Patents

Literature

71results about How to "Extended mission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

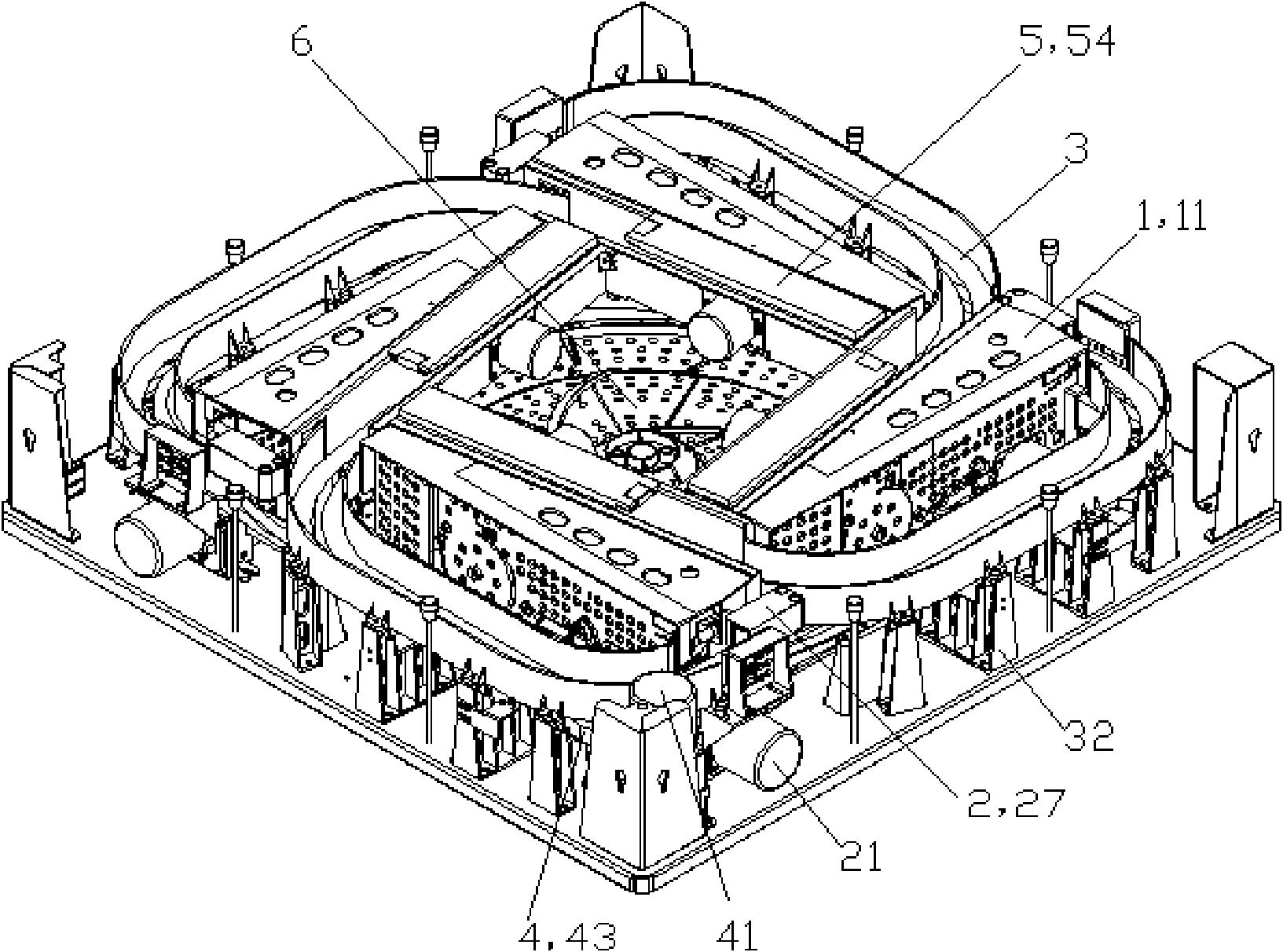

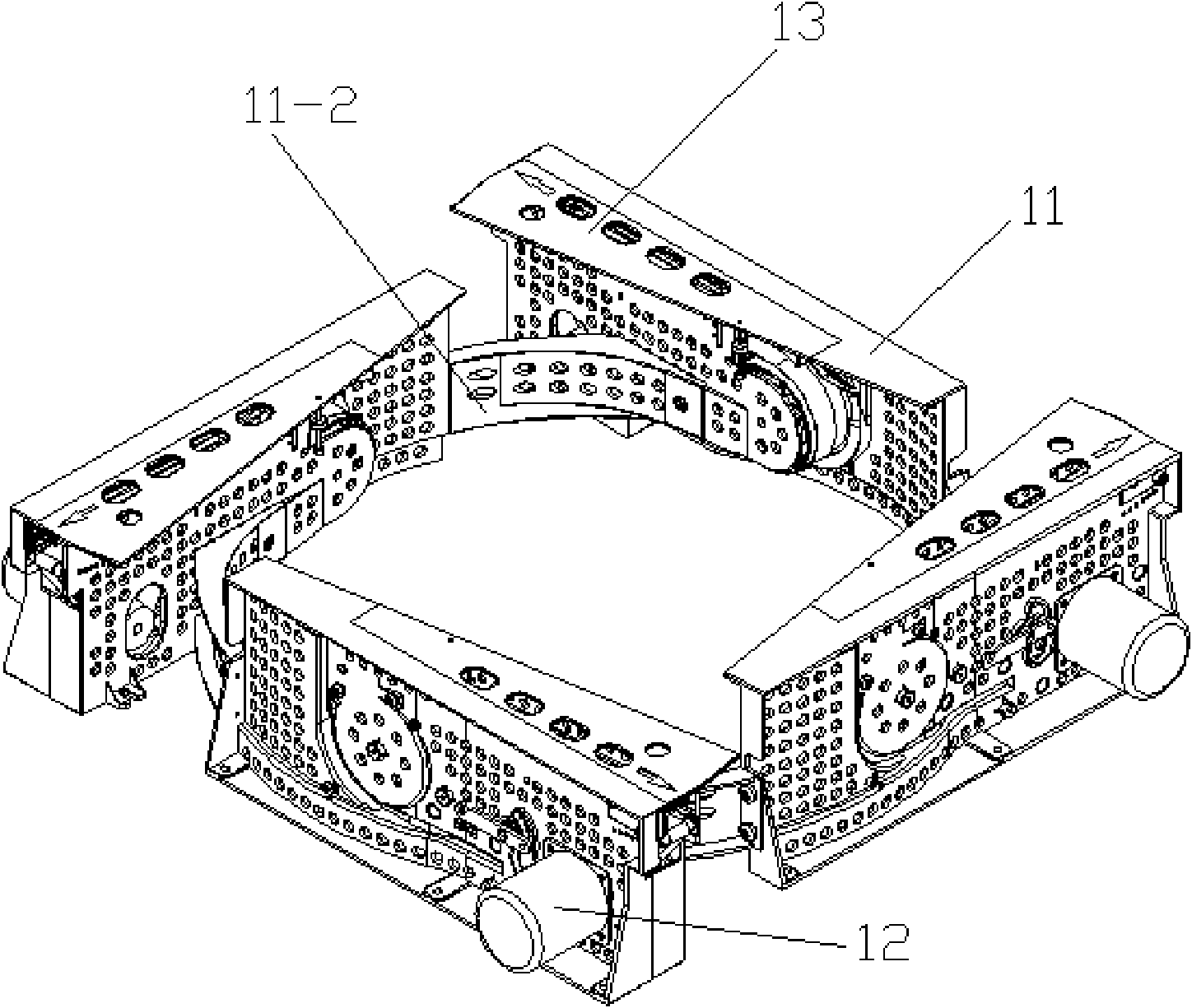

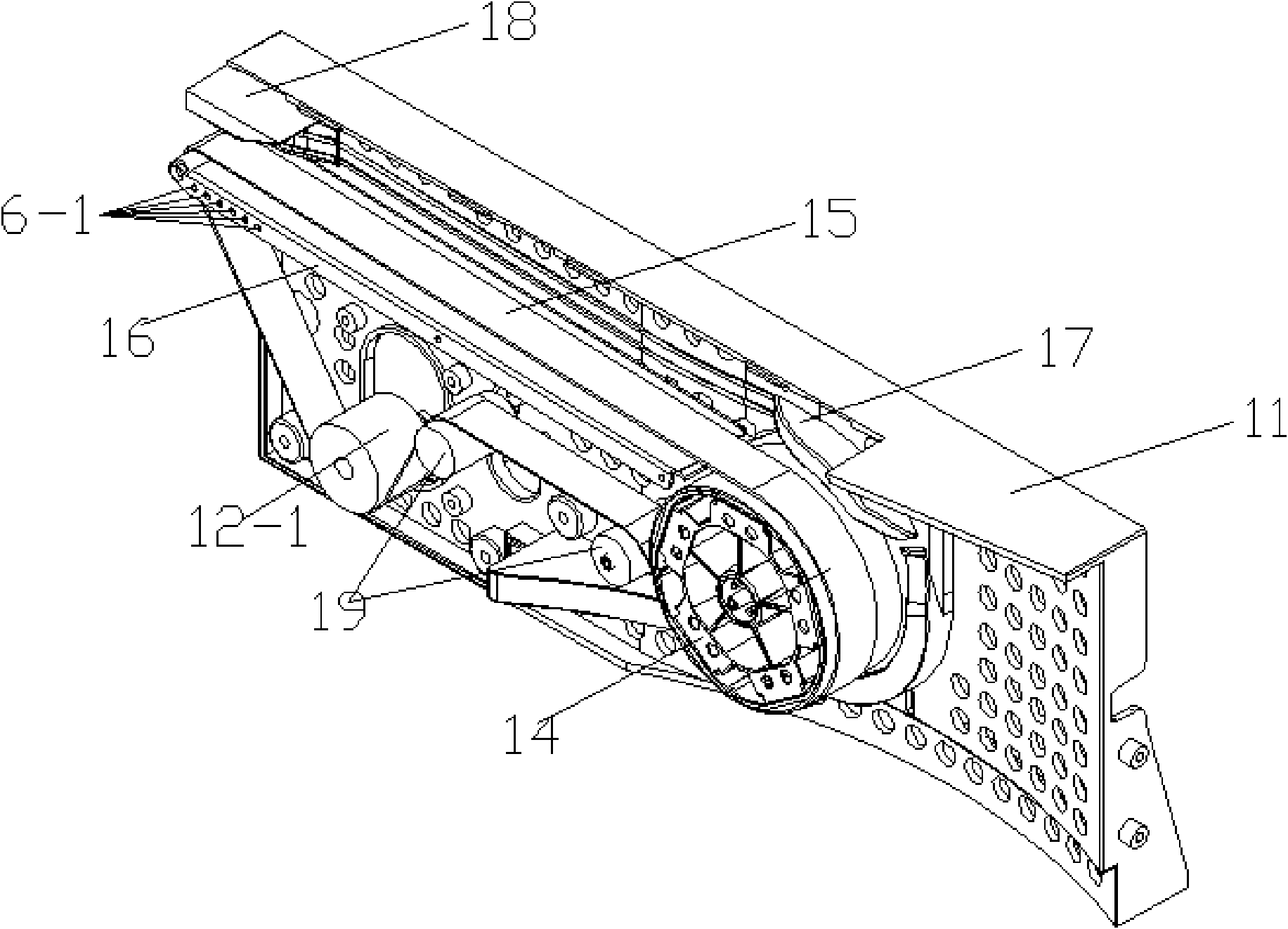

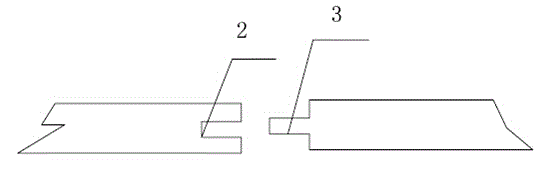

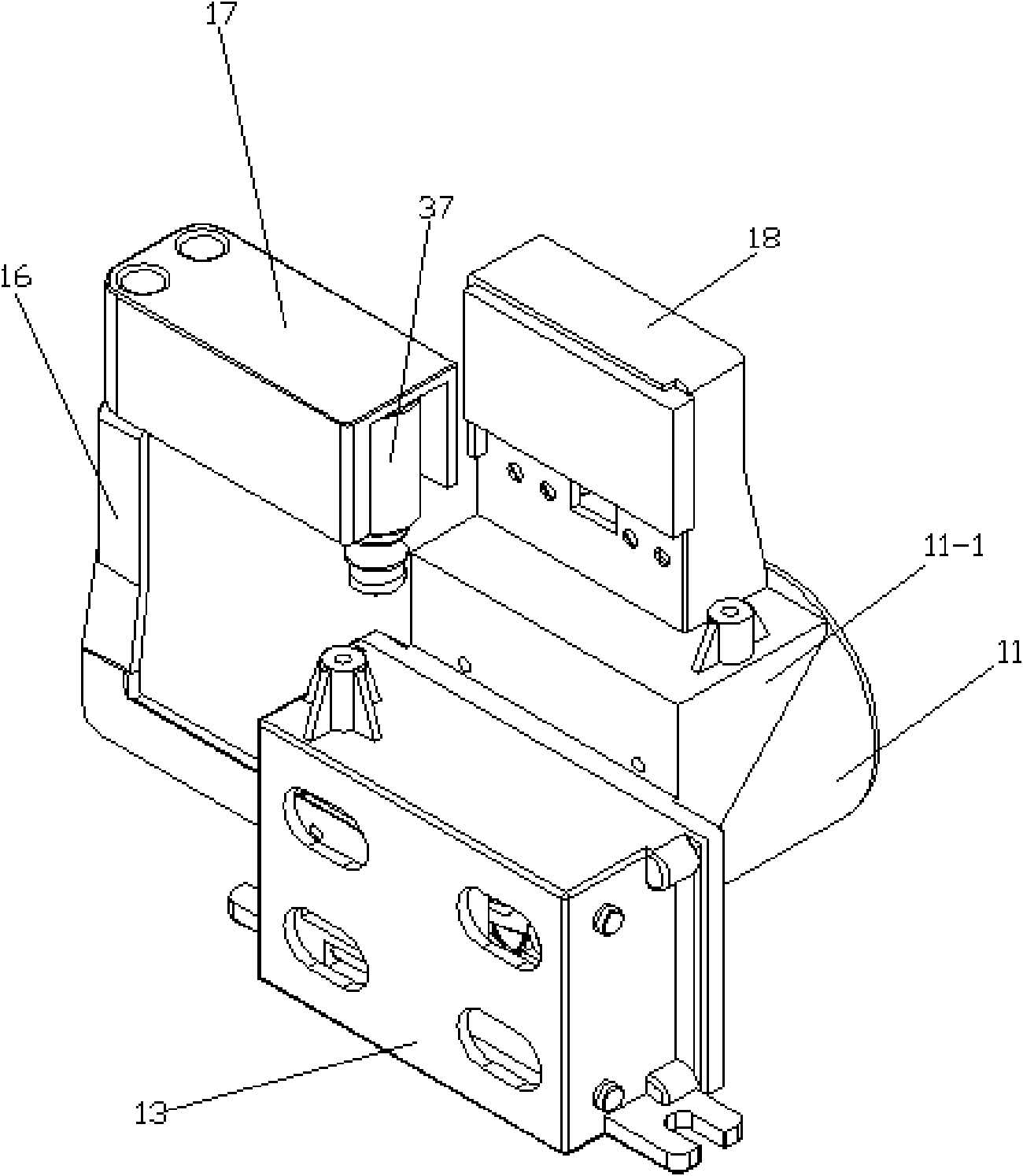

Fully-automatic mahjong machine

InactiveCN102133480AReduce manufacturing costGuaranteed uptimeIndoor gamesInlet channelTransmission belt

The invention relates to a fully-automatic mahjong machine comprising a board sending system, a board loading system, a board lifting system and a large shuffling disc. The board sending system comprises four board sending mechanisms, each board sending mechanism comprises a transmission rack, and a board sending motor, a board absorbing wheel, a transmission belt, a transmission platform, a board inlet guiding piece and a board outlet guiding piece fixed on the transmission rack; a board sending channel is arranged at the upper end of the transmission platform, the board absorbing wheel is tightly attached at the lower end of a board inlet opening of the board sending channel, the board inlet guiding piece is positioned above the board absorbing wheel, the board outlet guiding piece is positioned at a board outlet opening of the board inlet channel, the board sending motor is used for driving a motor guiding wheel, the motor guiding wheel is positioned below the transmission platform, and the transmission belt loops the motor guiding wheel, the board absorbing wheel and the transmission platform. In the invention, for the mahjong boards with different widths, the board sending mechanism of the mahjong machine can run normally by only replacing the corresponding board inlet guiding piece and the board outlet guiding piece, and a transmission rack cover does not need to be changed, so that the operation is simple and convenient, and the board inlet guiding piece and the board outlet guiding piece has extremely low production cost relative to the transmission rack cover.

Owner:程亮星

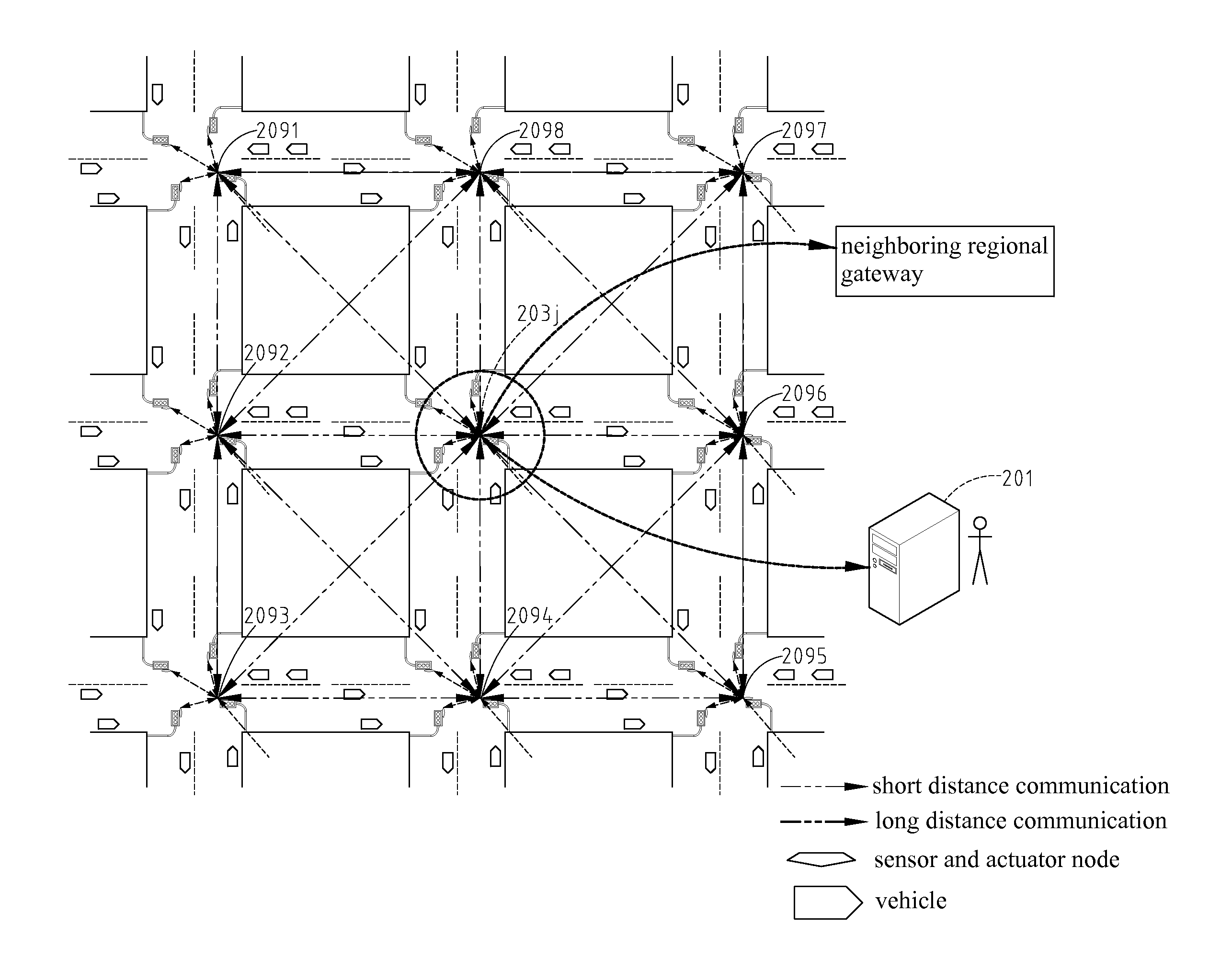

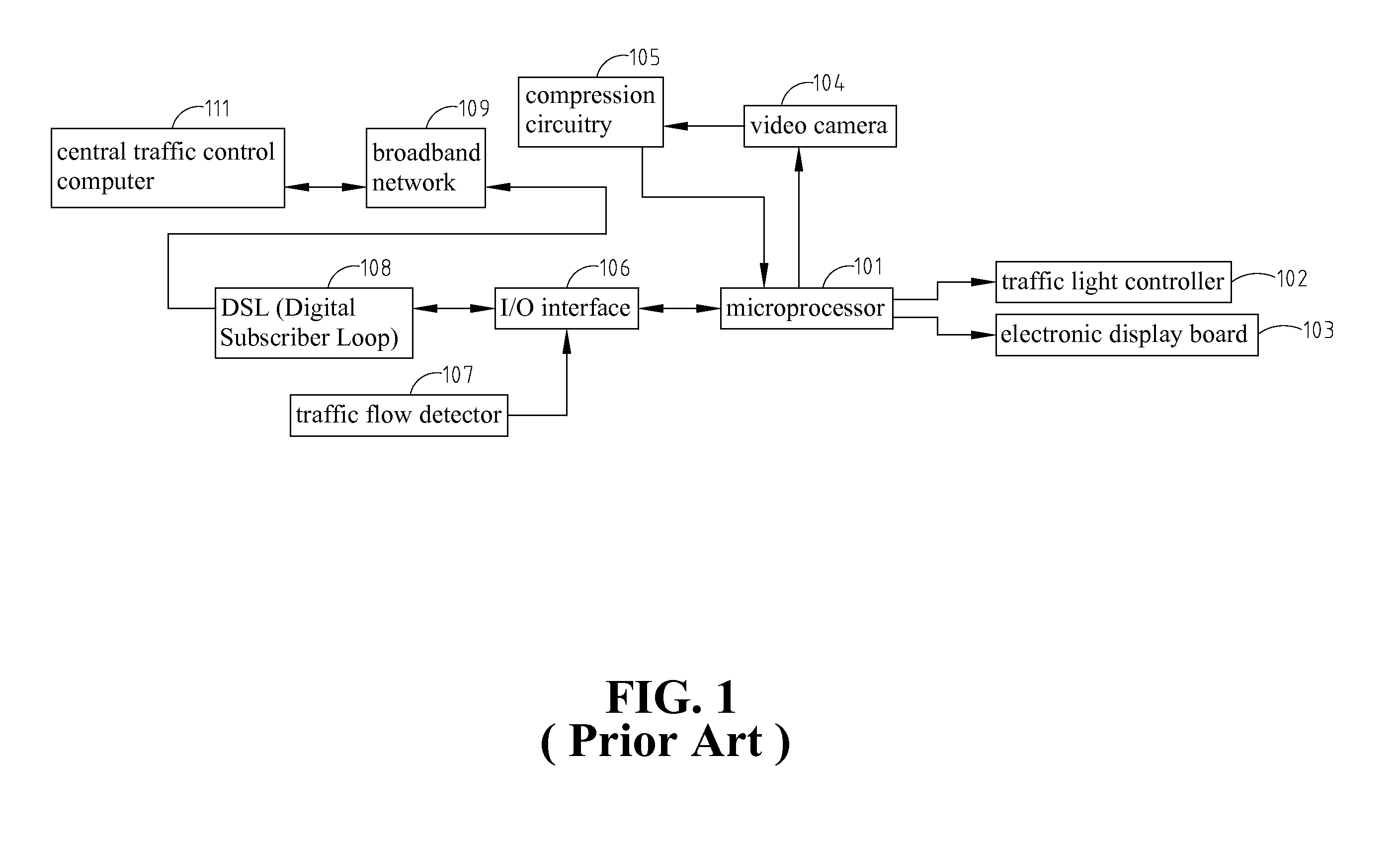

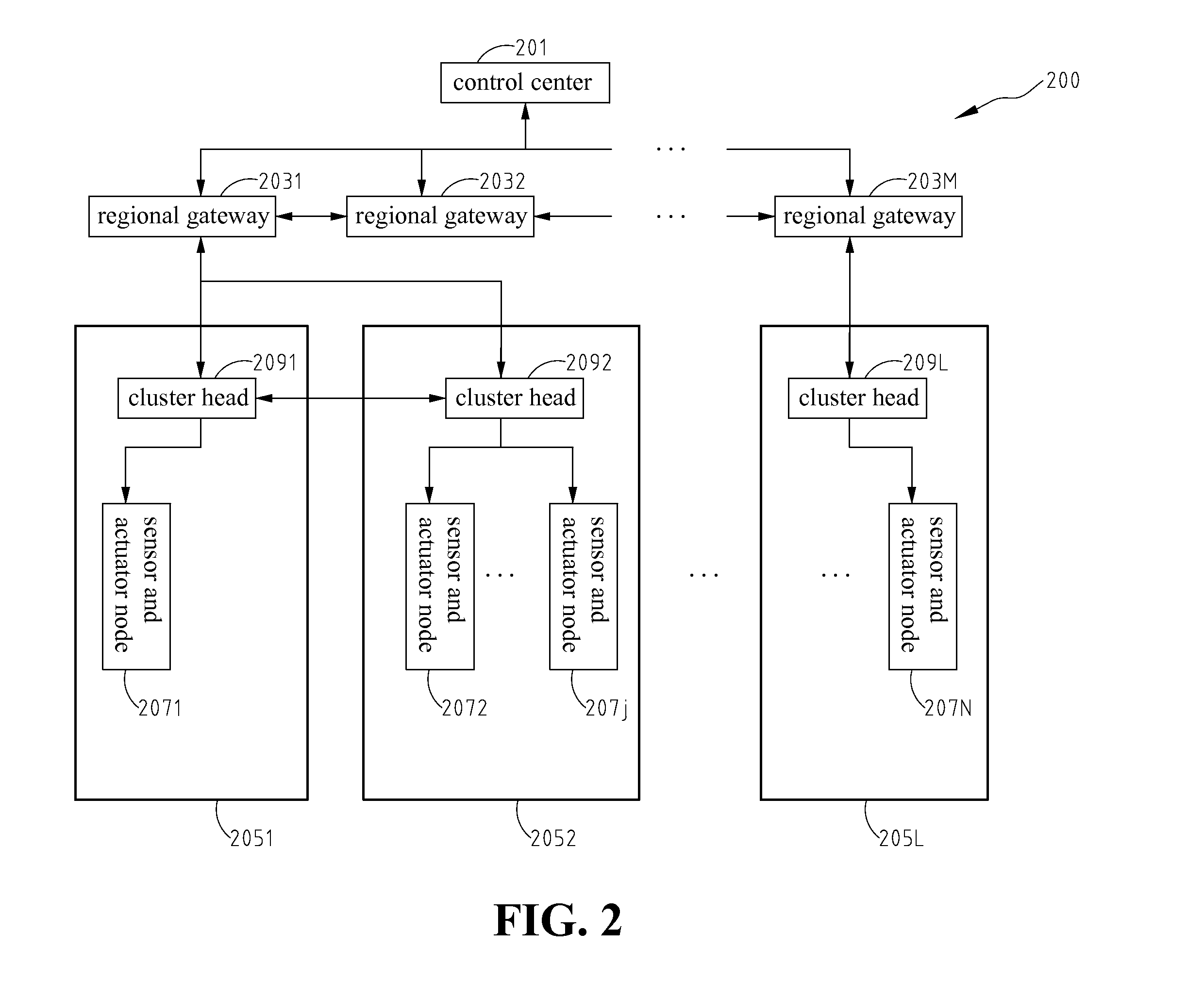

System And Method For Intelligent Traffic Control Using Wireless Sensor And Actuator Networks

InactiveUS20080238720A1Effective traffic light controlImprove communication reliabilityControlling traffic signalsError preventionTraffic capacityLine sensor

Disclosed is a system and method for intelligent traffic control using wireless sensor and actuator networks. The system comprises a control center, M regional gateways, and N sensor and actuator nodes. The N sensor and actuator nodes and L cluster heads form L clusters. Each cluster includes a cluster head and at least a sensor and actuator node. The control center, the M regional gateways, and the N sensor and actuator nodes form a multi-layer structure. Each N sensor and actuator node may real-time detect traffic states, and exchange information with other nodes via a wireless communication having a self-recovery function. The system and method applies a distributed computing strategy to automatically adjust the traffic control on each traffic flow, thereby achieving an efficient traffic control.

