Laminated battery cell forming system

A laminated battery cell technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low film production efficiency, easy to pull the diaphragm, and the tension of the isolation diaphragm, so as to improve the pass rate and improve Improvement of sheet production efficiency and molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

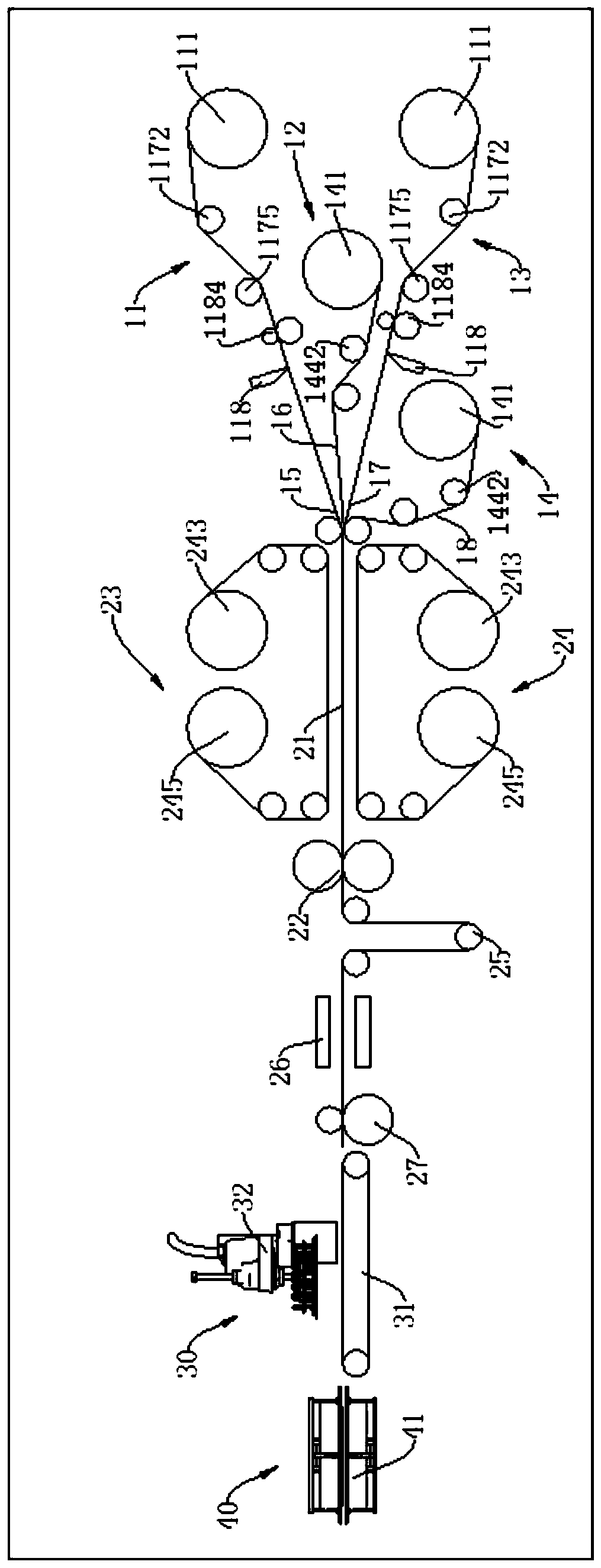

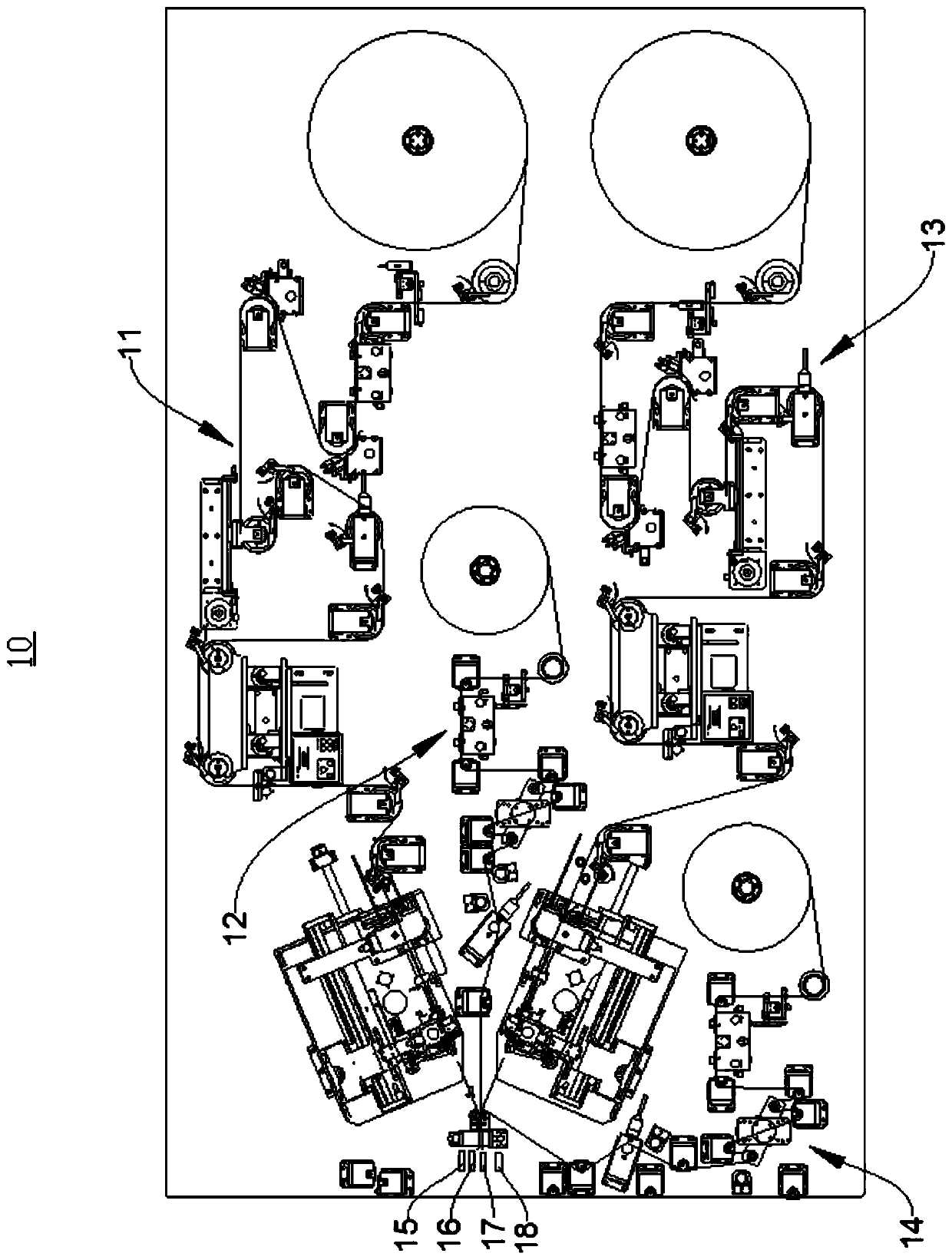

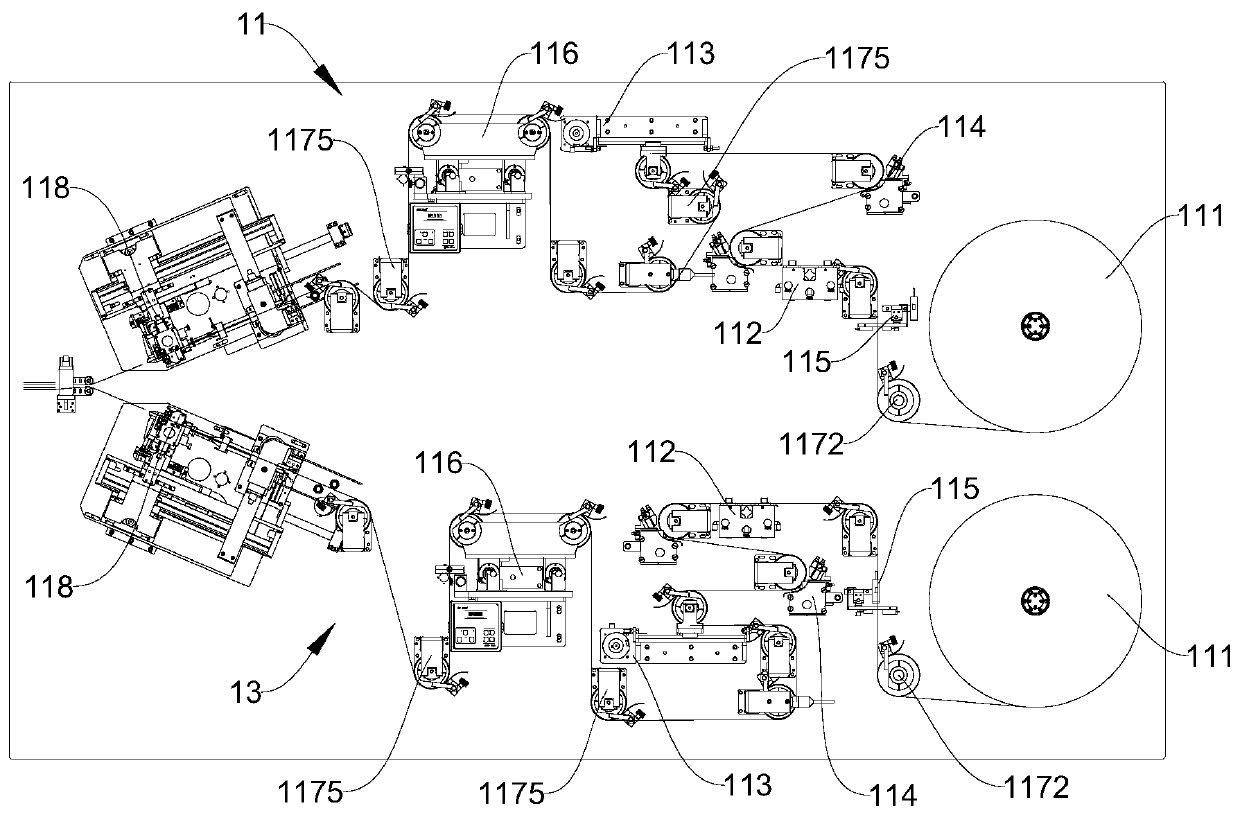

[0044] figure 1 For the overall flow diagram of the laminated cell forming system provided by the embodiment of the present invention, please refer to figure 1 shown.

[0045] The laminated cell forming system provided by the embodiment of the present invention includes a sheet making device 10, a thermal lamination device 20, a lamination device 30, and a thermal pressing device 40, which are used for thermal compound cutting and lamination in the manufacturing process of lithium power battery packs. The battery forming method of the process.

[0046] Wherein, the sheet making device 10 is in the process of cutting off the pole piece through the pole piece cutting mechanism 118 in the first pole piece making equipment 11 and the pole piece cutting mechanism 118 in the second pole piece making equipment 13. The film belt always keeps running at a constant speed, which greatly improves the production efficiency. The thermal lamination device 20 is used to heat and roll the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com