Direct current vibration motor

A technology of DC motors and vibrating motors, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as environmental protection, high noise, and large air consumption, and achieve the effects of mission improvement, low noise, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

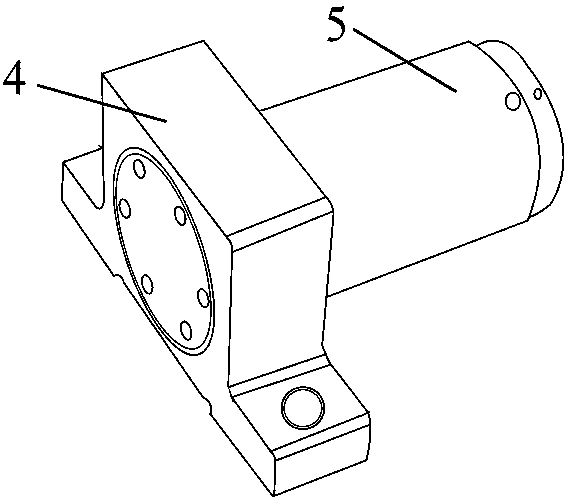

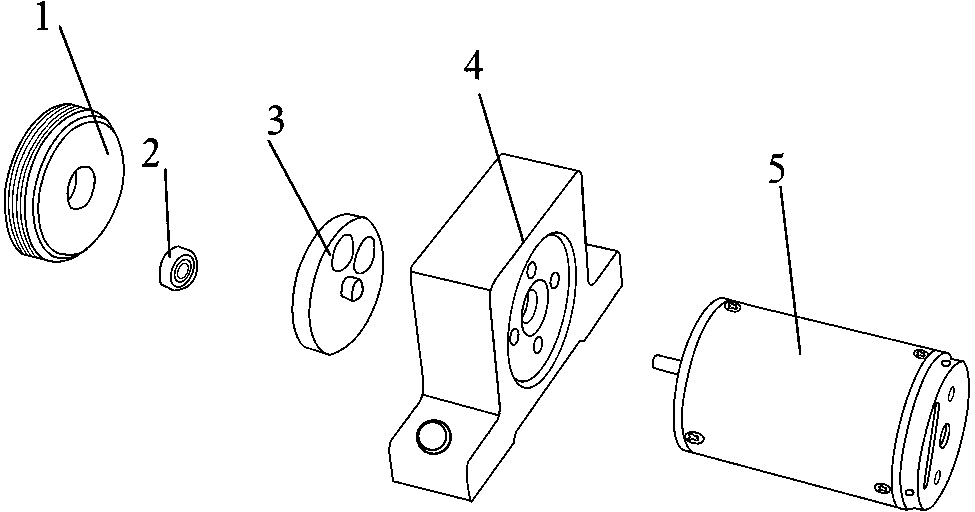

[0010] As shown in the figure: a DC vibration motor, characterized in that: the vibration motor is composed of a base body 4, a DC motor 5, an eccentric block 3, a left threaded end cover 1 and a bearing 2, and the DC motor 5 is connected with a screw The seat body 4 is fixed together, the eccentric block 3 is assembled on the 5-axis of the DC motor, and fixed with screws at the same time, and then connected with the 5-axis of the DC motor through the bearing 2 in the left internal thread end cover 1 to form a whole, when the power supply When the control switch is turned on, the DC motor 5 starts quickly, driving the eccentric block in the seat body 4 to rotate at a high speed, generating strong centrifugal vibration force, and then the vibration energy is transmitted to the required vibration equipment through the seat body 4 . At the same time, the vibration force can be adjusted freely through the digital display controller. In special occasions, when the installation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com