Self-repair flange gasket for pipeline connection

A flange gasket, self-repairing technology, applied in the direction of flange connection, piping system, pipe/pipe joint/fitting, etc., can solve the problems of torque loss, stress relaxation, stress relaxation and torque loss, etc., to avoid water damage The effect of further leakage, reducing the risk of large-scale leakage, avoiding failure or detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

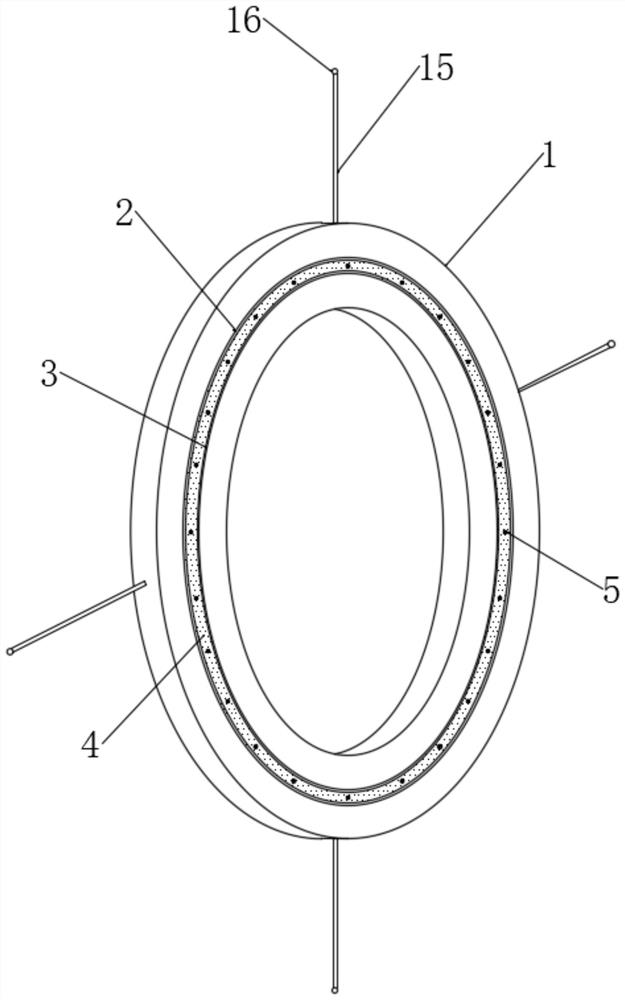

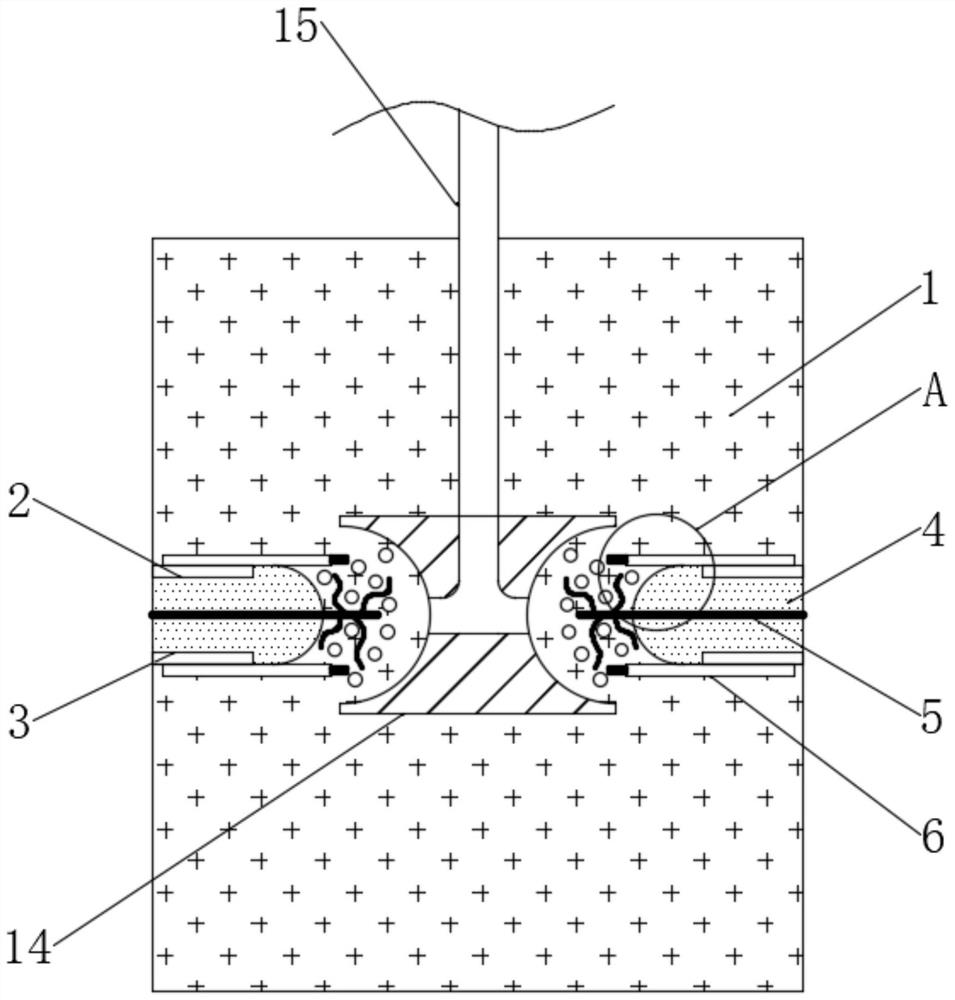

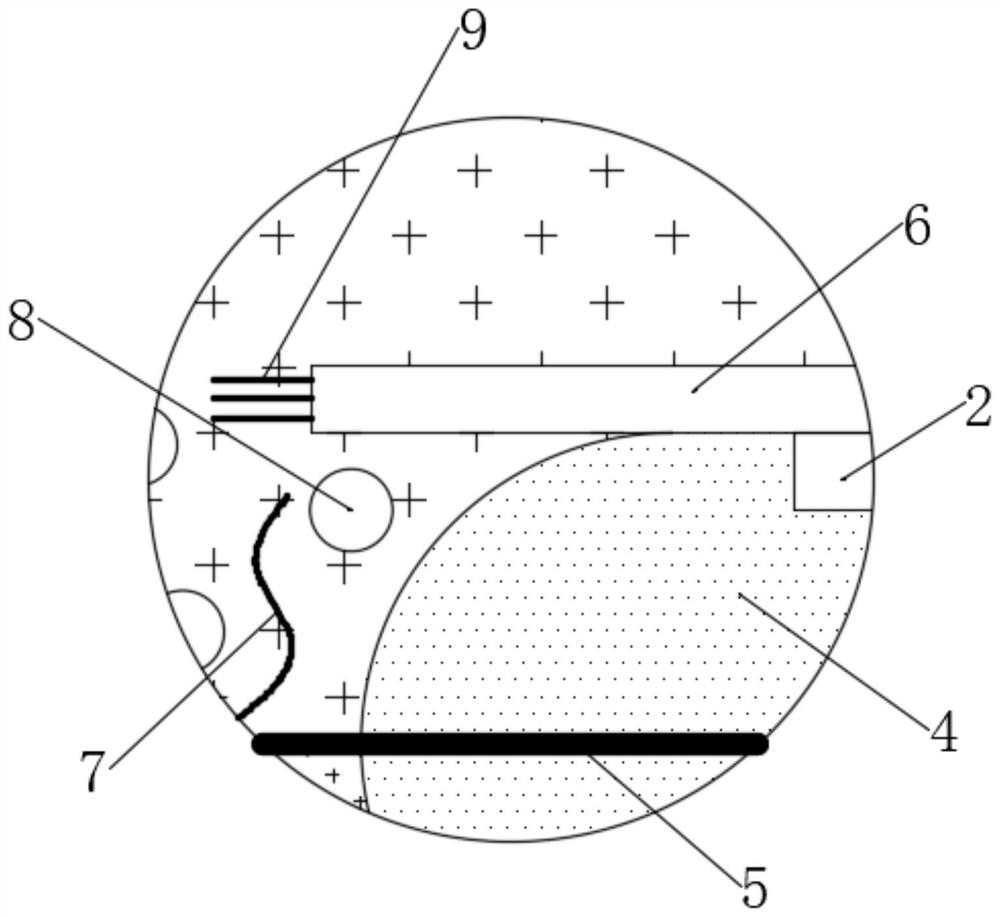

[0048] see figure 1 , a self-repairing flange gasket for pipeline connection, including a gasket body 1, the left and right side walls of the gasket body 1 are inlaid with water-swellable rubber rings 4, which have the effect of water-swelling, thereby realizing Preliminary anti-seepage, the outer edges of the upper and lower ends of the water-expandable rubber ring 4 are respectively inlaid and connected with the outer water-retaining ring piece 2 and the inner water-repelling ring piece 3, and the water-expandable rubber ring 4 is also inlaid and connected with multiple circular arrays. The leading water fiber bundle 5 plays the role of guiding water into the water-swellable rubber ring 4. On the one hand, it can contact the moisture-absorbing touch microspheres 8 to trigger the repair action, and on the other hand, it can make the water-swellable rubber ring 4 expand more. uniformly dense.

[0049] see Figure 2-3 The gasket body 1 is inlaid with a shaped air-blocking rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com