System of classifying/receiving work and method of classifying/receiving the same

A workpiece and storage box technology, applied in sorting, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of reduced operation rate, mixed electronic parts, long time, etc., to achieve short mechanical stop time and improve operation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

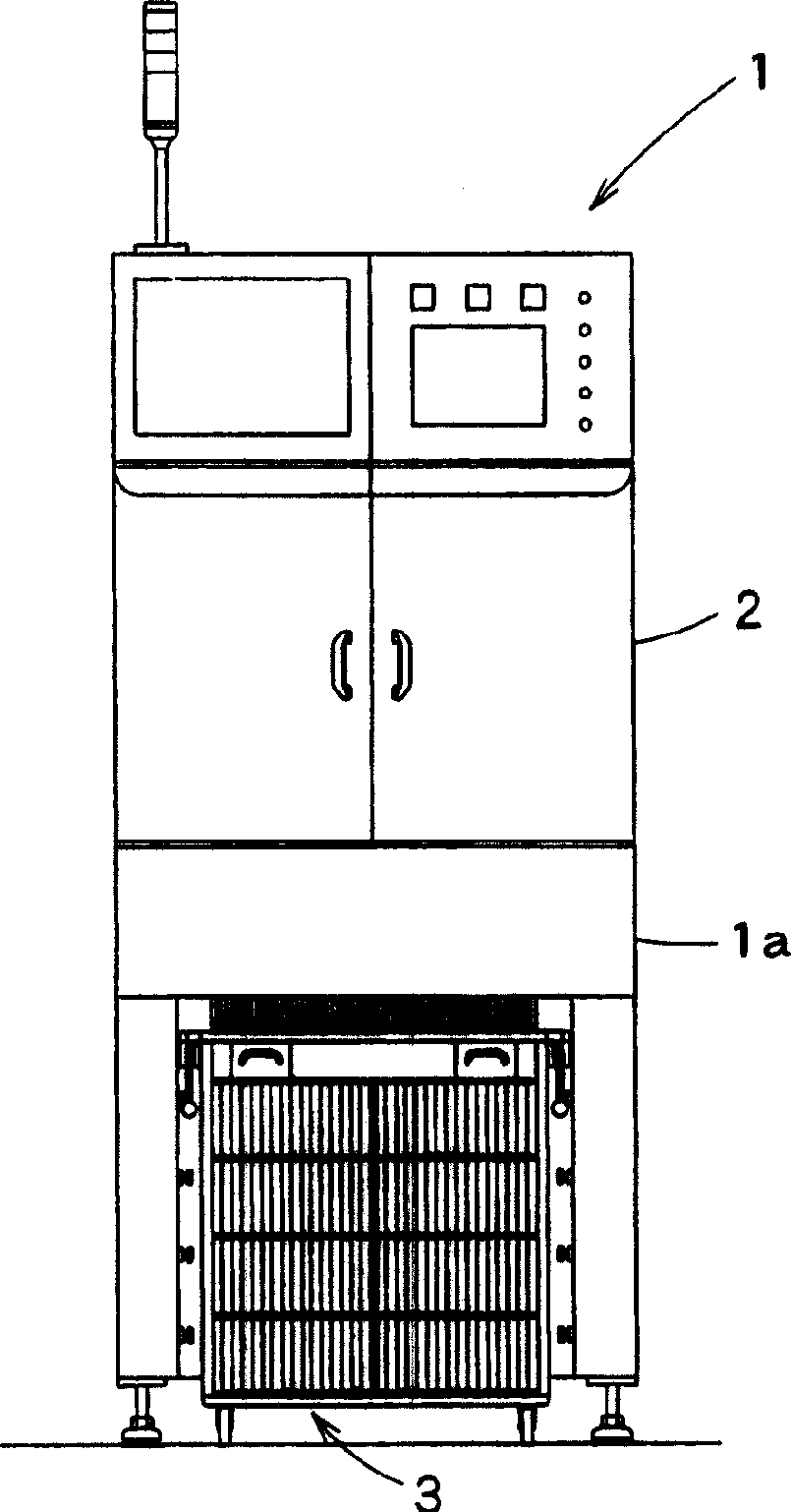

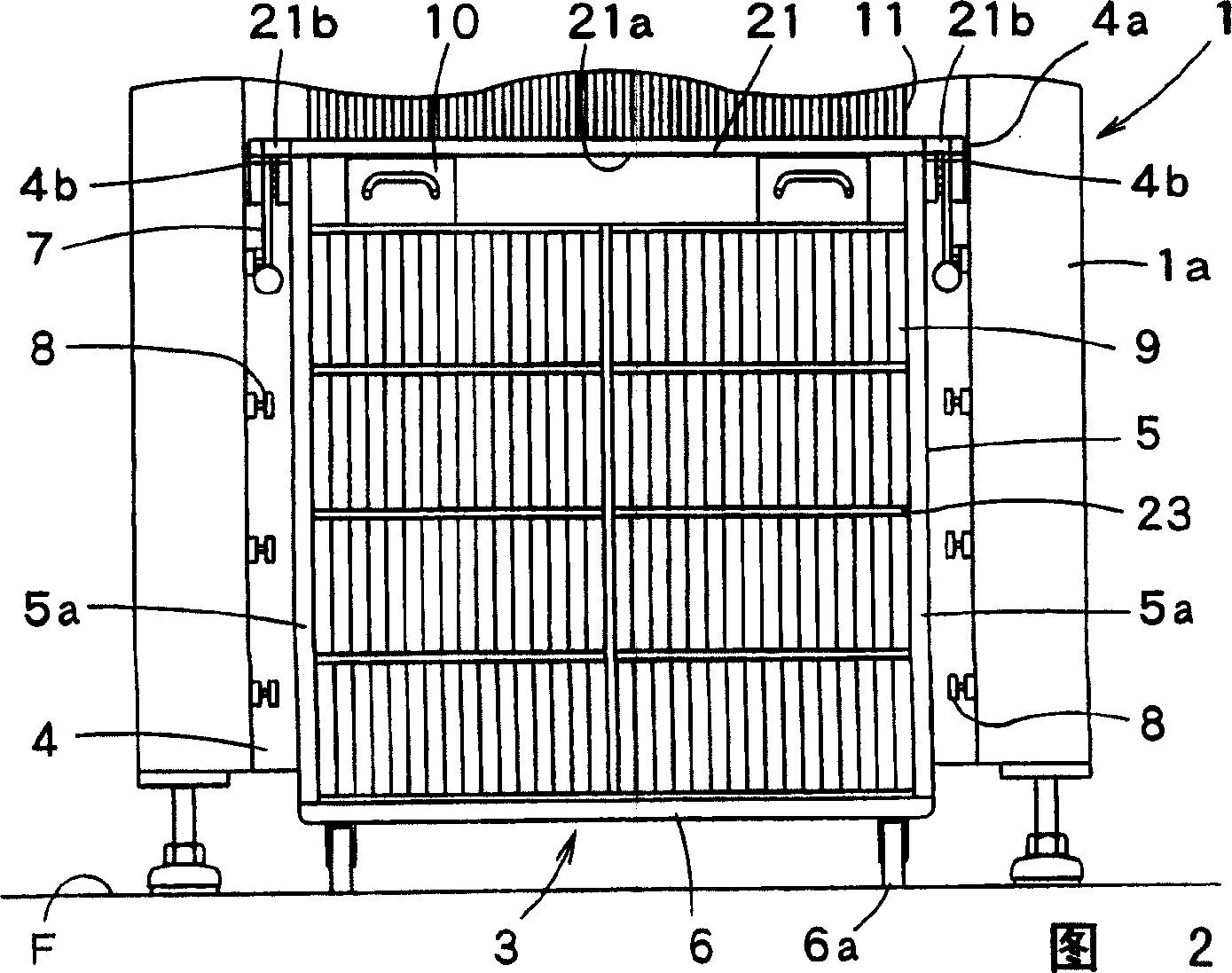

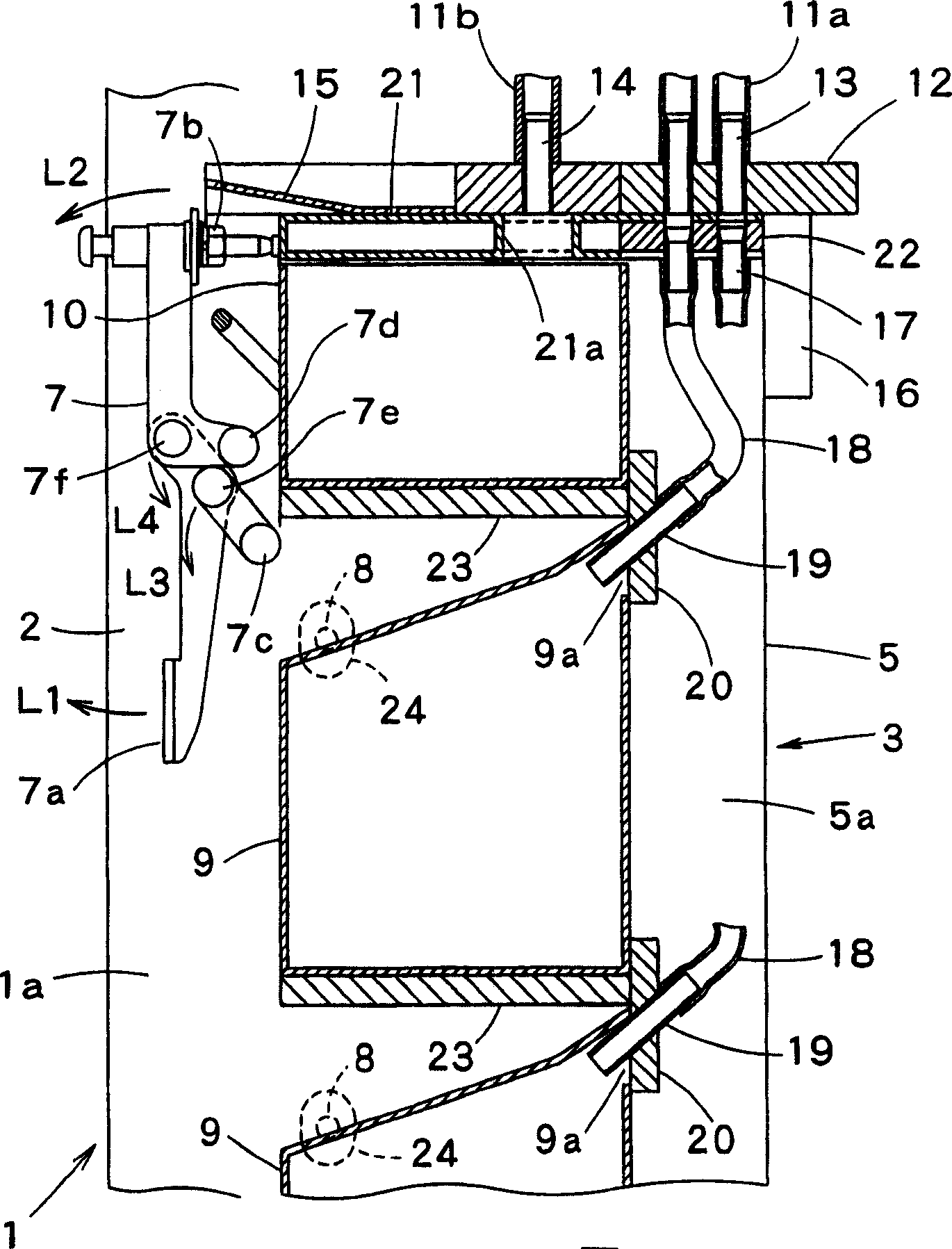

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 1 ~ Figure 4 It is a figure which shows 1st Embodiment of the workpiece sorting storage system and the sorting storage method of this invention.

[0036] Such as figure 1 As shown, the workpiece classification and storage system 1 includes: a frame body 1a; a classification