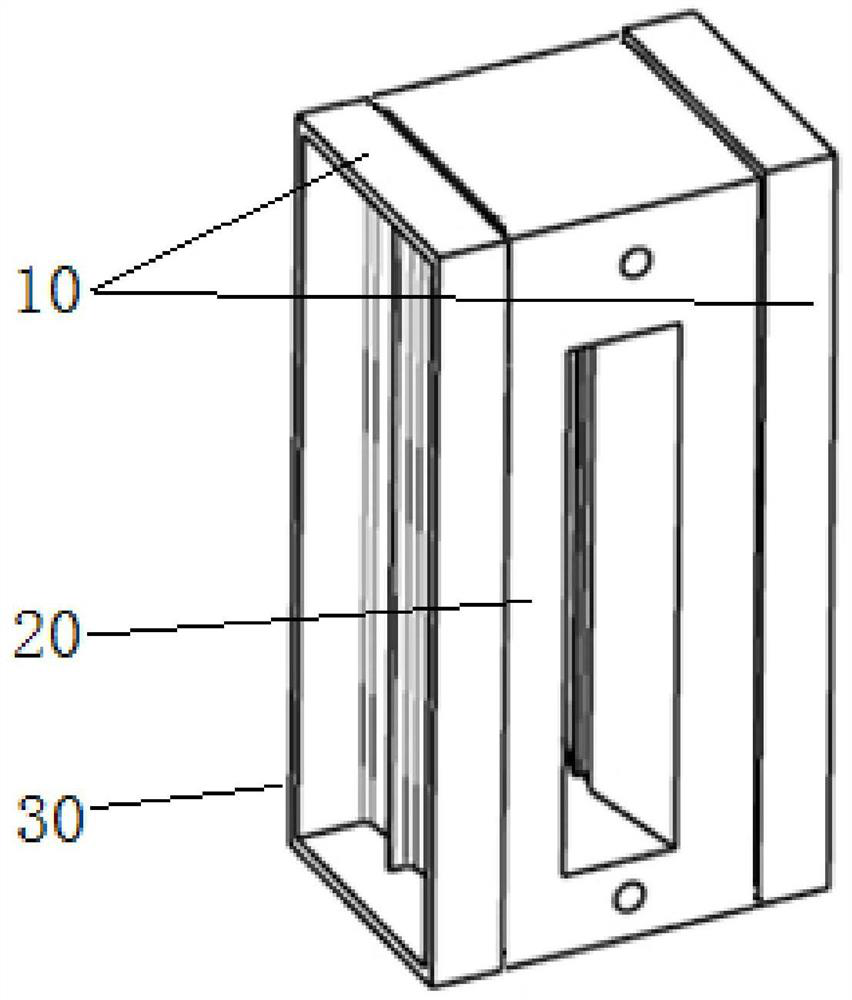

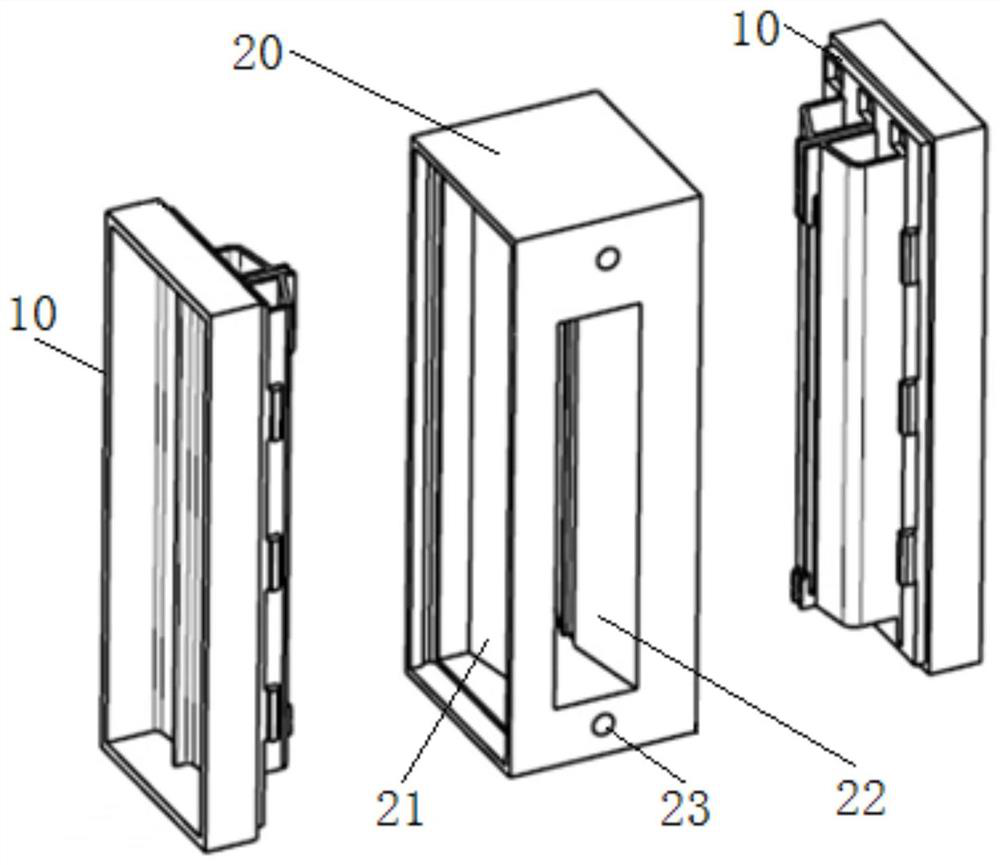

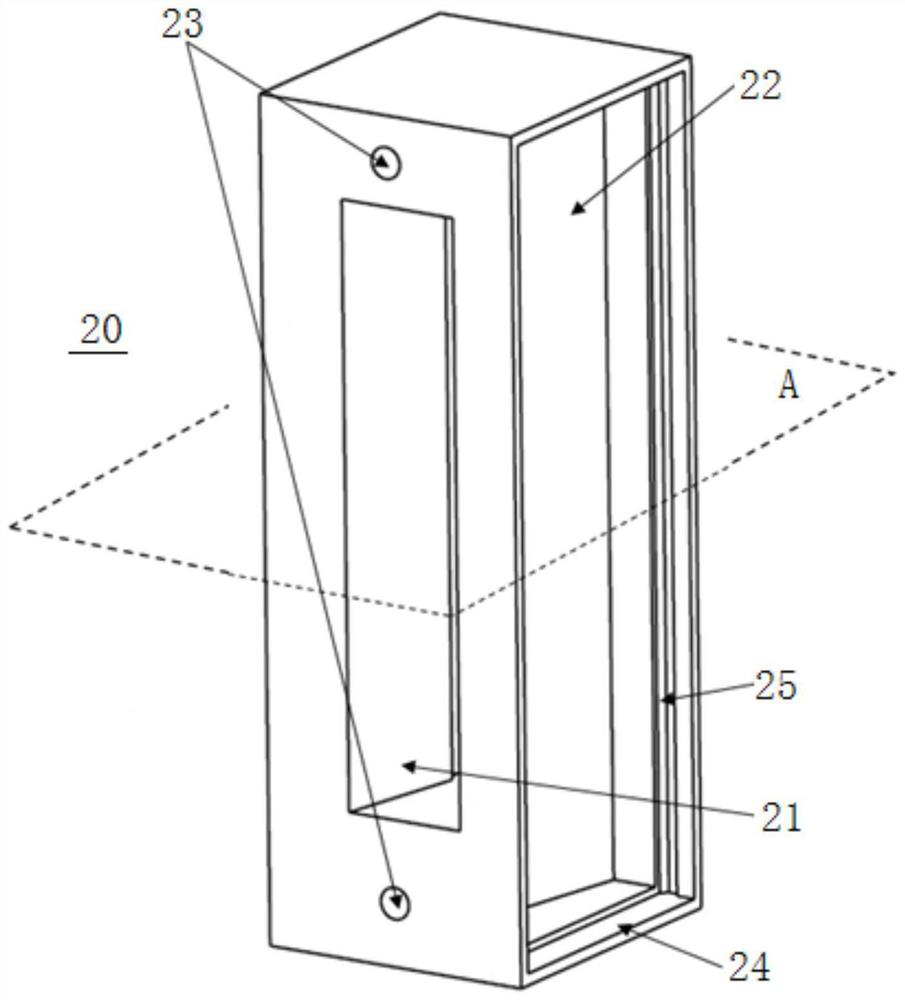

Soft package battery cell series connection fixing device, battery module, battery pack and automobile

ActiveCN112542662AEasy to installEasy to repair and replaceCell component detailsMechanical engineeringBattery cell

The invention discloses a soft package battery cell series connection fixing device, a battery module, a battery pack and an automobile. The soft package battery cell series connection fixing device comprises a tab opposite fixing block and two tab limiting plates; the two tab limiting plates are respectively arranged at two sides of the tab opposite fixing block; each tab limiting plate comprisesa base; the base is provided with more than two tab through holes which are parallel to each other and tab guide surfaces of which the number is the same as that of the tab through holes; at least one tab guide surface comprises a guide inclined surface, and the guide inclined surface inclines towards the same design position, so that a protruding part is formed on one surface of the base, and alimiting mechanism is arranged at the tip end of the protruding part and used for clamping the end part of the tab; accommodating cavities for allowing the protruding parts to extend into are formed in the two connecting side surfaces of the tab opposite fixing block; and a welding channel communicating with the accommodating cavities is formed in the tab opposite fixing block. On the basis of notchanging the chemical system of soft package battery cells, the large-scale grouping of the soft package battery cells is facilitated, and the grouping efficiency is improved.

