Cylindrical battery

A technology of cylindrical batteries and cells, which is applied to battery components, circuits, electrical components, etc., can solve the problems of battery short circuit, battery capacity drop, and easy misalignment, etc., and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

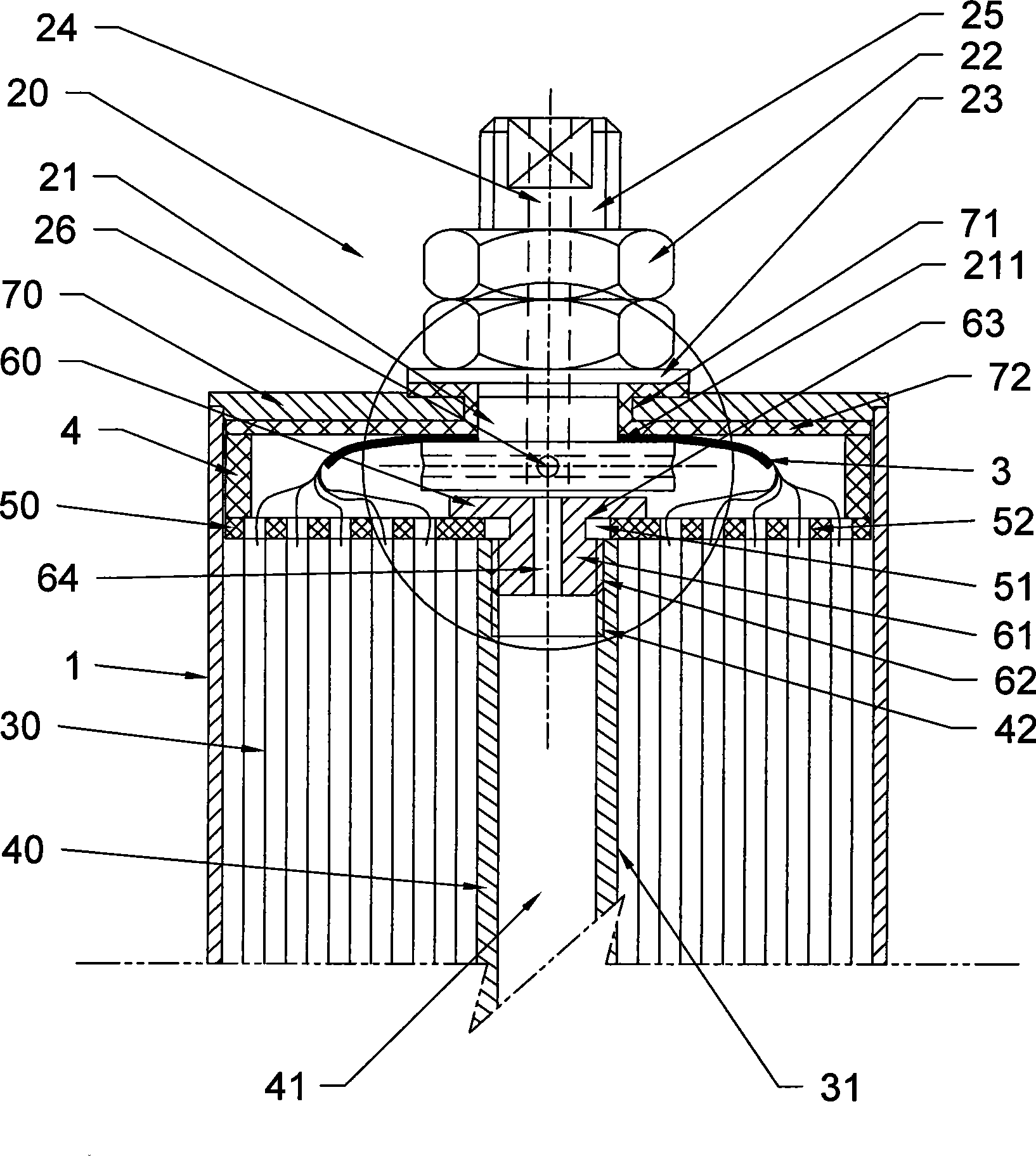

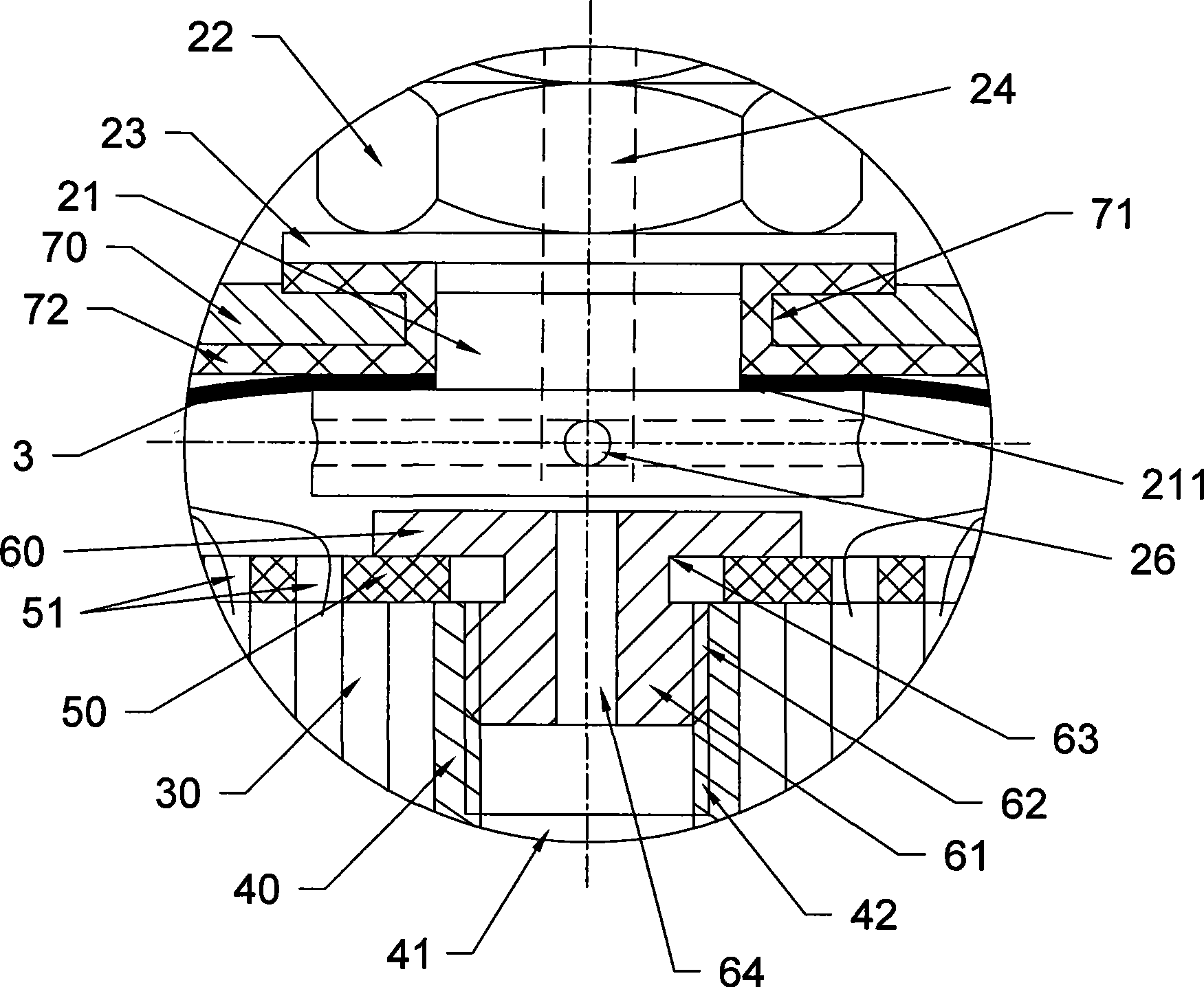

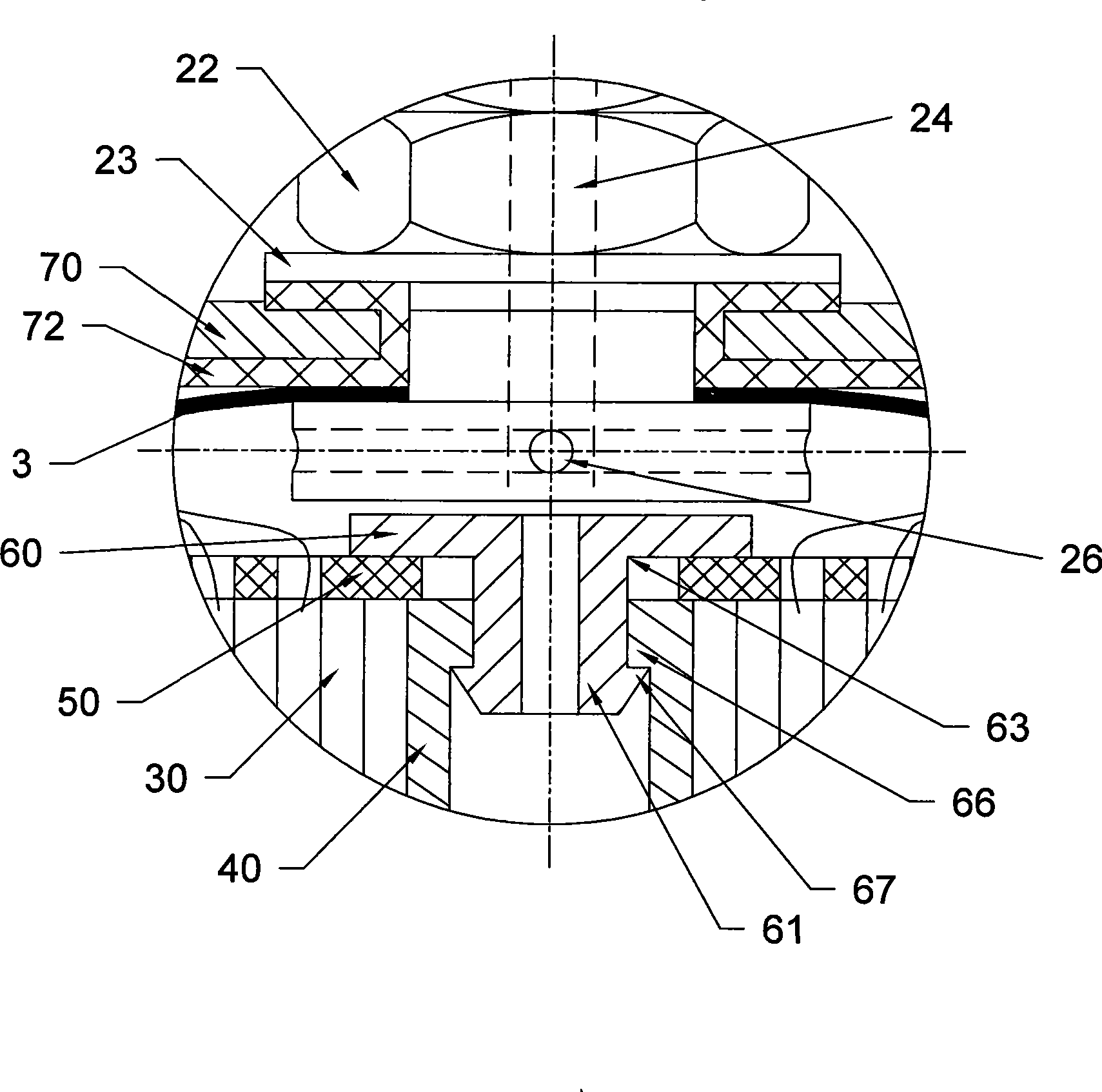

[0020] Such as figure 1 , 2 As shown, in a preferred embodiment of the cylindrical battery of the present invention, a casing 1 is included. The opening end of the casing 1 is provided with a sealing cover 70, and the casing 1 is provided with a battery core 30. Wherein, the casing 1 may be open at both ends, or may be open at one end, and the sealing cover 70 is sealed and arranged at the opening of the casing 1.

[0021] A winding needle 40 is provided in the reel hole 31 in the battery core 30. The winding needle 40 is preferably arranged in a hollow tube shape with a through hole 41 in the center. The through hole 41 is located at both ends of the winding needle 40 and is provided with internal threads 42 . The two ends of the battery core 30 are provided with spacers 50, the spacer 50 is provided with a central hole 51 facing the battery reel hole 31, and a fixed cover 60 is provided in the central hole 51, and the fixed cover 60 passes through the central hole 51 The insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com