Patents

Literature

131results about How to "Reduce lifting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

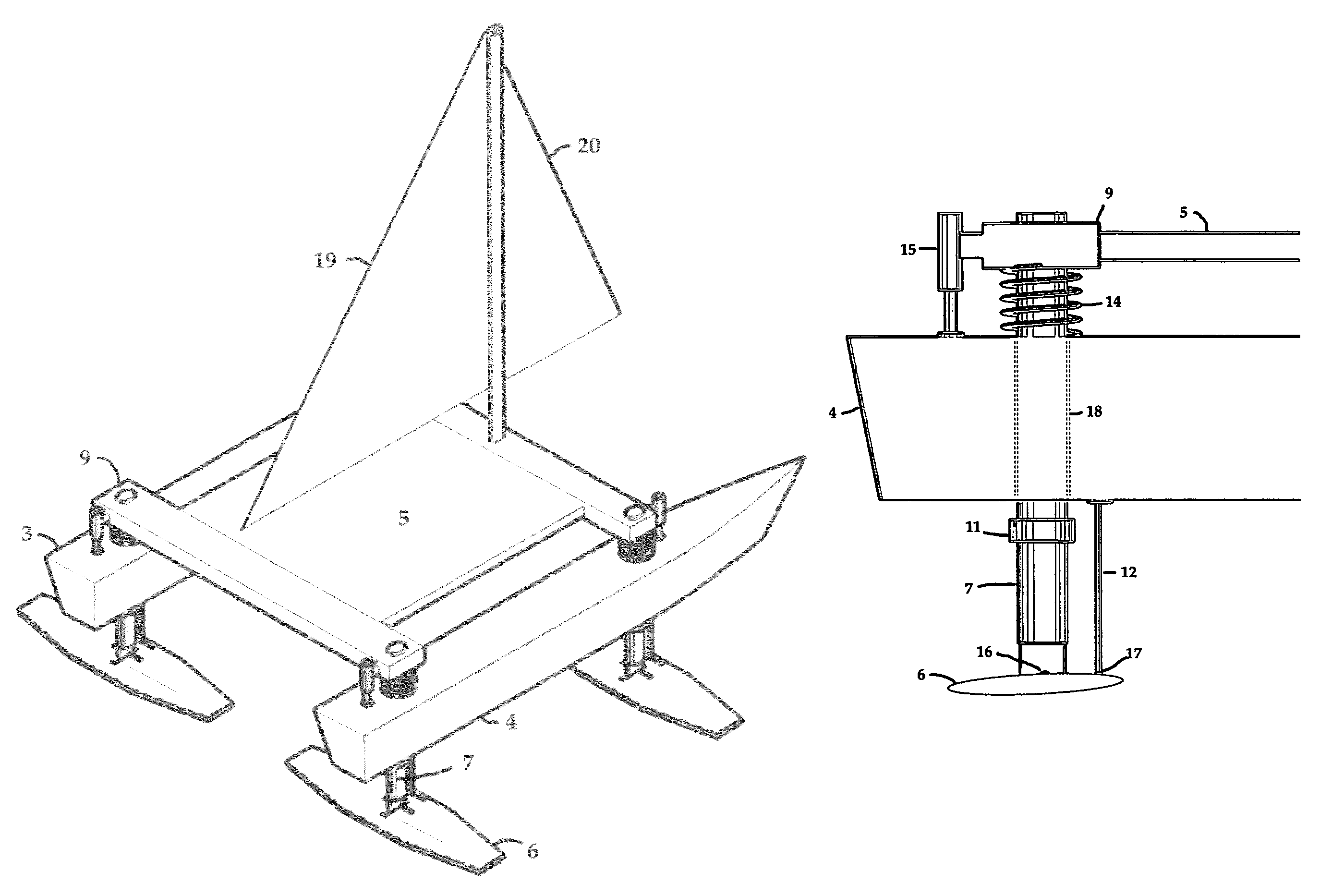

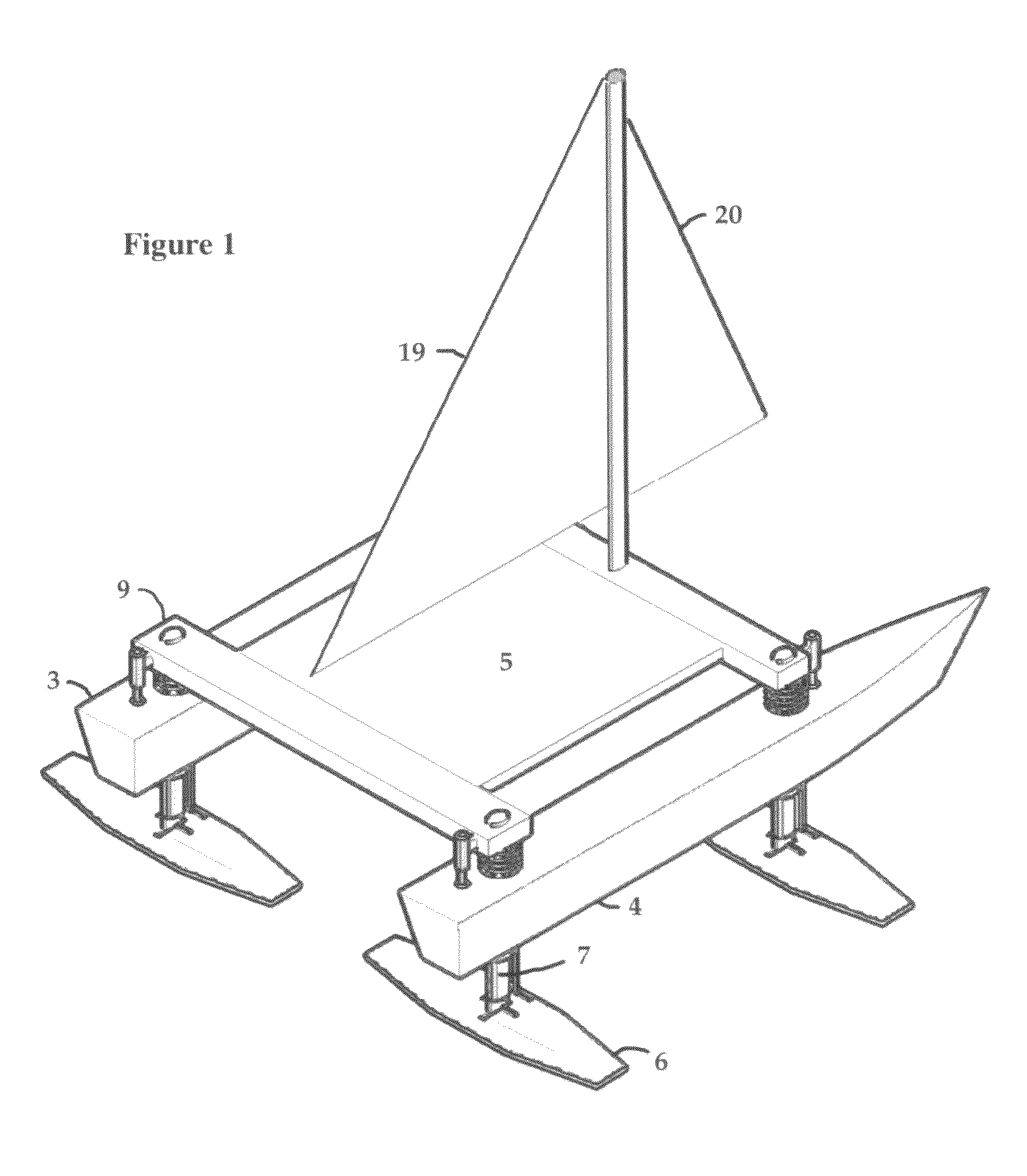

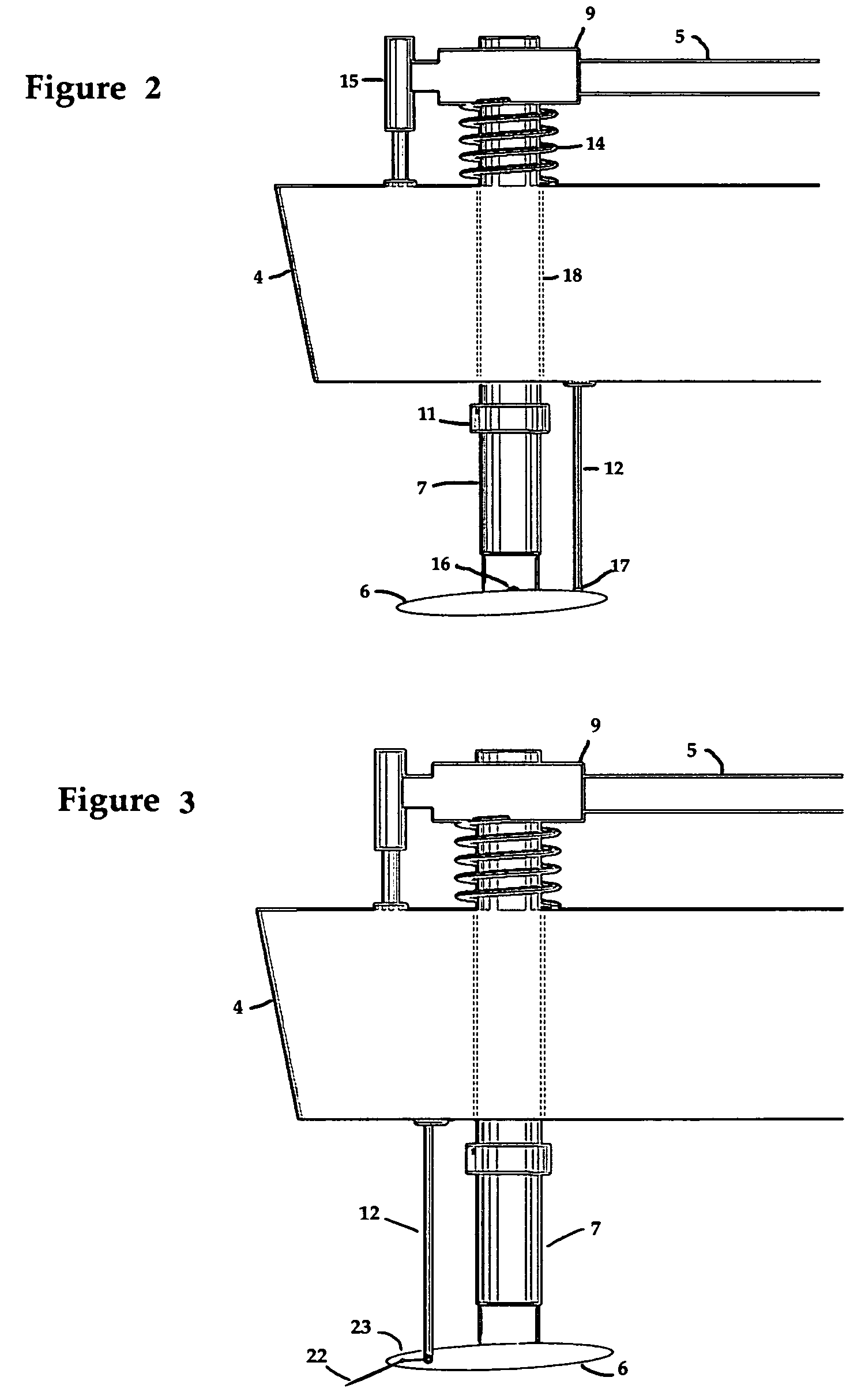

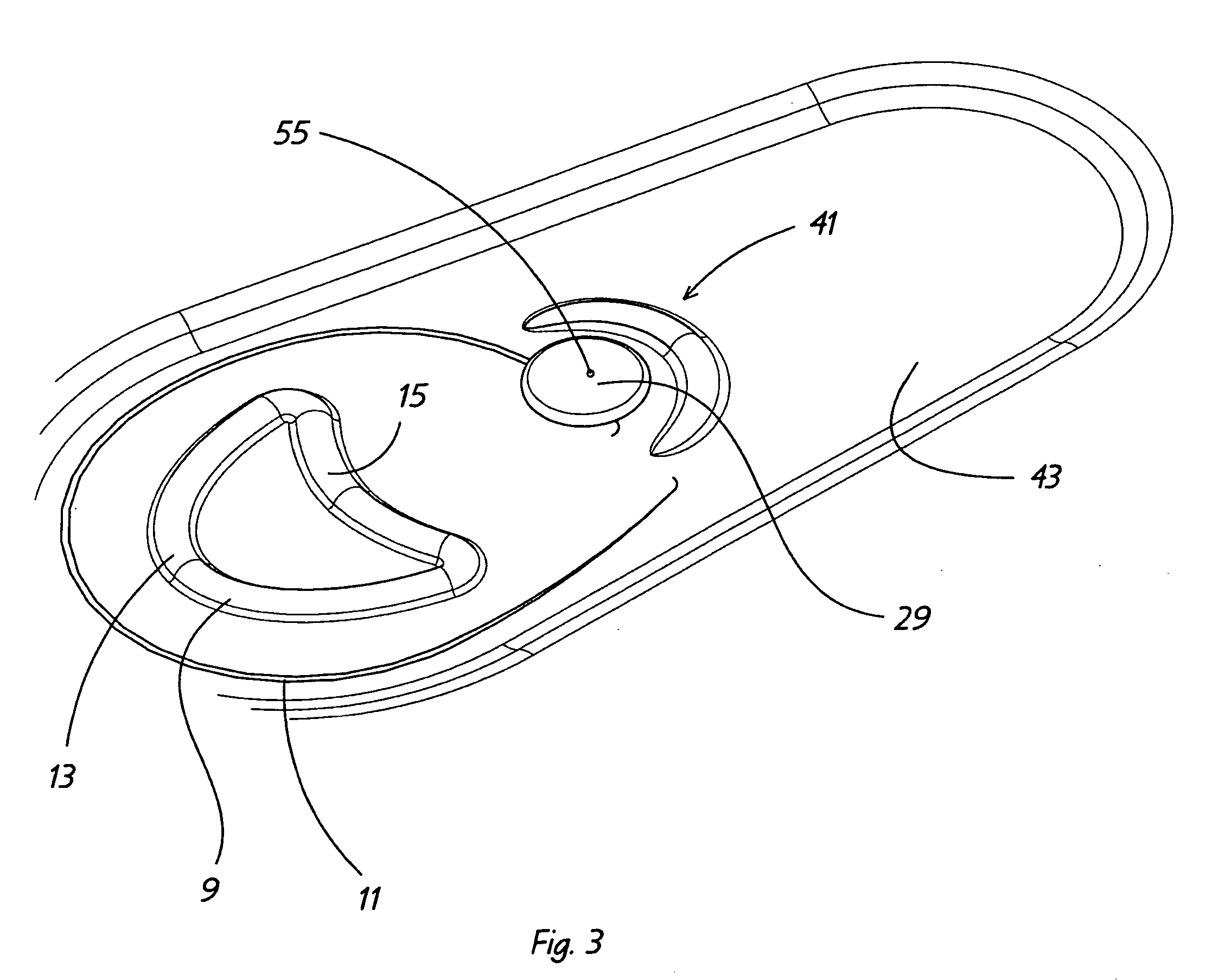