device 2, which is arranged in the frame body 1a, and classifies chip-like electronic parts (workpieces) according to their electrical characteristics; a storage device 3, which is freely mounted on the storage device In the housing part 4, the housing device housing part 4 is provided at the lower part of the frame main body 1a.

[0037] Among them, the storage device 3 has a rack 5, a plurality of parts storage boxes 9 for storing sorted parts, and a discharge product storage box 10 for storing out-of-standard parts. In addition, the stand 5 has side plates 5a, a top plate 21, and shelves ...

no. 2 Embodiment approach

[0056] Next, according to Figure 5 ~ Figure 10 , the second embodiment of the workpiece sorting storage system and the sorting storage method of the present invention will be described.

[0057] Figure 5 ~ Figure 10 In the shown second embodiment, on the side opposite to the stopper 16 of the frame main body 1a, instead of the clamp 7, a clamp (hinge clamp) 27 for positioning in the front-rear direction and the up-down direction is provided, and the others are the same as Figure 1 ~ Figure 4 The first embodiment shown is substantially the same.

[0058] about Figure 5 ~ Figure 10 In the second embodiment shown, for the Figure 1 ~ Figure 4 The same reference numerals are assigned to the same parts as those in the first embodiment shown, and detailed description thereof will be omitted.

[0059] Such as Figure 5 ~ Figure 10 As shown, a clamp 27 is provided on the surface of the frame main body 1 a opposite to the stopper 16 .

[0060] The jig 27 has a support portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com