Composite vacuum cup and manufacturing process thereof

A composite thermal insulation and production process technology, applied in the field of thermos cups, can solve problems such as high requirements for production equipment and workers' skills, affecting the manufacturing cost of thermos cups, and rising manufacturing costs of thermos cups. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

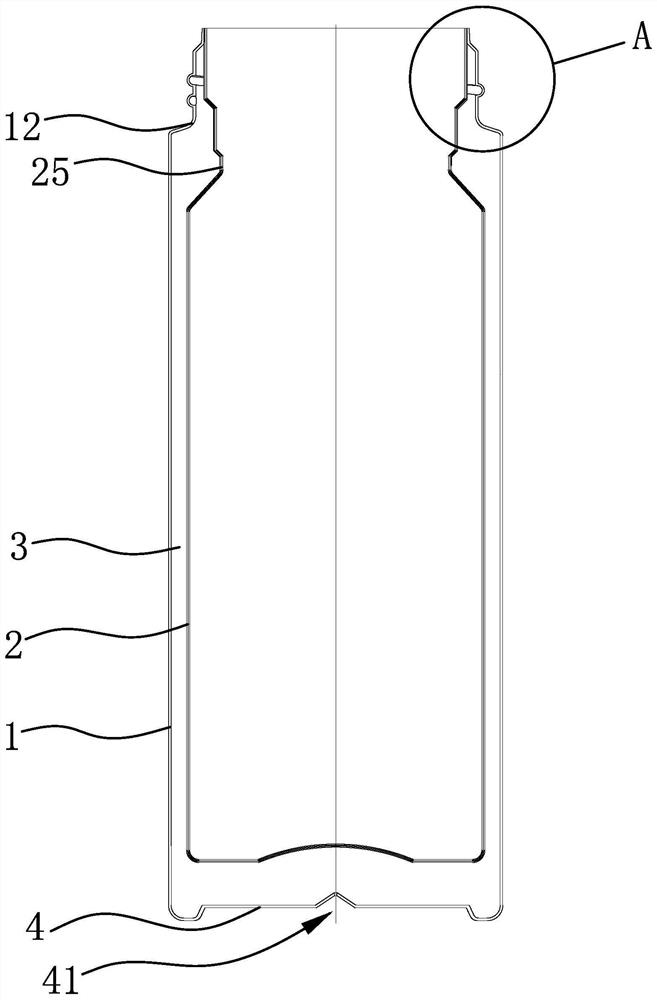

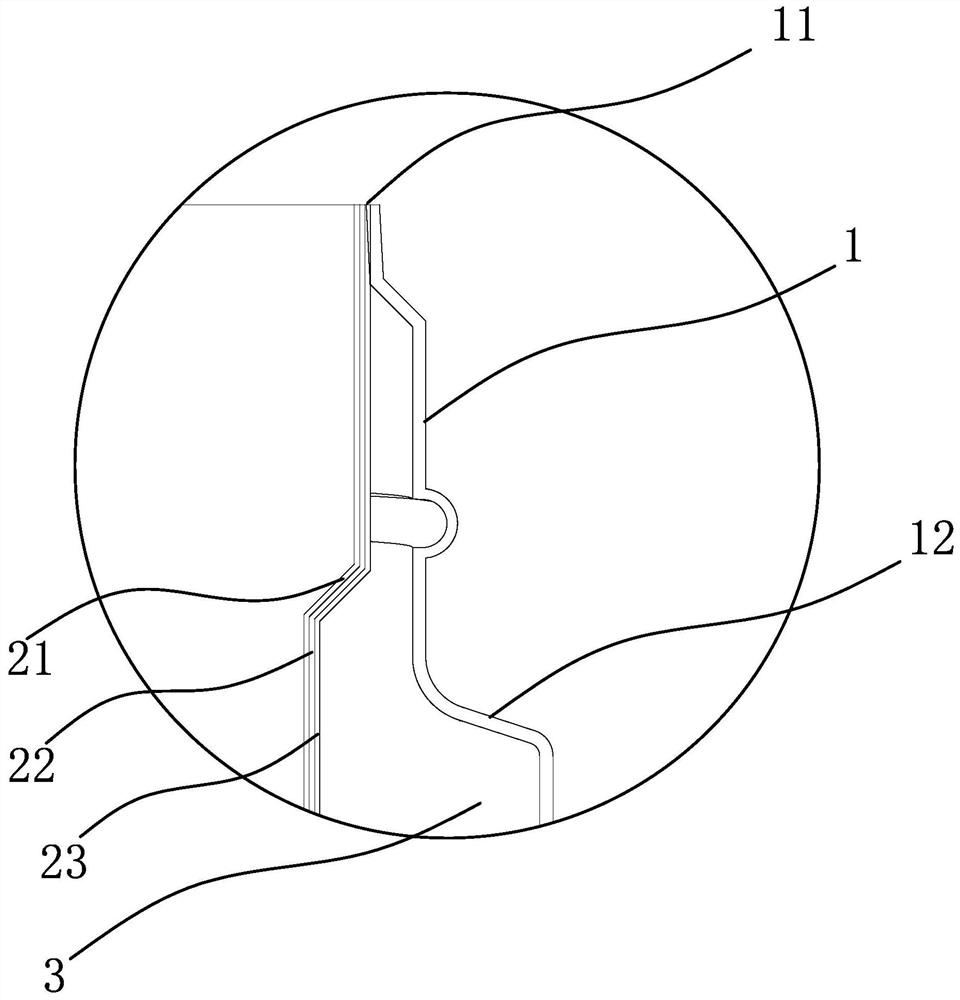

[0042] Such as figure 1 and figure 2 As shown, the composite thermos cup includes an outer shell 1 and an inner container 2 inserted in the outer shell 1. There is a vacuum layer 3 between the outer shell 1 and the inner container 2. The upper end of the inner container 2 is welded to the upper end of the outer shell 1. The outer shell 1 It is made of stainless steel, the inner tank 2 is made of composite board, and the inner layer 21 of the inner tank 2 is made of titanium metal or titanium alloy; the inner tank 2 is made of copper metal or copper alloy or aluminum metal or aluminum alloy. The middle layer 22 and the outer layer 23 are made of stainless steel. Further, the upper end of the housing 1 is inclined inwards and then extended upwards to form a straight cylindrical neck 11, the inner wall of the neck 11 abuts against the outer peripheral surface of the upper end of the outer layer 23 made of stainless steel and the two are welded and fixed.

[0043] In the presen...

Embodiment 2

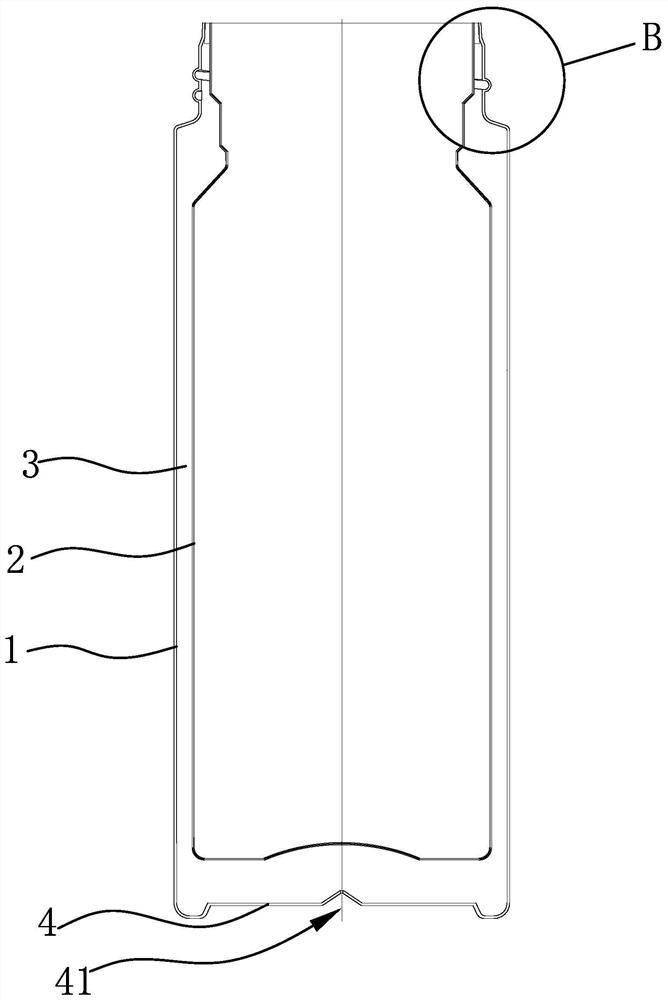