Owner:DONGFENG MOTOR CORP HUBEI

Metallurgy clamping pipe welding fixing device

PendingCN109262193AReduce misalignmentWelding Fixed SynchronizationWelding/cutting auxillary devicesAuxillary welding devicesPipe wrenchHydraulic cylinder

The invention relates to the technical field of metallurgy tools, in particular to a metallurgy clamping pipe welding fixing device. The device comprises a pipe wrench frame and a guide column runninginto the pipe wrench frame. At least one set of clamping assemblies are installed on the guide column. Supporting pieces matched with the clamping assemblies are arranged on the guide column; according to the metallurgy clamping pipe welding fixing device, by arranging a plurality of clamping assemblies controlled by a hydraulic cylinder to be clamped, pipeline connectors are synchronously clamped and fixed conveniently, welding is facilitated, and the welding line alignment tolerance is lowered. By arranging a supporting assembly, the device can fix pipelines of different sizes by adjustingthe length of the supporting assembly on the condition that the clamping range of the clamping assemblies is determined. By arranging positioning pieces on the clamping assemblies, after the pipelineis preliminarily fixed, the clamping assemblies are locked through the positioning pieces, and the phenomenon that the clamping assemblies are loosened due to fatigue of the hydraulic cylinder and therefore pipeline assembling failure is caused is avoided.

