Suspended ceiling light steel subsidiary keel and method of assembling suspended ceiling light steel subsidiary keel in special-shaped suspended ceiling

A technology of auxiliary keel and light steel, applied in the field of keel, can solve the problems of inability to achieve rapid installation, weak installation, poor positioning, etc., and achieve the effect of being conducive to firm engagement, good positioning effect, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

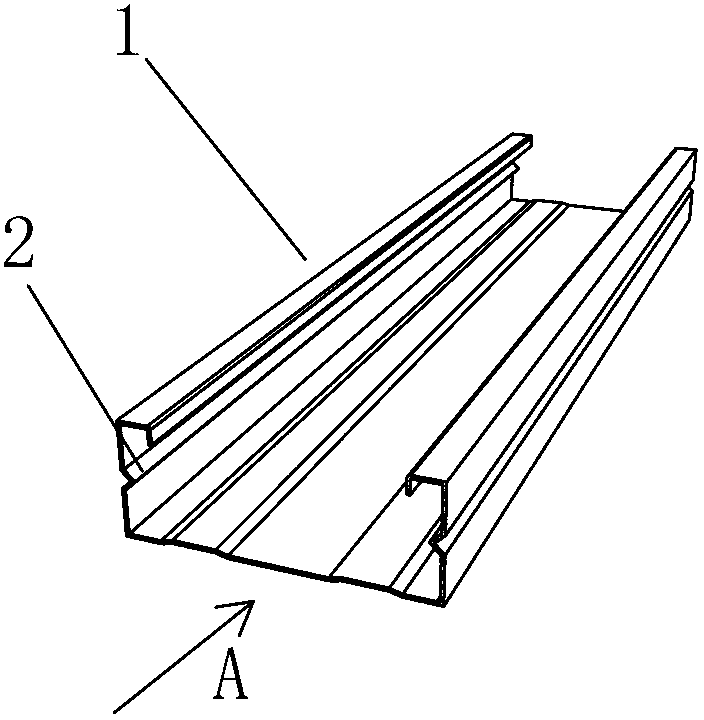

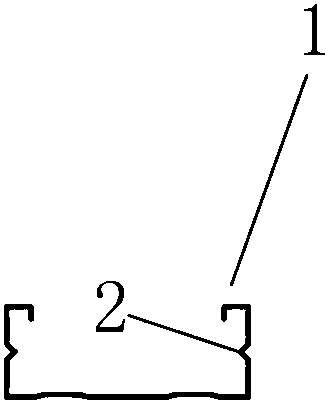

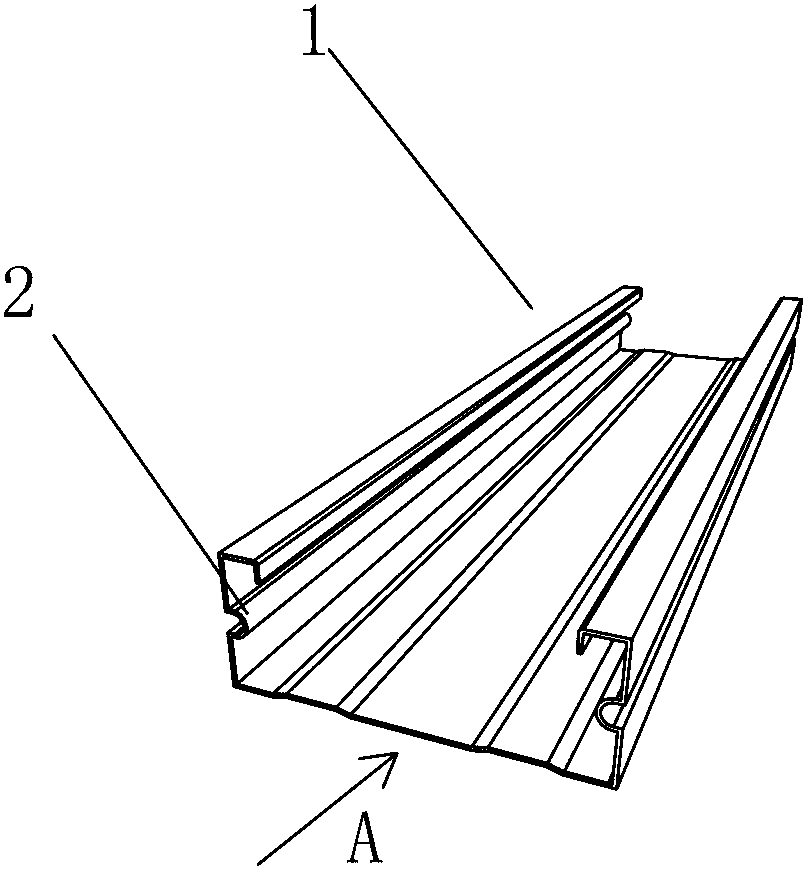

[0033] Such as Figure 1-Figure 6 As shown, the present invention is a light steel auxiliary keel for a suspended ceiling, which is mainly used in special-shaped suspended ceilings. The two side walls of the light steel auxiliary keel 1 for the suspended ceiling each have a grooved rib 2 for positioning. Groove rib 2 is for positioning when the light steel sub-keel of the suspended ceiling is connected with other parts to be connected.

[0034] When assembling, a connecting piece is used, and the connecting piece has corresponding strip grooves adapted to the grooved bars of the light steel auxiliary keel of the suspended ceiling, so as to realize positioning.

[0035] Compared with the previous method of directly achieving plane contact on the plane side wall by means of screws or the like, the present invention obviously has a better positioning effect, is more accurate and faster, and greatly improves the construction speed. It is worth mentioning that the light steel sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com