Owner:IND TECH RES INST

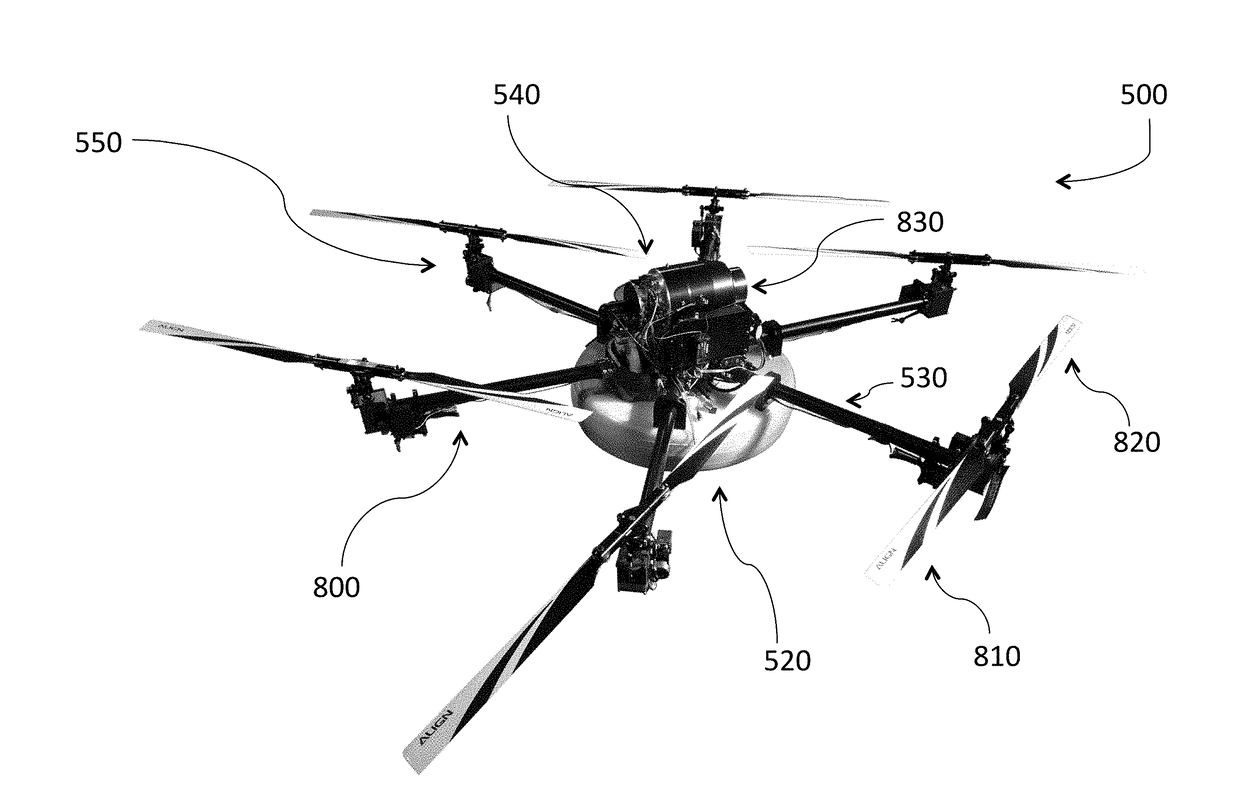

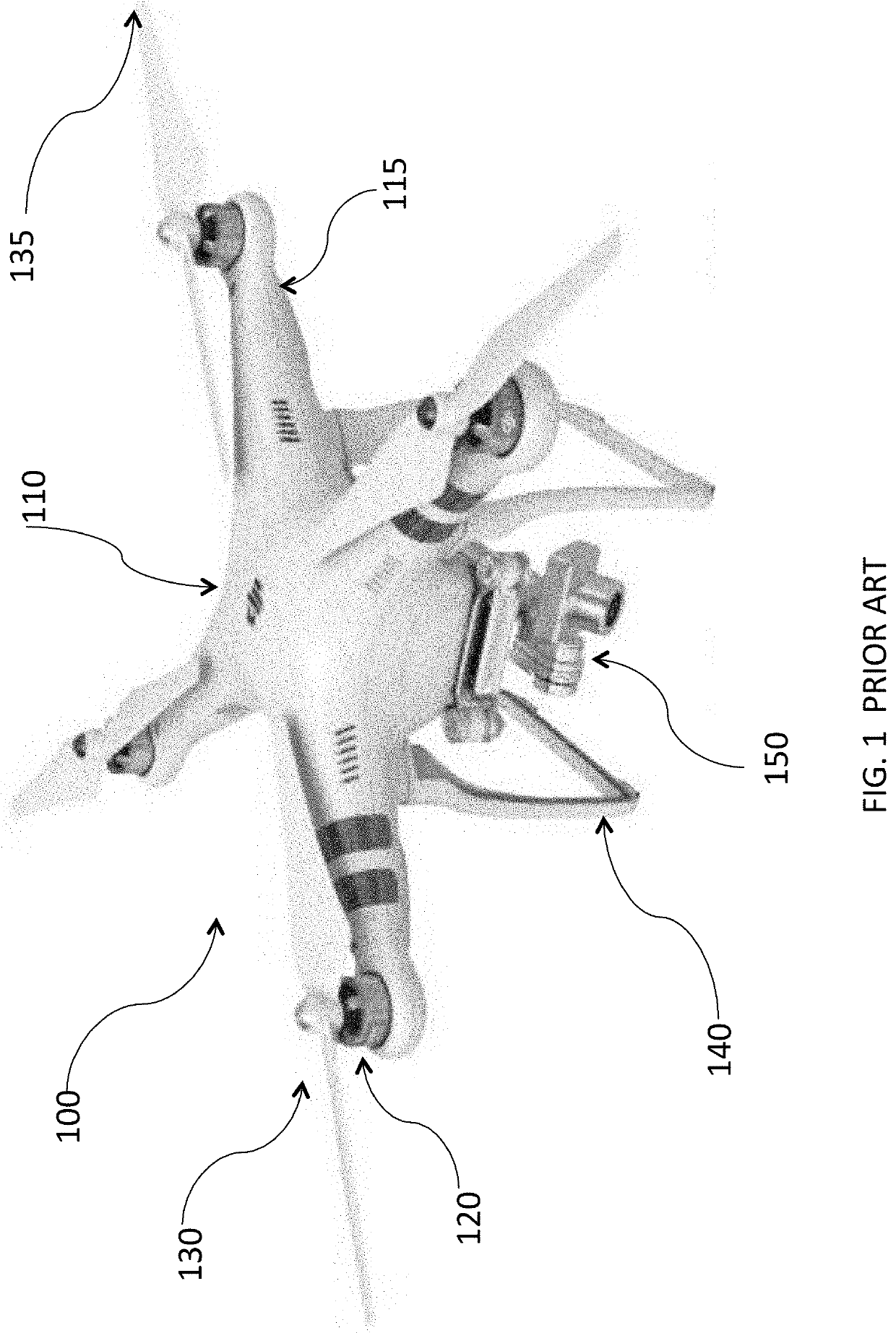

Rotary-wing vehicle and system

InactiveUS20170247107A1Sufficient payload capacitySmall surface areaRemote controlled aircraftDepending on number of propellersRotational axisFlight vehicle

An apparatus comprising a body defining a first vertical axis, two or more frame members each having a longitudinal axis and having an inner-end and an outer-end connected to the body at the inner-end and where a first horizontal geometrical plane is generally coincident with the longitudinal axis of each of the two or more frame members and where the first horizontal geometrical plane is generally orthogonal to the first vertical axis, two or more rotary-wings each comprising one or more blades whose rotation defines a first rotational axis which is configurable to be nearly parallel with the first vertical axis and comprising a second rotational axis which is configurable to be approximately parallel first horizontal geometrical plane where a first of the two or more rotary-wings having a blade-inner-end and a first blade-outer-end rotatably connected by its blade-inner-end to a first transmission is disposed substantially on the outer-end of a first of the two or more frame members, a second of the two or more rotary-wings having a blade-inner-end and a blade-outer-end rotatably connected by its blade-inner-end to a second transmission is disposed substantially on the outer-end of a second of the two or more frame members, where each of the first rotational axes is disposed on the opposite side of plane which is coincident with the first vertical axis, where the direction of rotation of a first of the two or more rotary-wings about its first rotational axis is opposite of that of the second of the two or more rotary-wings about its first rotational axis, and, where the rotational disk defined by the rotation of the blade-outer-end of the first of the two or more rotary-wings is at least partially coincident with rotational disk defined by the rotation of the blade-outer-end of the second of the two or more rotary-wings.

Owner:GEOSCOUT INC

Macromolecule leak-proof mending material and leak-proof tyre containing the same

InactiveCN101139516APlay a leak-proof effectExtended missionTyre partsOther chemical processesElastomerDynamic balance

The invention discloses a high polymer anti-leakage dense patching material, which comprises by weight hot plastic elastomer 40-60%, thickener 40-60%, softening agent 08%, anti-aging agent 0-2%, catalyst 0-1%, and filling agent 0-15%. The invention also discloses an anti-leakage tyre containing above mentioned high polymer anti-leakage dense patching material, which can efficiently prevent tyre from air leakage and tyre bursting due to pricking of the tyre, guarantee safety in running of vehicles and prolong the service life of tyres. And the use effect of the tyres will not be affected due to the machining (for example dynamic balancing, operation, braking, comfortableness and load bearing capacity, etc.).

Owner:陈芳

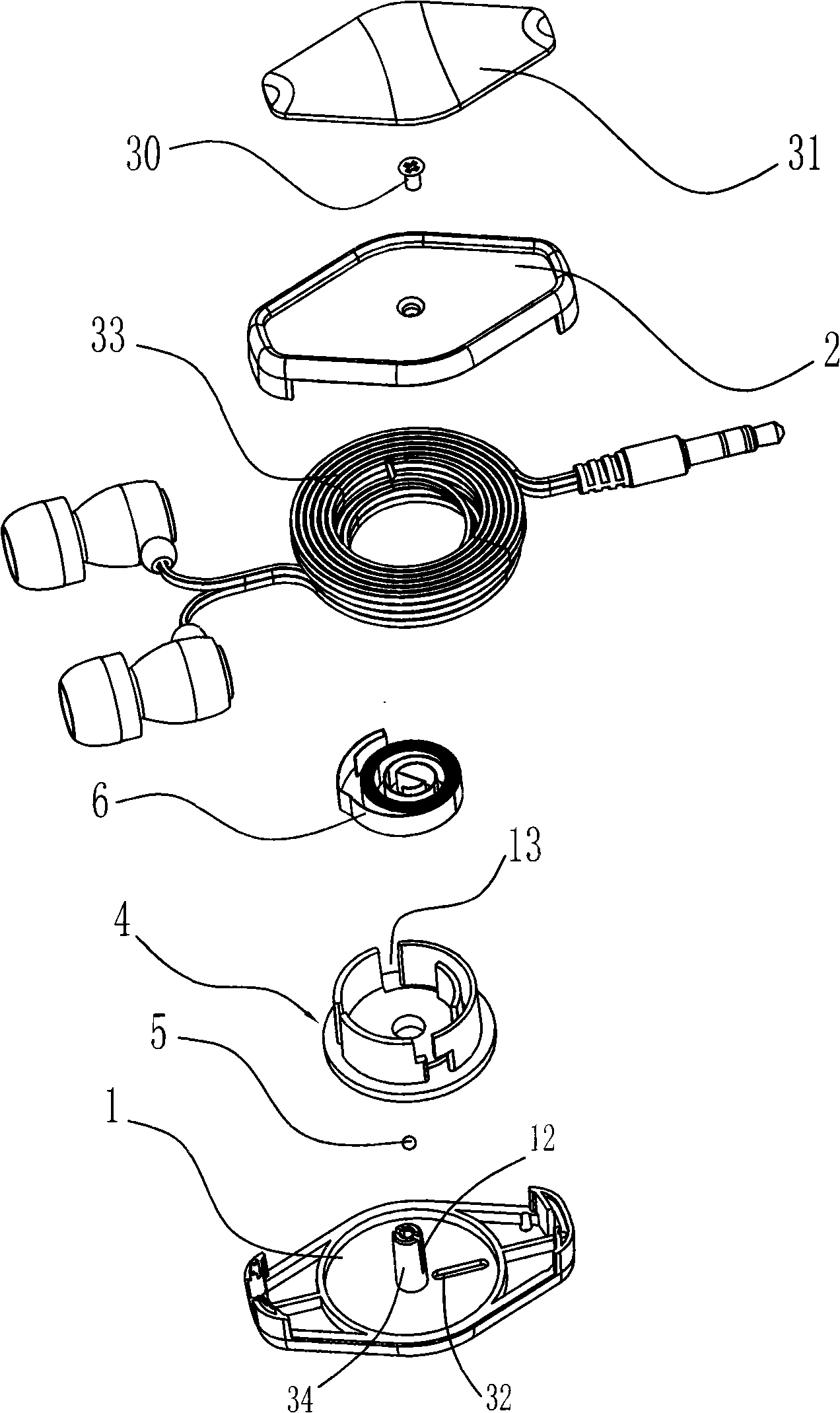

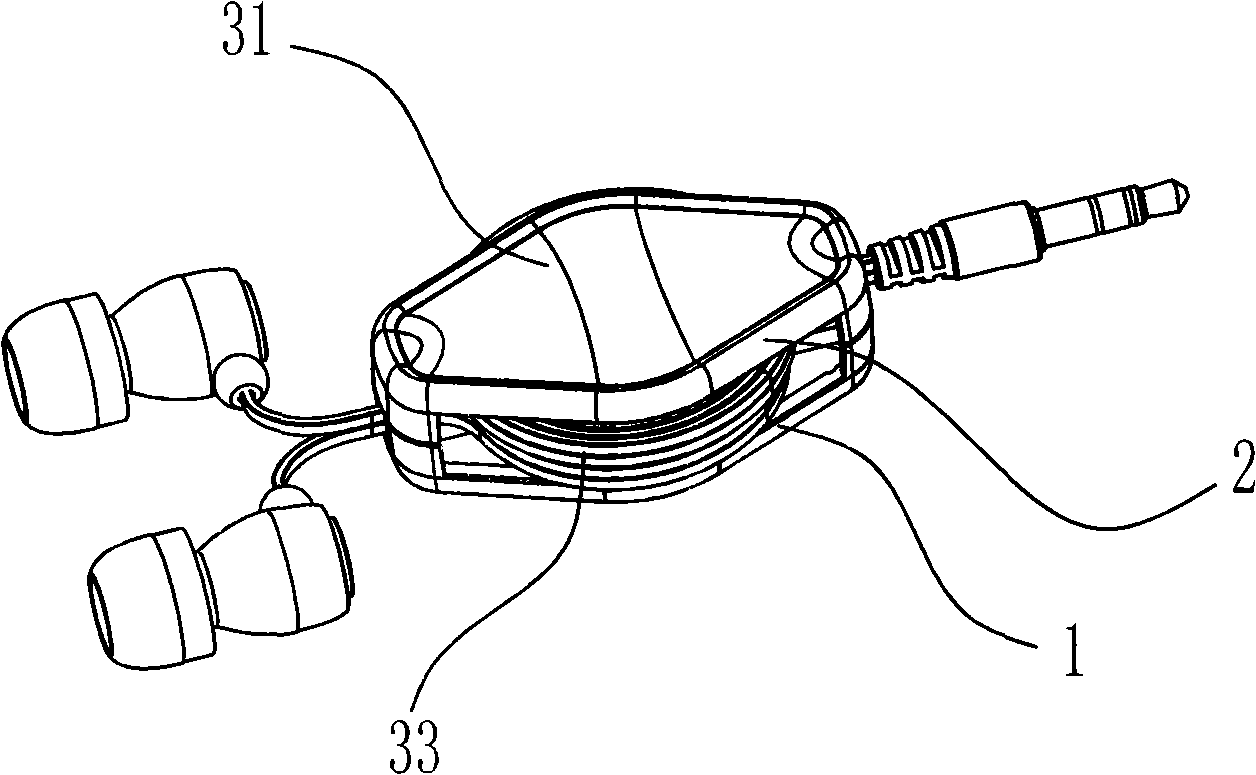

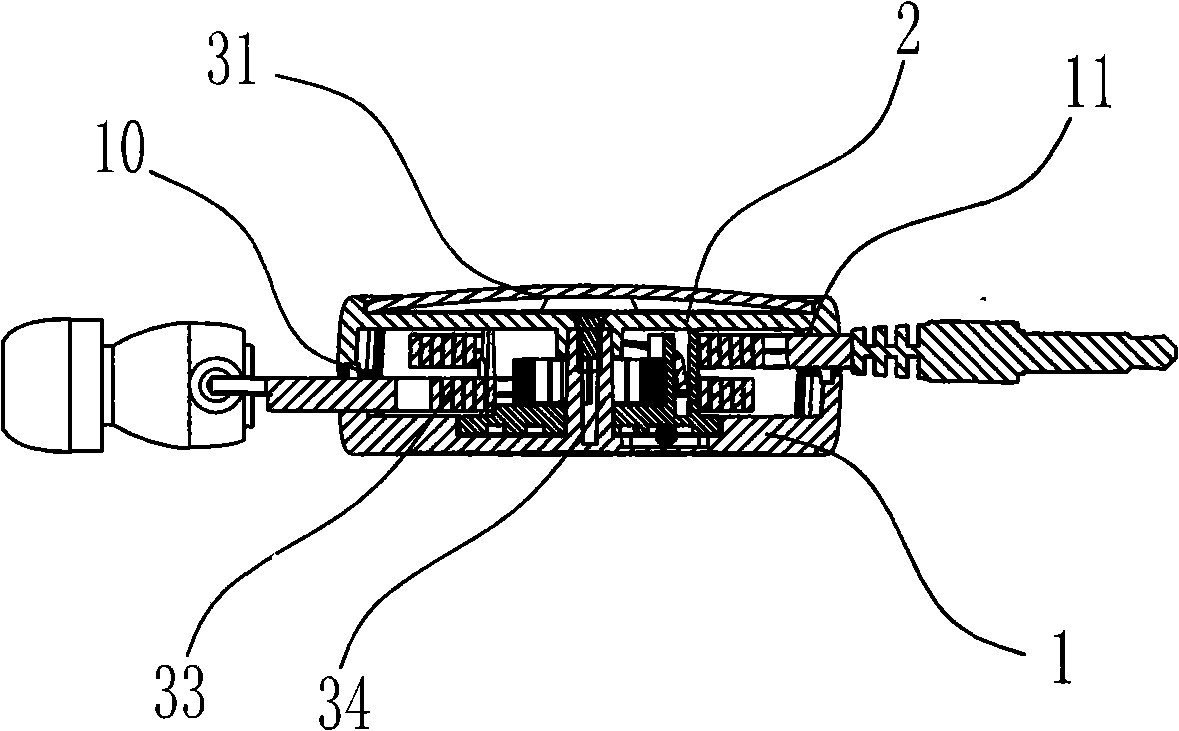

Automatic positioning coil winder

ActiveCN101282032AExtended missionEasy to useEarpiece/earphone cablesArrangements using take-up reel/drumEngineeringTransmission line

Owner:洪子敬

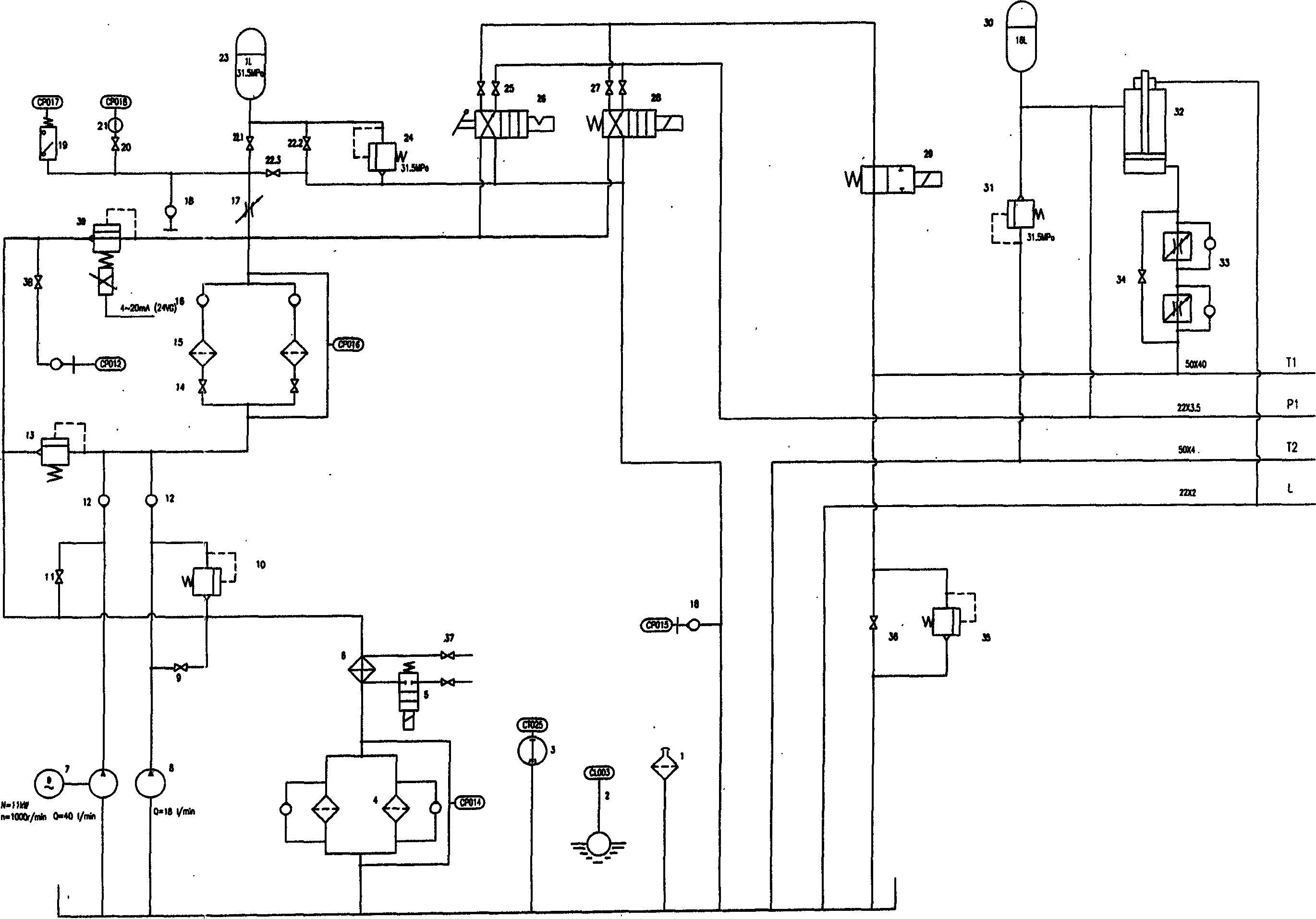

Hydraulic variable loading system for roller-plate coal mill

InactiveCN1672800AGrinding force to matchReduce operating load power consumptionCement productionGrain treatmentsSolenoid valveLow load

The hydraulic variable loading system for roller-plate coal mill in power station, cement mill, etc. consists of filter, motor, two-gang pump, high pressure bi-directional filter, pressure speed variator, energy accumulator, two-position four-way solenoid valve, hydraulic cylinder, proportional overflow valve, etc. The motor drives the two-gang pump to provide the hydraulic kinetic energy, and under the control in the central control room via the pressure speed variator, proportional overflow valve and the hydraulic variable loading system, the work pressure is applied to the hydraulic cylinder cavity. The system of the present invention is novel, safe and reliable, and makes the coal mill operate stably at low load.