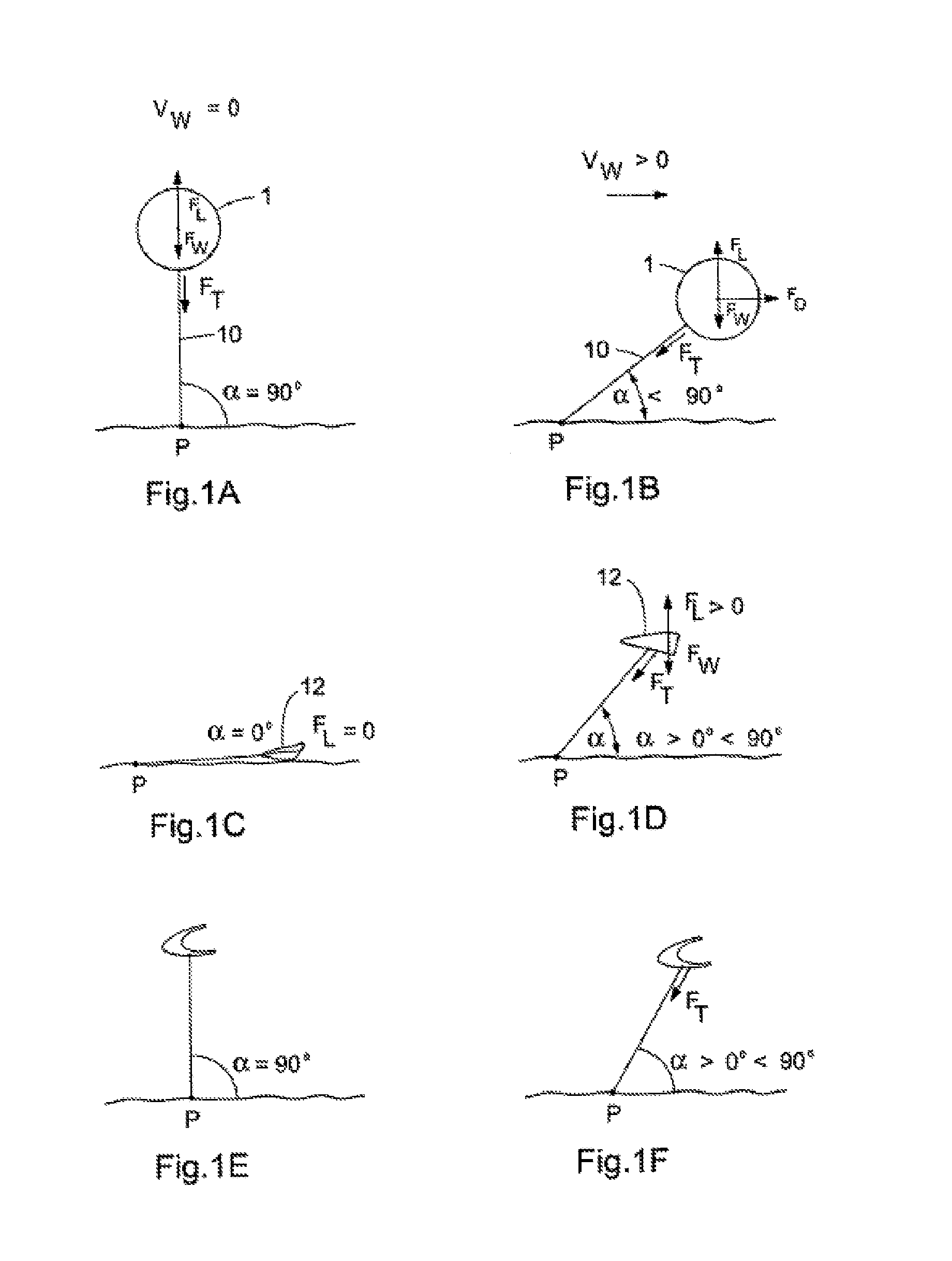

Multihull hydrofoil watercraft

InactiveUS7743720B1Reduce angle of attackReduce lifting forceVessel partsVessel movement reduction by foilsAutomatic controlAutomatic train control

A multihull hydrofoil watercraft incorporates a stabilization system wherein the buoyancy of the hulls is used as a sensing and control mechanism for the hydrofoils. The use of hull buoyancy to adjust the hydrofoil lift provides for automatic control of altitude, pitch and roll, and allows the craft to accommodate varying weather and sea conditions while providing a smooth ride for passengers. The stabilization technique eliminates the need for extraneous sensing mechanisms placed in or on the water surface which are subject to fouling, damage, or disruption by localized surface disturbances.

