Patents

Literature

77 results about "Repair - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

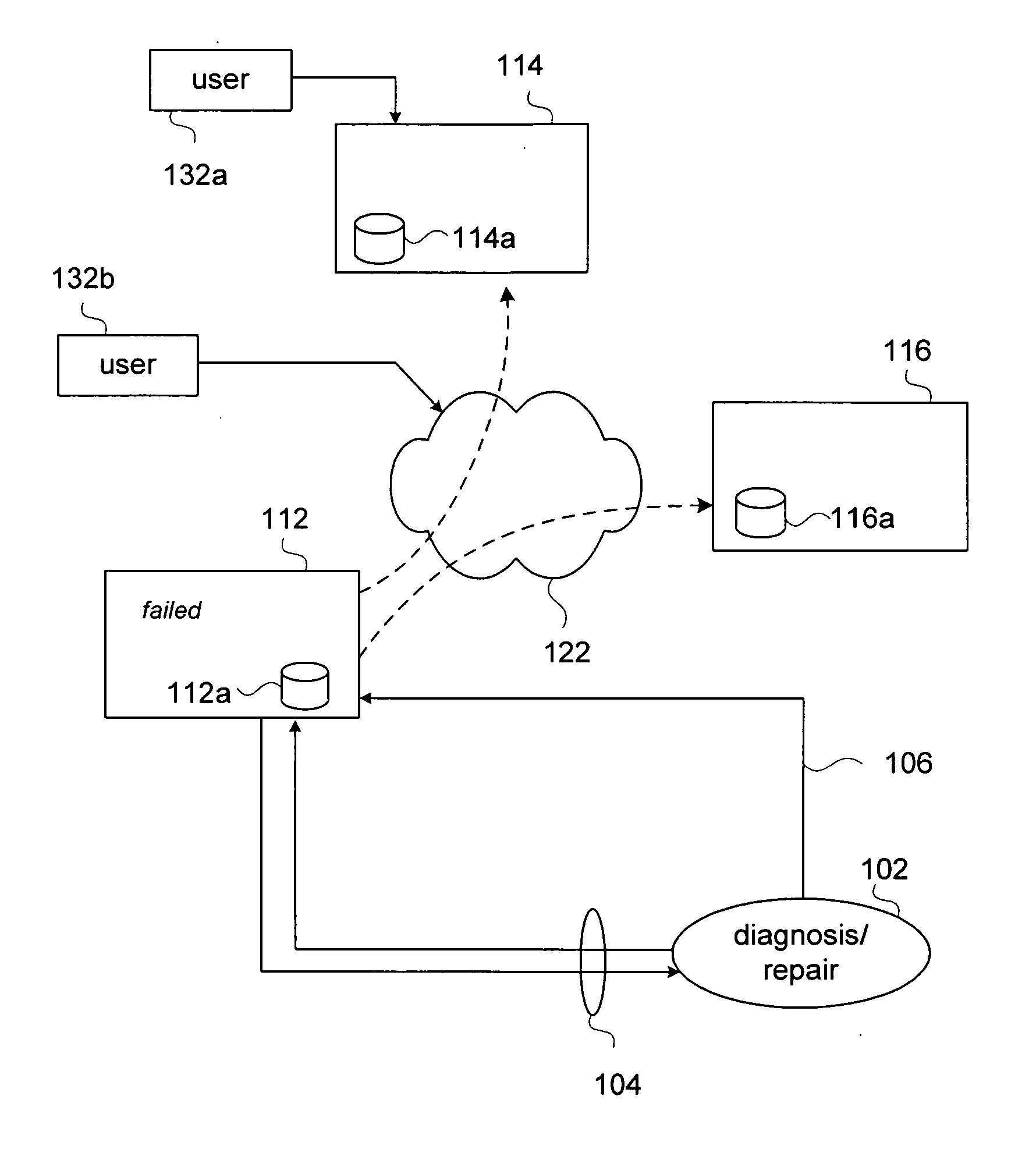

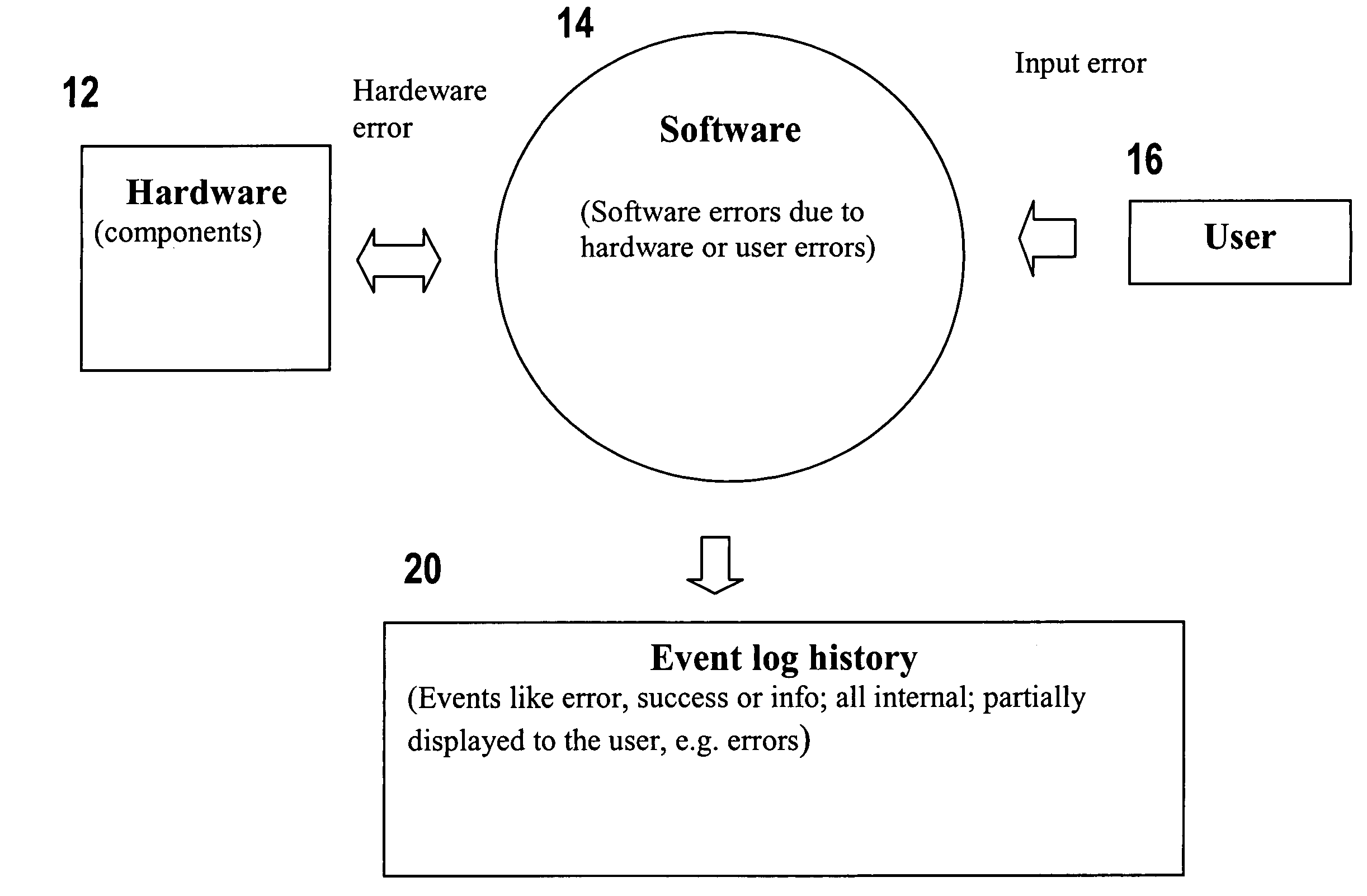

Model based diagnosis and repair for event logs

InactiveUS20060085689A1Easy to updateQuickly and cheaply distributeLogical operation testingNon-redundant fault processingProbit modelDiagnostic information

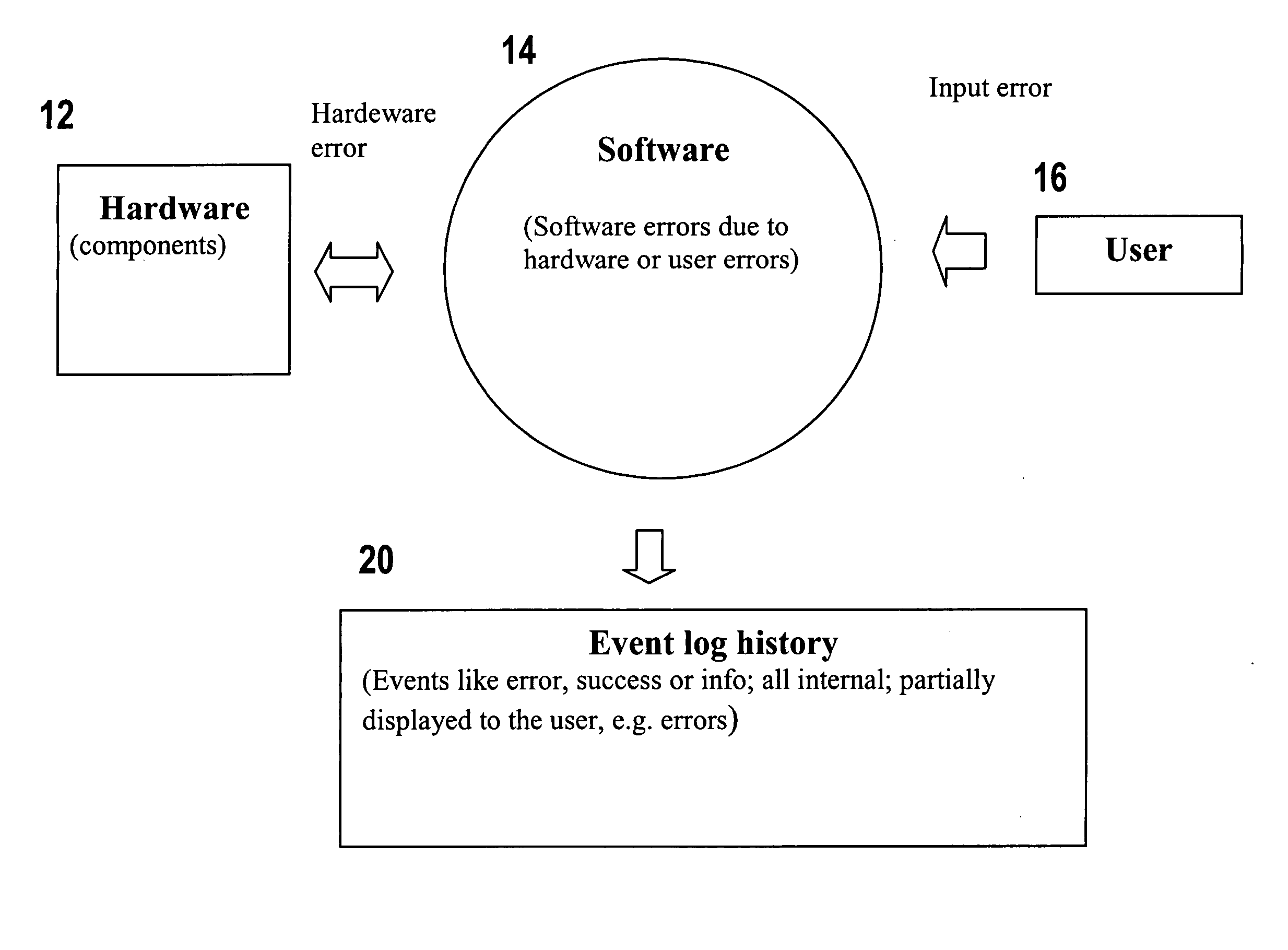

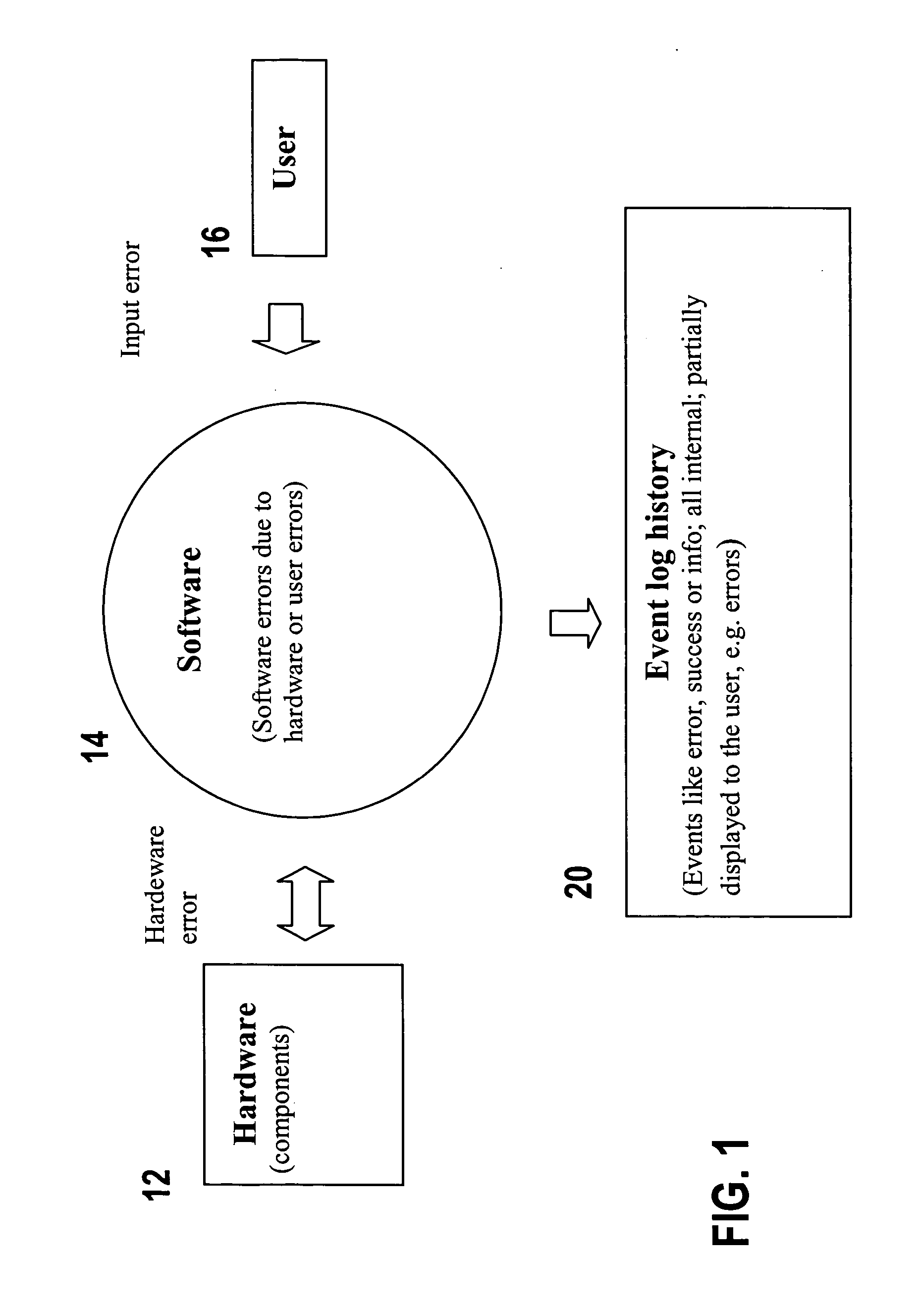

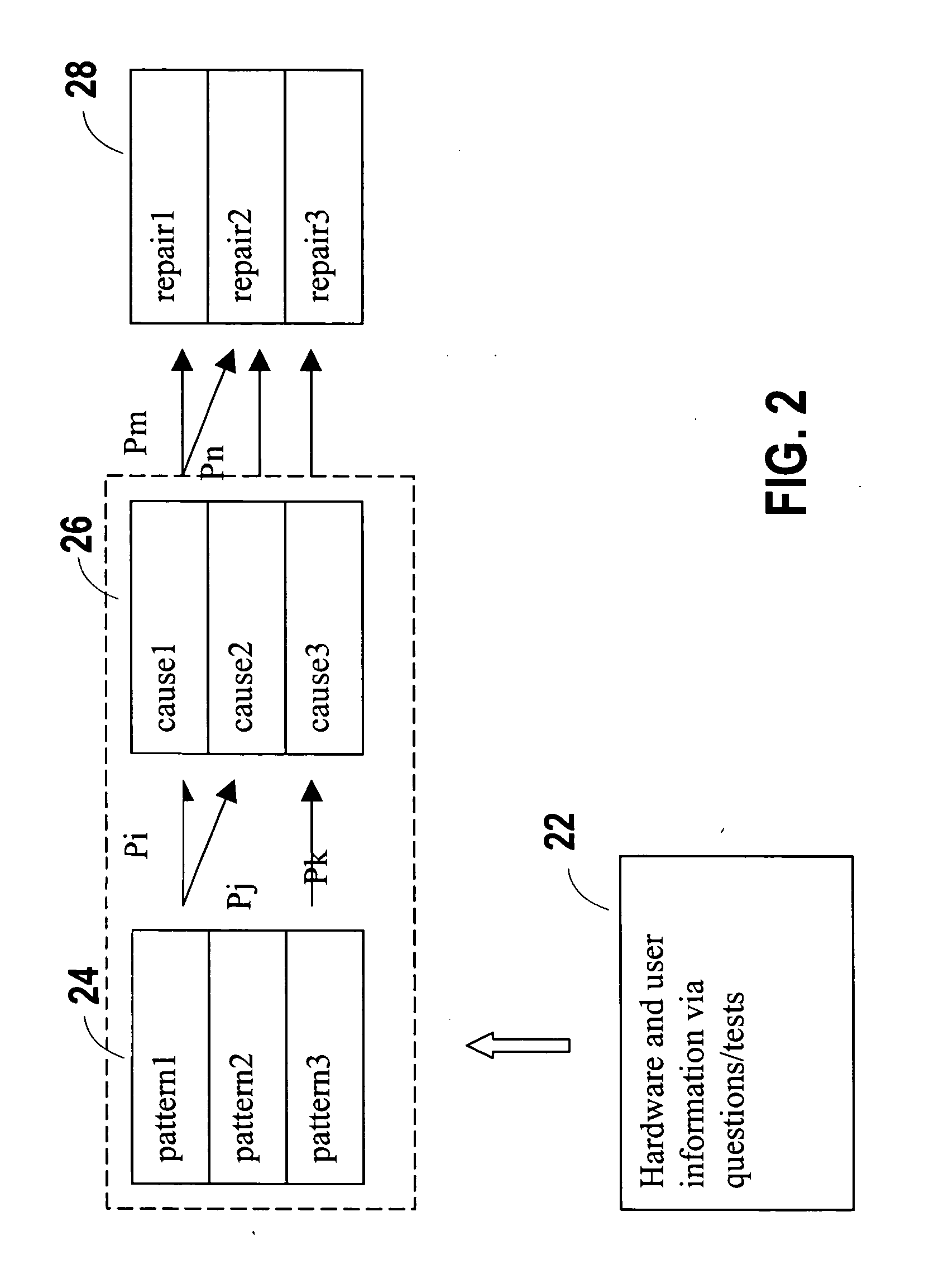

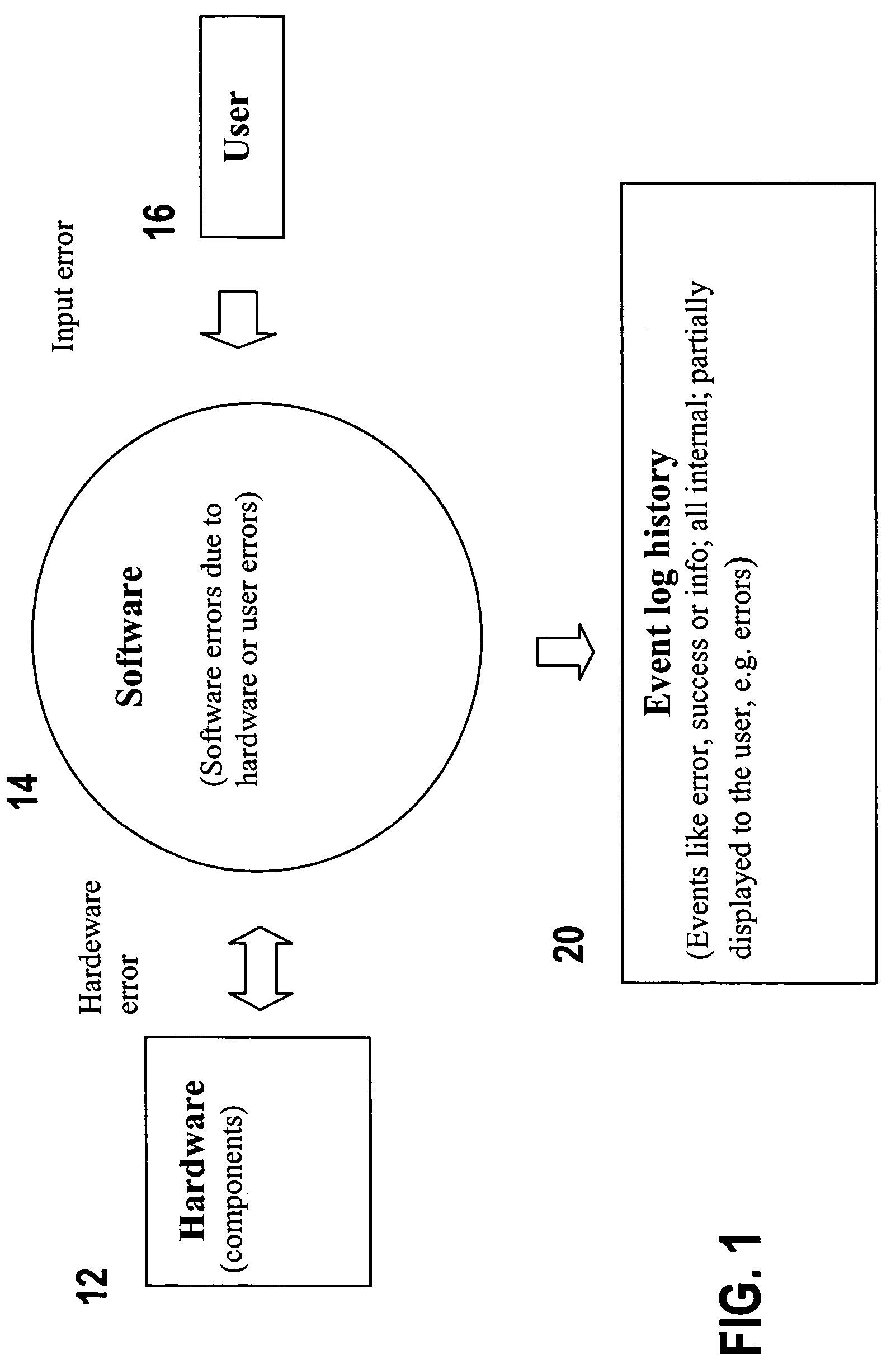

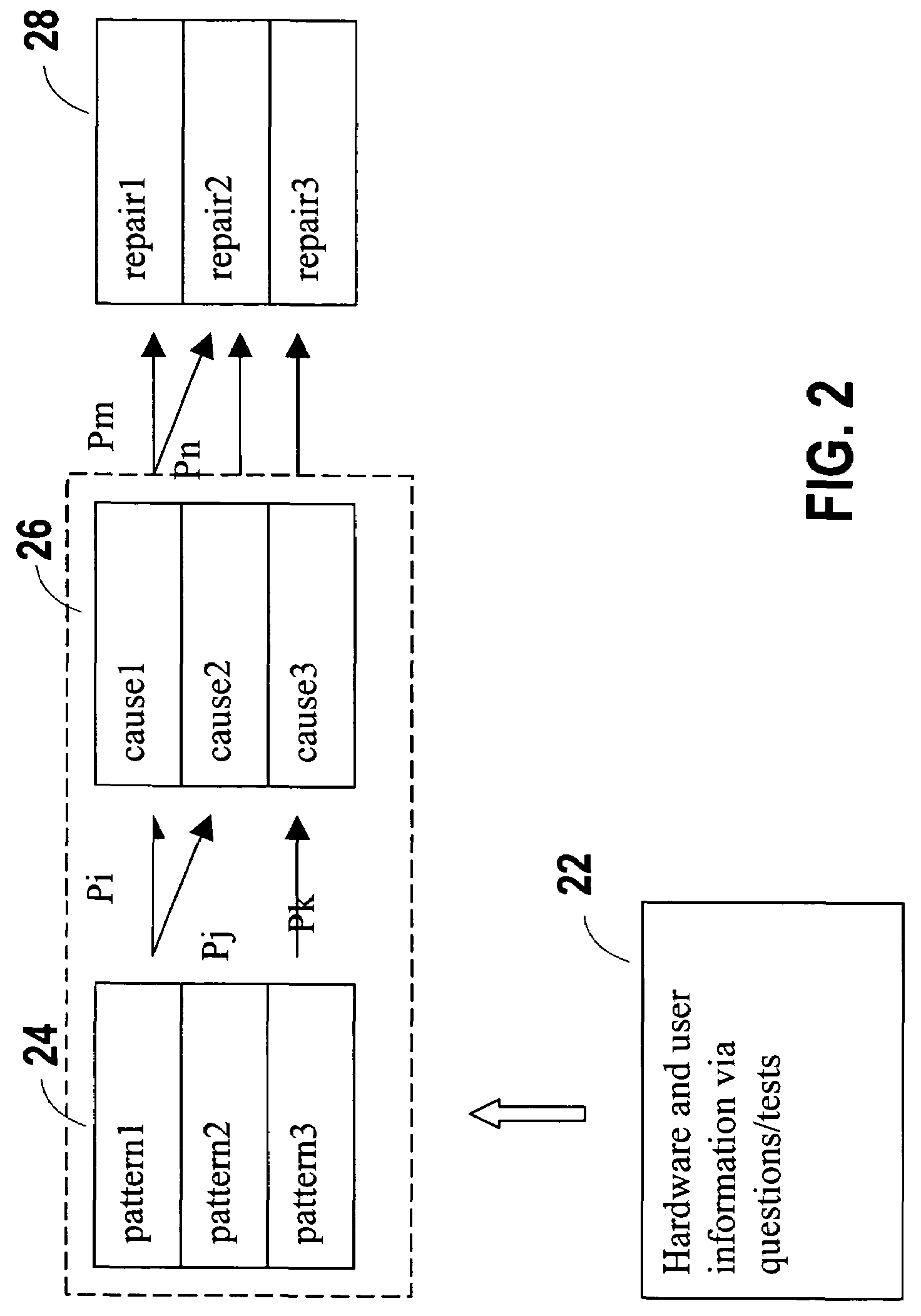

A system and appertaining method isolates a hardware or user error in a software controlled apparatus e.g., an NMR-apparatus. A diagnostic function is added to an event log that uses a causality model to analyze the event log. A series of events in the event log is evaluated by comparing the events with at least one of a number of root cause related patterns, and a best match of these patterns is used to assign a root cause for the error. Various repair actions may be associated based on a probabilistic model. Additional information may be utilized to modify or improve respective probabilities associated with causes and / or repair actions. This additional information may utilize other automated diagnostic information or may query users for additional information.

