Demoulding conversion apparatus and integrated candy moulding and packaging machine thereof

A conversion device and an all-in-one machine technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increased production costs, reliance on labor, and failure to realize the all-in-one machine design to achieve the effect of ensuring the accuracy of the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

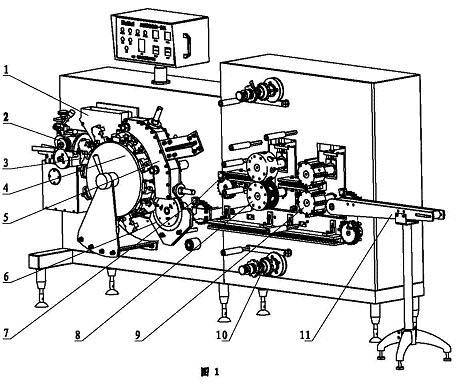

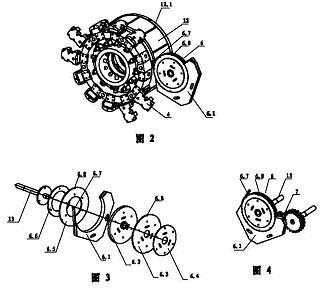

[0016] exist figure 1 , figure 2 , image 3 and Figure 4 In the illustrated demoulding conversion device 6 and the integrated candy forming and packaging machine to which the demoulding conversion device 6 is applied, the molding device comprising the molding die 4 and the transporting rod roller 12 is rotatably connected to the machine body. The molding area on the upper right of the device is fixedly equipped with an elastic pressure device including an arc-shaped pressure block 5, which can keep the candy forming cavity closed when the candy is formed, ensuring that the candy can be stably formed and obtained beautiful appearance. The stick bucket 1 is arranged at the upper left side of the molding device transport stick cylinder 12 with a gap, and the stick bucket 1 can be used to hold the sugar rod stick, and provides the sugar handle for the craft candy during work. The front body of the forming die 4 is provided with a feeding wheel 2, and a cutting knife 3 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com