Contact-finger installing tool for high-voltage isolating switch

A technology of isolating switches and installation tools, applied in electrical switches, circuits, electrical components, etc., can solve the problems of low work efficiency, injury of electric workers, insufficient safety, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

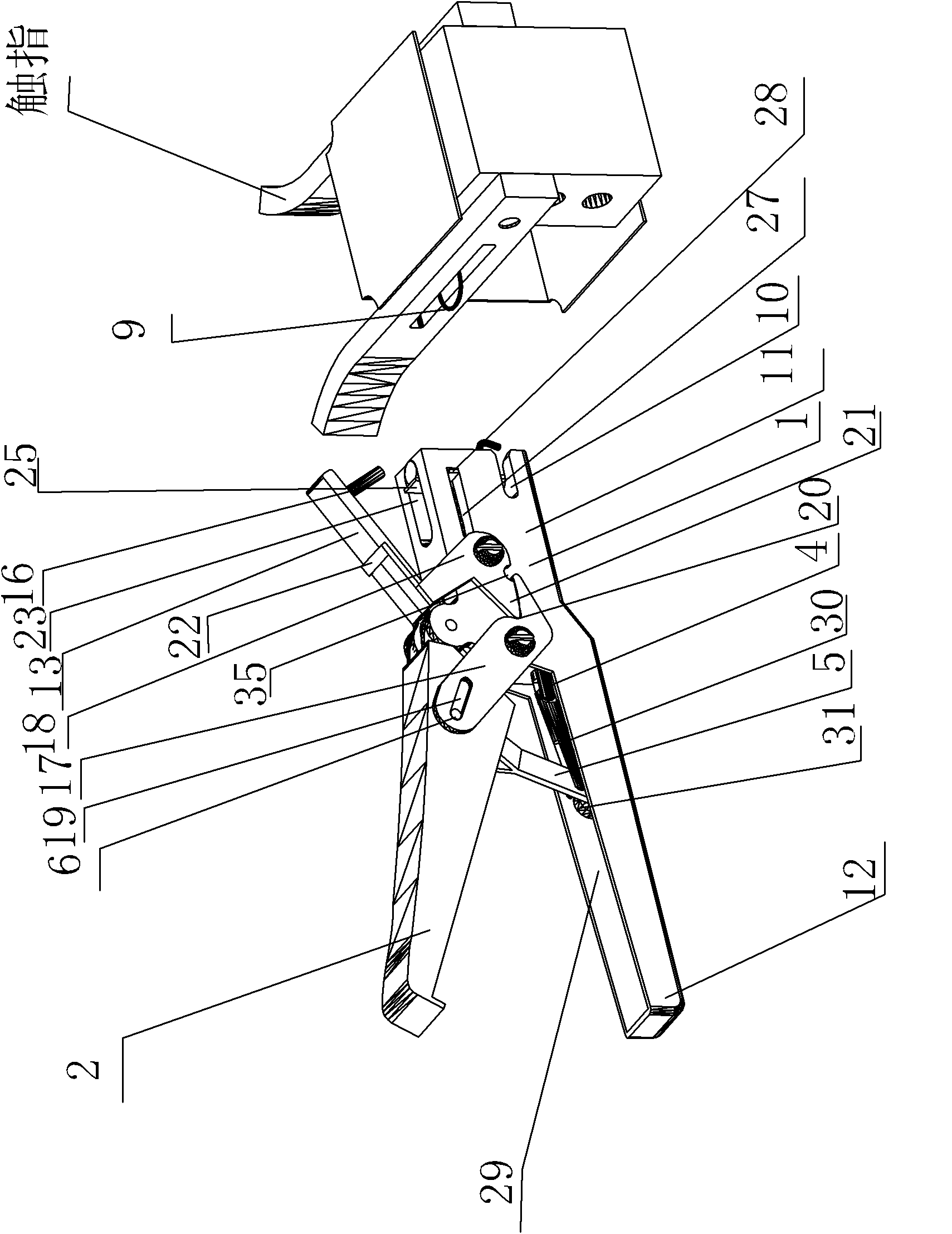

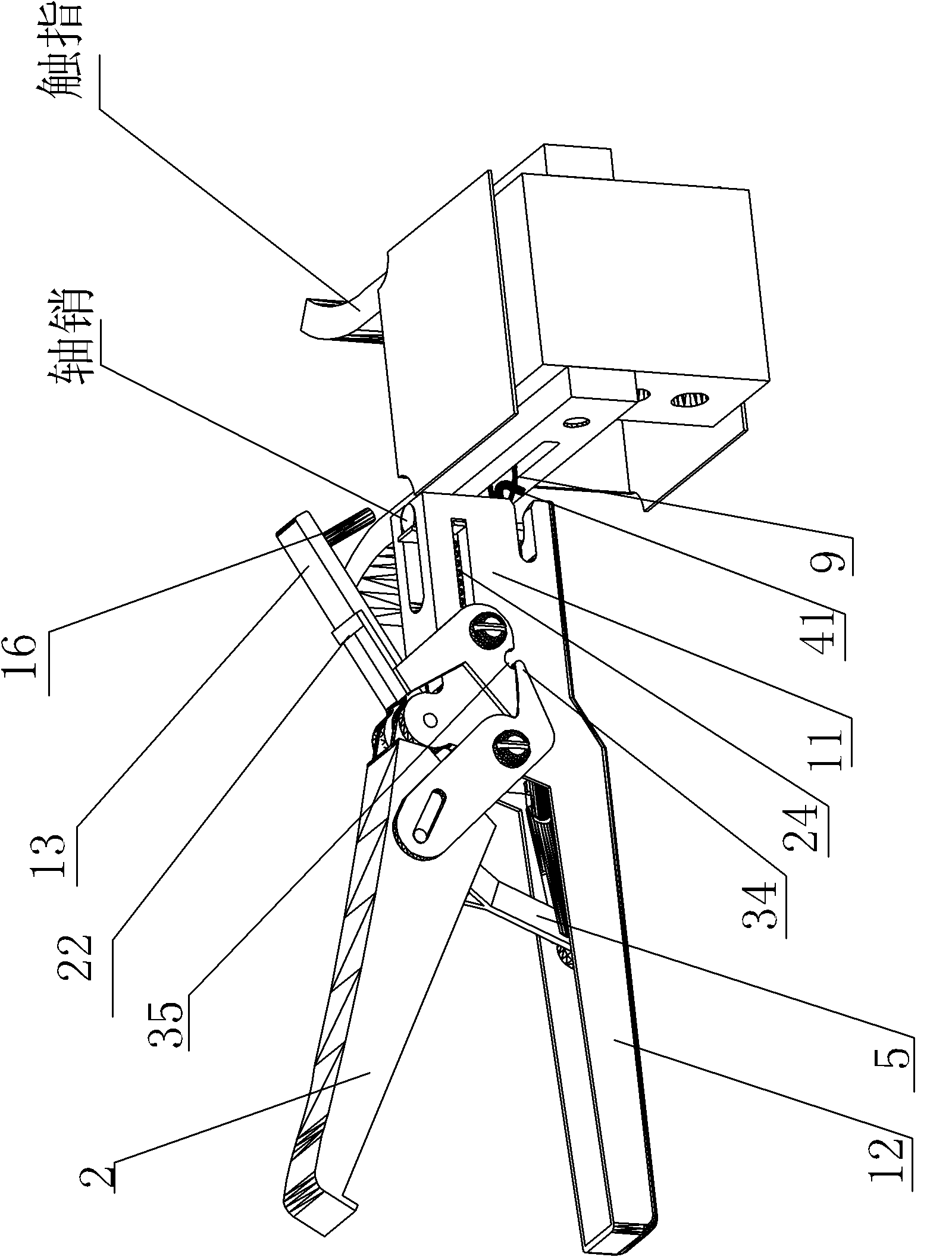

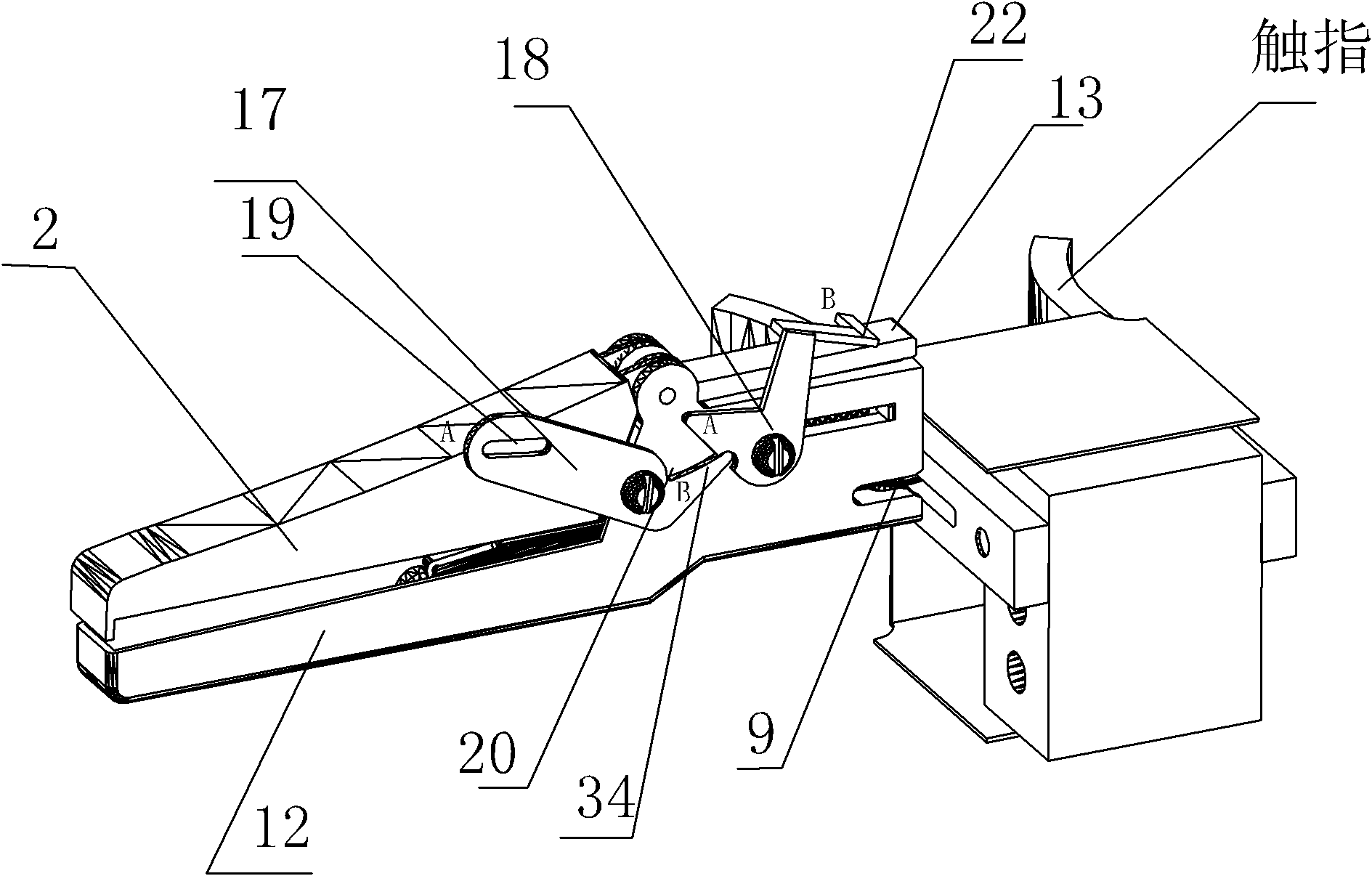

[0030] Embodiment 1: A contact finger installation tool for a high-voltage isolating switch, including a main body 1 and a hand pressing handle 2. The main body 1 includes a mounting part 11 and a fixed handle 12 extending from the rear end of the mounting part 11. The hand pressing handle 2 is axially connected to the At the rear end of the installation part 11, the hand pressure handle 2 is located above the fixed handle 12,

[0031] The lower part of the mounting part 11 is provided with a transverse channel 3, and the transverse channel 3 is provided with a connecting rod 4. The front end of the connecting rod 4 is provided with a hook 41, and the hook 41 stretches out from the front end of the mounting part 11. The rear end of the connecting rod 4 passes through the inclined The rod 5 is connected with the hand pressure handle 2, one end of the oblique rod 5 is axially connected to the hand pressure handle 2 through the first connecting shaft 6, the other end of the obliqu...

Embodiment 2

[0041] Embodiment 2: The other parts are the same as Embodiment 1, the difference is that the connecting rod 4 is connected with an adapter rod 30 , and the inclined rod 5 is axially connected with the transfer rod 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com