Completely-metal integrated illuminating and backlight LED heat radiating structural body

A structure and backlight technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as short service life and poor heat dissipation of LEDs, and achieve effective control and improvement of heating temperature The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

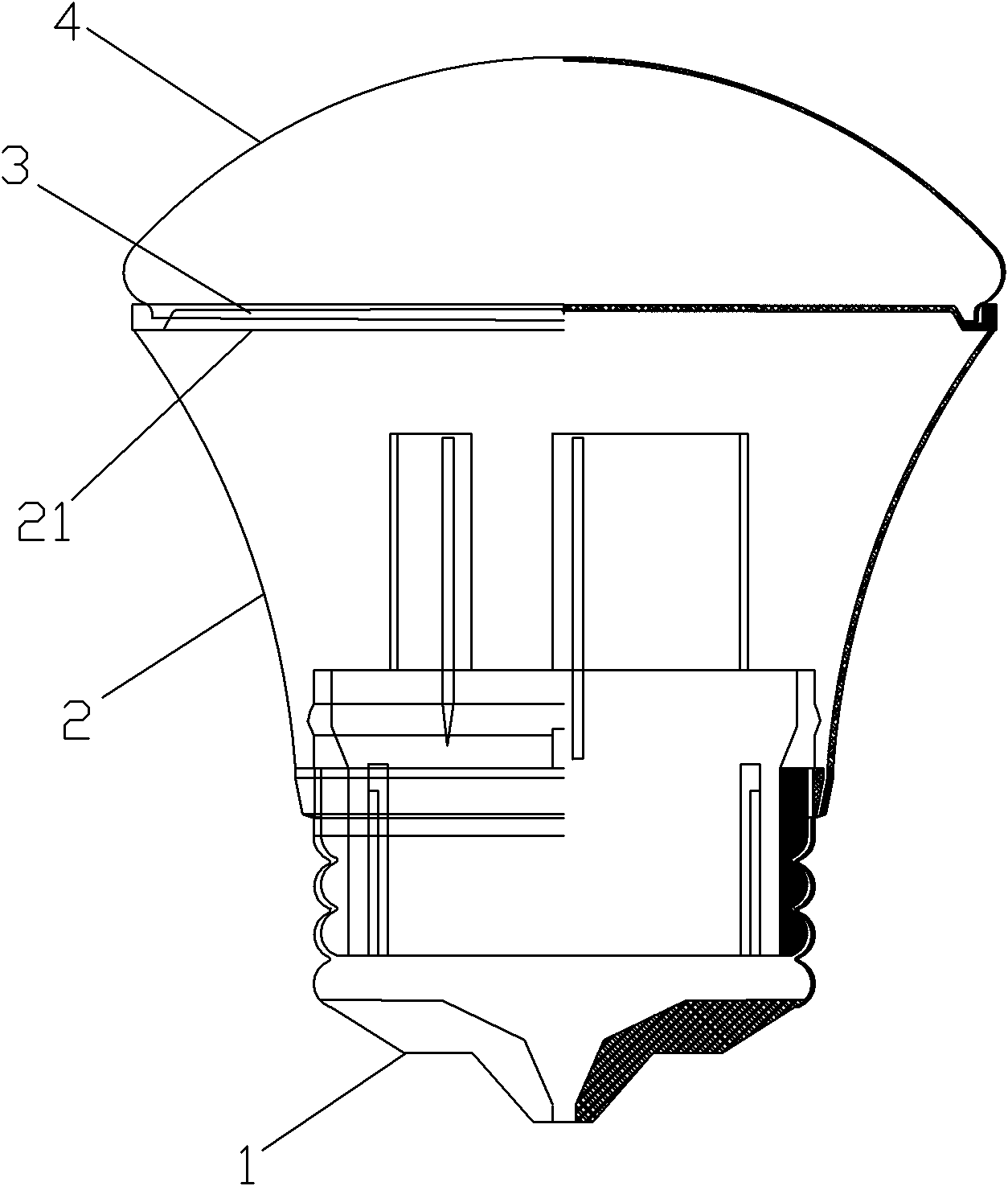

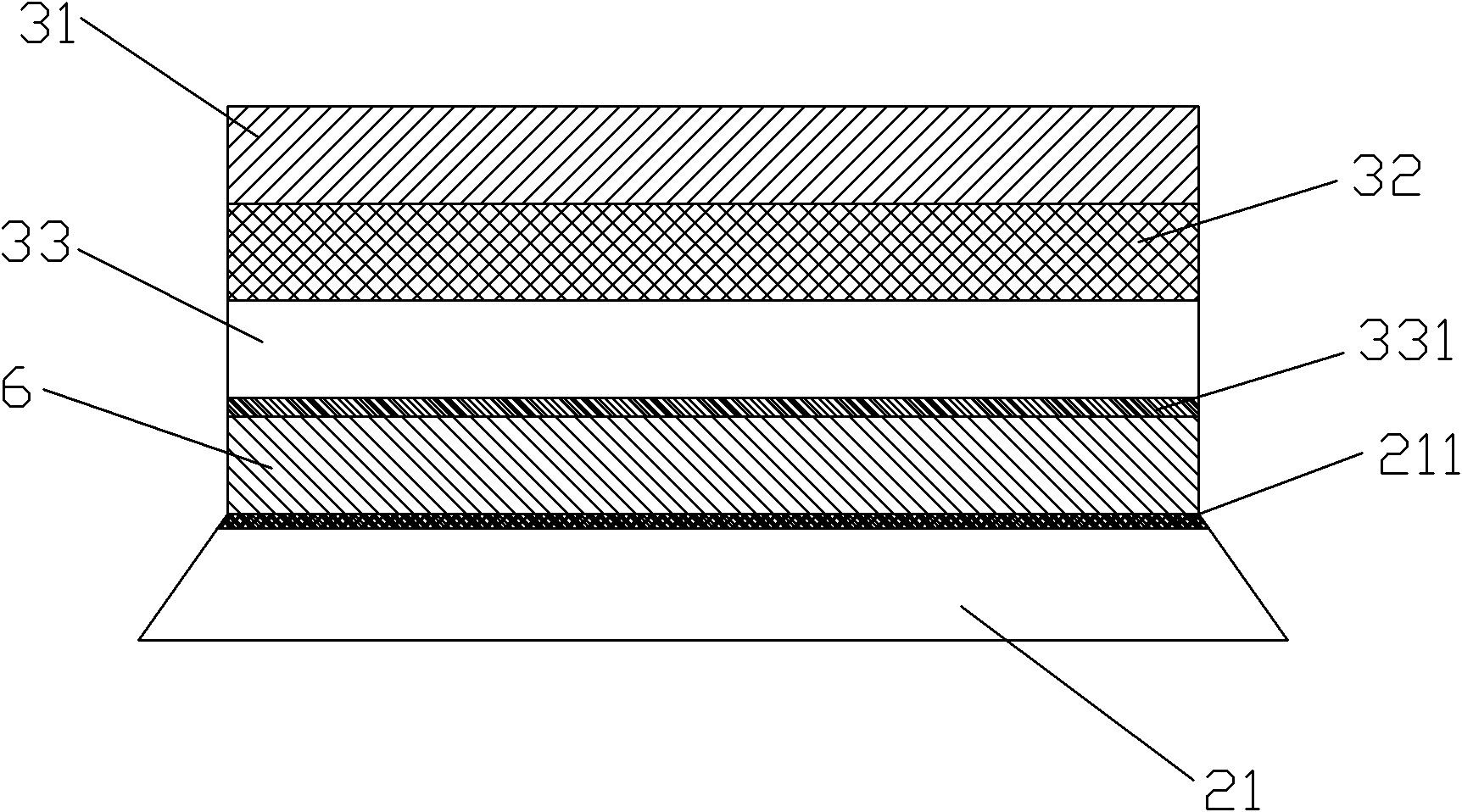

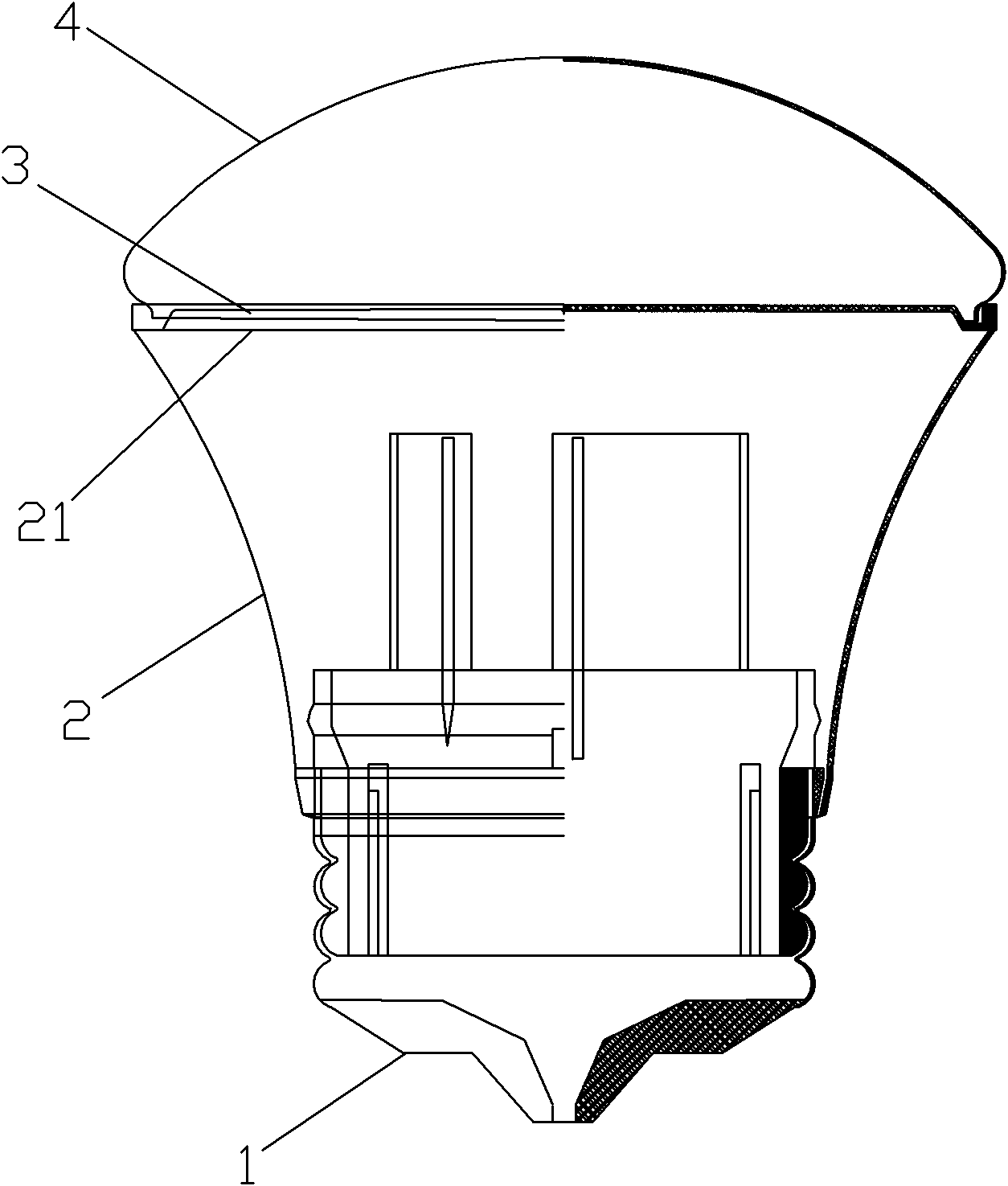

[0019] For the embodiment, please refer to the accompanying drawings, a fully metal-integrated LED heat dissipation structure for lighting and backlight of the present invention, including a lamp holder 1, a lamp cup body 2, a circuit board 3 with LEDs and a lampshade 4; the lamp holder 1 is fixedly connected to one end of the lamp cup body 2 through an insulating plastic case; the lampshade 4 is fixedly connected to the other end of the lamp cup body 2; the circuit board 3 is connected to the lamp cup body 2 and accommodated in the lamp cup body 2 and the lampshade 4 In the enclosed cavity; the lamp cup body 2 is an integral structure made of aluminum material; the side of the circuit board 3 connected with the lamp cup body 2 is set as an aluminum foil or aluminum plate layer 33, and the aluminum foil or aluminum plate layer 33 is coated with a first metal coating 331 on the outer surface; the side of the lamp cup body 2 connected to the circuit board 3 is provided with an al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com