Slide-wire resistor

A technology of sliding wire resistance and resistance wire, which is applied in the direction of sliding contact resistors, resistance terminals/electrodes, etc., can solve the problems of severe wear and reduced service life of sliding wire resistance, and achieve small wear, prolong service life, and precise control The effect of a change in resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

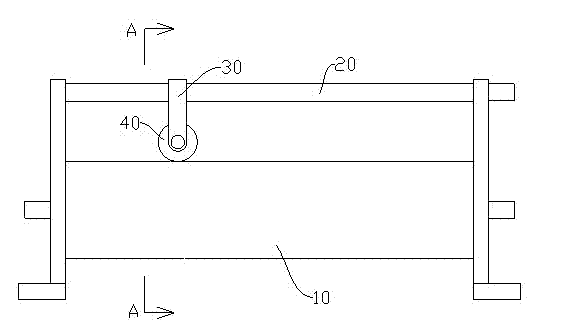

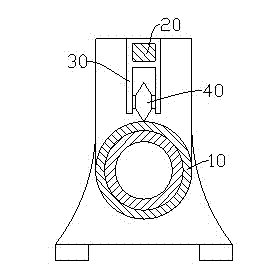

[0012] Examples, see figure 1 and figure 2 As shown: the sliding wire resistance, including the resistance wire layer 10 and the guide rail 20, of course, the resistance wire layer 10 and the guide rail 20 are respectively connected with terminals. Wherein, a slide bar 30 is provided on the guide rail 20 , and a contact wheel 40 is provided at the lower end of the slide bar 30 , and the contact wheel 40 is matched with the resistance wire layer 10 . That is, the edge of the contact wheel 40 is in close contact with the resistance wire layer 10 , so as to realize the electrical connection between the contact wheel 40 and the resistance wire layer 10 . At the same time, the guide rail 20, the slide bar 30, and the contact wheel 40 are electrically connected. Of course, the slide bar 30 is not rotatable relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com