Novel foam moulding machine as well as cooling method thereof

A molding machine and foam technology, applied in the field of foam molding equipment, can solve the problems of increased energy consumption, inability to adapt, poor cooling effect, etc., and achieve the effects of improving service life, ensuring normal operation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

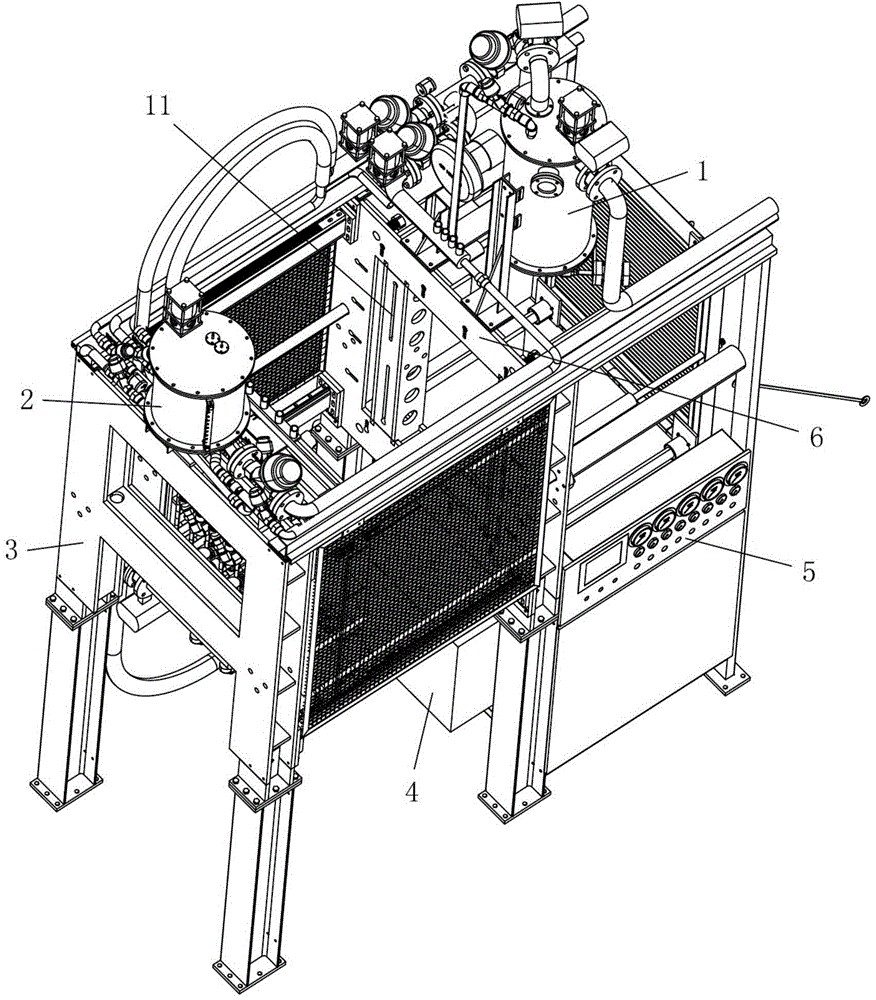

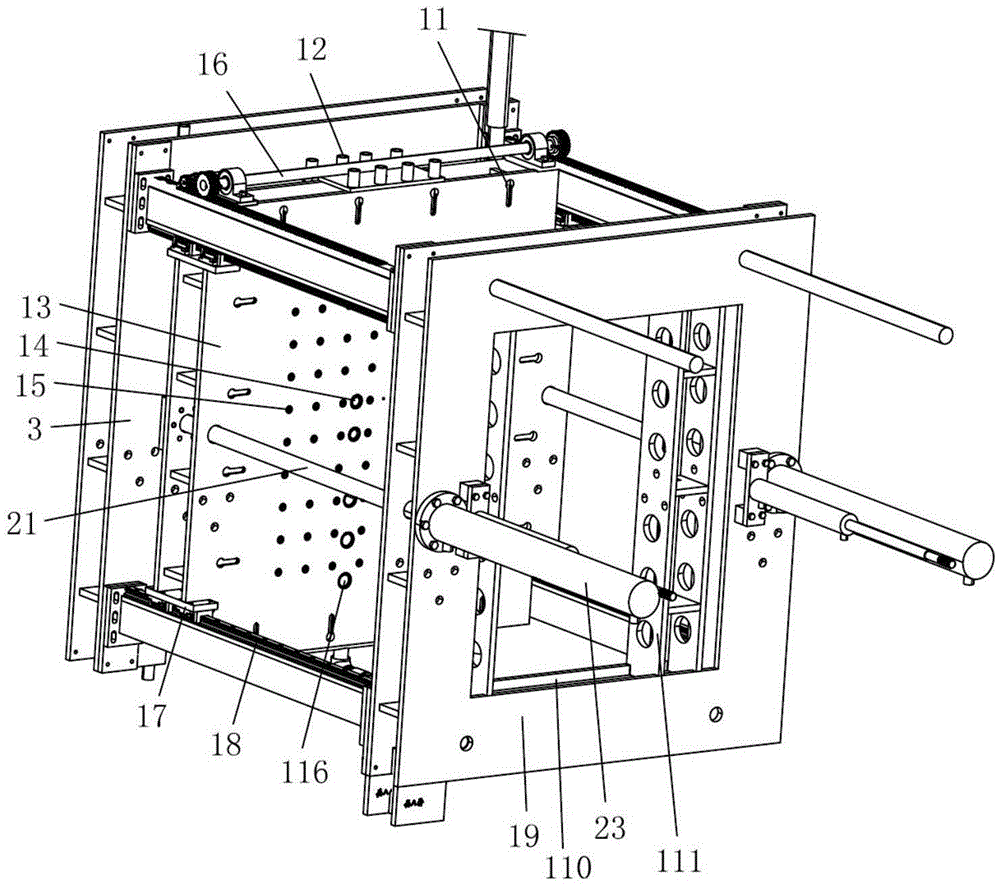

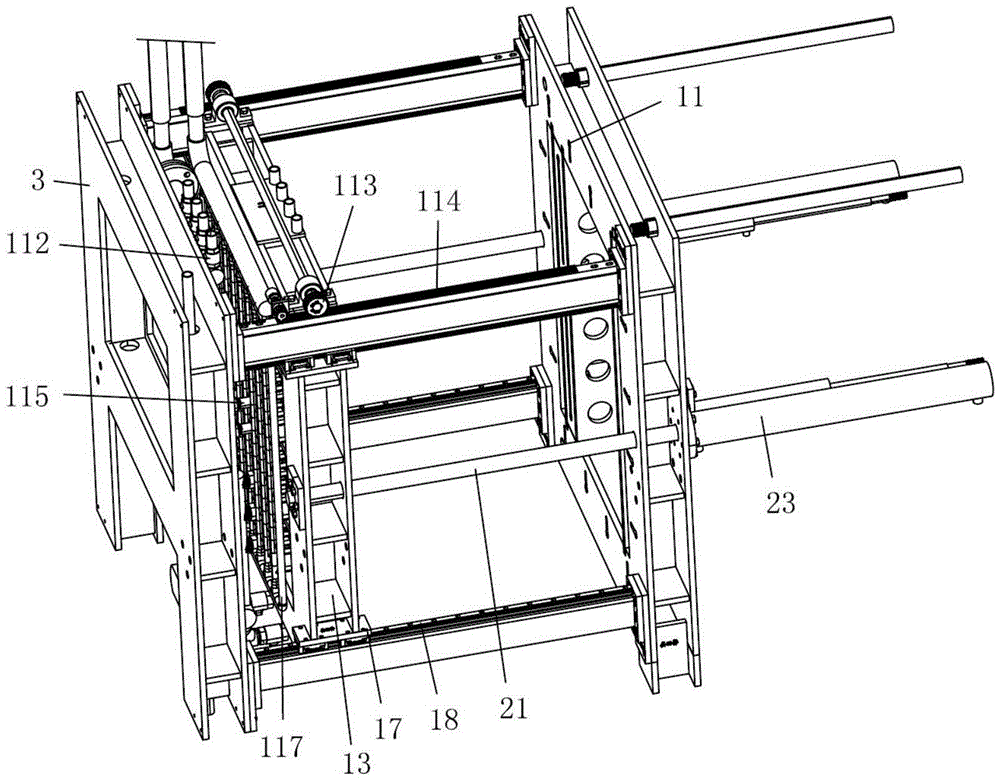

[0065] A new type of foam forming machine, equipped with an electrical automation control system 5, a pipeline system, a hydraulic system, a feeding system 1, a steam heating system, a cooling system, a mold installation mechanism and a demoulding mechanism on the frame, the The mold installation mechanism includes a solid template 19 and a movable template 13, and an oil cylinder 23 drives the movable template 13 to move left and right on the frame 3. The fixed template 19 is a frame, and a horizontal chute 110 is arranged in the frame, and the middle part of the frame is set There is a positioning bracket 111 that can move along the horizontal chute; the right side of the moving template 13, the left side of the positioning bracket 111, and the left side of the solid template 19 are all provided with mold mounting holes 11; when the mold volume is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com