Owner:SHENYANG HEAVY MACHINERY GROUP

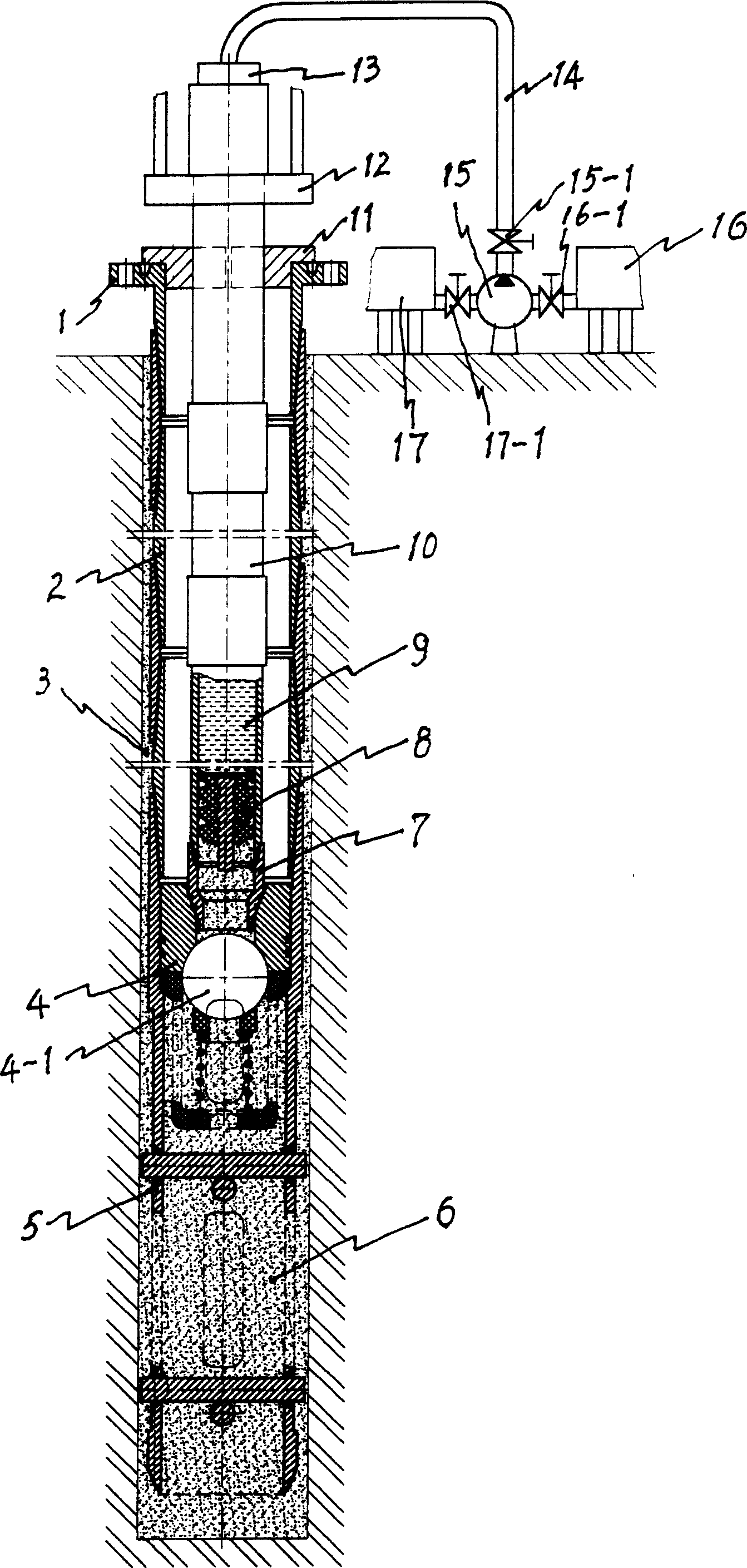

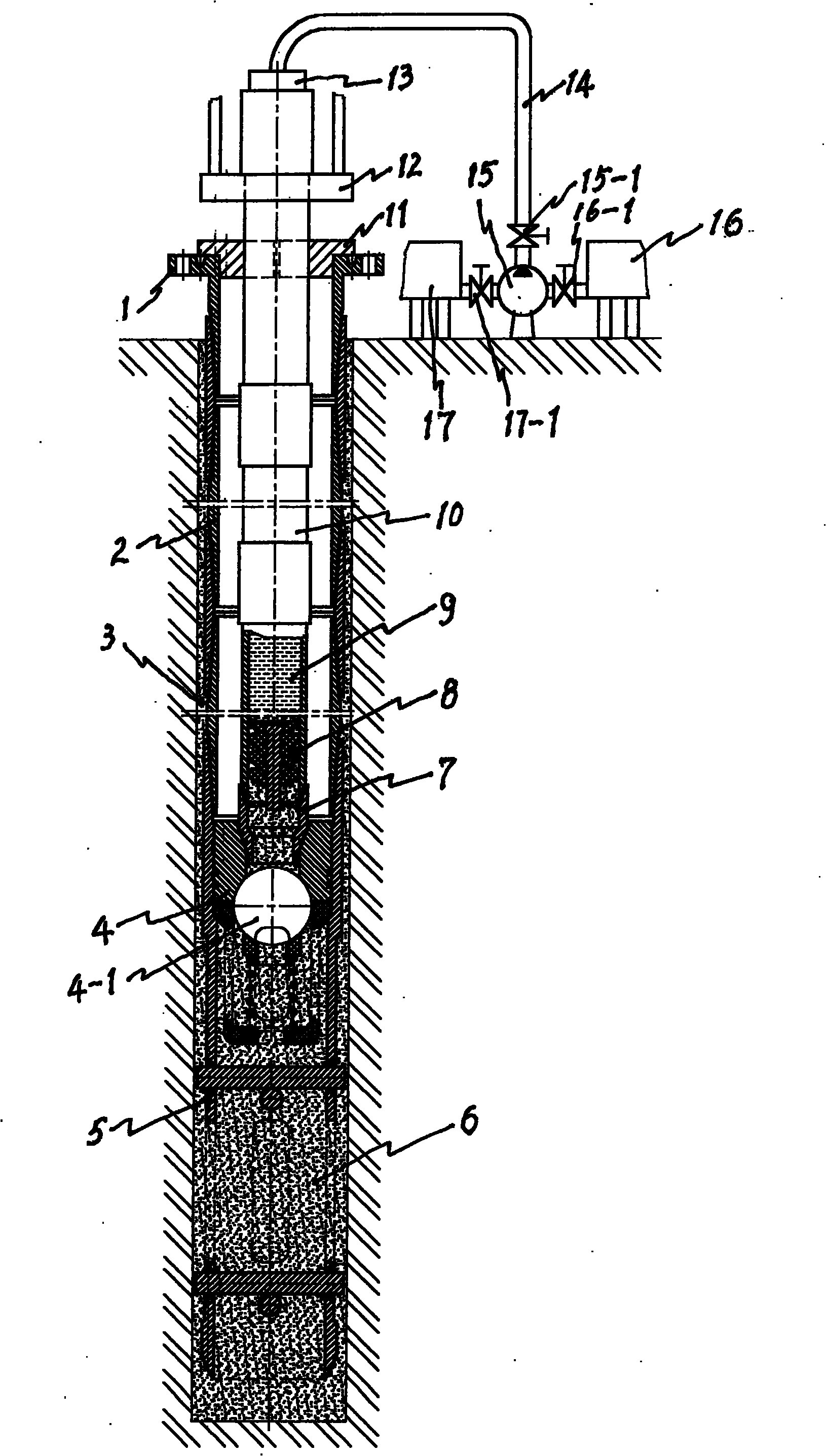

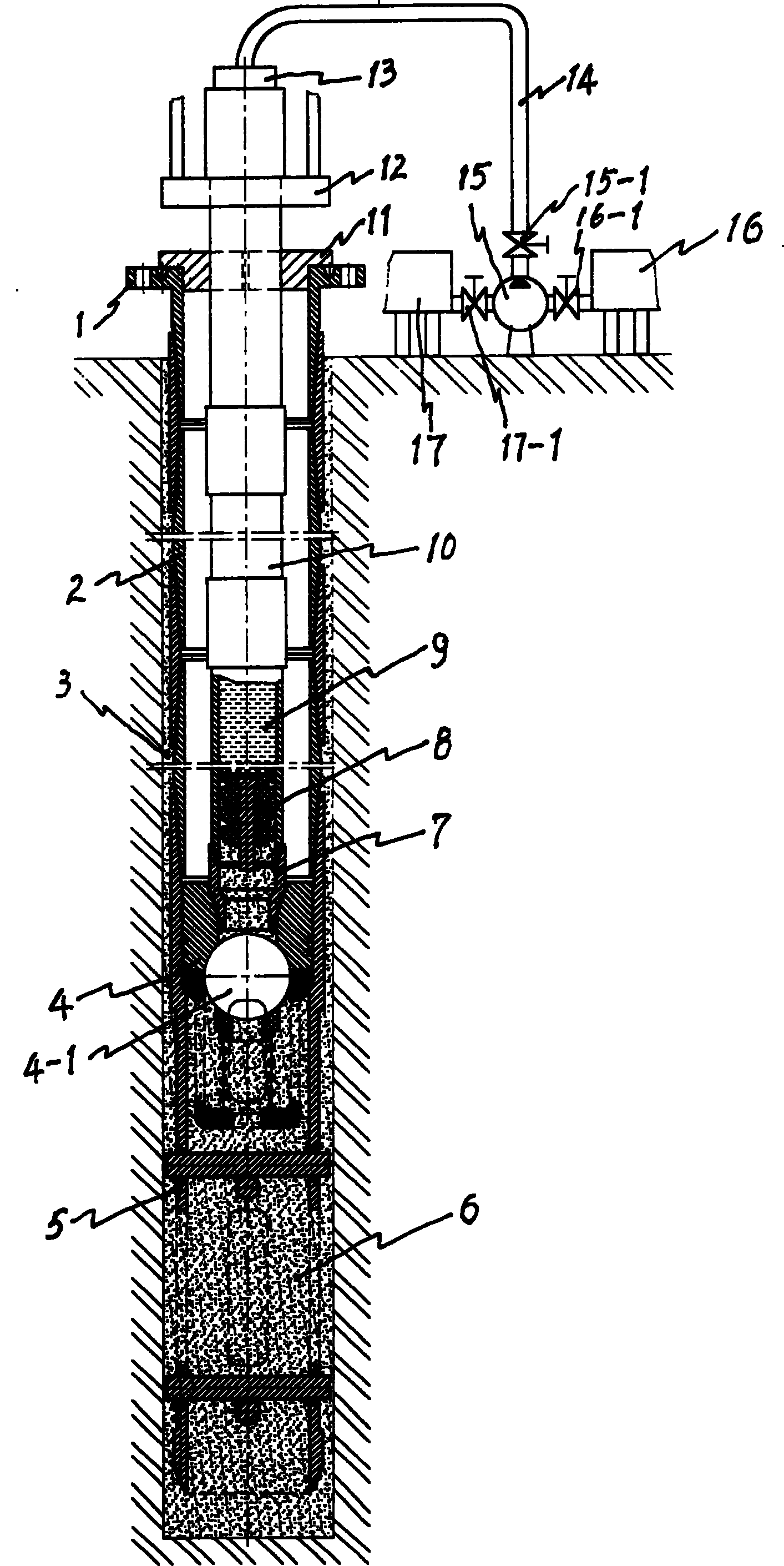

A fixation method for underground gas storage well bore

InactiveCN1837672AFirmly condensedAvoid pollutionContainer filling methodsContainer discharging methodsFixation methodPollution

The invention relates to a method for fixing underground gas storage well cylinder, which comprises a well cylinder whose bottom has a one-way valve and a fixing bracket inside the basic well; a irrigating device for mounting insertion tube and modulating the cement via the cement pump, insertion tube, and one-way valve to fill cement into the cylinder and the well wall; then removing the irrigating device; and waiting the cement be solidified. The invention can avoid pollution on the inner chamber of well cylinder, to eliminate the washing process. And it can improve the safety and service life of well cylinder.

Owner:自贡力源科技有限公司

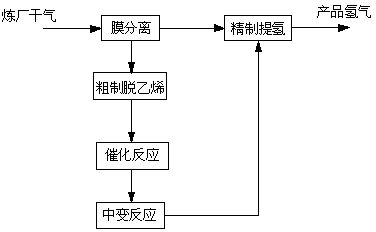

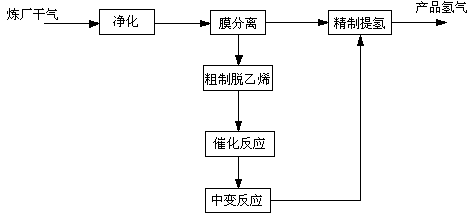

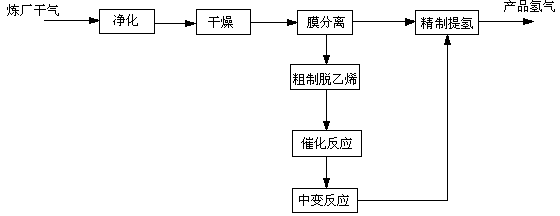

Method for producing hydrogen with high yield and high purity by reforming and transforming dry refinery gas

InactiveCN103552984AHigh yieldReduce load increaseHydrogen separationEnergy inputChemistryCarbon dioxide

The invention discloses a method for producing hydrogen with high yield and high purity by reforming and transforming dry refinery gas. The method comprises the following steps: (1) separating the dry refinery gas through a membrane, enriching hydrogen on a permeation side and enriching methane, ethylene, ethane and fractions higher than C2 on a non-permeation side; (2) carrying out pressure swing adsorption on the hydrogen enriched on the permeation side in the step (1) to obtain product hydrogen; (3) carrying out pressure swing adsorption on the gases on the non-permeation side to discharge the non-adsorbed methane, the ethane and other light hydrocarbon gases; (4) reacting the methane with water vapor under the action of a catalyst to generate a mixed gas of carbon monoxide, hydrogen and carbon dioxide; (5) reacting the carbon monoxide generated in the step (4) with the water vapor to generate a mixed gas of hydrogen and carbon dioxide; and (6) carrying out pressure swing adsorption on the mixed gases to obtain the product hydrogen. The method disclosed by the invention can be used for obtaining hydrogen with high purity and obtaining high hydrogen yield as well.

Owner:SICHUAN TECHAIRS +1

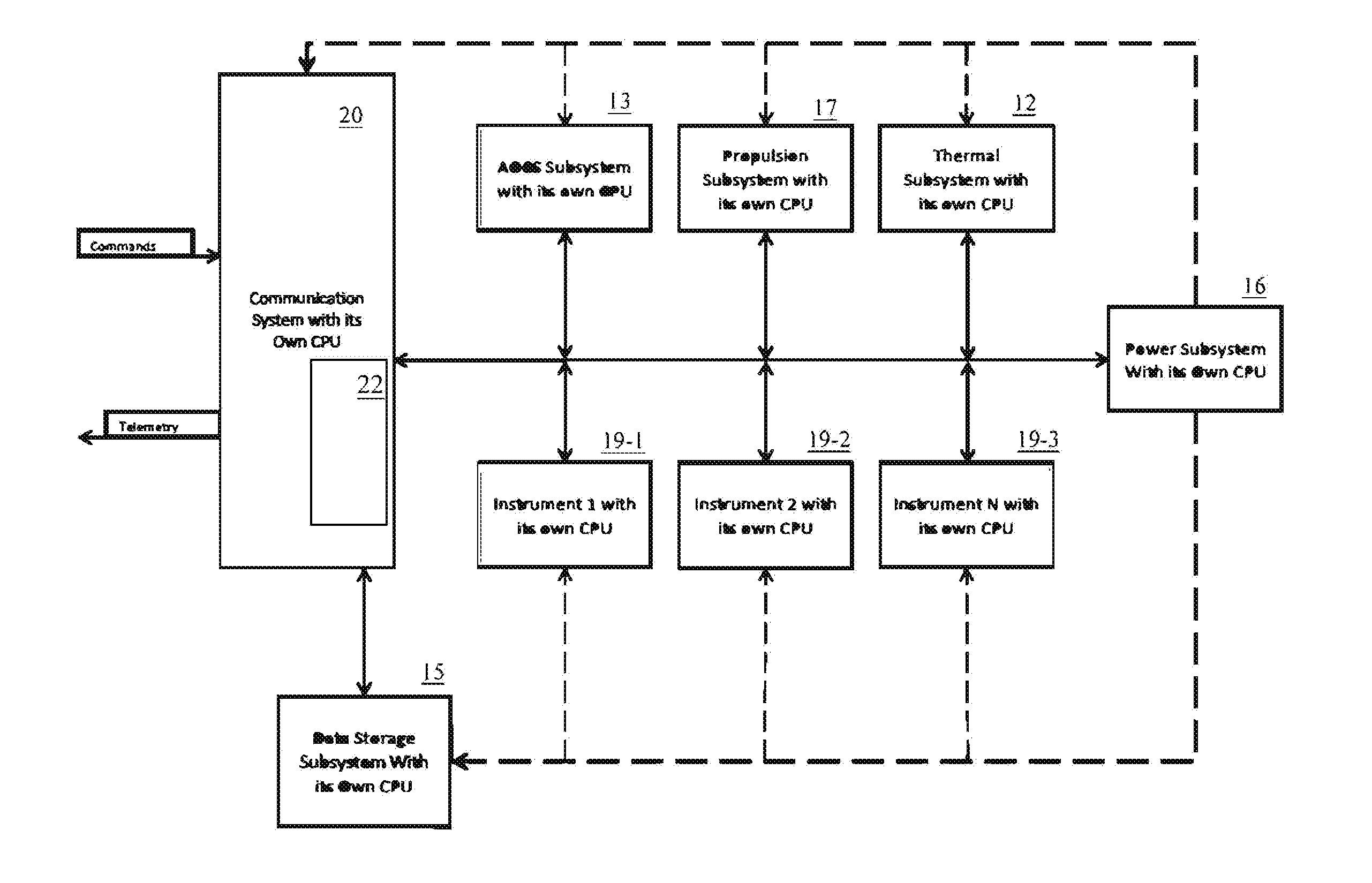

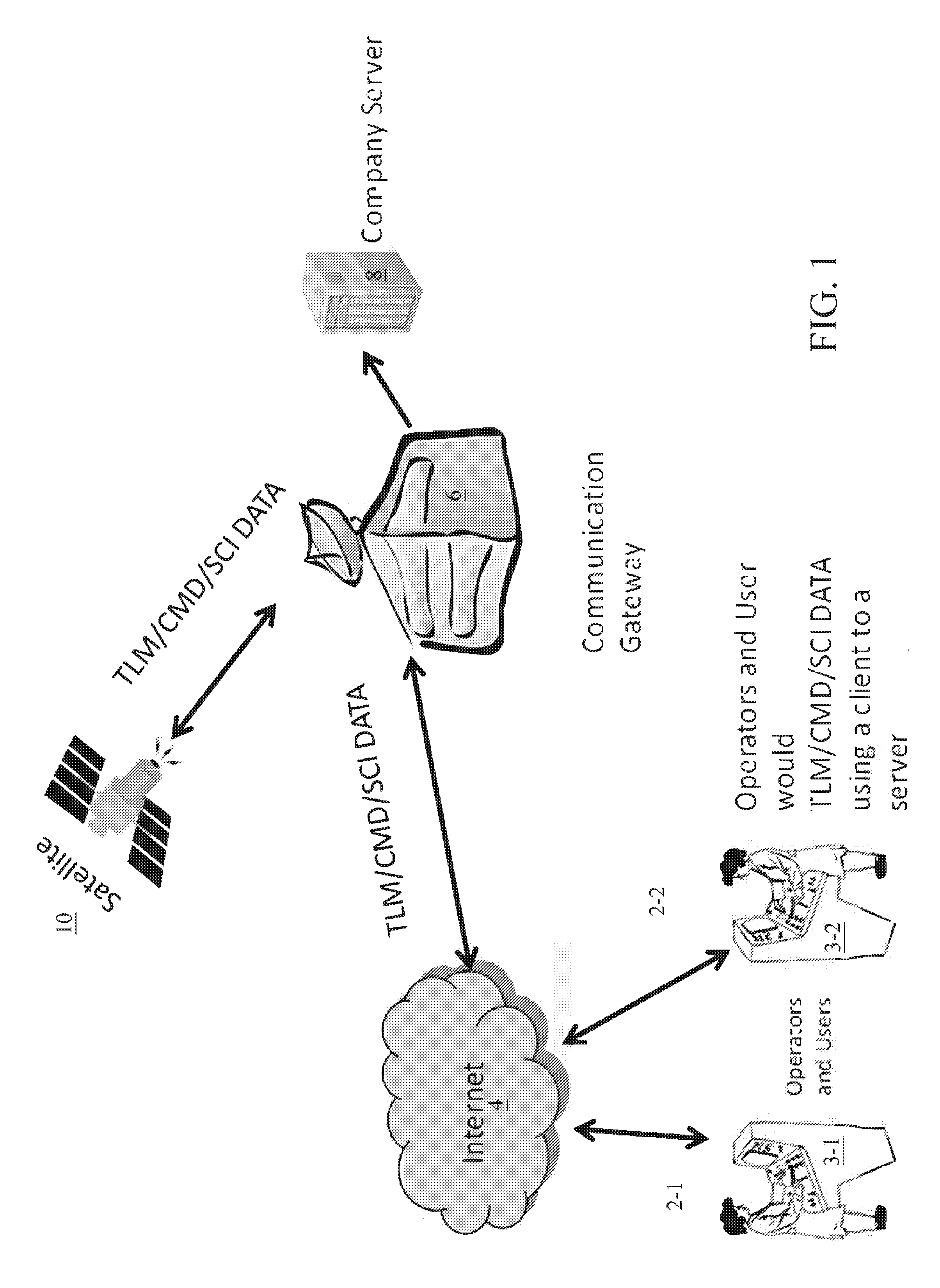

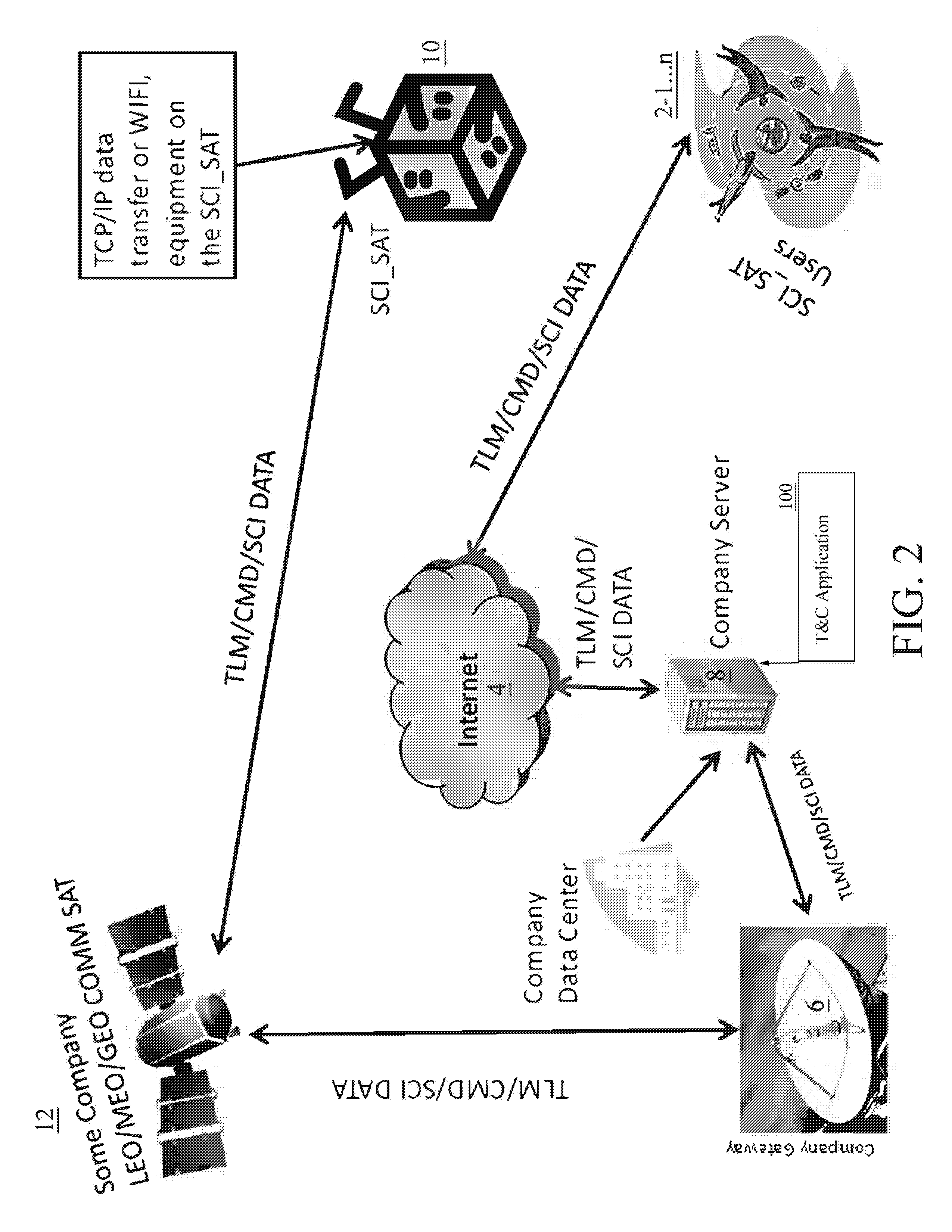

Ip-based satellite command, control, and data transfer

InactiveUS20160344685A1Increase efficiencyCost savingCosmonautic vehiclesWireless commuication servicesData transmissionCost savings

A method and system for satellite control in space using an IP-based satellite bus and all-IP compliant subsystems and payload(s) and a corresponding T&C system. Specifically, the present method / system includes a satellite-based IP Bus (connected as a network) that relies on Ethernet, USB, WIFI, or Bluetooth to connect various satellite components, satellite components configured to communicate on the IP bus, and a T&C system that understands the IP bus and can read its telemetry and commands. The system permits operations control on-orbit, in near real time within a secure system environment, with a dramatic increase in mission efficiency, an expansion of how much and what can be done on-orbit, and cost savings on future missions using IP-compliant spacecraft and payloads.