[0046] Such as image 3 and Figure 4 As shown, the content of this embodiment is basically the same as that of Embodiment 1, the difference is that: the inner layer 21 of the inner tank 2 in this embodiment is made of titanium metal or titanium alloy; the outer layer 23 of the inner tank 2 is made of copper Metal or copper alloy or aluminum metal or aluminum alloy and the outer surface of the upper end of the outer layer 23 has a welding ring 24 made of stainless steel; The side surface is flush with the upper end surface of the liner 2; the upper end of the shell 1 is inclined inward and then extends upward to form a straight cylindrical neck 11, the inner wall of the neck 11 is in close contact with the outer peripheral surface of the welding ring 24, and the two are welded firmly. Connecting, the inner and outer sides of the welding ring 24 are respectively attached to the outer peripheral surface of the liner 2 and the inner wall of the shell 1, which is convenient for w...

Embodiment 3

[0049] combine Figure 5 As shown, this embodiment discloses a manufacturing process of a composite thermos cup. The structure of the composite thermos cup is the same as that of the composite thermos cup in the first embodiment above. The inner tank 2 is made of a composite board, and the inner layer 21 of the inner tank 2 It is made of titanium metal or titanium alloy; the liner 2 has an intermediate layer 22 made of copper metal or copper alloy or aluminum metal or aluminum alloy and an outer layer 23 made of stainless steel; the manufacturing process of the composite thermos cup Include the following steps:

[0050] a. Make shell 1: use stainless steel pipes or circular plates to make shell 1;

[0051] b. Making the liner 2: take the composite plate that the inner layer 21 is made of titanium metal or titanium alloy material, the middle layer 22 is made of copper metal or copper alloy or aluminum metal or aluminum alloy material, and the outer layer 23 is made of stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com