Owner:SALANI STEVEN JOHN

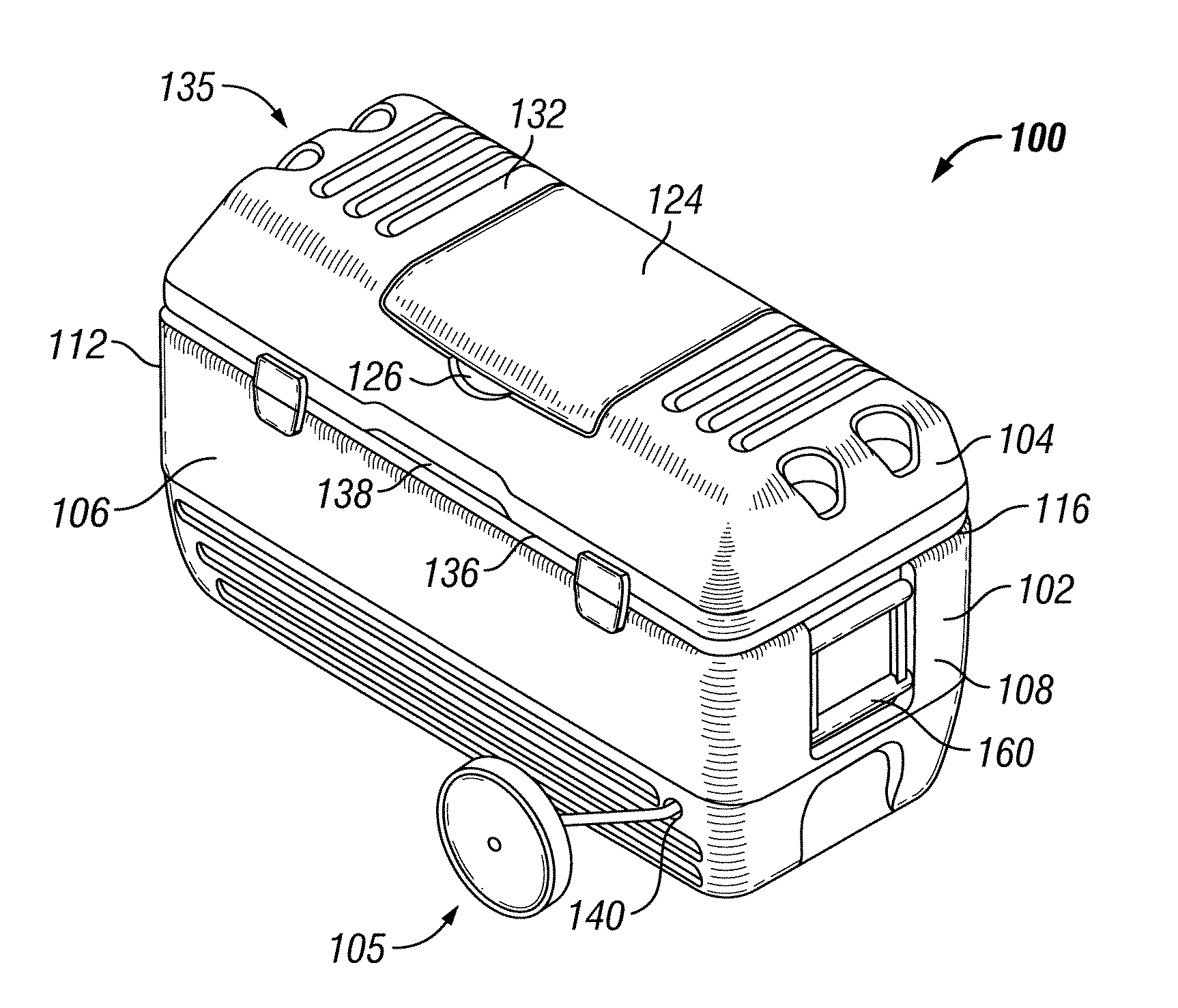

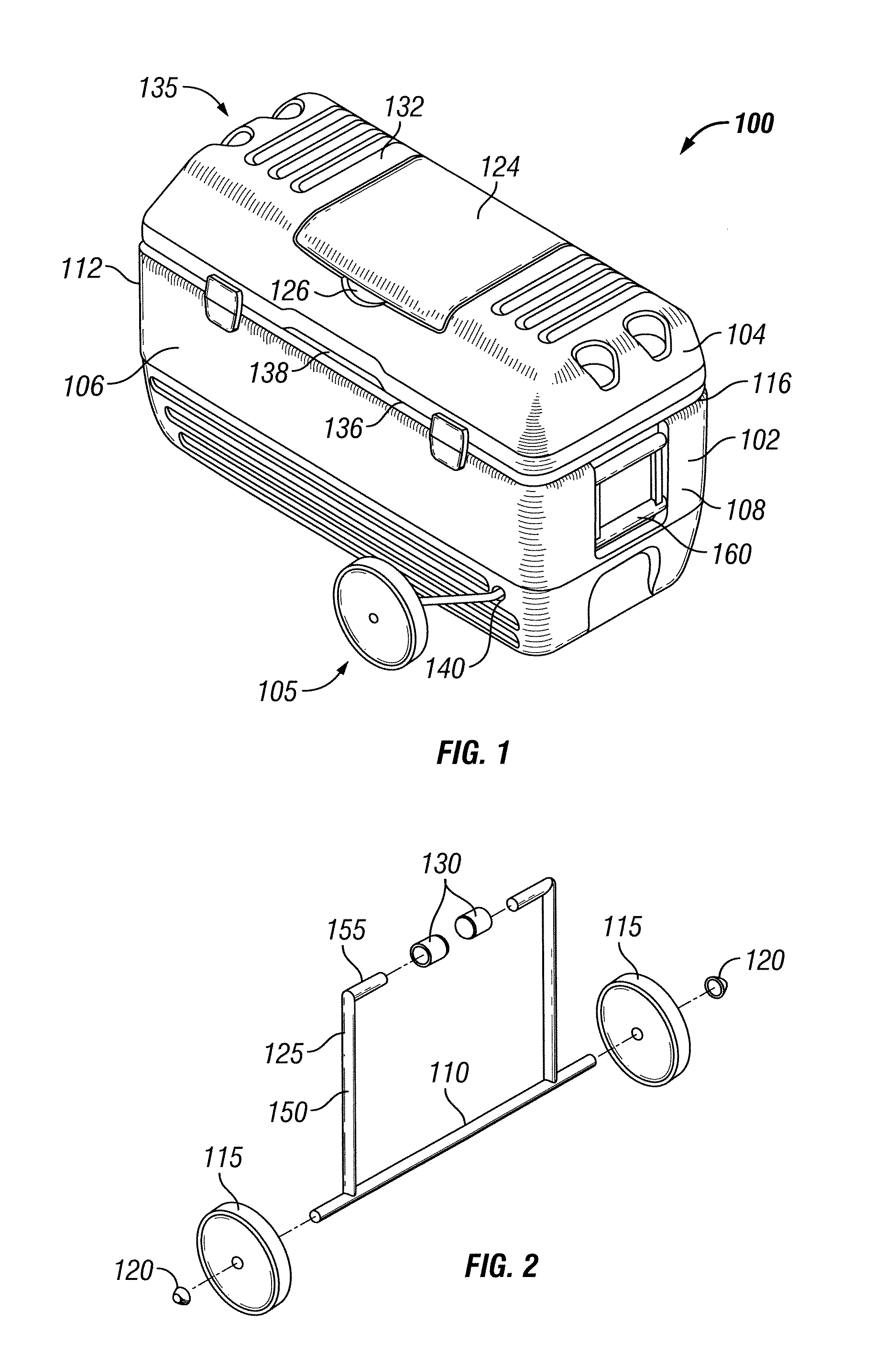