Owner:MAHARAJA RISHABH Y

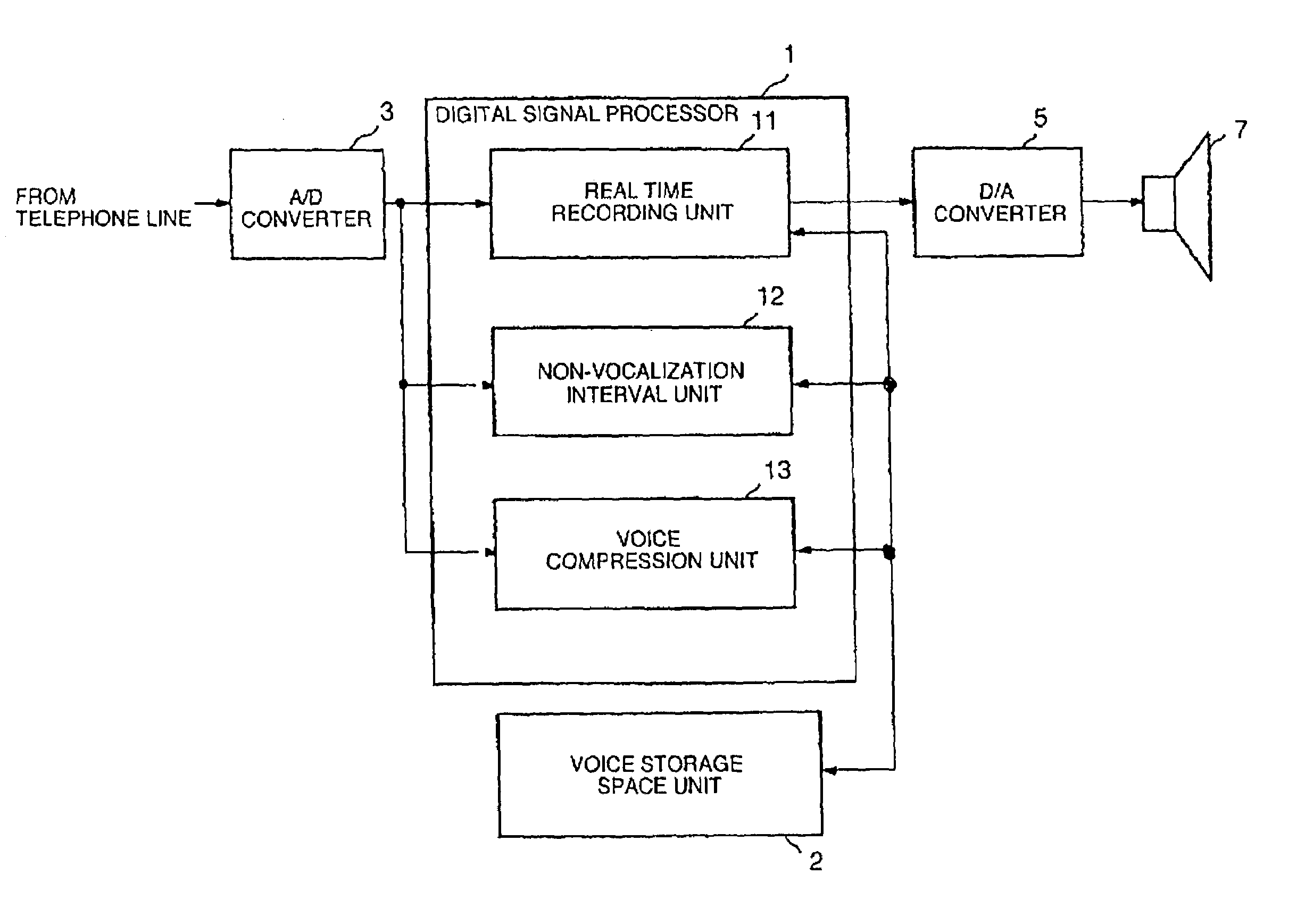

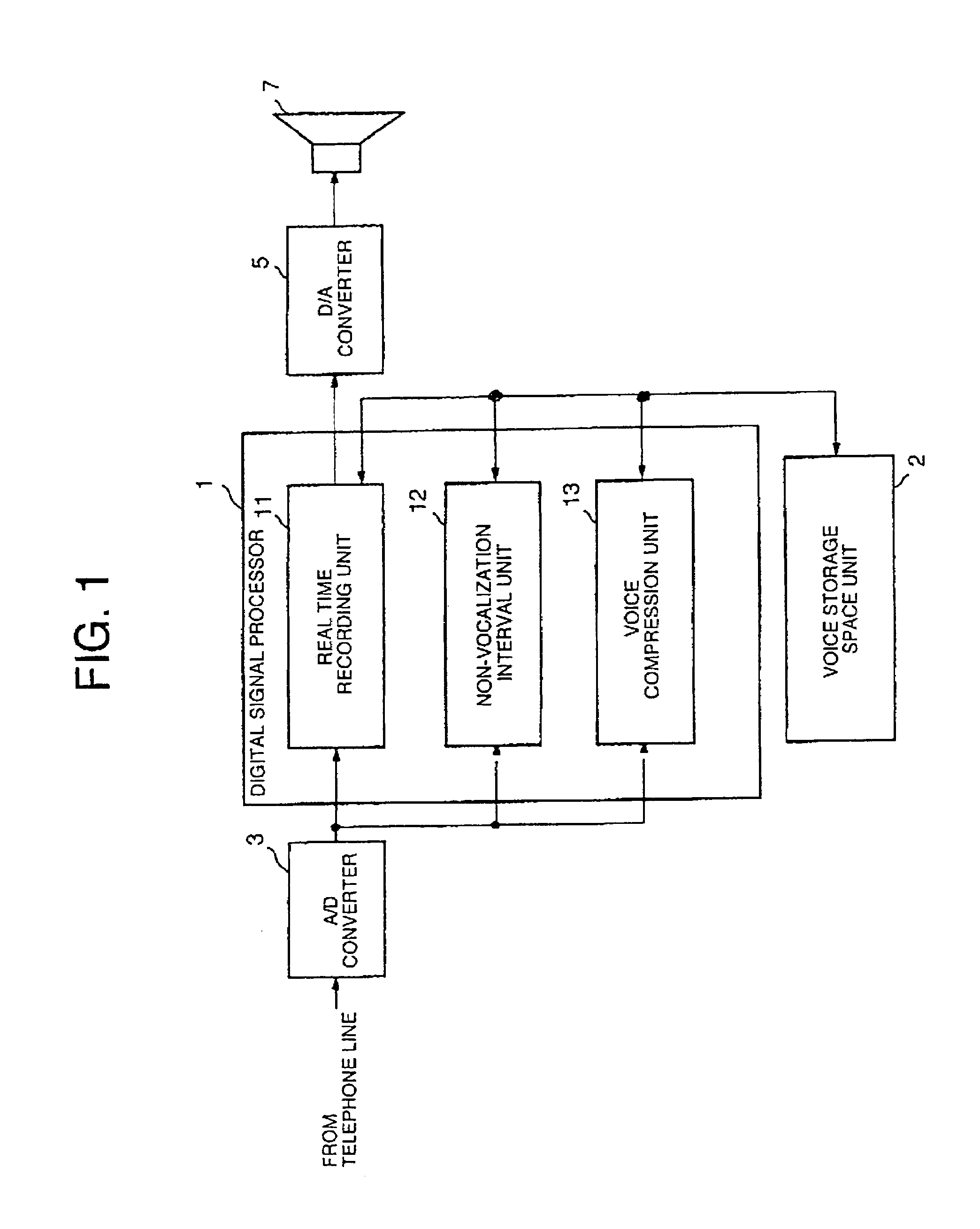

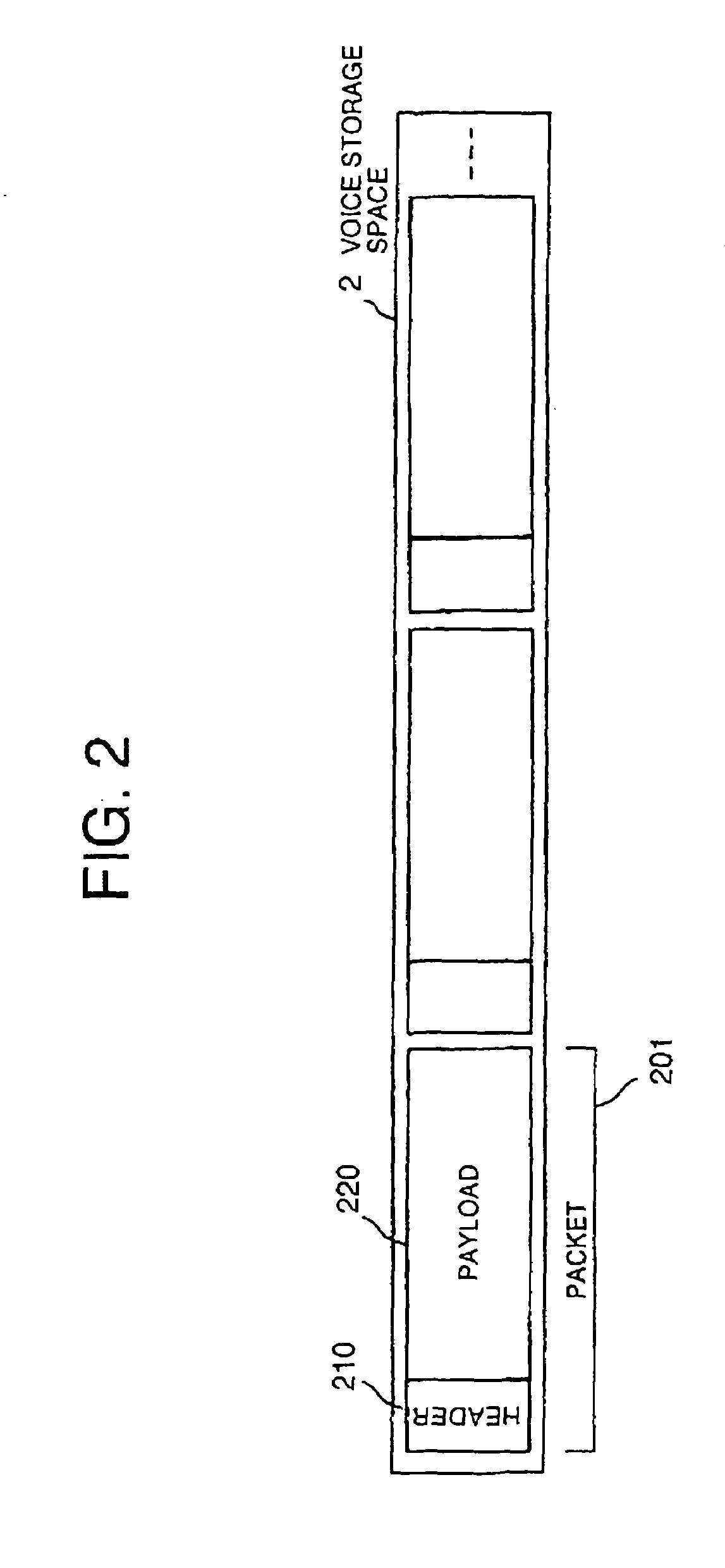

Voice storage device and voice coding device

InactiveUS7164755B1Extended missionRecord clearTelevision system detailsSpeech analysisCode bookSound quality

The voice storage device of the invention includes a storage means that stores a voice signal, and a voice compression means that compresses the voice signal requiring a re-coding compression, of the voice signal stored in the storage means, in accordance with a compression degree and a significance of the voice signal. The voice coding device includes: an LSP quantizer that quantizes LSP parameters, an LSP multi-stage quantizer that quantizes quantization error components that the LSP quantizer is impossible to express, a pitch component coder that attains pitch components from linear predictive errors, an excitation source coder in which an excitation source is configured with a multi-stage code book, an essential code output unit that outputs a code essential to decoding from the output of the LSP quantizer, the pitch component coder, and the excitation source coder, and a sound quality improving code output unit that outputs a code to improve a decoded sound quality from the output of the LSP multi-stage quantizer and the excitation source coder.

Owner:OKI ELECTRIC IND CO LTD

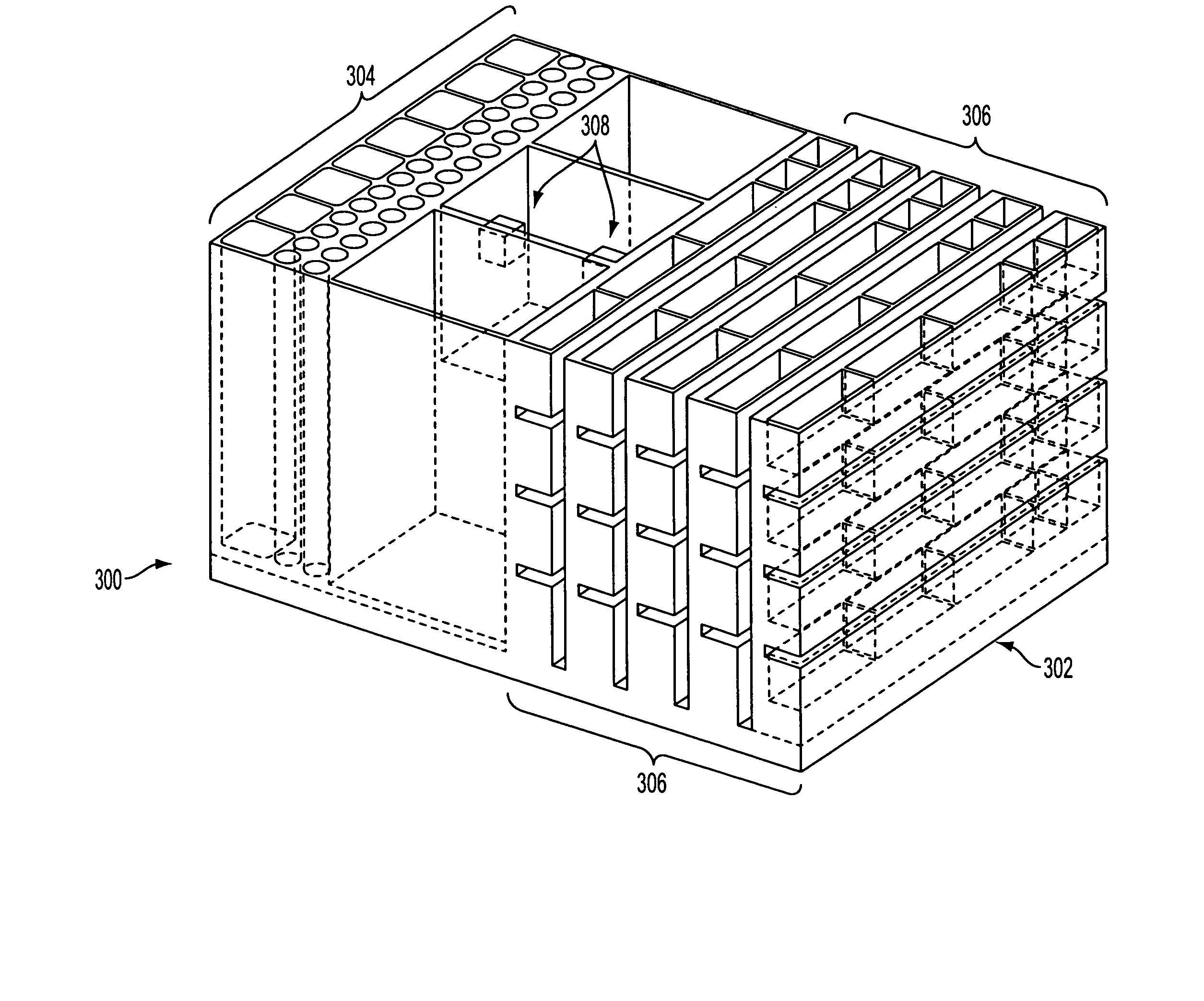

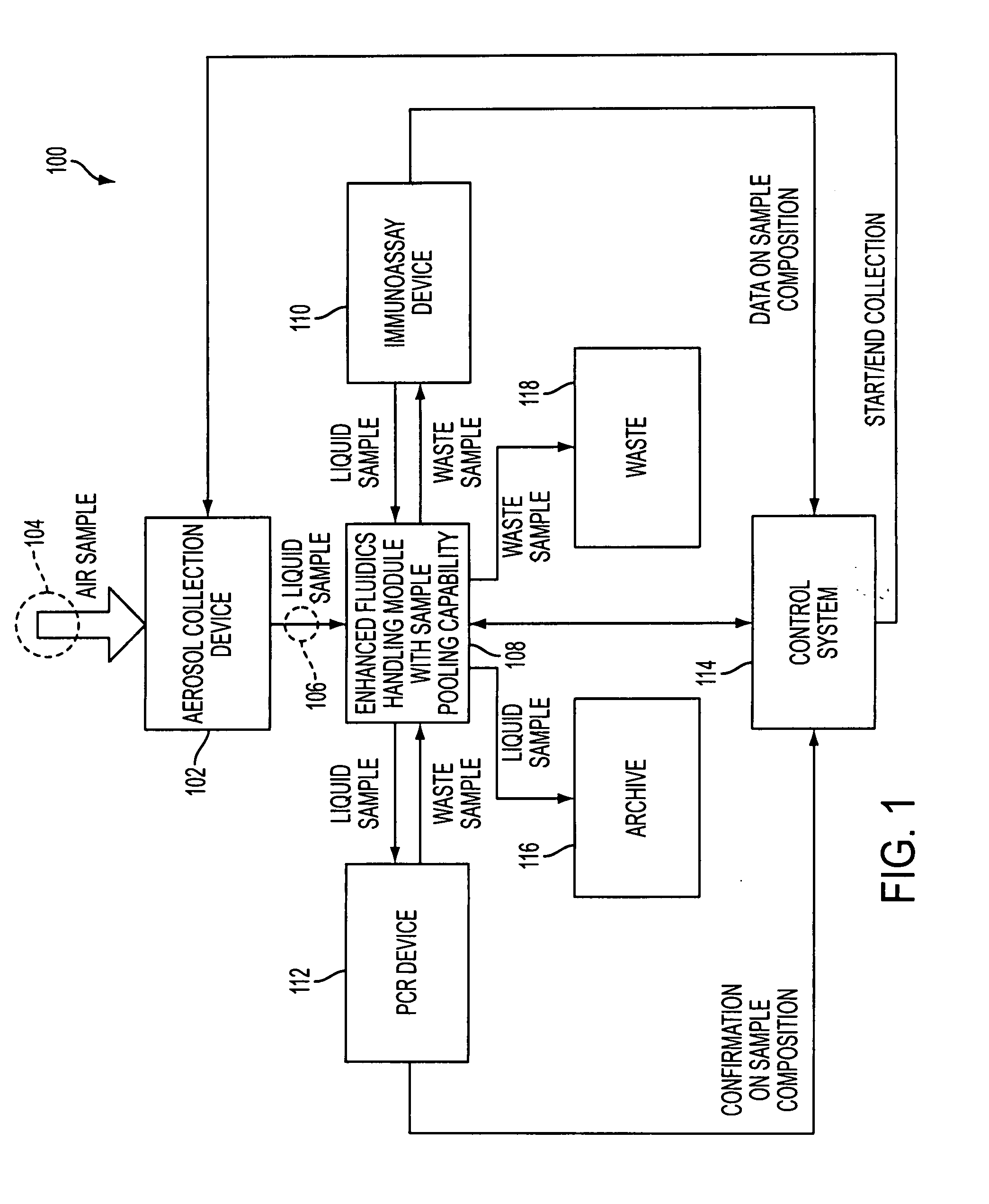

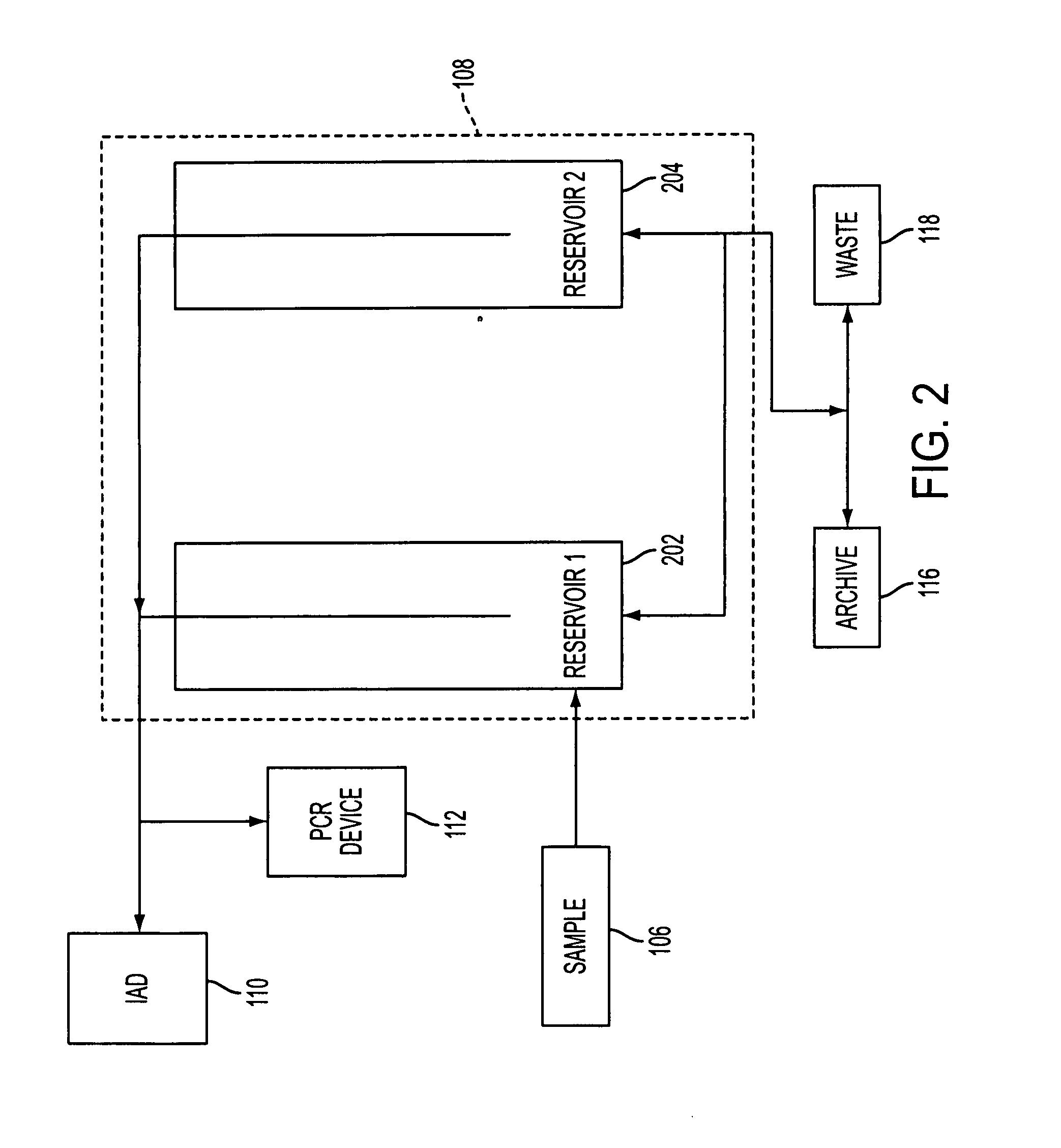

Enhanced biohazard detection system

InactiveUS20070292844A1Increase capacityReduce operating costsBioreactor/fermenter combinationsBiological substance pretreatmentsAir sampleBiological agent

An enhanced biohazard detection system and a method for detecting, screening and analyzing biological agents are disclosed. The system incorporates an immunoassay detection device to provide a more robust, less expensive method for detecting biological agents in air samples collected at strategically located monitored sites. The immunodetection based assays may be used either in parallel with, or as a prescreening assay for, a polymerase chain reaction based assay for detecting and identifying biological agents in air samples.