Owner:阿尔法(江苏)重工科技有限公司

Connecting structure between locking anchor pipe and steel rack and mounting method thereof

InactiveCN111335924AShorten the length in disguiseImprove the ability to resist settlement deformationUnderground chambersTunnel liningRebarCantilever

The invention discloses a connecting structure between a locking anchor pipe and a steel rack and a mounting method thereof. The connecting structure comprises an annular steel bar and a connecting steel bar, wherein the annular steel bar is fixed to the end surface, close to a surrounding rack, of the steel rack, perforated holes are exposed in two sides of the steel rack, separately, and two locking anchor pipes penetrate the two perforated holes, separately; and the connecting steel bar is U-shaped and two ends of the connecting steel bar are separately connected to the outer ends of the two locking anchor pipes. The connecting structure has the advantages that as the annular steel bar is welded to a wing plate outside the steel rack, the length of a suspending arm end of each locking anchor pipe is shortened, so that the anti-bending ability of the suspending arm end of each locking anchor pipe is improved in a disguised manner, and therefore, the ability of resisting settlement deformation of each locking anchor is improved greatly. By adopting the U-shaped connecting steel bar, the locking anchor pipes on two sides are stressed synergically, so that the pulling resistance ofeach locking anchor pipe is increased and the ability of resisting convergence and deformation of an initial supporting structure is improved. The ability of resisting convergence and deformation of an initial supporting structure is improved comprehensively by adopting a combination system of the annular steel bar and the connecting steel bar.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

Packaging method for bonding-wire-free high-color-rendering-index LED lamp filaments and bonding-wire-free high-color-rendering-index LED lamp filaments

InactiveCN105720048ASave expensive costsSolve the problem of reduced excitation efficiencySolid-state devicesSemiconductor devicesColor rendering indexFluorescence

The invention relates to a packaging method for bonding-wire-free high-color-rendering-index LED lamp filaments. The packaging method comprises the steps of manufacturing a small-sized packaging body; coating the surface, except a welding electrode surface, of a flip chip with fluorescent glue only containing red fluorescent powder; drawing multiple mutually-disconnected connecting circuits on a thin-strip-shaped substrate, wherein each connecting circuit comprises two conductive bonding pads, and the two conductive bonding pads are connected through a conductive circuit; arranging the small-sized packaging body on the substrate circuit in an eutectic welding manner; enabling welding electrodes to be welded with the conducive bonding pads on the two adjacent connecting circuits to enable the adjacent two connecting circuits to be conducted in sequence; and coating the front surface and the back surface of the thin-strip-shaped substrate with the fluorescent glue containing green or yellow green fluorescent powder to obtain the bonding-wire-free high-color-rendering-index LED lamp filaments. The problem of partial spectrum missing and excitation efficiency decline caused by the reason that the light emitted by green or yellow or other short-wave fluorescent powder is re-excited is solved, so that the purpose of increasing the color rendering index and lowering the fluorescent powder dosage is realized.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

