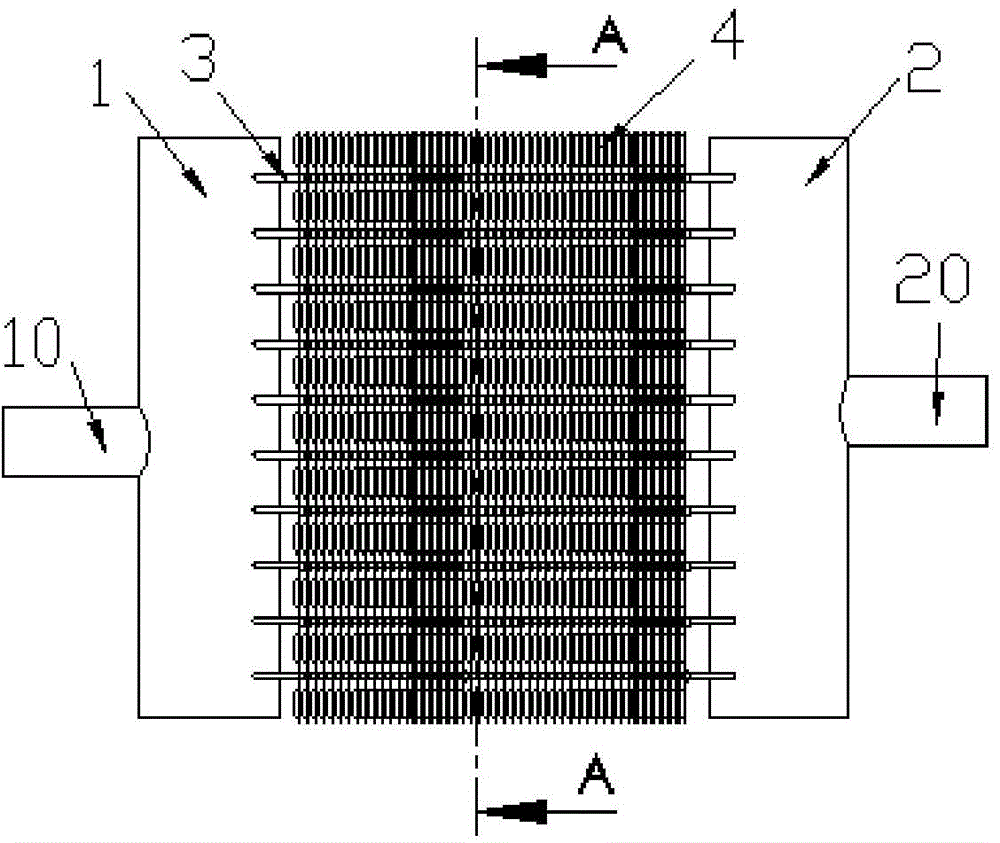

Heat pump type microchannel heat exchanger

A micro-channel heat exchanger and heat pump technology, applied in the field of air-conditioning heat exchangers and refrigeration and air-conditioning, can solve the problems of inability to achieve accurate positioning, end flanging and lodging, and different heights of fins, and achieve convenient installation and increased strength. , the effect of uniform spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

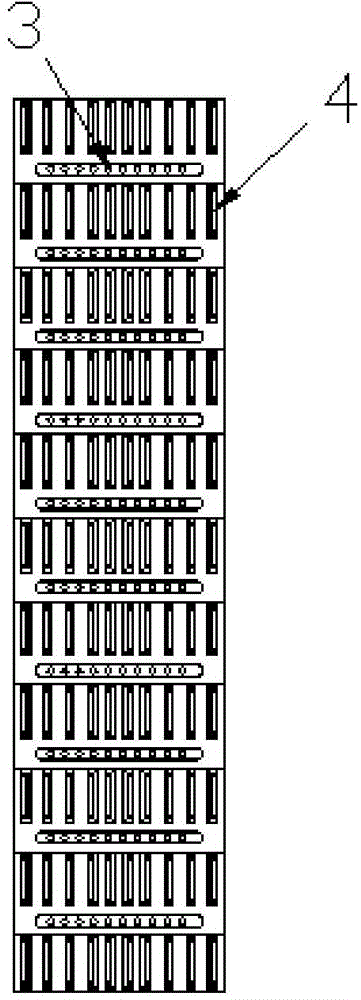

Method used

Image

Examples

Embodiment 2

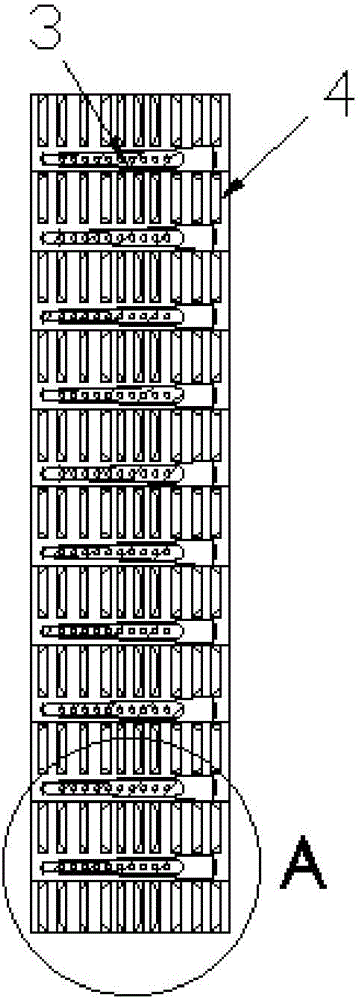

[0051] The technical solution of Embodiment 2 is to consider that when the heat exchanger is placed vertically, due to the small inclination angle of the two long sides of the flat tube, a slight inclination of the heat exchanger during initial installation or operation may cause the long side of the upper side of the flat tube to be caused. level, resulting in the retention of condensed water on the upper surface of the flat tube. When there is an included angle between the center line of the two short sides of the flat tube cross-section and the horizontal plane, the inclination of the long side of the flat tube is increased, thereby avoiding the above problems, and the condensed water on the flat tube can be discharged smoothly.

[0052] like Figure 12 and Figure 13 As shown, in Embodiment 3, both ends of the flat tube insertion hole 40 are provided with installation holes 401, the installation holes 401 are rectangular, and the flanges on both sides of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com