Patents

Literature

240results about How to "Not misplaced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

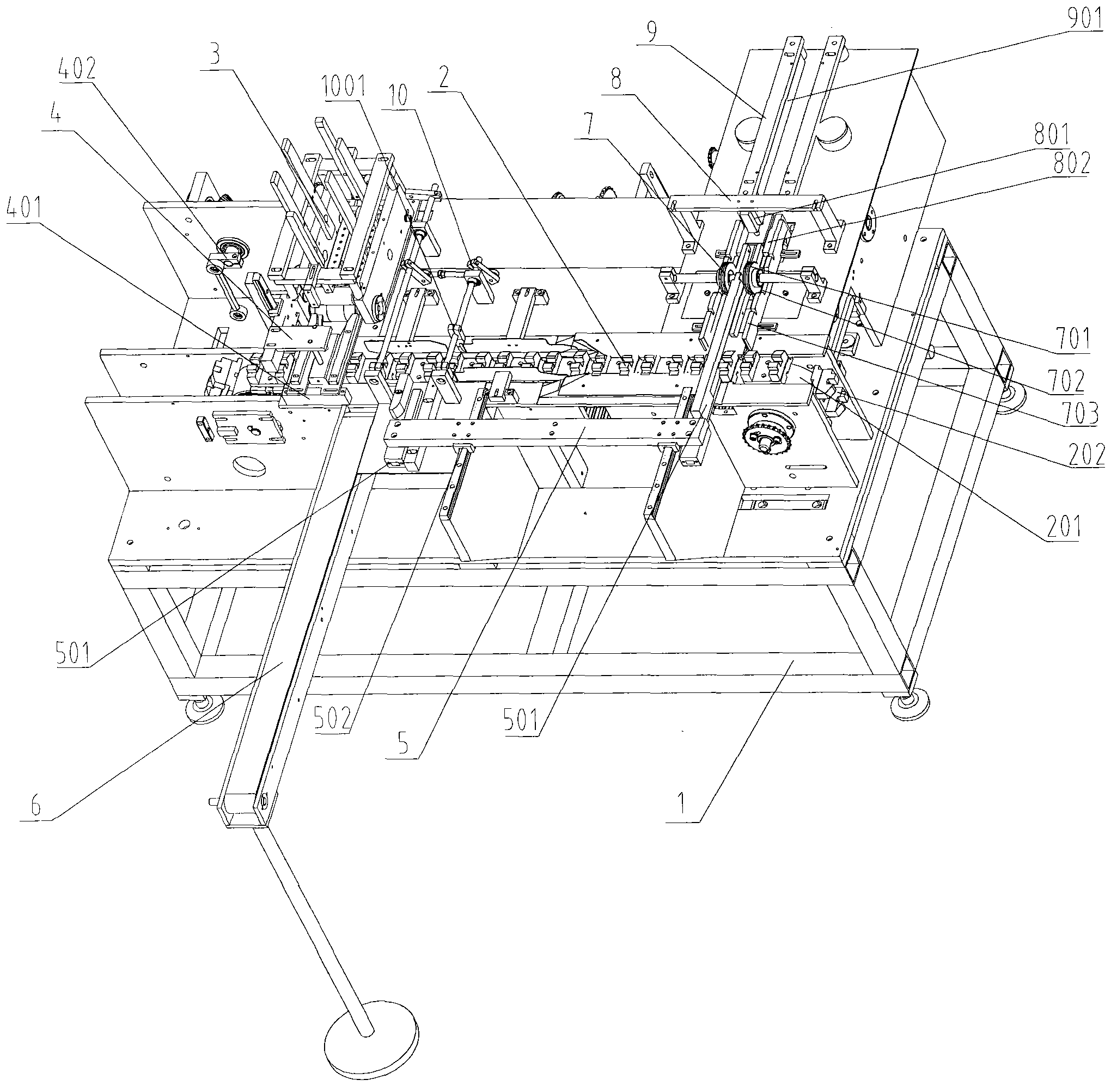

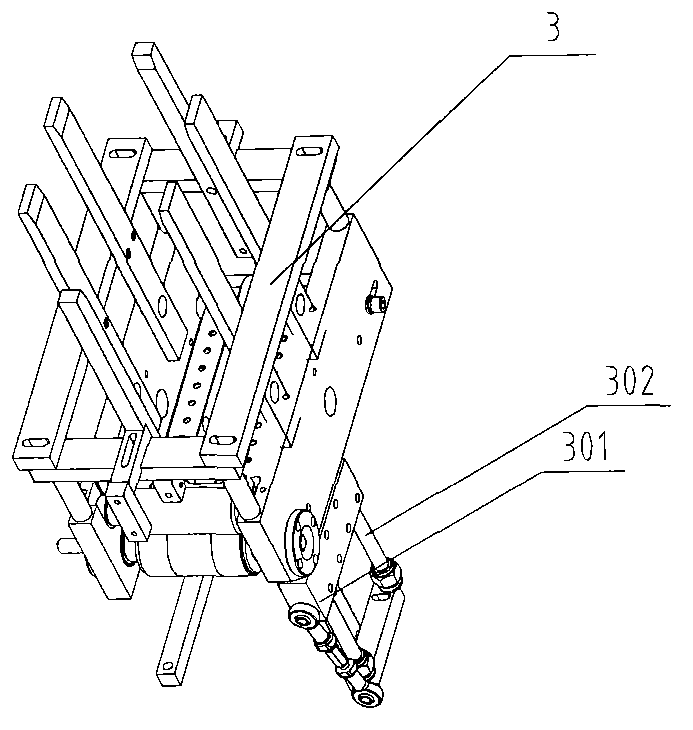

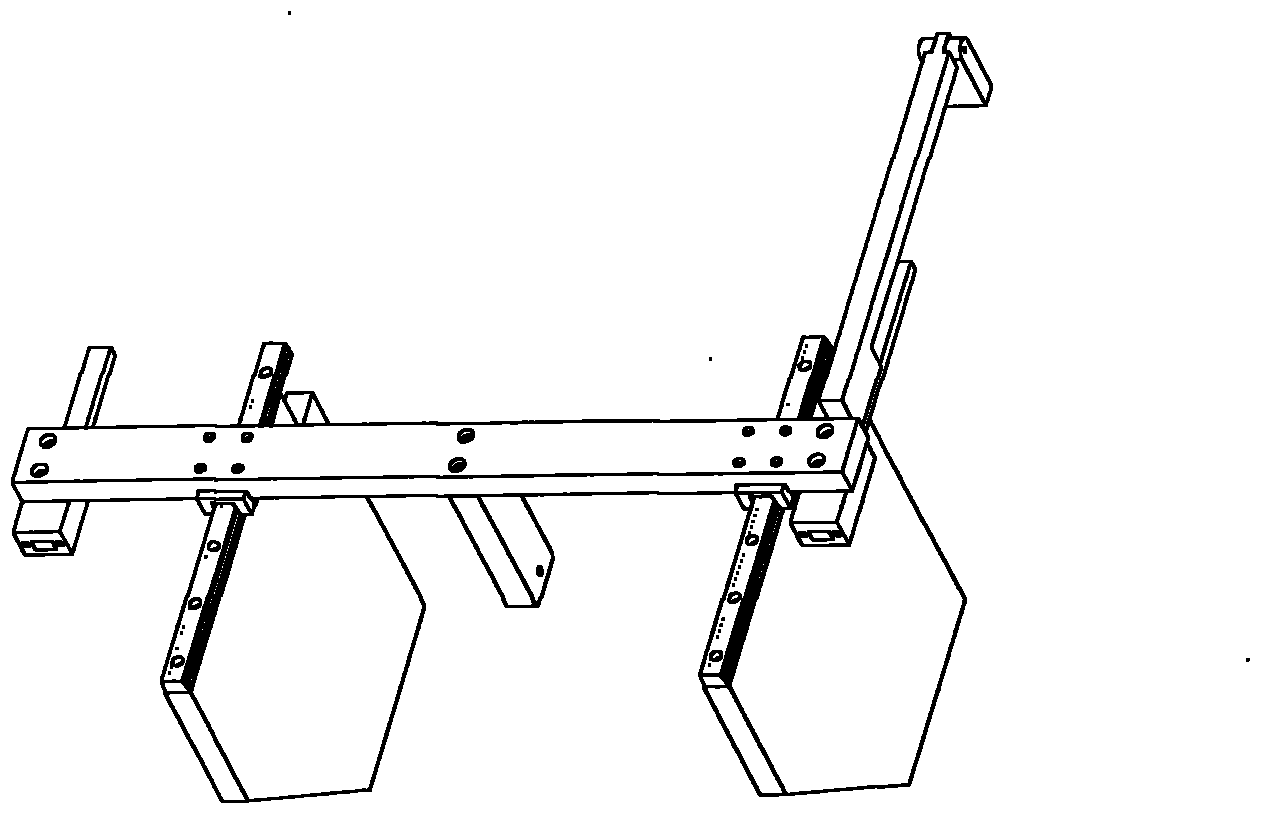

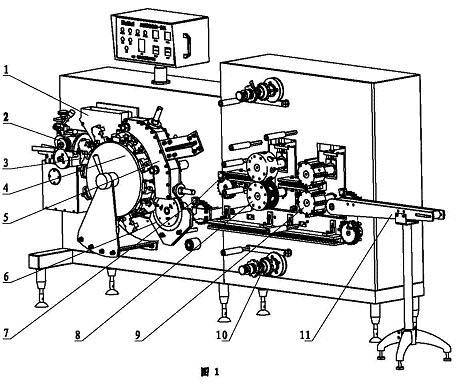

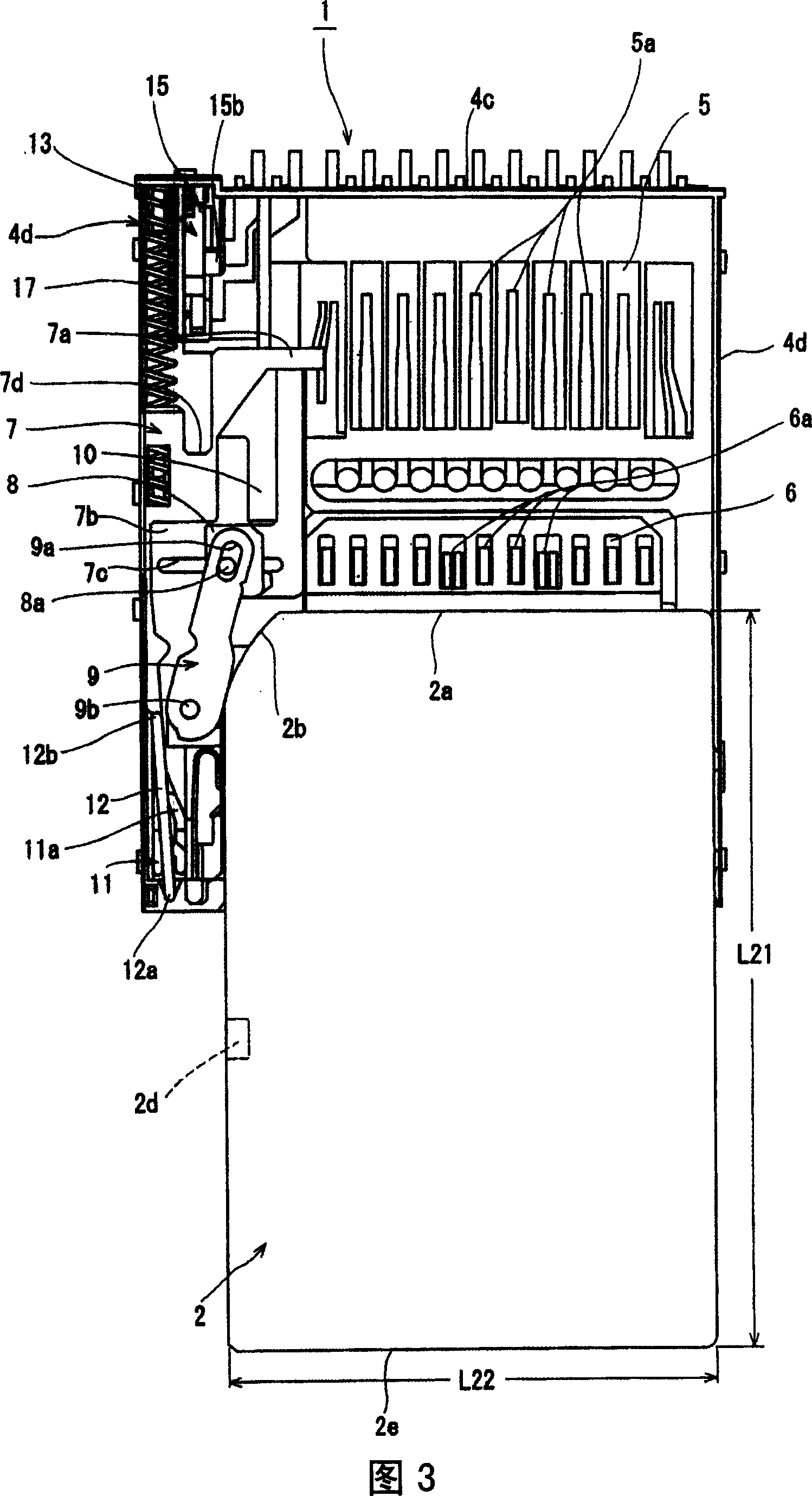

Tea-leaf boxing machine

ActiveCN103183140AGuaranteed success rateEliminate the problem of inaccurate positioningIndividual articlesDrive shaftPulp and paper industry

A tea-leaf boxing machine comprises a rack, as well as a paper box bin component, an air suction mechanism, a paper box forming module component, a paper box pressure block component, a paper box lug folding mechanism, a feeding mechanism, a material incoming and box outgoing push mechanism, a box gluing mechanism, a paper box shaping mechanism and an intermittent indexing drive device which are mounted on the rack, wherein the paper box bin component comprises a paper box bin and a paper box pressure block which are located on the same straight line, and the paper box pressure block is located above paper box forming modules; the air suction mechanism is arranged below the paper box bin component, and connected with a first rocker arm of a main transmission shaft; and the paper box forming module component comprises the paper box forming modules and a synchronous belt, the paper box forming modules are uniformly distributed on the synchronous belt, and the synchronous belt is connected with the intermittent indexing drive device. The invention provides the tea-leaf boxing machine which can perform mechanization packing, reduce the cost, and improve the efficiency.

Owner:浙江武义浩伟机械有限公司

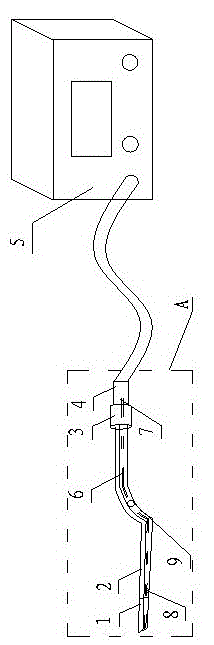

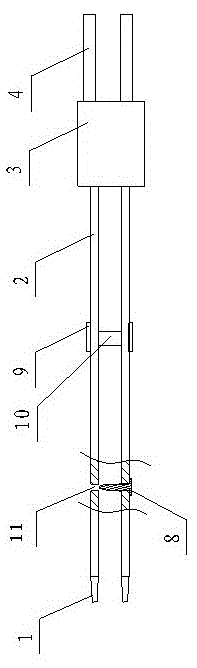

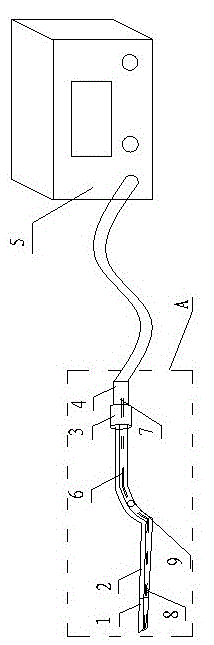

Electric coagulation forcep system with forcep point cleaning function

InactiveCN102743222AGuaranteed bonding effectEasy to operateEnemata/irrigatorsDiagnosticsMicrocontrollerMegasonic cleaning

The invention discloses an electric coagulation forcep system with a forcep point cleaning function, which comprises a forcep body and a host for providing a power source to the forcep body, wherein the forcep body comprises forcep points and forcep rods. The electric coagulation forcep system is characterized in that a temperature detecting device is arranged on the forcep points, the temperature detecting device feedbacks the detected temperature to a chip in the host; and the chip compares the temperature with the preset temperature and then adjusts the power output by the forcep points to adjust the temperature of the forcep points. The system further comprises an electric coagulation forcep supporting seat, wherein the electric coagulation forcep supporting seat comprises a base, grooves matched with two forcep rods of the electric coagulation forcep is formed in the base, the lower parts of the grooves are provided with a hollow cavity capable of holding forcep points; an ultrasound cleaner is arranged in the hollow cavity, a singlechip and a position sensing device for judging whether the forcep rods are arranged in the grooves are further arranged on the base; and a finish detecting device used for detecting the finish of the insides of the forcep points is arranged in the hollow cavity. The electric coagulation forcep system with the forcep point cleaning function is simple in structure; and by using the electric coagulation forcep system, the temperature of the forcep points are automatically detected and adjusted, and the forcep points are automatically cleaned.

Owner:CHONGQING RUNZE PHARM CO LTD

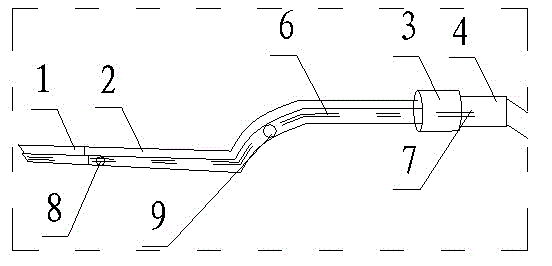

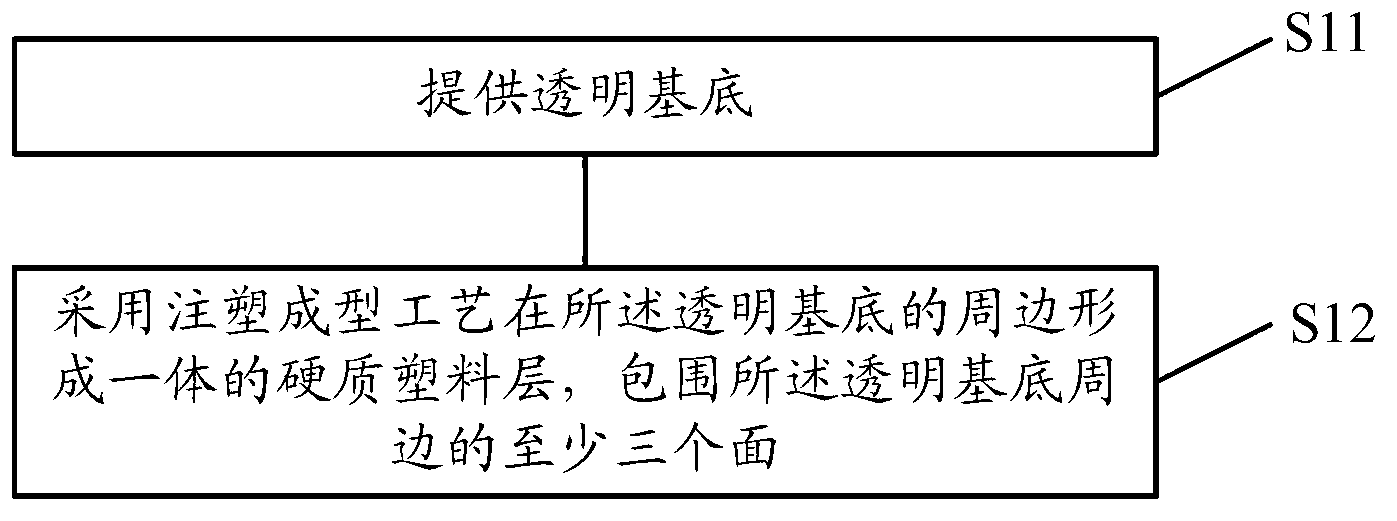

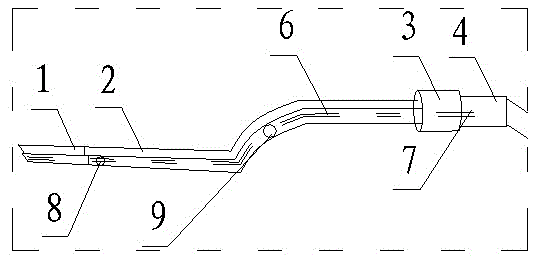

Car window assembly and binding method thereof

ActiveCN103057384AImprove adhesionImprove hemming efficiencyWindowsWindscreensEngineeringInjection moulding

Disclosed are a car window assembly and a binding method thereof. The car window assembly comprises a transparent base and an integrated hard plastic layer covering at least three peripheral sides of the transparent base. The binding method of the car window assembly includes: providing the transparent base; forming the integrated hard plastic layer on the periphery of the transparent base by injection molding to cover at least three peripheral sides of the transparent base. Bond between the plastic layer and glass in the car window assembly is higher, no dislocation occurs, binding efficiency is higher, and production cost is lowered.

Owner:SAINT-GOBAIN GLASS FRANCE

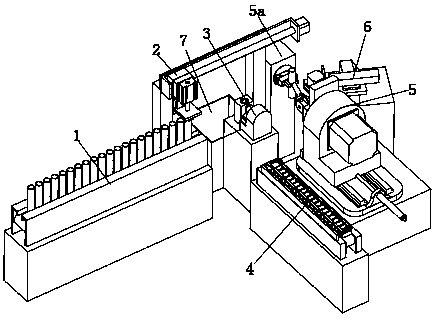

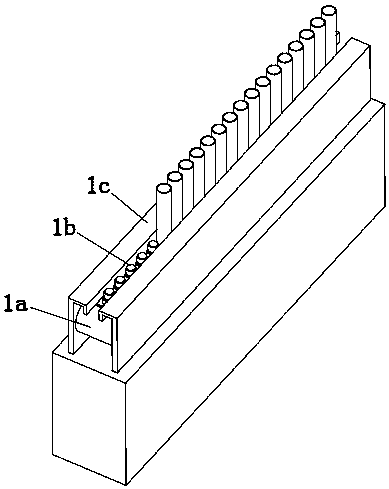

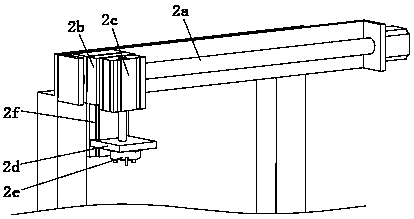

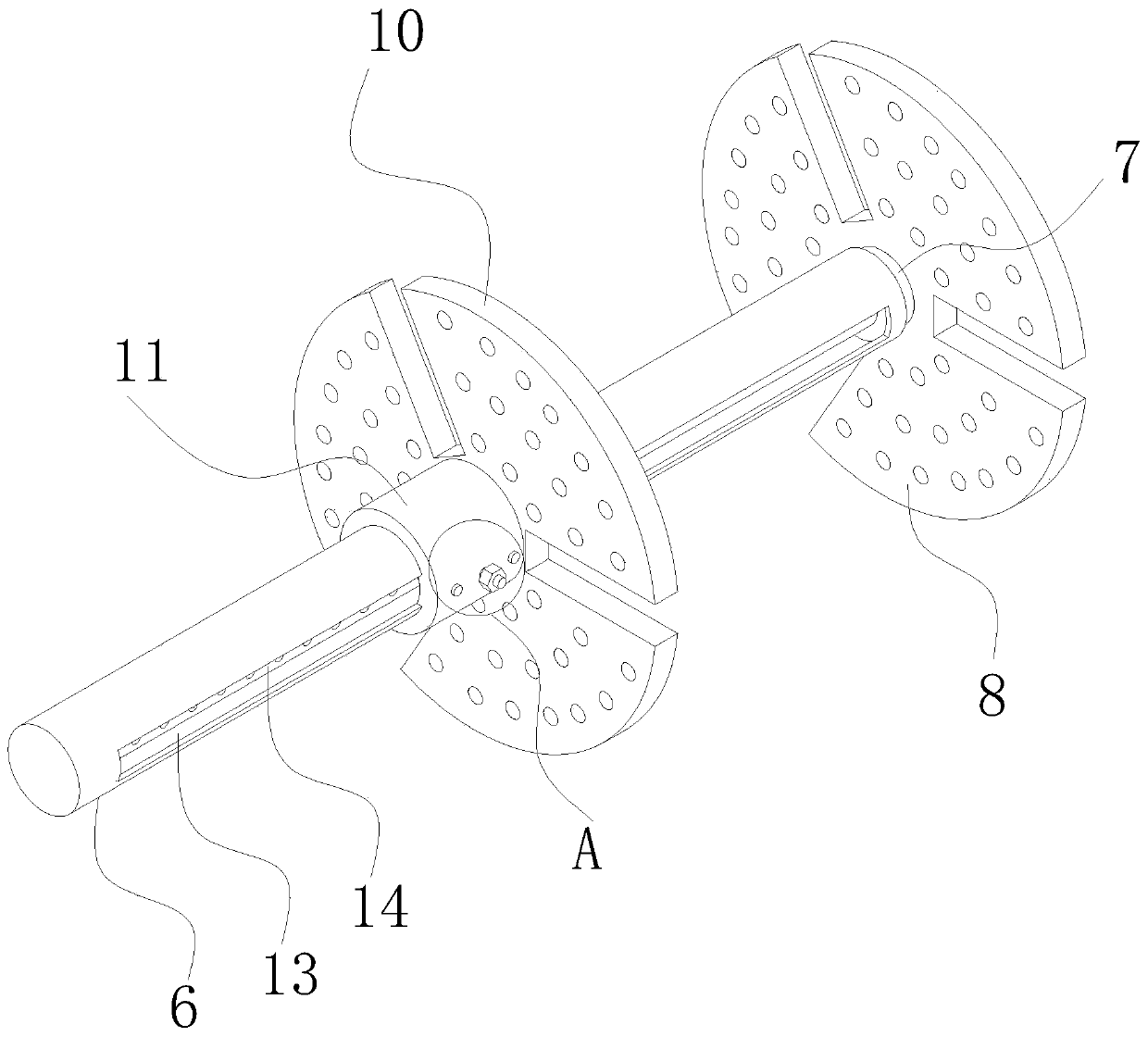

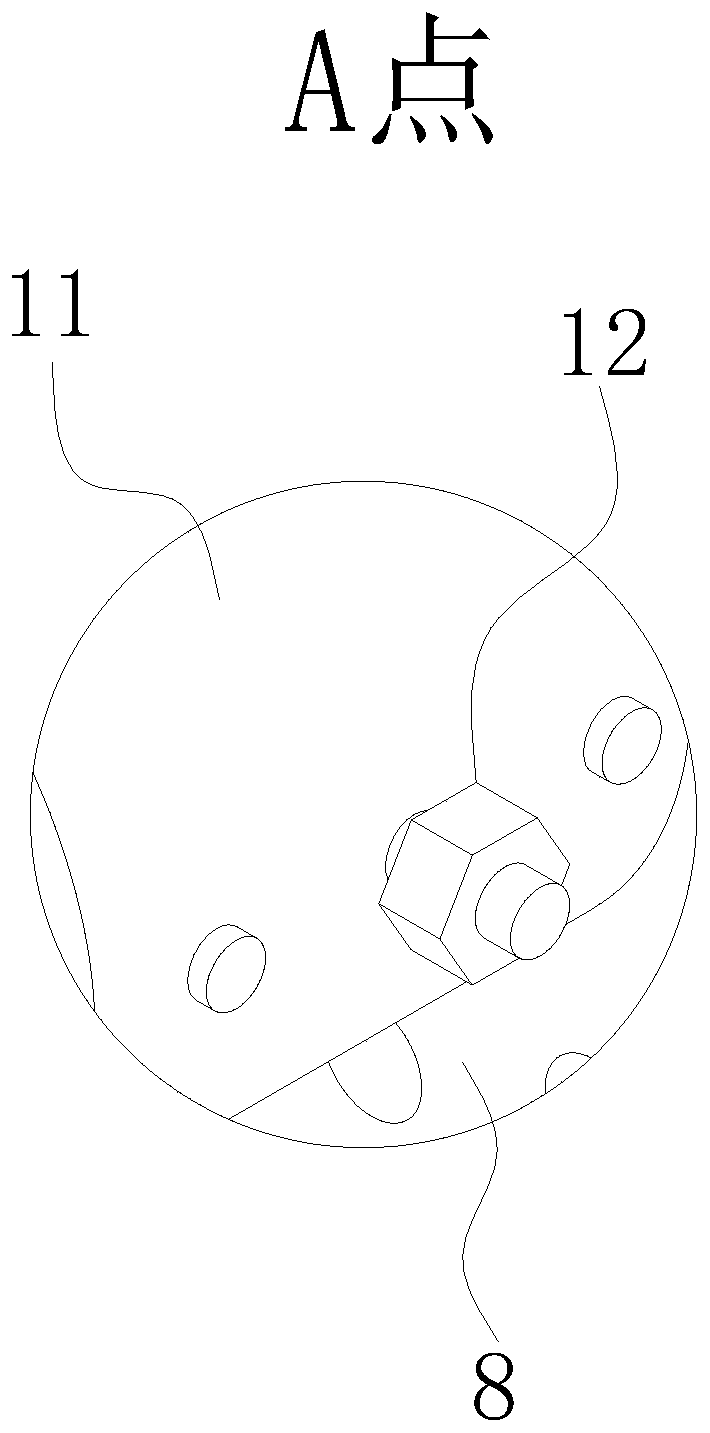

T-pipe welding robot

ActiveCN109175874AWide applicabilityFast processingWelding/cutting auxillary devicesAuxillary welding devicesPunchingEngineering

The invention relates to the field of T-pipe machining, in particular to a T-pipe welding robot. The T-pipe welding robot comprises a main pipe feeding mechanism, a transferring mechanism, a punchingmechanism, a branched pipe feeding mechanism, a positioning mechanism and a laser welding device. The punching mechanism is located at the tail end of the main pipe feeding mechanism. The transferringmechanism is mounted above the main pipe feeding mechanism and the punching mechanism. The positioning mechanism is located below the tail end of the transferring mechanism. The branched pipe feedingmechanism and the laser welding mechanism are separately located on the two sides of the positioning mechanism. The positioning mechanism comprises a main pipe clamping assembly, a first three-jaw chuck, an adjustment assembly, a driving assembly and a rotating assembly, wherein the driving assembly is mounted at the upper end of the rotating assembly, the adjustment assembly is mounted at one end of the driving assembly, and the first three-jaw chuck is mounted on the adjustment assembly. The T-pipe welding robot has the beneficial effects that welding of T-pipes can be automatically completed, and human-assisted feeding is not needed; and meanwhile, the T-pipe welding robot is suitable for welding branched pipes and main pipes with different included angles therebetween.