Owner:SIEMENS HEALTHCARE GMBH

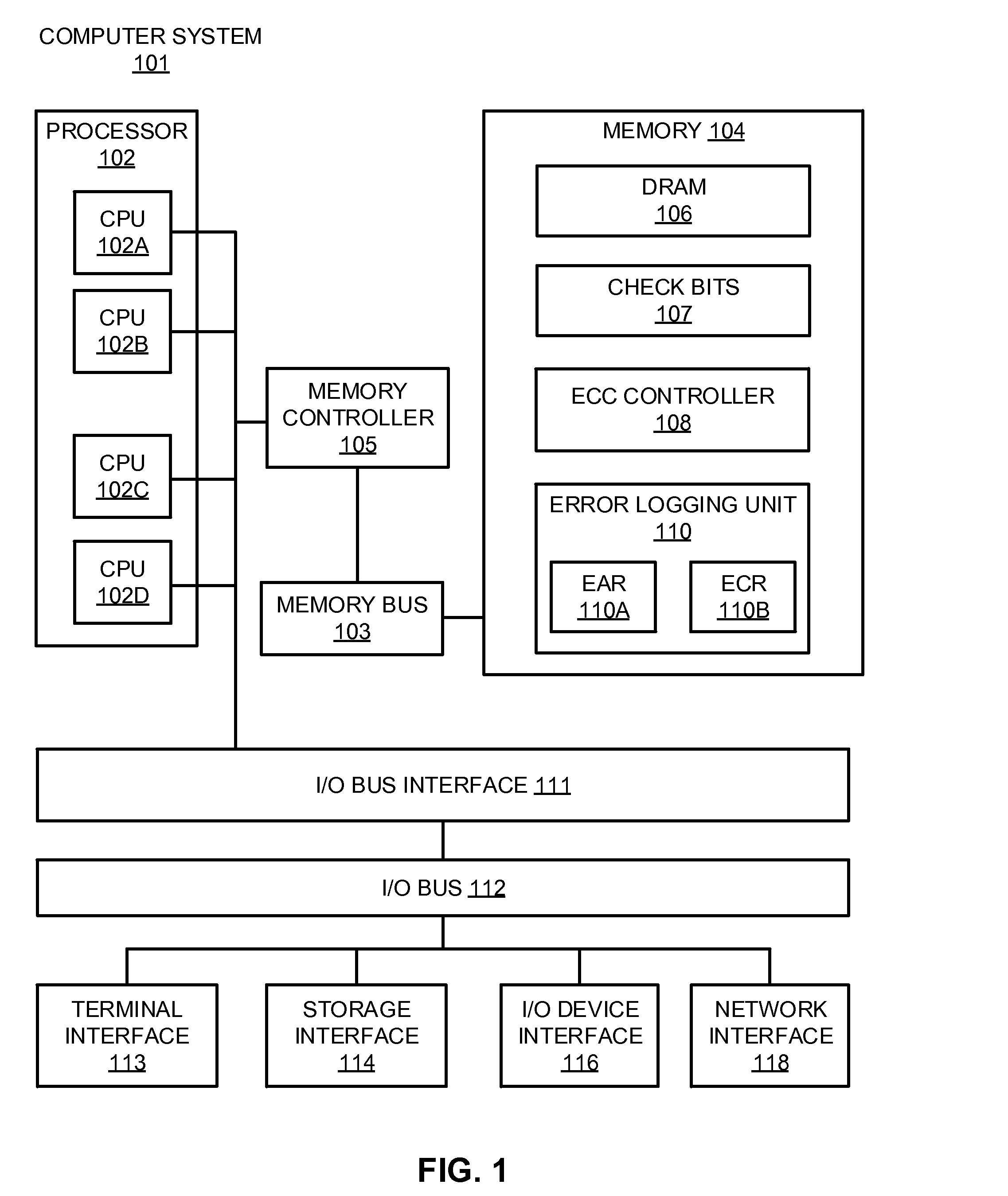

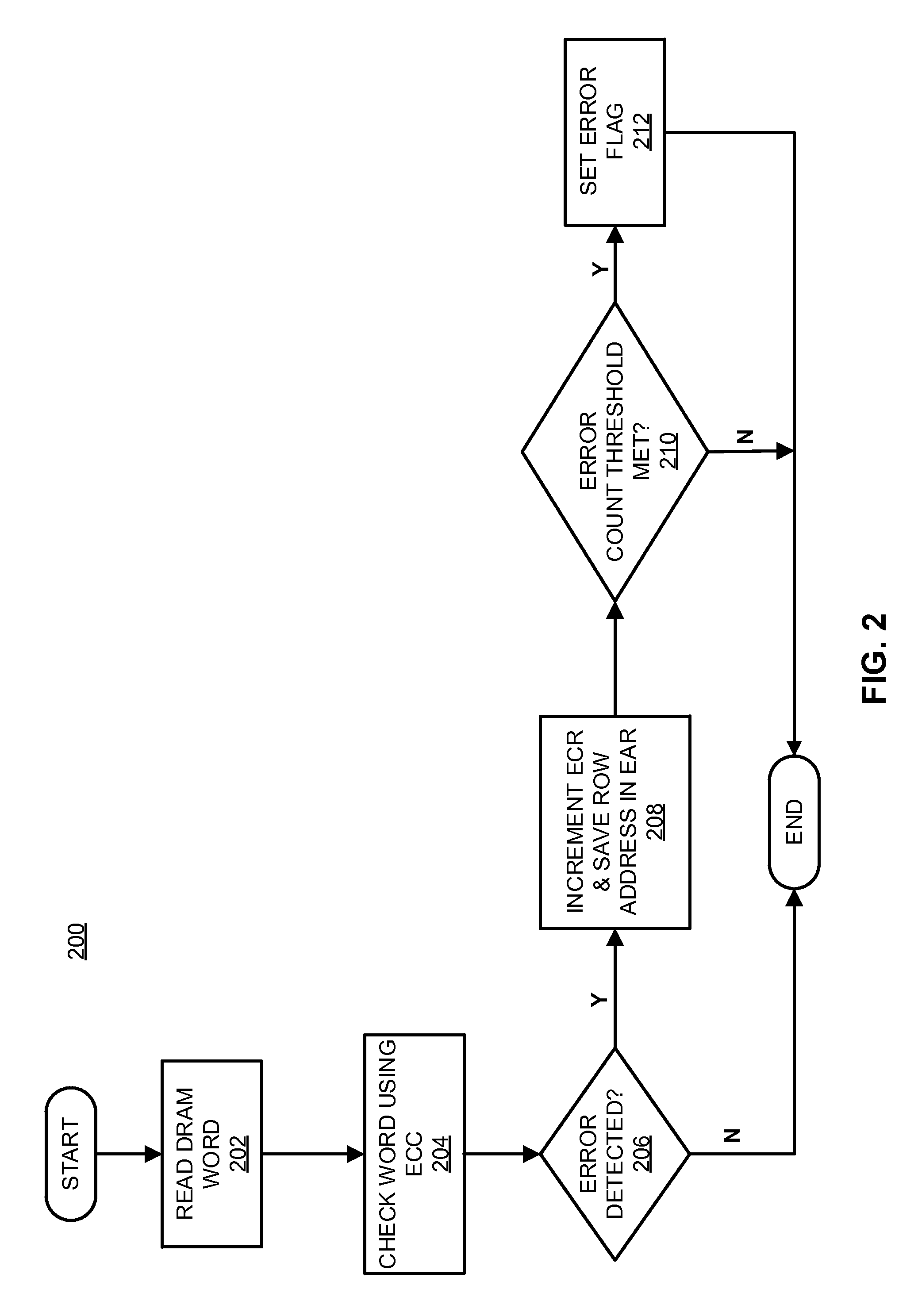

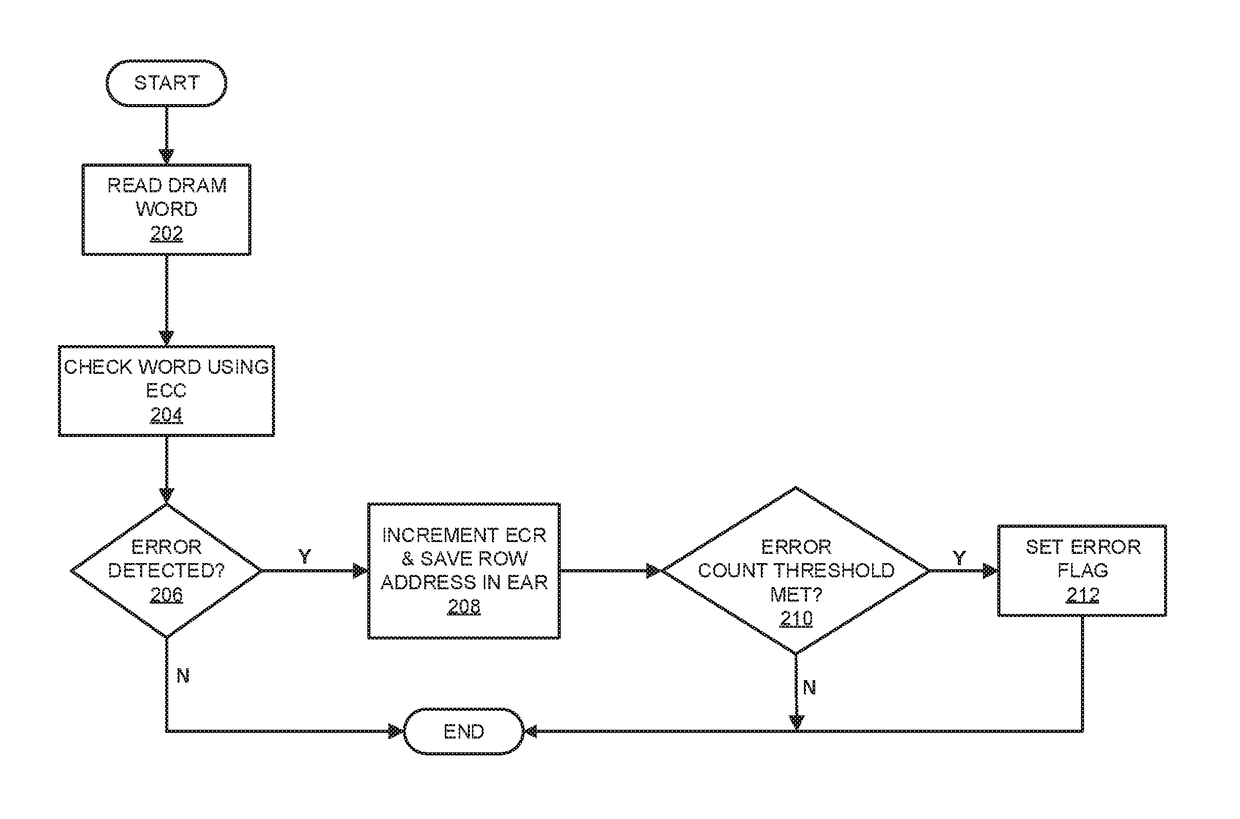

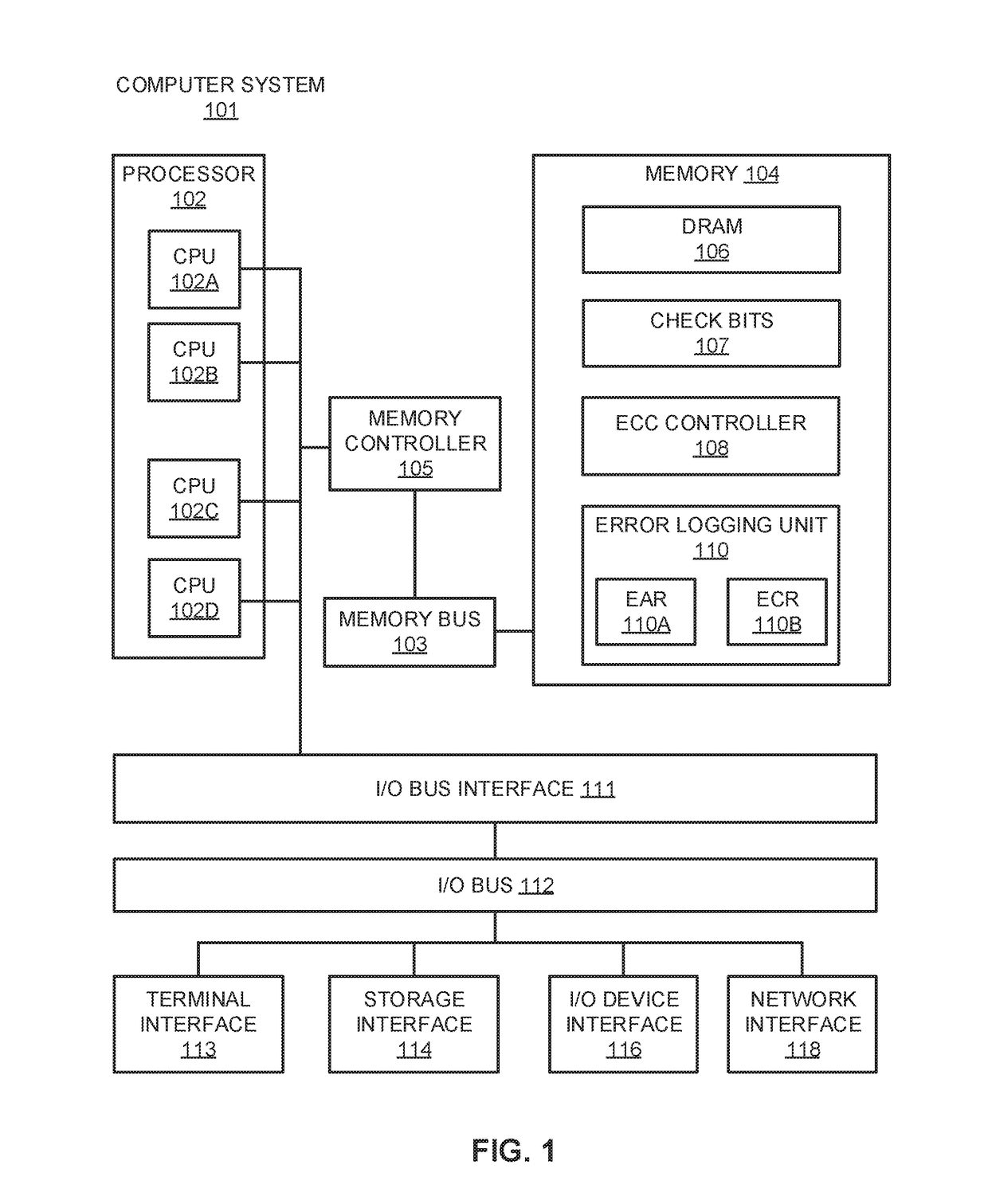

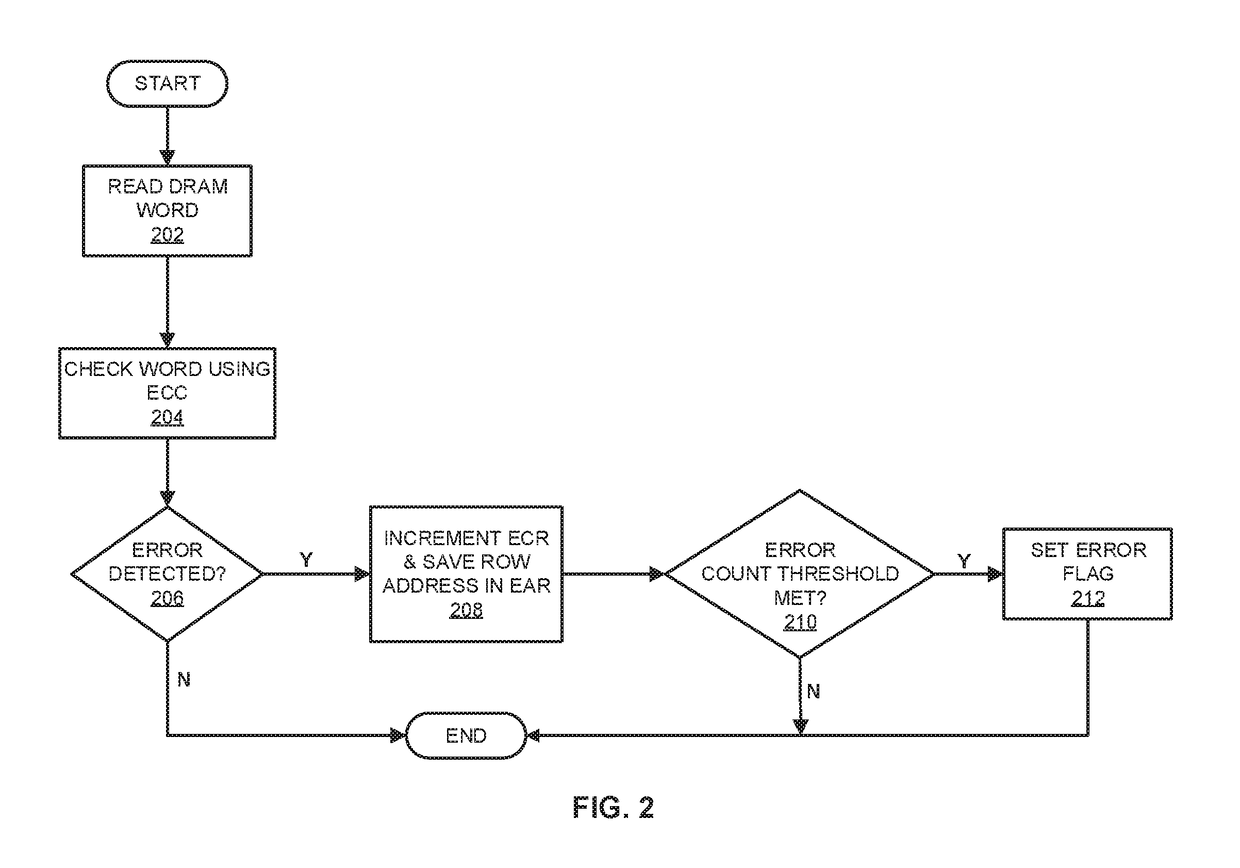

Error monitoring of a memory device containing embedded error correction

ActiveUS20160224412A1Input/output to record carriersCode conversionMemory controllerError correcting

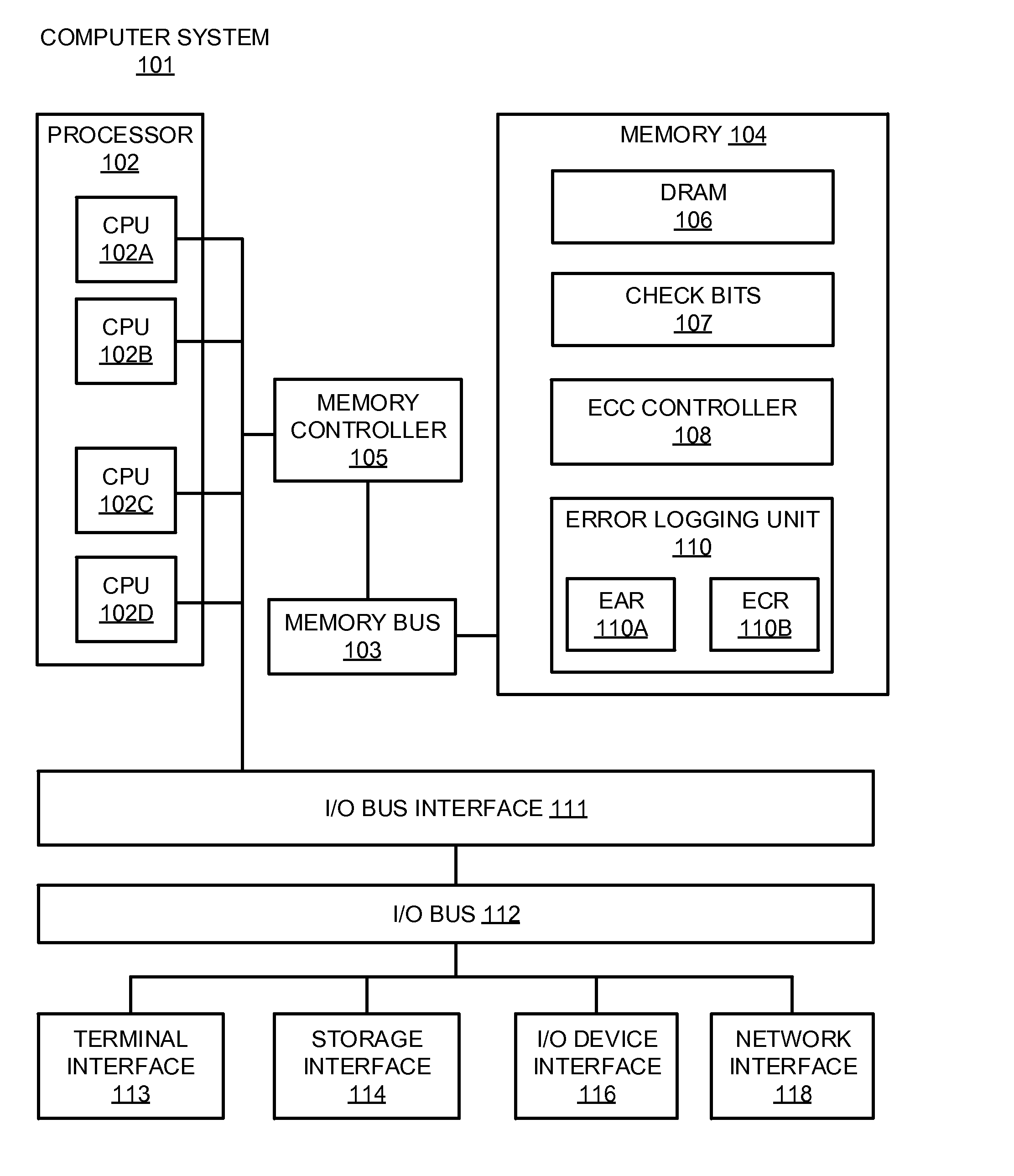

Embodiments of the present disclosure provide an approach for monitoring the health and predicting the failure of dynamic random-access memory (DRAM) devices with embedded error-correcting code (ECC). Additional registers are embedded on the DRAM device to store information about the DRAM, such as the number and location of soft errors detected by the device. When the DRAM device detects a soft error, it will update the information stored in the additional registers. A controller compares the information stored in the additional registers to associated thresholds. In some embodiments, after comparing the information to the associated thresholds, the controller may determine whether to schedule a repair action. In other embodiments, the controller may determine whether to alert the memory controller that the DRAM may be failing.

Owner:IBM CORP

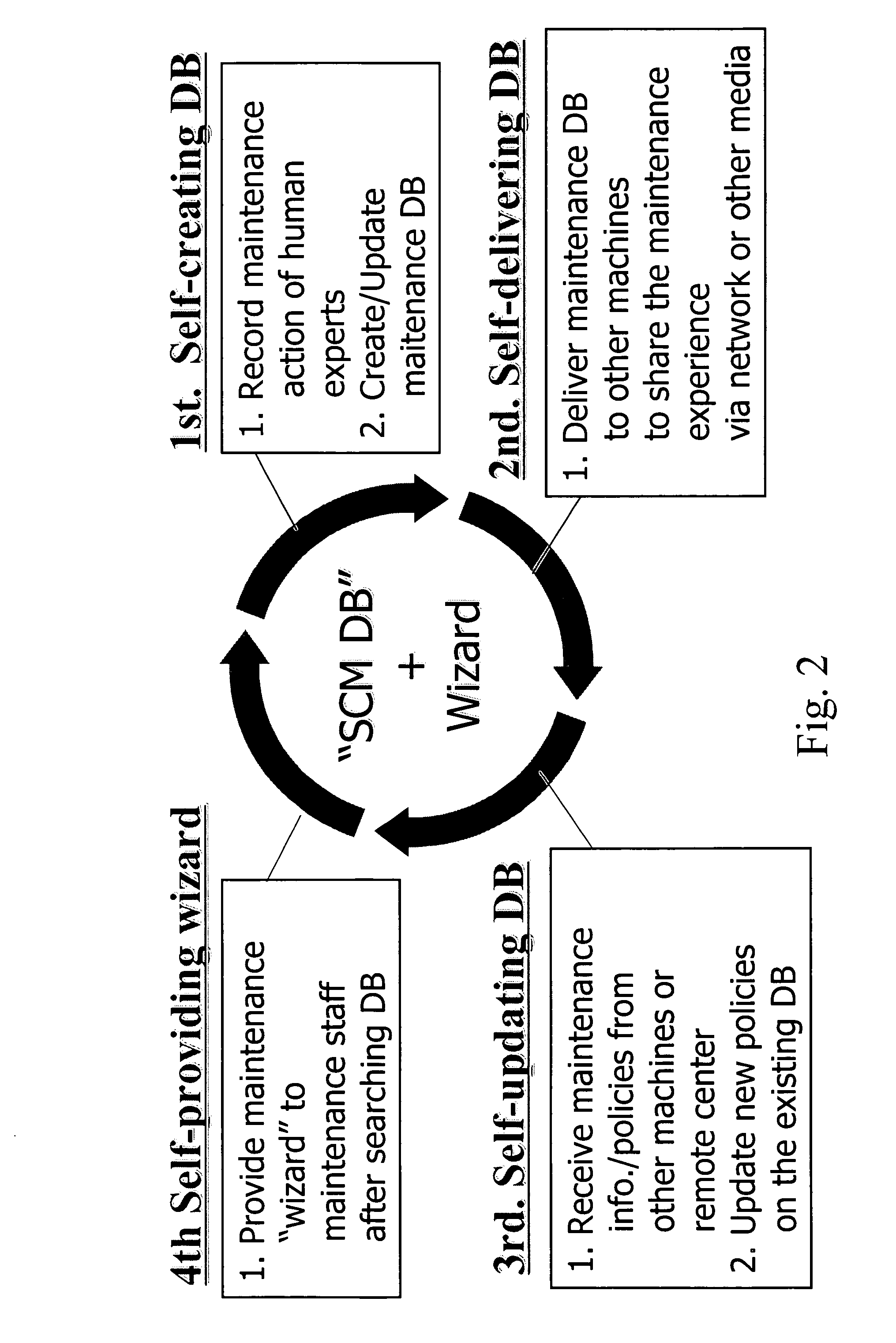

Self-creating maintenance database

InactiveUS20060174167A1Non-redundant fault processingDetecting faulty hardware using expert systemsGoal systemRepair - action

A maintenance database is described. Maintenance entries are maintained in the maintenance database relating to repair actions for failure modes in a target system. The failed components of the target system are identified for each failure mode, and repair actions are recorded along with the sequence of repair actions for each failure mode. For a given subsequent failure mode, the corresponding bit pattern is determined and a match is found in the maintenance database. The corresponding maintenance entry of the matching bit pattern can then be used to repair the failure mode, or to serve as a basis for initiating the repair activity.

Owner:HITACHI LTD

Knowledge Extraction Methodology for Unstructured Data Using Ontology-Based Text Mining

ActiveUS20120011073A1Digital data information retrievalDigital data processing detailsIdentifying problemsText mining

A method is provided for extracting data from service repair verbatims in a vehicle service reporting system. Each service repair verbatim includes a technician's comments concerning a part, a symptom associated with the part, and a repair action associated with the symptom. Each service repair verbatim includes information relating to an identified problem with at least one vehicle part. A diagnostic and prognostic ontology database is provided that is structured by vehicle part classification, a vehicle part sub-class classification, and a relationship classification, wherein the relationship classification includes symptom relationships and action relationships. Each of the service repair verbatims are reconstructed utilizing the diagnostic and prognostic ontology database. Combinations of information are extracted from the reconstructed service repair verbatims as a function of user input criteria. A frequency is determined of each combination extracted in the reconstructed service repair verbatims. The service repair verbatims are clustered for each combination.