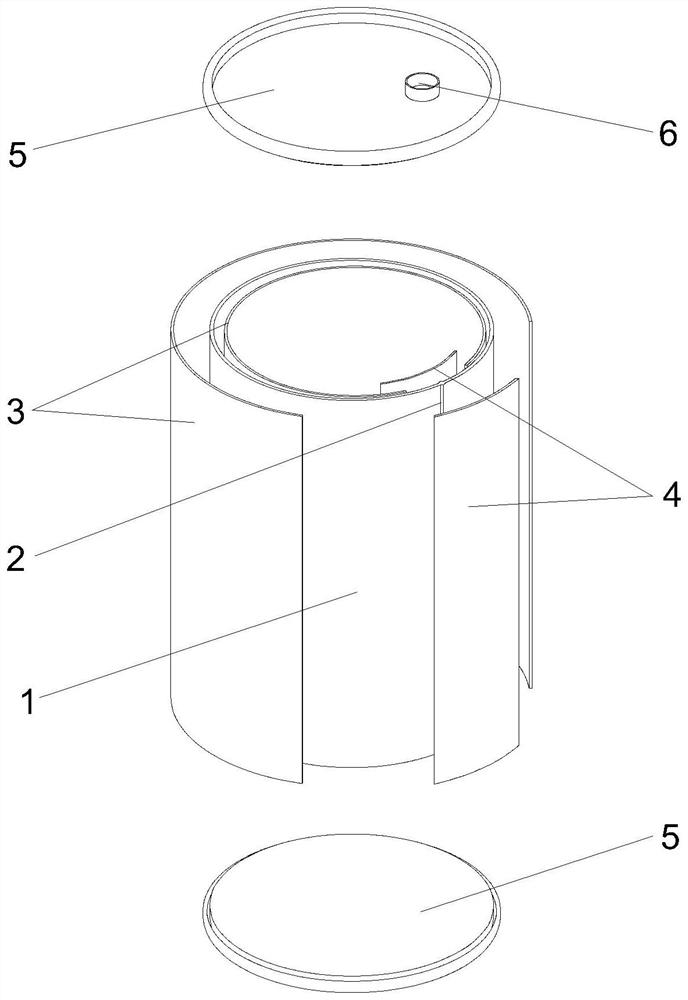

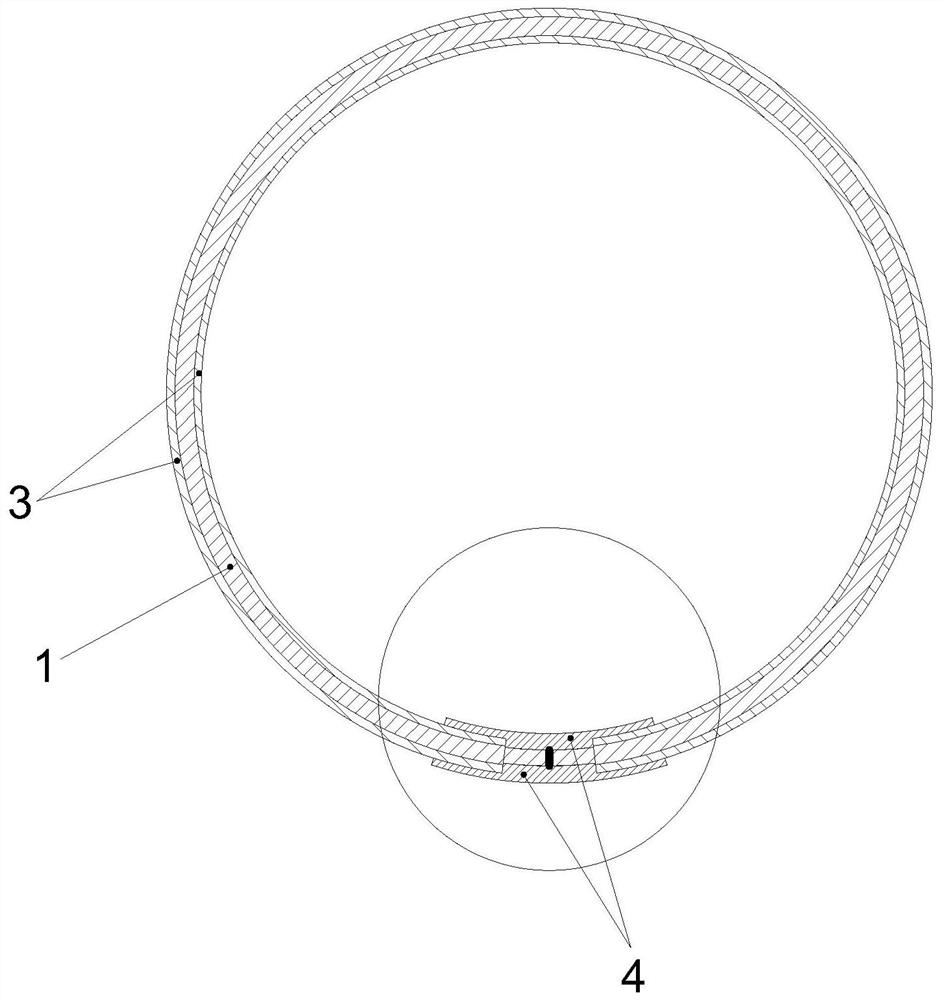

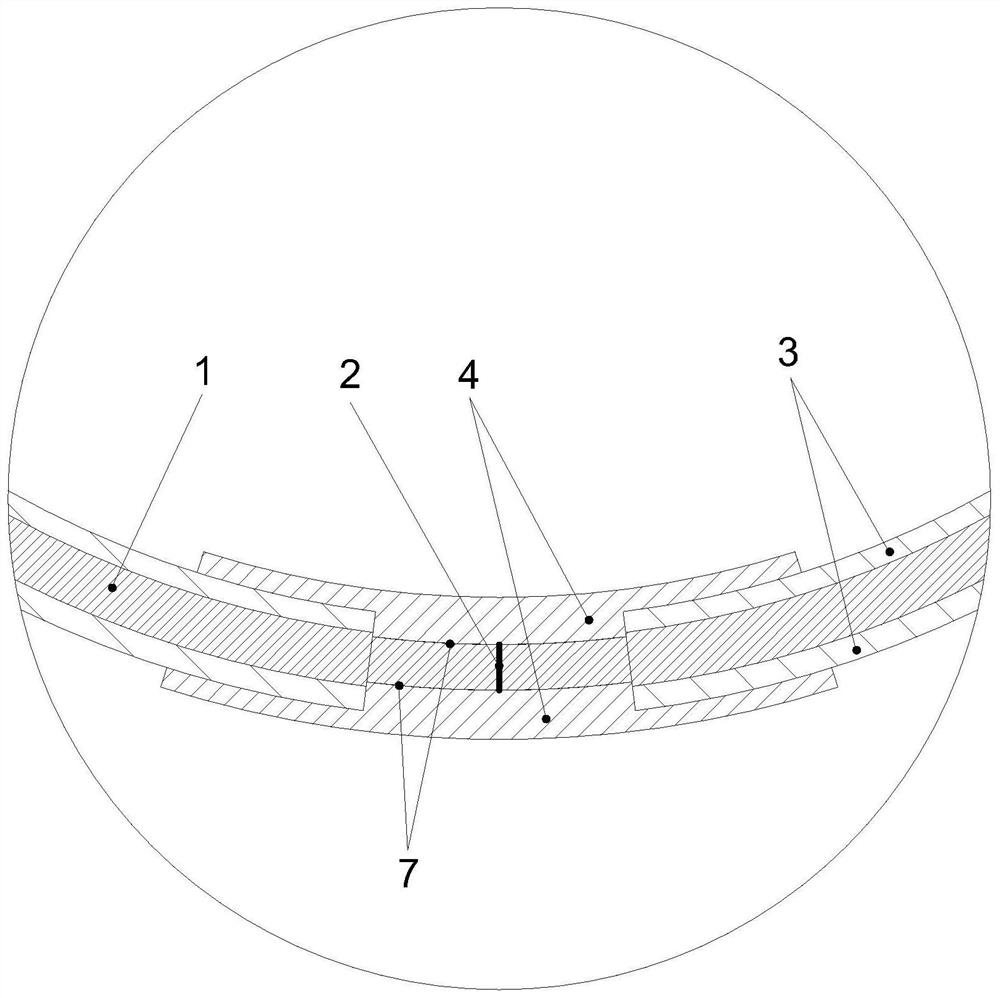

Film-coated barrel and preparation method thereof

PendingCN112777080AEasy to useGuaranteed service lifeLaminationLamination apparatusStructural engineeringWeld seam

The invention relates to a film-coated barrel and a preparation method thereof. The barrel comprises a barrel body formed by winding and welding a metal plate, end covers used for sealing the two ends of the barrel body, film-coated layers attached to the inner and outer surfaces of the barrel body and the end covers and film repairing layers attached to the inner and outer surfaces of the welding position of the barrel body. In the preparation process, the method mainly comprises the steps that the film-coated layers are attached to the front end face and the back end face of the metal plate, cutting is conducted, edge milling or edge grinding is conducted on the two ends, the barrel body is formed through welding, film repairing is conducted on welding seams, and edge curling and fixing are conducted on the end covers. Surface treatment of the barrel body is achieved in the mode that the inner surface and the outer surface of the barrel body are coated with films, and the problems that environmental pollution generated by spraying seriously exceeds the standard and the input cost is too high are solved. In the film covering process, the barrel body is provided with the welding seams, so that surface film covering treatment at the welding seams is achieved in a film repairing mode, and the using effect and the service life of the barrel body are effectively guaranteed.