Owner:ZHIMAIDE CO LTD

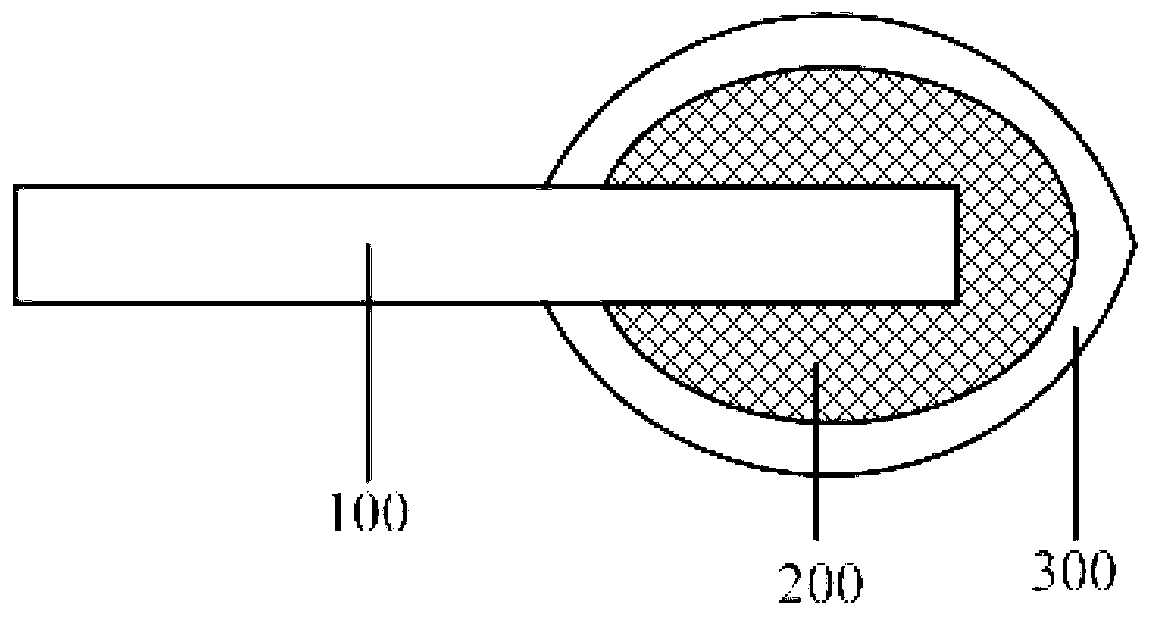

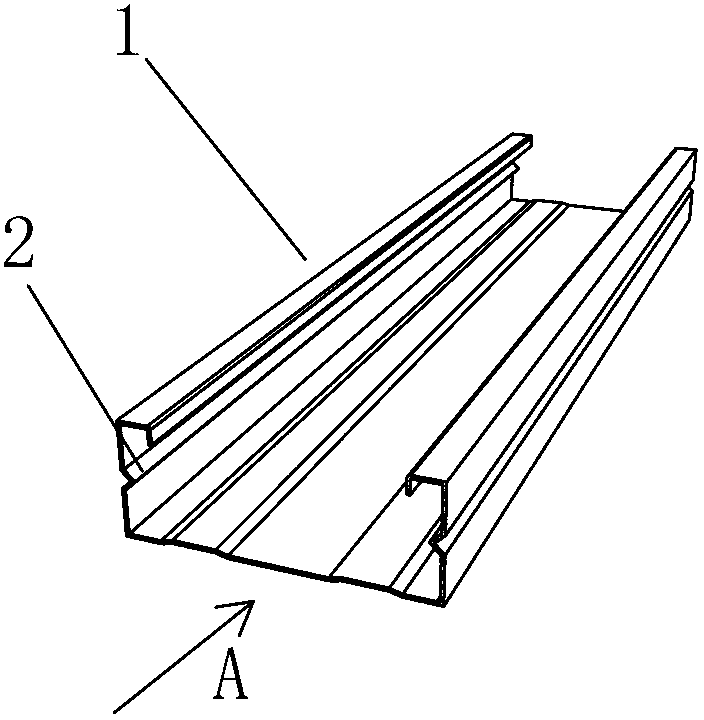

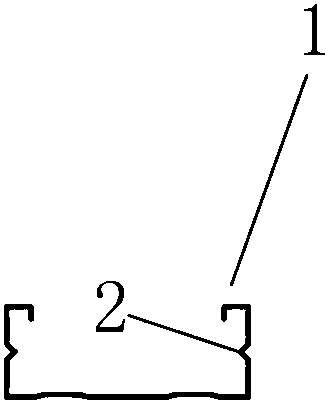

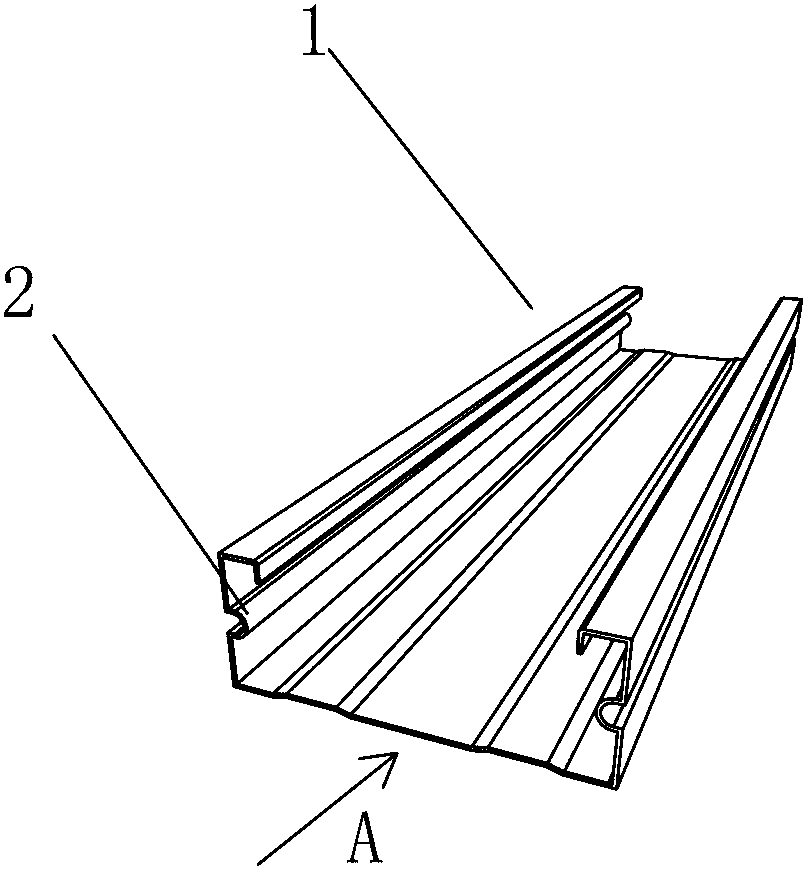

Suspended ceiling light steel subsidiary keel and method of assembling suspended ceiling light steel subsidiary keel in special-shaped suspended ceiling

Provided is a suspended ceiling light steel subsidiary keel. Side walls on two sides of the light steel subsidiary keel are respectively provided with one groove type rib. The invention further relates to a method of assembling the light steel subsidiary keel in a special-shaped suspended ceiling. According to the method of assembling the light steel subsidiary keel in the special-shaped suspended ceiling, a connection piece is needed to be matched. Strip-shaped grooves which are matched with the groove type ribs of the light steel subsidiary keel are formed in corresponding positions of the connection piece. The connection piece is inserted into a light steel keel and the light steel subsidiary keel, is positioned through the groove type ribs and the strip-shaped grooves in an insertion-connection mode and finally fixes the light steel keel and the light steel subsidiary keel through the connection piece. Compared with a previous screw fixation mode, the suspended ceiling light steel subsidiary keel and the method of assembling the suspended ceiling light steel subsidiary keel in the special-shaped suspended ceiling are good in fixing effect, capable of improving the construction speed, free from requirements of adding spare parts and auxiliary structures, low in cost, firm in connection and free from dislocation.

Owner:马自力

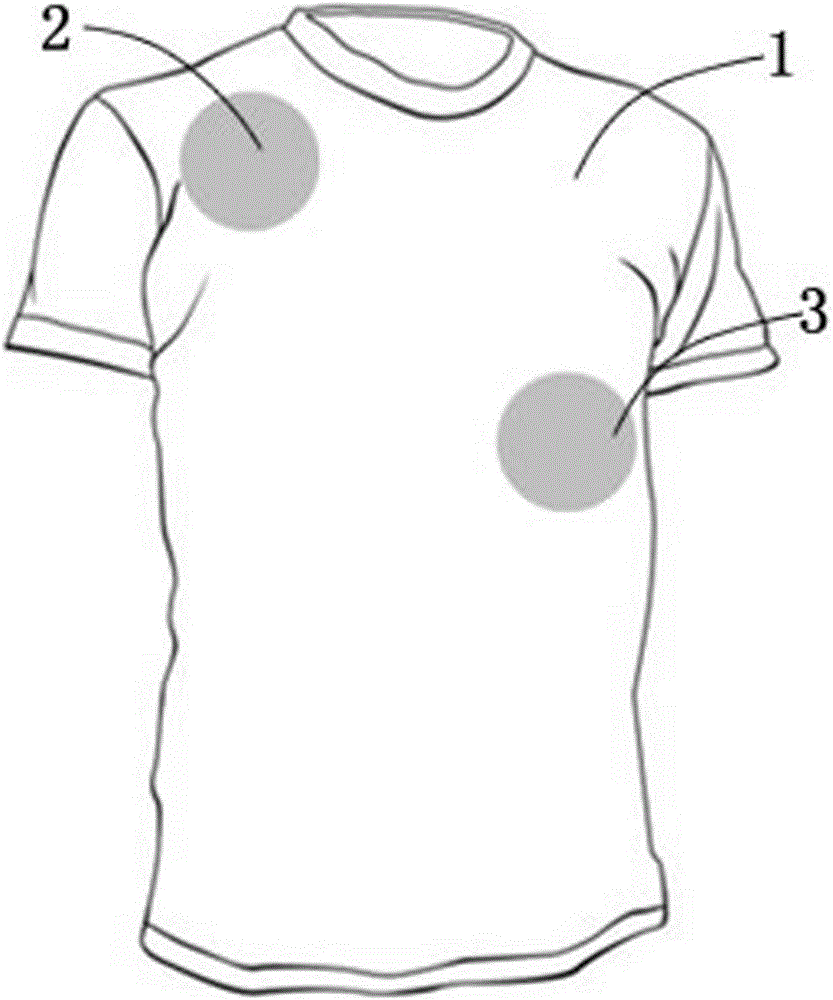

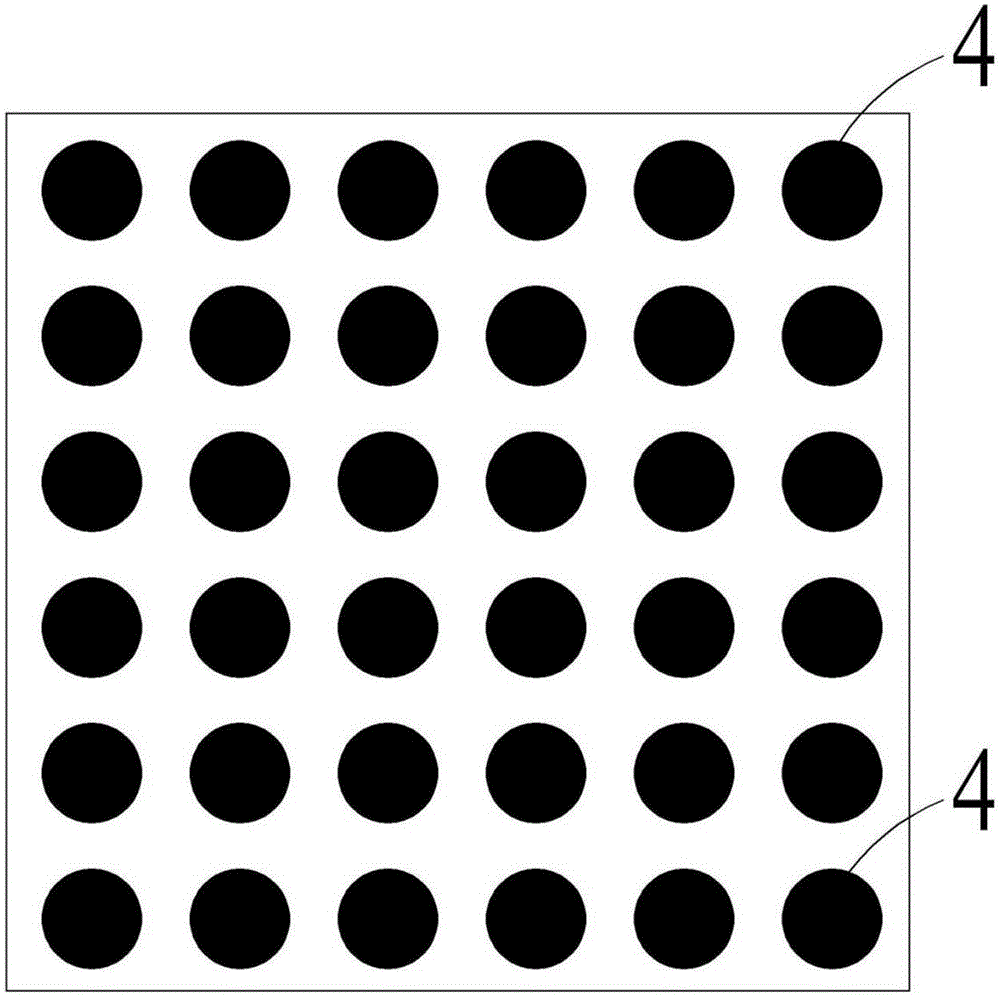

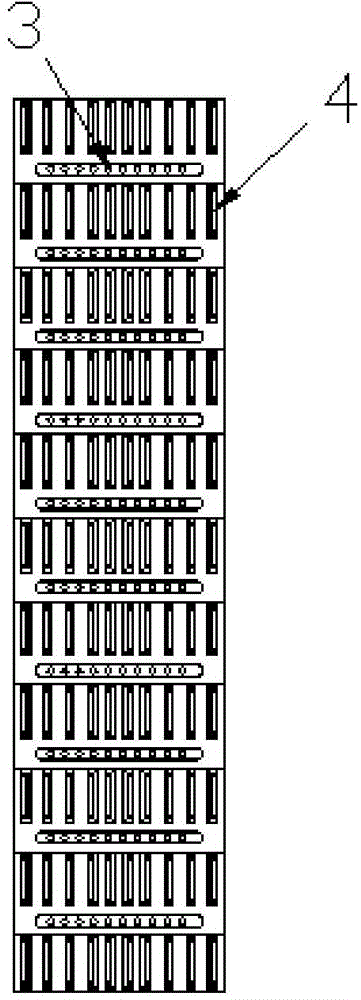

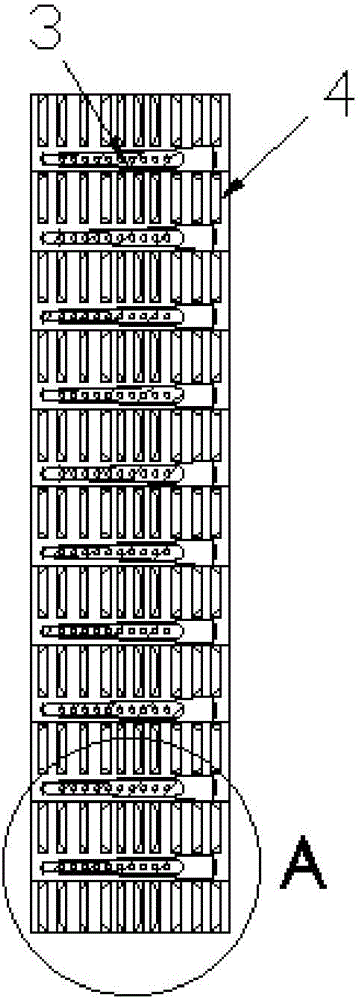

Electrode sensor distribution method for braided wearable electrocardiosignal sampling equipment

InactiveCN106175751AAcquisition stableNo dropDiagnostic recording/measuringSensorsAcquisition apparatusGuide wires

The invention relates to braided wearable electrocardiosignal sampling equipment and an electrode sensor distribution method. The sampling device comprises a wearable carrier, a first electrode sensor array arranged on the right upper position of the right side of the carrier and a second electrode sensor array located in the middle position. The first electrode sensor array and the second electrode sensor array are provided with multiple electrocardiosignal sampling electrodes distributed in arrays and connected in parallel. The electrocardiosignal sampling electrodes communicate with a sampling equipment input end through guide wires. The method goes on according to a first manner, a second manner or a third manner. An electrode sampling end is like clothes and worn by a tester. Electrodes are directly attached to the skin and do not fall down or badly attached. Multiple electrodes in each collection region are suitable for different body types. The function of broad application scope is fulfilled. The equipment is good in attachment performance. Elastic material is best option and can be closely attached to the skin. Without displacement of electrodes, the equipment is suitable for different types of bodies.

Owner:SHANGHAI GONGJIN COMM TECH

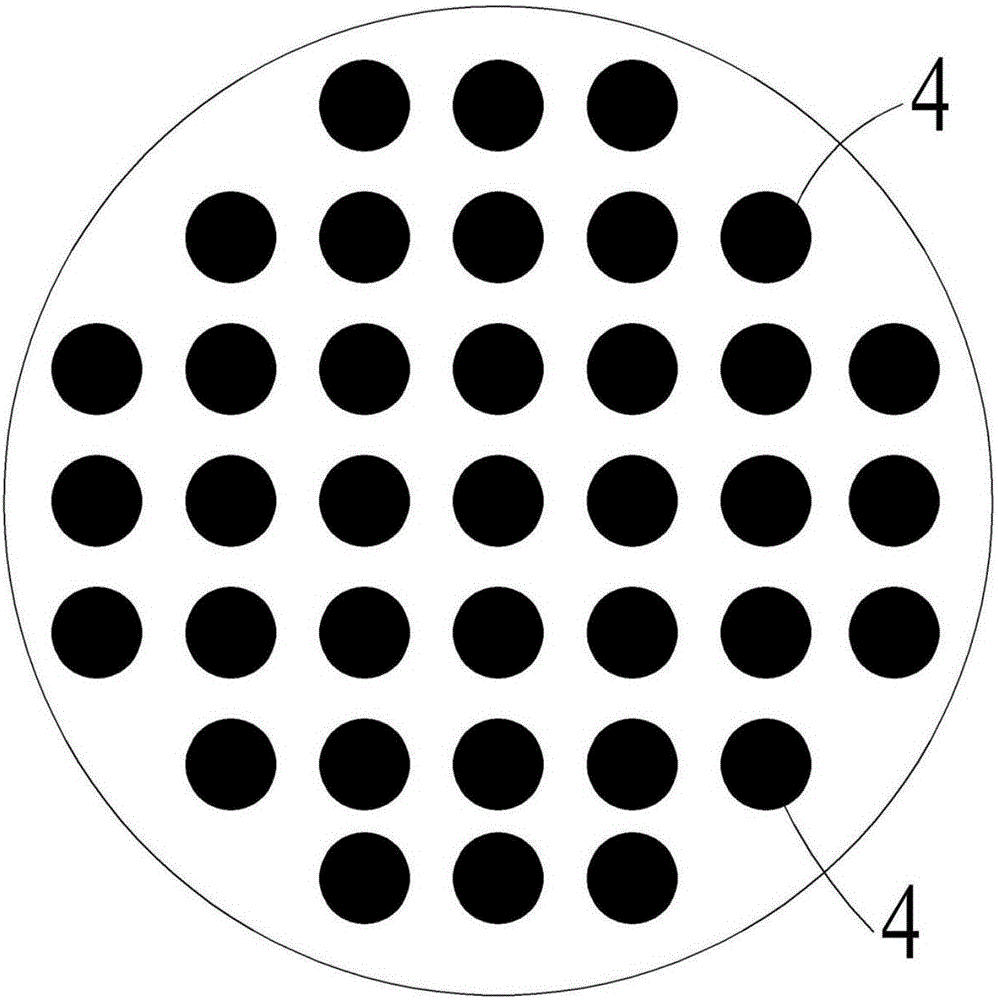

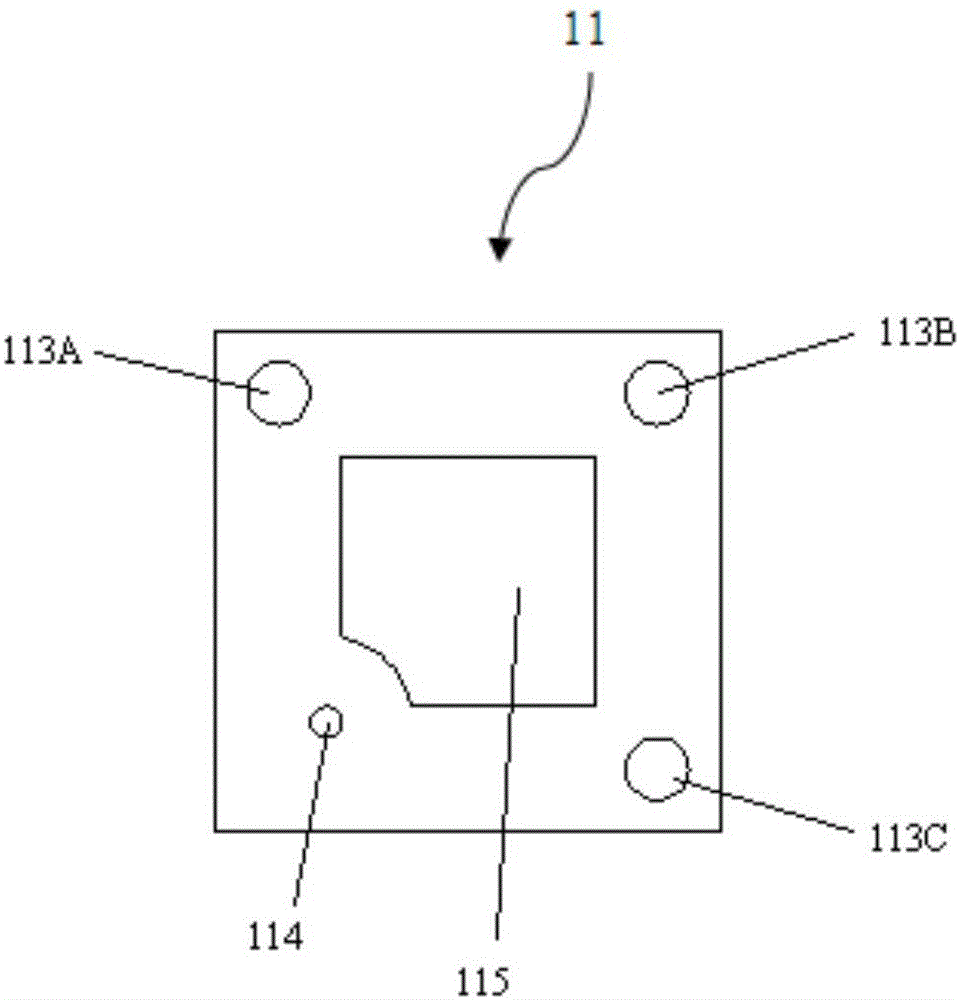

Sub module of power semiconductor device

ActiveCN104992934AImprove production qualification rate and service lifeNormal electrical connectionSemiconductor/solid-state device detailsSolid-state devicesDislocationPower semiconductor device

The invention relates to a sub module of a power semiconductor device. The sub module includes a conducting assembly including a first conductor, a second conductor arranged opposite to the first conductor, a chip arranged between the first conductor and the second conductor in an overlapped manner; and a clamping assembly accommodating the conducting assembly. The clamping assembly can exert clamping forces on the first conductor and the second conductor along the overlapping direction. By using the sub module, dislocation of the chip between first conductor and the second conductor can be avoided.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

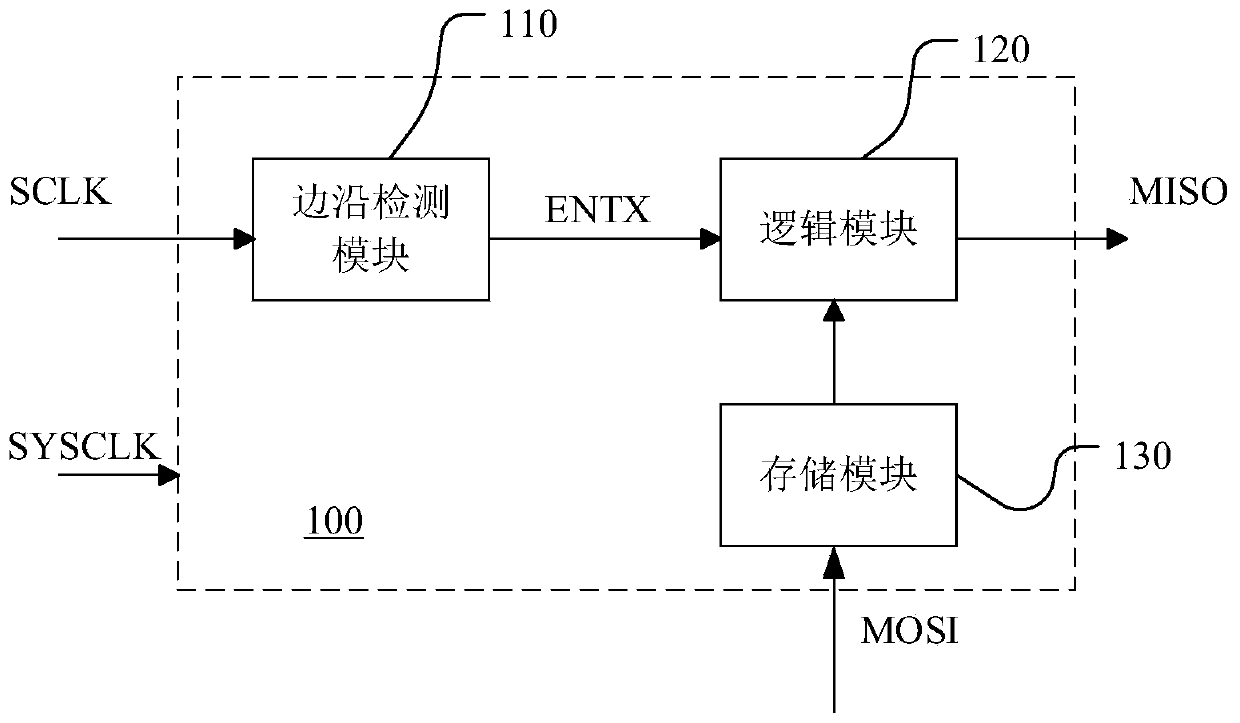

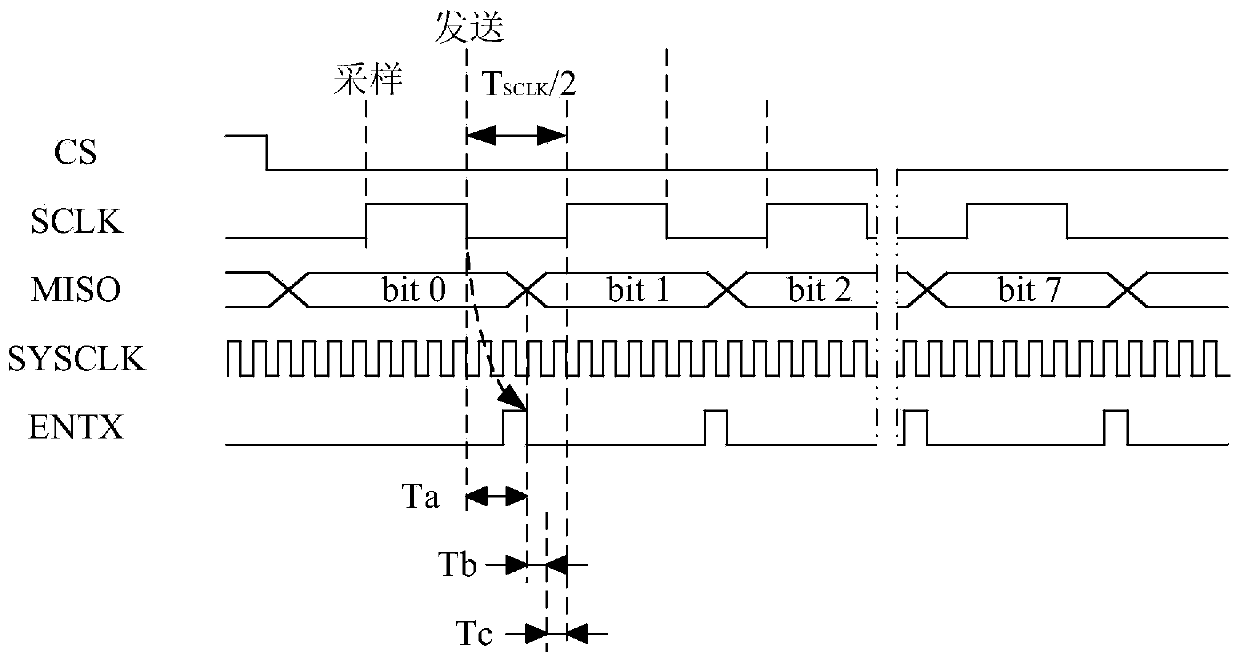

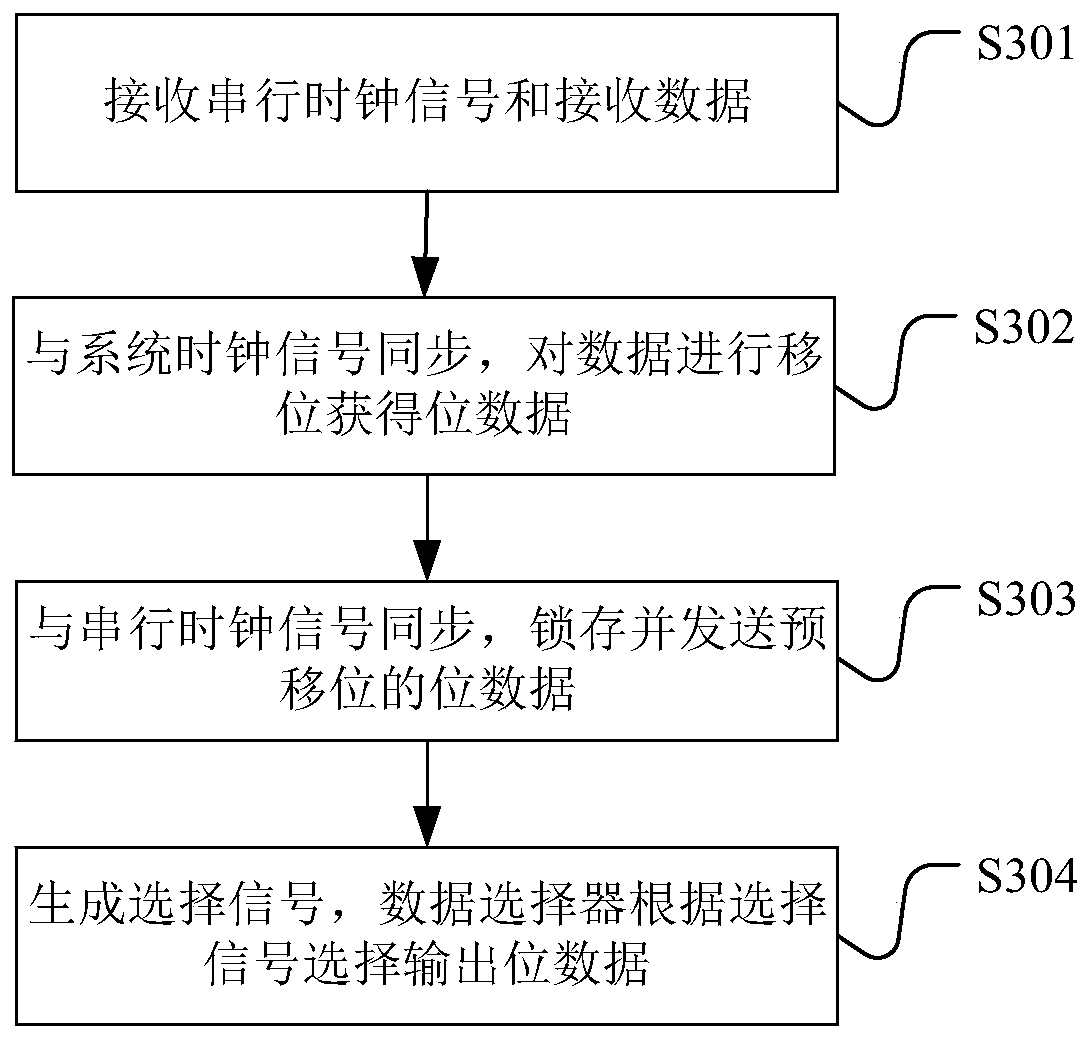

Slave devices and methods for serial communication

ActiveCN109710556AReduce frequency ratioGood build timeElectric digital data processingFrequency ratioData preparation

Disclosed are a slave device and method for serial communication. The method comprises: receiving a serial clock signal via a clock signal terminal; receiving data via a data input, the data comprising a plurality of consecutive bit data; Synchronizing with a system clock signal, and shifting the data to obtain bit data; wherein the serial clock signal and the system clock signal are synchronizedwith the serial clock signal, the bit data are latched, at least one part of latched bit data are sent through a data output end, the serial clock signal and the system clock signal are respectively provided with a first clock period and a second clock period, and the first clock period is larger than the second clock period. The method synchronizes shift bit data with a system clock signal and synchronously latches and transmits pre-shifted bit data with a serial clock signal, so that the transmission data preparation time is transferred to the position in front of a transmission edge, the frequency ratio of the system clock signal to the serial clock signal is lower, and the transmission rate can be increased.