Owner:GM GLOBAL TECH OPERATIONS LLC

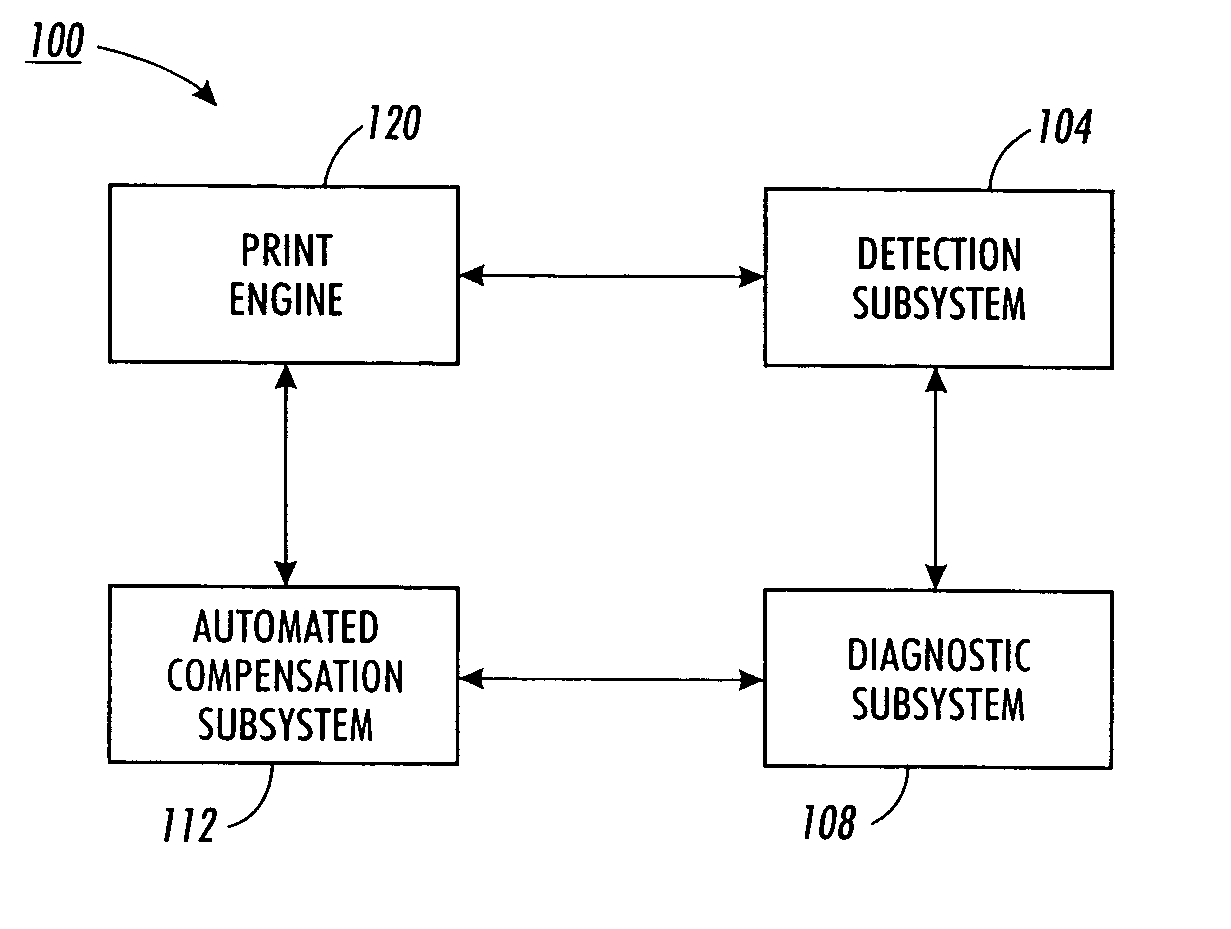

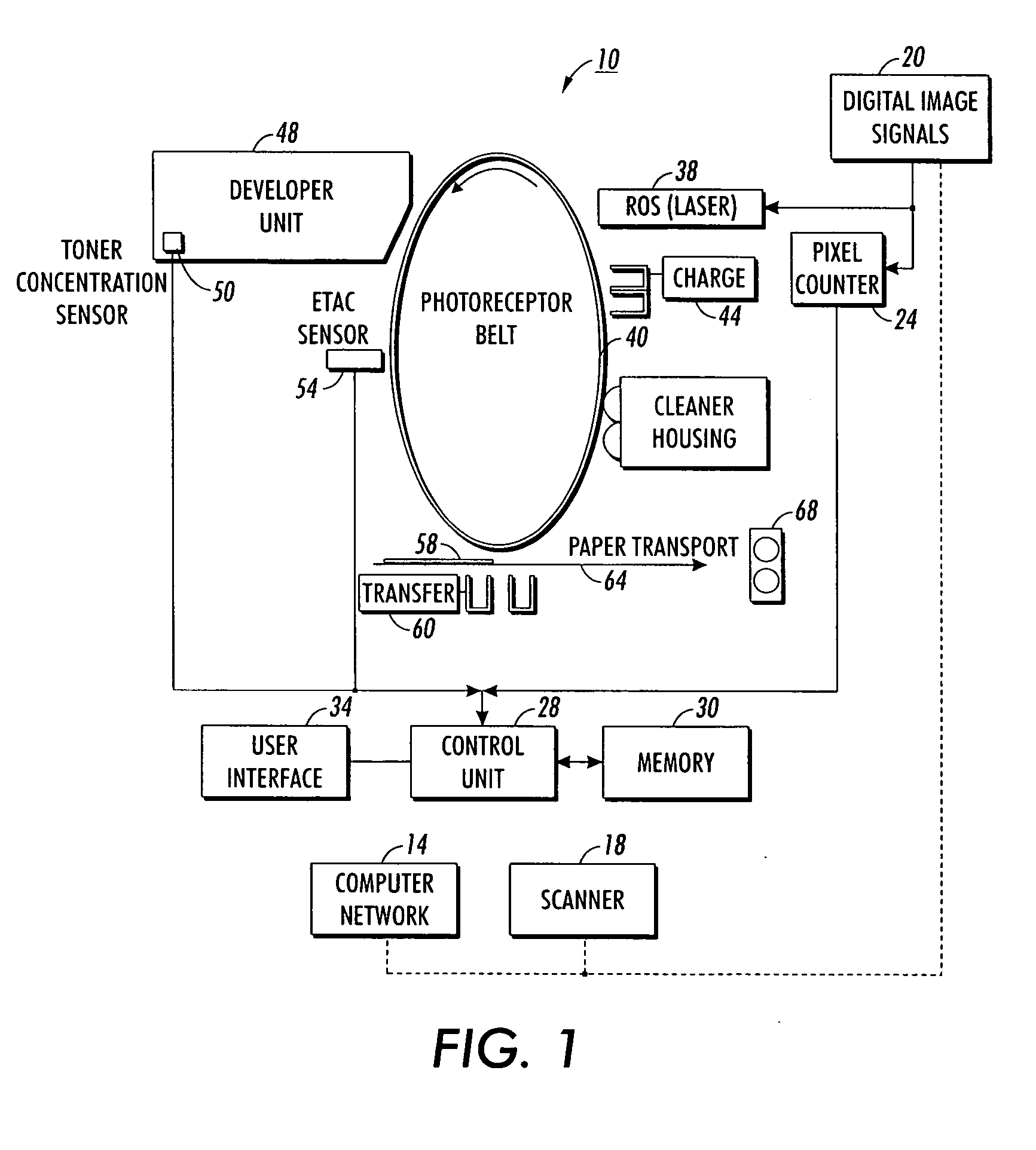

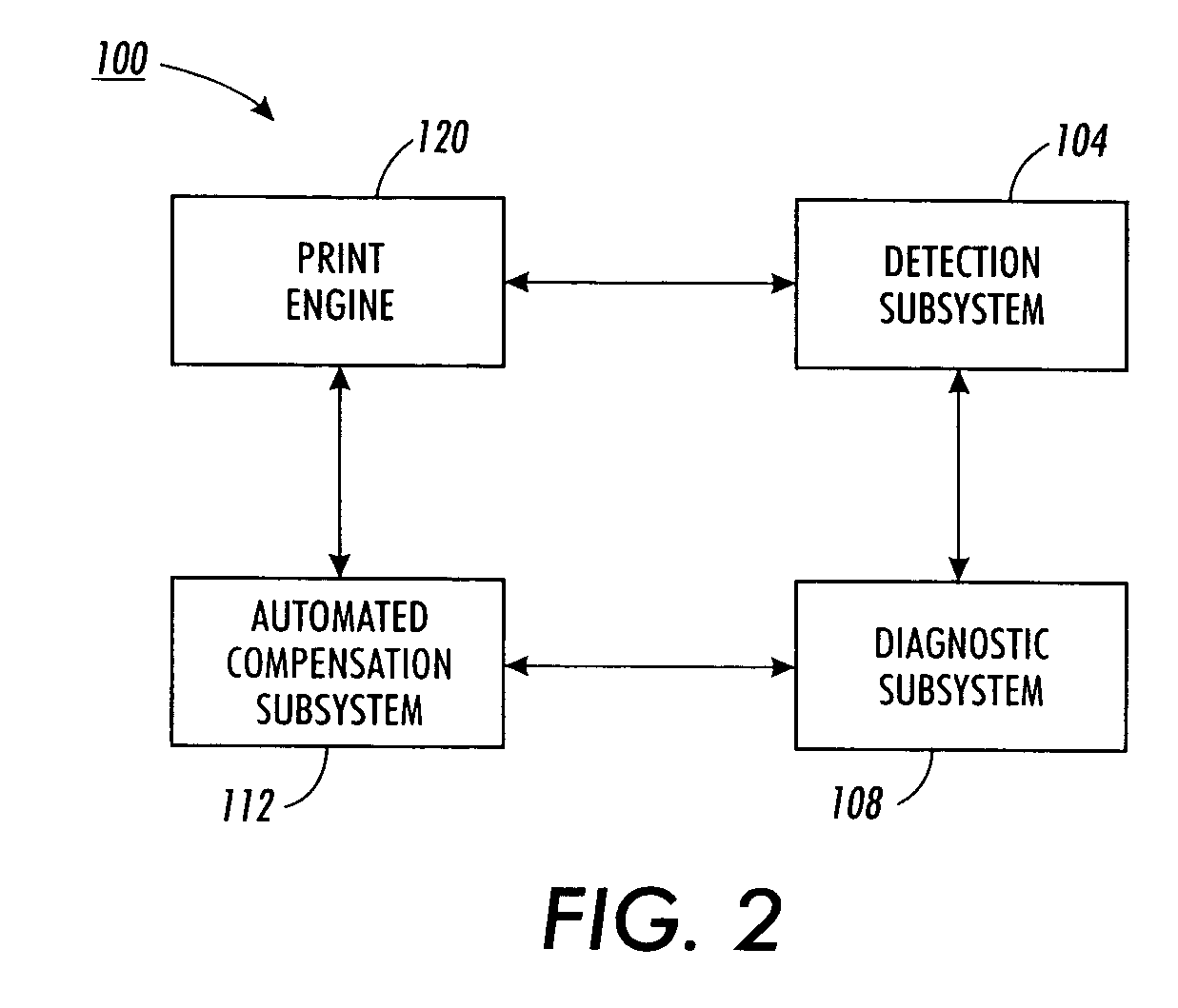

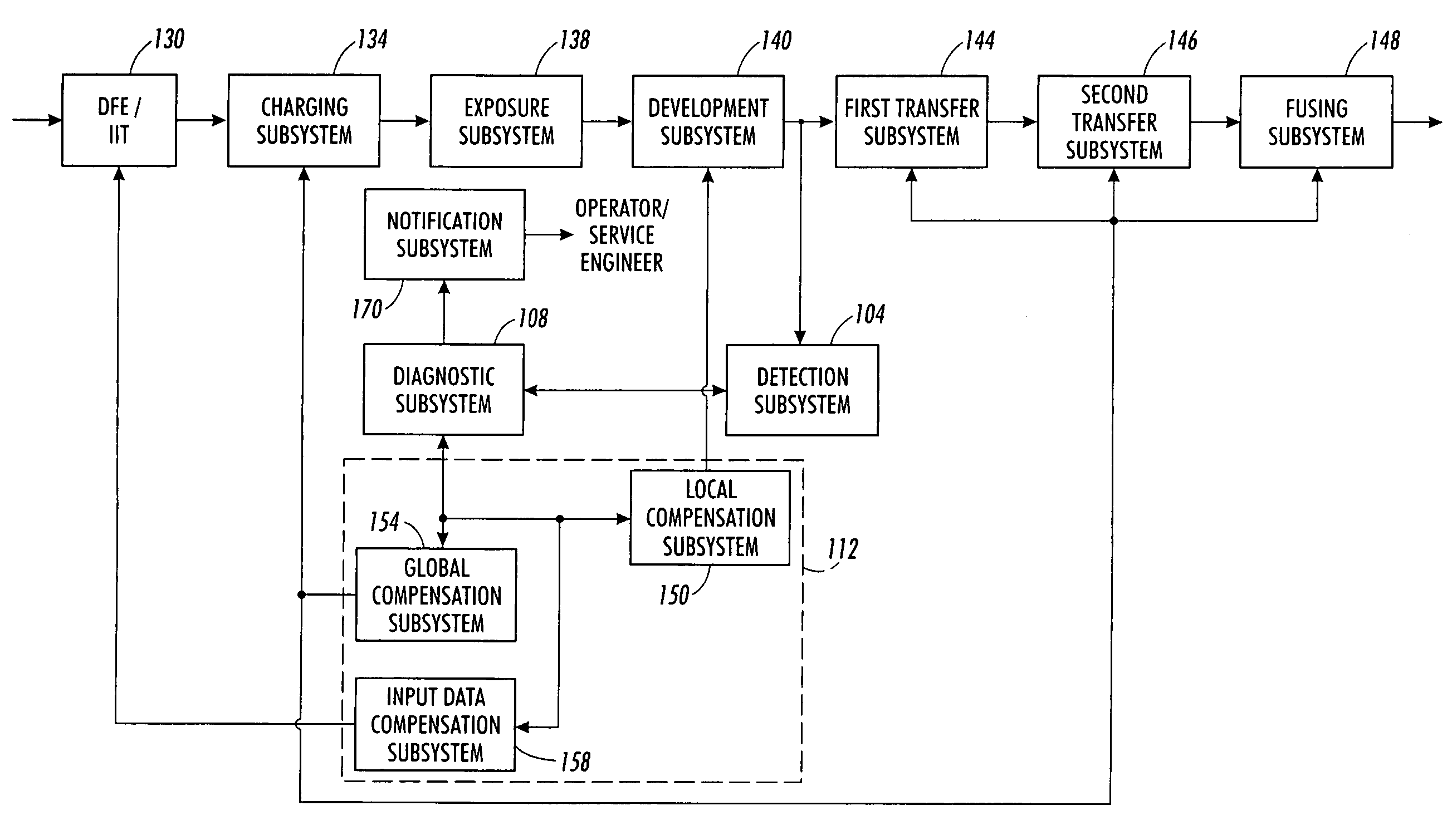

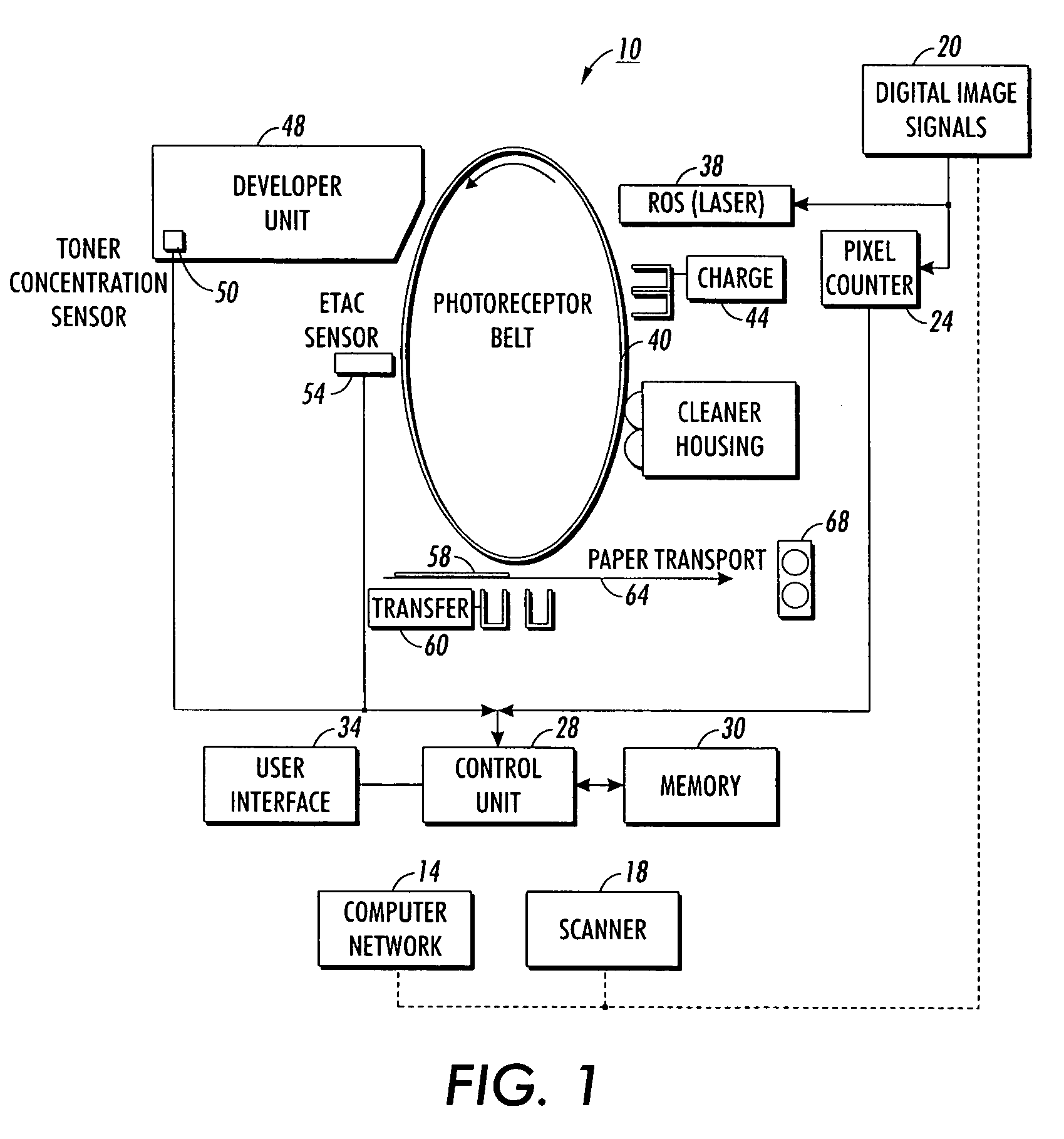

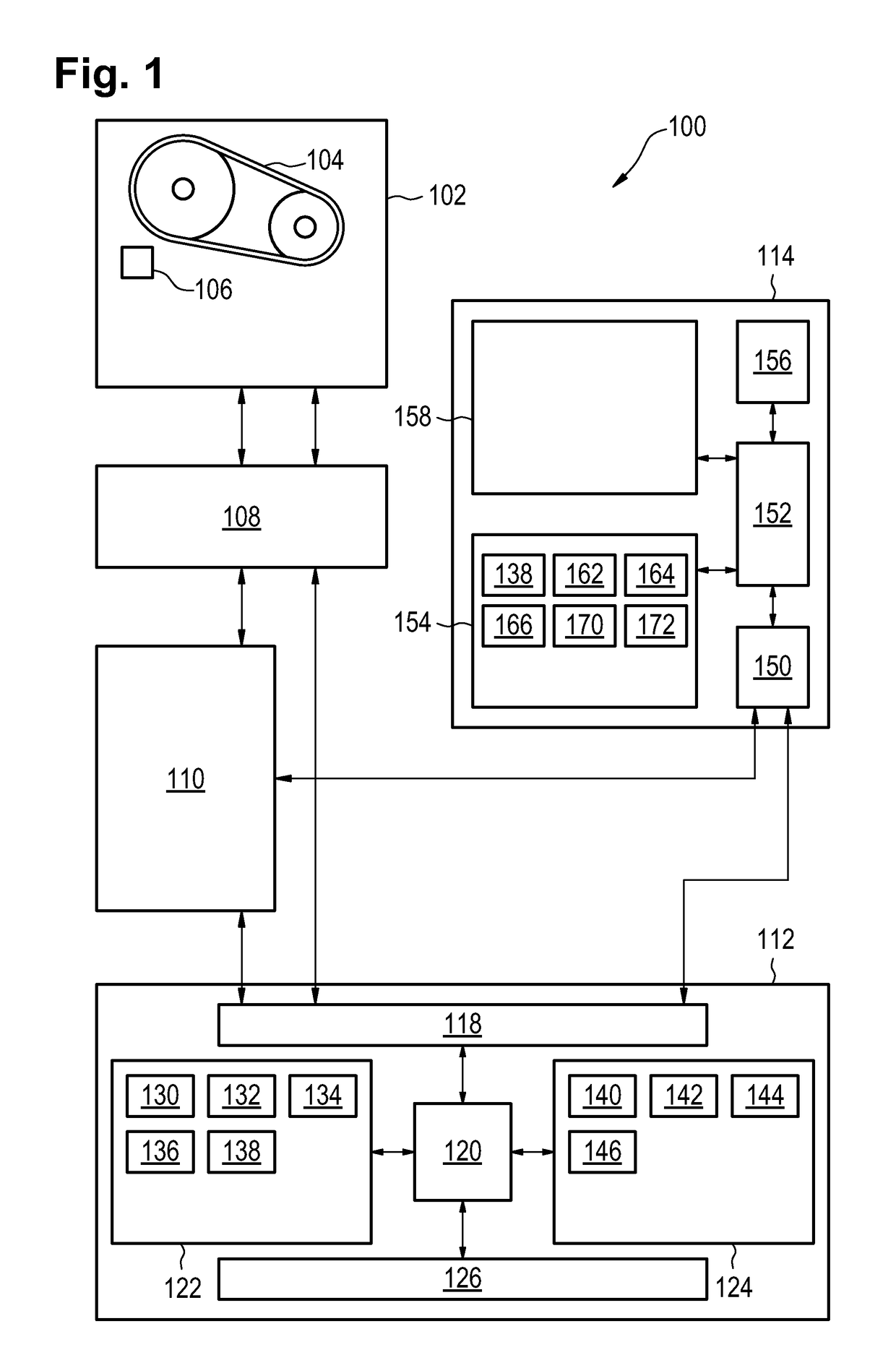

Method and system for automatically compensating for diagnosed banding defects prior to the performance of remedial service

InactiveUS20060071963A1Improve operational efficiencyAttenuate banding defectElectrographic process apparatusOther printing apparatusQuality levelOperational effectiveness

A system that extends the operational effectiveness of an image reproduction machine without requiring downtime for service by personnel includes a detection subsystem that monitors components of an image reproduction system for detecting a banding defect in the image reproduction system and an automated compensation subsystem for modifying operation of the image reproduction system to compensate for the detected banding defect so that the image reproduction system continues to generate images at an acceptable quality level. The automated compensation subsystem adjusts components and / or data used by image reproduction system to compensate for the identified banding defect without requiring immediate operator or service personnel intervention. This compensation may successfully attenuate the banding defect so that the image reproduction system continues to produce acceptable images without downtime while awaiting service by personnel. The system may also include a diagnostic subsystem for determining causes for a detected banding defect to further enhance the operation of the compensation system or to facilitate a repair action by a person.

Owner:XEROX CORP

Model based diagnosis and repair for event logs

InactiveUS7373552B2Easy to updateQuickly and cheaply distributeLogical operation testingNon-redundant fault processingProbit modelDisease causation

A system and appertaining method isolates a hardware or user error in a software controlled apparatus e.g., an NMR-apparatus. A diagnostic function is added to an event log that uses a causality model to analyze the event log. A series of events in the event log is evaluated by comparing the events with at least one of a number of root cause related patterns, and a best match of these patterns is used to assign a root cause for the error. Various repair actions may be associated based on a probabilistic model. Additional information may be utilized to modify or improve respective probabilities associated with causes and / or repair actions. This additional information may utilize other automated diagnostic information or may query users for additional information.

Owner:SIEMENS HEALTHCARE GMBH

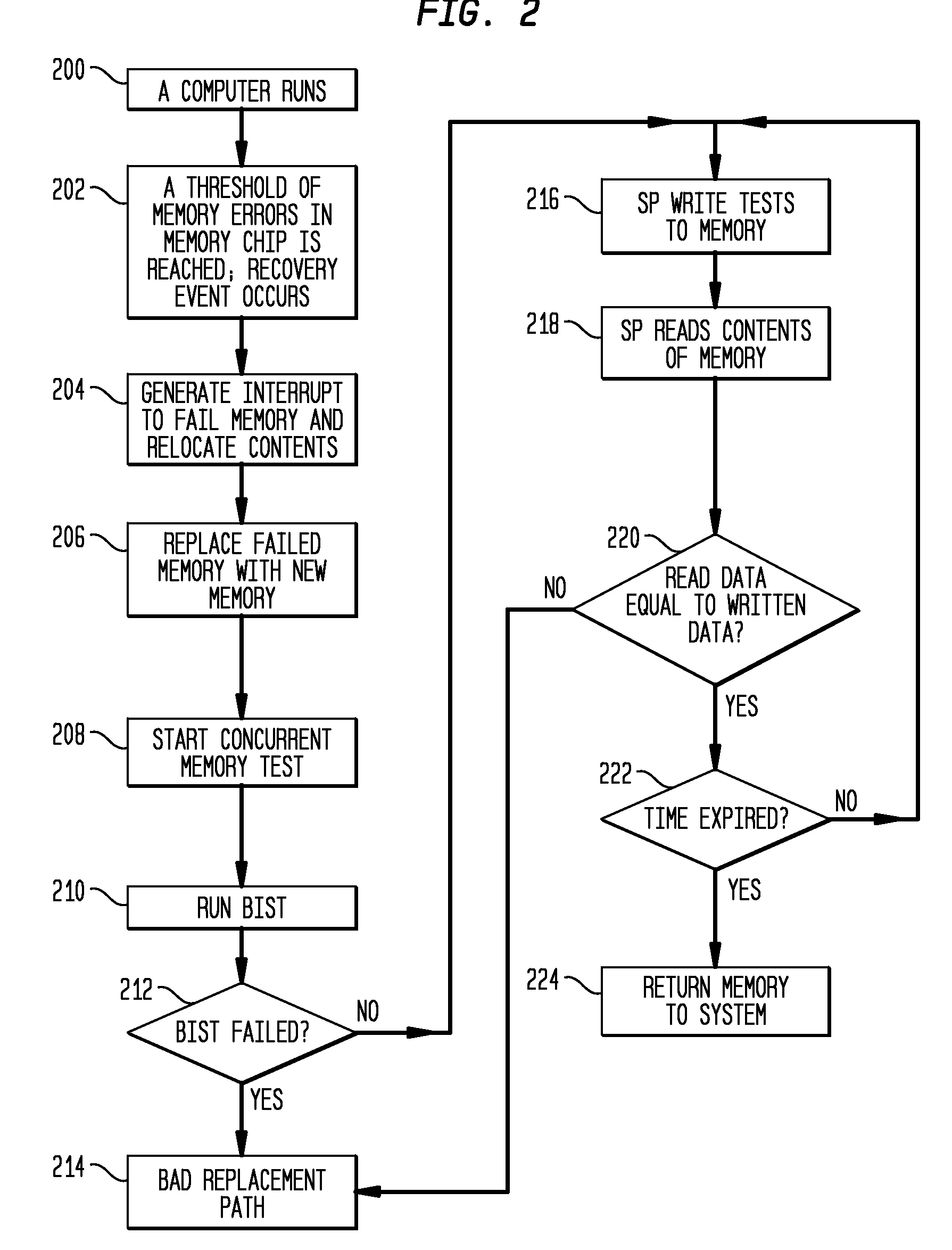

Method, Apparatus and Program Product to Concurrently Detect, Repair, Verify and Isolate Memory Failures

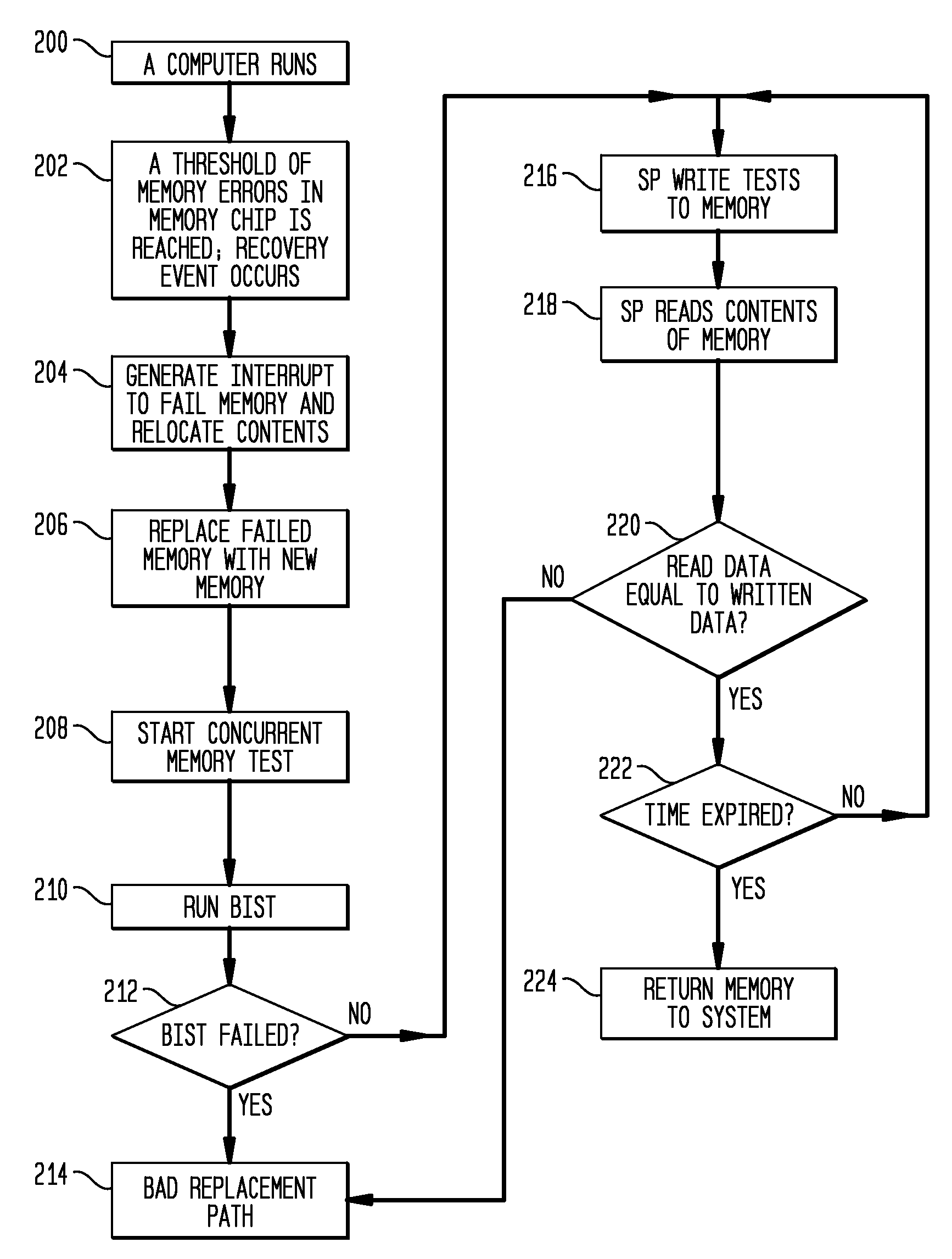

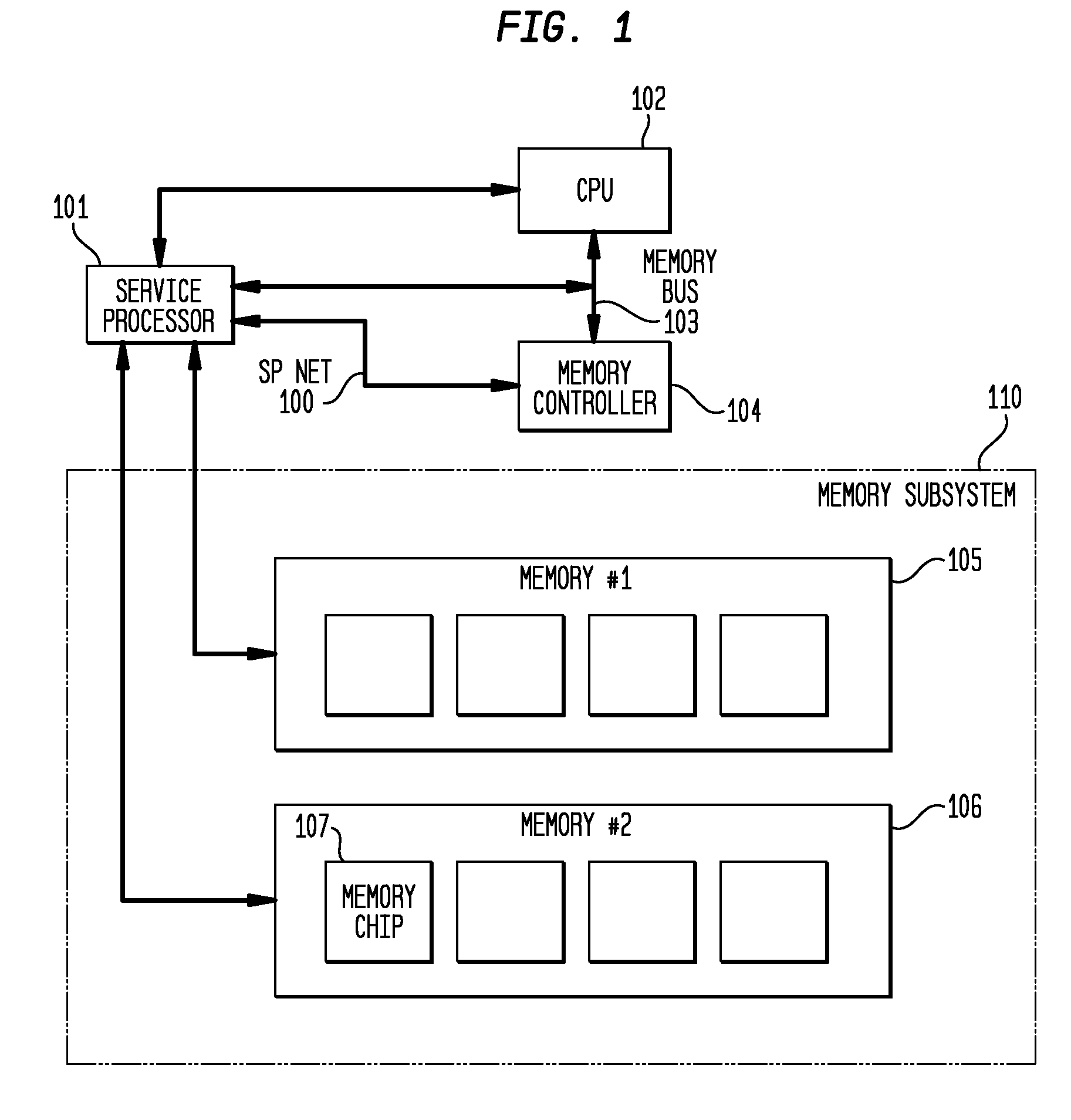

Method and system for repairing memory failure in a computer system in one aspect determines one or more test patterns and time duration for testing the new memory unit that replaced a failed memory unit. The test pattern is written to the new memory unit and read from the new memory unit. The read pattern is compared to the test pattern that was used to write. If the read test pattern and the written test pattern doe not match, a further repair action is taken. If they match, writing and reading of the test pattern repeats until the time duration for testing expires. The new memory unit may be configured as available for use when the write and read test completes successfully for the testing time duration.

