Anti-yellowing composite reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and membrane casting solution, which is applied in the field of separation membranes, can solve the problems of restricting the application and promotion of reverse osmosis membranes, reducing the service life of membranes, and affecting the appearance of membranes, so as to reduce the risk of cortex shedding, high hydrophilicity, The effect of improving hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

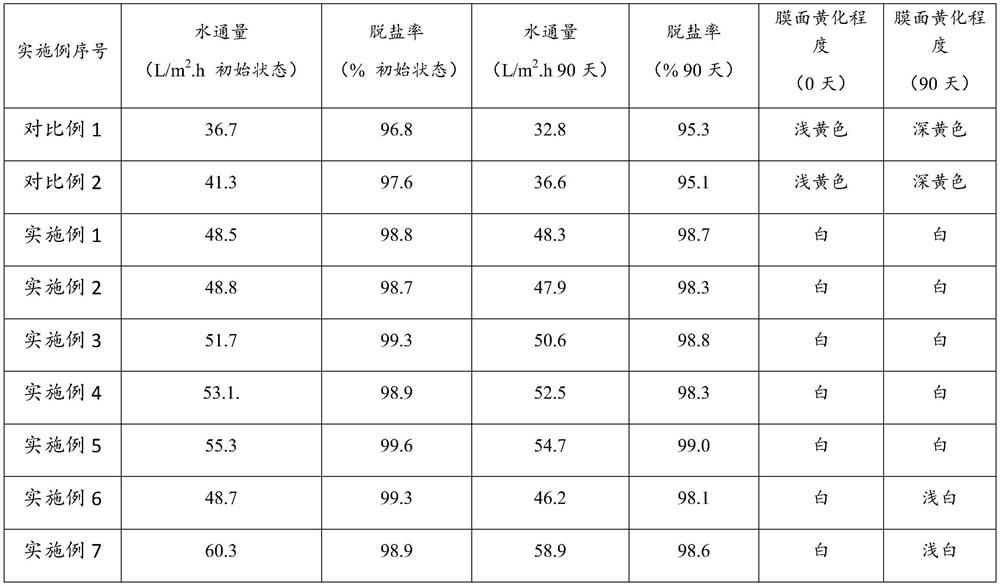

Examples

Embodiment 1

[0028] The amount of substance was added to IBMA, EGMA and AM of 2: 1: 1 to solvent xylene, and the amount of ultrasonic stirring was mixed at 25 ° C, and the amount of the substance was added to an initiator of 0.005, and the vacuum was taken. The reaction was stirred at 80 ° C for 8 h, and the anti-yellow copolymer particles were obtained by centrifugation.

[0029] 2% of the anti-yellow copolymer particles, 15% PVDF, 1% PVP K30 and 0.5% Tween 85 were added to 81.5% DMAC solution, mixed with mixed stirring at 65 ° C and decorating the cast film. liquid.

[0030] The inverted fluid is uniform in the nonwoven fabric, and the phase separation is performed in ultrapure water by a doctor blade film, and the functional ultrafiltration membrane is obtained.

[0031] The functional ultrafiltration membrane is immersed in aqueous phase solution in aqueous phase solution, wherein each component has a mass percentage of 2% IBMA, 2.5% ammine, 0.15% triethylamine and 0.25% camphor sulfonic a...

Embodiment 2

[0033] In addition to the amount ratio of the substances of IBMA, EGMA, and AM to 3: 2: 1, the other conditions are the same as in Example 1, resulting in anti-yellowing composite reverse osmosis membrane.

Embodiment 3

[0035] In addition to the amount ratio of the substances of IBMA, EGMA, and AM to 1: 2: 2, the other conditions are the same as in Example 1, resulting in anti-yellowing composite reverse osmosis membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com