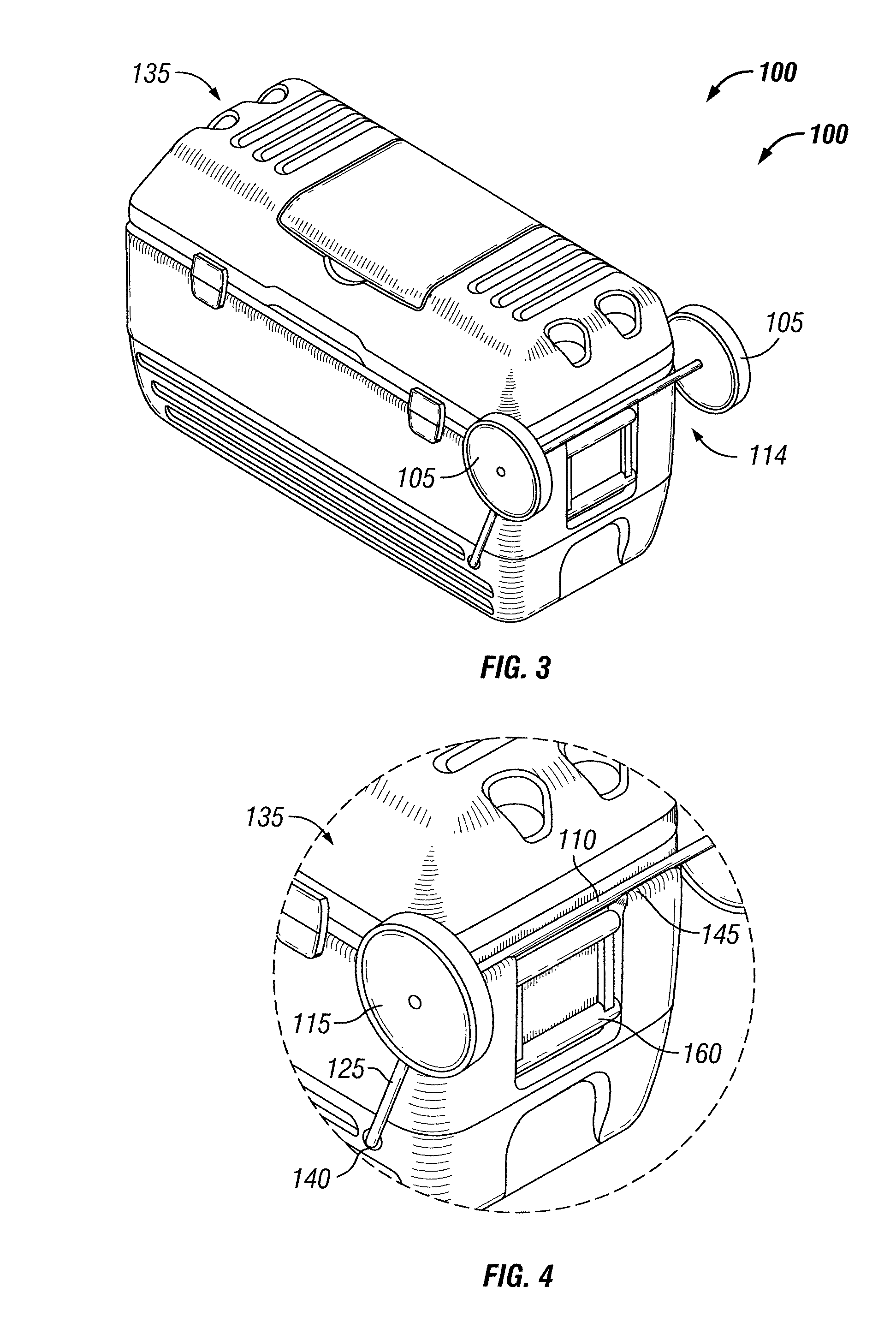

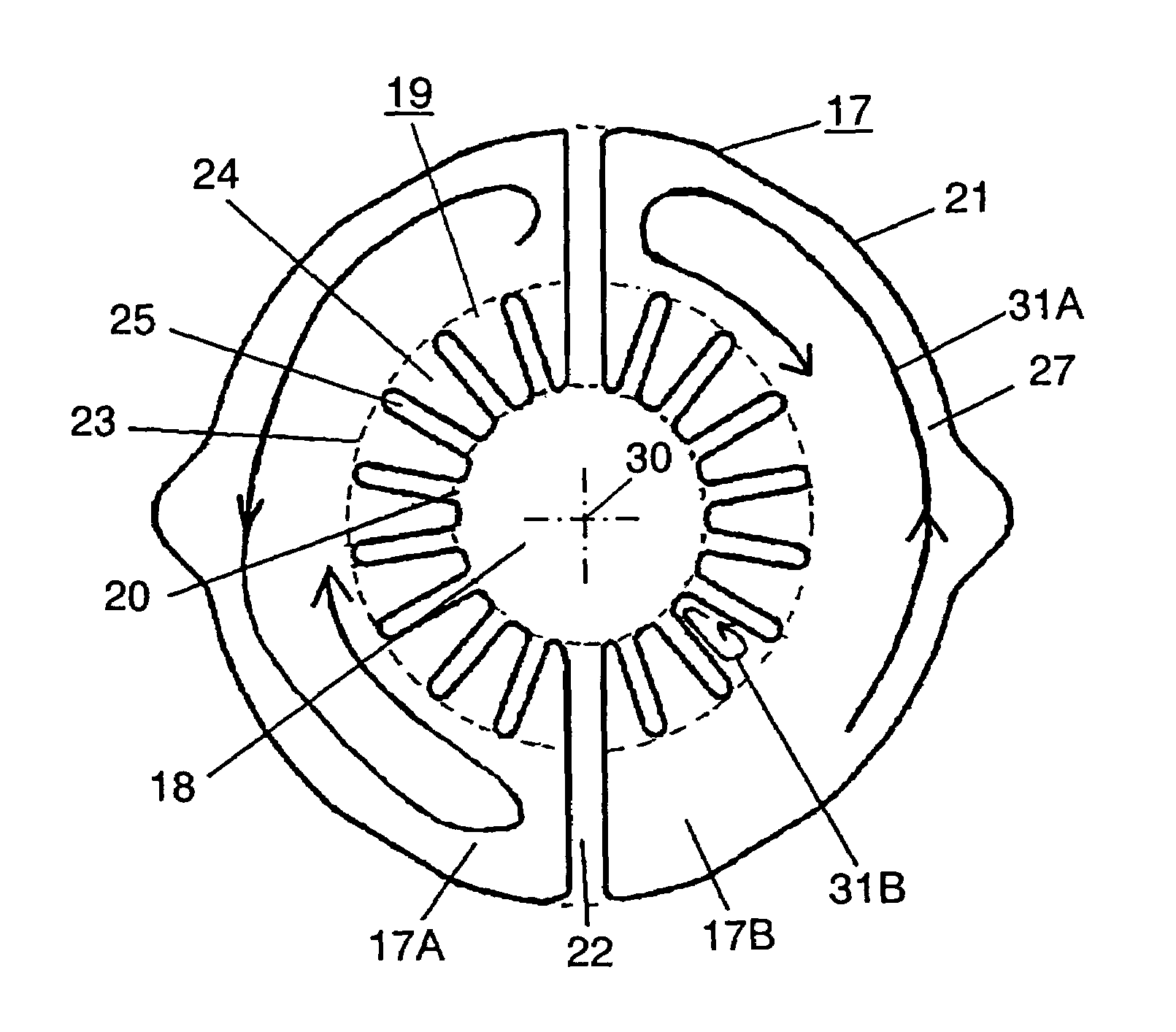

Rotatable wheel assembly for coolers

InactiveUS20080001373A1Increase distanceReducing unstable natureCarriage/perambulator with single axisLighting and heating apparatusRest positionEngineering