Owner:LENOVO GLOBAL TECH INT LTD

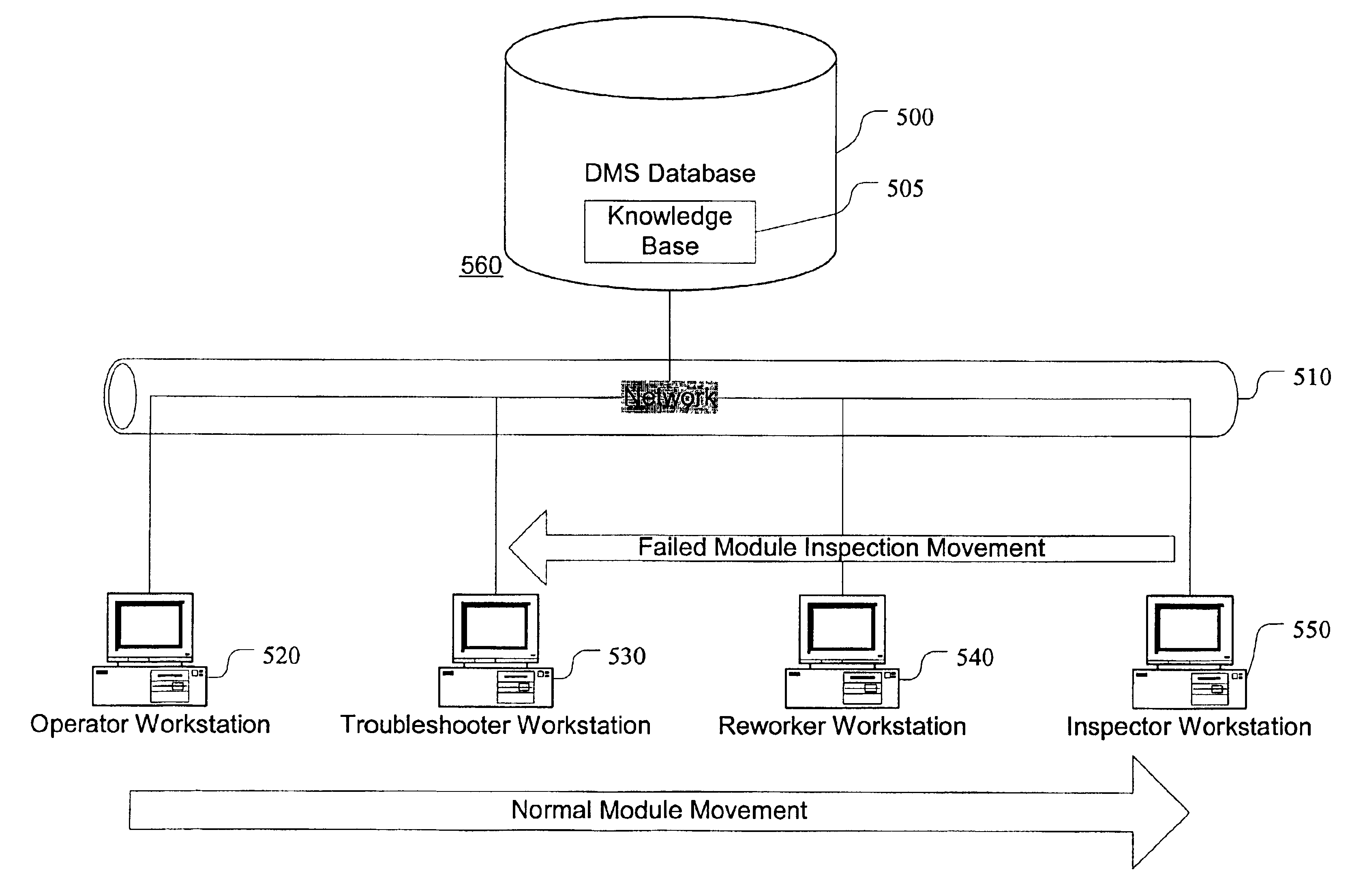

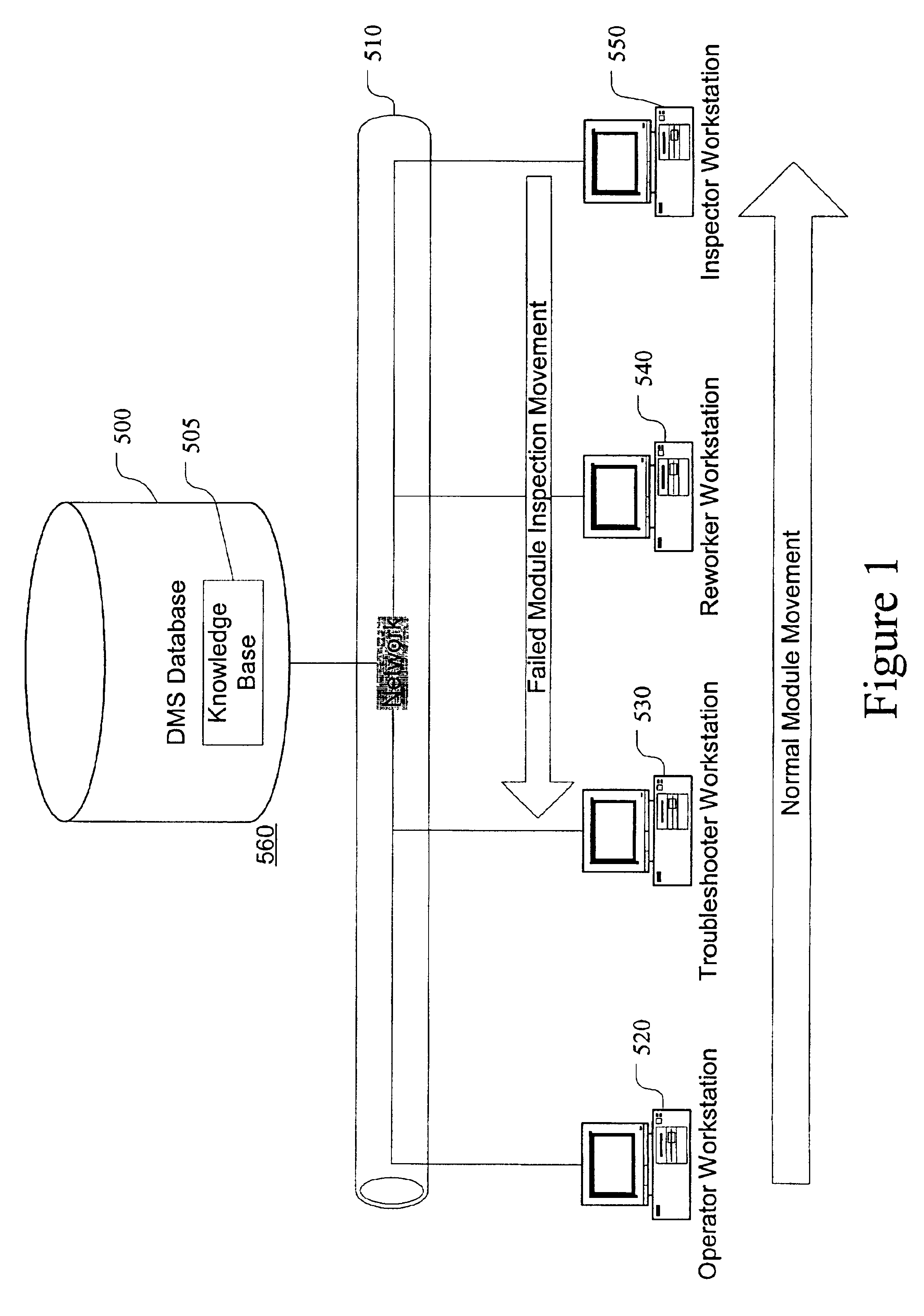

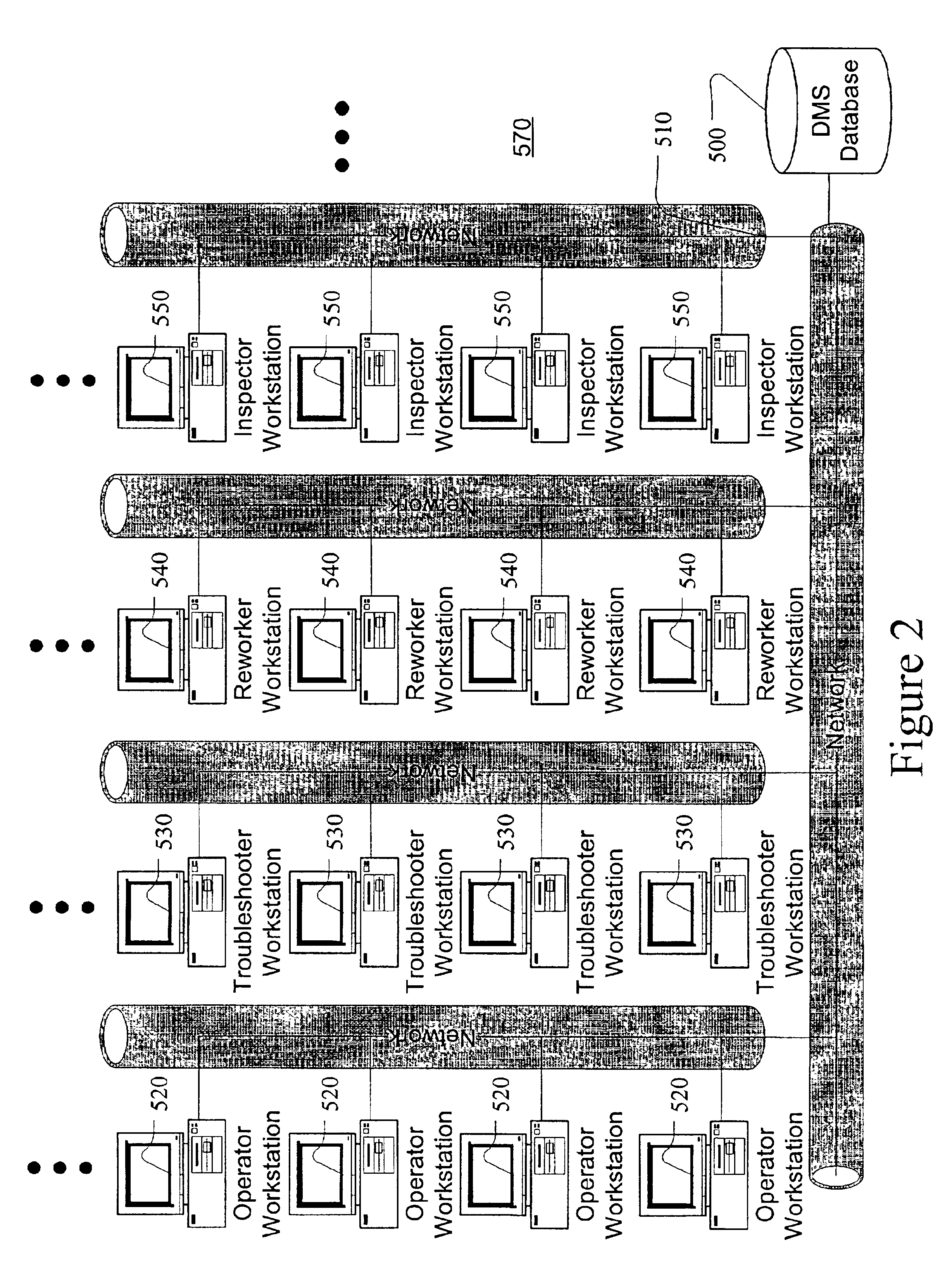

Method of improving quality of manufactured modules

InactiveUS6859676B1Quality improvementProgramme controlData processing applicationsComputer scienceSAPS II

A method of improving the quality of manufactured modules includes logging manufacturing information to a database and utilizing a knowledge base to determine defects of a manufactured module. A quality ticket is issued for defective modules that is used to log and store defect symptom information in the database. Defects may be determined based on the quality ticket and by utilizing the knowledge base. Repair suggestions may be made and logged to the quality ticket based on the defect determination. Repairs are performed and repair actions logged to the quality ticket. Tests are then performed on the repaired modules. Based on the test results, the knowledge base is updated. In other words, the knowledge base learns over time as more modules, symptoms, defects and actions are tracked. The knowledge base aids during troubleshooting by providing a list of repair actions and frequency of such repair actions that successfully repaired the defect identified in the quality ticket. Alternatively, the knowledge base may provide a list of defects and defect frequency for the symptom identified in the quality ticket. Using these techniques, the quality of a manufactured item may be improved.

Owner:CIENA

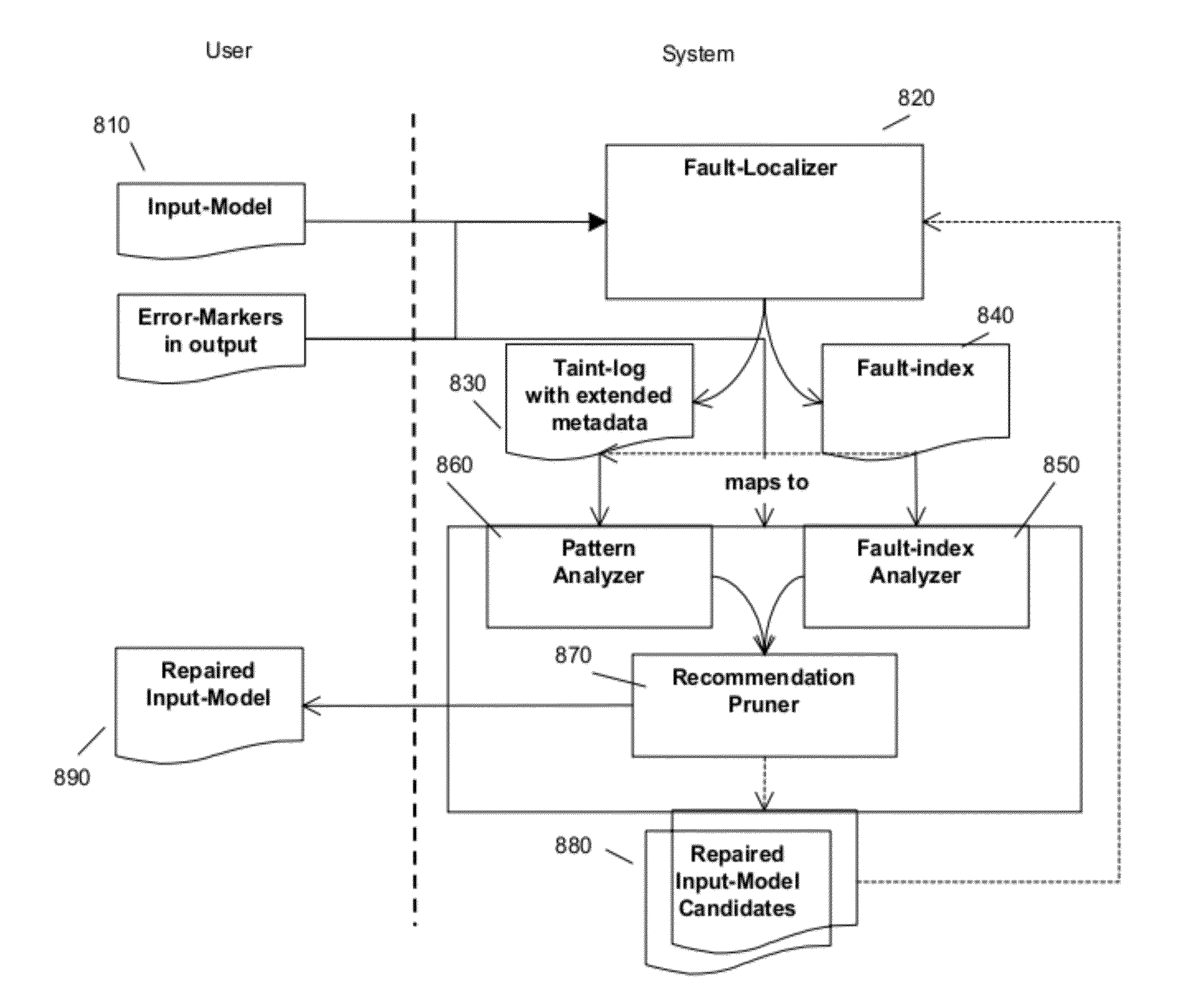

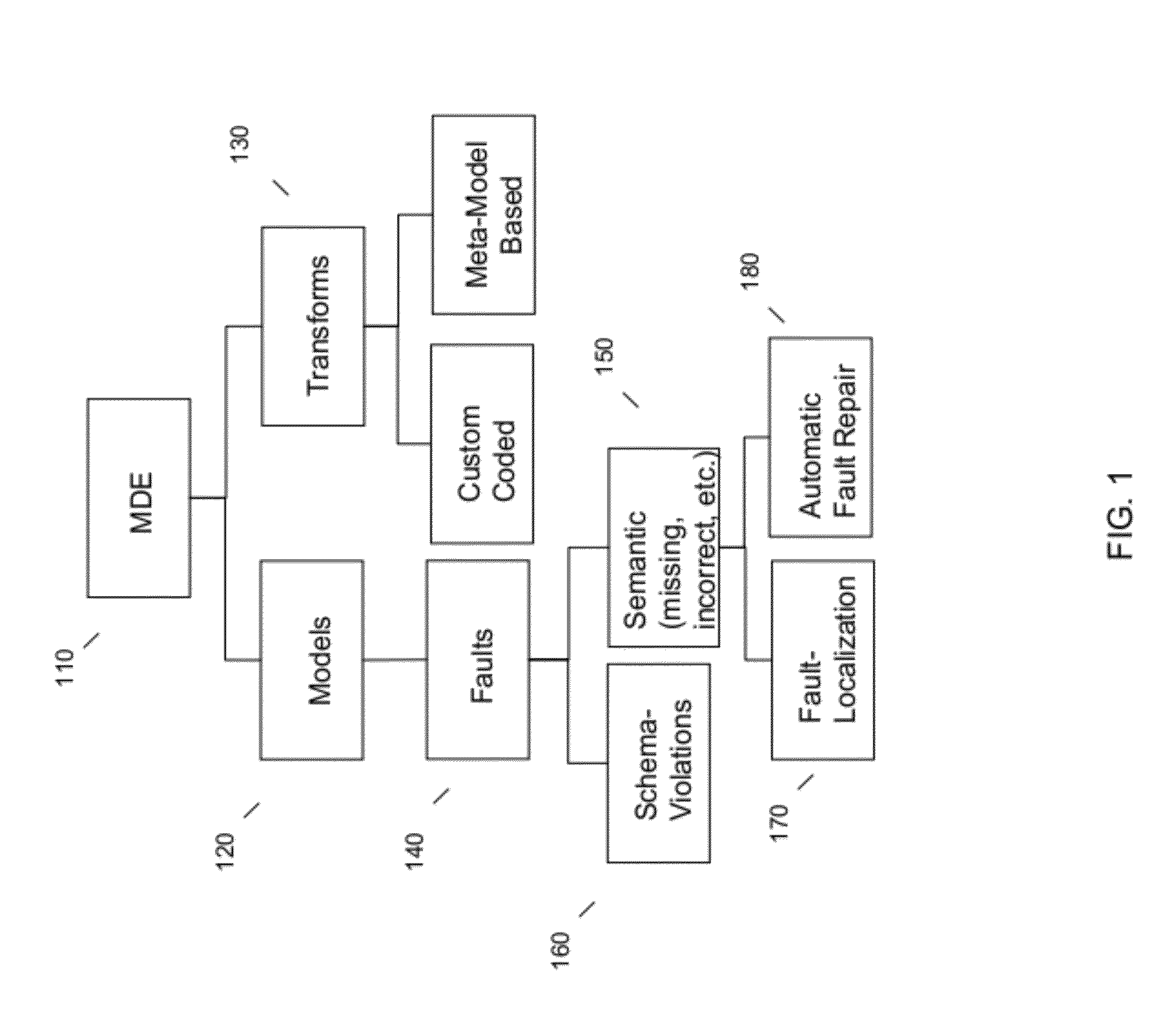

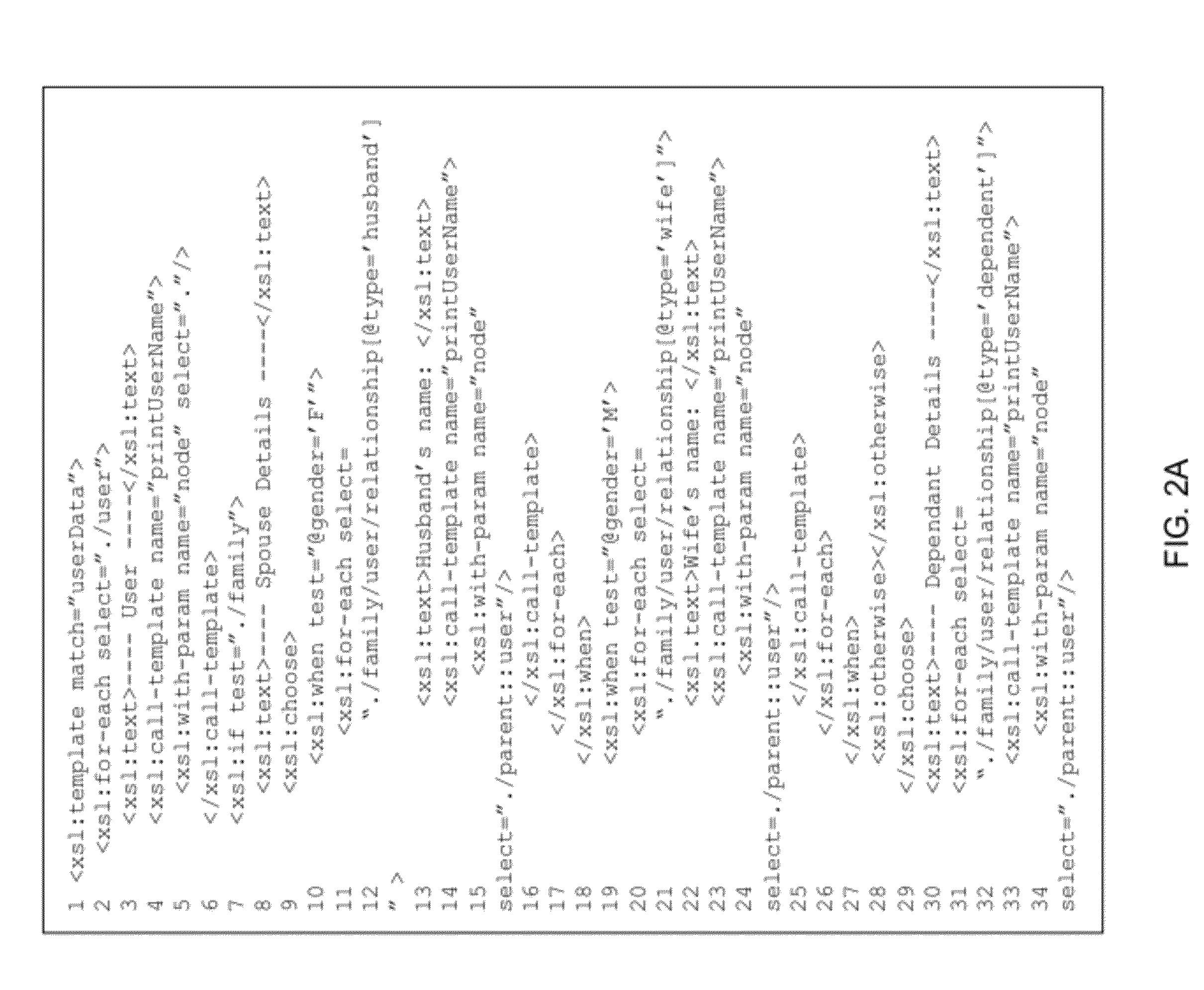

Systems and methods for automated support for repairing input model errors

Systems and associated methods for automated repair support for input model faults are described. Embodiments automate generation of fault repair support by producing one or more repair action suggestions for a given input model containing faults. Responsive to an indication of one or more faults within the model, embodiments utilize a fault index to ascertain the nature of faults within the model and to compile one or more repair action suggestions. Users can review the repair action suggestions, and preview the impact each of these suggestions will have on the model if implemented, and select an appropriate repair action for repairing a model containing faults.