Owner:NORTHROP GRUMMAN SYST CORP

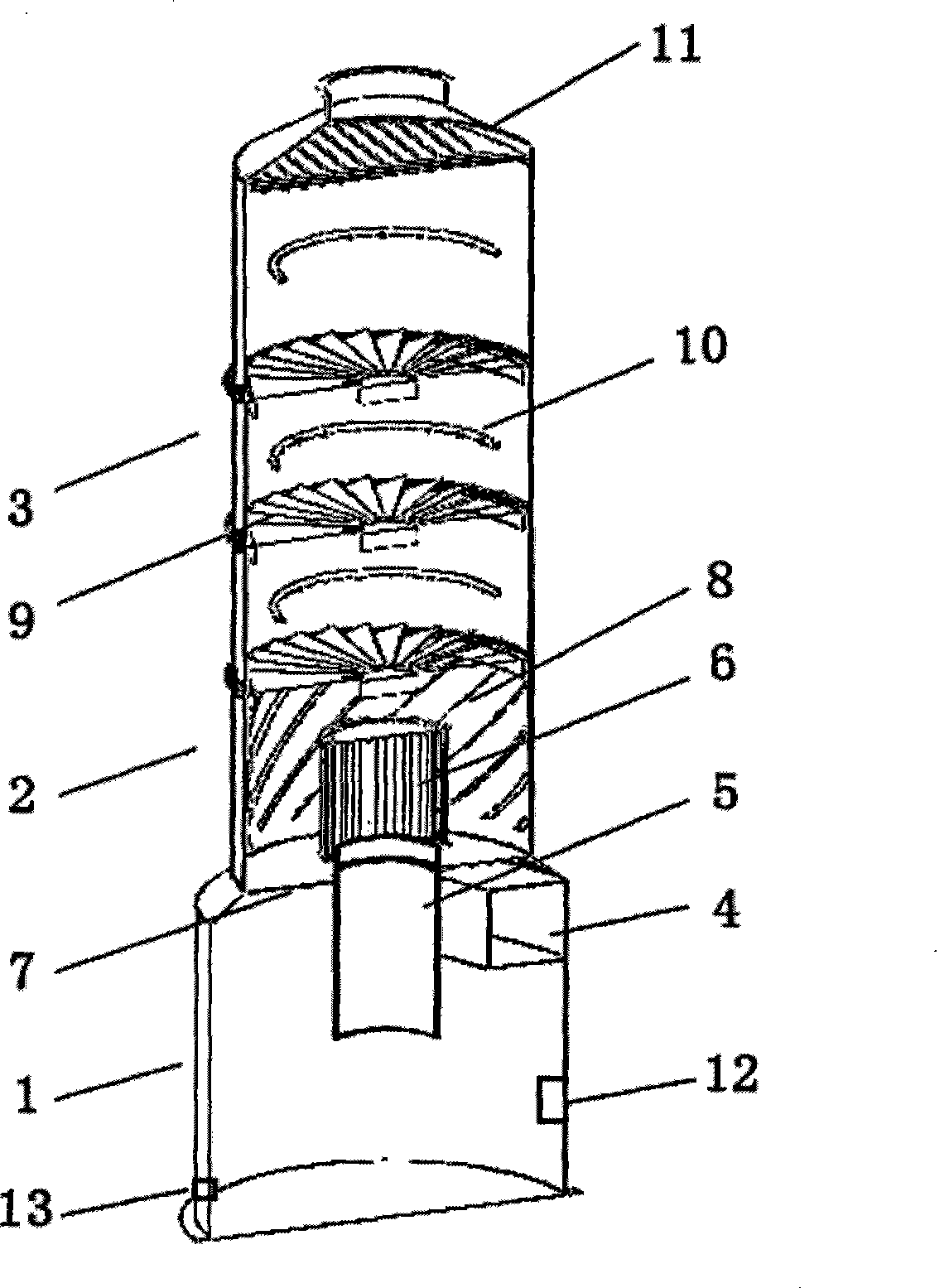

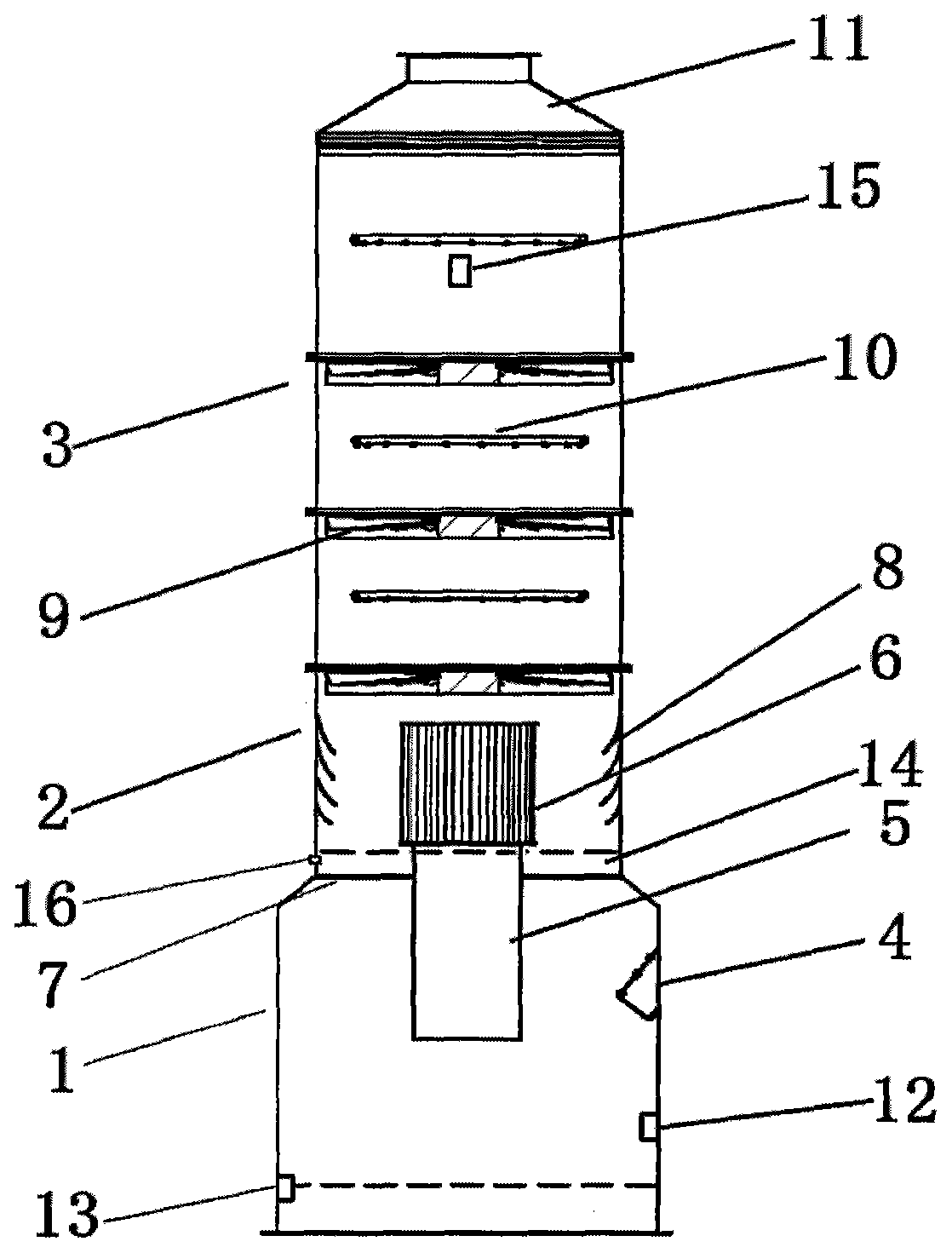

Rotational-flow type dust removing and desulfurization device

InactiveCN103463916AImprove purification effectSimple structureCombination devicesLiquid storage tankEngineering

The invention belongs to the technical field of environment-friendly equipment and relates to a rotational-flow type dust removing and desulfurization device for treating industrial waste gas and smoke dust before emission. The rotational-flow type dust removing and desulfurization device comprises a barrel body, wherein the barrel body is sequentially divided into a first chamber, a second chamber and a third chamber from bottom to top; a separation plate is arranged between the first chamber and the second chamber; a gas inlet is formed in the side wall of the first chamber; a water spraying pipe is arranged on the peripheral wall of the gas inlet; a gas guide pipe is arranged in a central area of the first chamber; the gas guide pipe is fixedly arranged on the separation plate and penetrates through the first chamber and the second chamber; a rotational flow device is mounted on the upper part of the gas guide pipe; the inner side of the barrel wall of the second chamber is provided with a baffle plate matched with the rotational flow device; a liquid storage tank is formed by the separation plate and the lower part of the peripheral wall of the second chamber; the third chamber is internally provided with a plurality of rotational flow plates and spraying nozzle groups from bottom to top; the rotational flow plates and the spraying nozzle groups are arranged at intervals. According to the rotational-flow type dust removing and desulfurization device, the exchange is intensified, water is discharged automatically and the multilayered dust removing and desulfurization is realized; the integration of dust removing, desulfurization and defogging is realized really.

Owner:庞永民

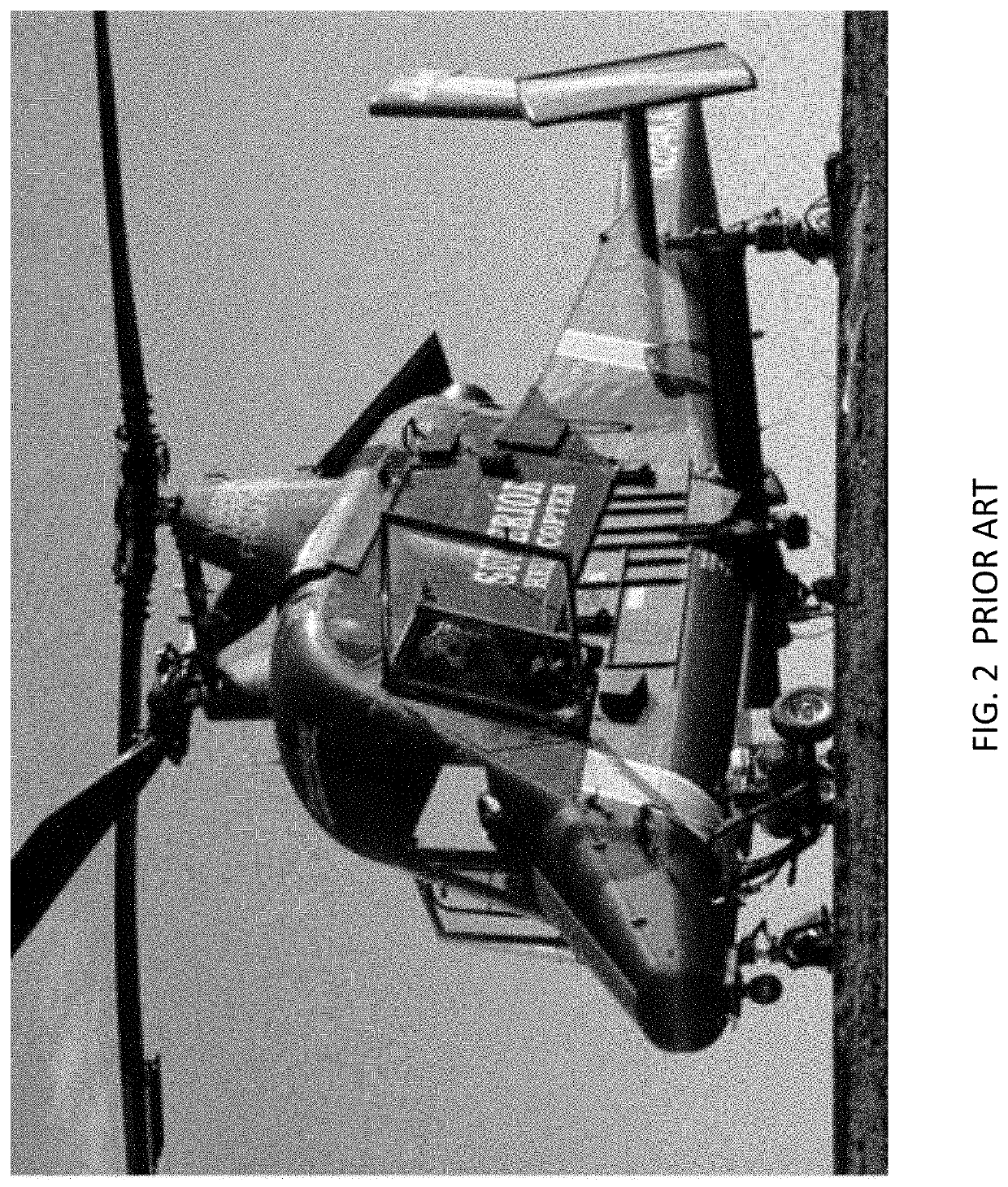

Rotary-wing vehicle and system

InactiveUS20210009279A1Sufficient payload capacitySmall surface areaUnmanned aerial vehiclesToothed gearingsGear driveGear wheel

A lift producing multi-rotor apparatus with a single gear, central drive gear unit actuating gear driven rotor-shaft units having pitch-controlled rotor heads where the rotor units are disposed directly opposite from each other, the direction of rotation of opposing rotor units are opposite from each other, and where the rotational-disk defined by each rotor overlaps two adjacent rotational disks.

Owner:GEOSCOUT INC

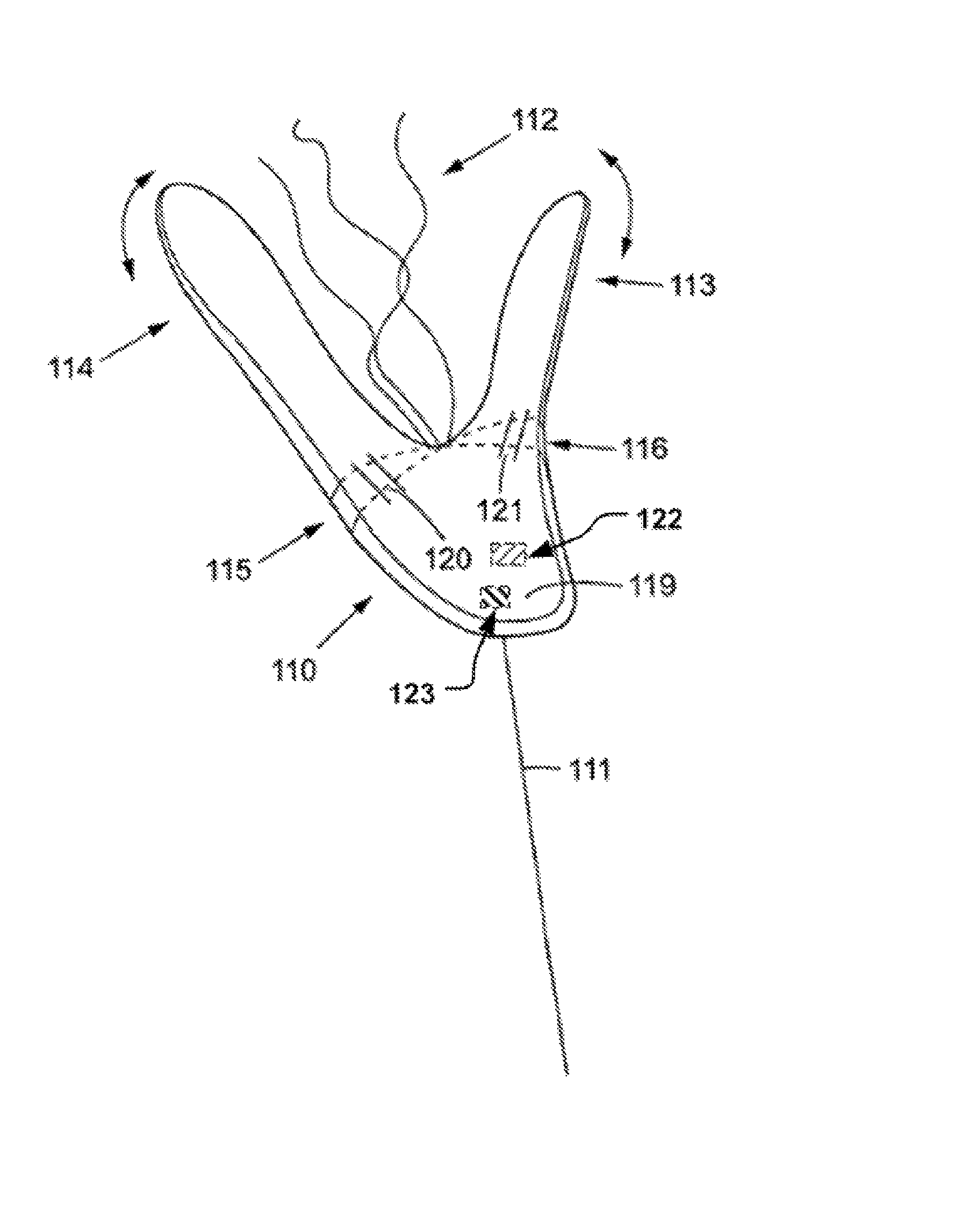

Location signaling device

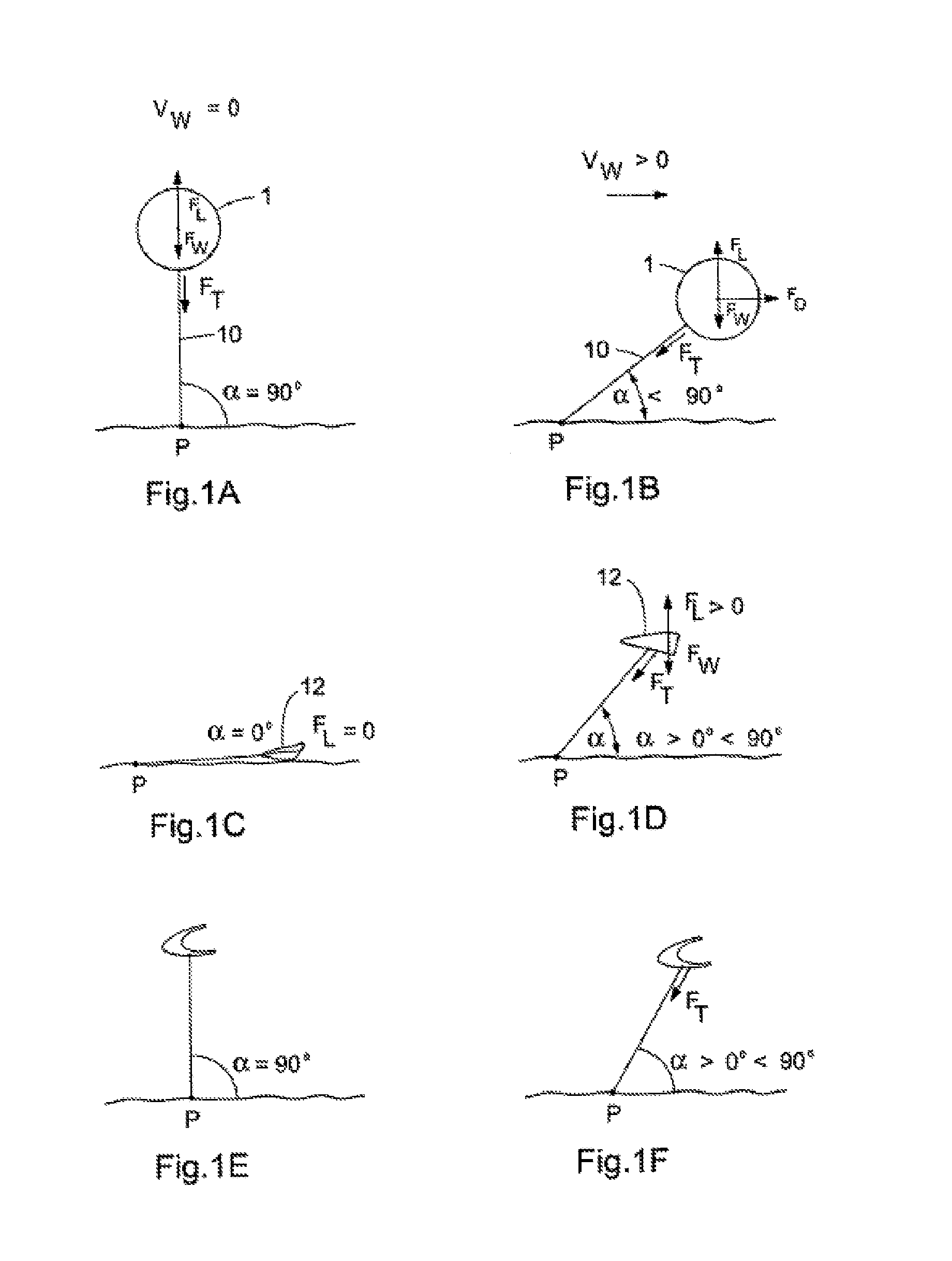

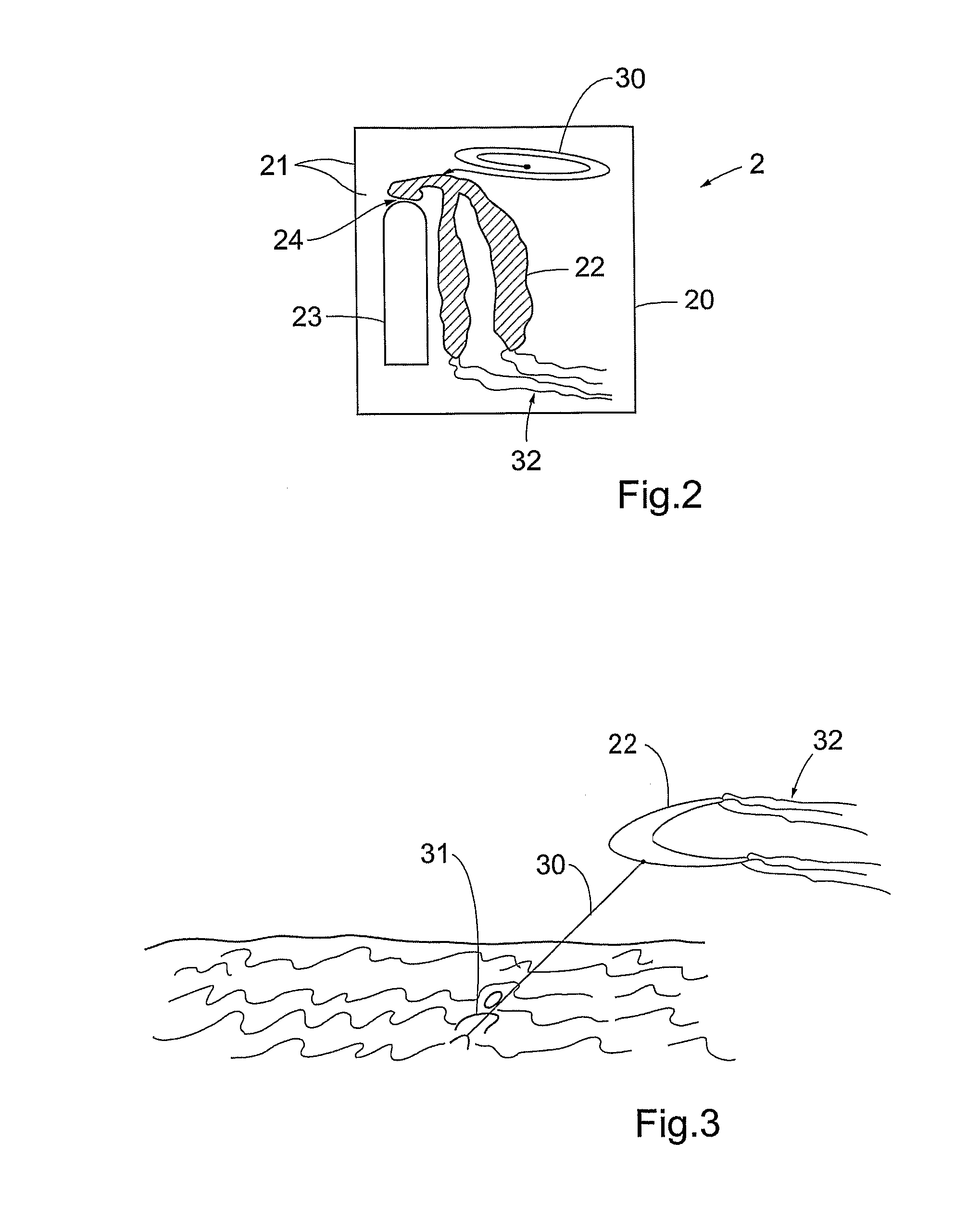

InactiveUS8356569B2Effective surface is reducedReduce lifting forceVessel signalling devicesLife-savingLighter than airAirbag deployment

A location signalling device comprising a wing balloon for signalling a location. The wing balloon is fixed to a tether line that itself is fixed to the location to be signalled. The wing balloon has an inflatable aerodynamically shaped hollow body to be at least partly be filled with a lighter-than-air gas and having a wing attack surface for air flowing relative to said wing balloon. The floating aloft of said wing balloon is supported by said air flow. When the wing balloon is inflated, a flexible wing portion is passively variable. The stronger the wind, the less attack is given. Thus, the dragging force on the tether line is generally static.

Owner:SJOBLOM HANS

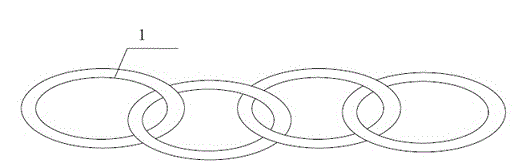

Long ring plastic chain

The invention discloses a long ring plastic chain which comprises a plurality of annular chain sections connected in series. The annular chain sections are oval chain sections which can be opened. The long axis of each annular chain section ranges from 5 cm to 7 cm, and the short axis of each annular chain section ranges from 2 cm to 3 cm. When each annular chain section is opened, the opened annular chain section is provided with two ends, the section of one end is inwards concaved to form a concave hole, and the other end protrudes out to form a protruding shaft. The annular chain sections are matched through the cooperation of the concave holes and the protruding shafts to form a closed ring. In addition, the length of the protruding shafts is 2 cm. The long ring plastic chain can be conveniently lengthened or shortened; furthermore, the service life can be prolonged, and materials can be saved.

Owner:WUXI HUIYUAN MECHANICAL TECH

Welded tube for calorizing and laser short processing

InactiveCN103014725AImprove product qualityExtended missionSolid state diffusion coatingFurnace typesSurface roughnessAlloy

The invention relates to a welded tube for calorizing and laser short processing. The welded tube is prepared from the following processing steps of carrying out thermal treatment on the surface of the welded tube in an aluminizing manner, wherein an Al atom and an Fe atom are subjected to physical and chemical change by convective diffusion and thermal diffusion to form a Fe-Al alloy layer at the surface of the welded tube, and then preparing the welded tube by laser shock processing. The welded tube disclosed by the invention is small in surface roughness and good in abrasive resistance.

Owner:JIANGSU TONGYU STEEL PIPE GRP

A fixation method for underground gas storage well bore

InactiveCN1837672BFirmly condensedAvoid pollutionContainer filling methodsContainer discharging methodsFixation methodPollution

The invention relates to a method for fixing underground gas storage well cylinder, which comprises a well cylinder whose bottom has a one-way valve and a fixing bracket inside the basic well; a irrigating device for mounting insertion tube and modulating the cement via the cement pump, insertion tube, and one-way valve to fill cement into the cylinder and the well wall; then removing the irrigating device; and waiting the cement be solidified. The invention can avoid pollution on the inner chamber of well cylinder, to eliminate the washing process. And it can improve the safety and service life of well cylinder.