Owner:CHIPONE TECH BEIJINGCO LTD

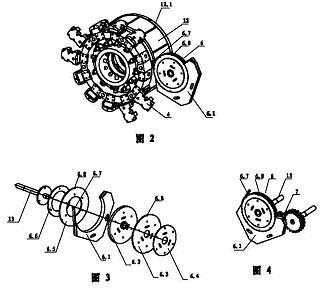

Demoulding conversion apparatus and integrated candy moulding and packaging machine thereof

InactiveCN102550771AWon't fall offLimited circumferential movementConfectionerySweetmeatsEngineeringMoulding device

The invention discloses a demoulding conversion apparatus which comprises a holding disc body, wherein, the outer circumference of the holding disc body is equantly provided with a plurality of holding grooves along an axial direction, and the holding grooves cohere with cambered surface holding seats in a manner of cambered surface gaps out of the holding disc body. The invention also discloses an integrated candy moulding and packaging machine which comprises a body, a forming device which is connected with the body and contains a forming die and a rod conveying roller, a rod bucket alternately arranged with the rod conveying roller, an elastic pressure device which is in contact connection with the forming die and contains an arc pressurization block and a paper feeding shaft arranged on the body; the demoulding conversion apparatus is adjacently installed behind the forming device, a candy conveying device is adjacently installed behind the demoulding conversion apparatus, and a pair of sealing wheels and a pair of cutting wheels are sequentially arranged in a conveying channel of the candy conveying device. According to the invention, automatic handover and conversion of candies with a handle from a moulding part to a packaging part can be realized, construction is reasonable, and high production efficiency is obtained.

Owner:江苏海特尔机械有限公司

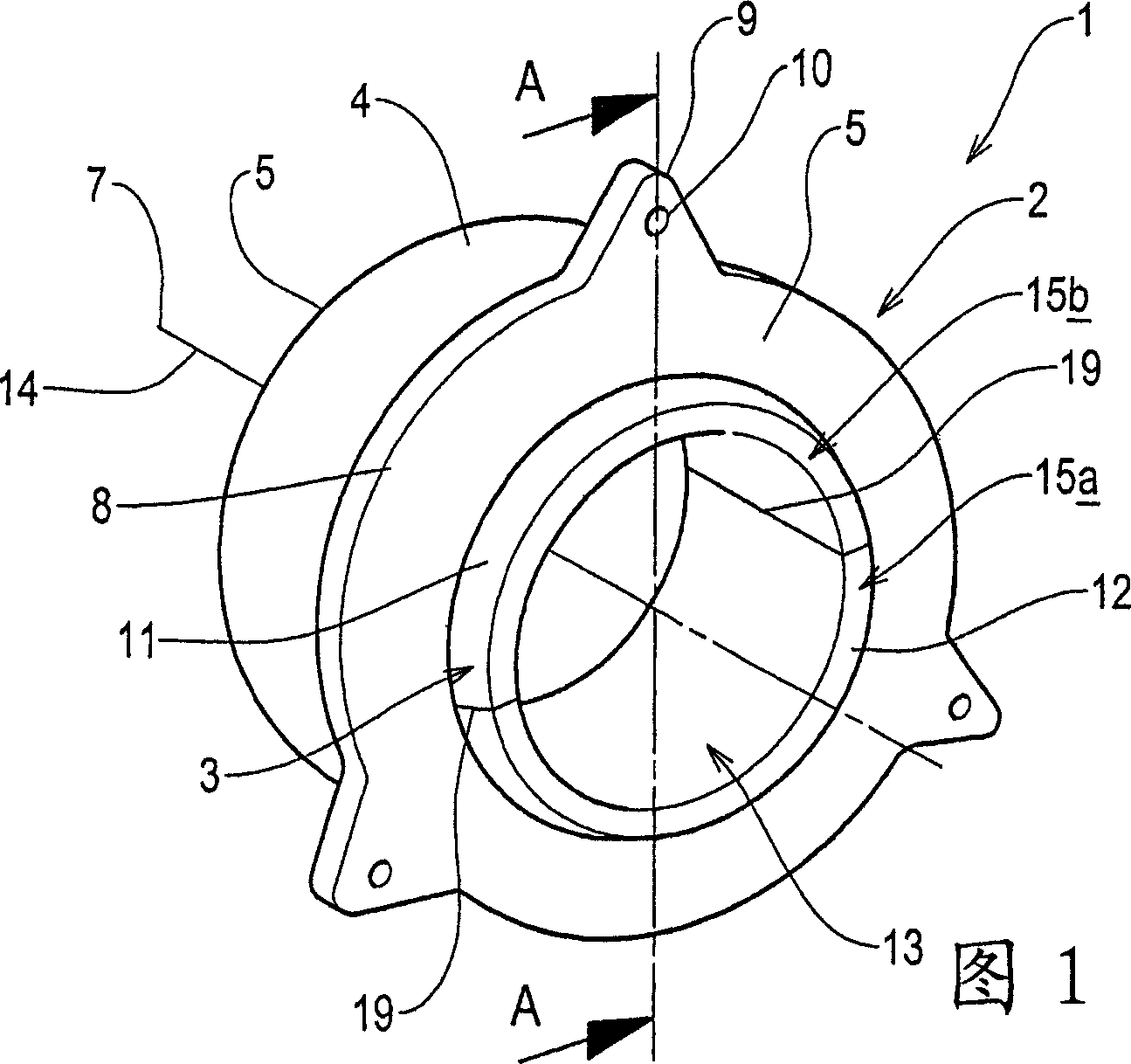

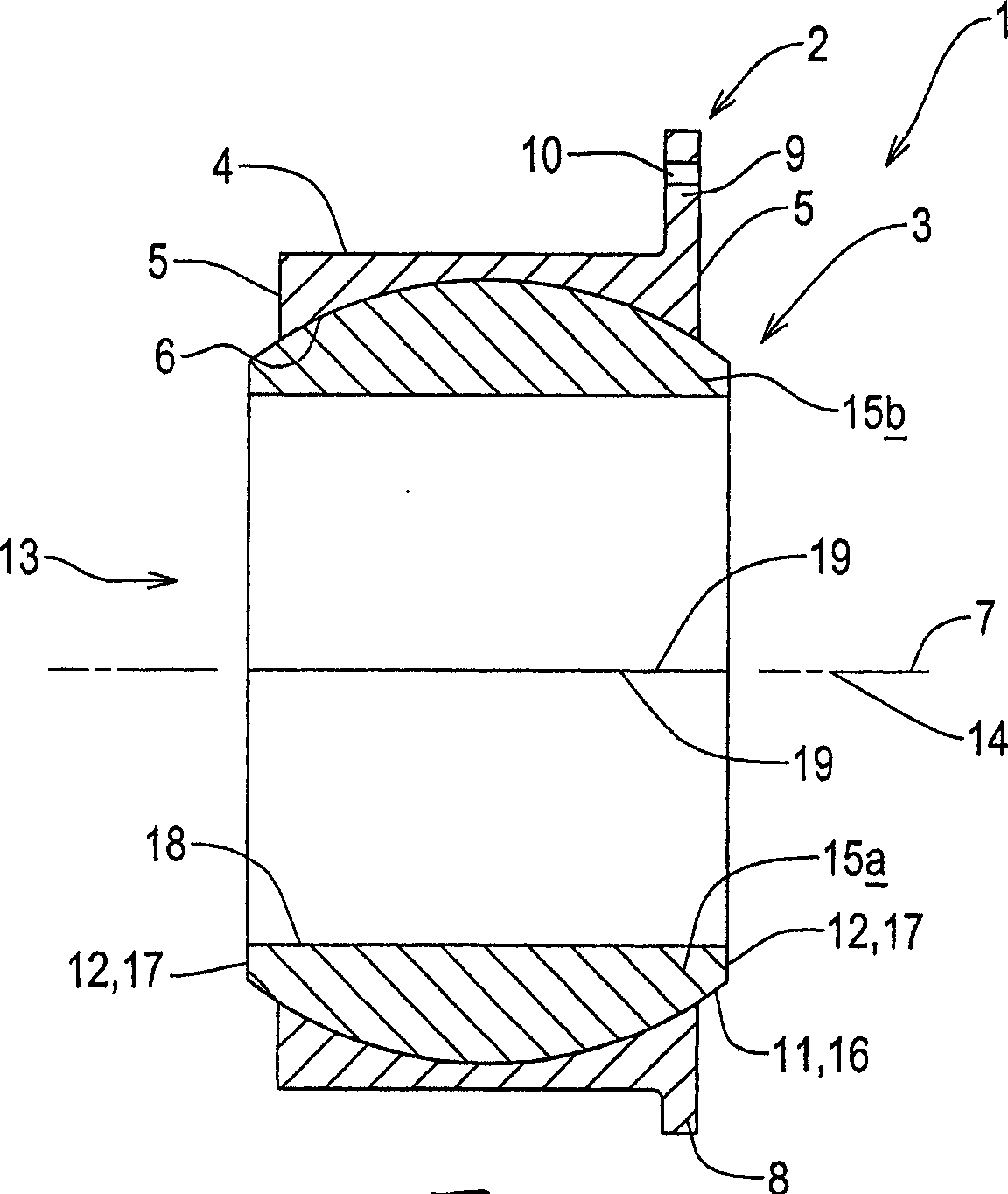

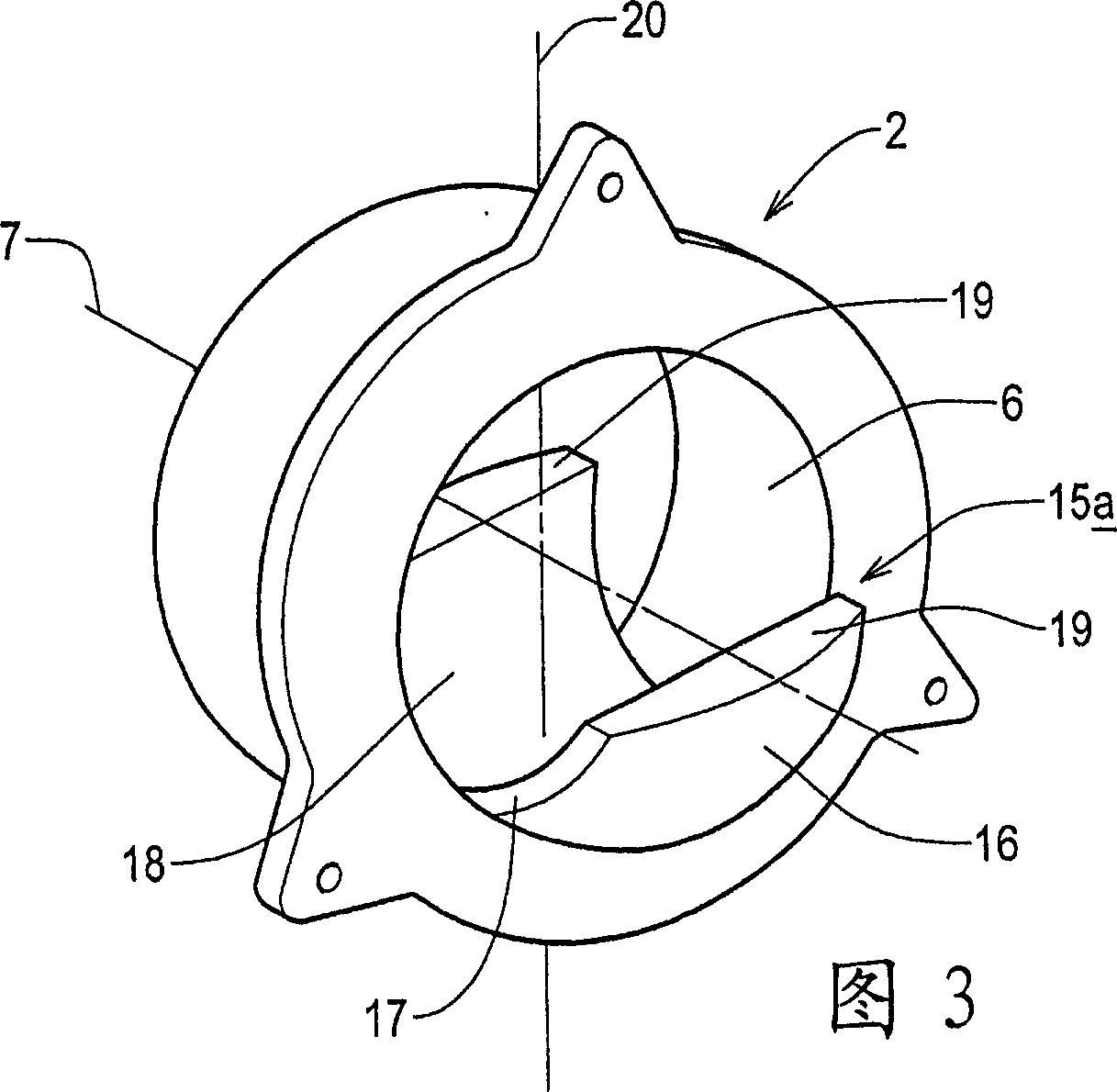

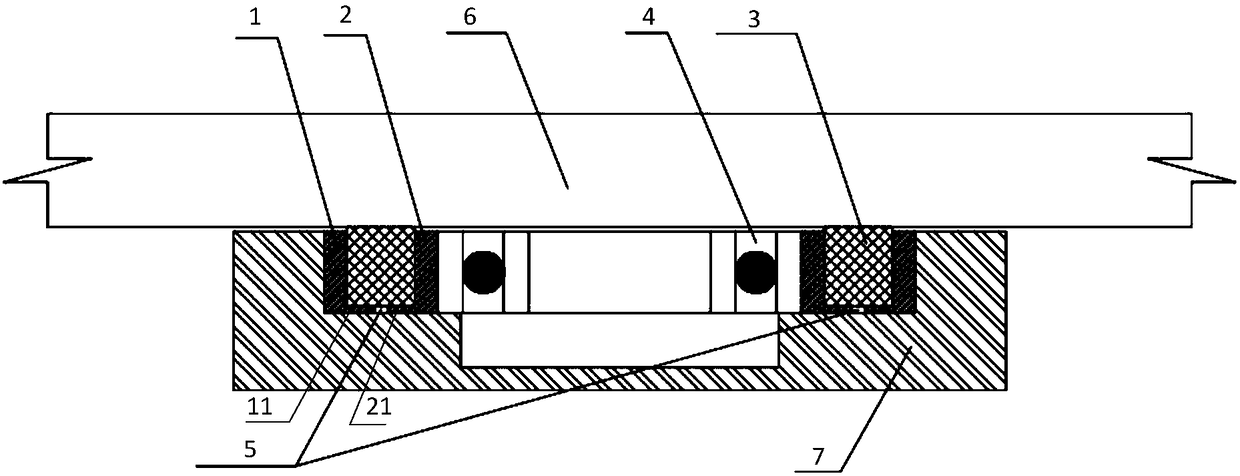

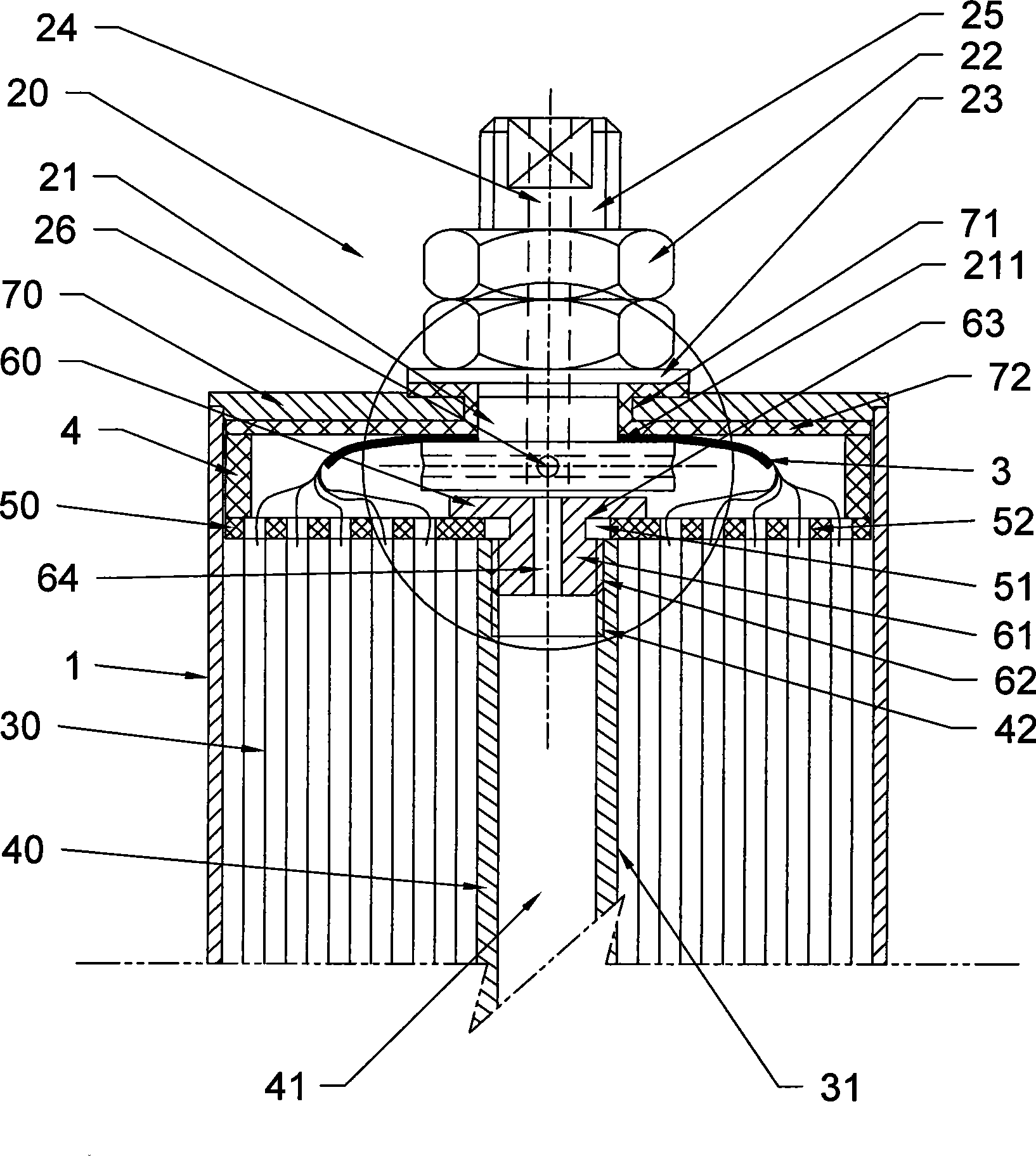

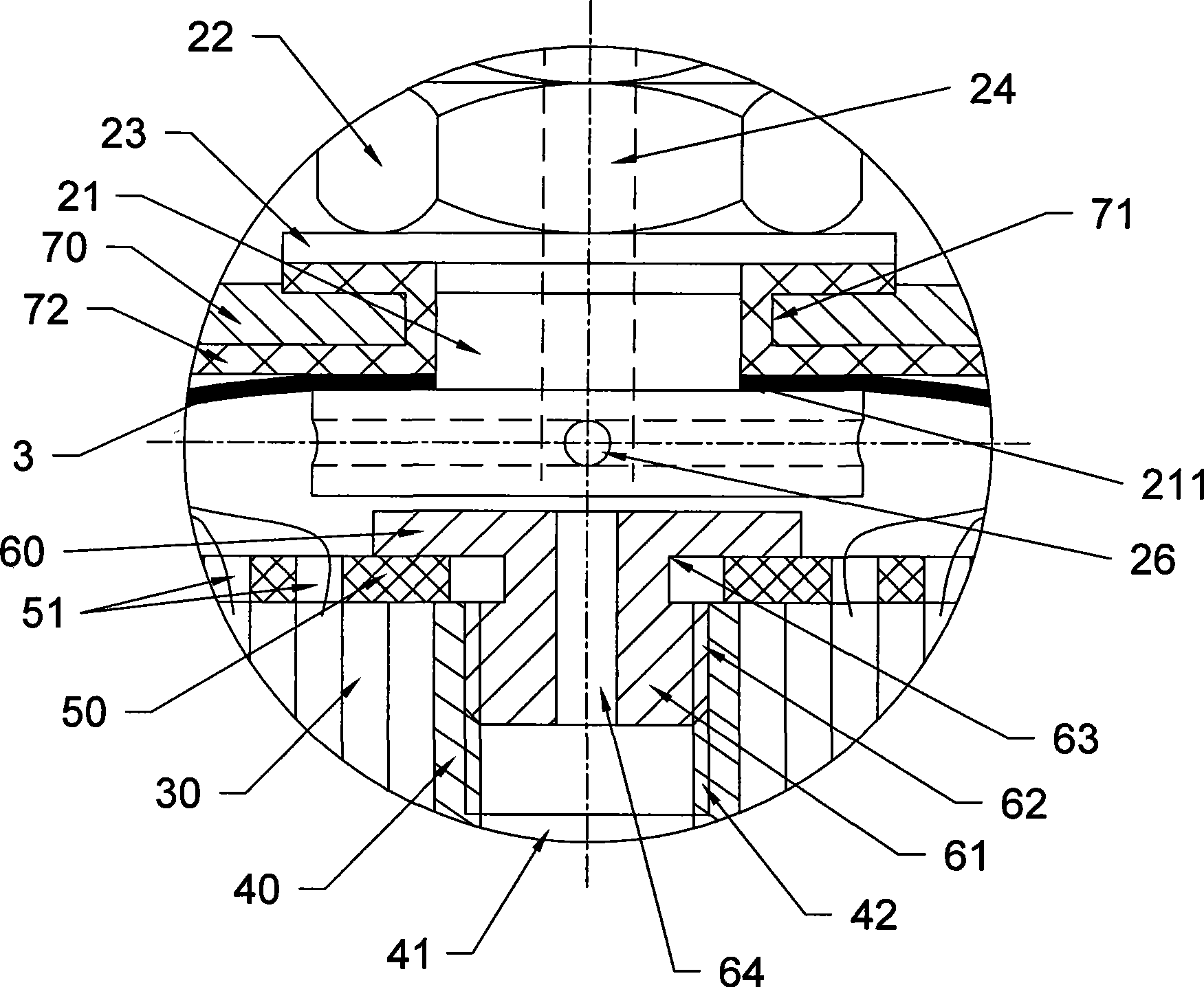

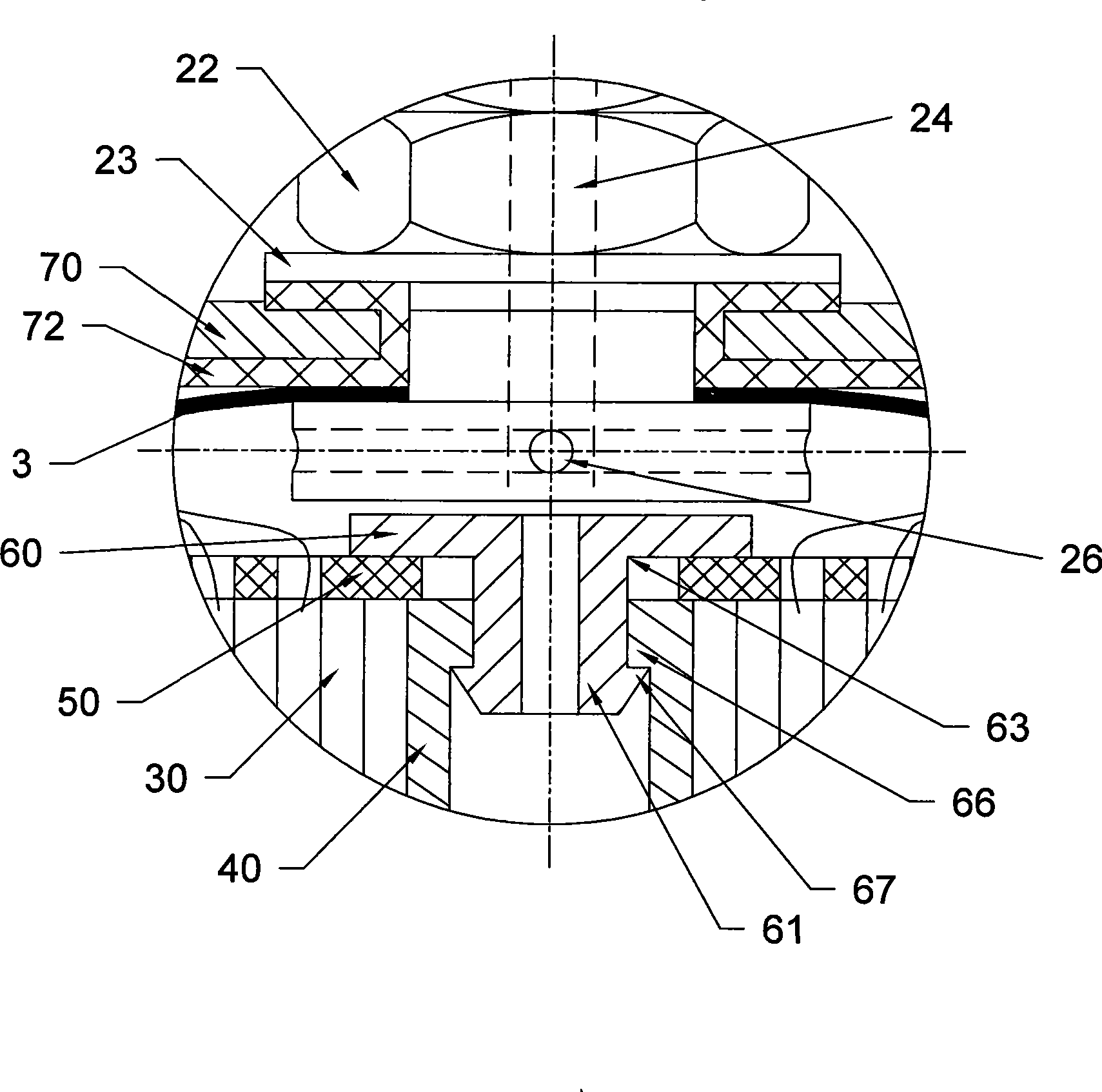

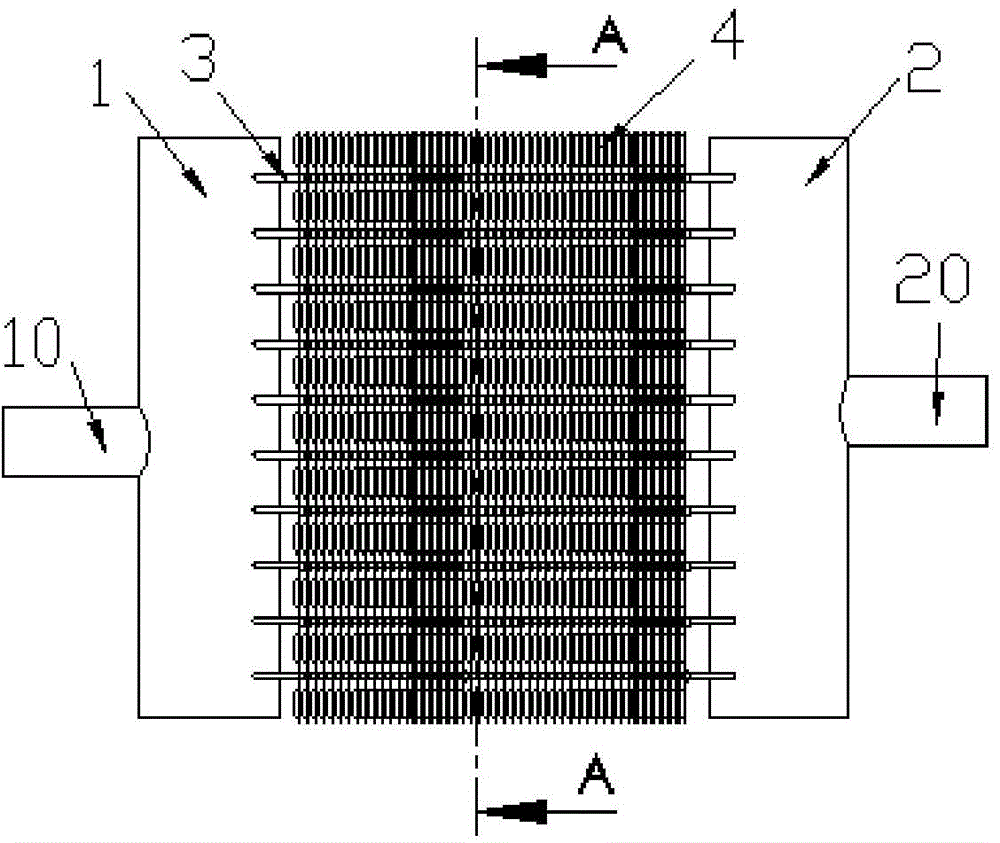

Spherical bearing arrangement

InactiveCN1752469ANot misplacedPivotal connectionsSliding contact bearingsSpherical bearingEngineering

A spherical bearing arrangement comprising: a bearing housing; a plurality of split-ball portions which are together arranged in the housing to produce a composite ball having a spherical bearing surface, the composite ball having a bore passing therethrough, the bore having a central axis; and a bushing secured in the bore of the composite ball. A method of assembling a spherical bearing arrangement is also disclosed.