Owner:IBM CORP

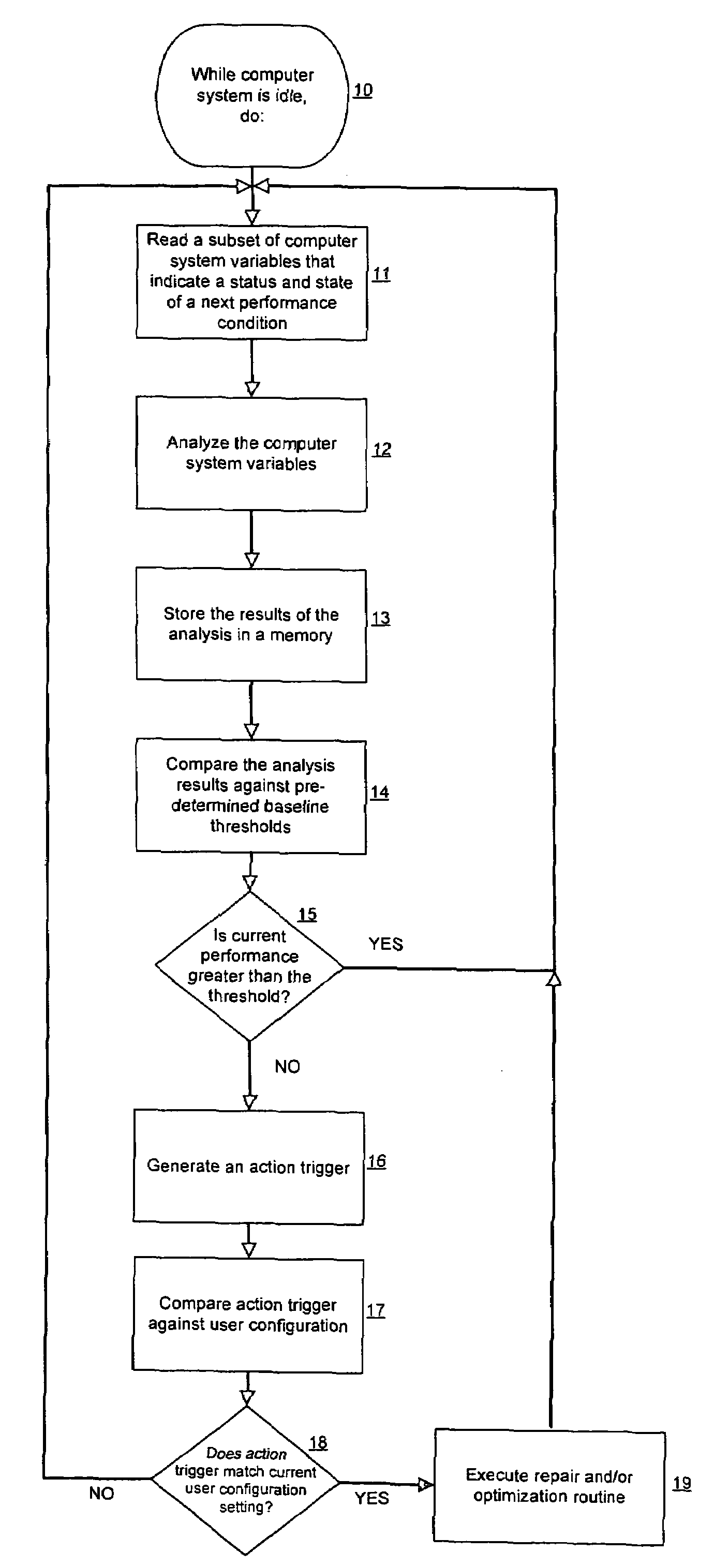

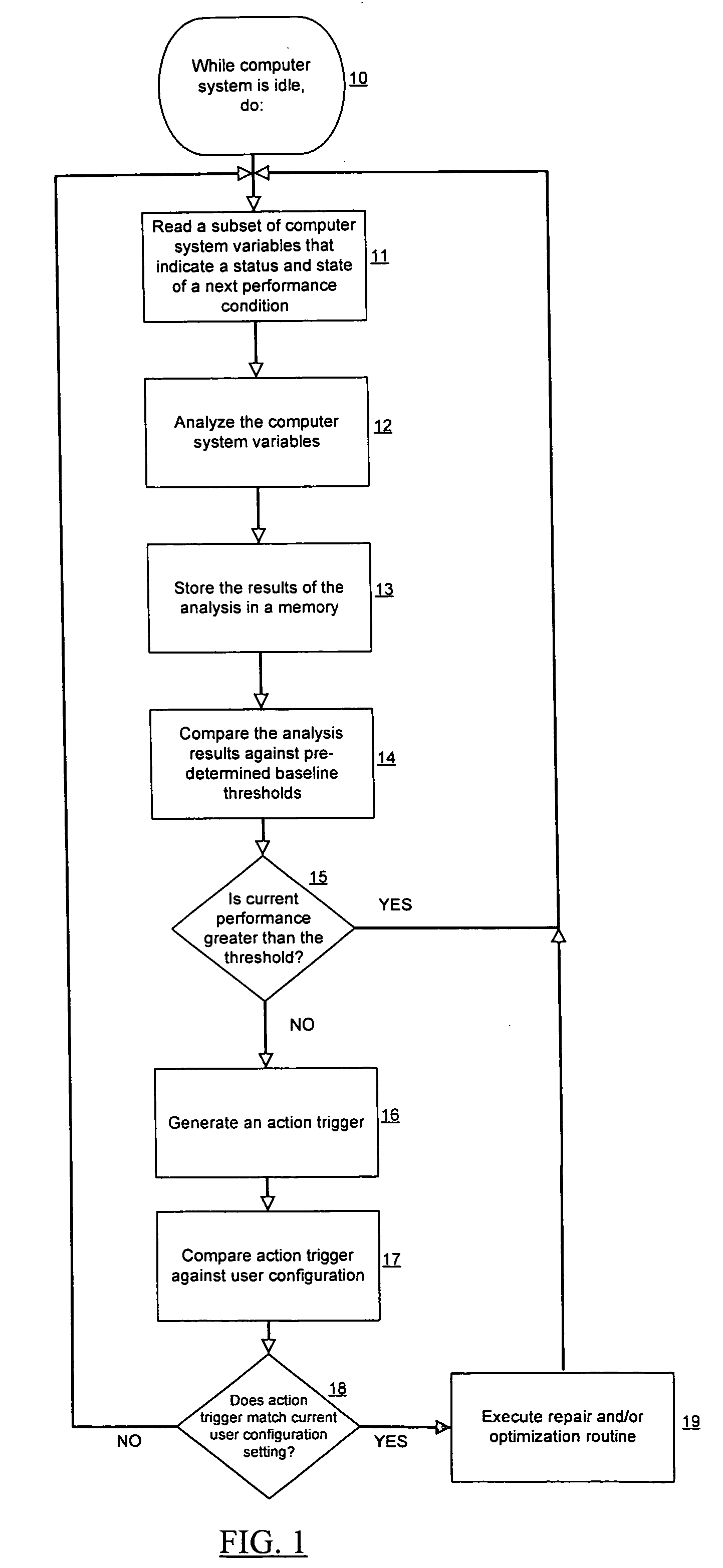

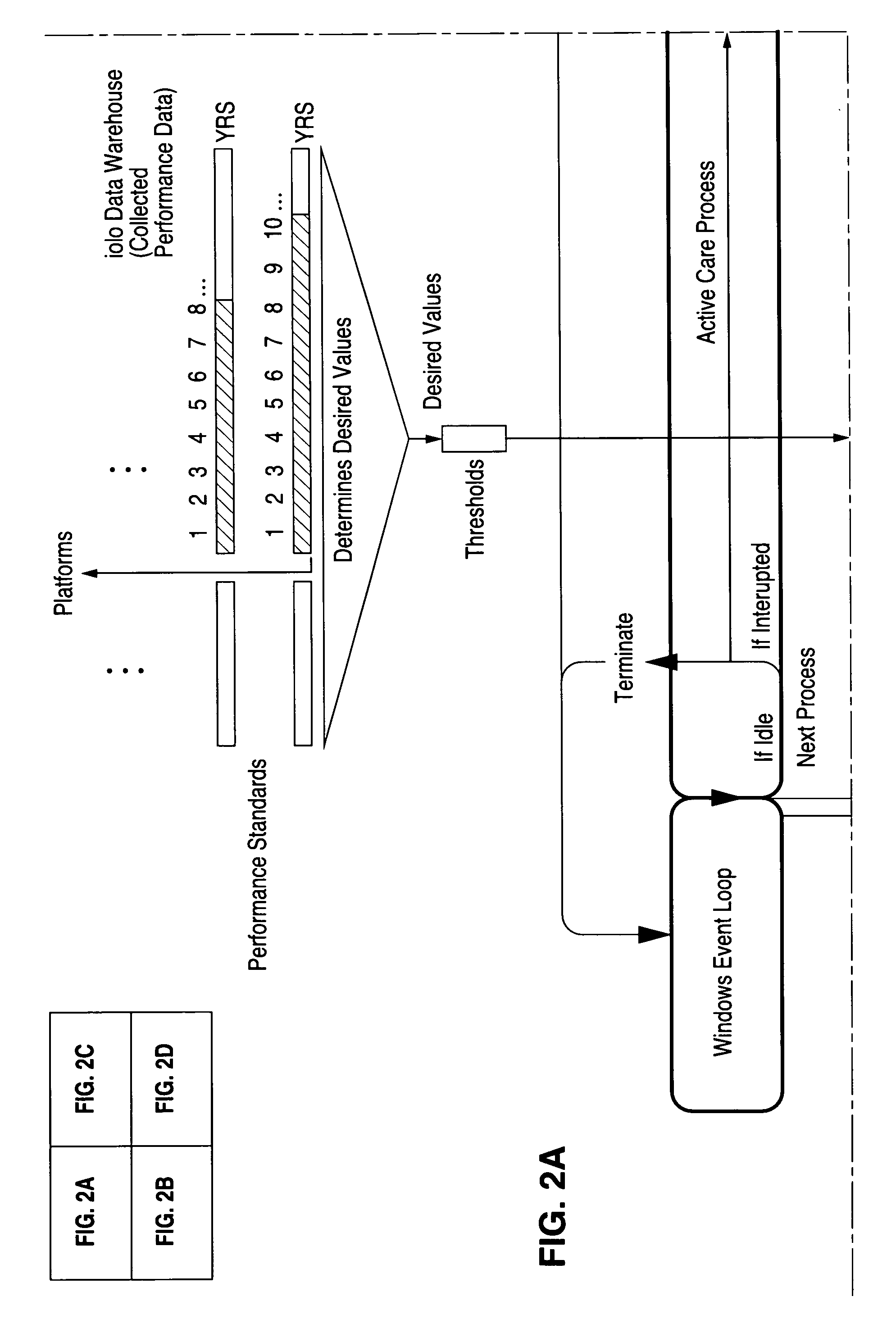

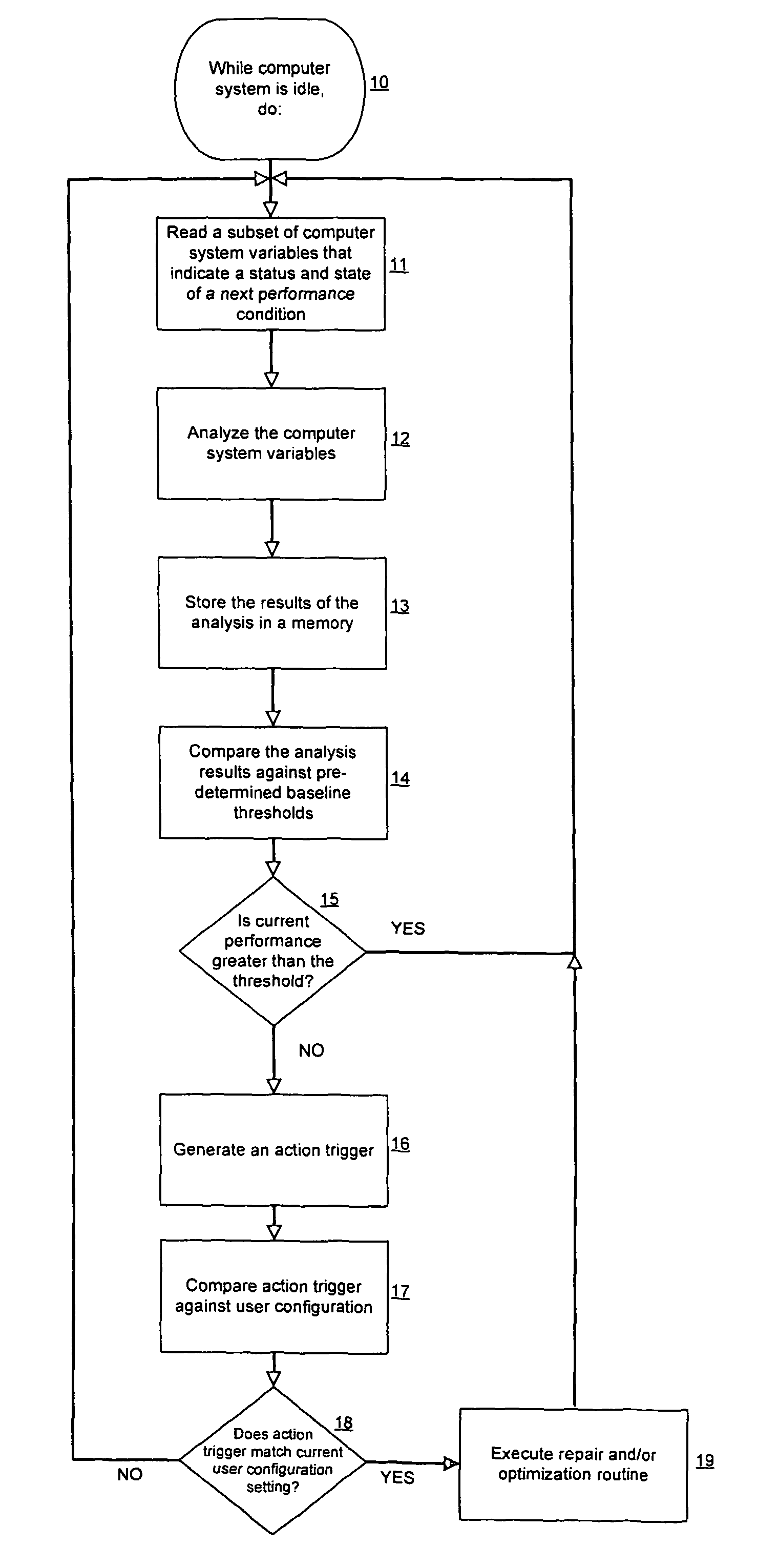

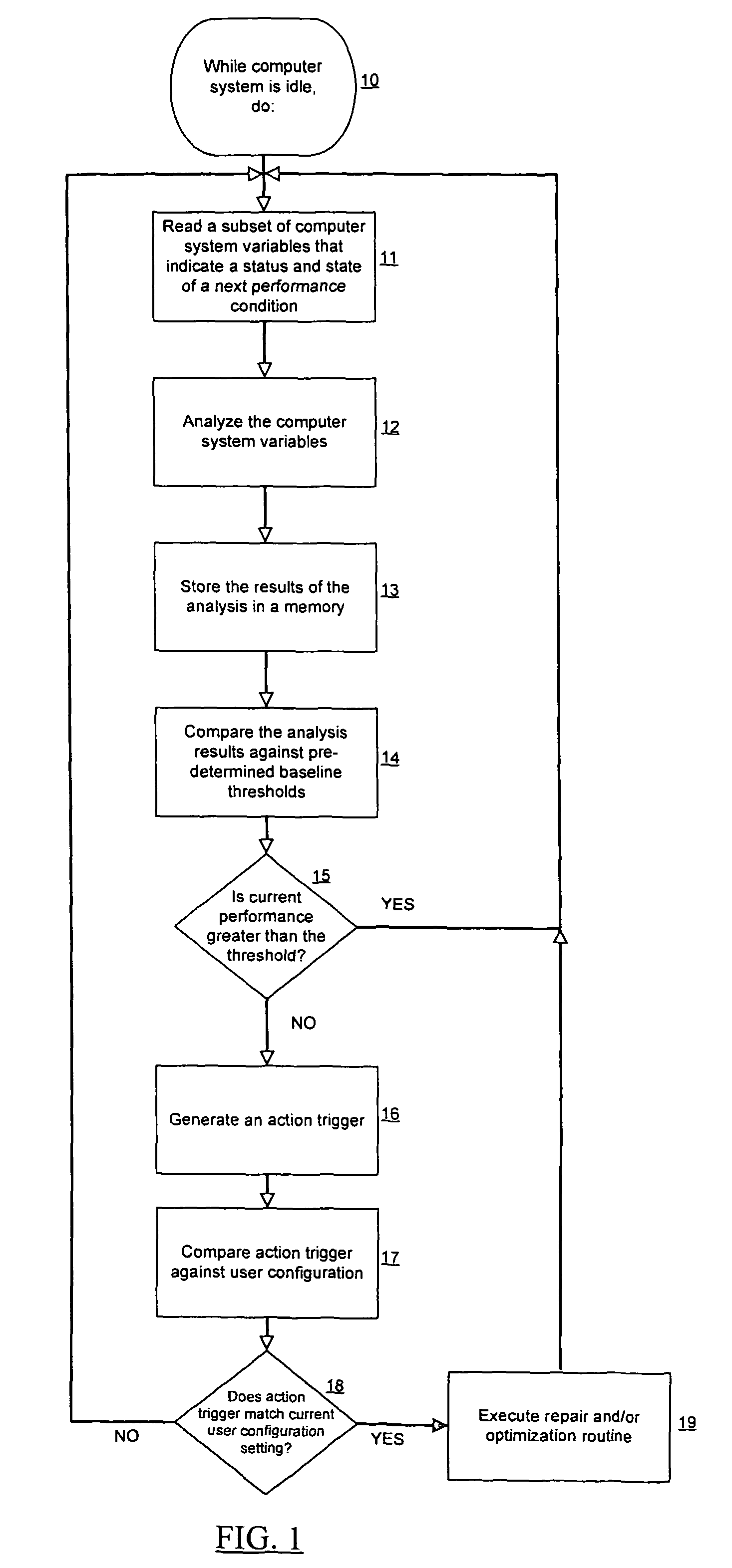

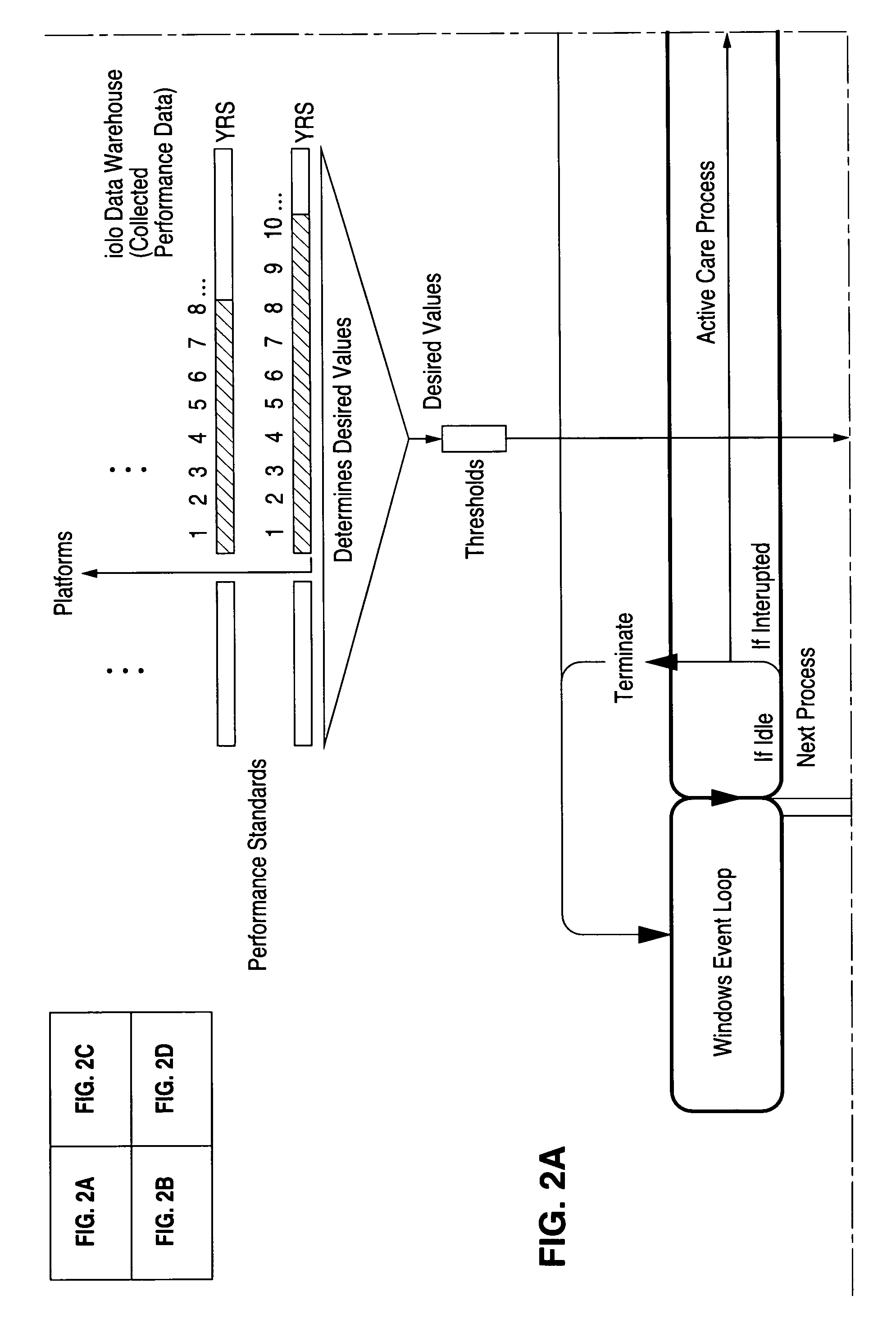

System and method for performance monitoring and repair of computers

ActiveUS20090144584A1Constant peak computer performanceWithout impacting computer performanceNon-redundant fault processingControlled releaseIdle time

A system and method for monitoring computer performance and repairing and / or optimizing system configurations. During these idle times, the present process executes a sequence of background system analyses that can trigger associated optimization, maintenance, or repair actions based on a comparison of current computer states and baseline optimal health data. If other tasks are initiated by a user of the system, while the present invention is performing any of its actions, the monitoring and repair program terminates itself and releases full control back to the user and operating system.

Owner:REALDEFENSE LLC

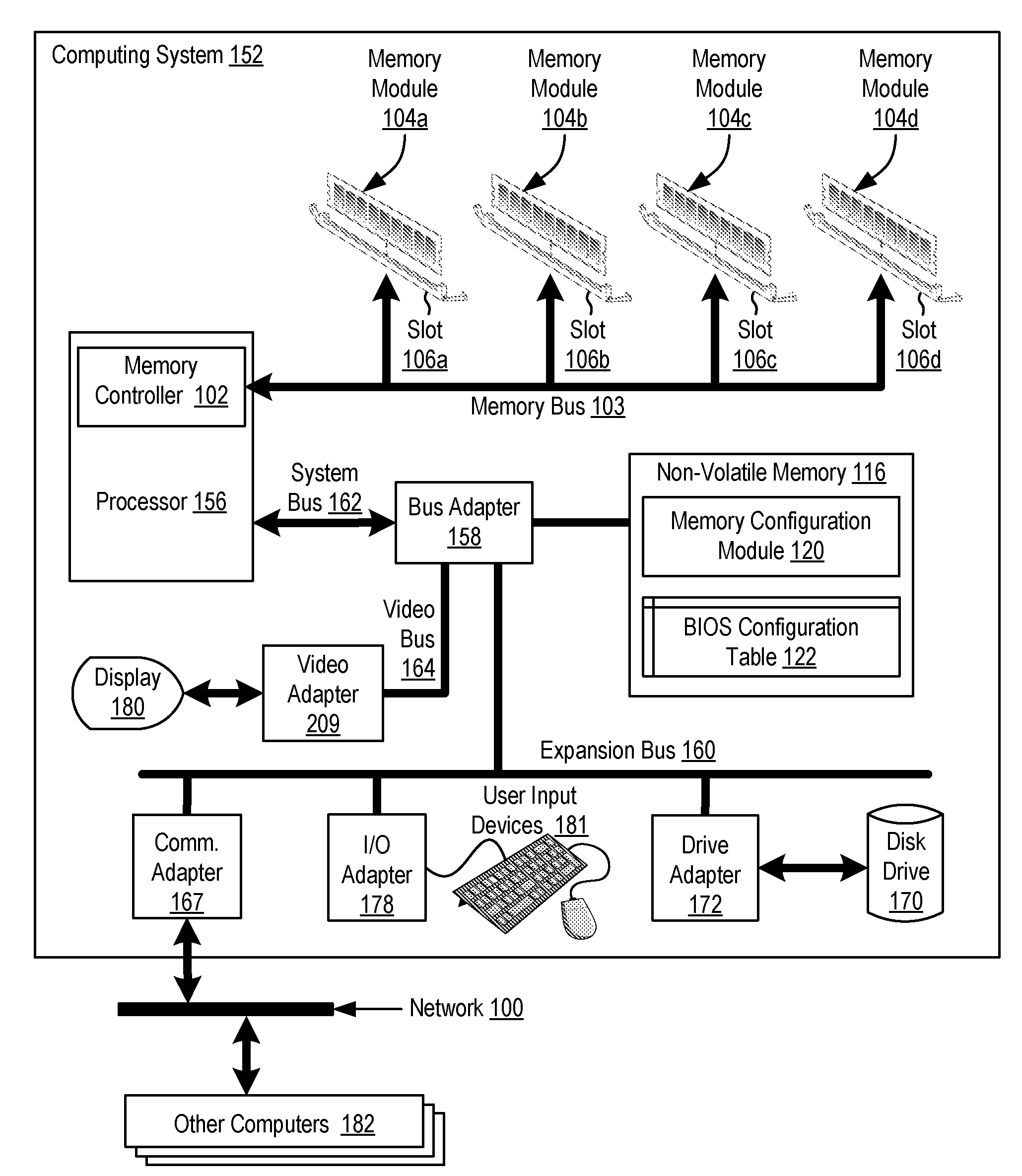

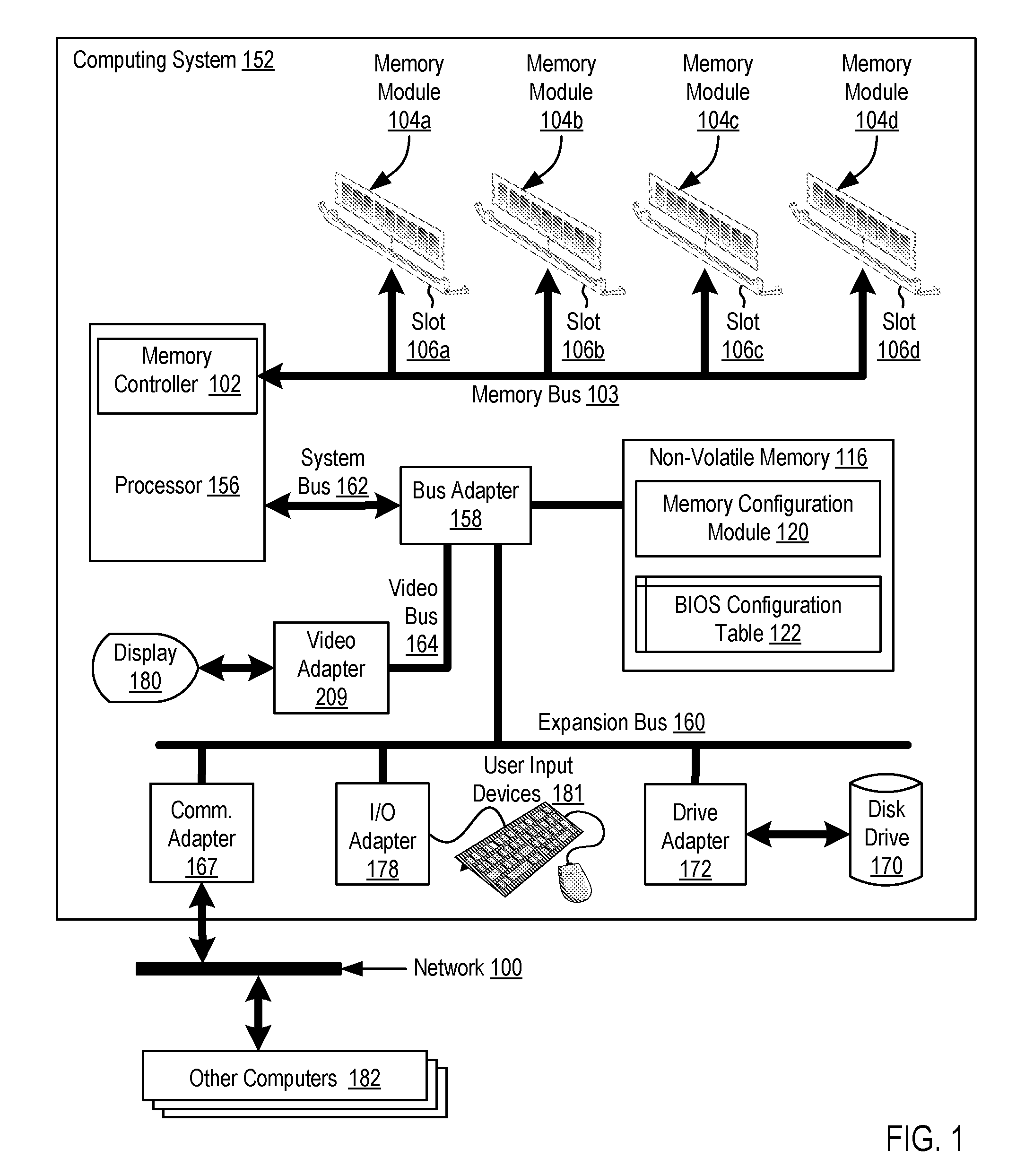

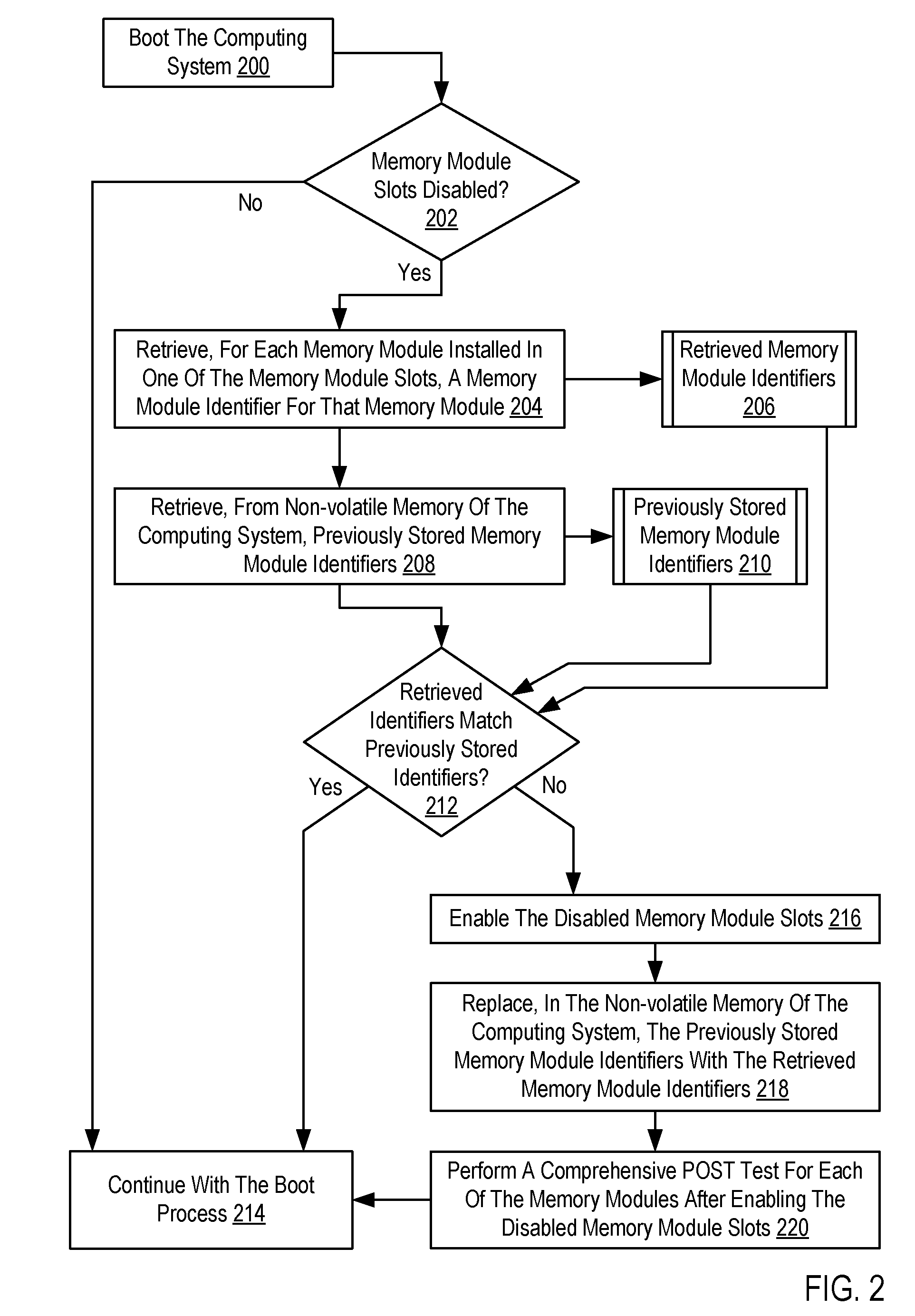

Enabling Memory Module Slots In A Computing System After A Repair Action

ActiveUS20090254732A1Memory adressing/allocation/relocationDigital computer detailsNon-volatile memoryMemory module

Methods, systems, and products are disclosed for enabling memory module slots in a computing system after a repair action, the computing system having a plurality of memory module slots and having at least one memory module installed in one of the memory module slots, that includes: determining, during a boot process for the computing system, whether any of the memory module slots are disabled; and if any of the memory module slots are disabled: retrieving, for each memory module installed in one of the memory module slots, a memory module identifier for that memory module, retrieving, from non-volatile memory of the computing system, previously stored memory module identifiers, determining whether the retrieved memory module identifiers match the previously stored memory module identifiers, and enabling the disabled memory module slots if the retrieved memory module identifiers do not match the previously stored memory module identifiers.

Owner:LENOVO GLOBAL TECH INT LTD

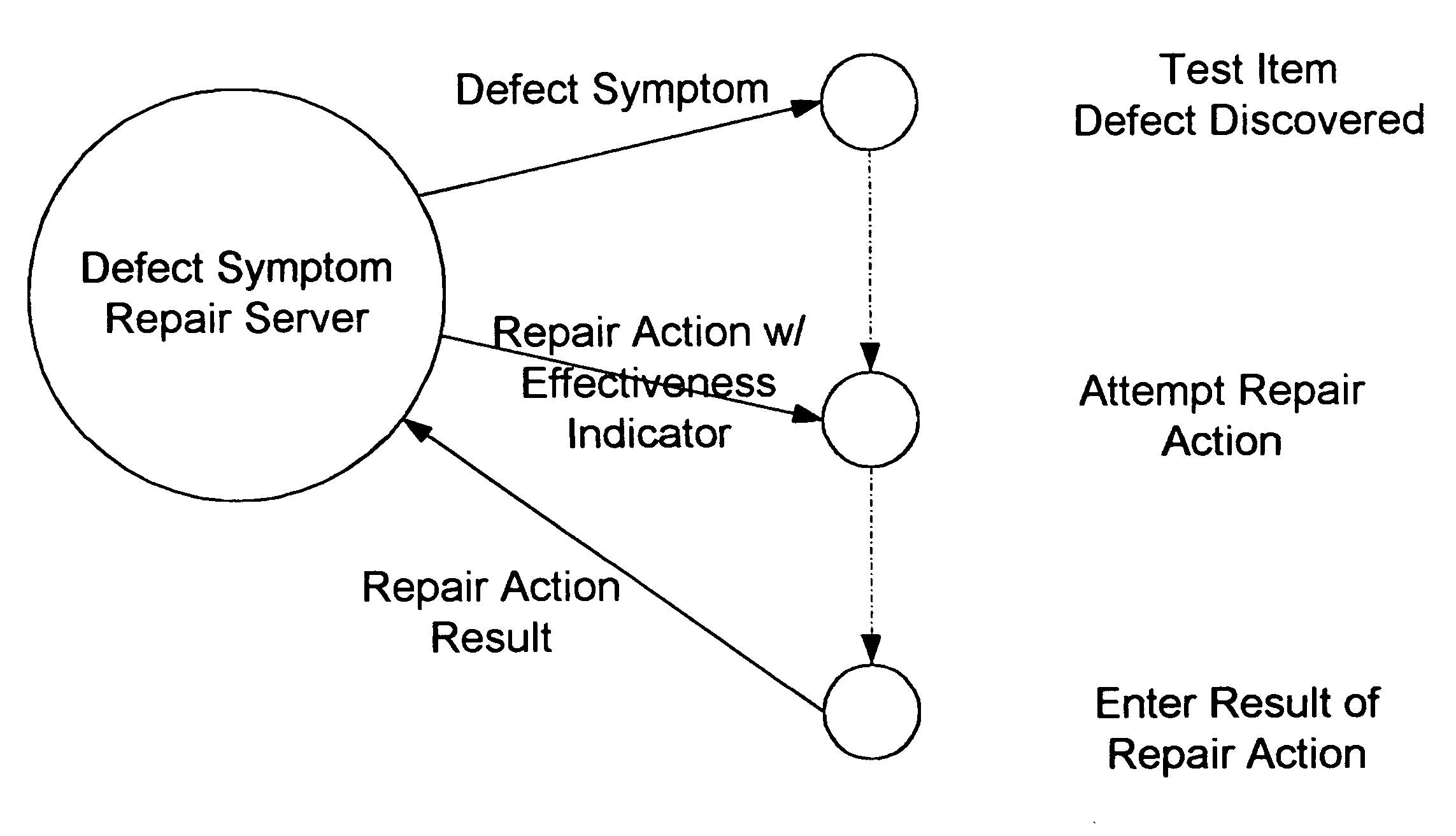

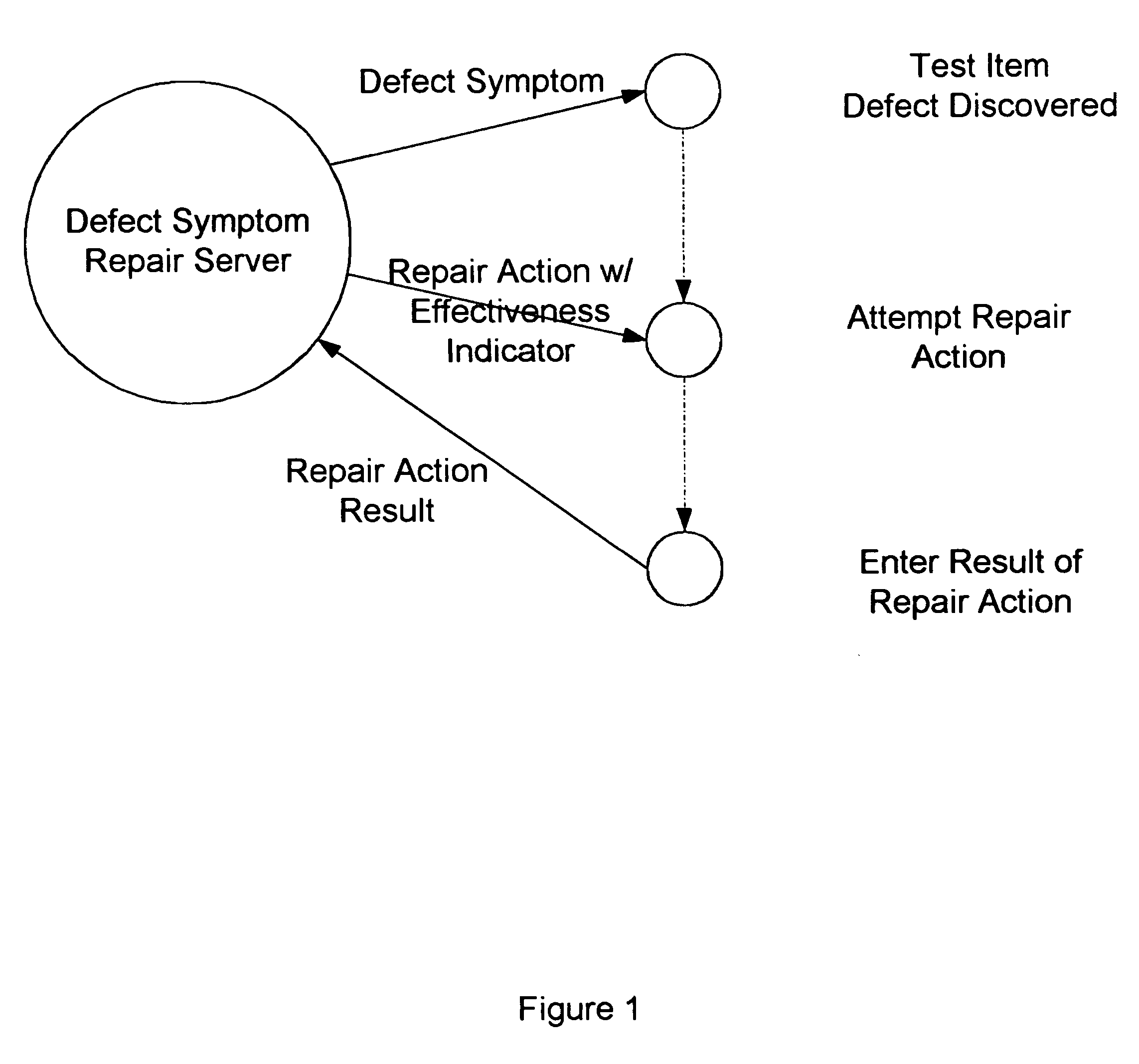

Defect symptom repair system and methods

InactiveUS20060156141A1Isolate defectRepair quickly and accuratelyProgramme controlElectronic circuit testingEngineeringRepair - action