Owner:自贡力源科技有限公司

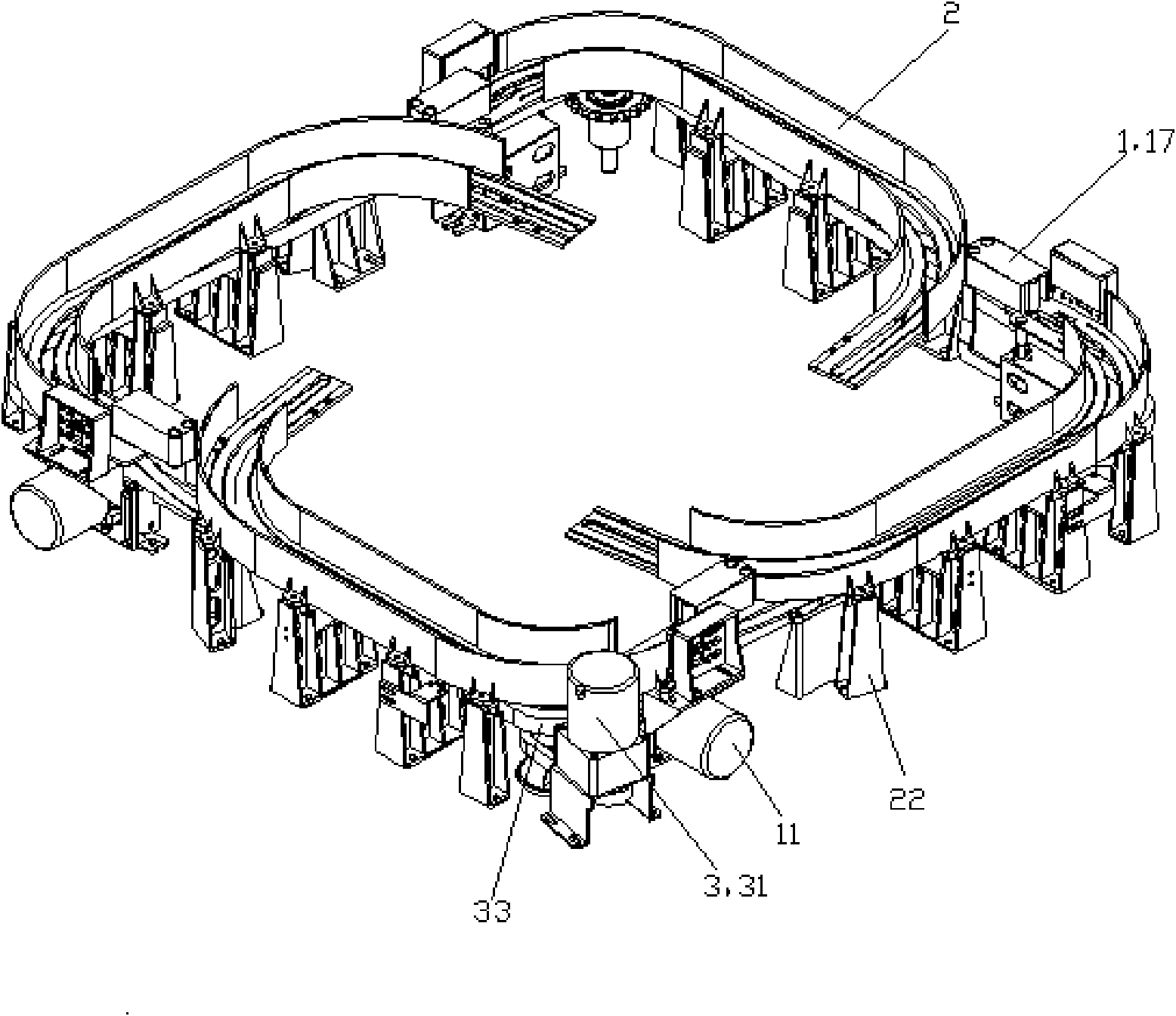

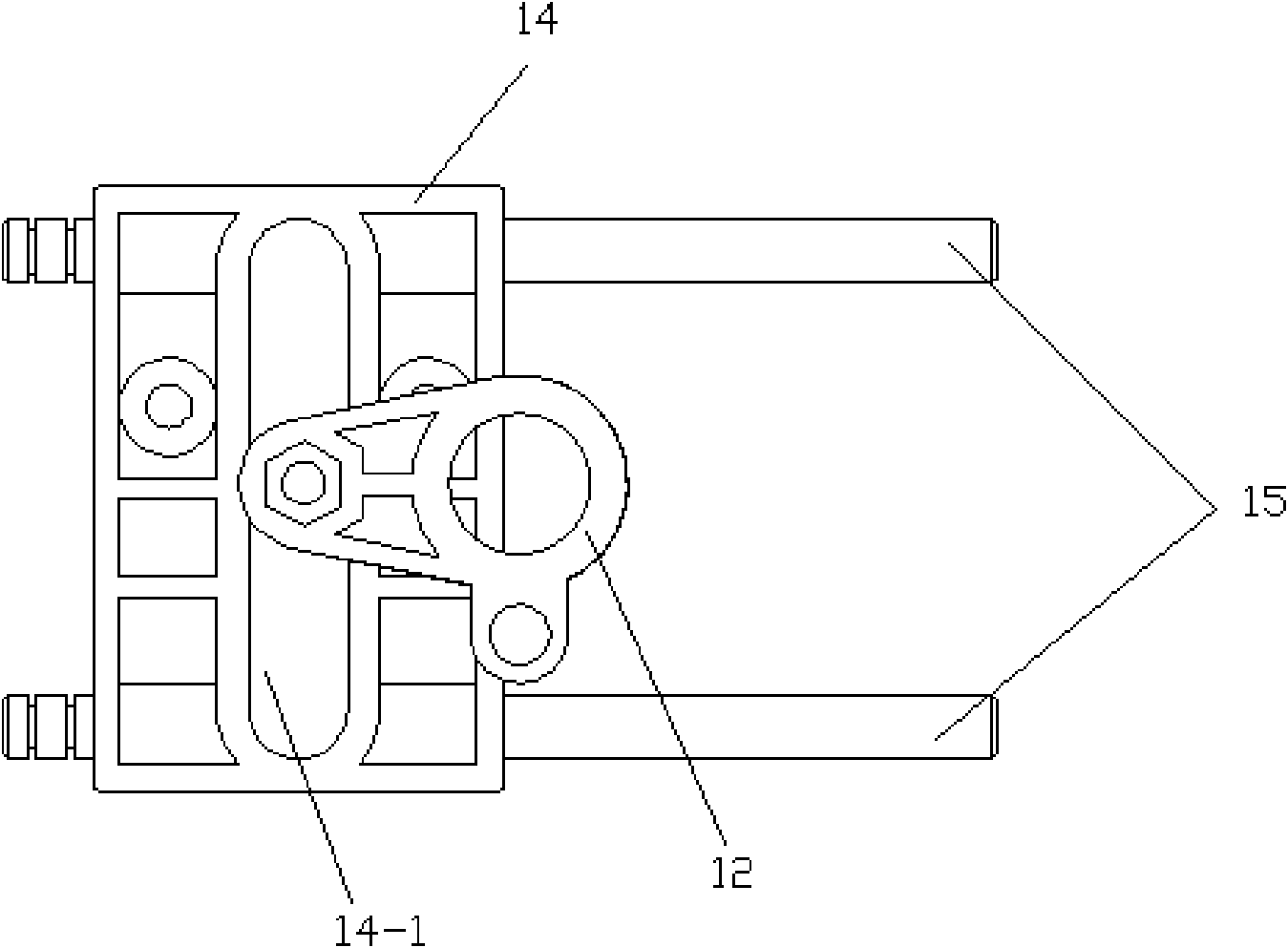

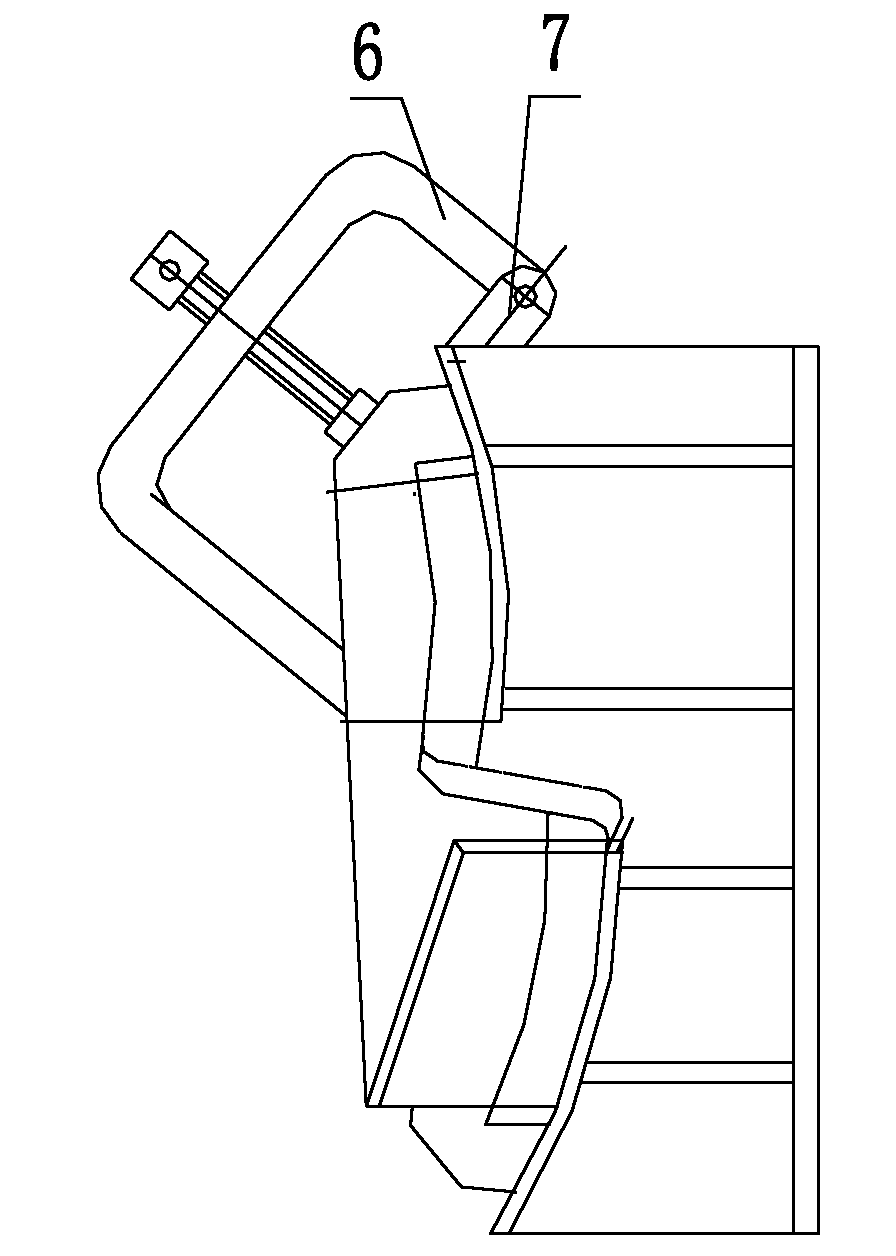

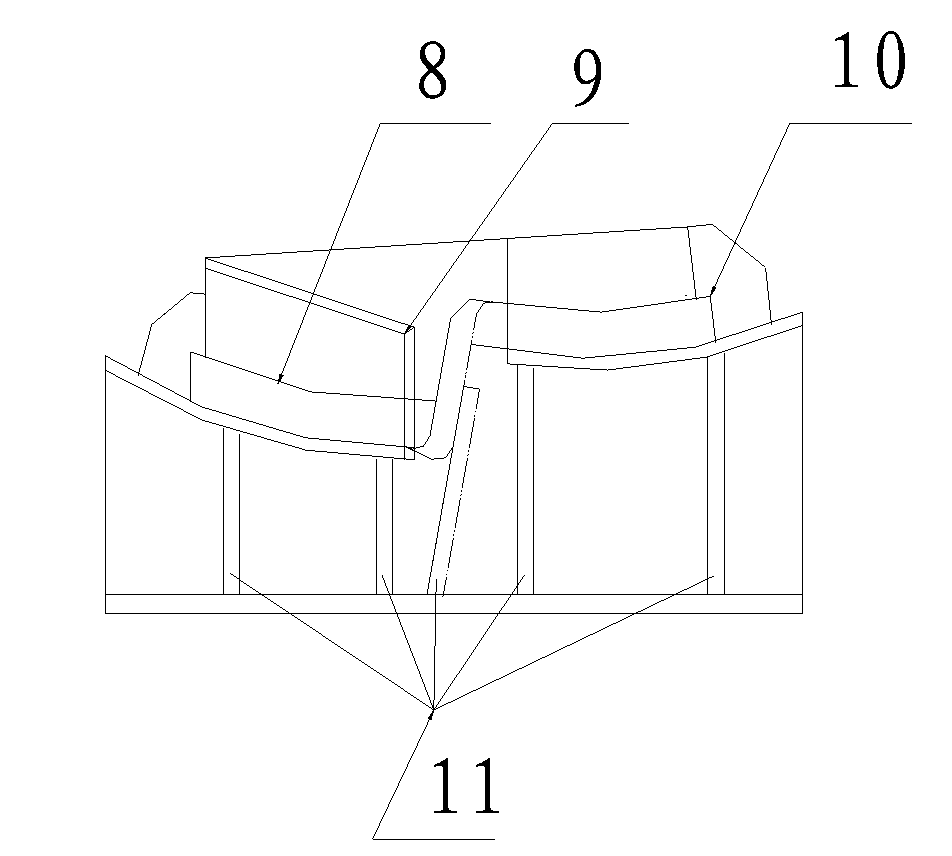

Mah-jongg placing system for full-automatic mah-jongg machine

InactiveCN102133478AThe effect of pushing cards is improvedStable structureIndoor gamesElectrical and Electronics engineering

The invention relates to a mah-jongg placing system for a full-automatic mah-jongg machine, and the system provided by the invention comprises four mah-jongg pushing devices, four horizontally arranged mah-jongg placing rails and a chain transmission device, wherein the chain transmission device is arranged below the four mah-jongg placing rails; each mah-jongg pushing device is respectively arranged at a mah-jongg inlet on one corresponding mah-jongg placing rail; each mah-jongg pushing device comprises a mah-jongg pushing head; guiding slots are arranged on the mah-jongg placing rails; the chain transmission device comprises a mah-jongg placing wheel; the mah-jongg pushing heads of the mah-jongg pushing devices are arranged above the starting ends of guide slots on the mah-jongg placing rails and are opposite to the mah-jongg inlets on the mah-jongg placing rails; the mah-jongg placing wheel is in sliding connection with the guide slots; slots, into which the mah-jongg placing wheel can slide, are arranged on the lower parts of the mah-jongg pushing heads; and the mah-jongg placing rails and the bottom of the mah-jongg machine are fixed through a rail bracket. The mah-jongg placing system for the full-automatic mah-jongg machine comprises the chain transmission device which is used for replacing the steel wire transmission in the prior art by the chain transmission, thus the mah-jongg pushing effect is greatly improved, and the structure is more stable.

Owner:程亮星

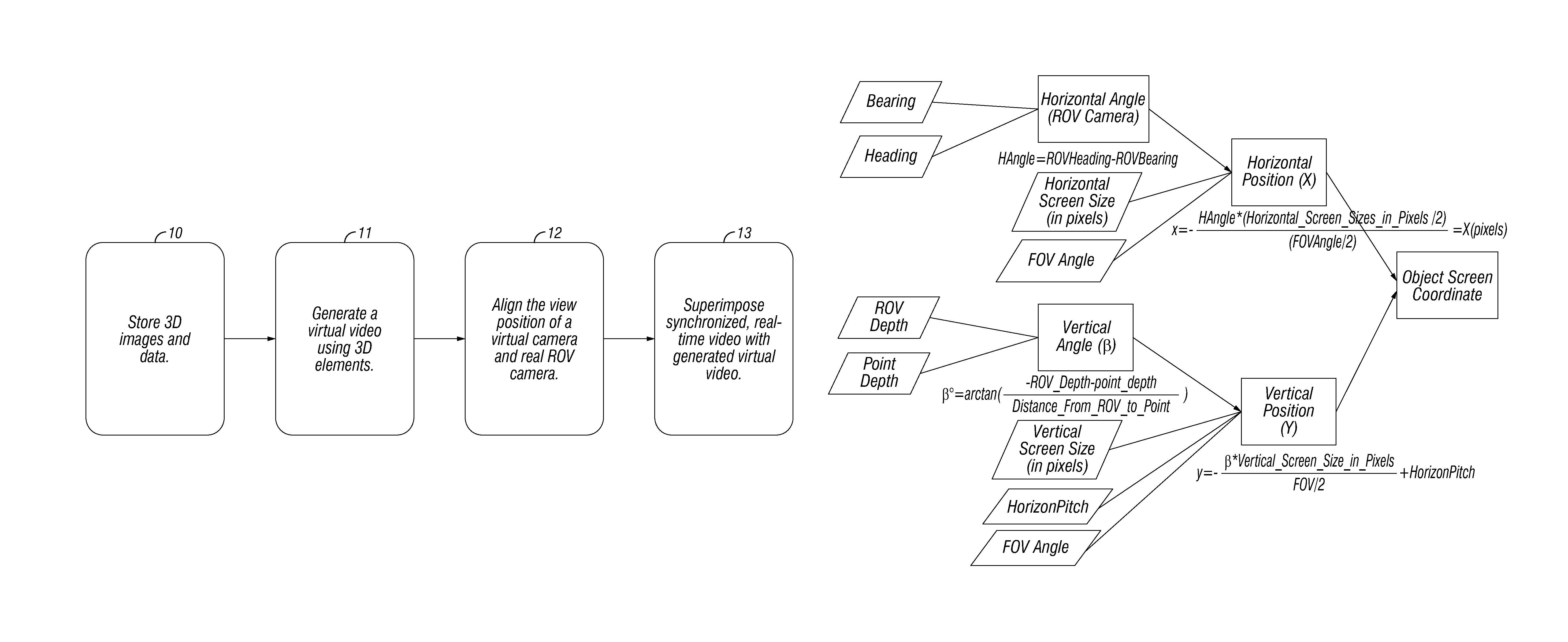

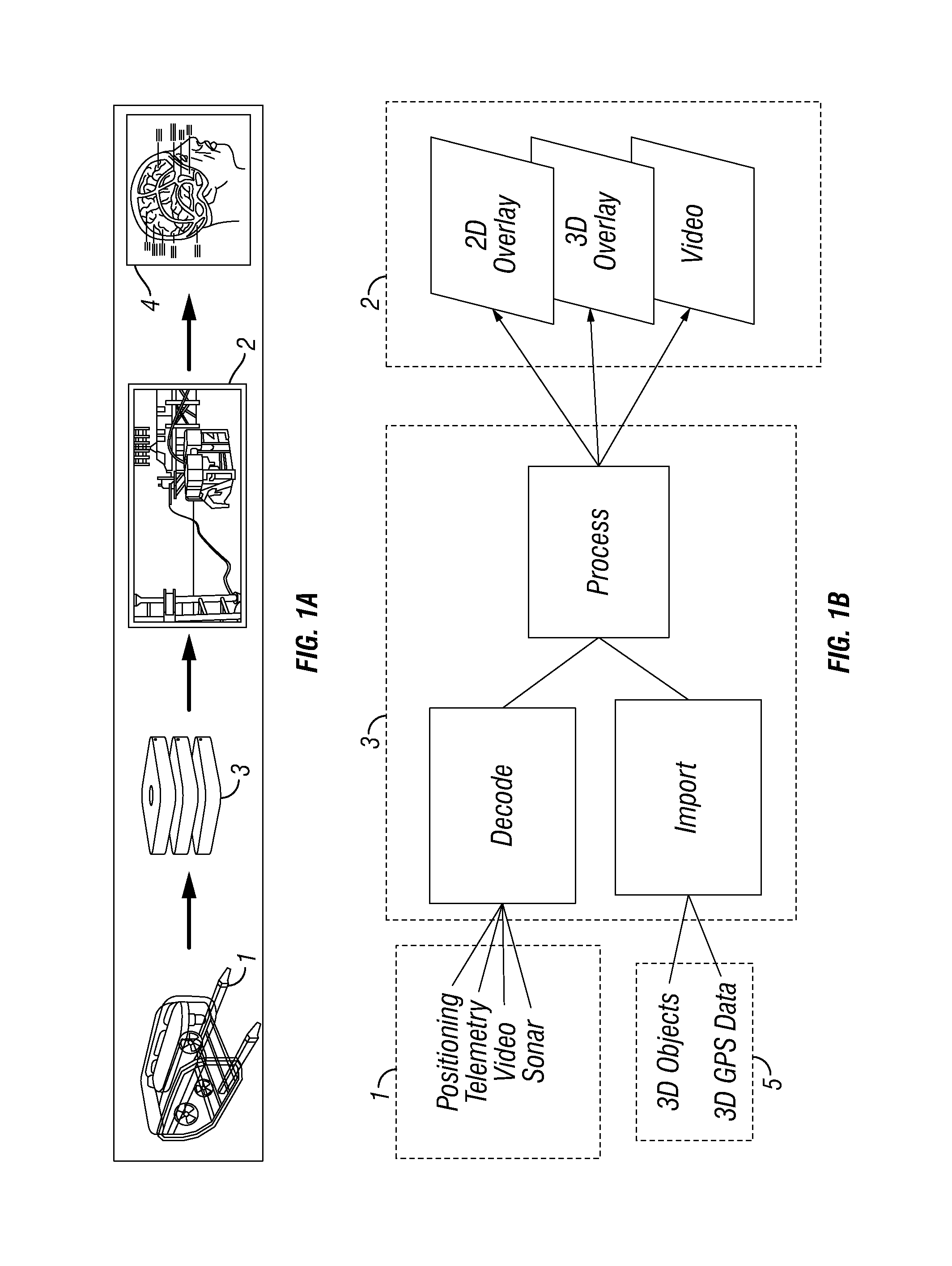

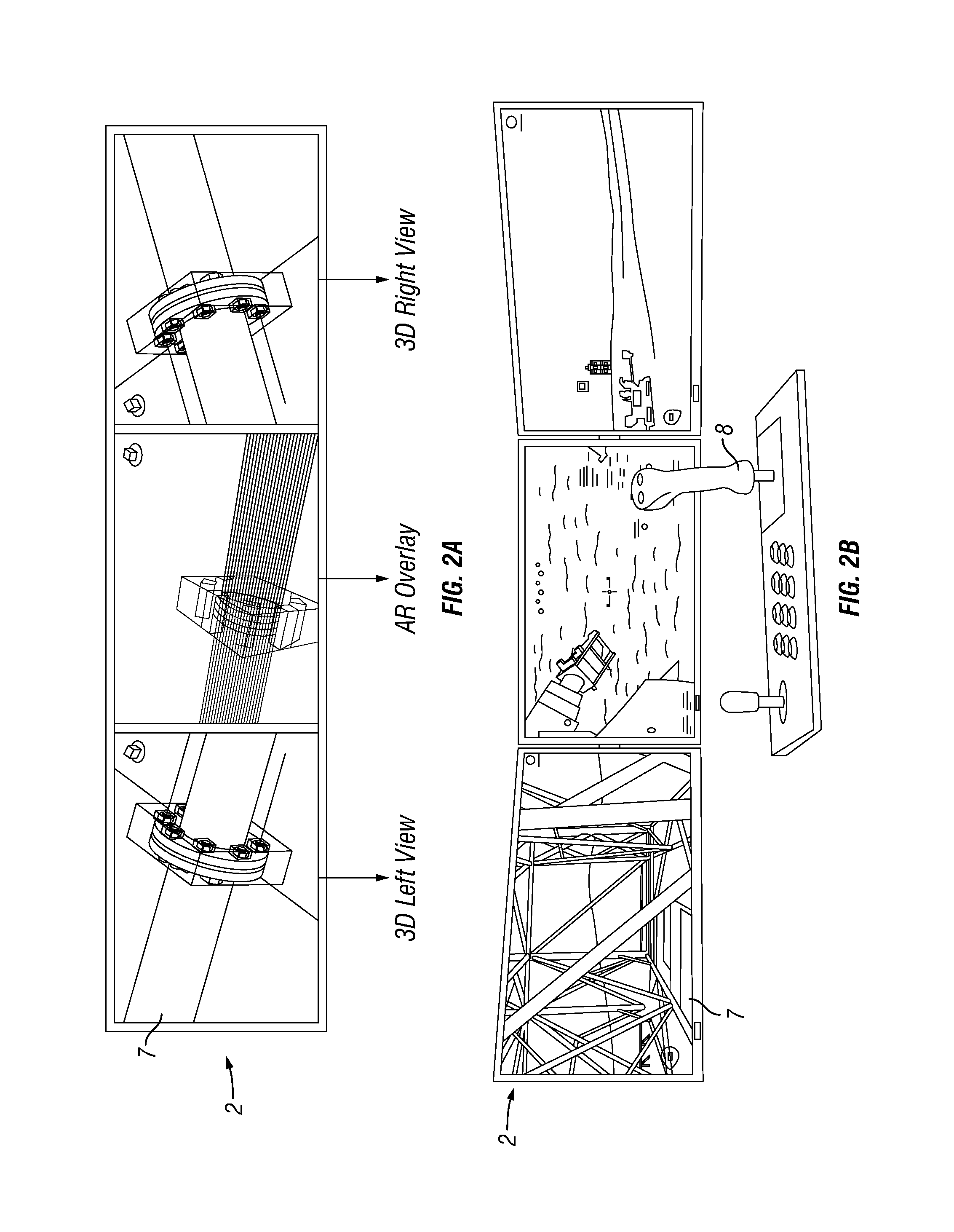

System and method of operation for remotely operated vehicles with superimposed 3D imagery

ActiveUS9195231B2Facilitate conductionUtilization periodImage enhancementTelevision system detailsGraphicsVisual perception

The present invention provides a system and method of utilizing superimposed 3D imagery for remotely operated vehicles, namely 3D, reconstructed images of the environment of the ROV. In another aspect, it includes generating a virtual video of 3D elements in the operation environment, synchronizing the angle and position of the camera of a virtual video with the angle and position of a real camera, superimposing the virtual video and the real video from the real camera; superimposing these video feeds such that one is manipulated to show transparencies in areas of less interest, in order to show through the other video. It furthermore may include superimposing information, whether graphic, textual or both on to the hybrid virtual-real 3D imagery. The subject invention is also networked, such that the immersive visual interface described above is accessible to a plurality of users operating from a plurality of locations.