Owner:MINEBEA CO LTD

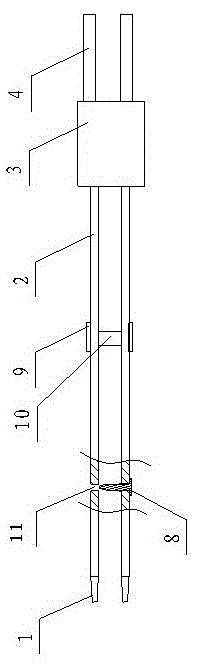

Novel intelligent electric coagulation forceps system

InactiveCN102743221AGuaranteed bonding effectAvoid overheatingSurgical instruments for heatingGradual increaseForceps

The invention discloses a novel intelligent electric coagulation forceps system which comprises a forceps body and a main machine for supplying power to the forceps body, wherein the forceps body comprises forceps tips and forceps rods. The novel intelligent electric coagulation forceps system is characterized by further comprising a current detection device and a voltage detection device which are used for respectively detecting current and voltage between the forceps tips. Impedance of an object between the forceps tips is calculated according to the ratio of the voltage to the current, and the main machine gradually decreases output power of the forceps tips along with gradual increase of the impedance. A water inlet channel is arranged on the forceps body, an outlet of the water inlet channel is located at the positions of the forceps tips, a first positioning rod is fixed in front of the forceps rod on one side, and a corresponding positioning hole is arranged on the forceps rod on the other side. The temperature of the forceps tips is controlled within a certain range by detecting the temperature of the forceps tips in real time, so that adhesion effect of the electric coagulation forceps is ensured, and a superheat phenomenon is avoided.

Owner:CHONGQING RUNZE PHARM CO LTD

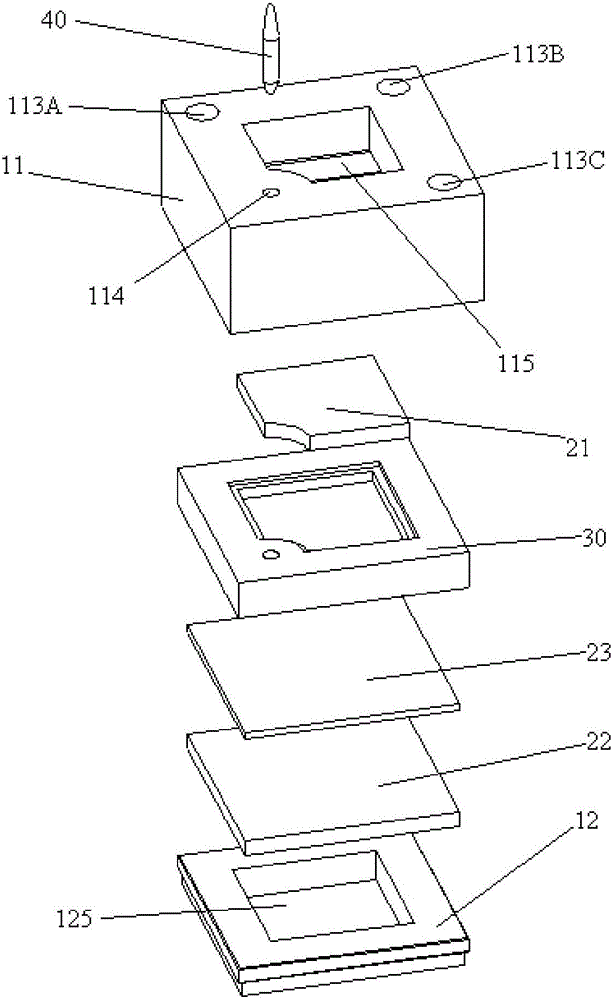

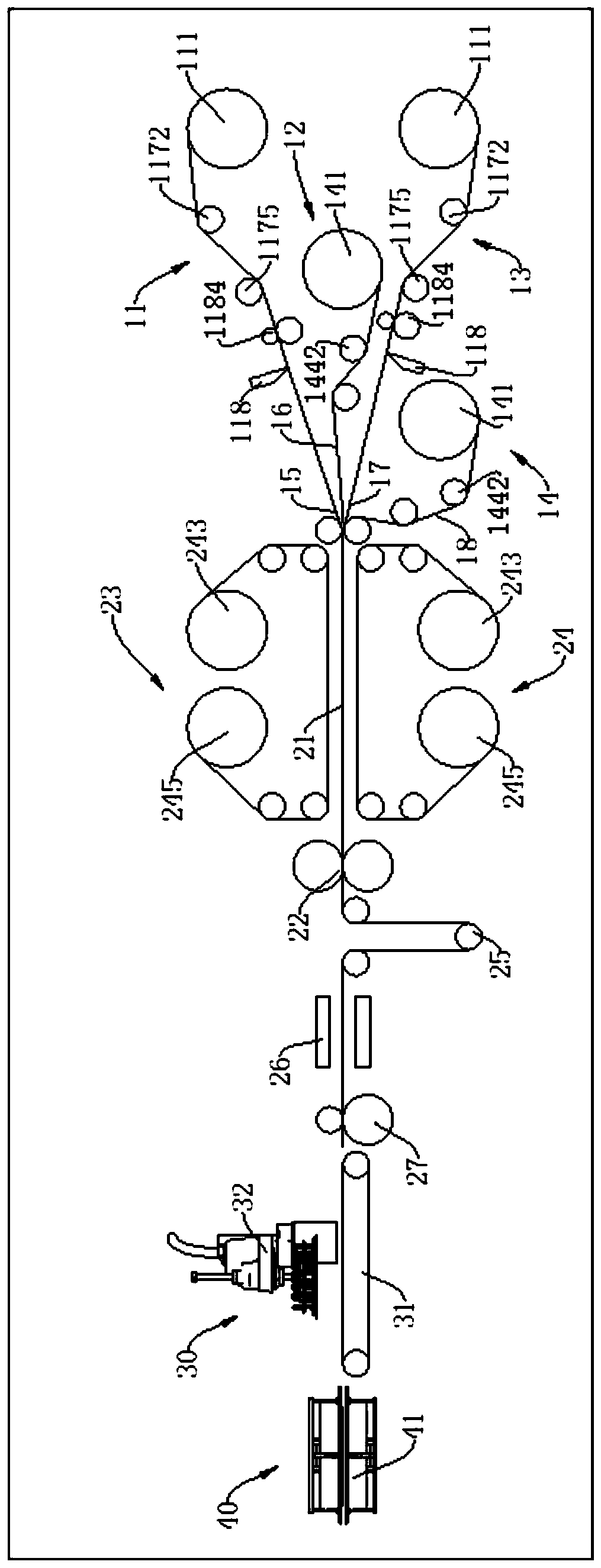

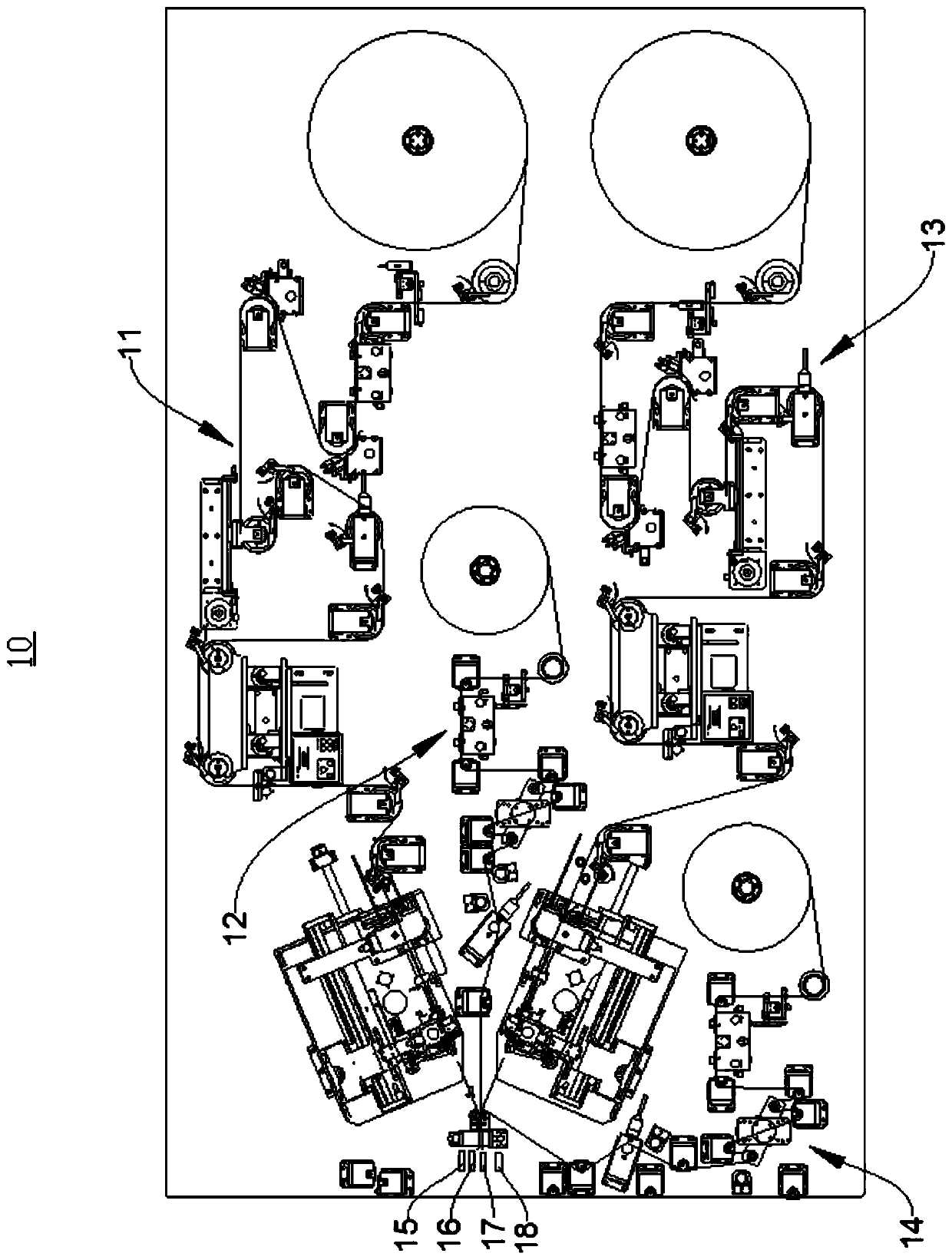

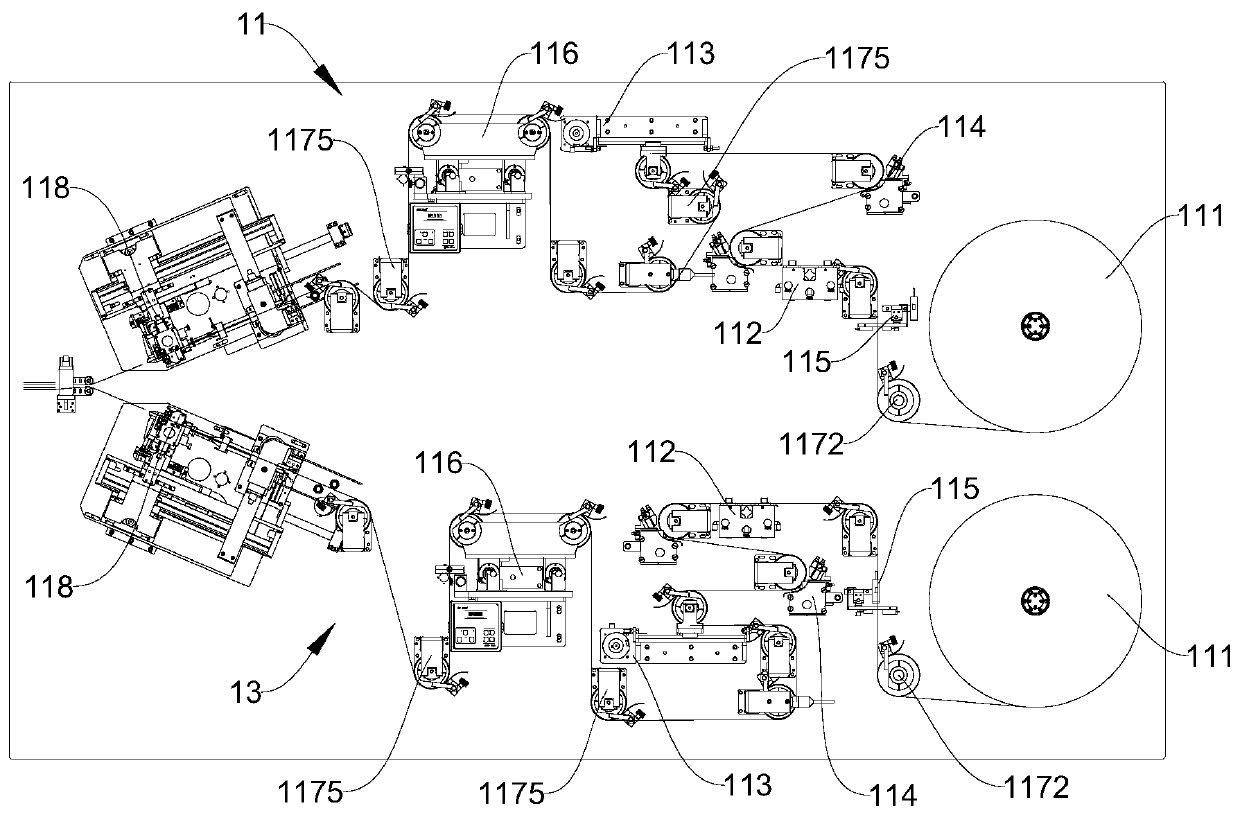

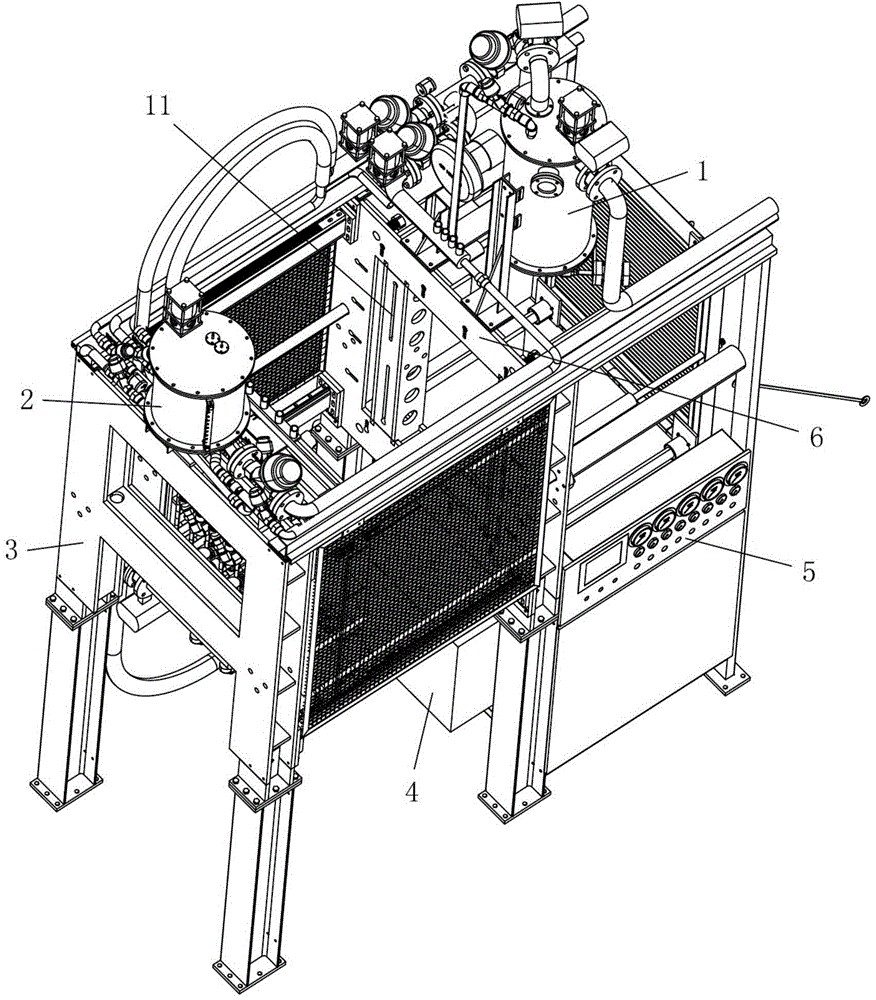

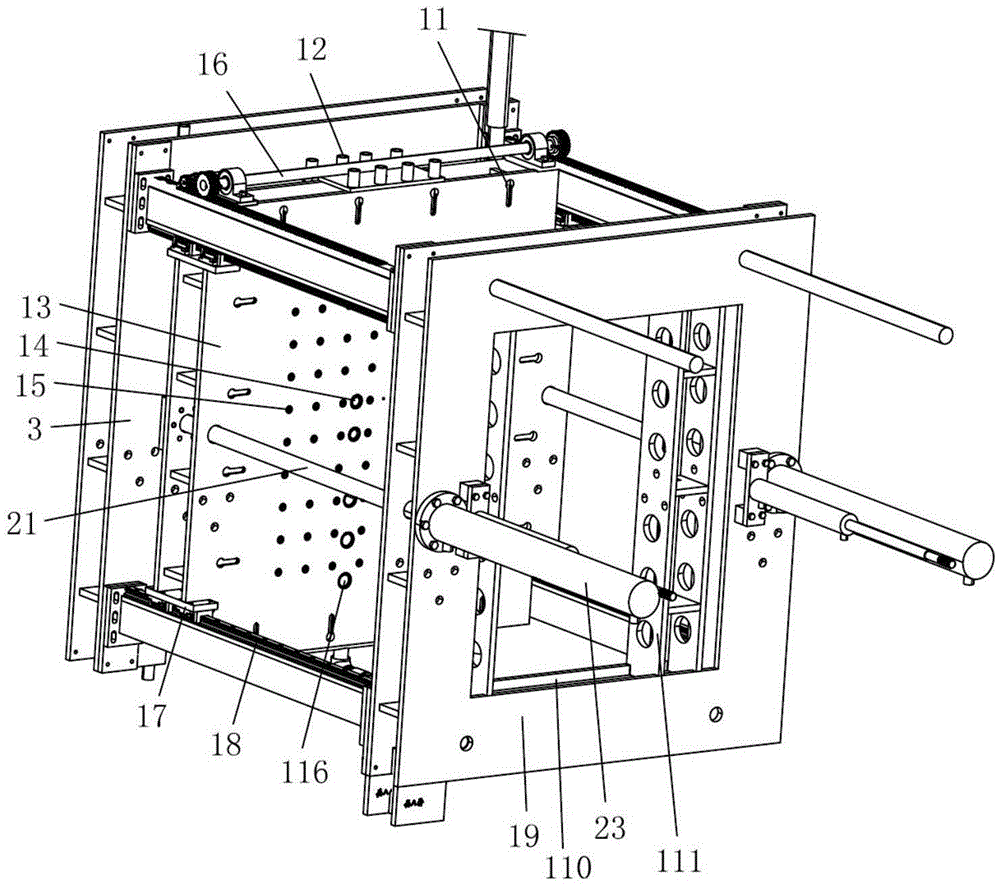

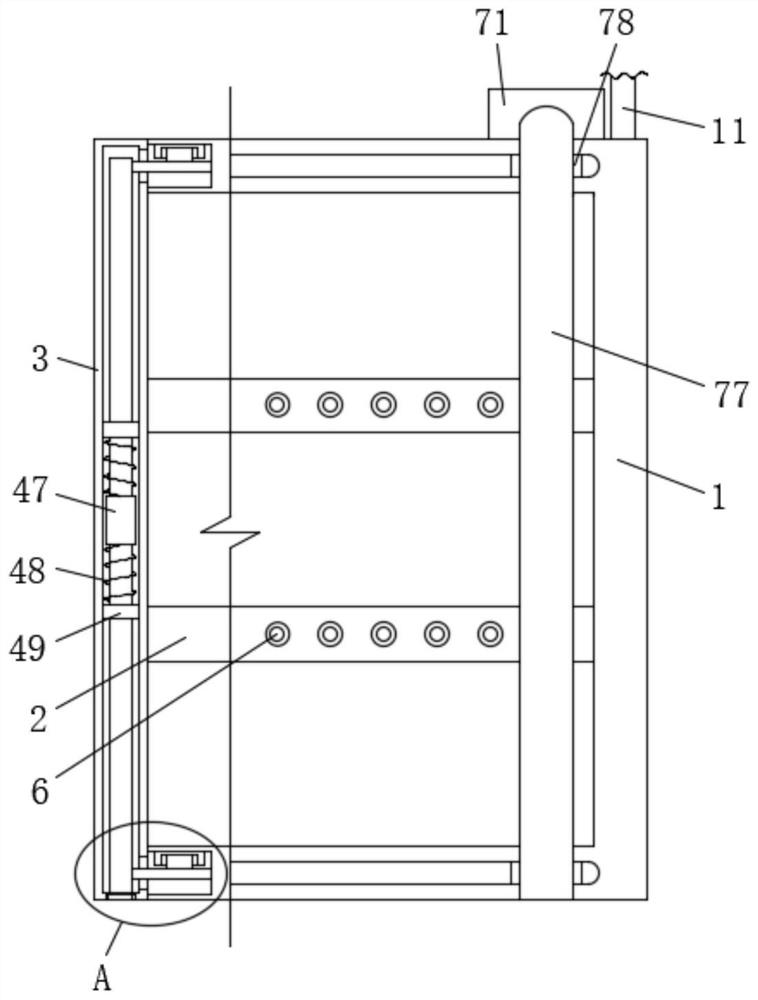

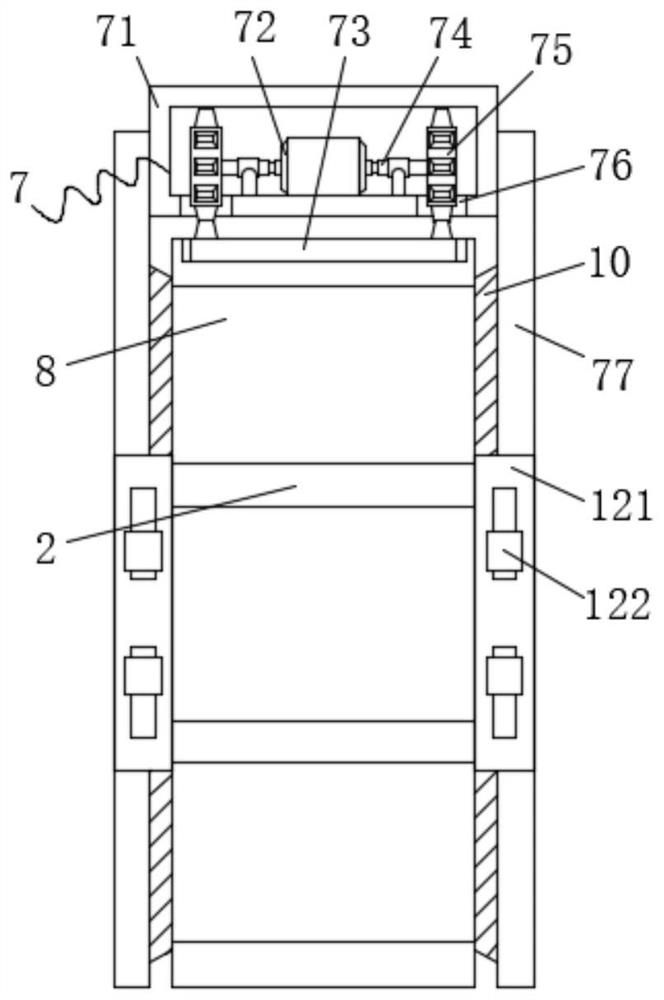

Laminated battery cell forming system

PendingCN109935915AAvoid breakingHigh forming precisionFinal product manufactureSecondary cellsManufacturing technologyBiochemical engineering

The invention discloses a laminated battery cell forming system, and relates to the technical field of battery cell manufacturing. The system comprises a piece making device, and the piece making device comprises first pole piece making equipment, a membrane assembly and second pole piece making equipment. The membrane assembly comprises middle membrane equipment and bottom membrane equipment, andthe middle membrane equipment is located between the first pole piece manufacturing equipment and the second pole piece manufacturing equipment and used for laying a middle membrane material strip, and the bottom membrane equipment is located at the side, away from the first pole piece manufacturing equipment, of the second pole piece manufacturing equipment and used for laying a bottom membranematerial strip. The first pole piece manufacturing equipment and the second pole piece manufacturing equipment are respectively used for cutting the pole piece material strips into a first pole pieceand a second pole piece with fixed lengths, so that the first pole piece, the middle membrane material strip, the second pole piece and the bottom membrane material strip form a battery cell materialstrip. The system improves the piece production efficiency, and an isolating membrane is not liable to damage, thereby improving the cell short-circuit detection qualification rate, and improving thecell precision.

Owner:GEESUN AUTOMATION TECH

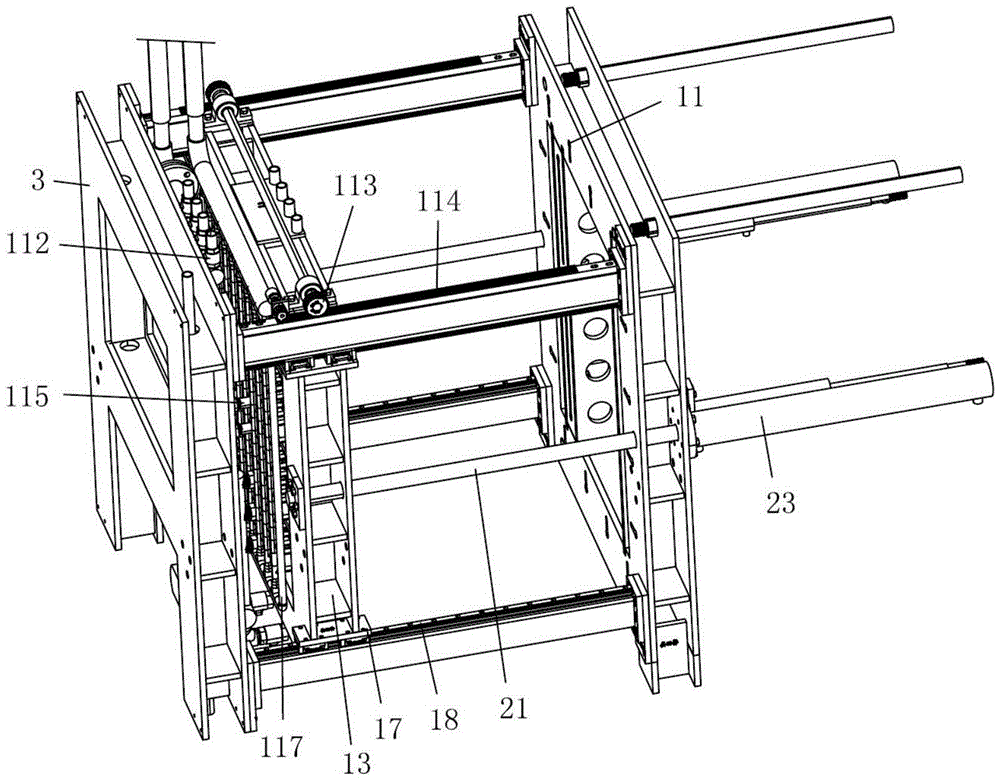

Novel foam moulding machine as well as cooling method thereof

The invention belongs to the technical field of foam moulding equipment and particularly relates to a novel foam moulding machine as well as a cooling method thereof. An electric automatic control system, a pneumatic pipeline system, a hydraulic system, a feeding system, a steam heating system, a cooling system, a die mounting mechanism and a demoulding mechanism are arranged on a frame; the die mounting mechanism comprises a die fixing plate and a die moving plate; a horizontal chute is arranged in the frame body of the die fixing plate, and a positioning bracket capable of moving along the horizontal chute is arranged in the middle part of the frame body; die mounting holes are formed in the right side face of the die moving plate, the left side face of the positioning bracket and the left side face of the die fixing plate; when the die is relatively small in volume, the positioning bracket can slide to a proper position on the die fixing plate and support the die which is fixed; steam pipelines on the rear side of the die moving plate are independent and are respectively provided with steam inlets, so that steam outlets on the front side of the die fixing plate can be independently controlled to ensure normal work of the foam moulding machine, and the foam moulding machine can be suitable for dies in different specifications.