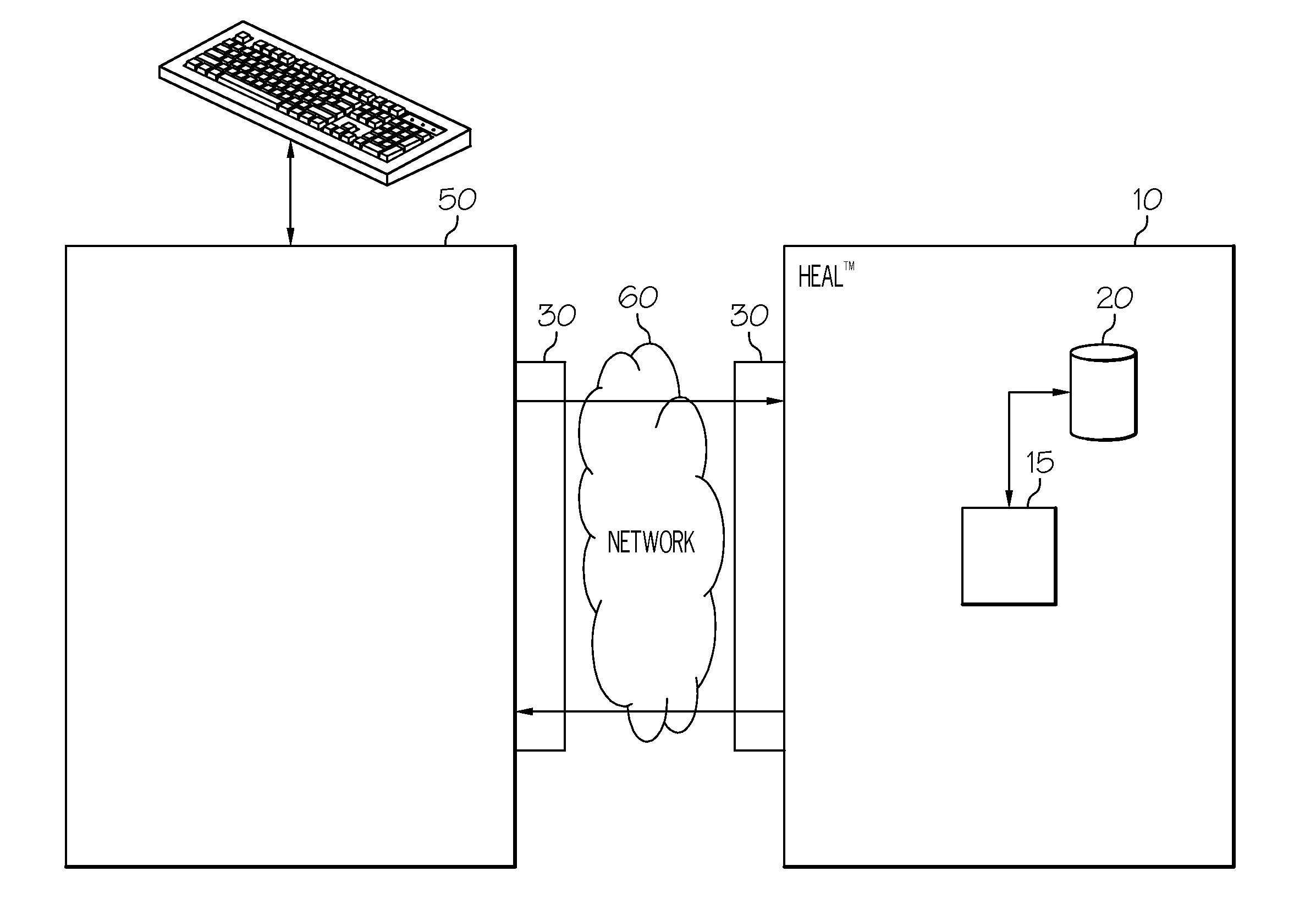

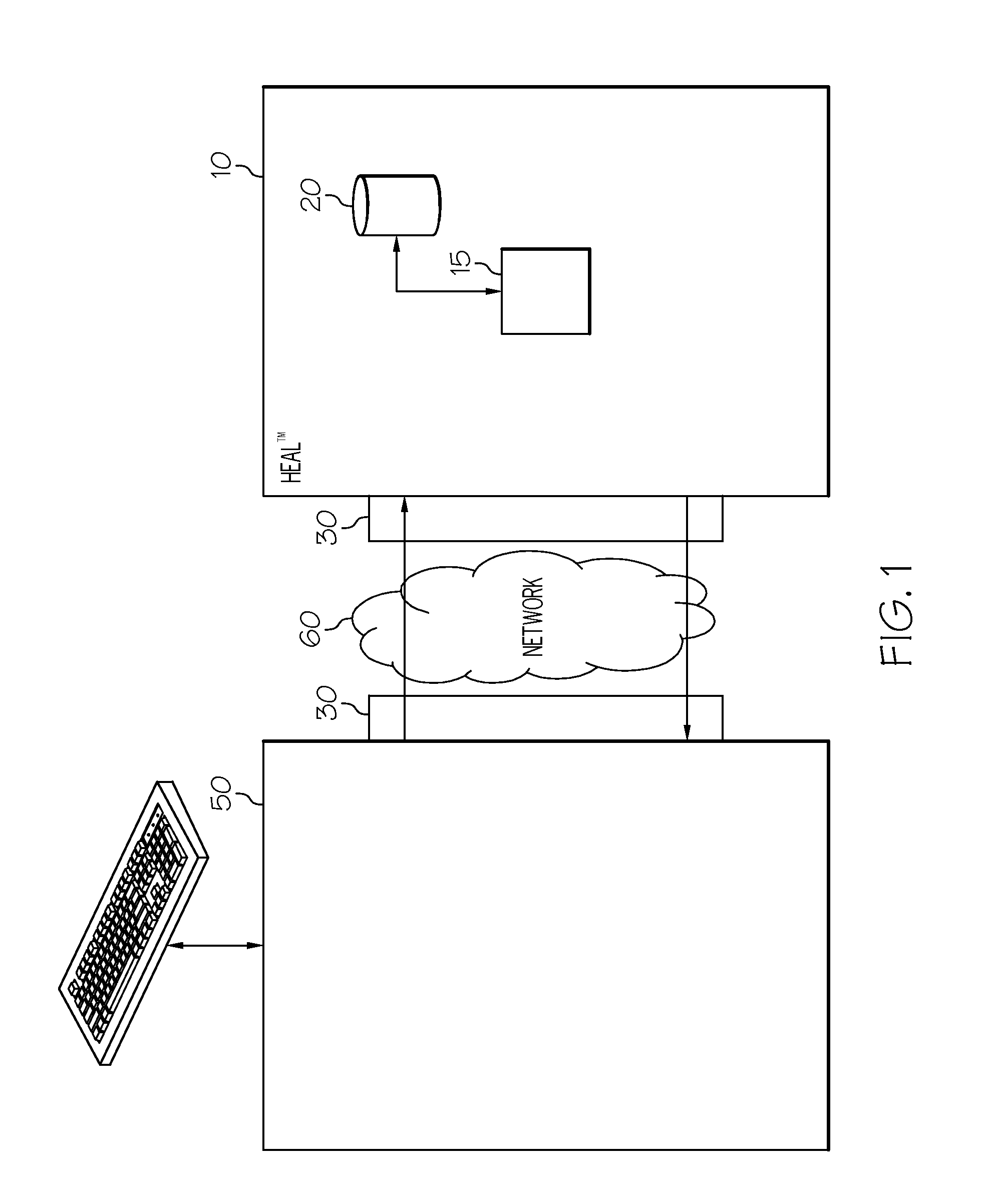

The present invention is related to the repair of defective items where the defect symptom does not readily suggest the action to repair the item. Test and repair technicians isolate and repair defects. The defect symptom repair system provides a means for the technicians to pool their experience without extensive effort and to make their experience readily available. The defect symptom repair system is implemented as a web server on the Internet and easily accessible with use of web enabled devices. A defect symptom repair web server provides defect symptoms and associated repair actions. Each repair action has an effectiveness indicator. The defect symptom is match with the observed symptom. A repair action associated with the defect symptom is selected based on the effectiveness indicator. The repair action is applied to the item. The result, success or failure, is entered into the defect symptom repair web server and the effectiveness indicator of the repair action is computed including the most recent result. If the observed symptom does not match a defect symptom from the server, a defect symptom is created in the server. If a new repair action for a defect symptom is attempted, a repair action is added and the effectiveness indicator is calculated based on the result of the repair action attempt.

Owner:PNC BANK NAT ASSOC

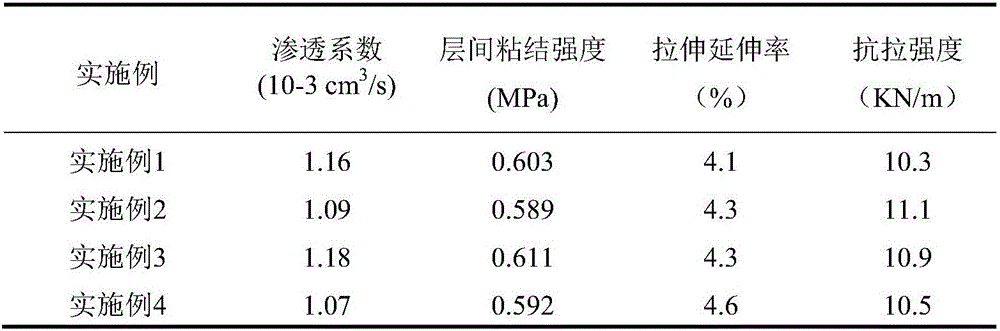

Composite pavement bonding material and preparation method thereof and waterproof crack resistant layer

The invention discloses a composite pavement bonding material and a preparation method thereof and a waterproof crack resistant layer. The bonding material comprises a high polymer adhesive and a self-repairing microcapsule. A high polymer adhesive waterproof layer is capable of effectively preventing underground water from entering an asphalt upper layer through cement concrete base cracks to avoid damaging an asphalt surface layer. The self-repairing microcapsule is infiltrated into a cement concrete panel hole and is capable of delaying further expansion of cement concrete diseases through the repairing action. The waterproof crack resistant layer comprises a polyester glass fiber fabric crack resistant layer, at least one bonding layer and at least one stripping layer, wherein the bonding layer is prepared from the bonding material and is arranged on at least one surface of polyester glass fiber fabric; and the at least one stripping layer is arranged on the surface of the bonding layer. When the waterproof crack resistant layer is in use, only the stripping layer needs to be torn and is attached to a cement concrete pavement.

Owner:江苏北极星交通产业集团有限公司

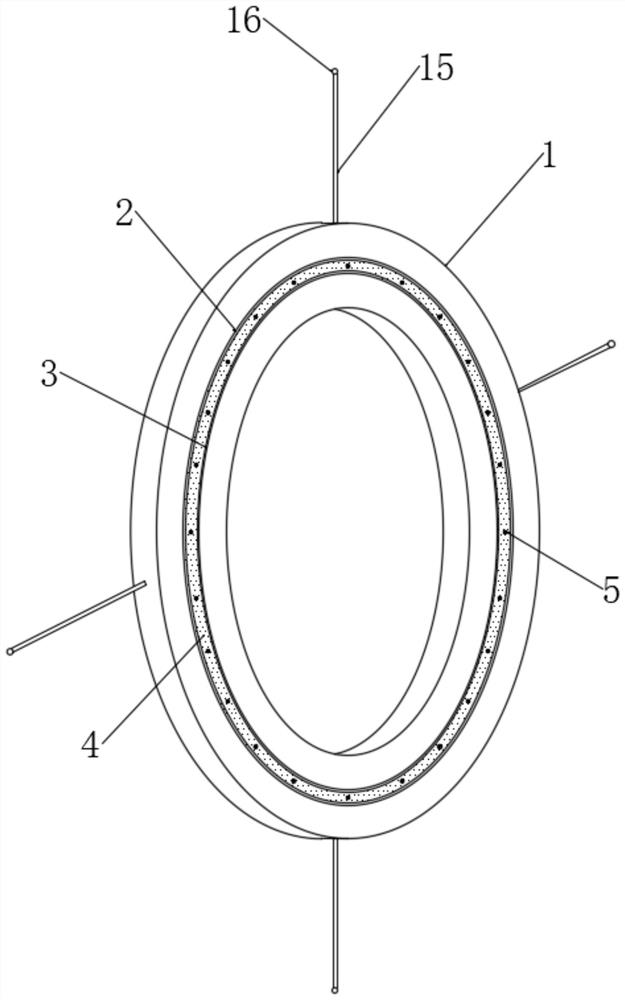

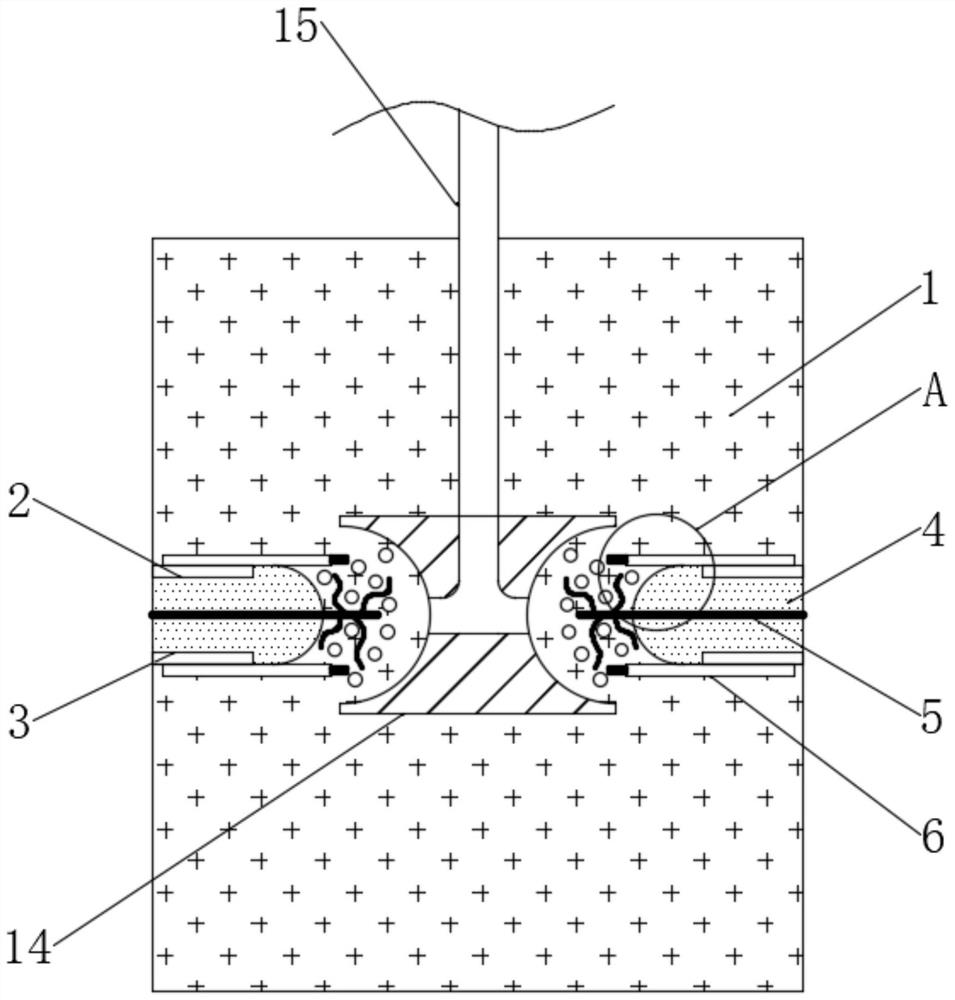

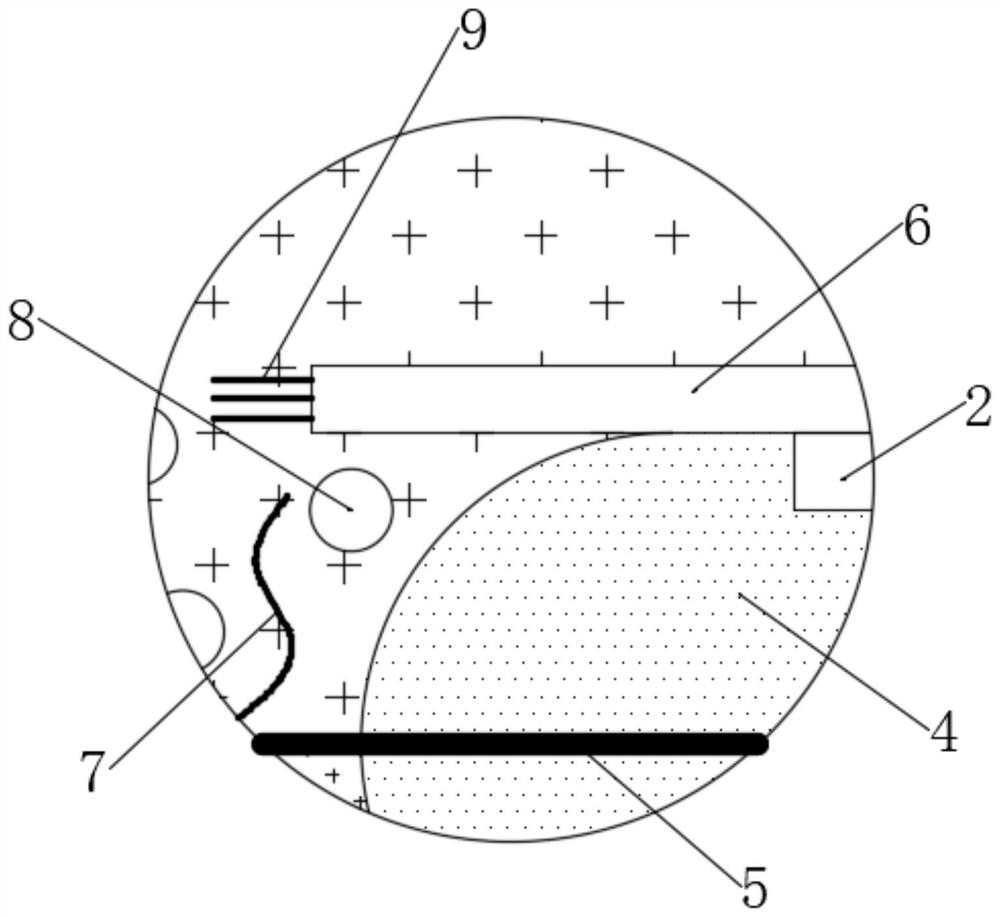

Self-repair flange gasket for pipeline connection

ActiveCN111734901AReduce the risk of large-scale spillsAvoid failureFlanged jointsPipeline systemsAdhesiveEngineering

The invention discloses a self-repair flange gasket for pipeline connection, and belongs to the technical field of sealing elements. The self-repair flange gasket for pipeline connection can make a rapid response and trigger a self-repair action when a crack appears at the initial failure stage of the flange gasket. On the one hand, rapid development is performed to remind a technician in time byutilizing the characteristics of sensing moisture. On the other hand, the crack is actively filled based on the characteristics of gas expansion by using a prearranged repair layer, then, melting guidance is performed on a hot-melt adhesive by using a spontaneous heating material, a continuous adhesion ring is formed to cooperate with the repair layer for repair, and certain strength is achieved to resist the erosion of water to avoid the failure or separation of the adhesion ring. Effective seepage prevention is achieved for the crack, the risk of large-scale leakage caused by further failureof the flange gasket is reduced, precious time is gained for the technician to perform maintenance, and thus high losses caused by pipeline leakage are reduced.

Owner:江阴市国祥锻造有限公司

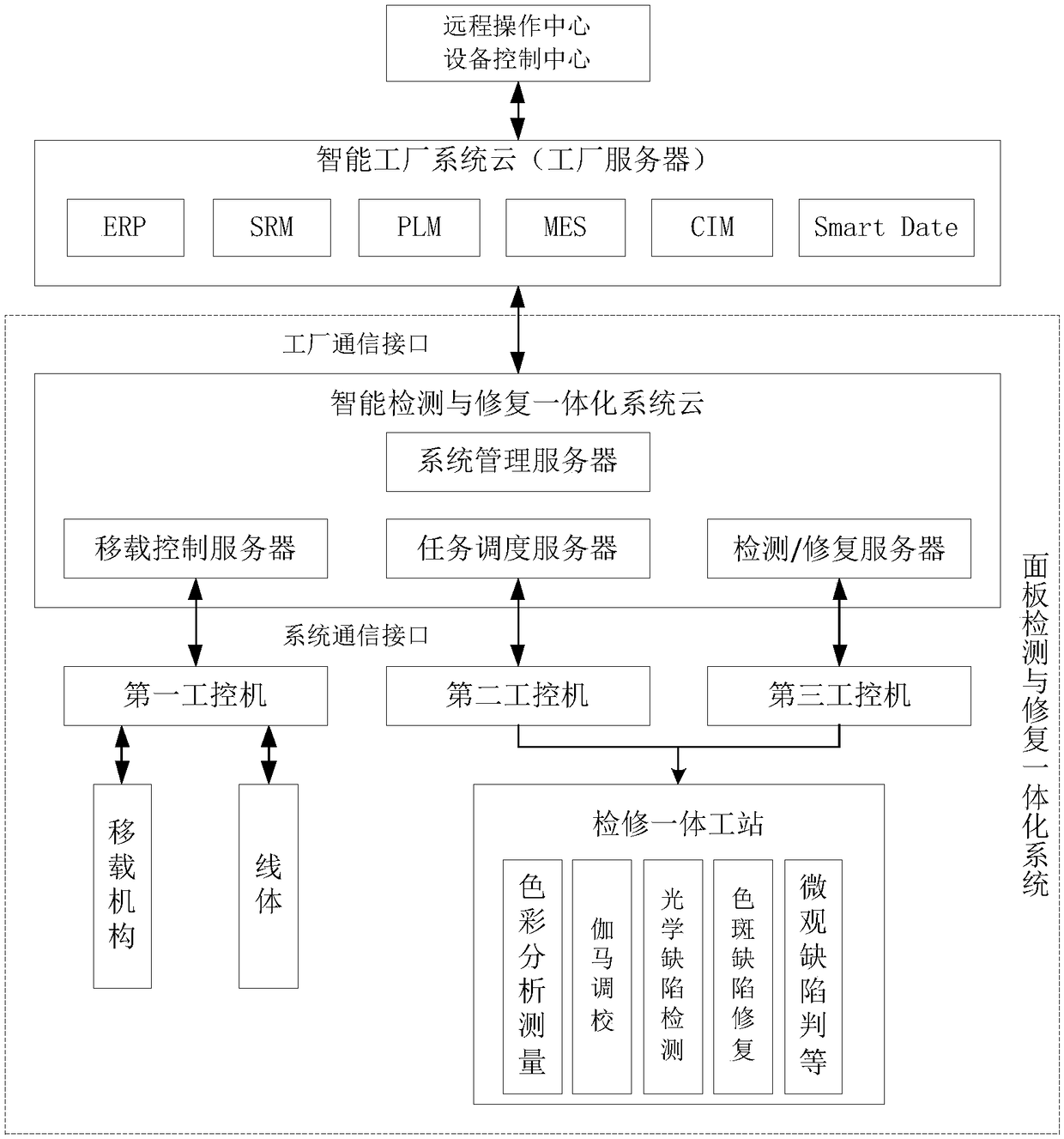

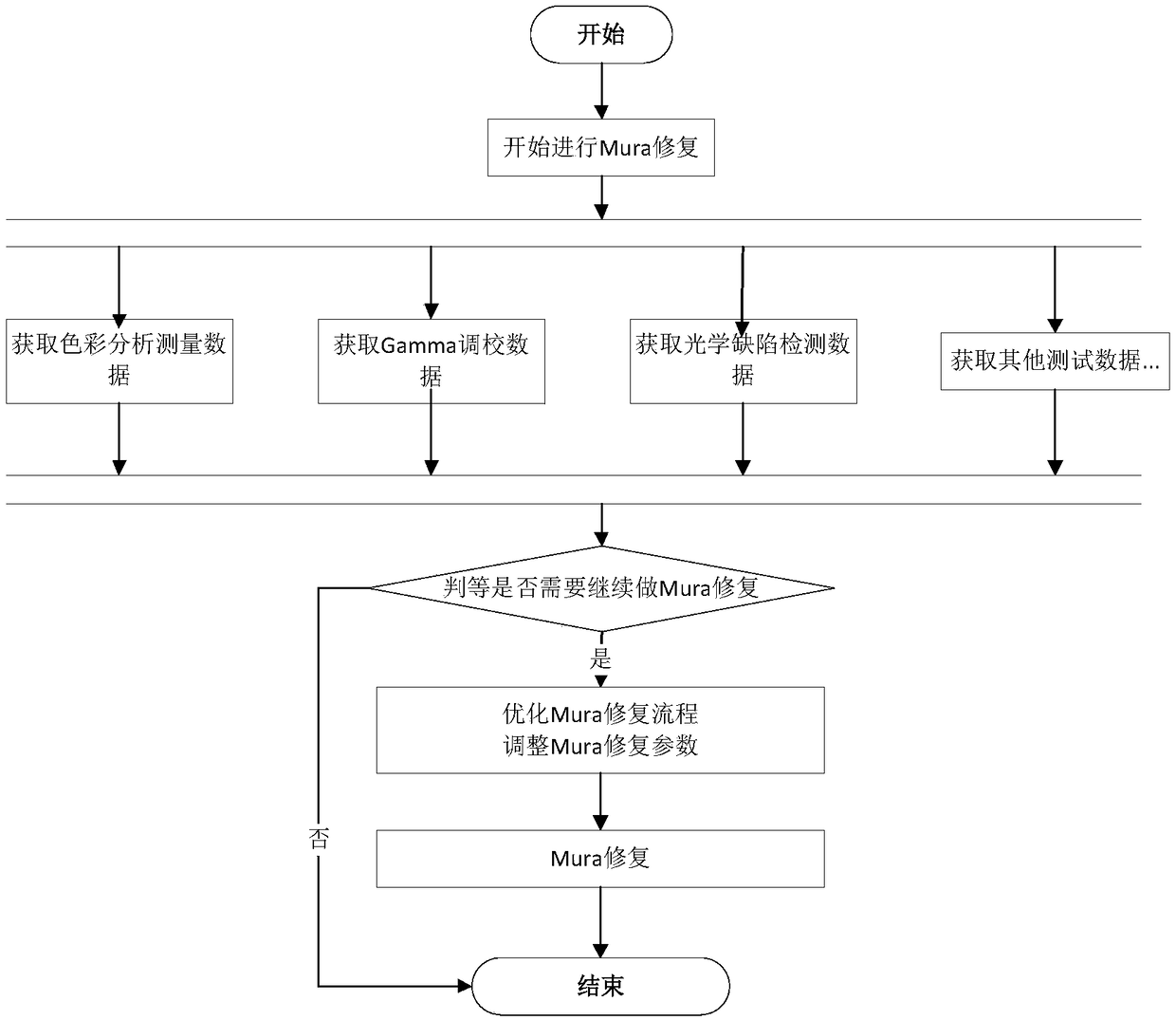

Cell detection and repairing integrated system

ActiveCN108594484AGuaranteed cooperationIncrease productivityNon-linear opticsProduction linePower station

The invention discloses a cell detection and repairing integrated system. The system comprises a line body, a transplantation mechanism, multiple detection and repairing integrated work stations distributed on the line body as well as a first industrial personal computer, a second industrial personal computer and a third industrial personal computer; the first industrial personal computer adjustswork tasks of the transplantation mechanism and mechanisms in the multiple detection and repairing integrated work stations according to a transplantation control instruction; the second industrial personal computer adjusts work tasks the multiple detection and repairing integrated work stations according to a task scheduling instruction; the third industrial personal computer performs detection or repairing action on the multiple detection and repairing integrated work stations according to a detection / repairing instruction. The multiple detection and repairing integrated work stations are distributed on the line body, the matching intensity of actions of all links can be effectively guaranteed, the stability and the timeliness of a whole test procedure of the production line are improved, and the production efficiency and the product yield of the production line are increased.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

System and method for performance monitoring and repair of computers

ActiveUS7873877B2Without impacting computer performanceImprove performanceNon-redundant fault processingControlled releaseIdle time

A system and method for monitoring computer performance and repairing and / or optimizing system configurations. During these idle times, the present process executes a sequence of background system analyses that can trigger associated optimization, maintenance, or repair actions based on a comparison of current computer states and baseline optimal health data. If other tasks are initiated by a user of the system, while the present invention is performing any of its actions, the monitoring and repair program terminates itself and releases full control back to the user and operating system.