Owner:ABYSSAL SA

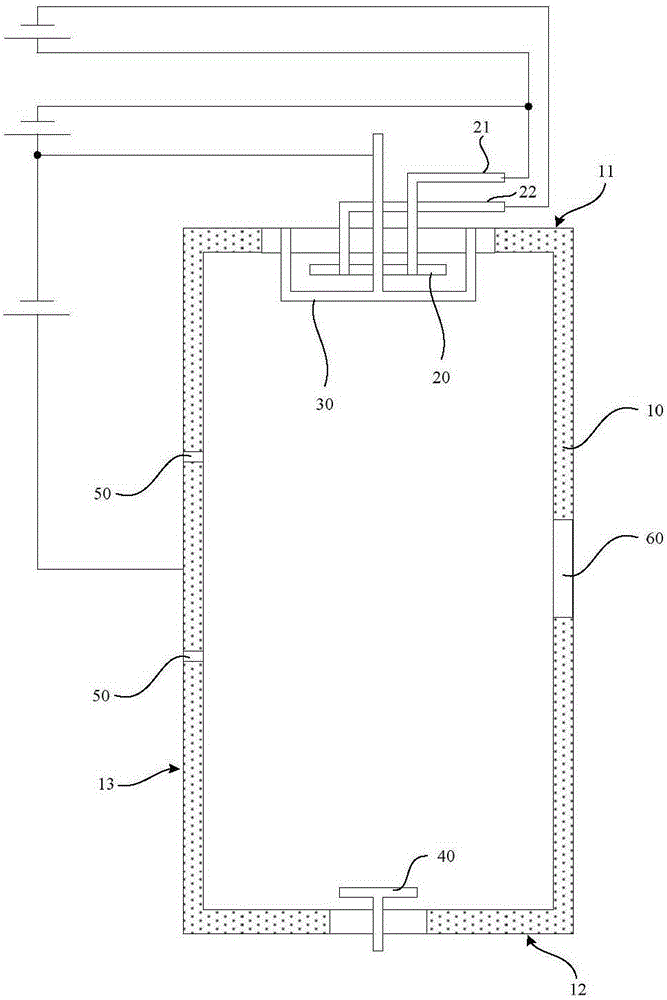

Ion forming container and ion source

ActiveCN106498360AExtended missionFlat surfaceVacuum evaporation coatingSputtering coatingLanthanumVoltage

The invention provides an ion forming container and an ion source. The ion forming container comprises a container body, a first cathode electrode and a second cathode electrode, wherein the container body comprises a first side wall and a second side wall which are oppositely arranged; the first cathode electrode is arranged in the first side wall, and first voltage is exerted onto the first cathode electrode; the second cathode electrode is arranged in the first side wall and surrounds the first cathode electrode, second voltage is exerted onto the second cathode electrode, and third voltage is exerted onto the container body; and the second cathode electrode is made of a tungsten lanthanum alloy material, the first voltage is smaller than the second voltage, and the second voltage is smaller than the third voltage. According to the ion forming container and the ion source, the second cathode electrode adopts the tungsten lanthanum alloy material, in the process of forming hot electrons, lanthanum metal enables the surface of the second cathode electrode to keep smooth, the surface of the second cathode electrode keeps smooth, the service life of the second cathode electrode is prolonged, and therefore the short circuit phenomenon, caused by expansion of the second cathode electrode, of the second cathode electrode and the container body is avoided, and the service life of the ion source is prolonged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Technical method of dehydrogenating alcohols

InactiveCN1164553CNo carbon depositExtended missionOrganic compound preparationCarbonyl compound preparationAlcoholActive component

A process for dehydrogenating alcohols features that after the dehydrogenating catalyst whose active component is nano-class metal component is loaded in reactor, the dehydrogenating reaction on raw alcohol takes place to generate aldehyde and ketone whose number of C atoms isequal to that of alcohol. Its advantages are high selectivity, low reaction temp and long service life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

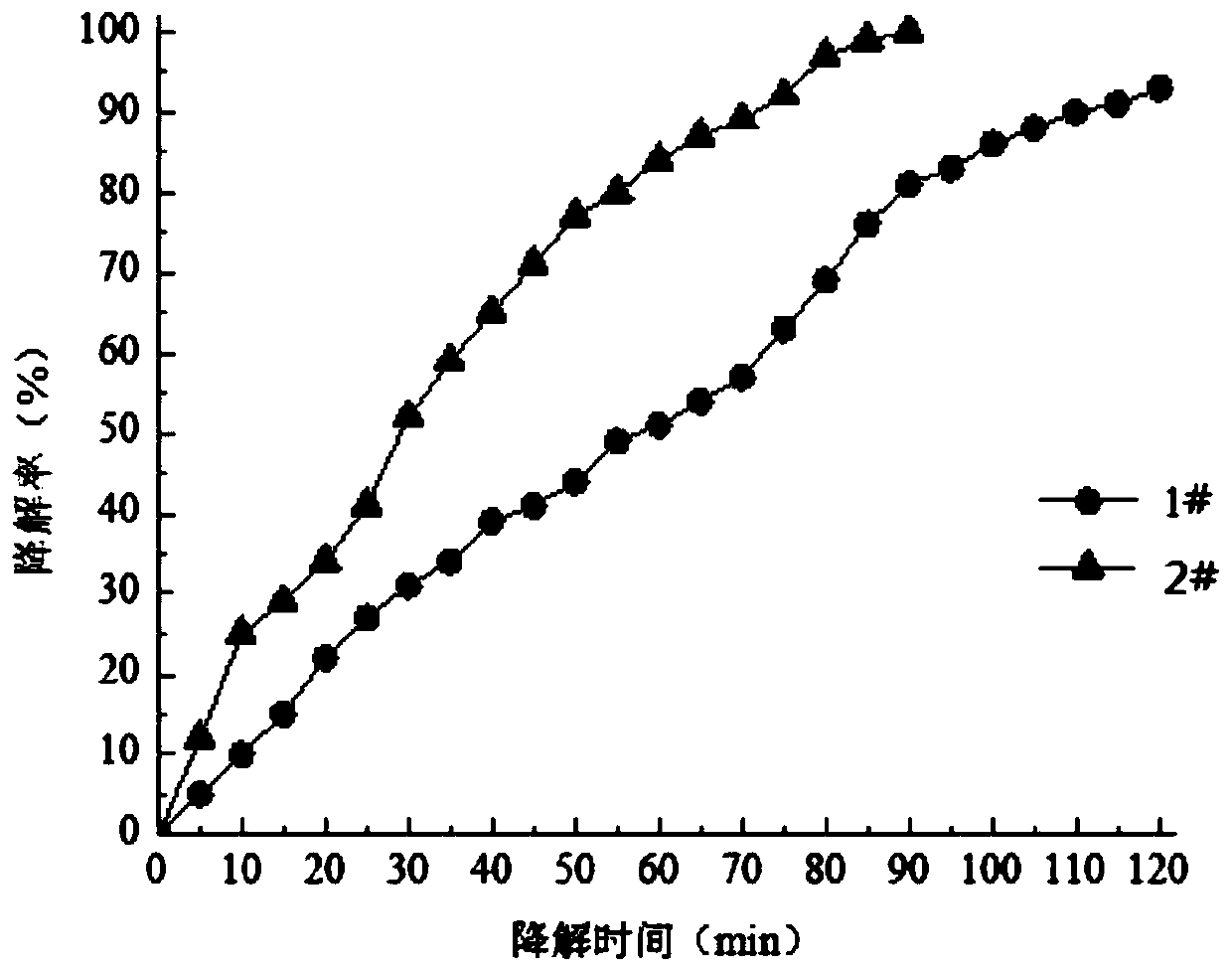

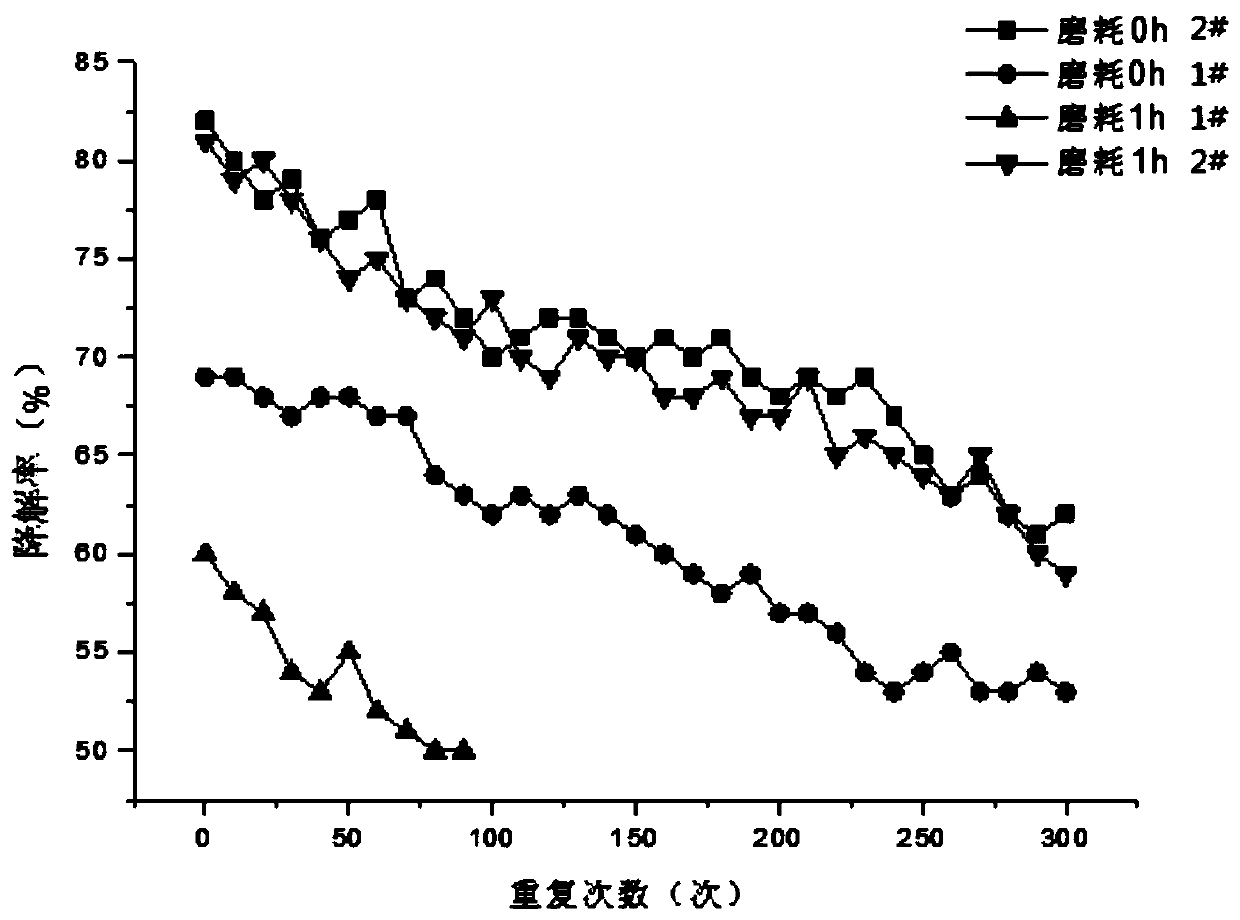

High-efficiency and durable exhaust gas degradation material and preparation method thereof

InactiveCN110003725AImprove abrasion resistanceExtended missionUnspecified rubber coatingsExhaust gasNano tio2

The invention belongs to the technical field of automobile exhaust gas treatment, and particularly discloses a high-efficiency and durable exhaust gas degradation material and a preparation method thereof. The high-efficiency and durable exhaust gas degradation material is prepared from, by mass, 40%-45% of nano TiO2, 43%-48% of Al2O3 and 8%-12% of rubber powder. The exhaust gas degradation material is composed of the nano TiO2, the Al2O3 and the rubber powder, wherein the addition of the Al2O3 and rubber powder modifies the nano TiO2, compared with a pure nano TiO2 material, the material is prepared into a coating, the coating is applied on the road surface, the material has a faster and higher exhaust gas degradation rate and better wear resistance, thereby making the nano TiO2 be betterapplied and popularized in the field of automobile exhaust gas degradation.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

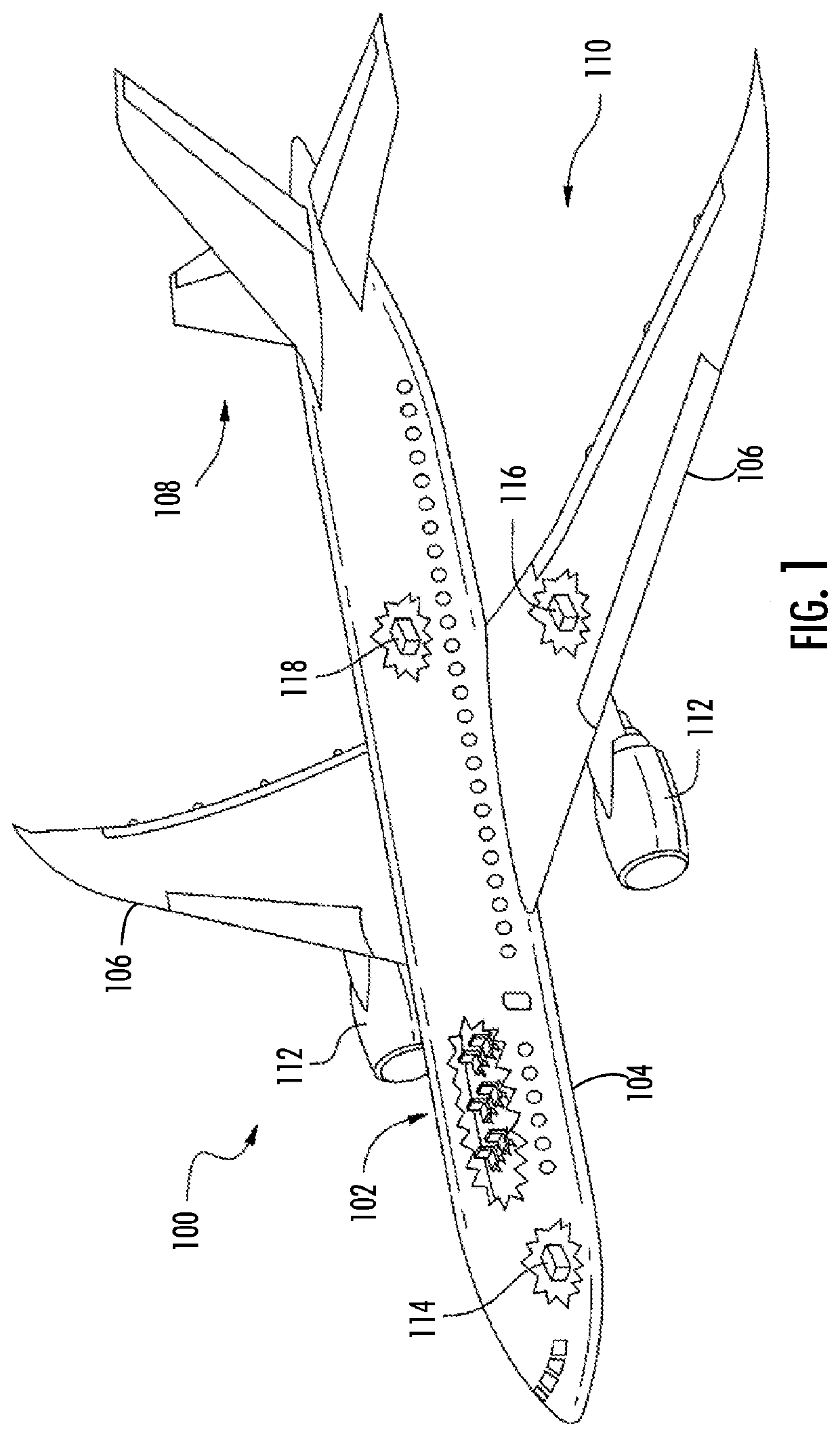

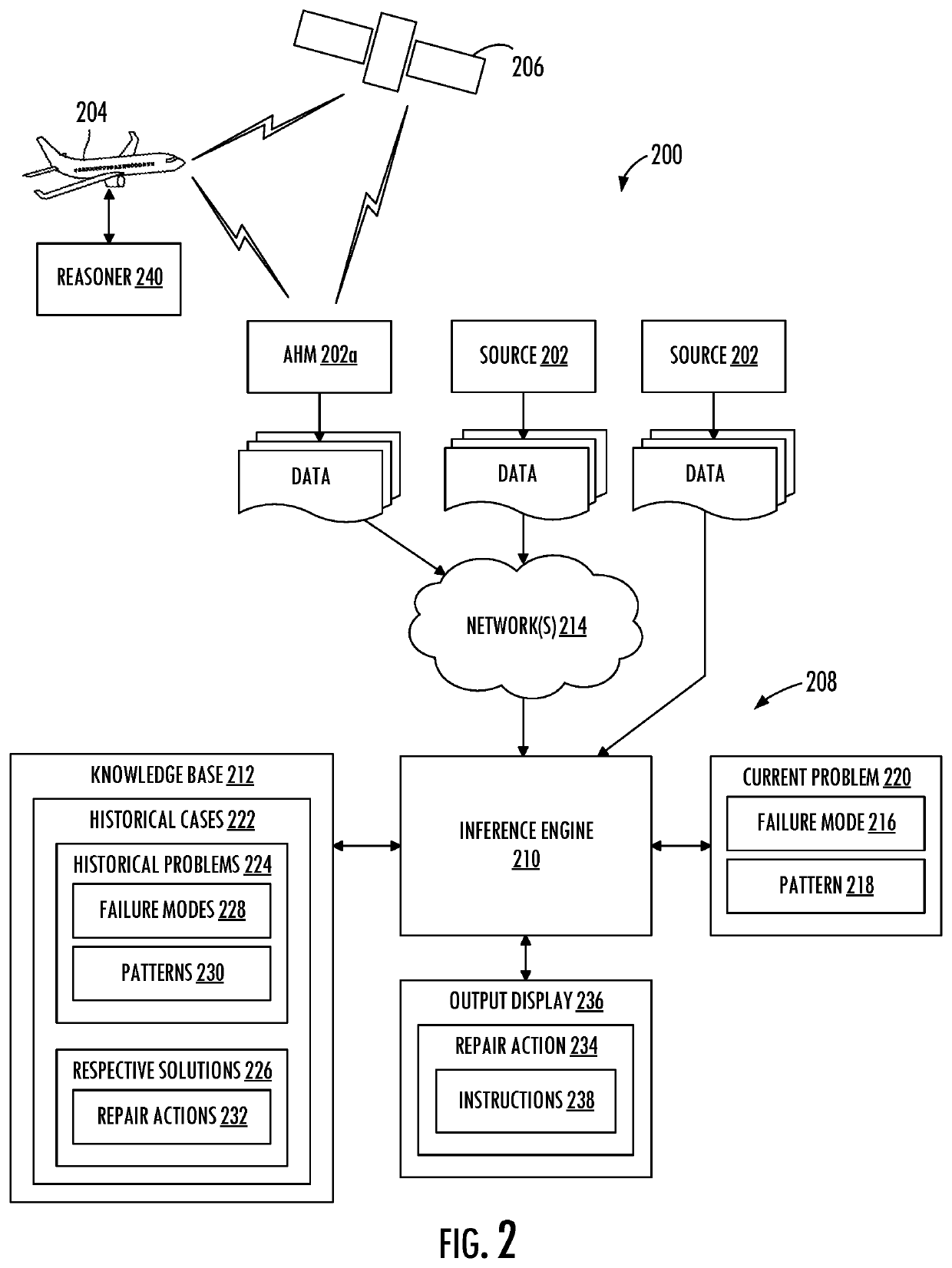

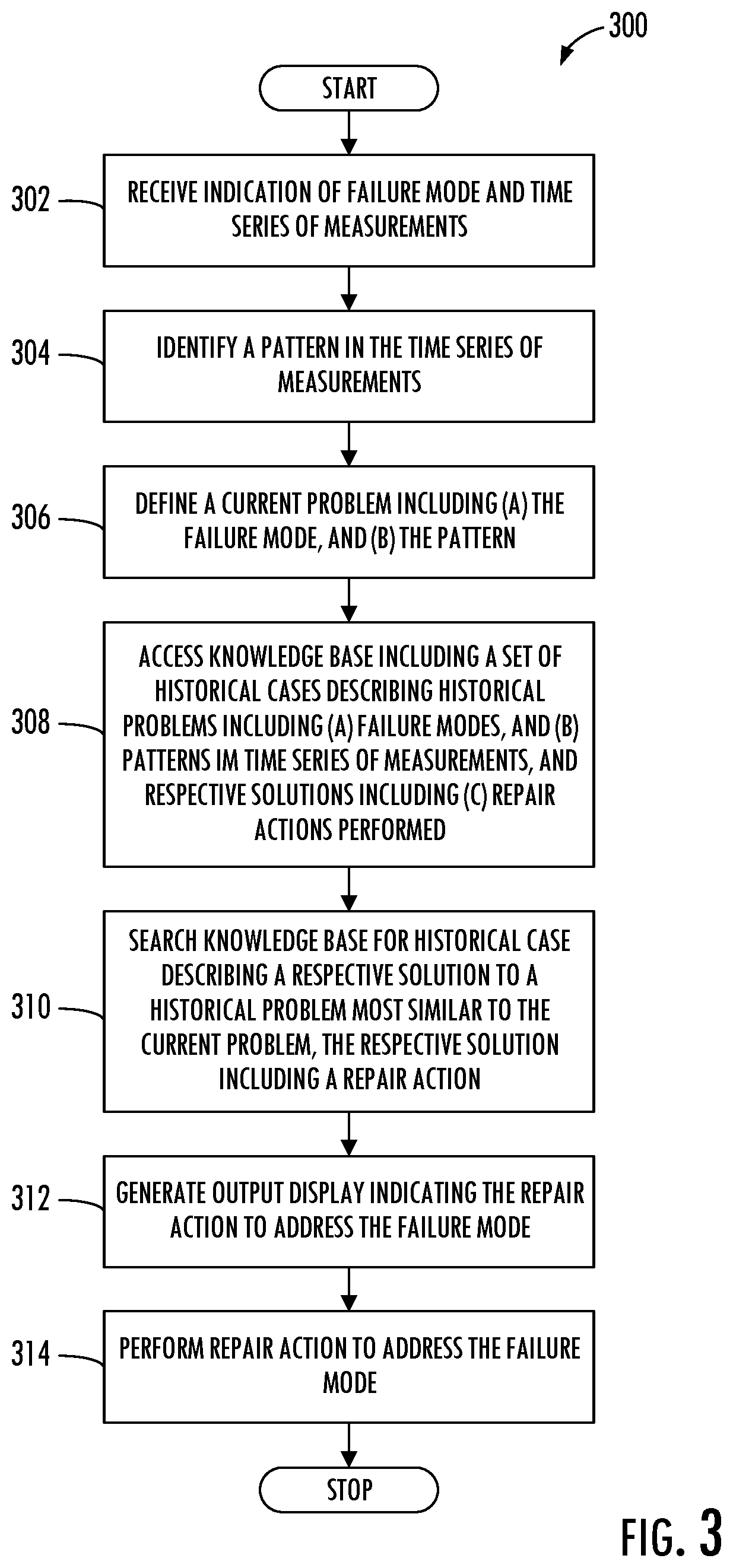

Data analytics for more-informed repair of a mechanical or electromechanical system

PendingUS20220036205A1More-informed repairShorten the timeElectric testing/monitoringKnowledge representationControl engineeringMachine

A method is provided for repair of a mechanical or electromechanical system of a machine. An inference engine receives indication of a failure mode of the system, and measurements of operating conditions of the machine, and the inference engine defines a current problem including (a) the failure mode of the system, and (b) a pattern in the measurements. The inference engine searches a knowledge base with historical problems including (a) failure modes of systems of the machine, and (b) patterns in measurements of the operating conditions, and respective solutions with (c) repair actions performed to address the respective ones of the failure modes, for a respective solution to a historical problem most similar to the current problem. This is inferred as a solution to the current problem, and the inference engine generates an output display indicating the repair action of the solution to address the failure mode of the system.

Owner:THE BOEING CO

Thermal treatment process of copper tube perforation needle

InactiveCN102676782AExtended missionExtended service lifeFurnace typesQuenching agentsRoom temperatureFree cooling

The invention relates to a thermal treatment process of a copper tube perforation needle. The thermal treatment process is characterized by comprising the following process steps of: (1) performing first-stage heating treatment on a perforation needle in a salt bath furnace of 820-850 DEG C, and performing second-stage heating treatment on the perforation needle in a salt bath furnace of 1,020-1,050 DEG C; (2) cooling the perforation needle in quenching oil of 50-80 DEG C, discharging oil when the perforation needle is cooled to 300-250 DEG C, and naturally cooling to 100-120 DEG C in air; (3) performing tempering treatment: performing tempering treatment on the perforation needle, which is subjected to quenching and cooling treatment, at 560-600 DEG C, preserving heat for 8-12 hours and then naturally cooling in air to room temperature; and (4) repeating the operation of the step (3) for two to three times to finish the thermal treatment process of the perforation needle. According to the thermal treatment process of the copper tube perforation needle, the service life is prolonged, a new process for thermal treatment of the perforation needle is developed, the service life can be prolonged by six times, and the hardness of the copper tube perforation needle after thermal treatment can be 47-52 HRC (Rockwell hardness).