Owner:浙江武义速达包装材料有限公司

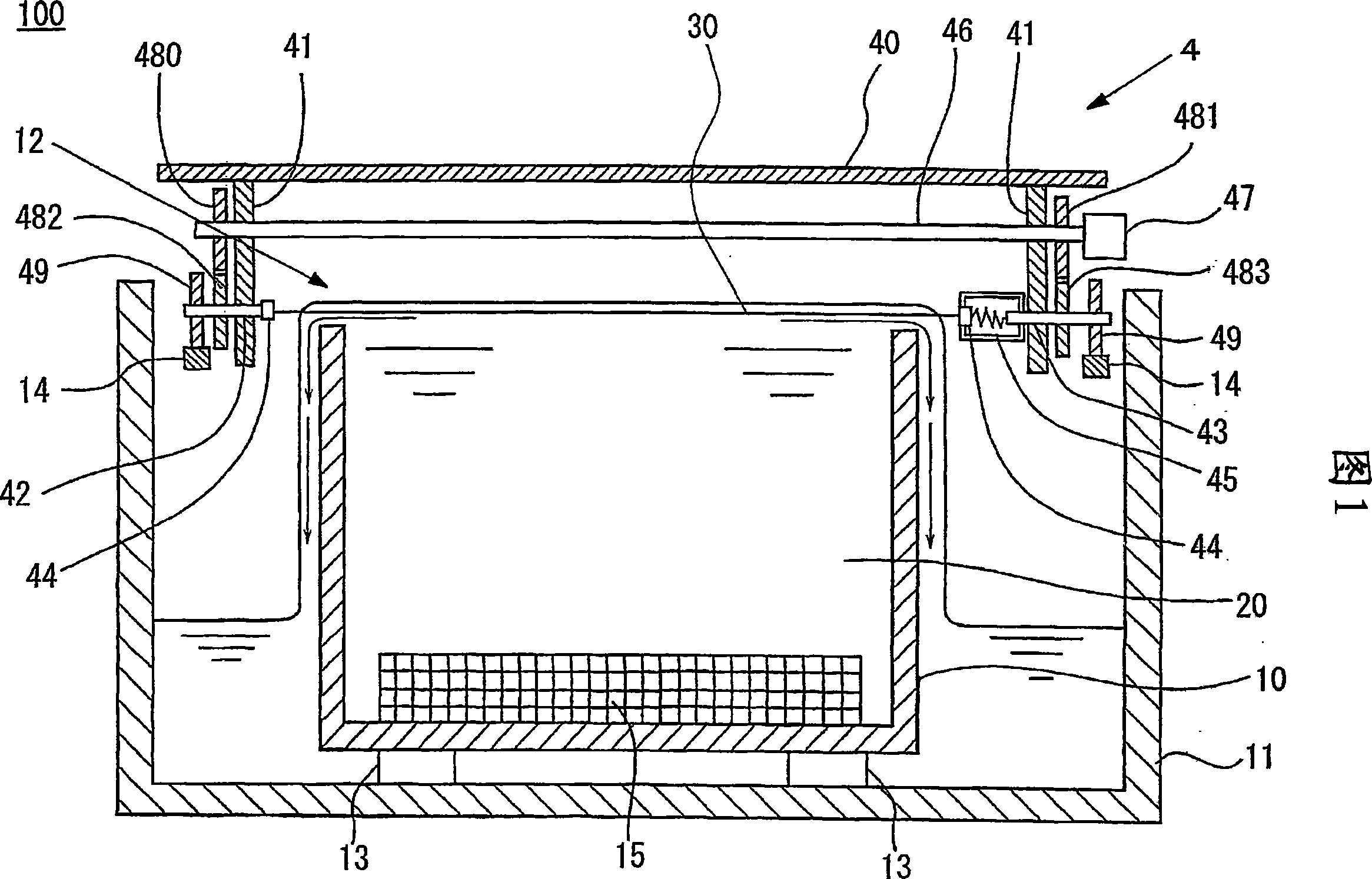

Manufacturing method of electro-moulding pipe and electro-moulding pipe, thin wire used for manufacturing same

The invention provides a method of producing an electrocast tube having a fine inner diameter, and an electrocast tube. It also provides a thin wire material for production of an electrocast tube having a fine inner diameter. An electrocast tube producing method comprising the steps of forming an electrodeposit around a thin wire material (30) by electrocasting, and removing the thin wire material (30) from the electrodeposit, wherein the thin wire material (30) is removed either by heating the electrodeposit for thermal expansion or by cooling the thin wire material (30) for contraction, so as to form a clearance between the electrodeposit and the thin wire material (30), followed by gripping and pulling, or sucking the thin wire material (30) or physically pushing it away or blowing gas or liquid to push it away.

Owner:LUZCOM

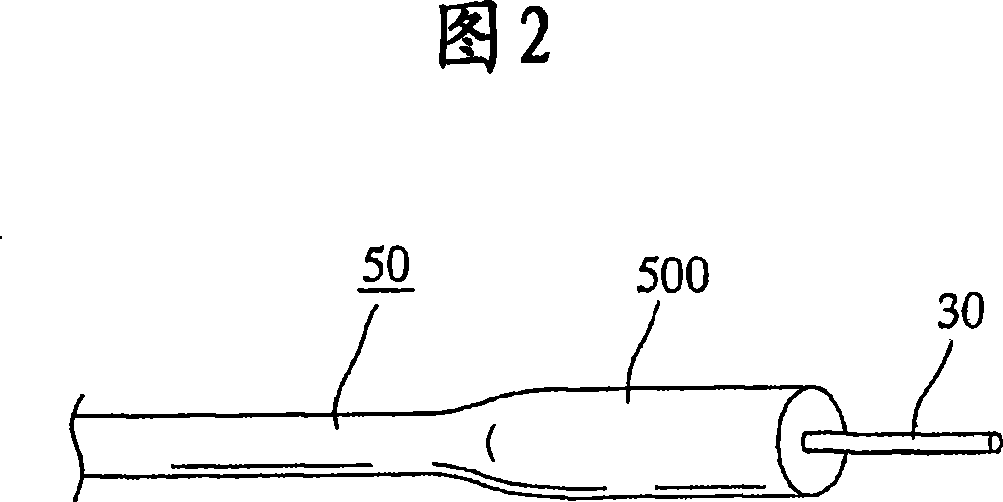

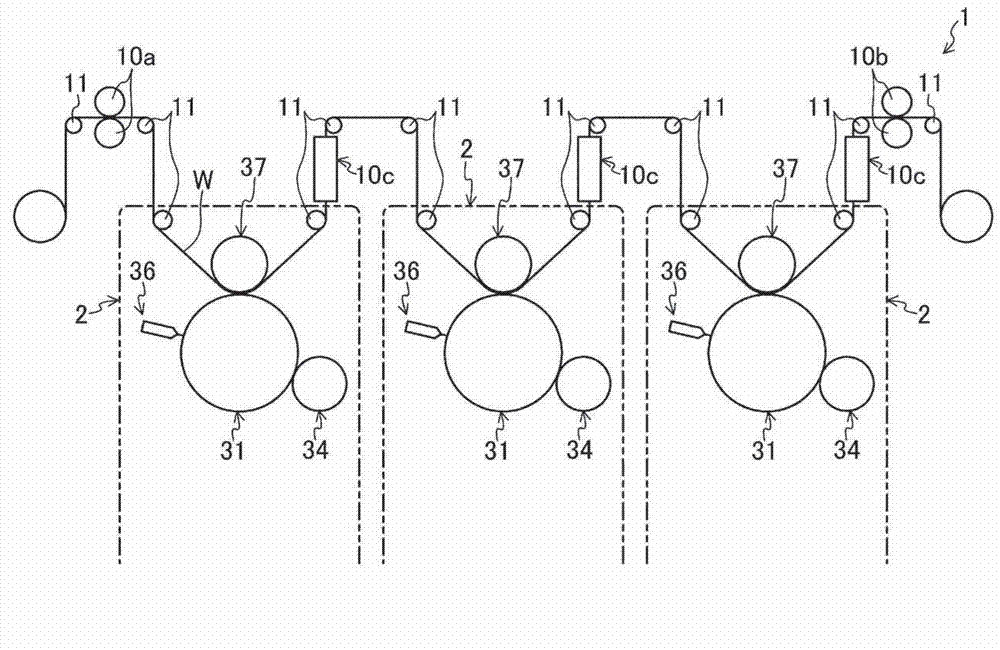

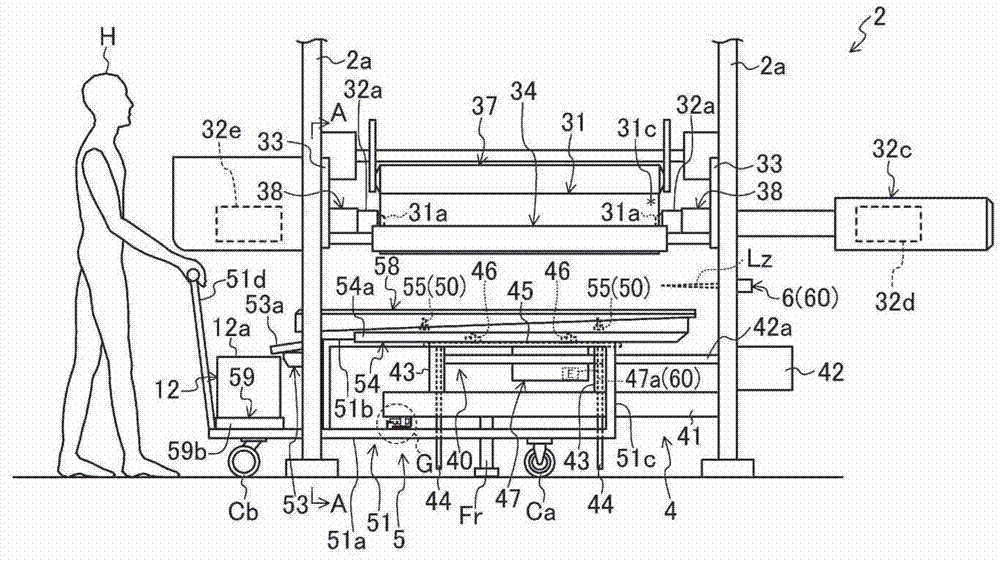

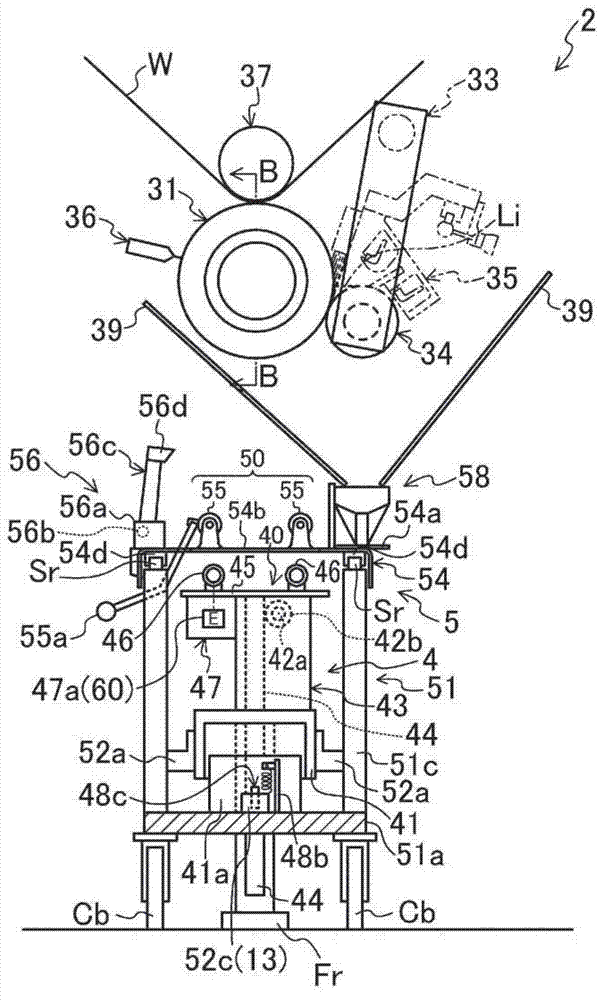

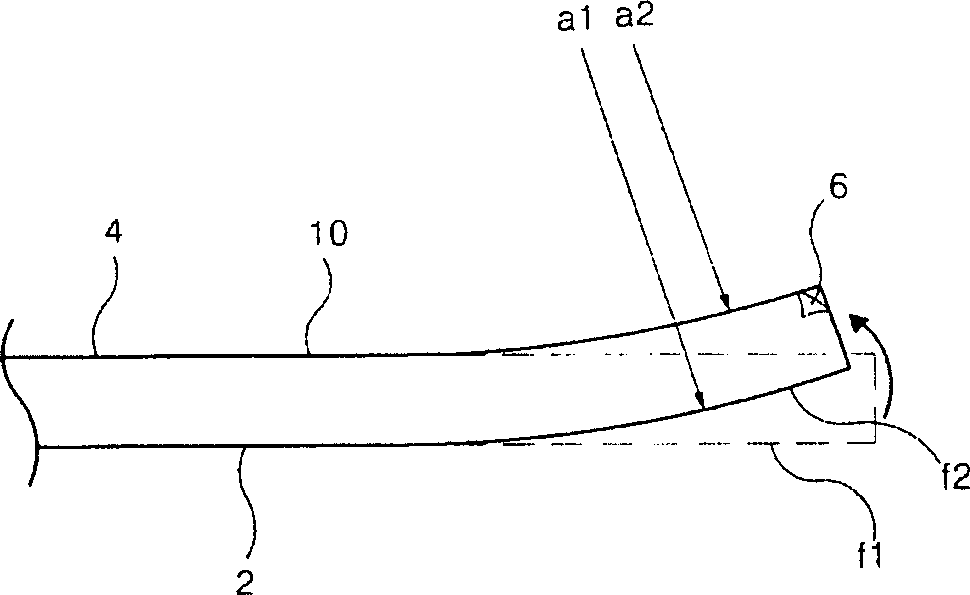

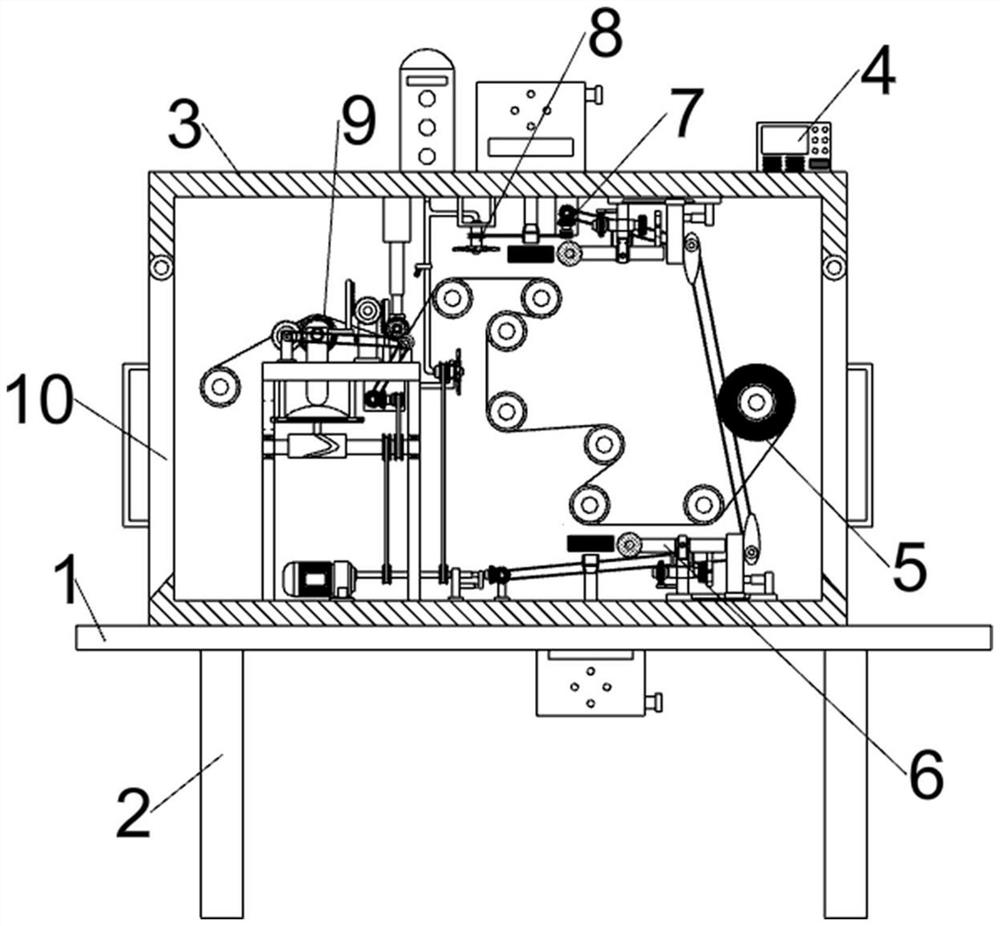

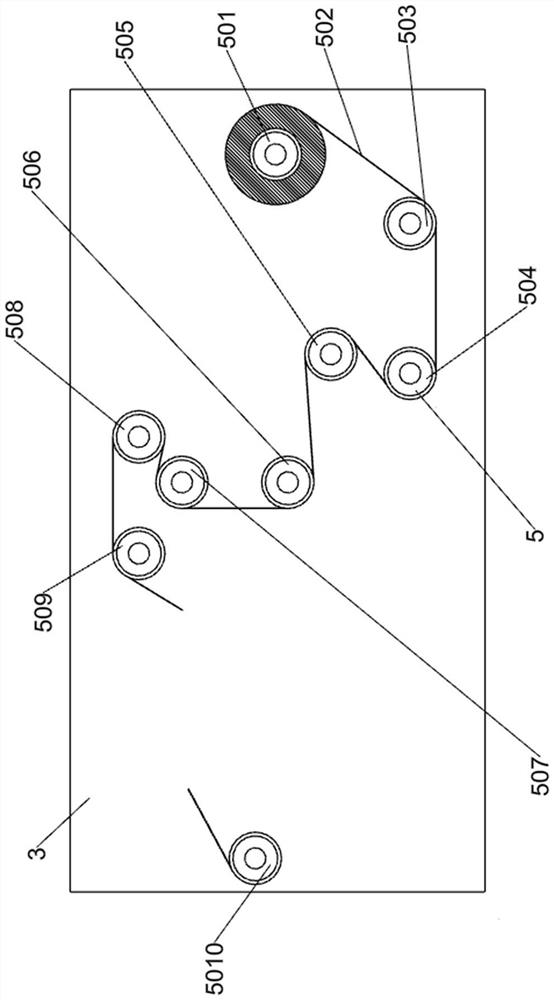

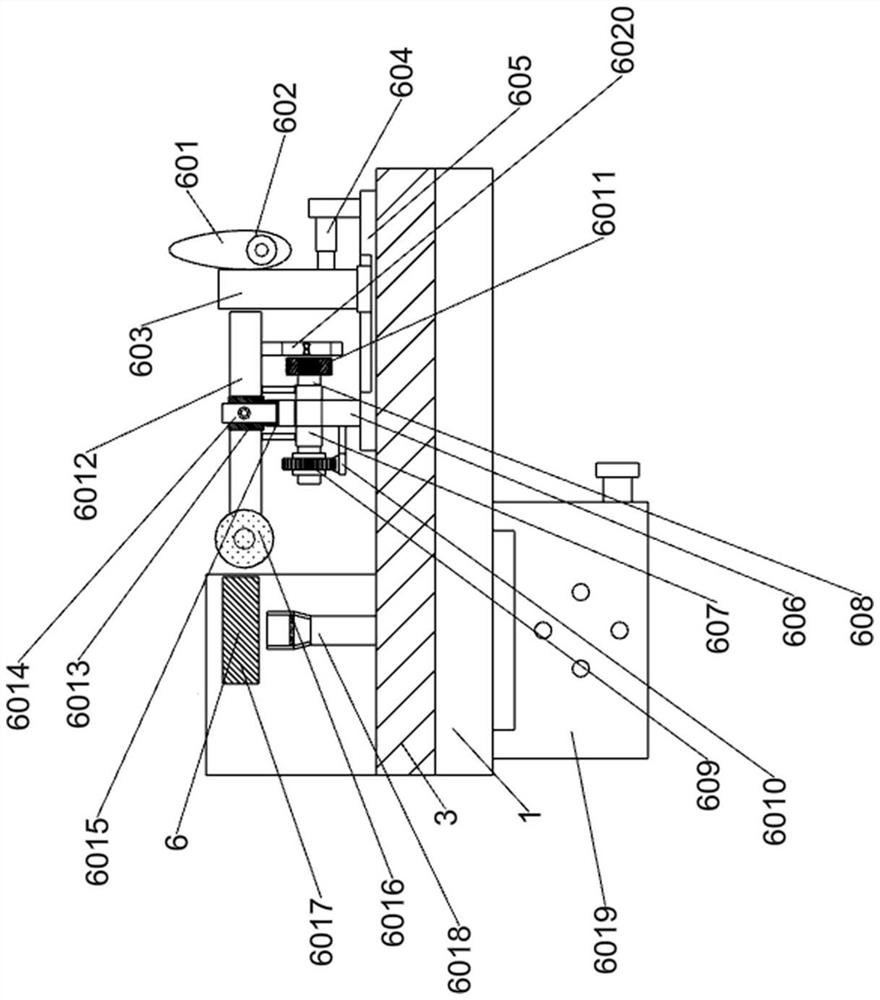

Printer and method for replacing plate cylinder thereof

ActiveCN103158346AShort stop timeImprove work efficiencyRotary intaglio printing pressPrinting press partsStop timeEngineering

The invention discloses a printer and a method for replacing a plate cylinder thereof. The plate cylinder (31) comprises a key groove (31b) and a registration mark (31c). The plate cylinder (31) is moved above or off from a printing unit (2) by a cart (5). The printing unit (2) comprises a plate cylinder hand-over mechanism (4), by which the plate cylinder (31) is handed over between two vertical frames (2a) and the cart (5), and a key groove position detection mechanism (60) for detecting the position of the key groove (31b). The cart (5) is provided with a plate cylinder rotation part (50) which enables the plate cylinder (31) to rotate around an axle center so that the registration mark (31c) can be positioned at a pre-determined position. The angle of the key groove (31b) and the registration mark (31c) around the axle center can be calculated by a control panel (7). Accordingly, the stopping time of the printer when the plate cylinder is replaced can be shortened, and the efficiency can be bettered.