Owner:REALDEFENSE LLC

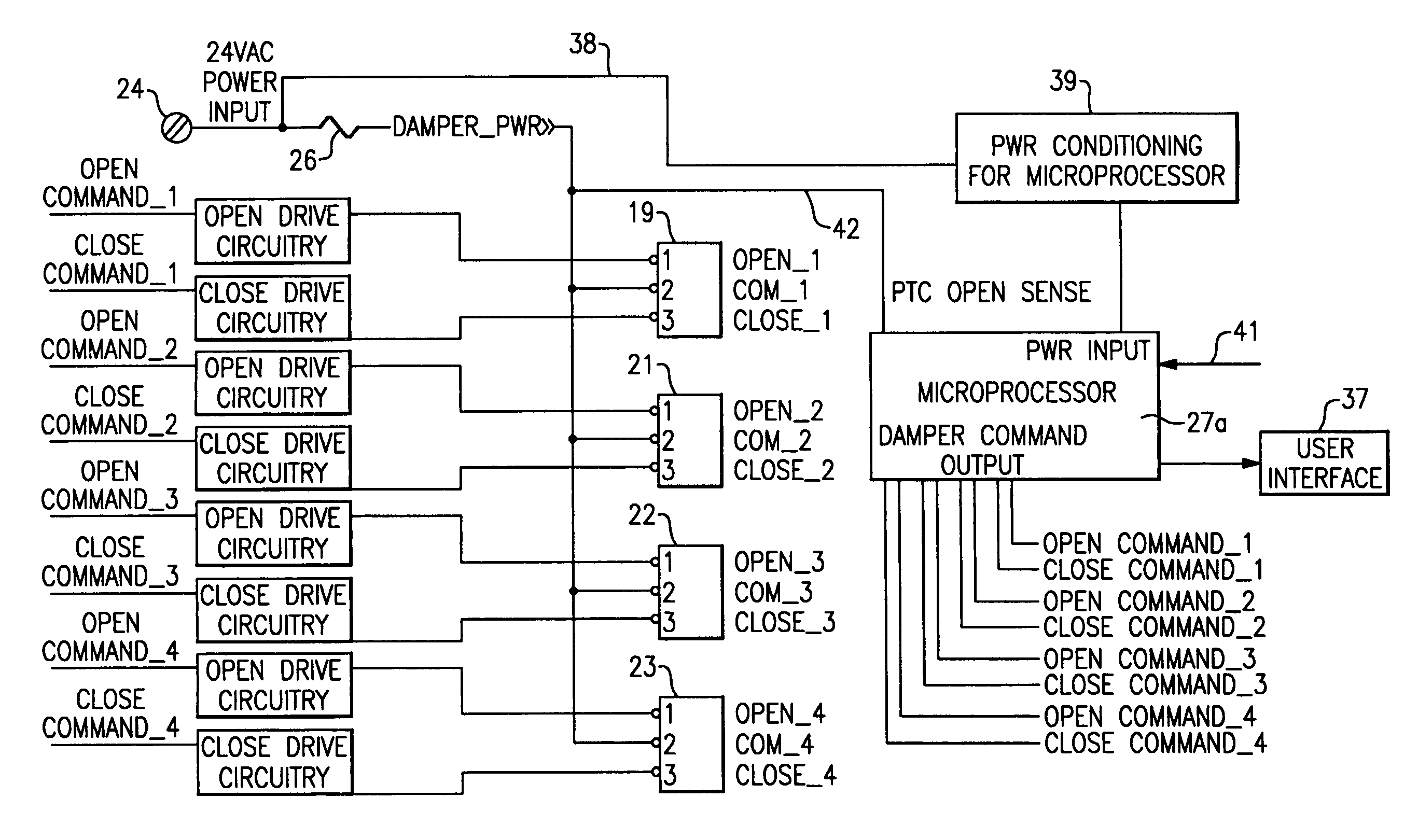

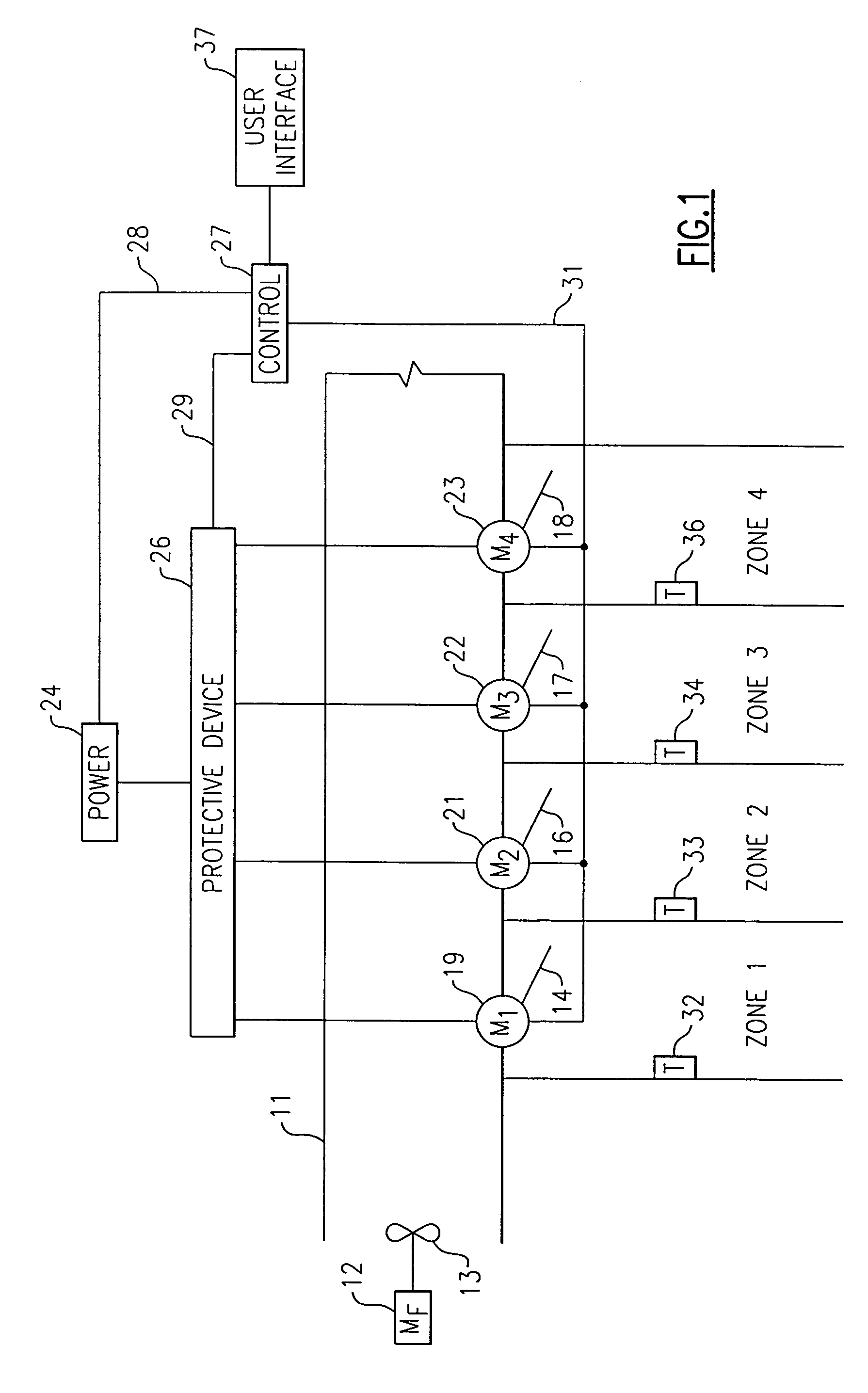

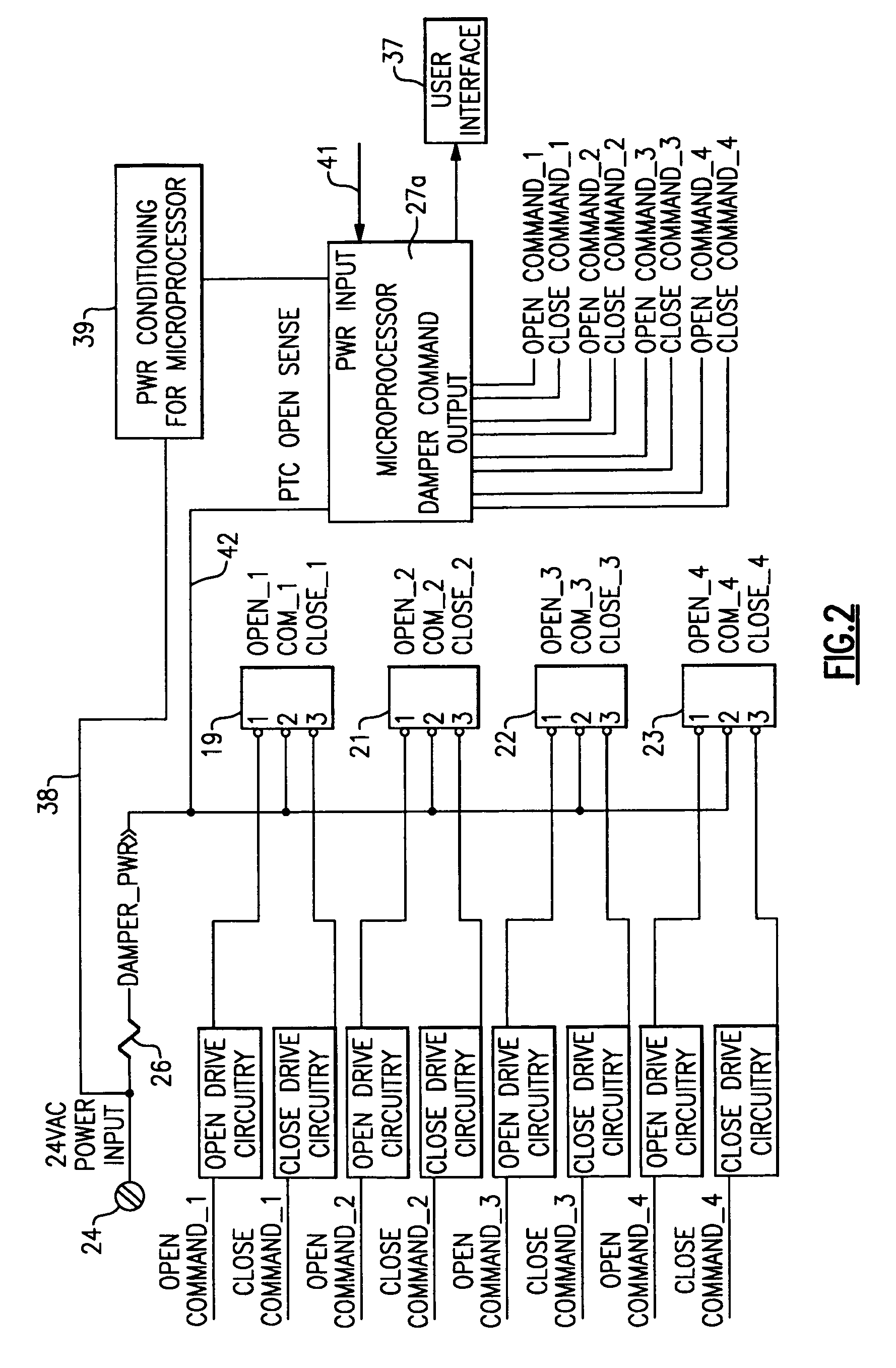

Self diagnosing HVAC zone configuration

In a drive circuit in which a plurality of drive motors are connected to a power source through a protective device which trips when the flow of current is excessive, provision is made to detect which circuit or circuits were active at the time of the failure. A microprocessor is provided to both control the activation of each of the various circuits and to also sense which circuits were active at the time of the failure. Appropriate signals are sent from the microprocessor to a user interface so that proper diagnostic and repair action can be taken.

Owner:CARRIER CORP

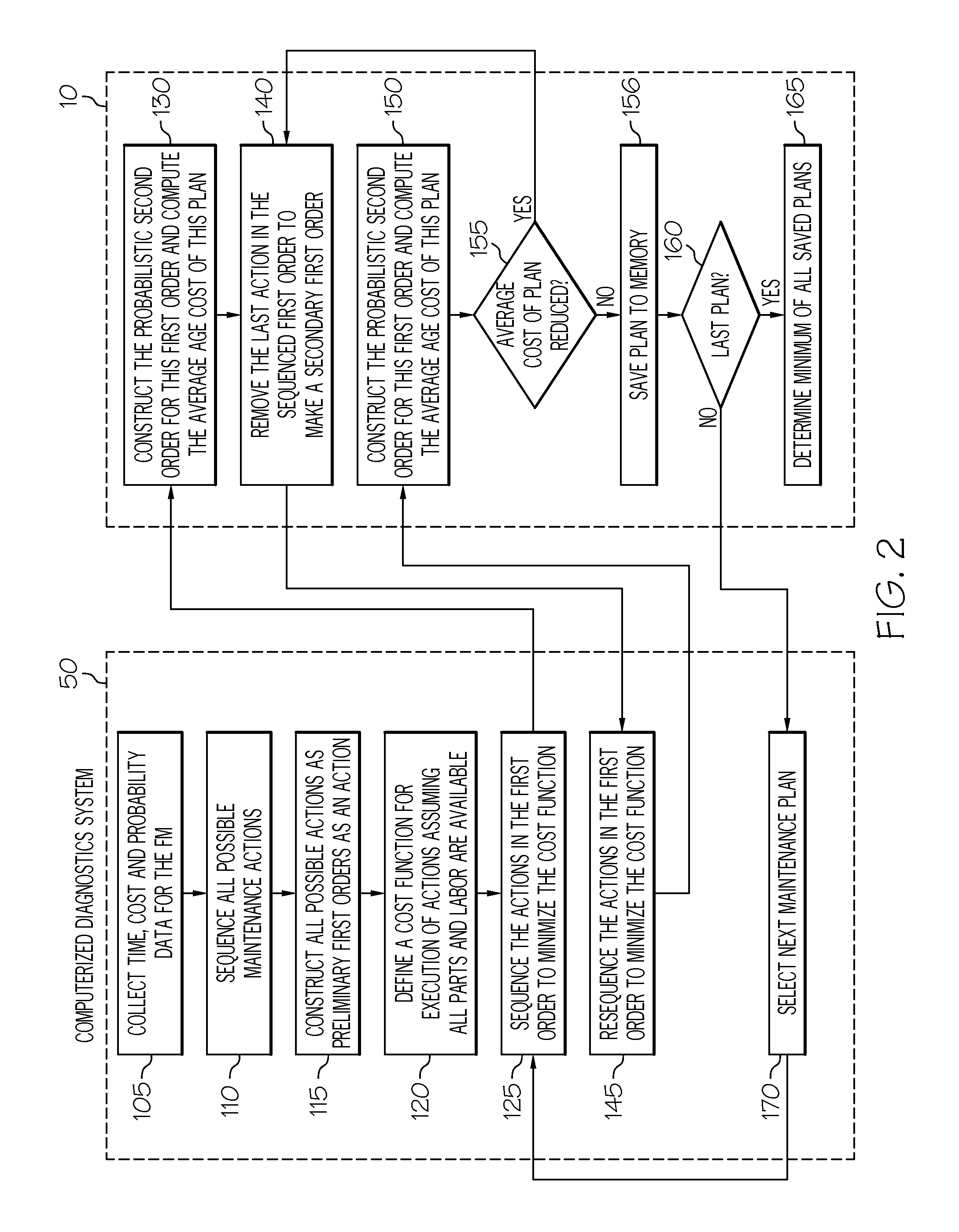

Systems and methods for the solution to the joint problem of parts order scheduling and maintenance plan generation for field maintenance

Methods and apparatus are provided for selecting a maintenance plan such that the cost of the maintenance plan is the lowest or near the lowest. The method comprises receiving a set of maintenance actions, wherein one of the repair actions is likely to repair the failure mode. The set of maintenance actions is sequenced in the increasing order of their waiting times. Each maintenance action has an associated cost equal to a waiting time cost, an execution time cost and a material cost, wherein the waiting time of each maintenance action is the time required to requisition and receive material required to perform the maintenance action. The method also constructs a maintenance plan comprising a first requisition and a second requisition by assigning each of the sequence of maintenance actions to one of the first or the second requisition.

Owner:HONEYWELL INT INC

Error monitoring of a memory device containing embedded error correction

InactiveUS20170123882A1Input/output to record carriersCode conversionProcessor registerForward error correction

Embodiments of the present disclosure provide an approach for monitoring the health and predicting the failure of dynamic random-access memory (DRAM) devices with embedded error-correcting code (ECC). Additional registers are embedded on the DRAM device to store information about the DRAM, such as the number and location of soft errors detected by the device. When the DRAM device detects a soft error, it will update the information stored in the additional registers. A controller compares the information stored in the additional registers to associated thresholds. In some embodiments, after comparing the information to the associated thresholds, the controller may determine whether to schedule a repair action. In other embodiments, the controller may determine whether to alert the memory controller that the DRAM may be failing.

Owner:INT BUSINESS MASCH CORP

Knowledge extraction methodology for unstructured data using ontology-based text mining

ActiveUS8489601B2Digital data information retrievalDigital data processing detailsText miningKnowledge extraction

A method for extracting data from service repair verbatims in a vehicle service reporting system. Each service repair verbatim includes a technician's comments concerning a part, a symptom associated with the part, and a repair action associated with the symptom. Each service repair verbatim includes information relating to an identified problem with at least one vehicle part. A diagnostic and prognostic ontology database is provided that is structured by vehicle part classification, a vehicle part sub-class classification, and a relationship classification, wherein the relationship classification includes symptom relationships and action relationships. Each of the service repair verbatims are reconstructed utilizing the diagnostic and prognostic ontology database. Combinations of information are extracted from the reconstructed service repair verbatims as a function of user input criteria. A frequency is determined of each combination extracted in the reconstructed service repair verbatims. The service repair verbatims are clustered for each combination.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and system for automatically compensating for diagnosed banding defects prior to the performance of remedial service

InactiveUS7400339B2Improve operational efficiencyAttenuate the banding defectData processing applicationsElectrographic process apparatusQuality levelOperational effectiveness

A system that extends the operational effectiveness of an image reproduction machine without requiring downtime for service by personnel includes a detection subsystem that monitors components of an image reproduction system for detecting a banding defect in the image reproduction system and an automated compensation subsystem for modifying operation of the image reproduction system to compensate for the detected banding defect so that the image reproduction system continues to generate images at an acceptable quality level. The automated compensation subsystem adjusts components and / or data used by image reproduction system to compensate for the identified banding defect without requiring immediate operator or service personnel intervention. This compensation may successfully attenuate the banding defect so that the image reproduction system continues to produce acceptable images without downtime while awaiting service by personnel. The system may also include a diagnostic subsystem for determining causes for a detected banding defect to further enhance the operation of the compensation system or to facilitate a repair action by a person.

Owner:XEROX CORP

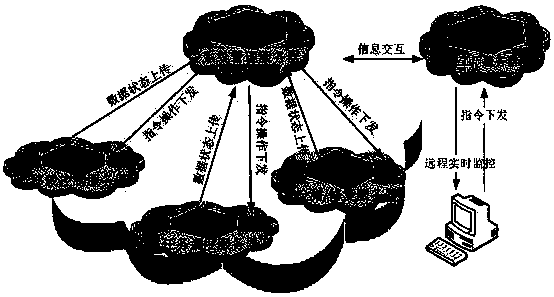

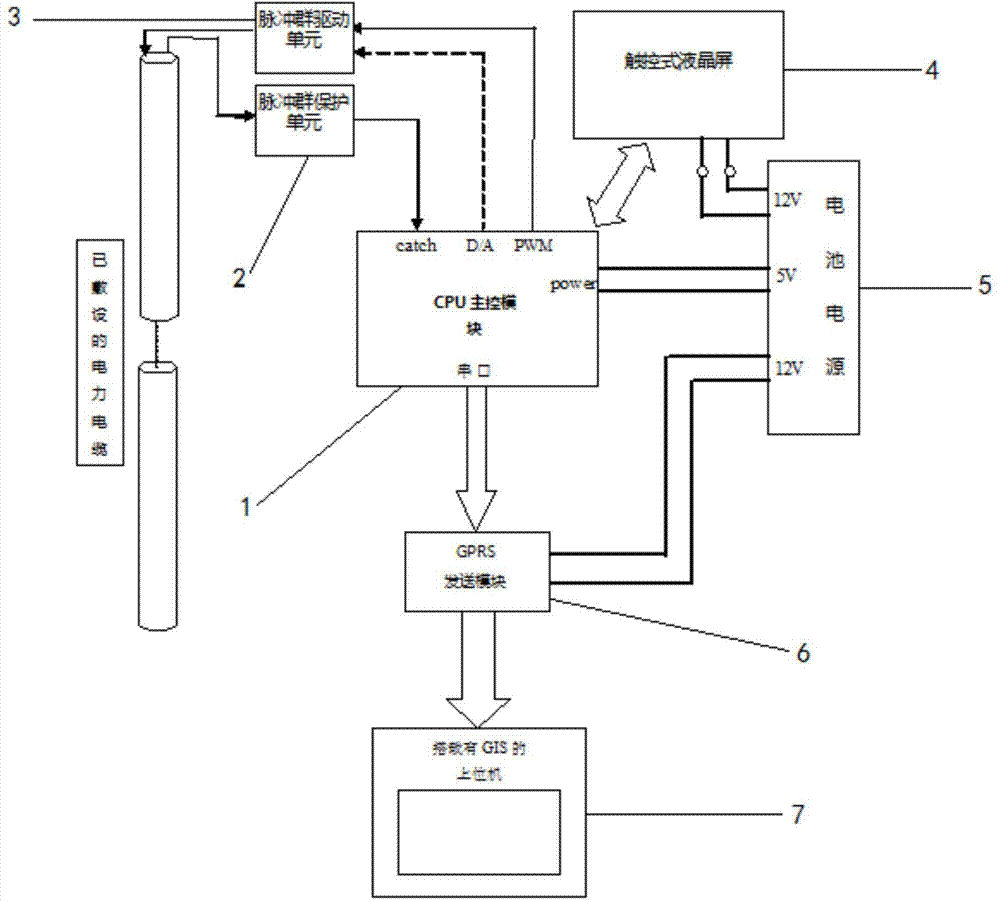

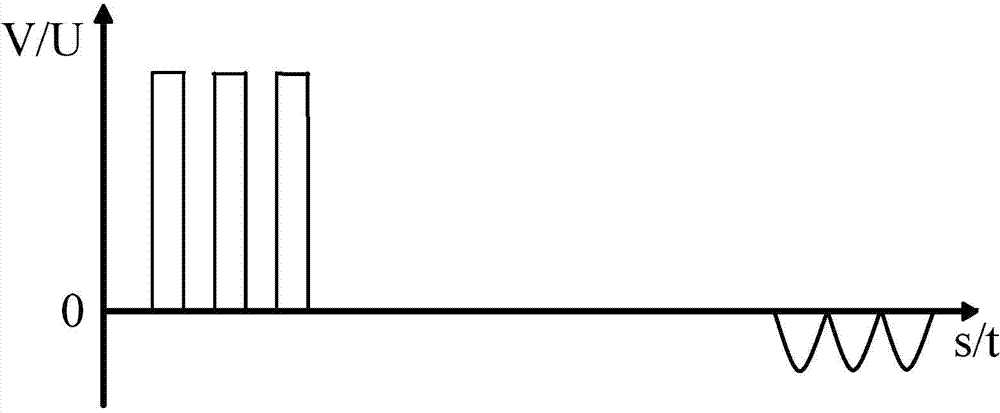

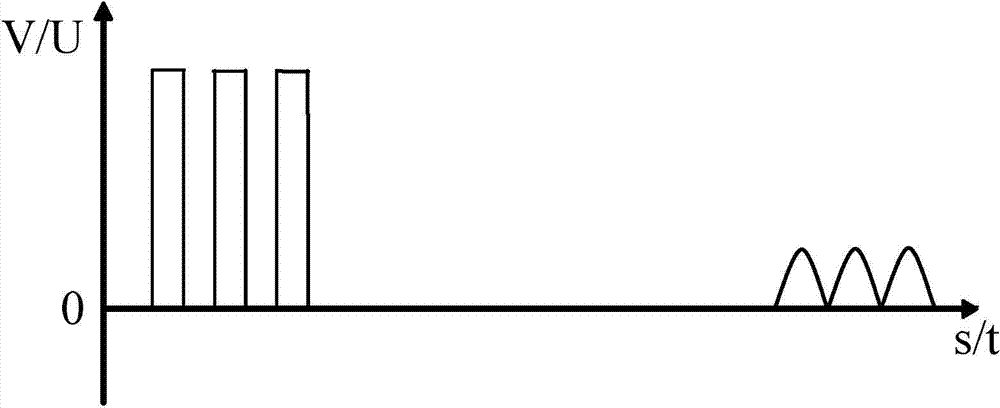

GIS-based anti-theft monitoring and positioning system for power cables and monitoring method

InactiveCN103592576AReduce lossTimely and accurateFault location by pulse reflection methodsPower cableLow voltage

The invention discloses a GIS-based anti-theft monitoring and positioning system for power cables and a monitoring method. A small signal pulse train formed by a plurality of low-voltage pulse signals is sent in a short time, so that misinformation is prevented to a certain extent, and positioning accuracy is improved. The small pulse train is transmitted in a cable shielding layer, the loss of pulse in the transmission process of the small pulse train in the cable shielding layer is smaller than the loss of the pulse in the transmission process of the small pulse train in a core wire, and therefore electric energy is saved to a certain degree. Due to the fact that a GPRS message sending module is adopted, an upper computer and a terminal can be always connected, and it is ensured that a warning message can be send out timely and accurately. The upper computer is provided with a GIS in a carried mode and can accurately determine the geographic position of the site where the power cables are stolen, optimized rush repairing action routes for arriving at the site where the power cables are stolen can be given out, and workers can go to the site where the power cables are stolen for rush repairing immediately.