Owner:苏州贝氏包装科技有限公司

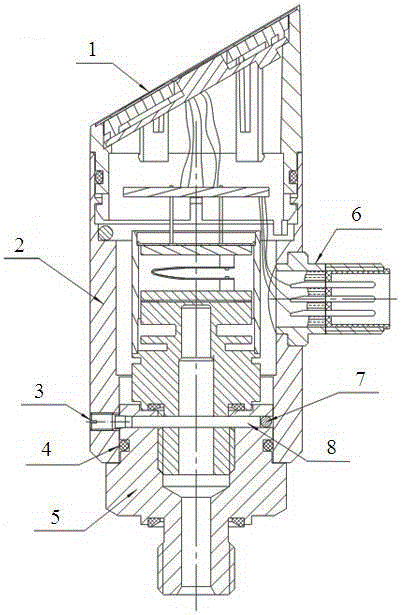

Digital display pressure sensor adopting steel wire to position rotating angle

InactiveCN105181183AEasy to weld and fixNot easy to fall offFluid pressure measurement by electric/magnetic elementsForce measurementBody jointsEngineering

The invention relates to a digital display pressure sensor adopting a steel wire to position a rotating angle. The digital display pressure sensor comprises a display panel; an outer tube is arranged below the display panel; a side surface of the outer tube is provided with an electrical interface; an elastic body joint is arranged at the lower part of the outer tube; the upper surface of the elastic body joint is provided with a circular groove; an arc-shaped steel wire bar is arranged in the circular groove; the arc-shaped steel wire bar is located at the inner circular arc edge of the circular groove; the radius of the circular arc of the arc-shaped steel wire bar is identical to the radius of the circumferential periphery of the circular groove; and the arc-shaped steel wire bar is fixed to the bottom of the circular groove. The arc-shaped steel wire bar of the digital display pressure sensor has little possibility of falling off. The digital display pressure sensor has the advantages of long service life and flexible rotation.

