Printer and method for replacing plate cylinder thereof

A printing plate cylinder and printing device technology, which is applied to printing, printing machines, rotary printing machines, etc., and can solve problems such as cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

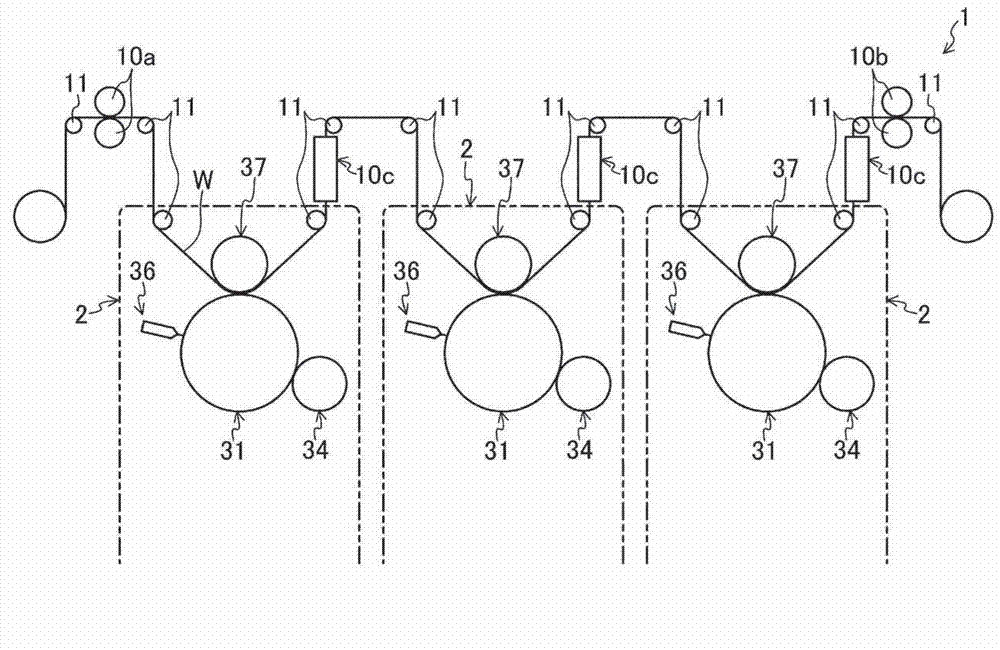

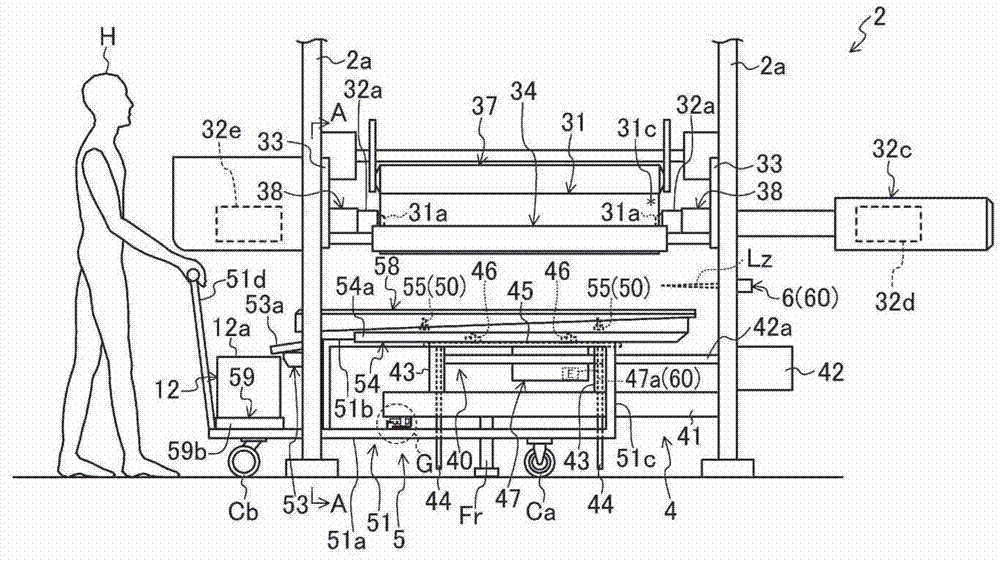

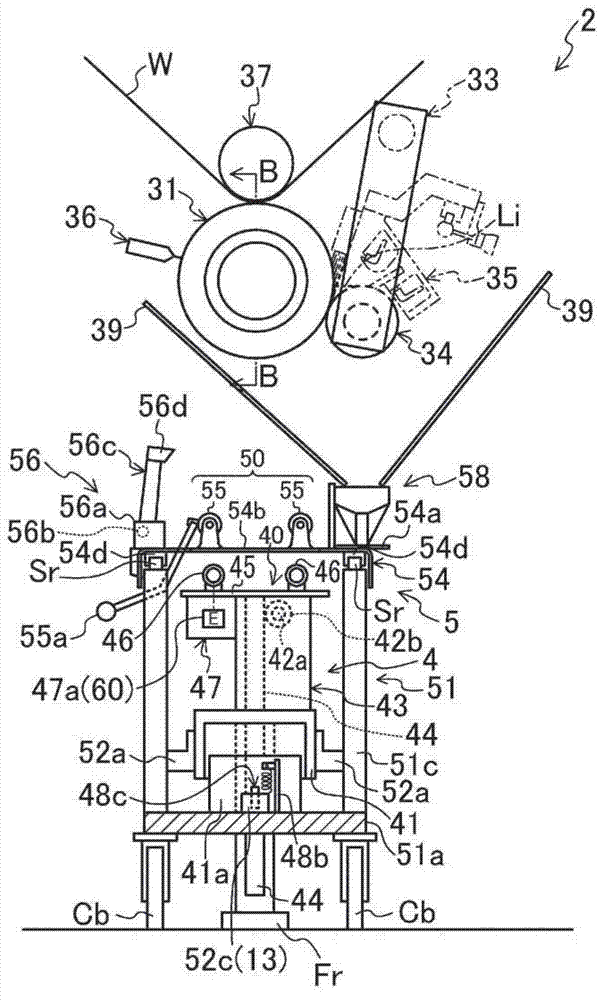

[0085] figure 1 The printing device 1 according to the first embodiment of the present invention is shown. This printing device 1 includes: a printing unit 2 that supports a printing plate cylinder 31 that transfers ink or the like to a substrate W such as a plastic film and allows the printing plate cylinder 31 to rotate; The bottom of the unit 2 or the cart 5 that is moved out from the bottom of the printing unit 2 (refer to figure 2 and image 3 ). There are three printing units 2 arranged side by side.

[0086] exist figure 1 The upper left side of the paper surface is provided with a delivery roller 10a that sends out the printed material W. On the other hand, on the figure 1 A winding roller 10b for winding up the substrate W is provided on the upper right side of the paper. A plurality of guide rollers 11 are provided between the delivery roller 10a and the take-up roller 10b, and the printed material W is wound on each of the guide rollers 11 and conveyed while ...

no. 2 approach )

[0220] Figure 20 A printing device 1 according to a second embodiment of the present invention is shown. The difference between this second embodiment and the first embodiment is only as follows: the printing unit 2 is one, and when the printing plate cylinder 31 is replaced, the printing plate cylinder 31 is supported by the two vertical frames 2a to be able to rotate, and then The registration mark 31c is positioned relative to the substrate W and printing is started. Other points are the same as the first embodiment. Therefore, the detailed description will be omitted below.

[0221] Therefore, according to the second embodiment of the present invention, even if there is only one printing unit 2, it is possible to know in advance what is required to position the printing plate cylinder 31 in the state where the printing plate cylinder 31 has been loaded on the cart 5. For the position data of the registration mark 31c, the time spent from pushing the trolley 5 to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com