Owner:WUXI HONGDA HEAT TREATMENT FORGING

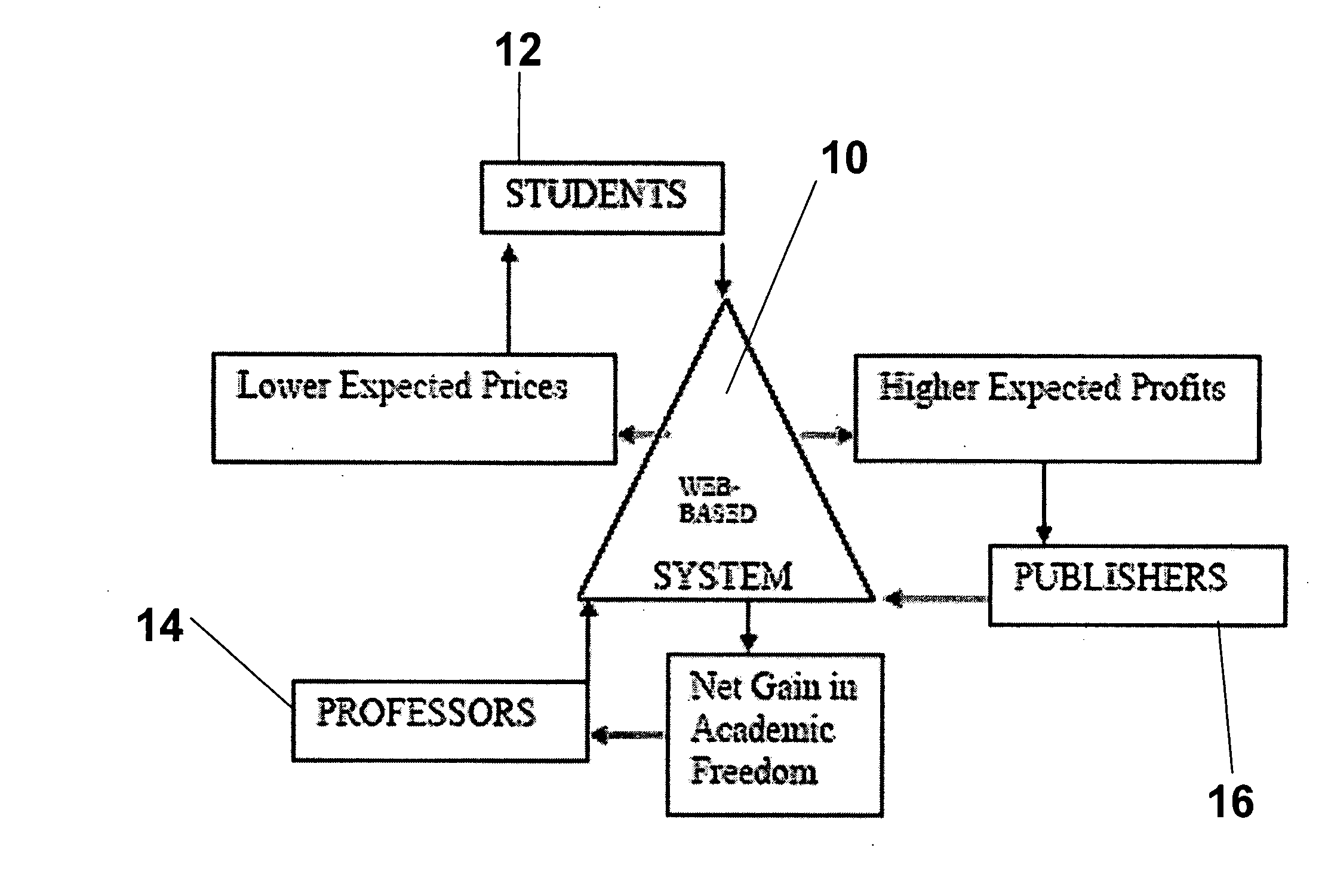

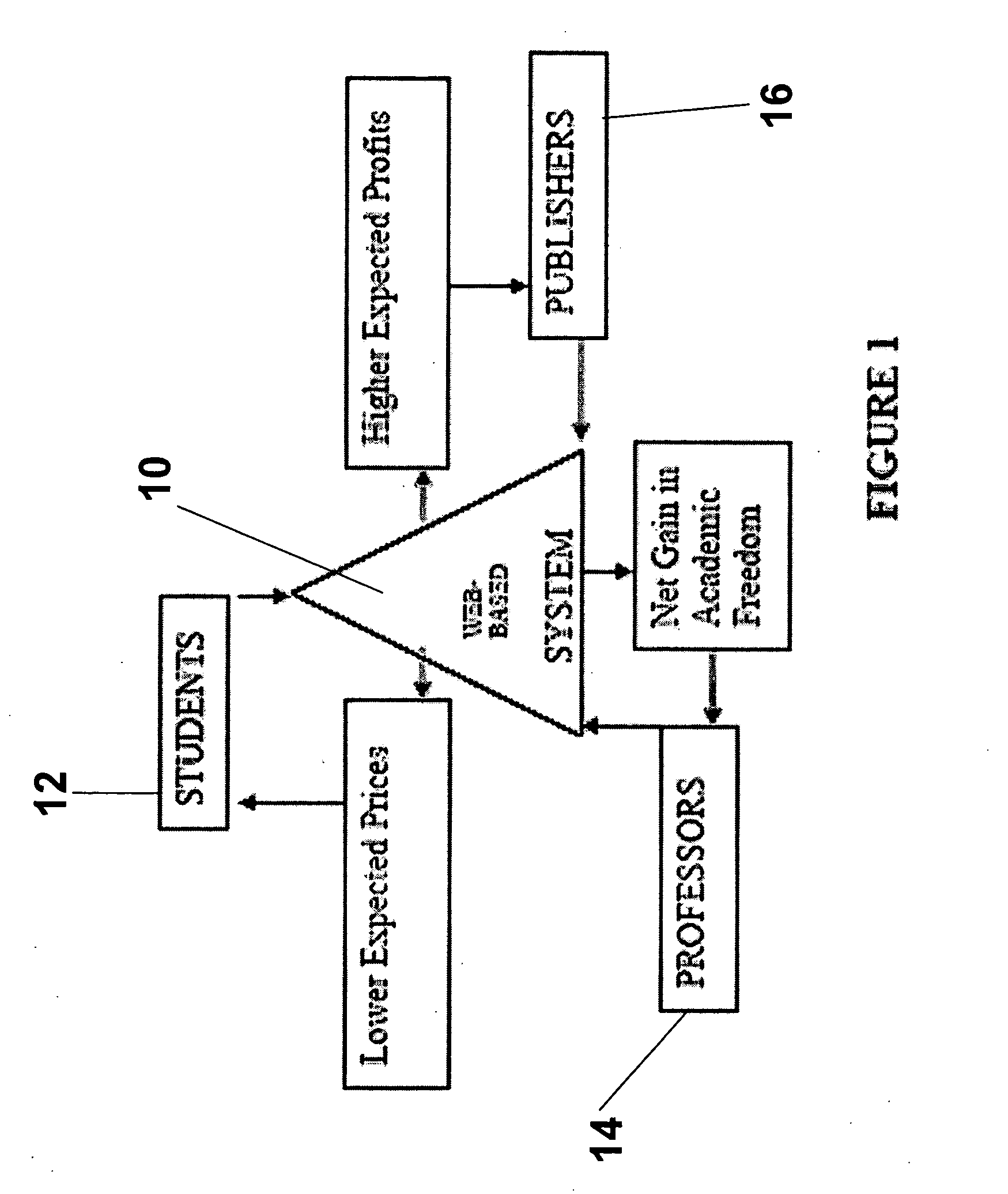

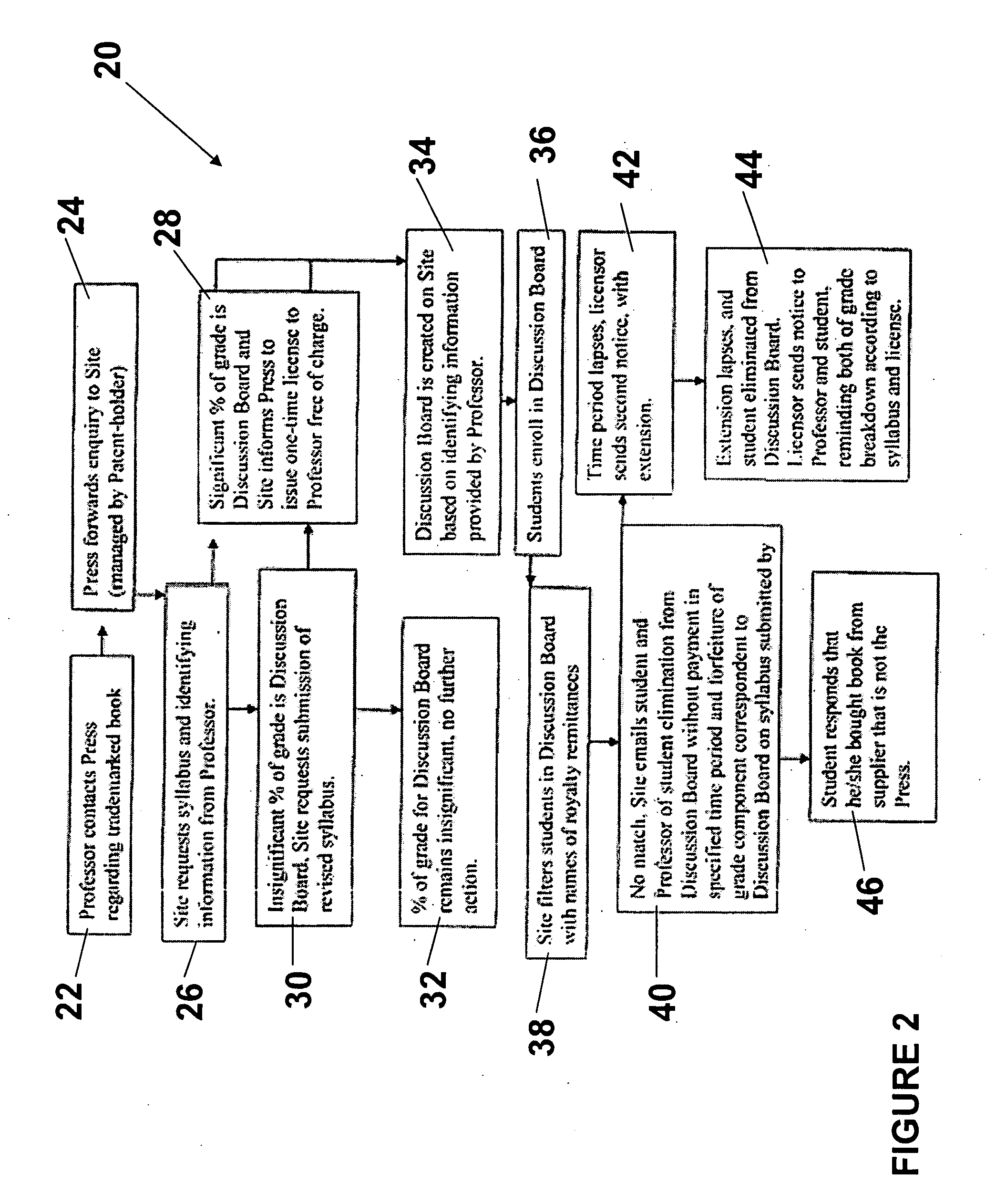

Web-based system and method for preventing unauthorized access to copyrighted academic texts

InactiveUS20080076105A1Prevent unauthorized accessEnhancing overarching academic missionComputer security arrangementsElectrical appliancesTrademarkLibrary science

A system and method for preventing unauthorized access to copyrighted academic texts is provided in which trademark licenses, discussion boards, and grade content are integrated into a web-based system that aligns the interests of teaching professionals, students, and publishers while also enhancing the overarching academic mission to create and disseminate knowledge.

Owner:VOGEL JOSEPH HENRY

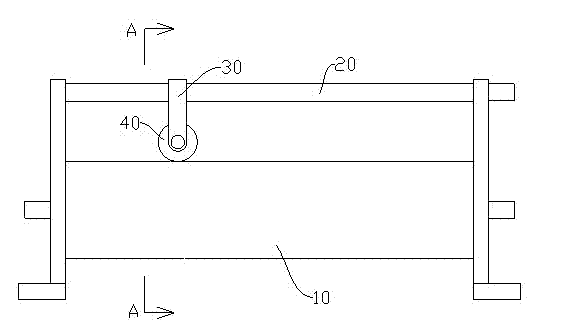

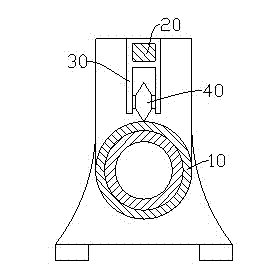

Slide-wire resistor

InactiveCN102810374AExtended missionExtended service lifeResistor terminals/electrodesResisitors with sliding contactResistance wireEngineering

The invention discloses a slide-wire resistor which comprises a resistance wire layer and a lead rail, wherein a sliding rod is arranged3on the lead rail and provided with a contact wheel at the lower end; the contact wheel is in match with the resistance wire layer; and moreover, the lead rail, the sliding rod and the contact wheel are electrically connected. Preferentially, the edge of the contact wheel is in shape of a pointed cone. The slide-wire resistor has the advantages that the service life of the slide-wire resistor is relatively long, and the resistance variation precision is relatively high.

Owner:TAIZHOU SHUANGYU ELECTRONICS

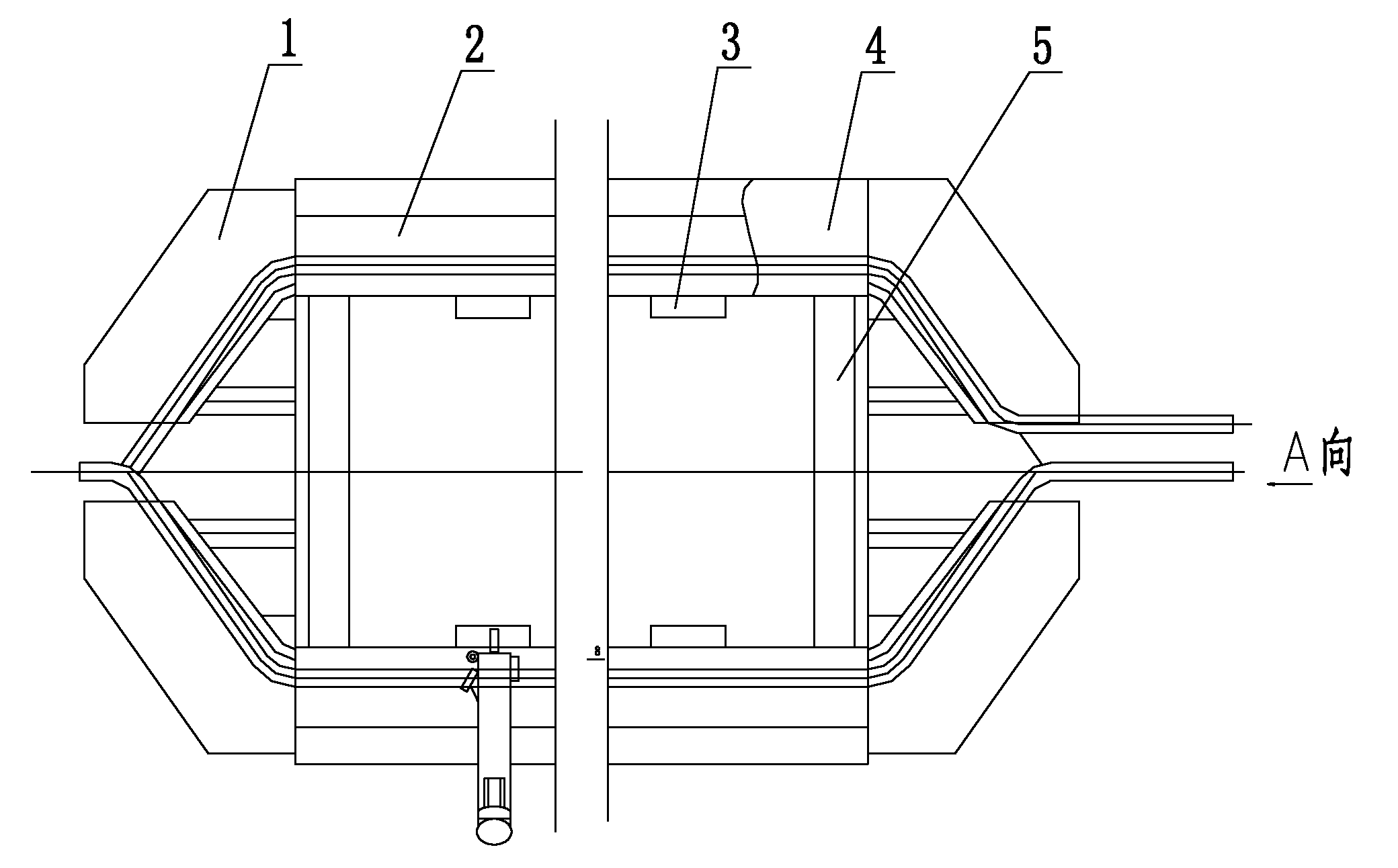

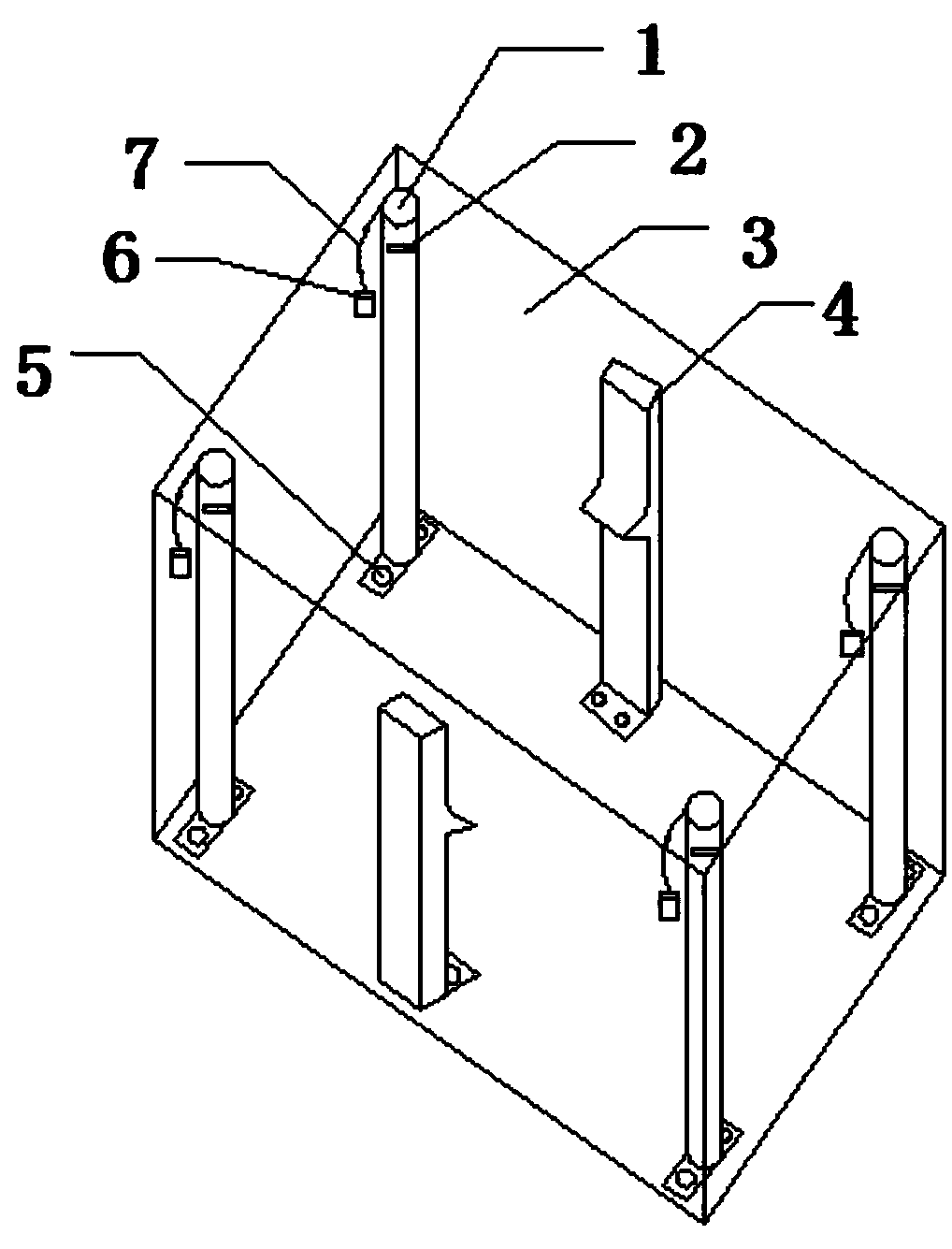

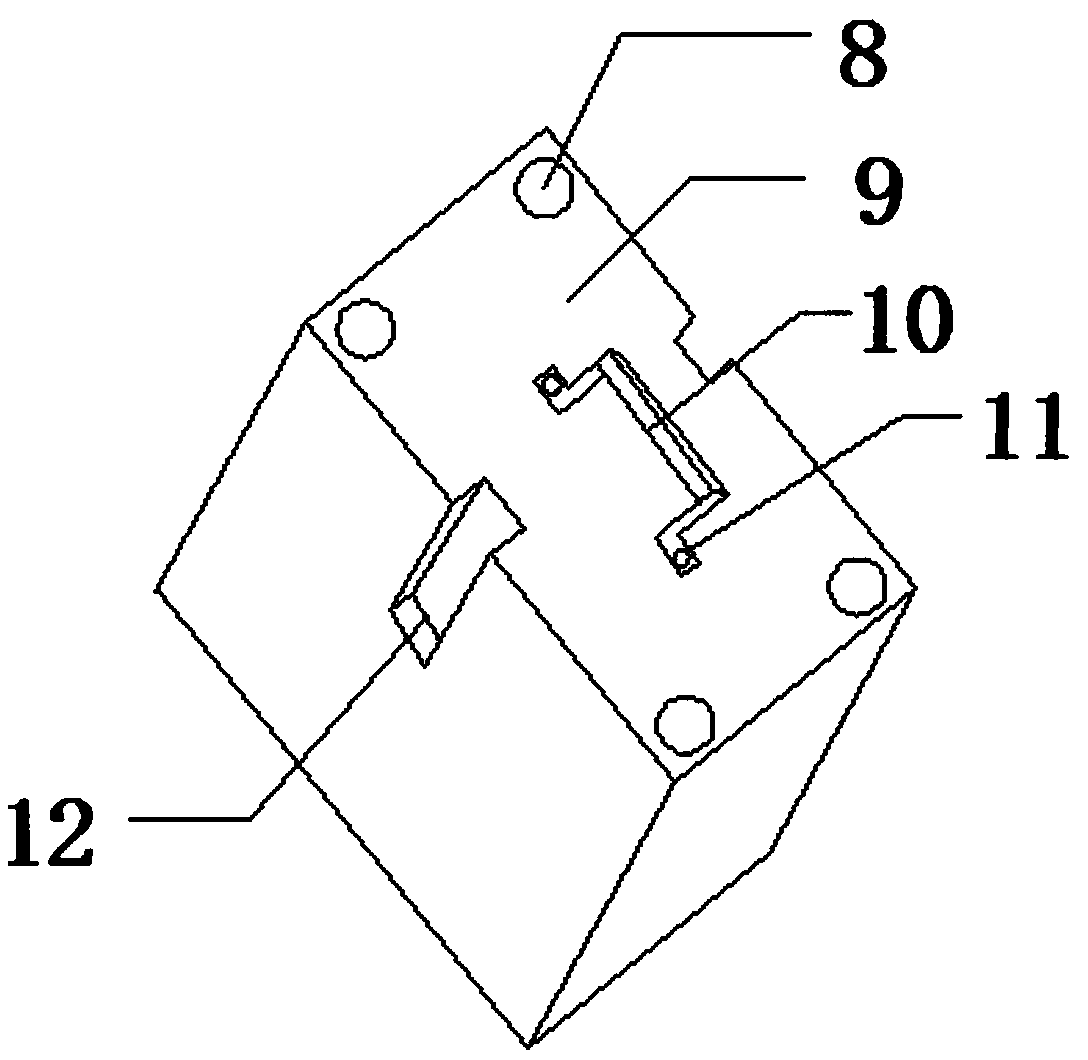

High-voltage motor stator coil end part splicing and shaping method

ActiveCN102005871AReduce the main sizeGuaranteed uptimeEmbedding prefabricated windingsStator coilEngineering

The invention relates to a high-voltage motor stator coil end part splicing and shaping method, and belongs to the technical field of hydraulic generators. The high-voltage motor stator coil end part splicing and shaping method is characterized in that: the stator coil end splicing and shaping is carried out by a shaping and gelling mold; the shaping and gelling mold comprises an end mold, a linear weight, a check block, a linear frame, a flange lug, a flange, an end plate, a side plate, an end part weight, and a support plate; and the process of manufacturing the shaping and gelling mold comprises the following steps of: 1) splicing the linear frame according to an angular template; 2) making a cylindrical fixture according to the size of an R position at the corner of the end part of the stator coil, and heating and bending the side plate on the cylindrical fixture to meet the requirement of the size of the R angle on the end part; 3) welding the end plate and the side plate together to form the end part weight; and 4) in the process of assembling the end mold of the shaping and gelling mold, arranging the end part support plate. The method has the advantages that: the process is reliable, the parts are convenient to assemble, the assembly is time-saving and labor-saving, the insulation is not damaged, the motor is small, the assembly quality is high, the energy is saved, the consumption is reduced, the service life of the motor is prolonged, and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Easy-to-operate battery module fastening device

InactiveCN108832051ASolve storage problemsEasy to storeCell component detailsBatteriesElectrical and Electronics engineeringCorner angle

The invention provides an easy-to-operate battery module fastening device which comprises a storage battery box, a storage battery, a positioning column, a positioning column hole, a positioning plugpin, a plug pin hole and a connecting chain, wherein the positioning column hole is assembled at the corner angle of the storage battery; a buckling slot is arranged in the left end surface of the storage battery; the positioning column is mounted at the corner angle of the lower end surface of the storage battery box; the positioning plug pin is connected with the positioning column through the connecting chain; the upper end of the positioning column is provided with the plug pin hole; a metal buckle is mounted at the middle of the lower part of the lower end surface of the storage battery box; the connecting chain is mounted at the upper end of the positioning column. The device provided by the invention prevents the storage battery from moving up and down to improve the stability of the battery module, avoids left-right movement of the storage battery to make the battery module firmer, and thus greatly prolongs the service life of the storage battery, facilitates the use and has strong practicability and is safe and reliable.

Owner:许春燕

Macromolecule leak-proof mending material and leak-proof tyre containing the same

InactiveCN101139516BExtended missionAffect the use effectTyre partsOther chemical processesElastomerPtru catalyst

The invention discloses a high polymer anti-leakage dense patching material, which comprises by weight hot plastic elastomer 40-60%, thickener 40-60%, softening agent 08%, anti-aging agent 0-2%, catalyst 0-1%, and filling agent 0-15%. The invention also discloses an anti-leakage tyre containing above mentioned high polymer anti-leakage dense patching material, which can efficiently prevent tyre from air leakage and tyre bursting due to pricking of the tyre, guarantee safety in running of vehicles and prolong the service life of tyres. And the use effect of the tyres will not be affected due to the machining (for example dynamic balancing, operation, braking, comfortableness and load bearing capacity, etc.).

Owner:陈芳

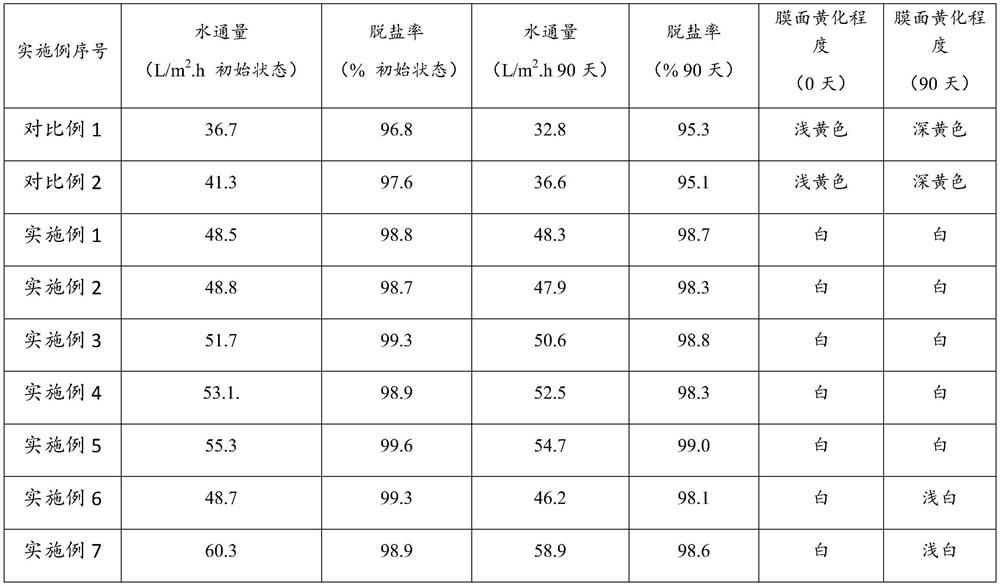

Anti-yellowing composite reverse osmosis membrane and preparation method thereof

ActiveCN113244781AImprove hydrophilicityPlay a protective effectMembranesSemi-permeable membranesPolymer scienceEthyleneglycol dimethacrylate

The invention relates to a preparation method of an anti-yellowing composite reverse osmosis membrane and an application thereof, and the preparation method comprises the following steps: synthesizing poly (ethylene glycol dimethacrylate (EGMA) / isobutoxyacrylamide (IBMA) / acrylamide (AM) ternary anti-yellowing copolymer particles, fixing the ternary anti-yellowing copolymer particles in an ultrafiltration membrane, adding IBMA in the interfacial polymerization process, forming two anti-yellowing layers, and cross-linking IBMA with multi-element acyl chloride or self in interfacial polymerization to form a flexible network, so that the stability of the desalting layer is improved. The test results show that compared with the existing reverse osmosis membrane, the anti-yellowing composite reverse osmosis membrane prepared by the invention has excellent anti-yellowing performance, longer service life and higher flux and desalination performance.

Owner:JIANGSU LONGMEM ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com