Owner:FIRSTRATE SENSOR

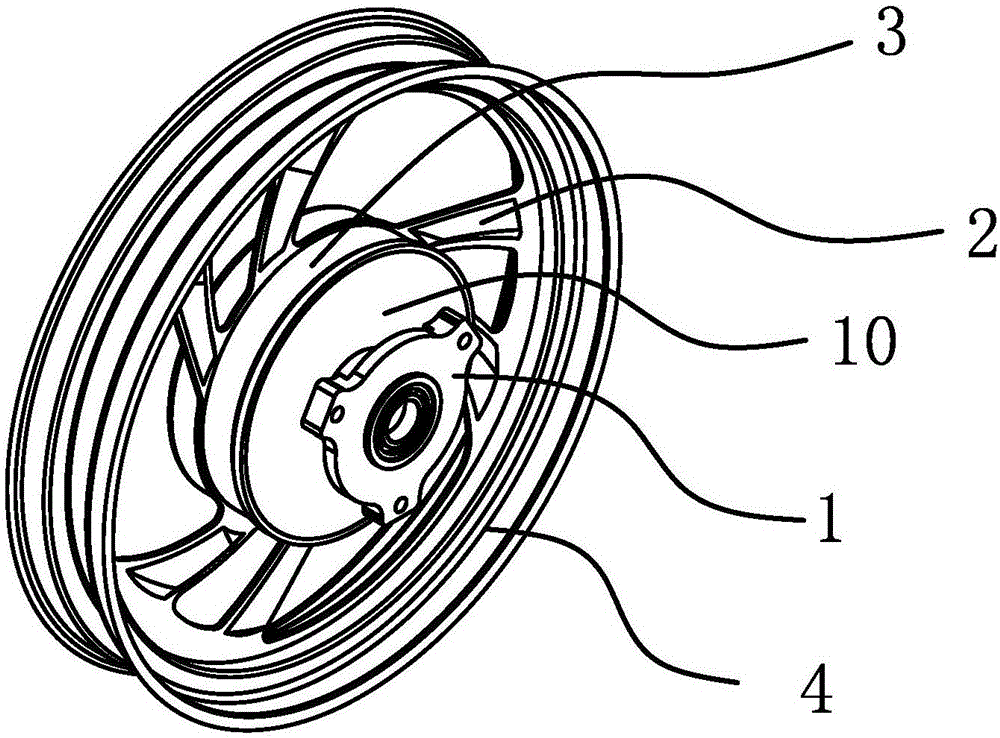

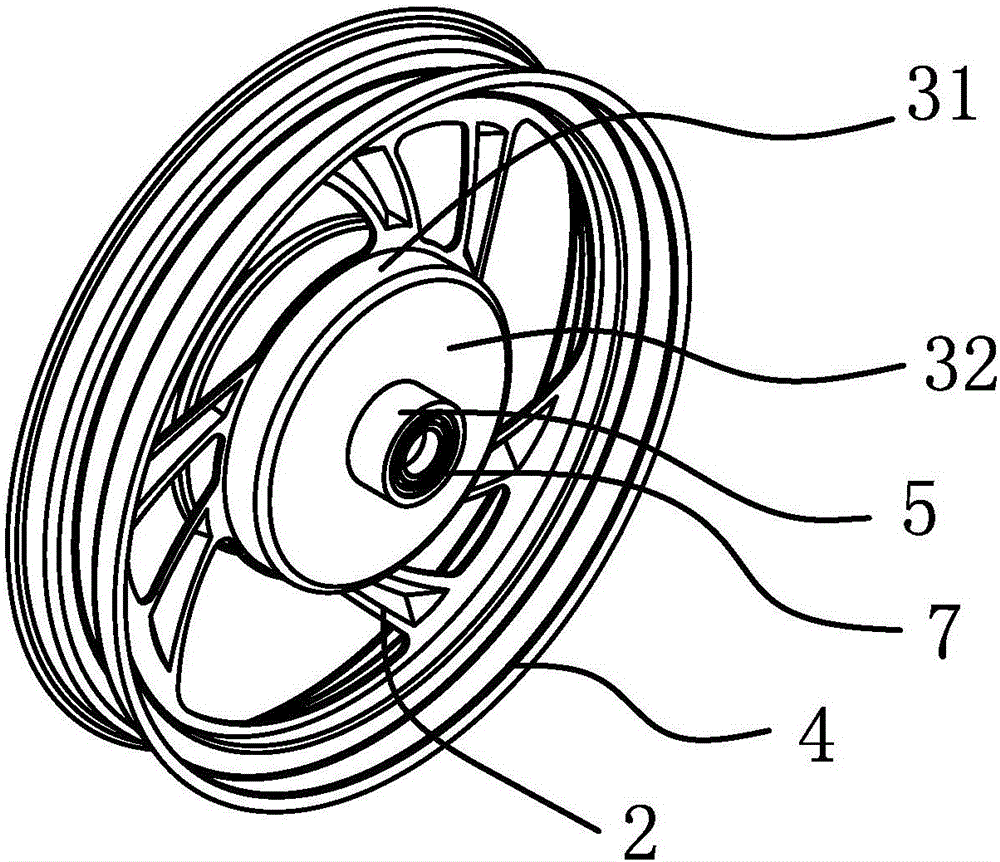

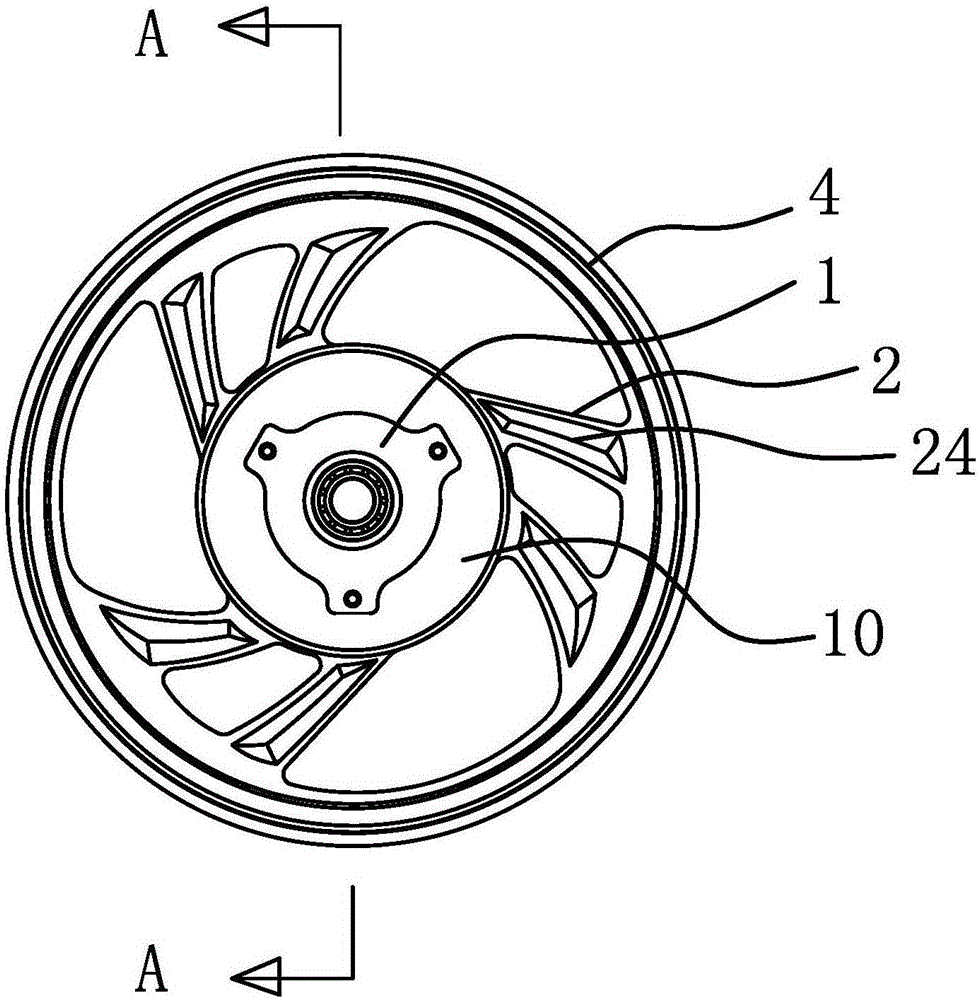

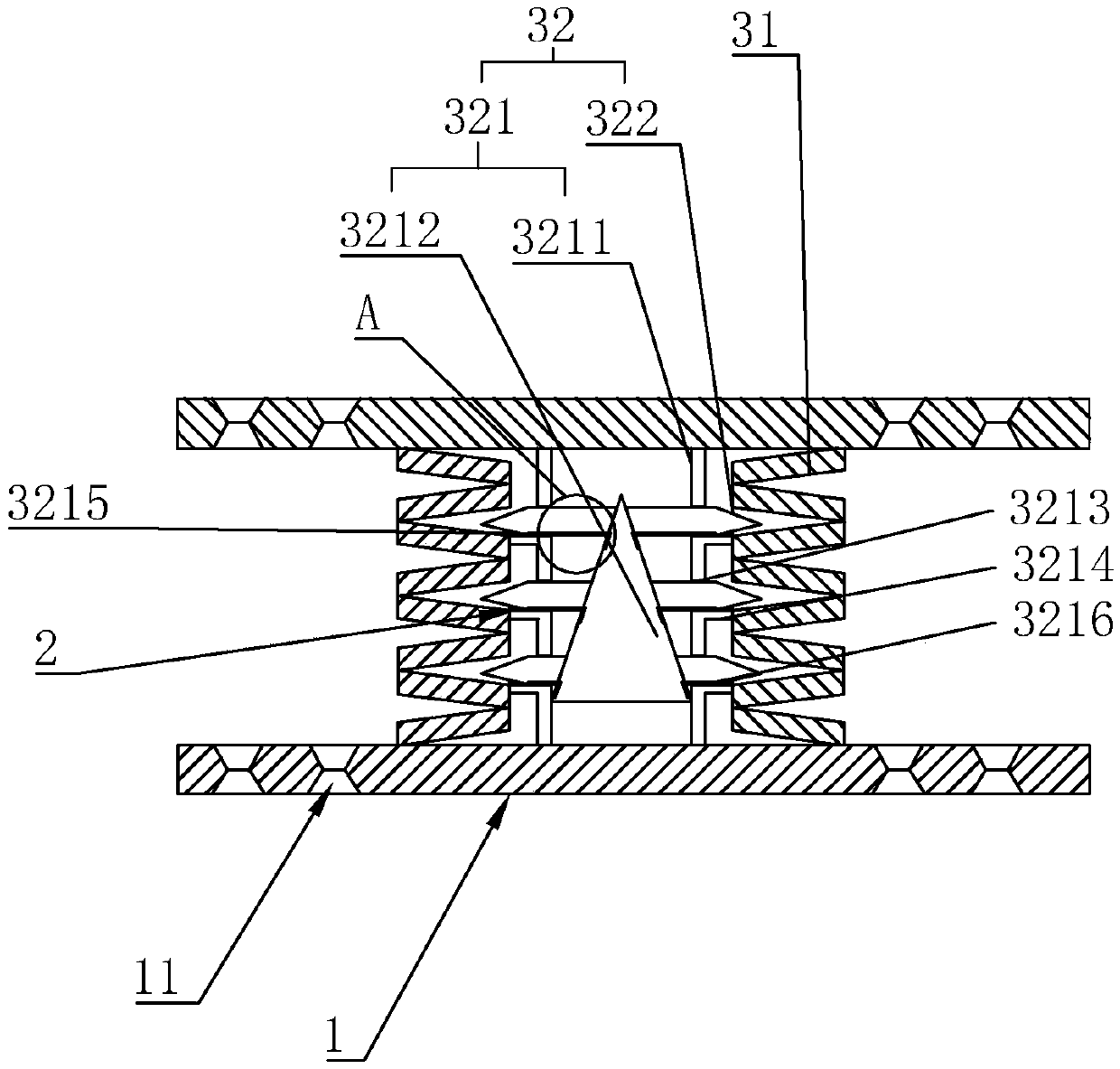

Hub enabling mutual refit of drum brake and disc brake

PendingCN106379291AImprove convenienceRelieve pressureBraking element arrangementsPulp and paper industrySpoke

The invention provides a hub enabling mutual refit of a drum brake and a disc brake, belonging to the technical field of locomotive hubs. The technical problem of the existing hub that mutual refit of a disc brake or drum brake cannot be realized is solved. The hub enabling mutual refit of a drum brake and a disc brake comprises a mounting flange for mounting a disc brake plate, a spoke, a cylindrical brake drum and a rim, wherein the brake drum is fixedly connected with the rim through the spoke; the two ends of the brake drum are an open end and a closed end respectively; the hub also comprises a cover plate independent of the brake drum; the cover plate is fixed at the open end of the brake drum through welding, in a detachable manner or through rivet connection; a bushing II penetrating through the cover plate is inserted into the middle of the cover plate; the inner end of the bushing II is fixedly connected with the cover plate; the outer end of the bushing II is fixed with the mounting flange; and the bushing I, the bushing II and the brake drum are coaxially arranged. In the invention, mutual refit of the drum brake and disc brake can be realized, the universality is high, the convenience of enterprise production is greatly improved, and the stock pressure is reduced.