Owner:FUJI KIKAI IND

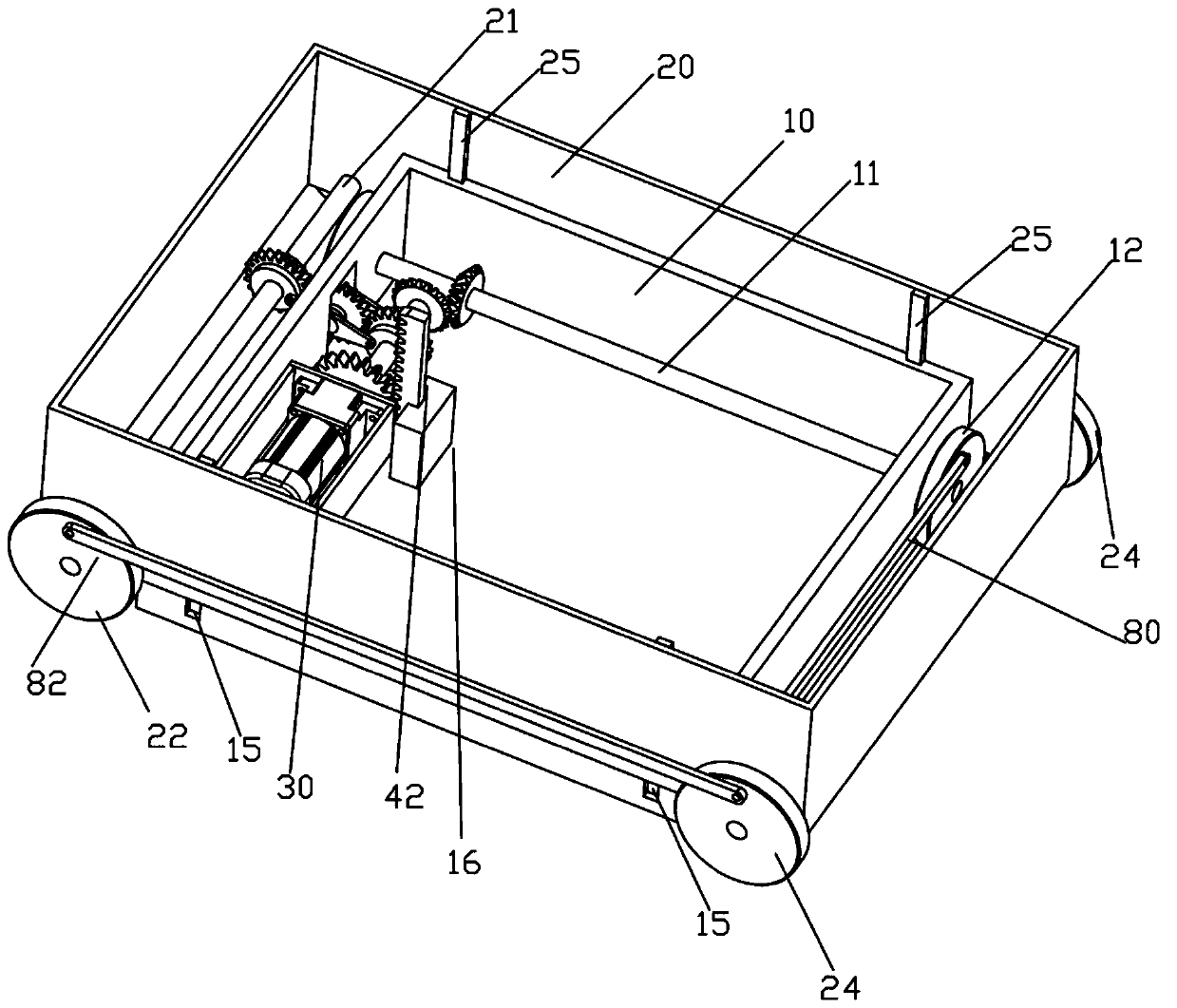

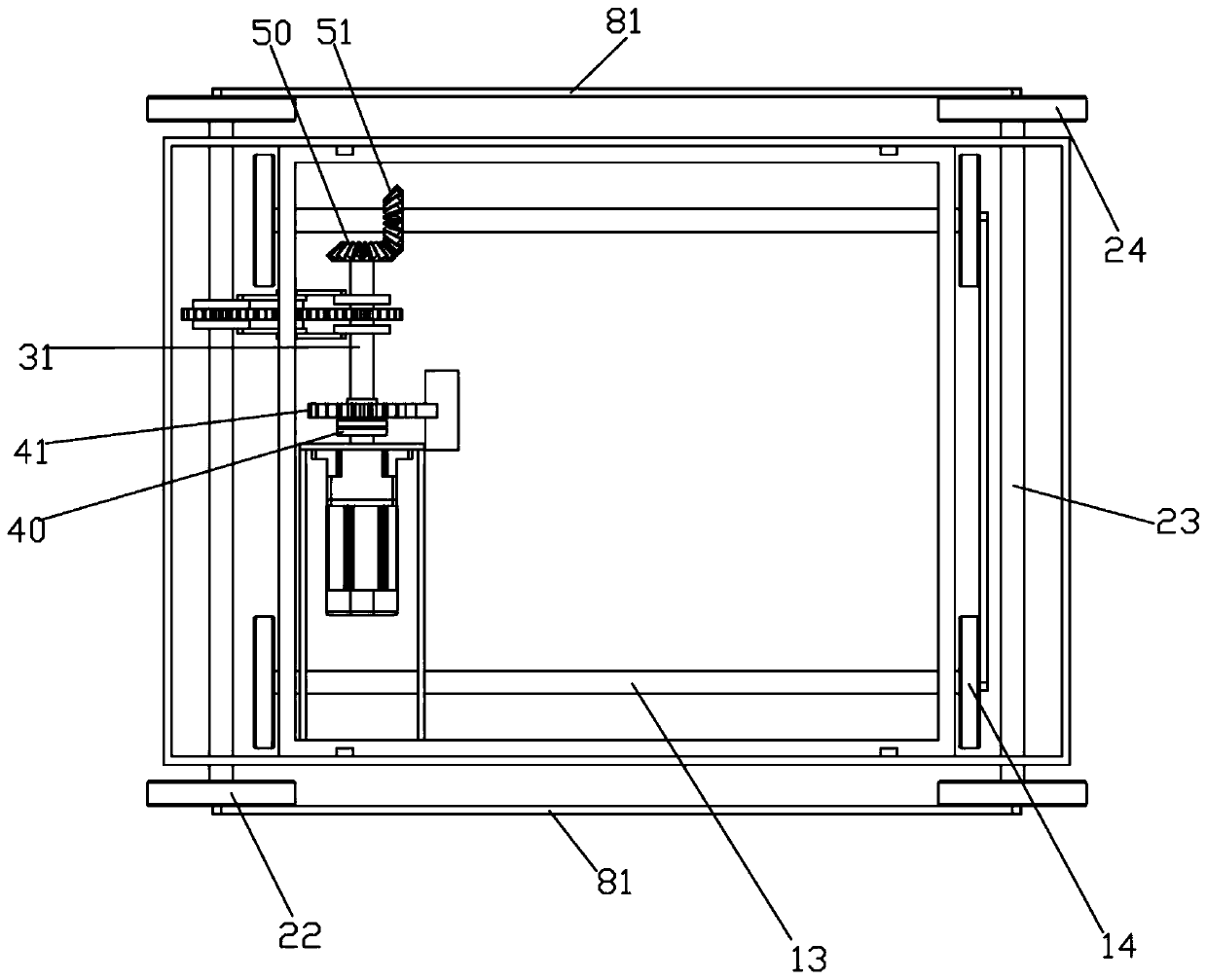

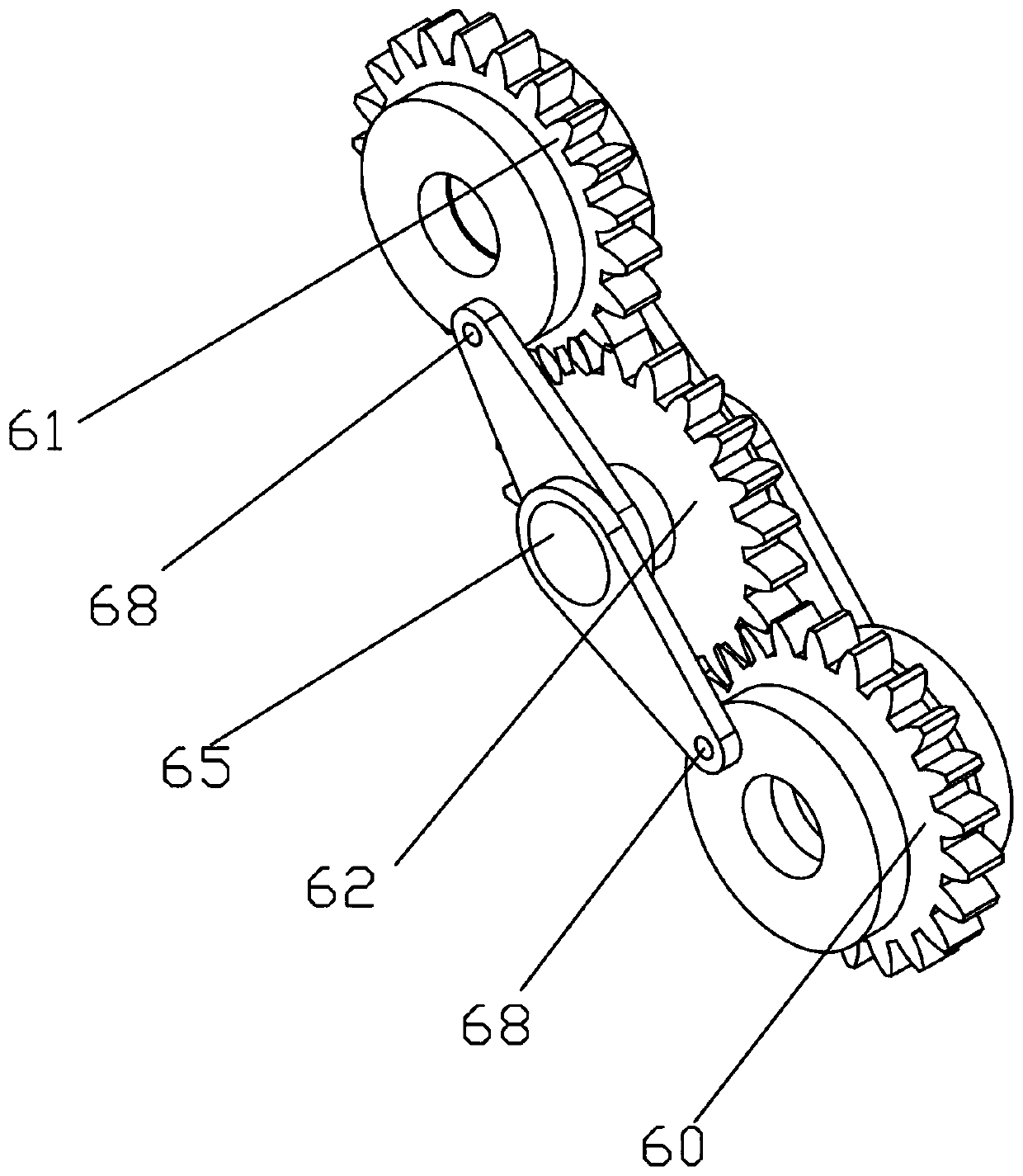

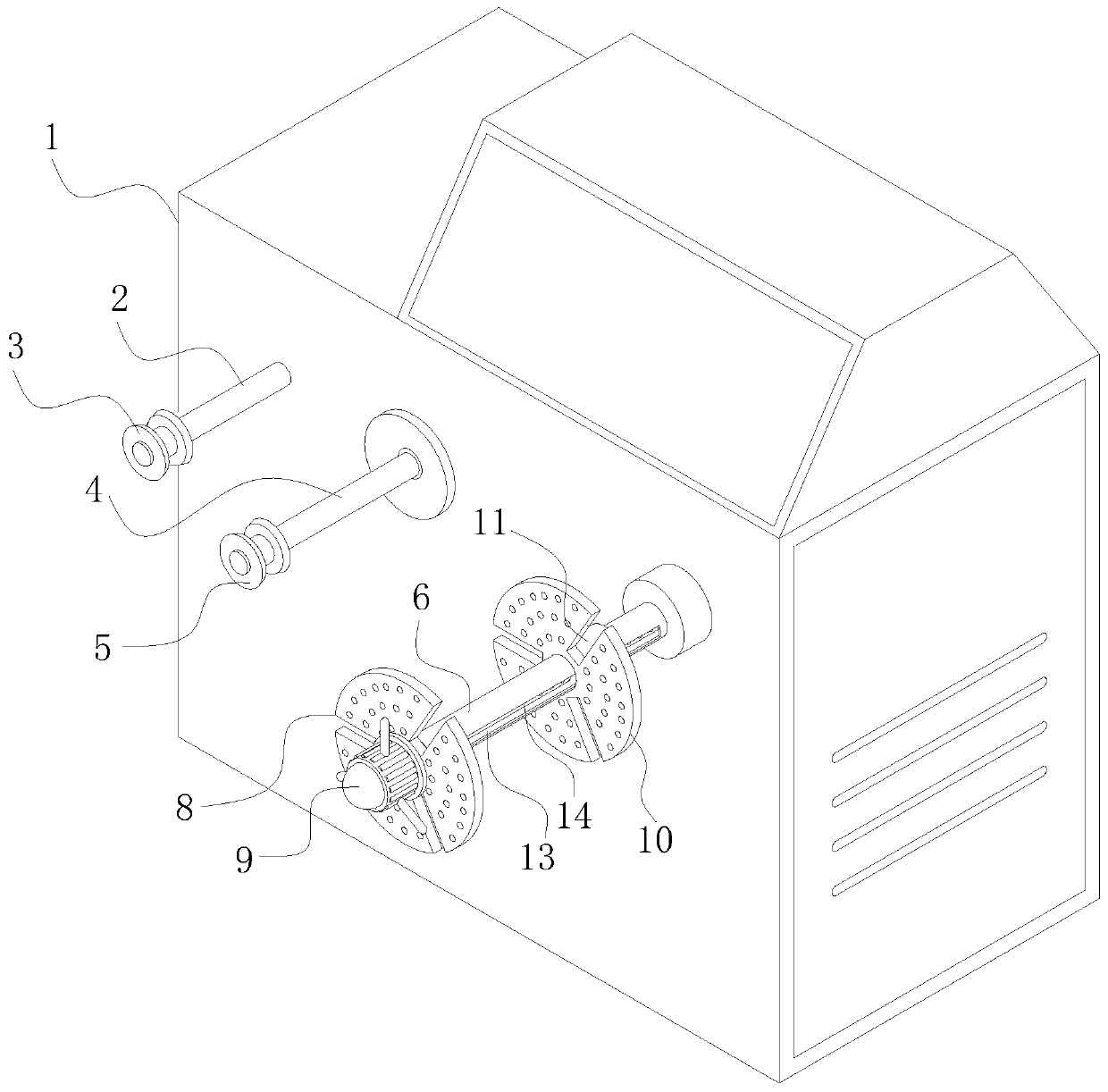

Jacking and walking co-driving type carrying device

PendingCN110733841ARealize lifting functionNot misplacedConveyorsStorage devicesWheel driveBevel gear

The invention relates to the field of transportation equipment, and discloses a jacking and walking co-driving type carrying device. The jacking and walking co-driving type carrying device comprises amain frame body, a lifting frame body, a first transmission shaft, a first rotating wheel, a first driven transmission shaft, a first driven rotating wheel, a driving device, a power output shaft, afirst transmission mechanism and a lifting transmission mechanism, wherein the first transmission shaft provided with the first rotating wheel is arranged on the main frame body, and the first driventransmission shaft provided with the first driven rotating wheel is also arranged on the main frame body; the driving device fixed on the main frame body drives the first transmission shaft to rotatethrough the power output shaft and the first transmission mechanism; and the driving device can drive the lifting frame body to ascend or descend through the lifting transmission mechanism. The poweroutput shaft is not parallel to the first transmission shaft, and the angle can be adjusted by adjusting the tooth ratio of a first bevel gear and a second bevel gear of the first transmission mechanism. According to the carrying device, the jacking and moving functions of the device can be realized only by one driving device.

Owner:北京快仓智能科技有限公司

External faced board structure for door of refrigerator

InactiveCN1435645ANot misplacedBending process is easy to realizeDomestic cooling apparatusLighting and heating apparatusPlastic filmEngineering

A panel structure of door for refrigerator is composed of front panel and side panels integral with front panel. It is made up of a metal plate covered by ethylene-base plastic film, and is characterized by that said side panels are made by bending the edge part of front panel and the upper and lower side panels have a rectangular notch on each at the position to be bent in order to prevent the protective film from dislocating on bending.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

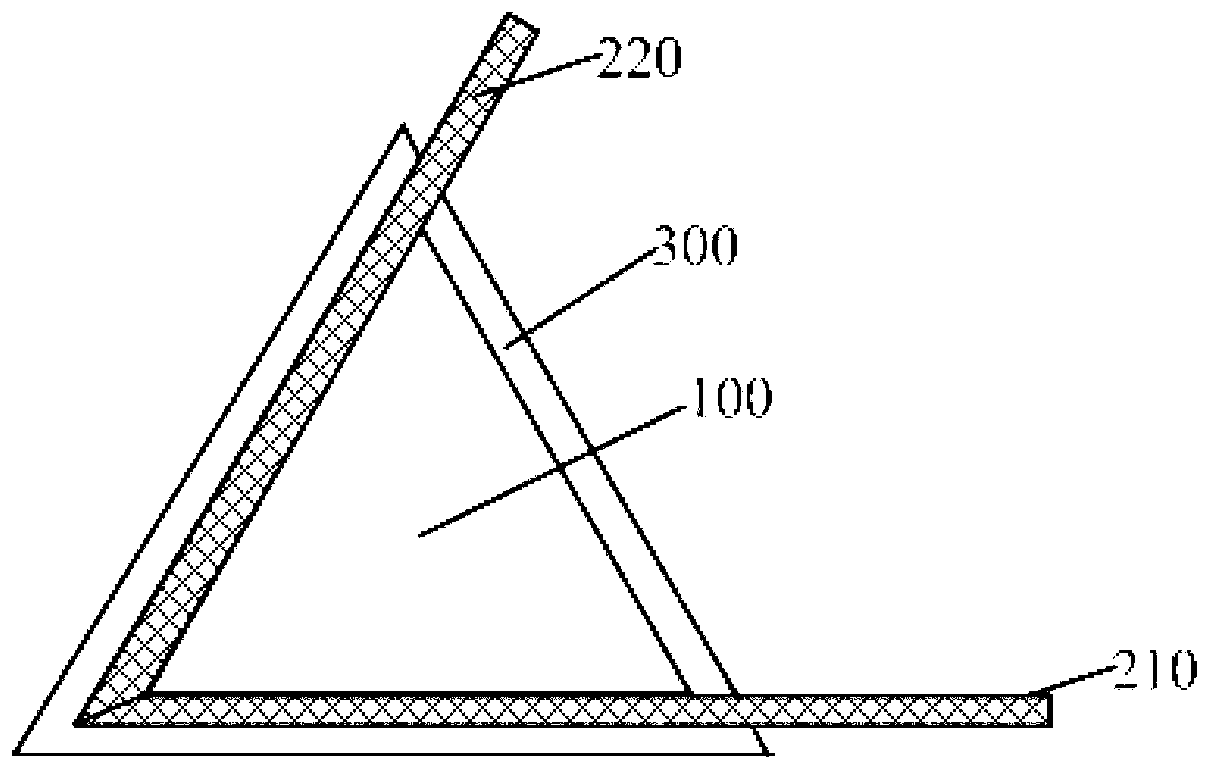

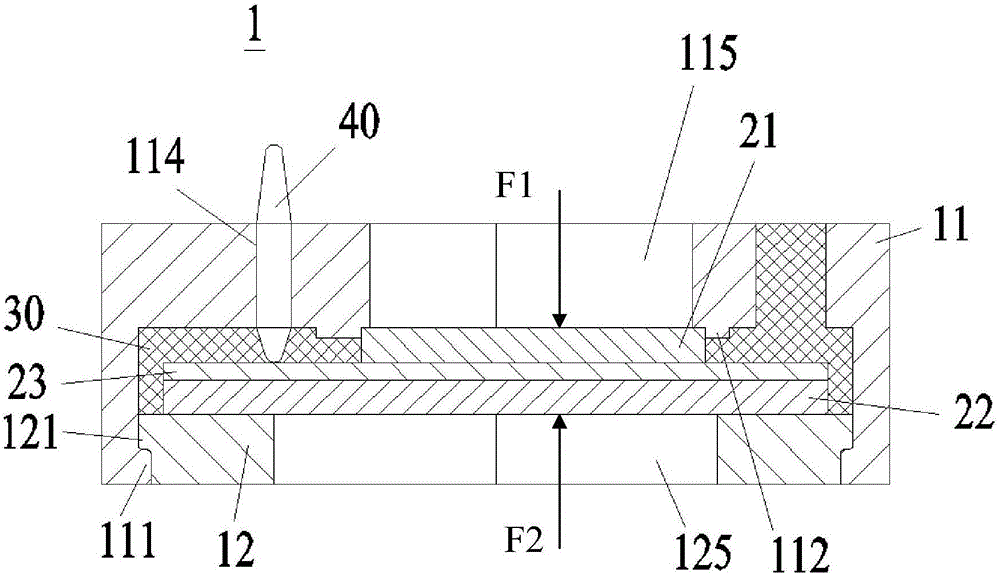

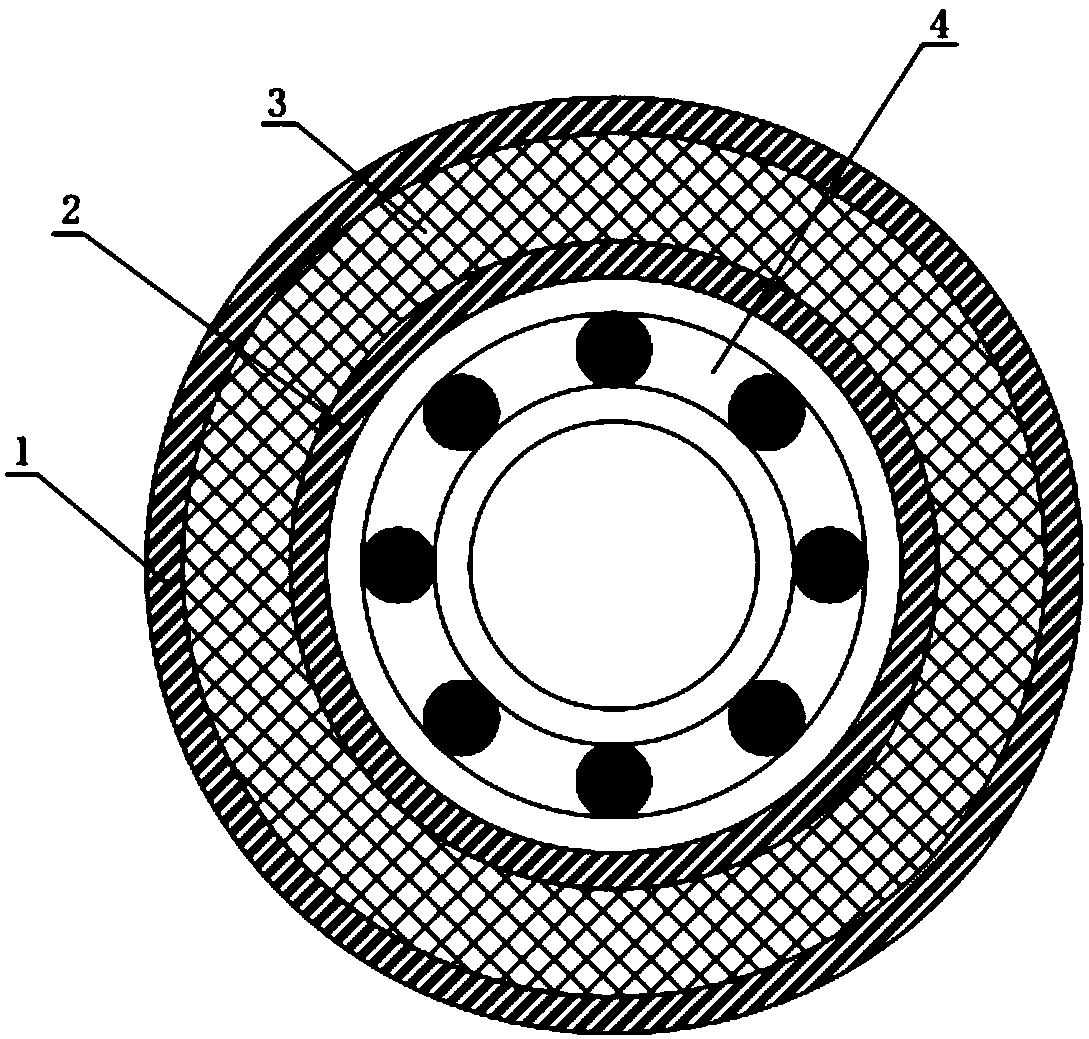

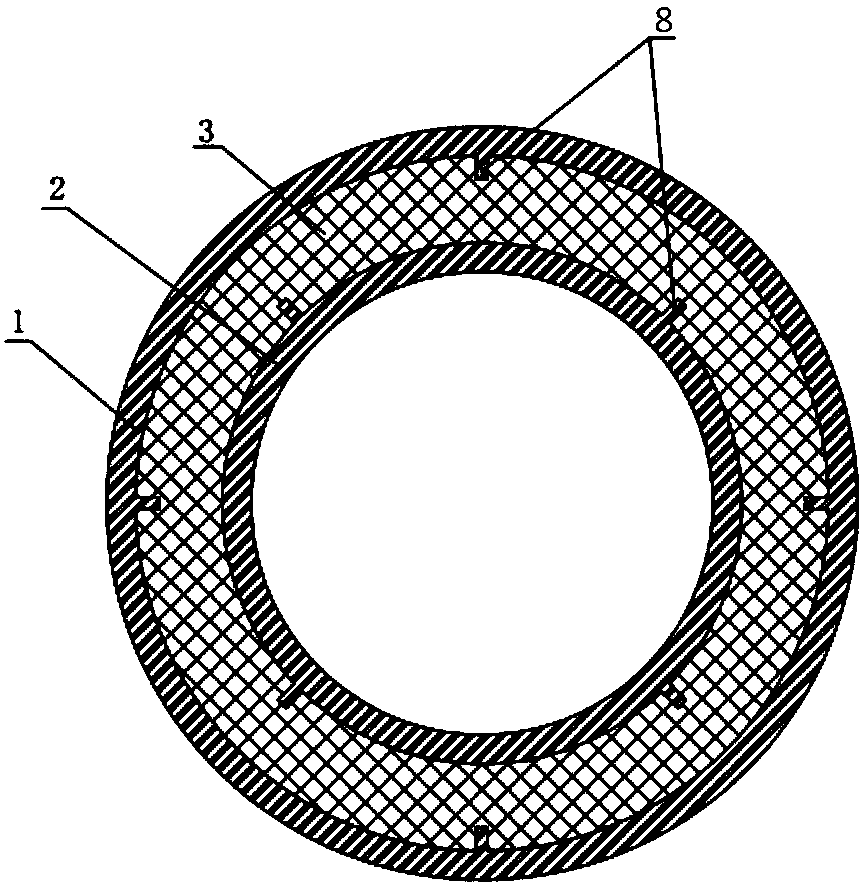

Damping shock absorber and manufacturing method thereof

PendingCN108150605ACrossed smoothlyLower resonance frequencyVibration suppression adjustmentsSpatial structureEngineering

The invention provides a damping shock absorber comprising an inner ring (2), an elastic shock absorption part (3) and an outer ring (1) which are installed fixedly and sequentially from inside to outside in the radial direction of a bearing (4). The elastic shock absorption part (3) is of a space structure which deforms in the radial direction of the bearing (4) when subjected to the action of external force. The invention further provides a method for manufacturing the damping shock absorber. The damping shock absorber is installed in the radial direction of the bearing (4). The inner ring (2), the elastic shock absorption part (3) and the outer ring (1) are arranged sequentially along the bearing (4) from inside to outside. During operation of equipment, shock in the radial direction ofthe equipment can be eliminated through the elastic shock absorption part (3), particularly for a flywheel accumulator, resonant frequency can be lowered through the damping shock absorber in the radial direction of the bearing (4), the elastic shock absorption part (3) can be stressed and deforms in the radial direction, shock and noise can be reduced, the effect that a rotor goes over a resonance point smoothly is ensured, and high-speed operation is achieved.

Owner:ERZHONG DEYANG POWER TECH CO LTD

Aluminum plating device

InactiveCN112030132ANot misplacedRapid cooling and solidificationVacuum evaporation coatingSputtering coatingPlastic filmMachine tool

The invention relates to the field of aluminum plating, in particular to an aluminum plating device. The aluminum plating device is provided to solve the technical problem. Based on the technical scheme, the aluminum plating device comprises a conveying roller mechanism, a primary aluminum plating mechanism, a secondary aluminum plating mechanism, a cooling and solidification mechanism, a fastnessdetection mechanism, a communication cabin door and the like, and the lower portion of a working machine tool plate is welded to supporting bottom feet. According to the aluminum plating device, double-sided aluminum plating of a plastic film is achieved, aluminum on the surface of the plastic film is rapidly cooled and solidified after one side of the plastic film is aluminized, then aluminum plating operation is conducted on the other side of the plastic film, and then rapid cooling and solidification are conducted again, so that the plastic film is ensured to be in a tensioned state all the time in the aluminum plating process so as not to be misplaced, meanwhile, aluminum plating on two sides of a conveying roller in the device by means of aluminum steam is avoided, and the effect ofrespectively detecting the fastness of aluminum layers on two surfaces of the plastic film after rapid cooling and solidification is achieved.

Owner:张跃兵

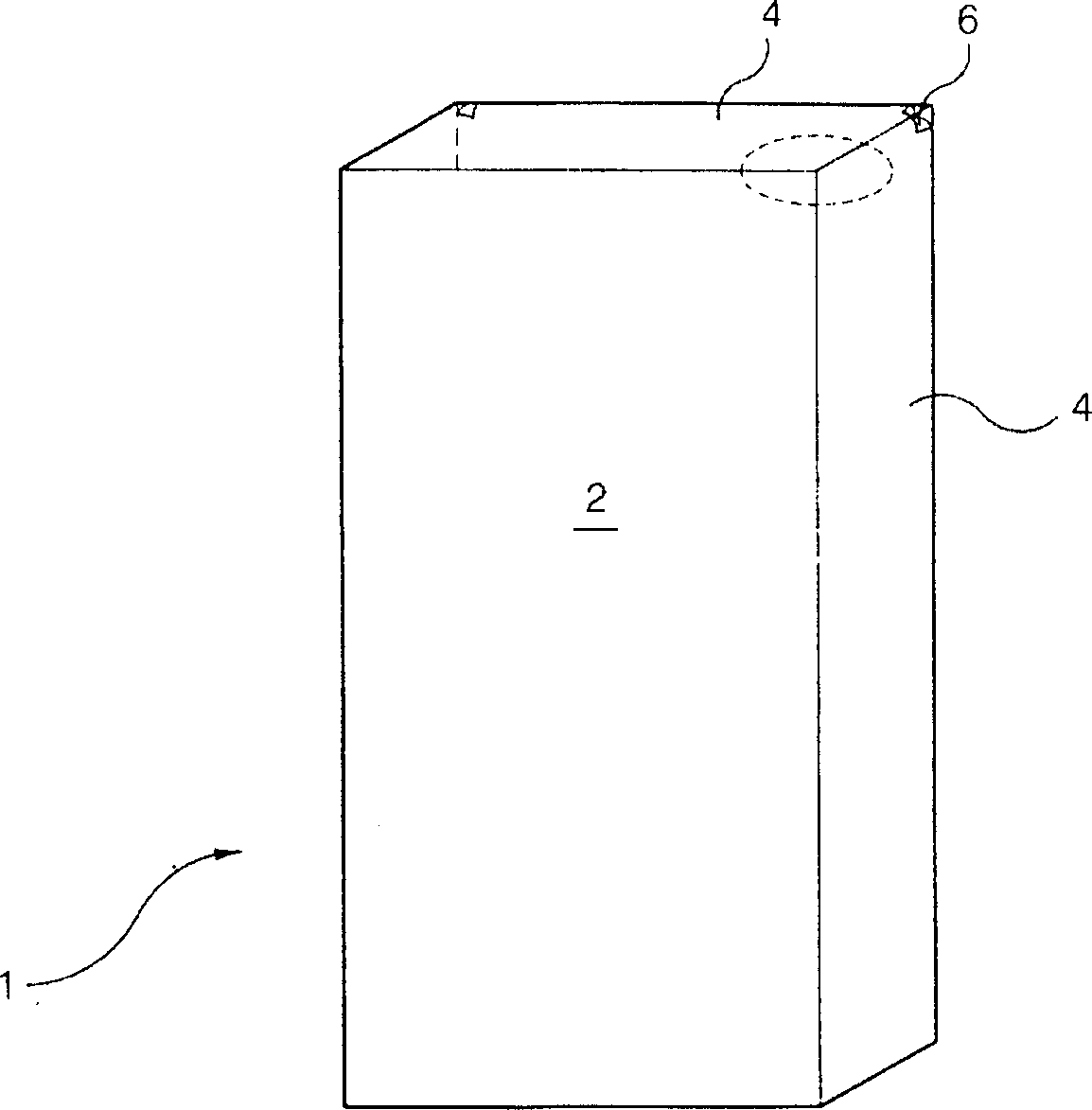

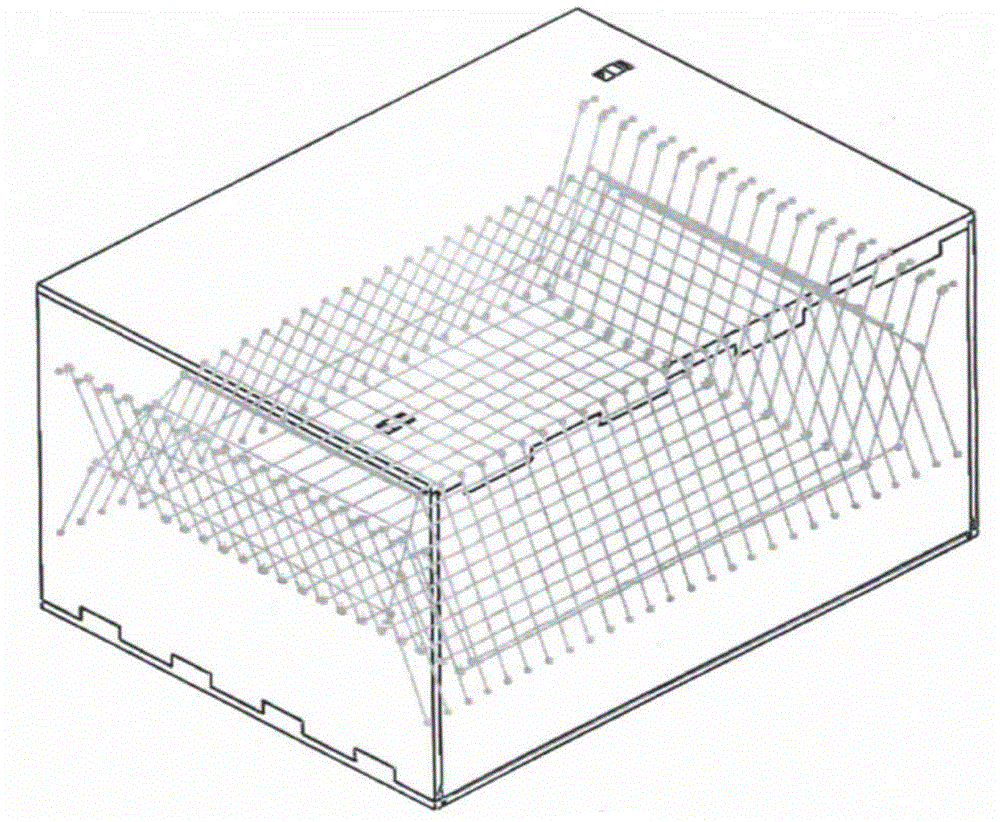

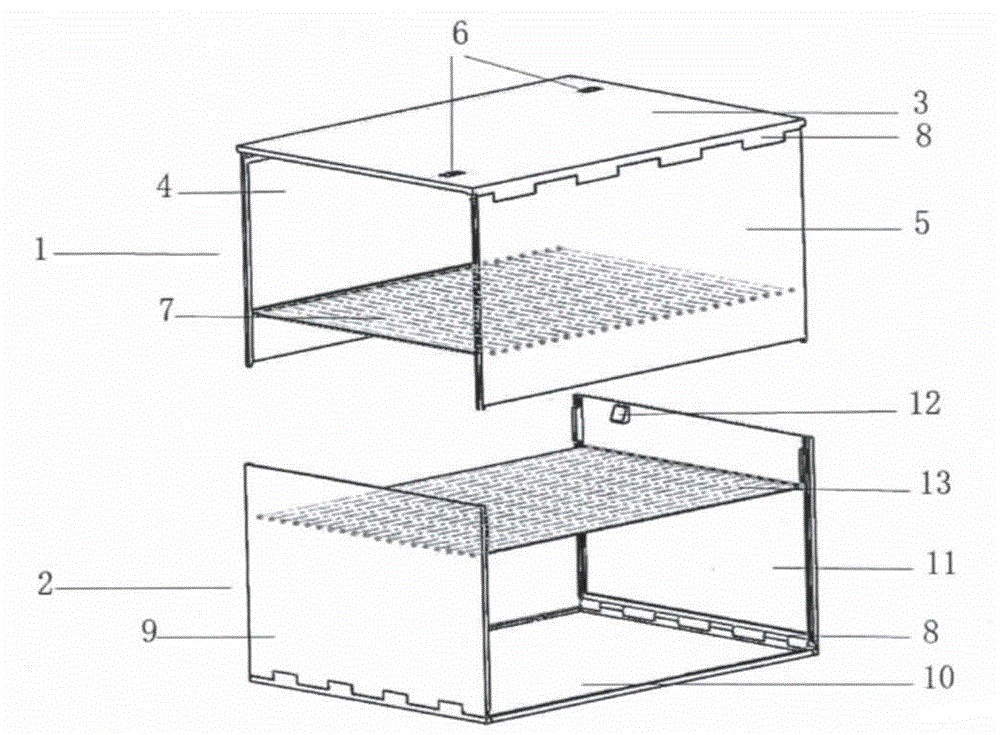

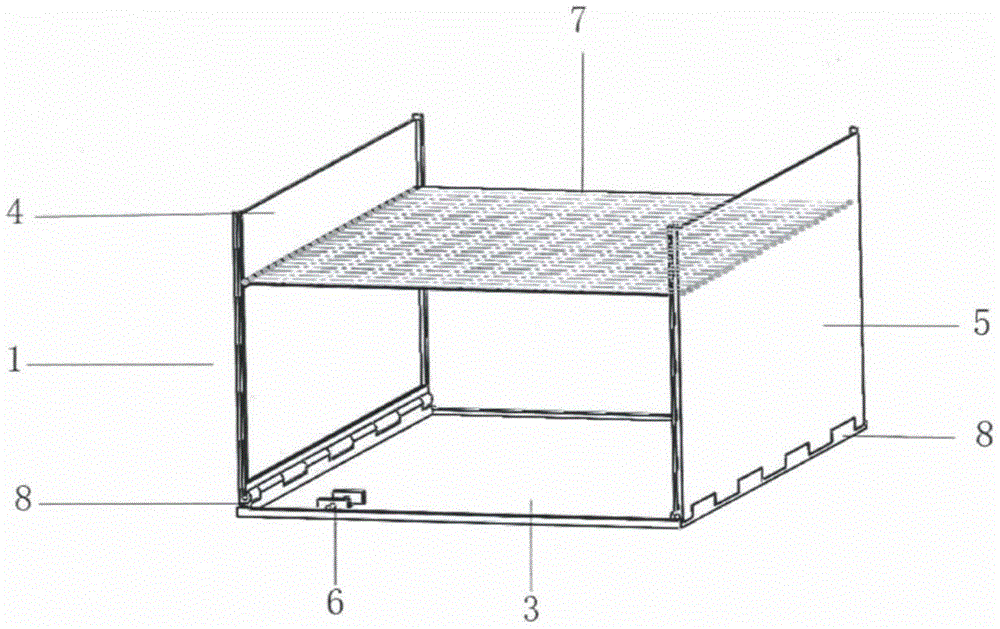

Buffering folding packaging box with elastic layers

ActiveCN104787430ANot misplacedEasy to manufactureContainers to prevent mechanical damageRigid containersSlide plateEngineering

The invention relates to the technical field of packaging, in particular to a buffering folding packaging box with elastic layers. The elastic layer buffering packaging technology is adopted, one side of a top plate and a front plate are movably connected through a rotary shaft, the other side of the top plate and a rear plate are movably connected through a rotary shaft, one side of a bottom plate and a left plate are movably connected through a rotary shaft, and the other side of the bottom plate and a right plate are movably connected through a rotary shaft; the two side ends of the upper elastic layer are fixed to the front plate and the rear plate respectively; the two side ends of the lower elastic layer are fixed to the left plate and the right plate respectively; sliding rails on the front plate and the rear plate are movably connected with sliding grooves in the left plate and the right plate in a sliding mode; the inner sides of the upper edges of the left and right plates are fixed to a clamping protrusion; the two sides of the inner surface of the top plate are fixed to a plate A and a plate B, a movable shaft is fixed to a sliding plate and sleeved with a spring, the two ends of the spring abut against the sliding plate and the plate B respectively, a sliding hole in the top plate is movably connected with the sliding plate in a left-right sliding mode, the two ends of the movable shaft are movably connected with a movable shaft hole of the plate A and a movable shaft hole of the plate B respectively in a left-right sliding mode, and the clamping protrusion is buckled with a movable shaft of a connector. The buffering folding packaging box with the elastic layers is used for packaging products and is ingenious in structure and good in effect.