Owner:陕西澜跃电子科技有限公司

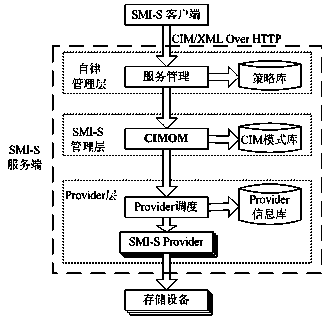

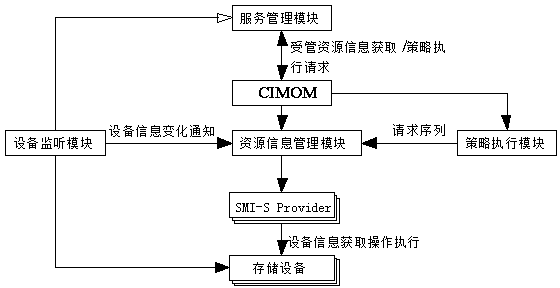

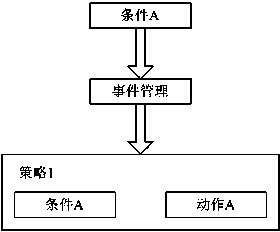

Autonomic computing-based storage management initiative specification (SMI-S) unified storage management model

InactiveCN103986611AReduce complexityReal-time fault monitoringData switching networksStrategy executionStorage Management Initiative – Specification

The invention discloses an autonomic computing-based storage management initiative specification (SMI-S) unified storage management model. An SMI-S-based autonomic computing model is provided on the basis of an SMI-S technical system structure and consists of an SMI-S client, an SMI-S server and storage equipment, wherein the SMI-S server consists of an autonomic management layer, an SMI-S management layer and a Provider layer. Meanwhile, the autonomic computing model comprises an equipment monitoring module, a resource information management module and a strategy execution module. The autonomic computing model is based on SMI-S specification, a failure state of the storage equipment is actively discovered through the equipment monitoring module, and corresponding measures can be taken for fixing the failure; various configuration and repair actions of the storage equipment are finished through the strategy execution module; namely, according to a strategy-based autonomic management method, different managed objects in a heterogeneous storage network environment are managed in a unified mode.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

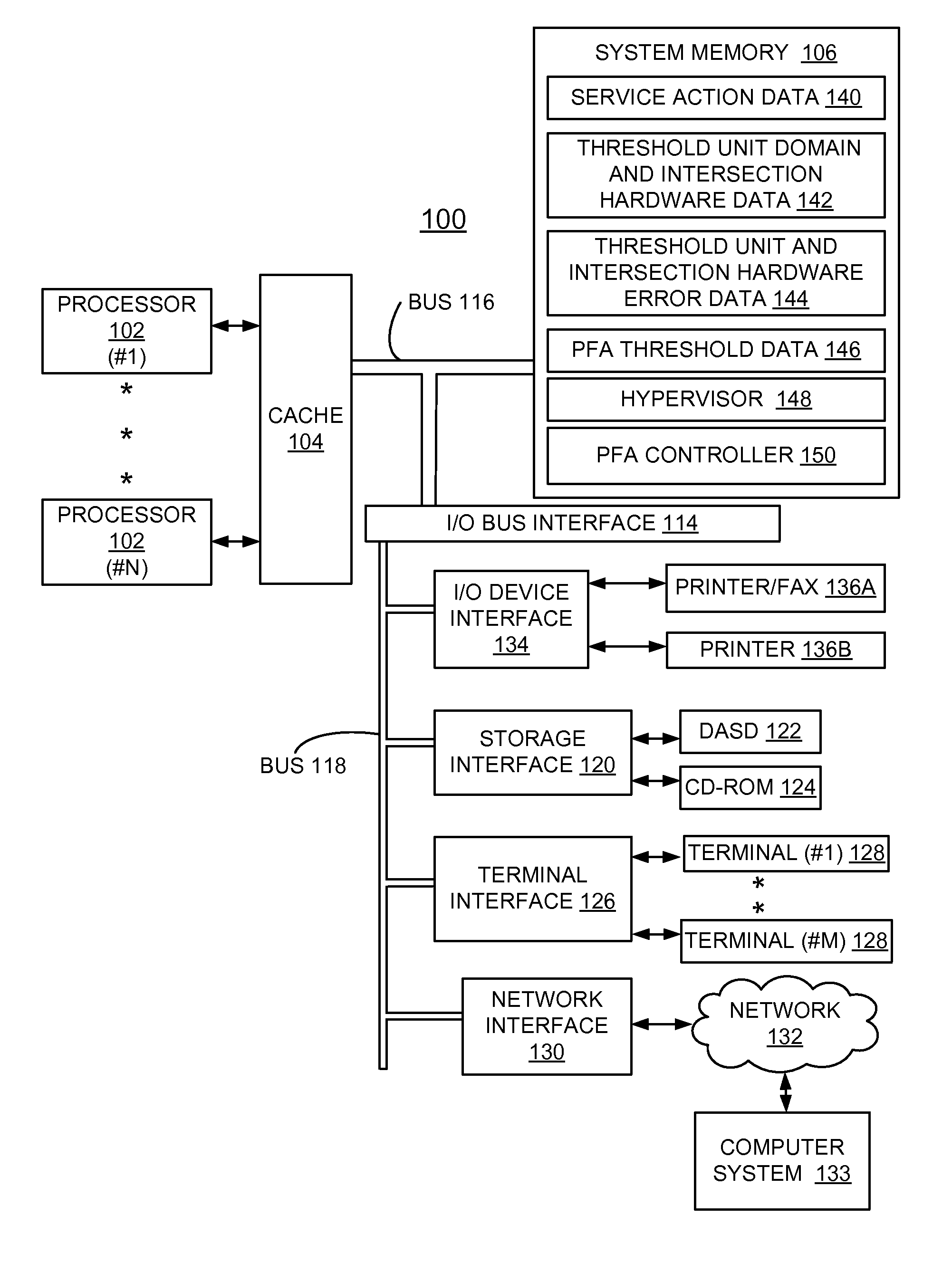

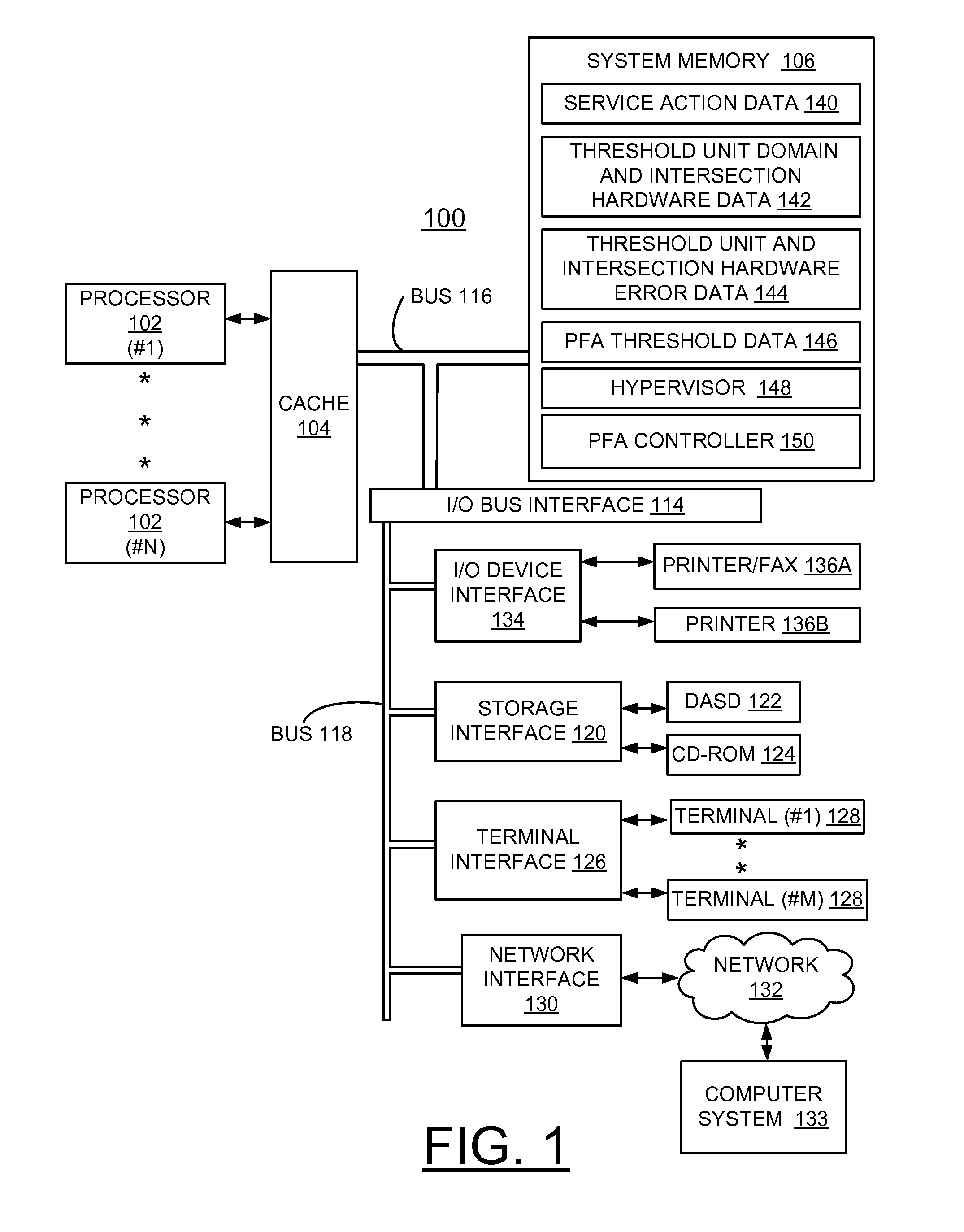

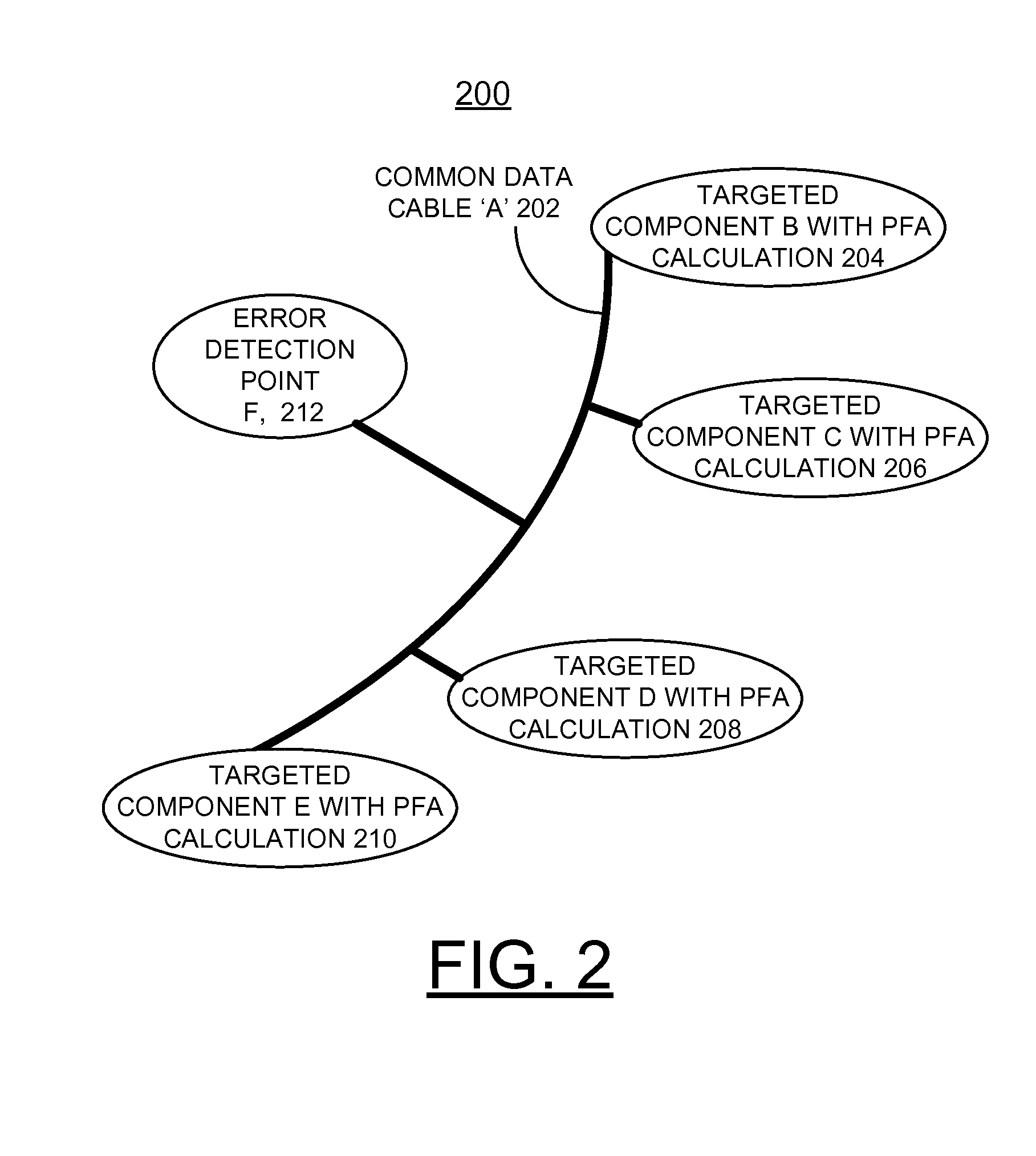

Implementing tiered predictive failure analysis at domain intersections

InactiveUS20150286514A1Failed analysisNegative effectNon-redundant fault processingPredictive failure analysisComputerized system

A method and apparatus are provided for implementing enhanced tiered Predictive Failure Analysis (PFA) at domain intersections in a computer system. When recoverable errors trigger PFA calculations on an individual threshold unit, PFA calculations are performed on the individual threshold unit. A threshold domain of all intersection hardware with the individual threshold unit is established. PFA calculations are performed on all intersection hardware in the threshold domain. A repair action is triggered based upon comparing the PFA calculations for the individual threshold unit and comparing the PFA calculations for each intersection hardware.

Owner:IBM CORP

Self-Repairing and Self-Sustaining Autonomous Machines

ActiveUS20140050844A1Ensure effectivenessConserve valuable mineral resourceLayered productsLaminationShear stressSurface layer

The metallurgical composition of a machine surface may be determined. Based on the composition of the surface layer and its substrate materials, a mixture of pure metal nanoparticles, each coated with a monomolecular organic layer adsorbed on its surface can be mixed with catalysts, reaction initiators, and / or other necessary ingredients for the repair action of the machine surface, depending on the specific machine, operational type, and / or the nature of the damage. The nanoparticles are applied to the machine surface, the organic monolayer wears away from the nanoparticles under shear stresses and the nanoparticles adhere to the machine surface to form a repair layer on the machine surface, thereby providing a repaired surface.

Owner:GEORGE WASHINGTON UNIVERSITY

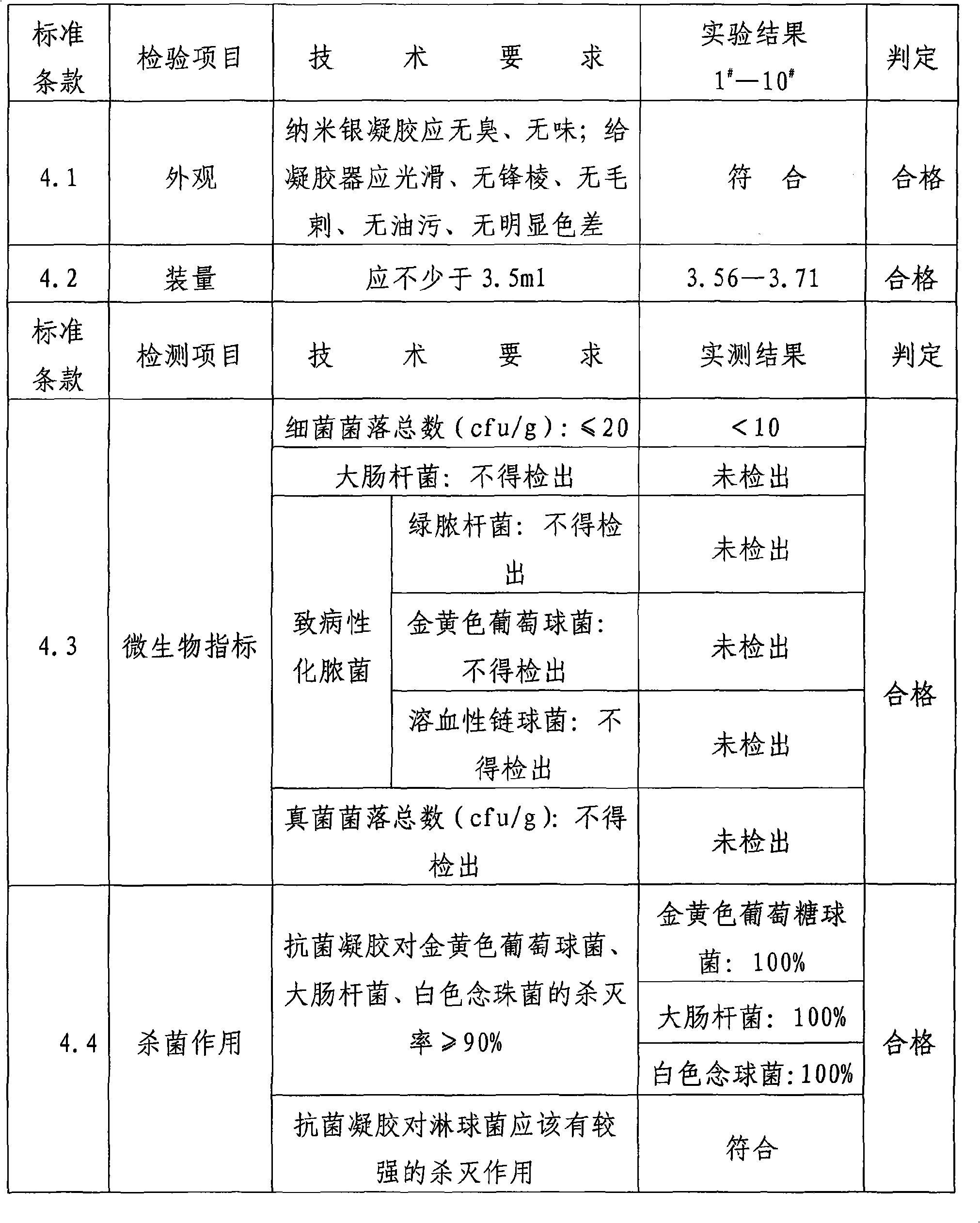

Nanometer Ag antibiotic gent for women and its preparation method

InactiveCN101305983AGood killing effectTreatment reachedInorganic active ingredientsPharmaceutical delivery mechanismAntibiotic YMycoplasma

The invention discloses a woman nano-silver antimicrobial gel which comprises the components as follows: golden yellow nano-silver liquid is 5 to 15g, excipient is 7 to 15g, and thinner is 15 to 25g. The invention also discloses a preparation method of the woman nano-silver antimicrobial gel, which comprises the steps as follows: the golden yellow nano-silver liquid is weighed first, then the excipient and the thinner are added in the golden yellow nano-silver liquid, the mixed solution is stirred, and the woman nano-silver antimicrobial gel is obtained after the homogeneous reduction reaction. The woman nano-silver antimicrobial gel not only well kills mycoplasma, Chlamydia and gonococcus, but also has lubrication and repair actions to vagina.

Owner:钱爱民

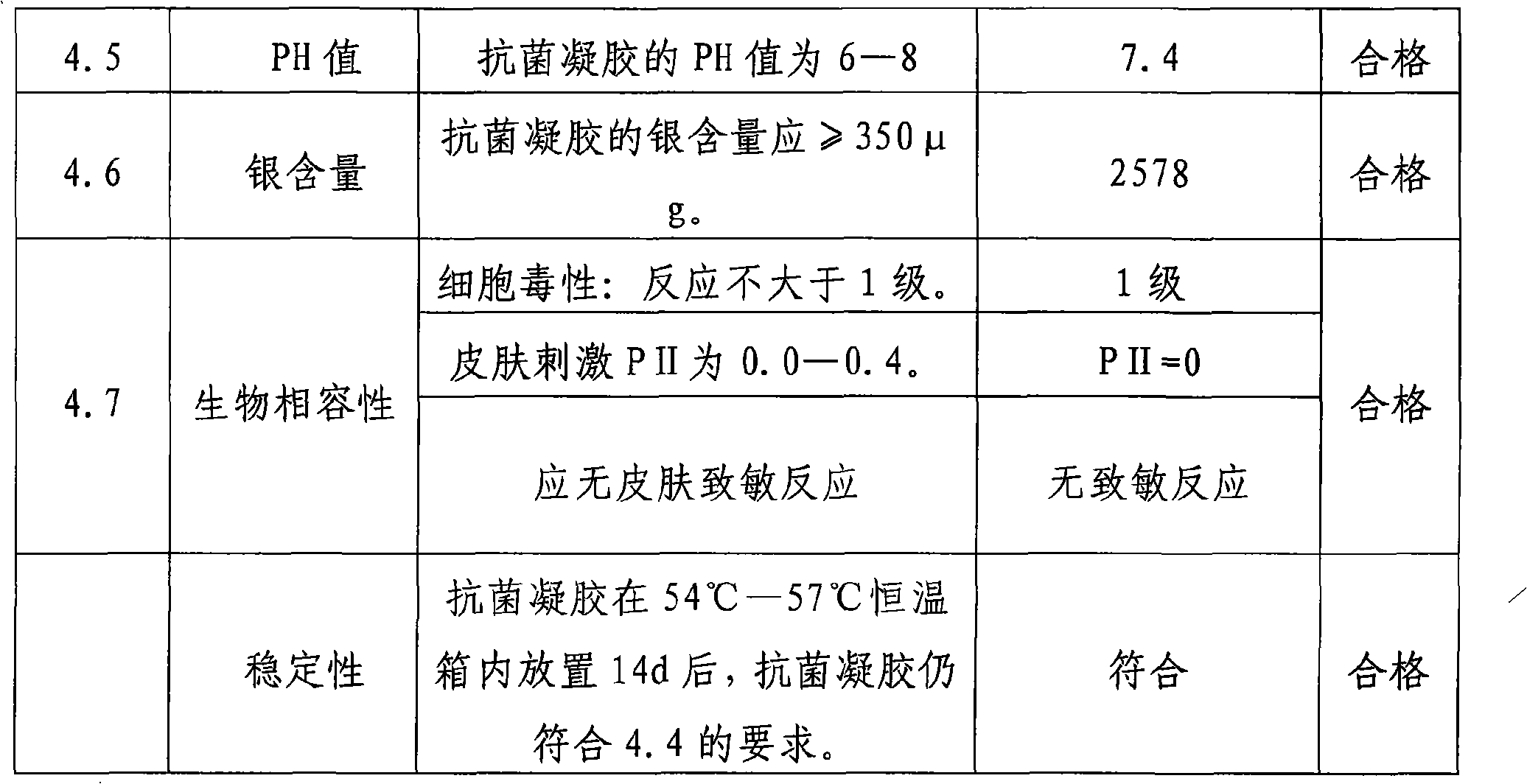

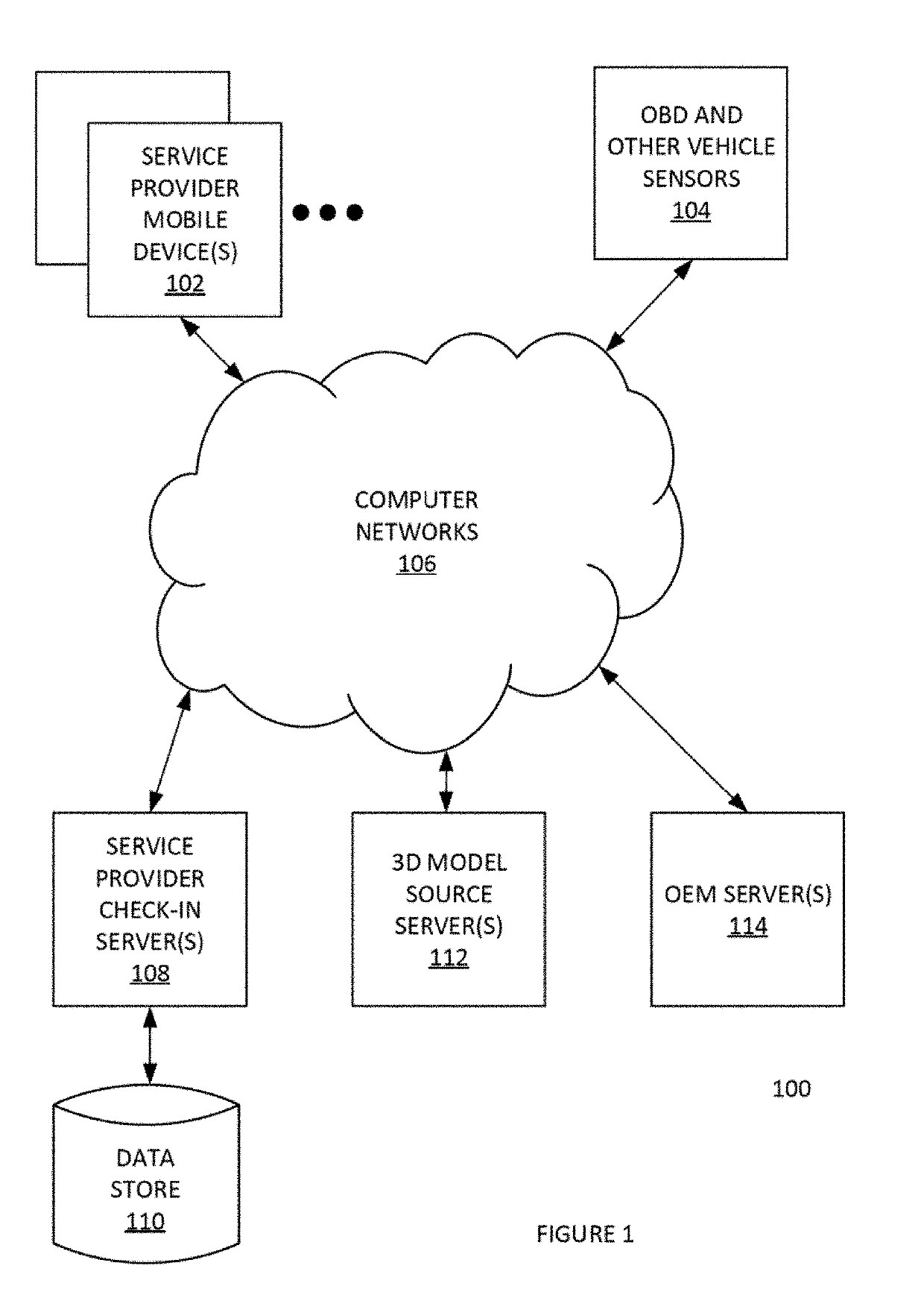

Methods and systems of retail automotive check-in with a mobile device

InactiveUS20190102749A1Substation equipmentSensing record carriersDisplay deviceCustomer information

In one aspect, a computerized method implements a vehicle check-in process at an automobile dealership with a mobile device includes the step of detecting the presence of the vehicle. The method includes the step of obtaining a customer information and a vehicle information. The method includes the step of matching the, vehicle with a service consultant. The method includes the step of communicating an electronic message comprising a notification to the mobile device of the service consultant. The method includes the step of implementing a set of vehicle diagnostics to determine a set of vehicle repair actions. The method includes the step of generating an estimate of costs to service the set of vehicle repair actions. The method includes the step of communicating the set of vehicle repair actions and the estimate of the costs to service the set of vehicle repair actions to the mobile device of the service consultant in a format for rendering on a display of the mobile device.

Owner:TEKION CORP

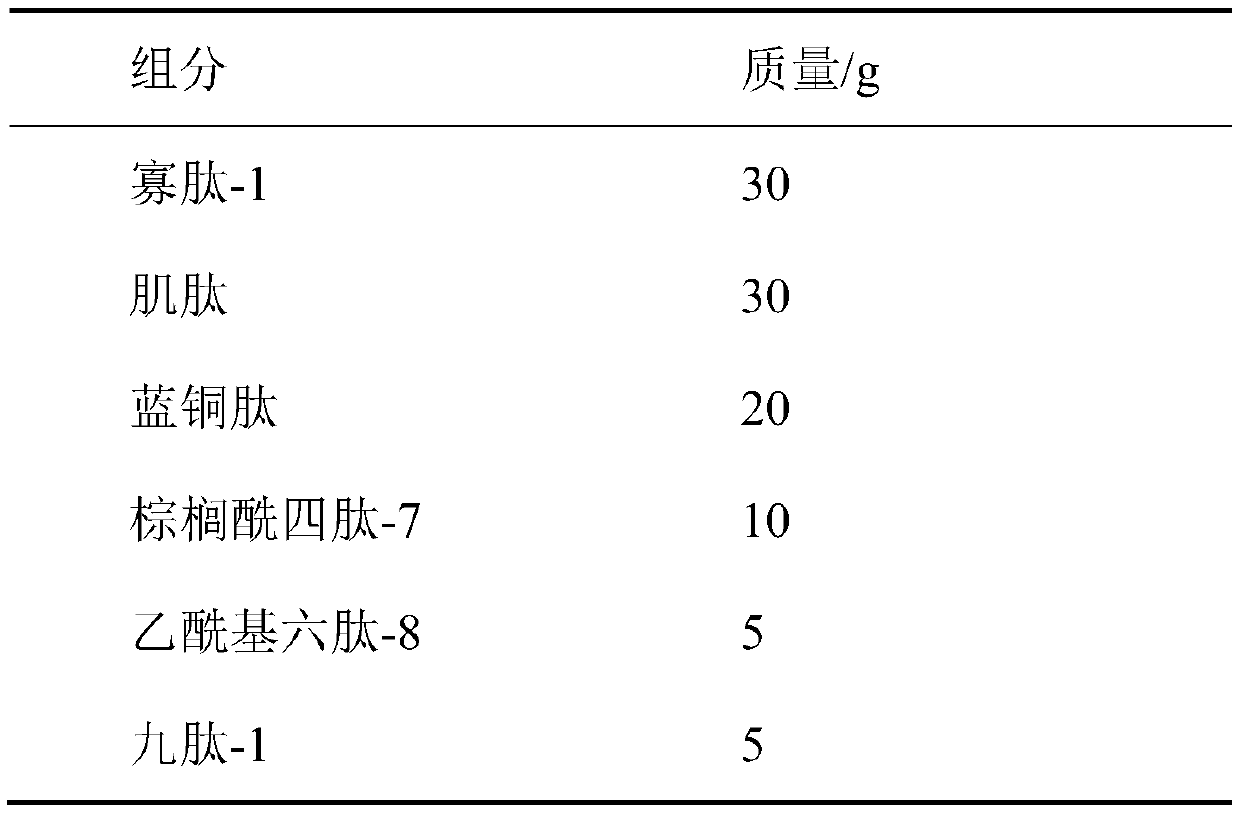

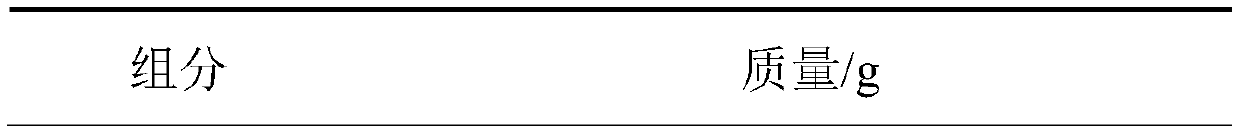

Multi-effect repair polypeptide composition and application thereof in cosmetics

ActiveCN110179687AGood moisturizing effectImprove antioxidant capacityCosmetic preparationsToilet preparationsAction sitesCarnosine

The invention provides a multi-effect repair polypeptide composition and application thereof in cosmetics. The polypeptide composition comprises oligopeptide-1, carnosine, blue copper peptide, palmitoyl tetrapeptide-7, acetyl hexapeptide-8 and nonapeptide-1. The invention compounds the six polypeptides for the first time, and the mechanism and the action sites of the polypeptide components for playing a repairing action are different, so that the components not only can independently come into play aiming at different skin problems, but also can have synergistic effect aiming at the same skinproblem, can come into play by a combination of measures, can effectively repair the skin barrier, and can return the skin to a smooth, moist and elastic health state. The polypeptide composition of the present invention is added to cosmetics. The obtained cosmetics have comprehensive repair effects of moisturizing skins, resisting oxidation, removing speckle, resisting wrinkle and relieving sensitive stimulation, and can enhance glossiness and firmness of skin and restore health of skin.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

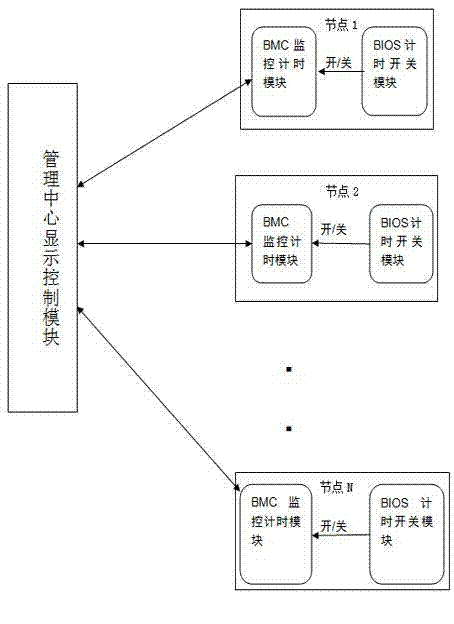

Method for remotely monitoring crash of system power-on process

The invention provides a method for remotely monitoring the crash of a system power-on process. The method is characterized in that a data center based on a large-scale server nodes brings unprecedented flexibility to computer room administrators through the flexible monitoring management of a main architecture, the workload of maintenance and debugging personnel is reduced greatly, and the production working efficiency is improved. According to the method for remotely monitoring the crash of the system power-on process, the purposes of effectively locating a node position and controlling repair actions for the abnormal crash condition occurring in a data computer room debugging process can be achieved, so that the traditional monitoring management architecture taking upper-layer monitoring as a core is made up with regard to deficiency, is made meet the requirements of the social development at present, and thus, the method has a wide development prospect.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Generation of instructions for repairing an electromechanical system

ActiveUS9684553B2Reduce the amount requiredEasy to useFault responseData acquisition and loggingMechanical componentsTransfer system

The invention provides for an electromechanical system comprising a machine. The machine comprises at least one mechanical component and at least one electrical sensor for acquiring measurement data. The system further comprises a data logger computer system for logging the measurement data and error reports as historical data, wherein the error reports are descriptive of one or more failure modes of the at least one mechanical component, wherein the error reports are further descriptive of repair actions taken to repair the one or more failure modes. The system further comprises a machine monitor comprising a repair solution engine, wherein the machine monitor comprises a memory containing processor instructions that implement the repair solution engine, wherein the machine monitor comprises a processor for executing the processor instructions. The system further comprises a data transfer system for transferring the data from the machine to the machine monitor. The system further comprises a client computer system. Execution of the processor instructions cause the processor to: receive the measurement data from the data transfer system; receive the historical data from the data logger computer system; search the historical data to determine a current failure mode and a selected repair action, wherein the current failure mode is selected from the one or more failure modes of the historical data, wherein the selected repair action is selected from the repair actions; generate repair instructions using the selected repair action; and transfer the repair instructions of the selected repair entry to the client computer system.

Owner:SAP AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com