Owner:TAIZHOU HUARUI AUTOMOBILE & MOTORCYCLES PARTS CO LTD

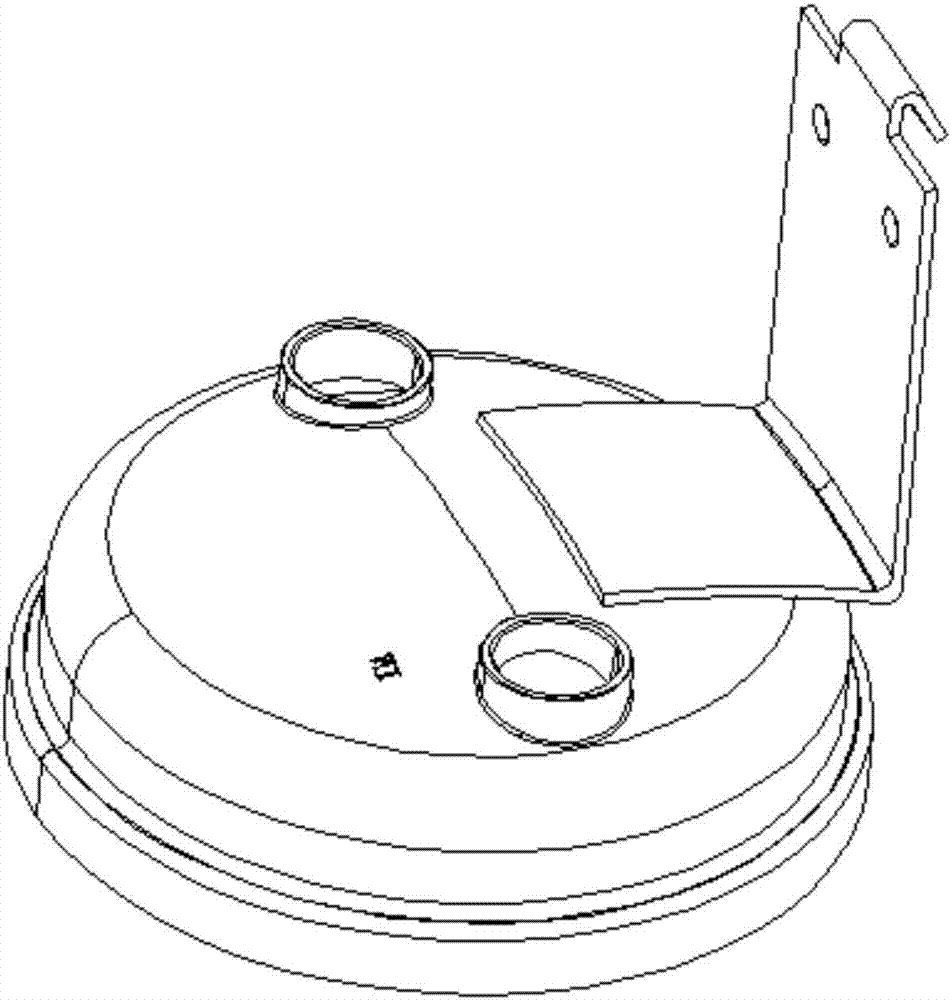

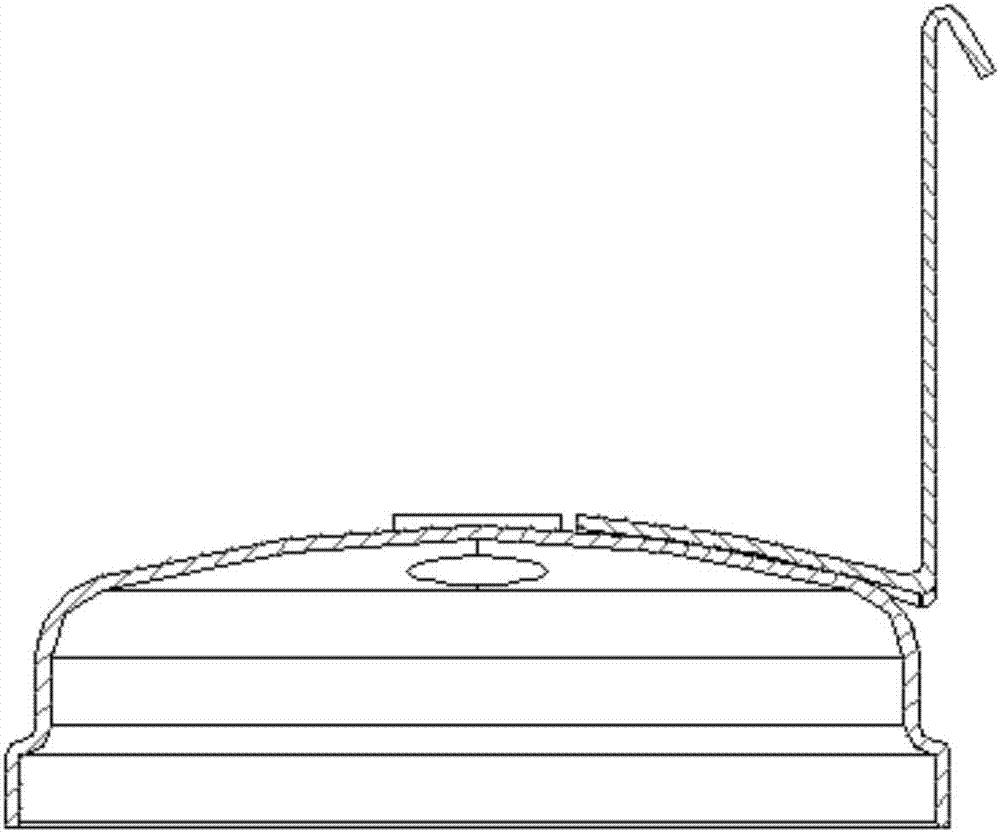

Disk spring set for shock insulation support

ActiveCN109610668AAdjustable stiffnessAvoid the problem of poor vibration isolation effectProtective buildings/sheltersShock proofingVibration detectionComputer engineering

The invention discloses a disk spring set for a shock insulation support. The disk spring set comprises a disk spring and a rigidity adjusting mechanism arranged in the disk spring, two ends of the disk spring are fixedly connected with an external upper connecting plate and an external lower connecting plate respectively; and the section of the disk spring is of a corrugated pipe structure; the rigidity adjusting mechanism comprises a vibration detection assembly and an elastic block slidably embedded in an interlayer of the disk spring, the elastic block is in linkage with the vibration detection assembly, fixing plates are arranged at two ends of the disk spring, a plurality of welding holes are formed in a fixing plate, and the welding holes penetrate through two faces of the fixing plate. According to the disk spring set for the shock insulation support, through the arrangement of the rigidity adjusting mechanism, the rigidity of the disk spring set can be effectively adjusted, and therefore the problem that shock insulation cannot be achieved due to the fact that the disk spring set is too high in rigidity to deform in the prior art is solved.

Owner:中震华创(深圳)技术有限公司

Assembly method for end covers of gas-liquid separator or oil-gas separator

ActiveCN107150184AEasy to weld and fixSimple and accurate welding positioningArc welding apparatusMetal working apparatusElectric resistance weldingRejection rate

The invention discloses an assembly method for end covers of a gas-liquid separator or oil-gas separator, and relates to the technical field of air conditioner part assembly. The assembly method comprises the following steps: one of the end covers is connected with brackets by adopting electric resistance welding, the end cover is fixed with a device body in a welding manner by adopting CO2 protective welding, and finally the other end cover is welded at the other end of the device body by adopting the same method, so as to complete the disassembly of the end covers and refrigeration equipment. According to the assembly method for the end covers of the gas-liquid separator or oil-gas separator, the fixation between the end covers and the brackets is convenient, the assembly difficulty is reduced, the rejection rate is low, the welding time is short, and the positioning precision is high.

Owner:WUHU SANHUA REFRIGERATION FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com