Owner:李世亮

Cable winding and packaging device

The invention discloses a cable winding and packaging device. A shell is included. The front side of the shell is provided with a fixing pulley, a horizontal moving pulley and a winding pipe. A limiting rod is fixedly connected to the front end of the winding pipe. A first baffle and a limiting threaded sleeve are arranged on the surface of the limiting rod. The end, close to the shell, in the winding pipe is provided with a position adjustable second baffle and a sliding sleeve. One side of the sliding sleeve is provided with a locking mechanism in a penetrating manner. Long holes are symmetrically formed in the two sides of the winding pipe. The sliding sleeve is fixedly connected with the winding pipe through the locking mechanism. Through adjustment of the distance between the first baffle and the second baffle, the packaging width can be changed, meanwhile, operation is simple, and the packaging size adjusting efficiency is improved. Cable processing enterprises can produce cablewinding bags different in packaging size according to actual needs of the market, the usage requirements of people for the cable packaging size can be met, more selections are provided for customers so that the sale volume can be increased, and economic benefits are improved.

Owner:ZHEJIANG LIZHOU CABLE

Manufacturing method of zero-formaldehyde plywood

InactiveCN101659071AGood product qualityIncrease productivityWood veneer joiningFormaldehyde freeHeat press

The invention discloses a manufacturing method of zero-formaldehyde plywood, which comprises the following steps: (1) plate layout: taking a rectangular supporting plate as a datum, aligning, sequentially arranging and fixing single plates and formaldehyde-free adhesive films to form plywood, and adopting the rectangular supporting plates separating plywood, and preparing a plate assembly; (2) hot-pressing: preheating a hot press, putting the plate assembly in the hot press for prepressing, pressurizing the hot press after the prepressing is finished, and decompressing after the pressurizationis finished; (3) cold-pressing: putting the plate assembly after being depressed in a cold press for pressurizing and cooling; and (4) molding: separating the plywood after cold-pressing in the plateassembly from the rectangular supporting plates, and molding the plywood according to specifications to prepare the zero-formaldehyde plywood. The invention can produce the zero-formaldehyde plywoodon a large scale and has better product quality as well as higher production efficiency.

Owner:SHENZHENSHI HUANWEI WOODS

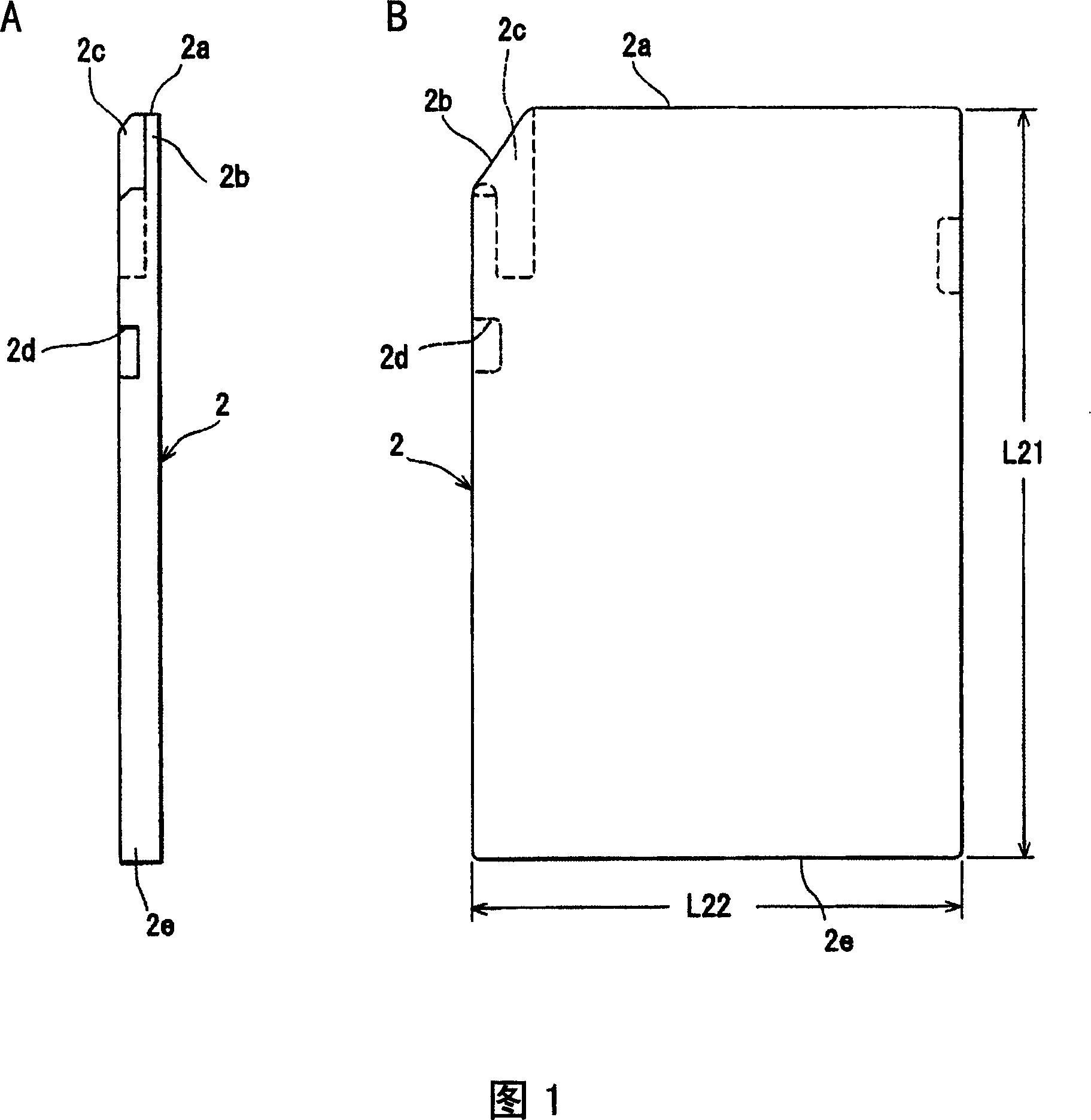

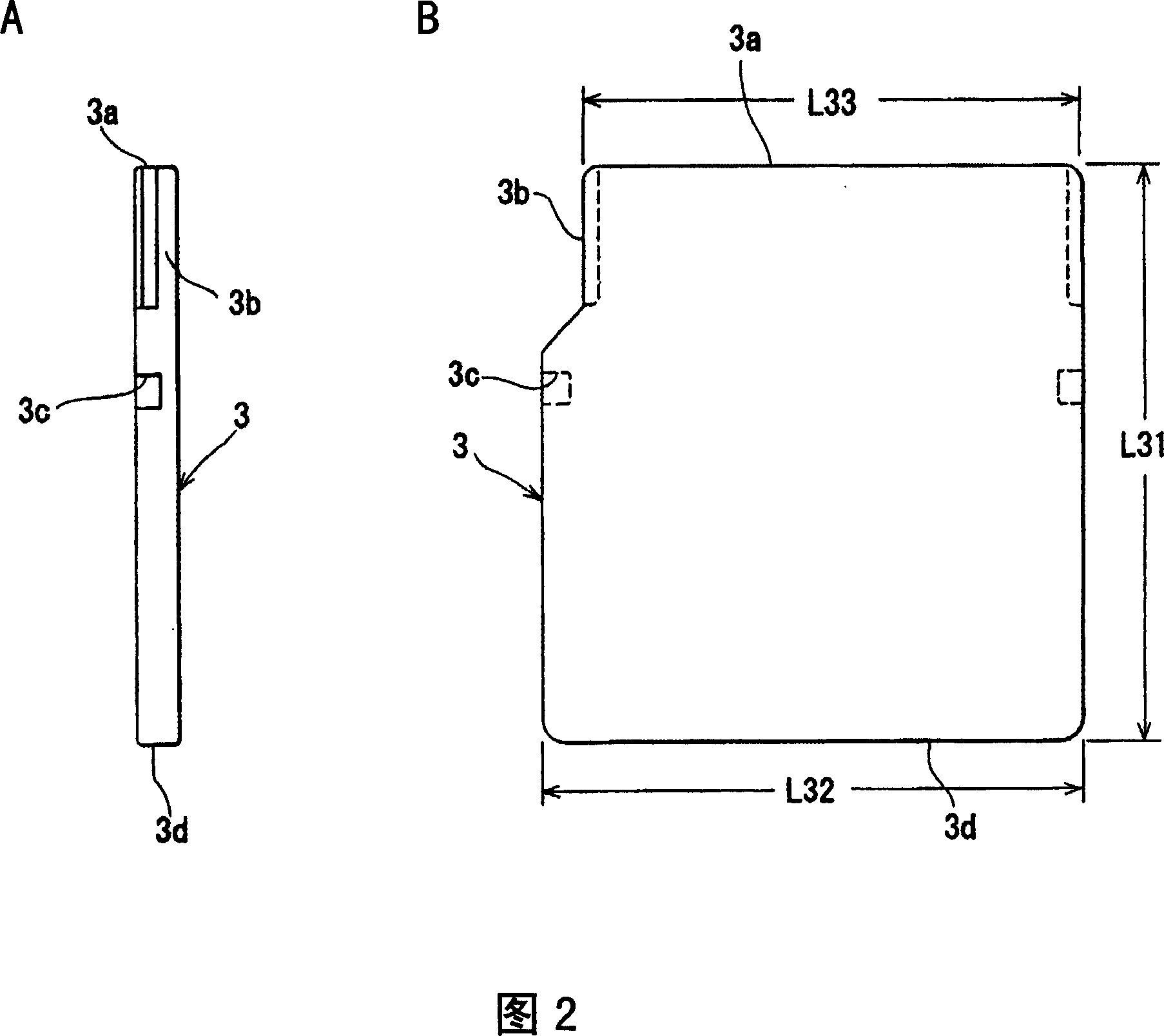

Connector device for card

InactiveCN1983726AWon't shakeNot misplacedCoupling device detailsCo-operative working arrangementsEngineering

The present invention provides a card connector device, which can reliably fit the second card to the card fitting part without to wrong position even insert the second card to the cart fitting part again and again. The case of the card connector device (1) of the present invention formed with card inserting path for sliding the first or second card (2, 3) when inserting them to the first or second card fitting part (5, 6), the spacing component (8) is supported by the sliding component (7) and can slide in the orthogonal direction to the inserting direction of the first or second card. The spacing component (8) can retreat to the retreating part (7b) departing from the card inserting path when fitting the first card (2) to the first card fitting part (5). The spacing component (8) lies inthe inserting path when fitting the second card (3) to the second card fitting part (6), the front part (3a) of the second card that inserted to the card inserting path is abutting to the spacing component.

Owner:ALPS ALPINE CO LTD

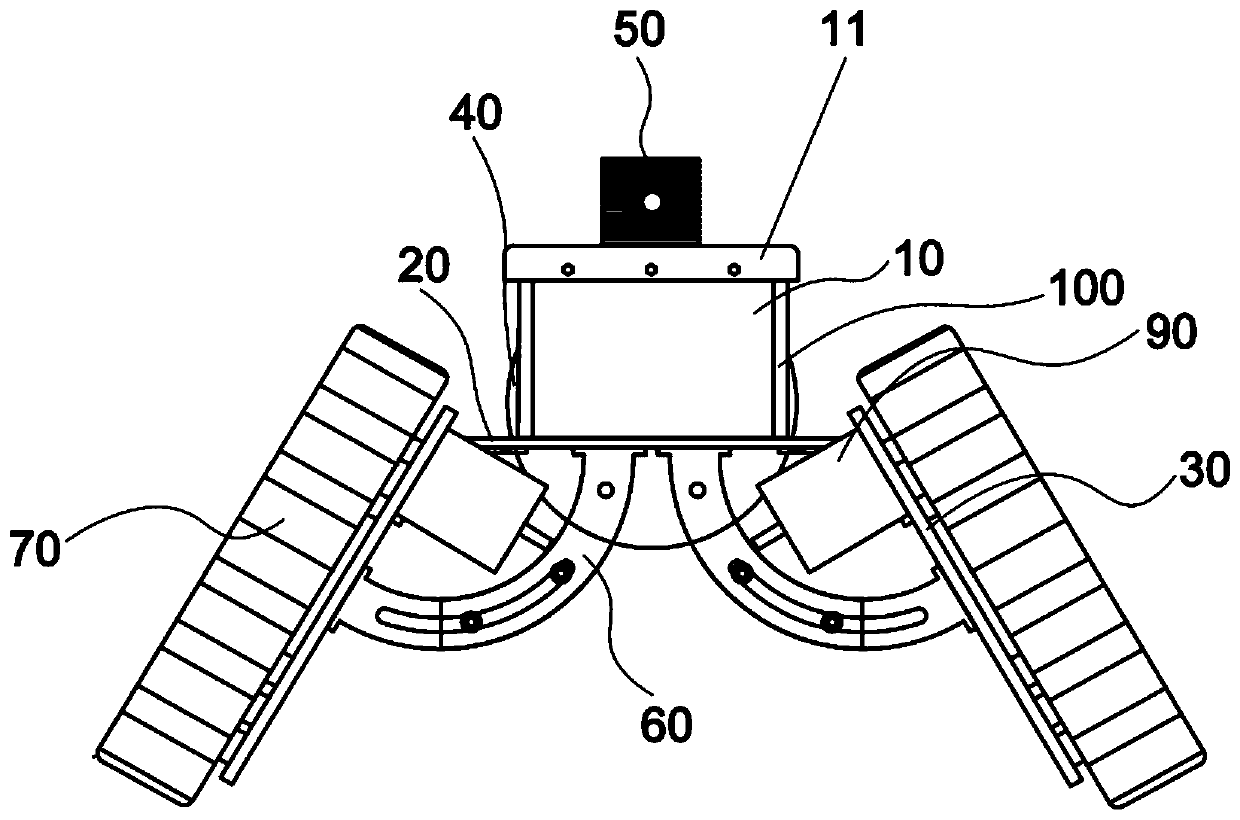

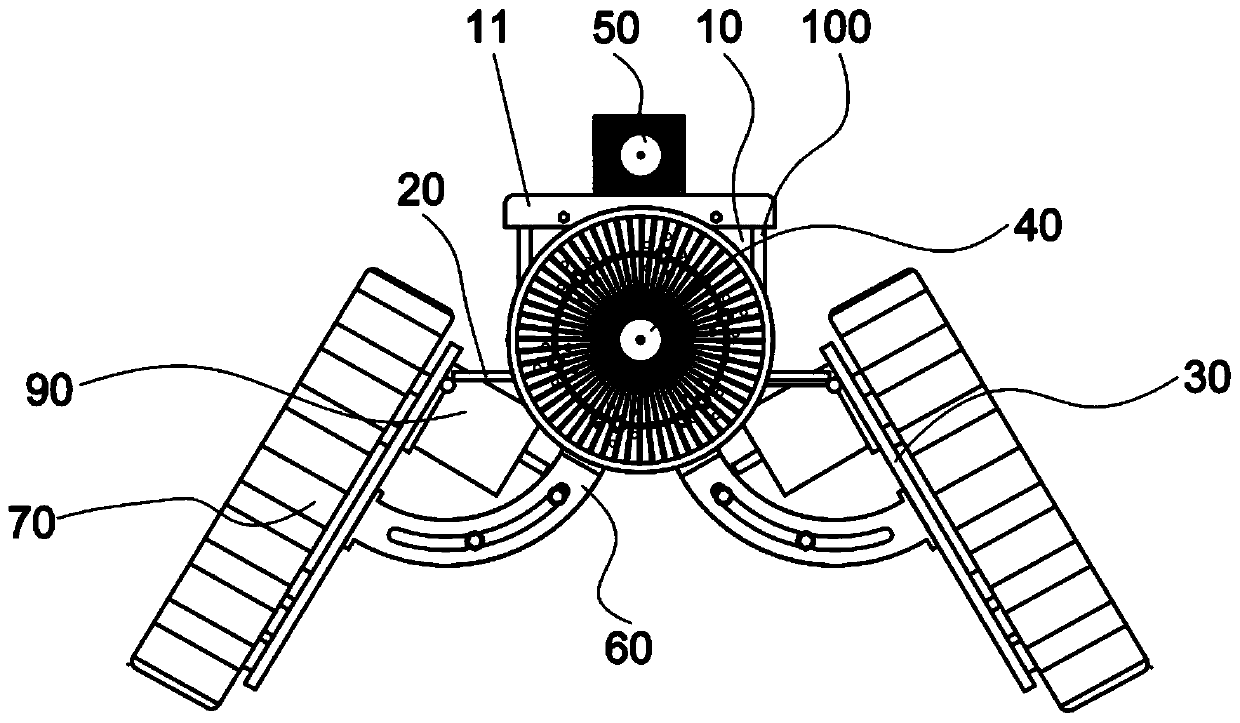

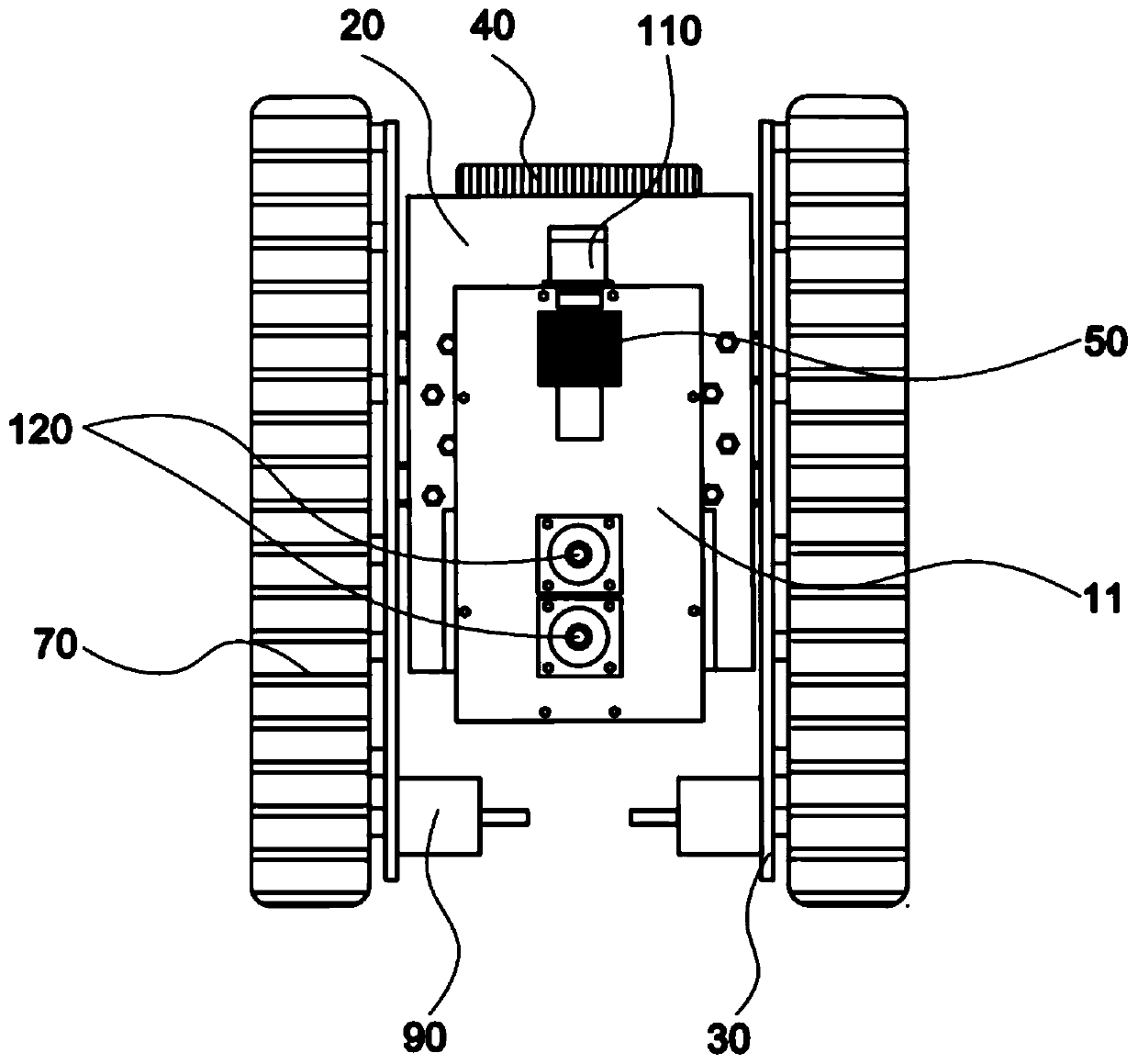

Crawler type pipeline crawling robot

InactiveCN111156368AReduce dredging costsReduce road closure timePigs/molesElectric machineryLight source

The invention discloses a crawler type pipeline crawling robot. The crawler type pipeline crawling robot comprises a compartment, a pair of metal side plates, an illuminating lamp, a high-definition camera, a pair of first slotted cards, a pair of crawler belts and a pair of motors. The lower end of the compartment is connected with a metal base plate. The pair of metal side plates are located onthe two sides of the metal base plate correspondingly. The illuminating lamp is arranged at the front end of the metal base plate. The high-definition camera is arranged at the top end of the compartment. The first slotted cards are arranged between the corresponding metal side plates and the metal base plate. The crawler belts are arranged on the outer sides of the corresponding metal side plates. Driving wheels are mounted on one sides of the corresponding crawler belts. The motors are arranged on the inner sides of the corresponding metal side plates. The driving wheels are sleeved on output shafts of the corresponding motors. The crawler type pipeline crawling robot can adapt to different pipe diameters, adopts a crawler type crawling mode, is stable in crawling, adopts the high-definition color two-degree-of-freedom camera of 4 megapixels or more and the illuminating lamp with a circular surface light source and can move in a pipeline with the high water level and detect hidden danger in the pipeline in time.

Owner:福建丽塔智能科技有限公司

Cylindrical battery

The invention relates to a cylindrical battery, comprising a shell body, an electric core which is arranged in the shell body and a sealing cover which seals the shell body, ring spacers are respectively arranged at the two ends of a winding needle in a scroll hole of the electric core, and the ring spacers are fixedly connected with the two ends of the winding needle by fasteners or fastening structures. The electric core is tightly clamped between the two ring spacers by fixedly connecting the ring spacers which are positioned at the two ends of the electric core and the ends of the winding needle which is positioned in the scroll hole of the electric core, thereby fixedly connecting the three together, being capable of resisting the impacts caused by severe vibration and further leading the cylindrical battery to be safer during the using process and being applicable to various environments with strong vibration and heavy jolt.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Heat pump type microchannel heat exchanger

InactiveCN104949395AEasy to installHigh strengthEvaporators/condensersTubular elementsDislocationEngineering

The invention discloses a heat pump type microchannel heat exchanger which comprises flat tubes and fins. A flat tube insertion hole is formed in each fin, the width dimension of each flat tube is H1, the width dimension H2 of each flat tube insertion hole is larger than the width dimension H1 of each flat tube, the flat tubes are clamped into the corresponding flat tube insertion holes and fixed in a welded mode, turned edges are arranged on each fin along the periphery of the corresponding flat tube insertion hole, an installation hole with the width larger than that of the corresponding flat tube is reserved at one end or at the two ends of each flat tube insertion hole. According to the technical scheme, the installation hole with the width larger than that of the corresponding flat tube is reserved at one end or at the two ends of each flat tube insertion hole to form a larger space or a cutting edge, and the space can be used for installing flat tube installation guide rails to fix the relative positions of the fins, so that dislocation of fins does not occur, and installation of the flat tubes is convenient.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

Modular glass partition wall with fireproof function for indoor installation

PendingCN112160459ALow costImprove the fixed effectCarpet cleanersWallsEngineeringStructural engineering

