Welded tube for calorizing and laser short processing

A laser shock and aluminizing treatment technology, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve the problems of reducing the corrosion resistance of aluminized steel, the brittleness of high aluminum phase, the installation and construction of aluminized steel, etc. Achieve the effect of improving surface hardness, improving use mission and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

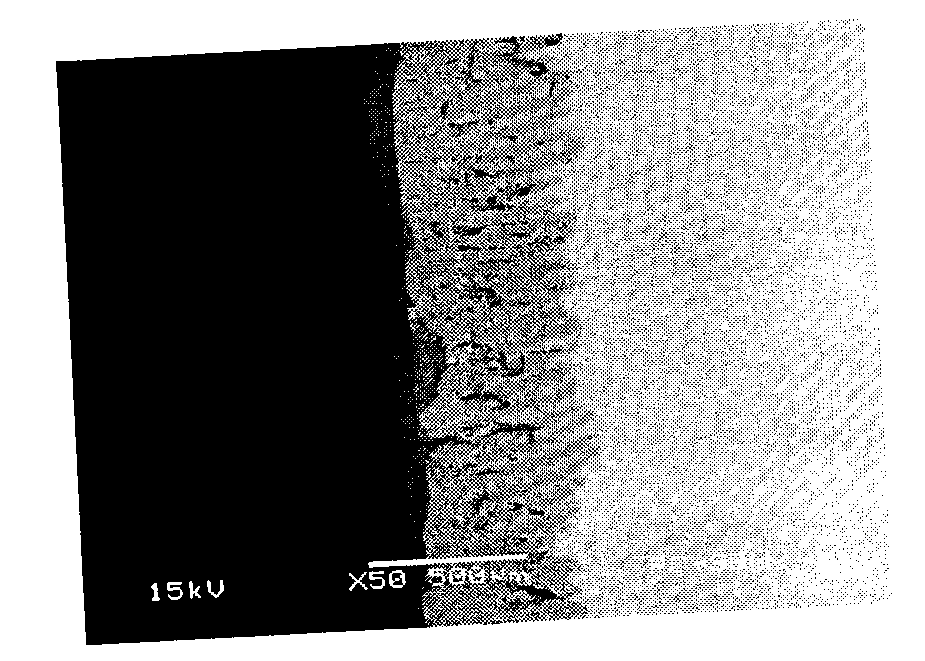

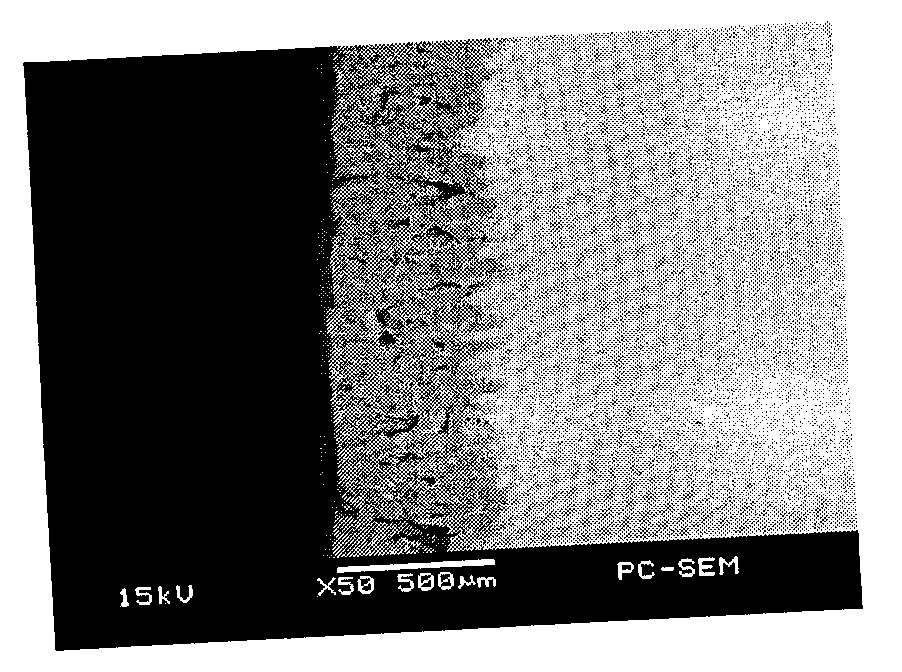

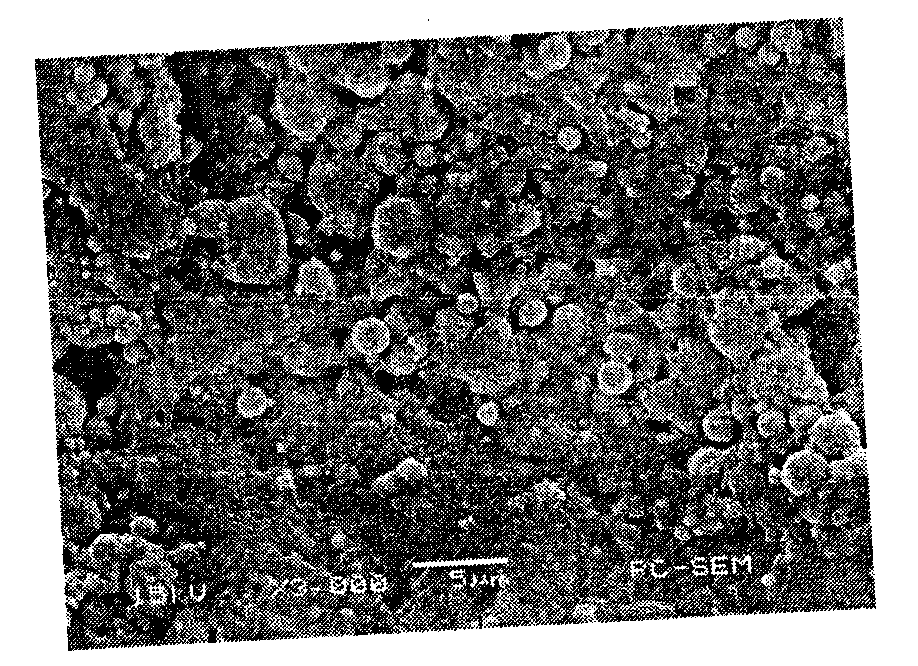

[0021] In the present invention, the surface is heat-treated by hot-dip aluminizing, and Al atoms and Fe atoms in the matrix undergo a series of physical and chemical changes through convective diffusion and thermal diffusion, forming a Fe-Al alloy layer on the surface of the matrix. The alloy layer is divided into two layers: the outer pure aluminum layer and the middle metal compound. Fe and Al are fully infiltrated, and the original structure and properties of the matrix are well maintained, but the porosity is relatively high. After laser shock treatment, the porosity is significantly reduced, such as figure 1 , figure 2 As shown, the surface roughness is reduced and the wear resistance is good, and the corrosion resistance ability is improved, such as image 3 , Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com