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

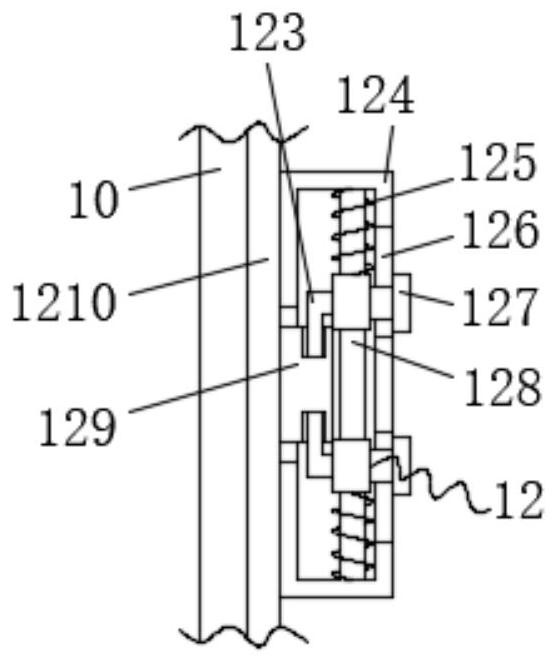

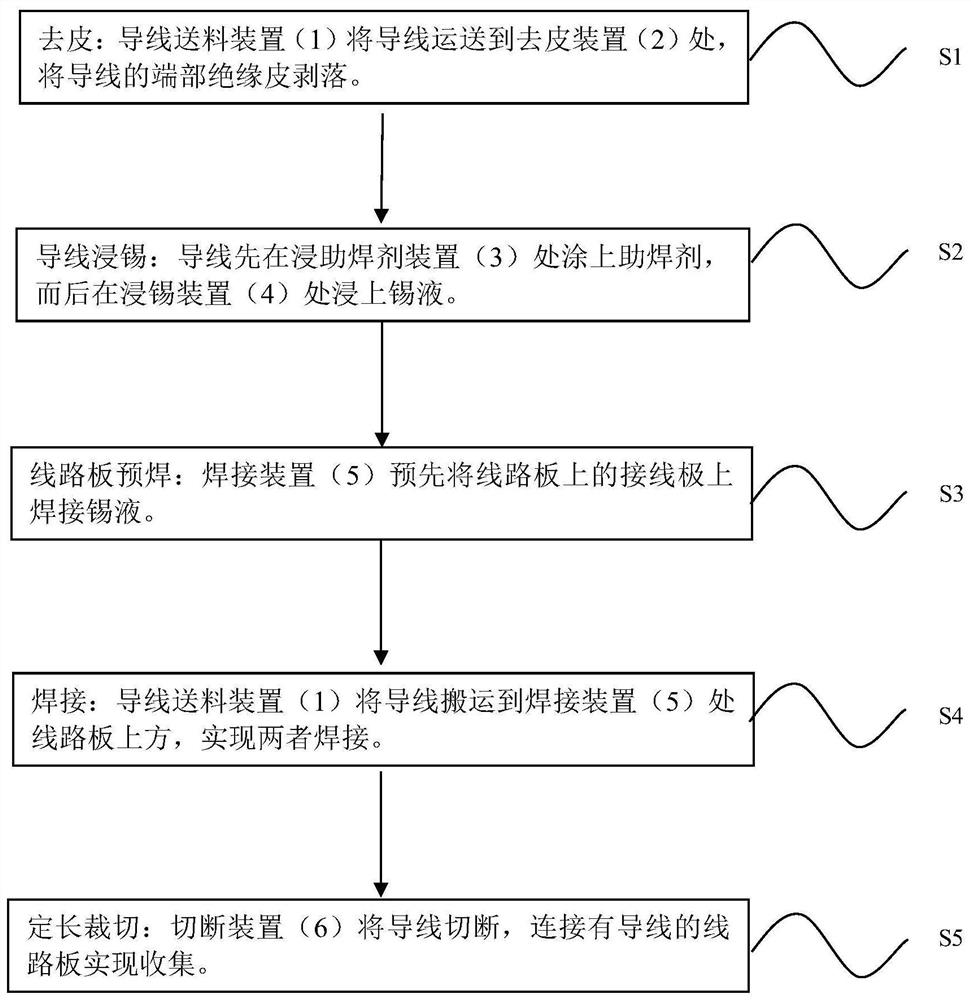

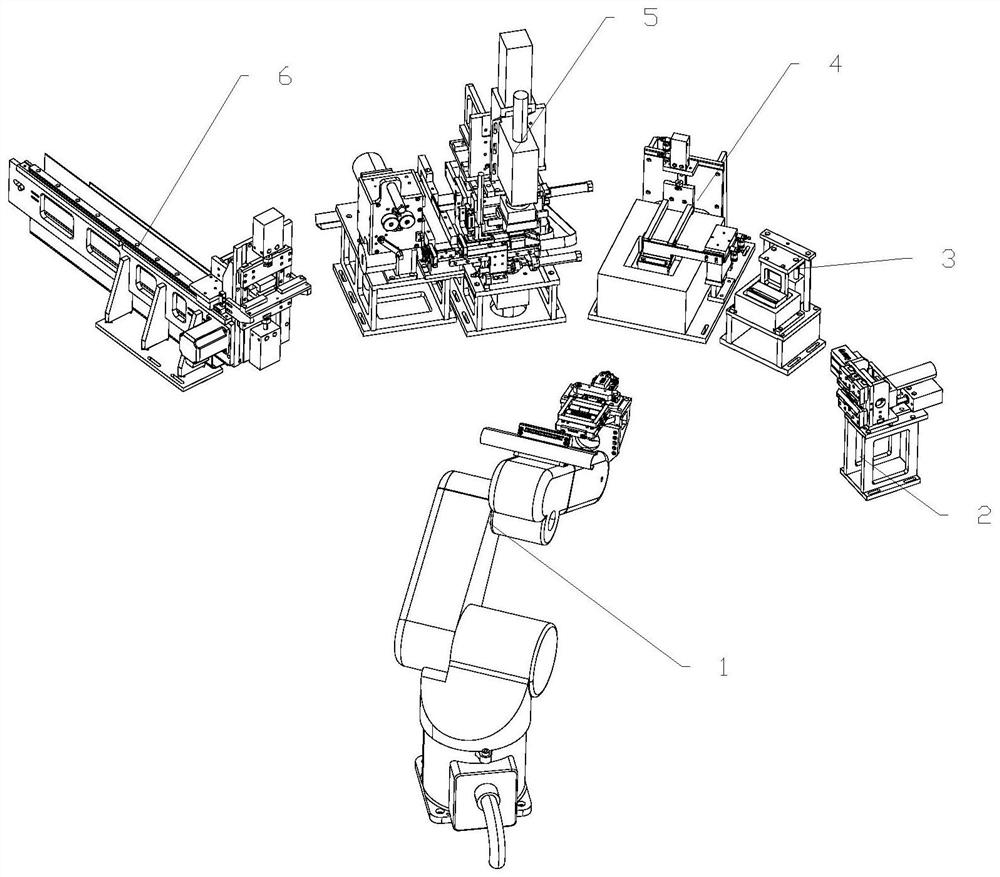

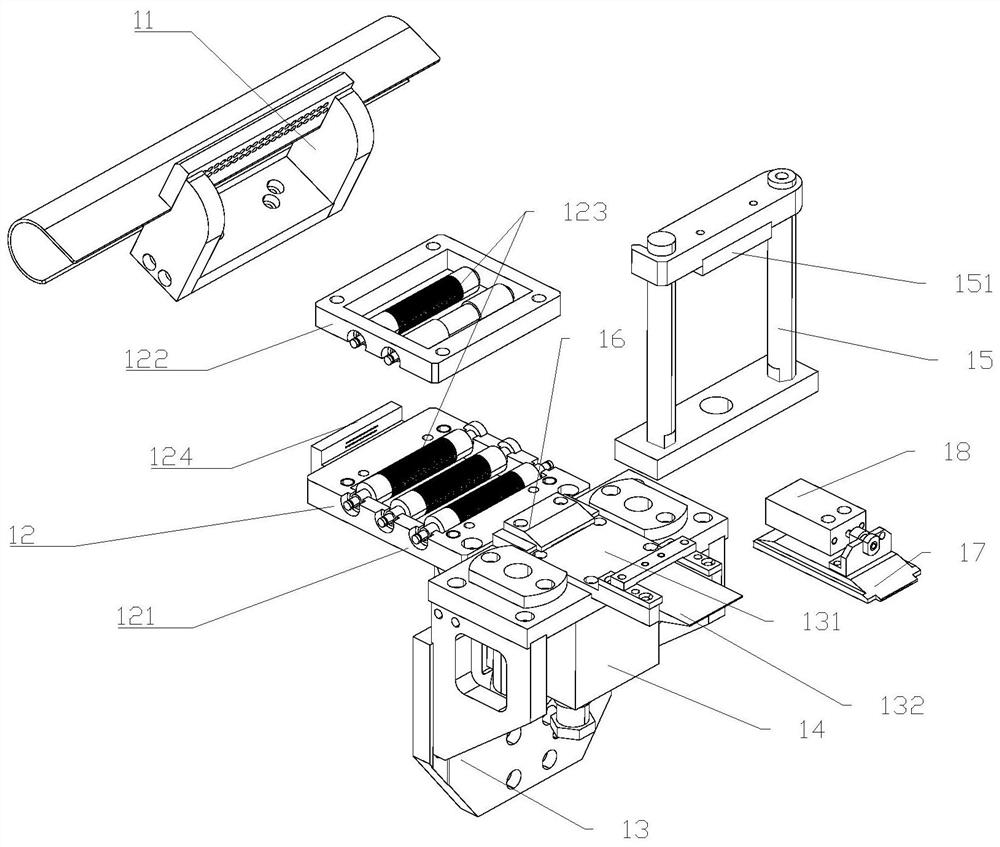

PCB (printed circuit board) pre-welding device and method and circuit board welding equipment

InactiveCN113333890AImprove accuracyImprove delivery efficiencyPrinted circuit assemblingMetal working apparatusEngineeringMechanical engineering

The invention discloses a PCB (printed circuit board) prewelding device. The prewelding device comprises a first base, a tin wire feeding assembly, a circuit board feeding assembly, a second base, a circuit board feeding rail, a circuit board pushing assembly, a lifting base assembly, a traction assembly, a wire pressing assembly and a welding assembly, the tin wire feeding assembly and the circuit board feeding assembly are arranged on the first base, the second base is arranged on the side of the first base, the circuit board feeding rail is fixedly arranged on the second base and is connected to the side of the circuit board feeding assembly, the lifting seat assembly is connected to the circuit board feeding rail, the wire pressing assembly corresponds to the upper portion of the circuit board feeding rail, the traction assembly is arranged on the second base, the traction assembly corresponds to the wire pressing assembly from the side, the circuit board pushing assembly is connected to the circuit board feeding assembly and the circuit board feeding rail, and the welding assembly is arranged on the second base and corresponds to the lifting base assembly from top to bottom. The prewelding device has the advantages that materials are fed simultaneously, and the welding efficiency is high.

Owner:郑晓静

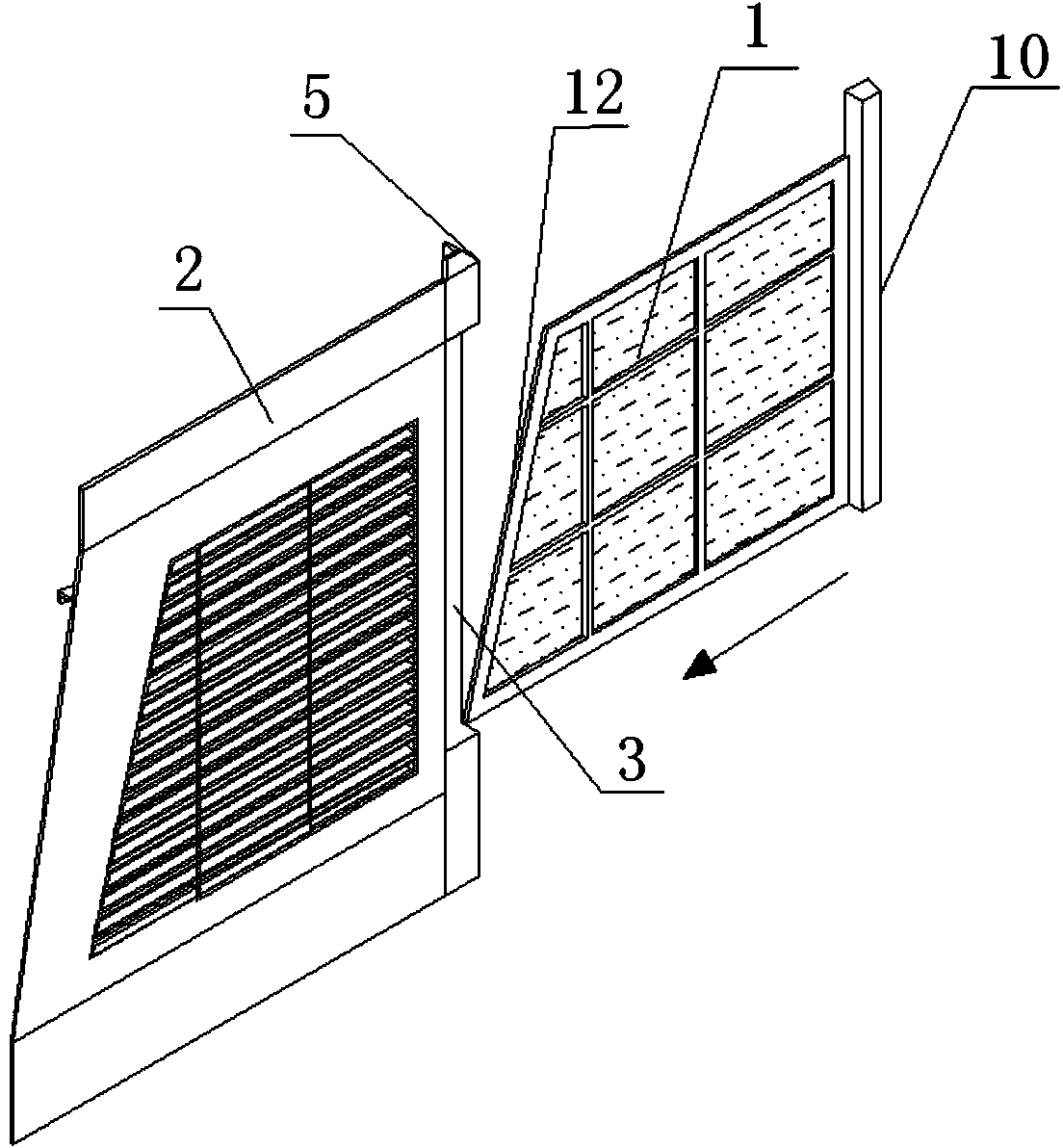

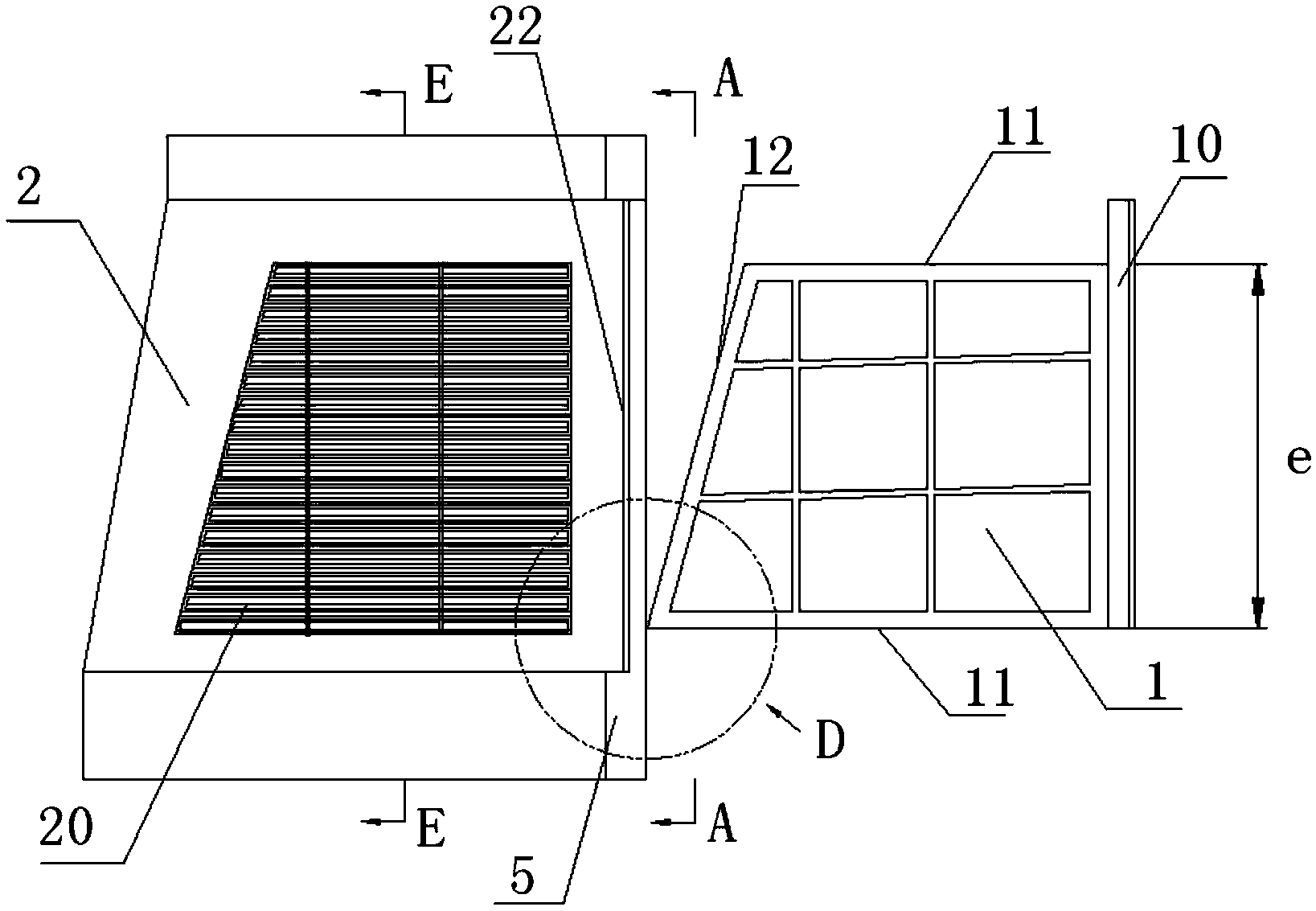

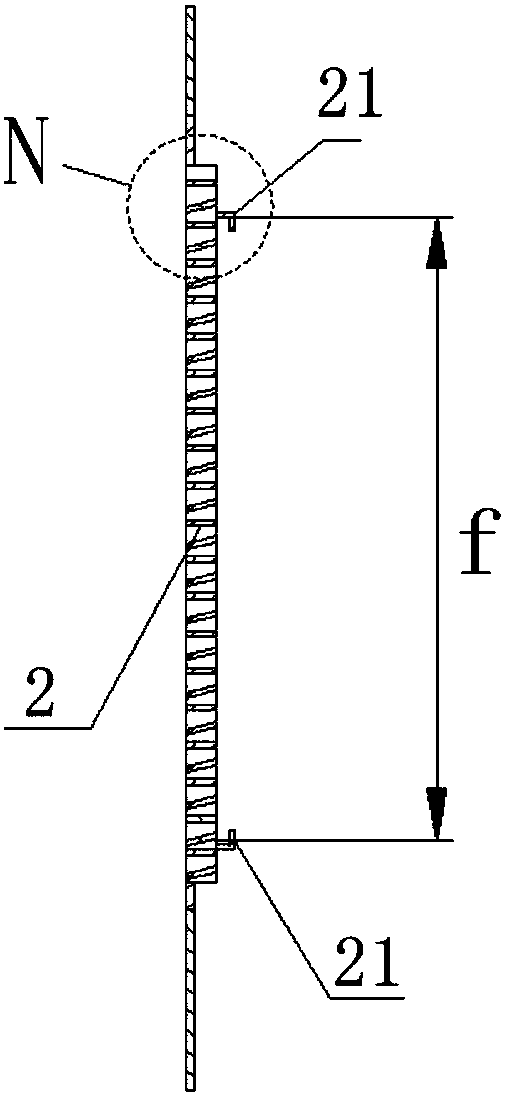

Dehumidifier filter screen inserting device and dehumidifier

ActiveCN103727647AEasy to insertInsert smoothlyLighting and heating apparatusSpace heating and ventilation detailsArchitectural engineering

The invention provides a dehumidifier filter screen inserting device and a dehumidifier. The dehumidifier filter screen inserting device comprises an inserting plate, a filter screen and a backup plate, wherein a side surface of the inserting plate is fixedly provided with two guide rails in parallel; the filter screen, the thickness of which is a, is provided with two parallel edges; each guide rail comprises a vertical plate the first end of which is vertically fixed on the inserting plate, and a flat plate fixed on the second end of the vertical plate; the flat plates and the inserting plate are parallel, the vertical plates, the inserting plate and the flat plates can form a guide rail groove for containing the parallel edges, the width of the guide rail groove is b, and the b is equal to (1-1.3)?a; the backup plate is fixed opposite to the inserting plate and is positioned on the outer side of an inserting end of the inserting plate, the backup plate and the flat plate are positioned on a same plane, a gap, the width of which is c, is formed between the backup plate and the side edge, and the c is equal to (1.4-2)?a. The dehumidifier filter screen inserting device provided by the invention has the advantages that the coordinating relationship among the thickness of the filter screen, the guide rail groove and the gap is limited, and thus the filter screen can be inserted into the guide rails conveniently.

Owner:GUANGDONG KELON AIR CONDITIONER

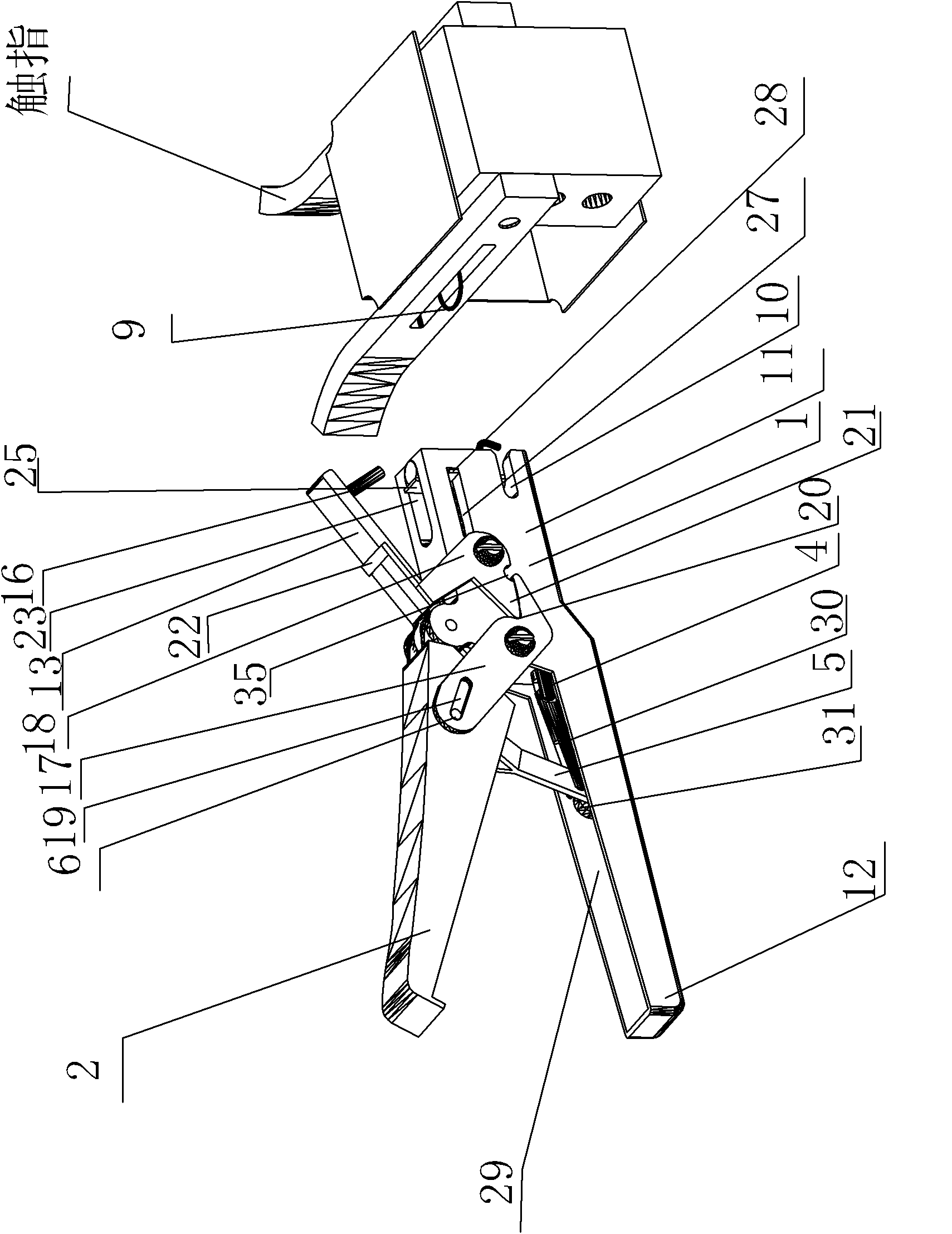

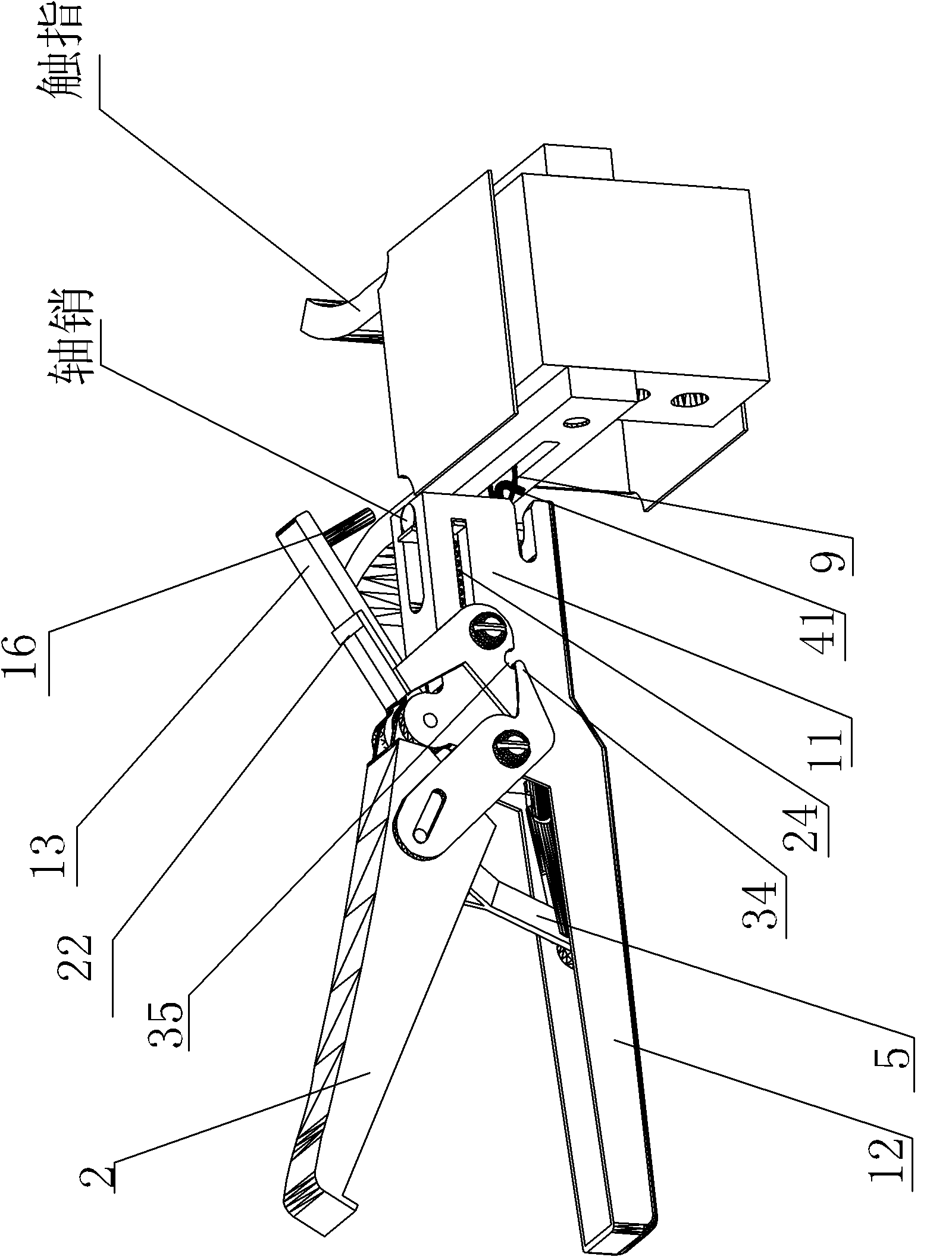

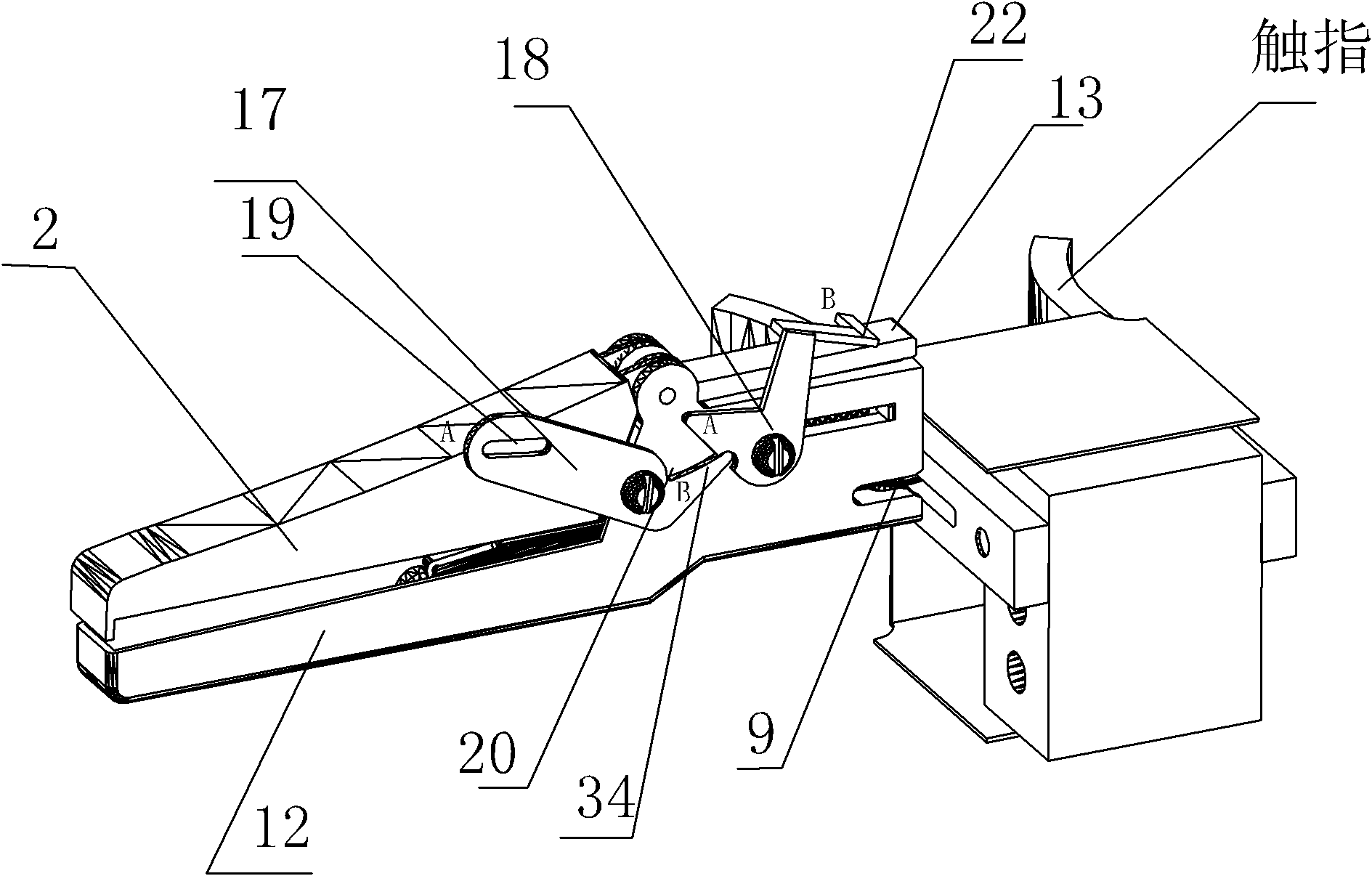

Contact-finger installing tool for high-voltage isolating switch

InactiveCN102074396ADestruction will notEasy to operateElectric switchesEngineeringMechanical engineering

The invention discloses a contact-finger installing tool for a high-voltage isolating switch, wherein a transverse passage is arranged in the lower part of an installing part, a connecting rod is arranged in the transverse passage, a hook is arranged at the front end of the connecting rod, the hook extends out of the front end of the installing part, the rear end of the connecting rod is connected with a hand-pressing handle through an inclined rod, a shaft-pin passage which is vertical to the transverse passage is arranged at the front end of the installing part, a pin outlet is arranged at the lower part at the front end of the installing part, the pin outlet is communicated with the shaft-pin passage, the pin outlet is communicated with the transverse passage, an open slot which can beused for containing the end part of a contact-finger stretched spring is arranged at the front end at the lower part of the installing part, the upper end of the installing part is in shaft connection with a pressure plate, a second reset spring is arranged between the pressure plate and the installing part, a column body for downwards pushing and pressing a shaft pin is arranged at the front endof the pressure plate, and a pushing and pressing mechanism is arranged between the pressure plate and the hand-pressing handle. The invention has the advantages that when the installing tool is operated, the hand-pressing handle only needs to be pressed to pull out the contact-finger stretched spring, meanwhile, the shaft pin is nailed into the end hole of the contact-finger stretched spring, and the installing tool is quite convenient to operate.

Owner:NINGBO ELECTRIC POWER BUREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com