The rotatable wheel assembly includes an axle and wheels. Mounting arms with mounting pins or L-shaped rods are coupled to the axle and may include end caps covering portions of the mounting pin or rod. The mounting pin or end cap is inserted into a receptacle on opposing sides of a cooler. Alternatively, the mounting arms may have an eyelet that may be rotatably coupled to a mounting stud on each side of the cooler. The assembly may be placed in a resting or rolling position along the cooler body. In the resting position, the assembly rests or snaps into a groove along the side of the cooler and out of contact with the surface. The assembly can be rotated from the resting position to a rolling position with the axle positioned under the cooler and the wheels in contact with the surface to assist in transporting the cooler.

Owner:IGLOO PROD CORP

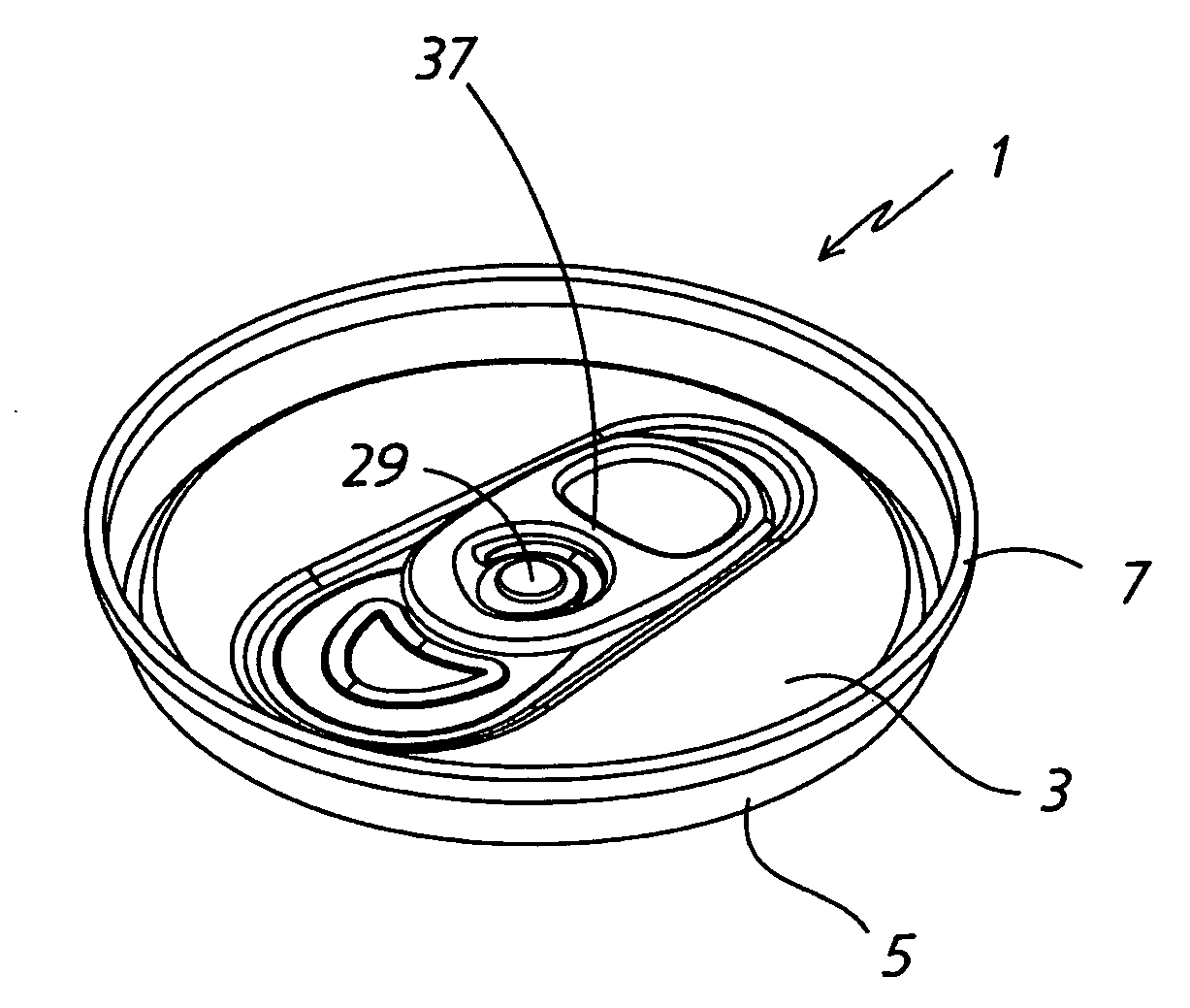

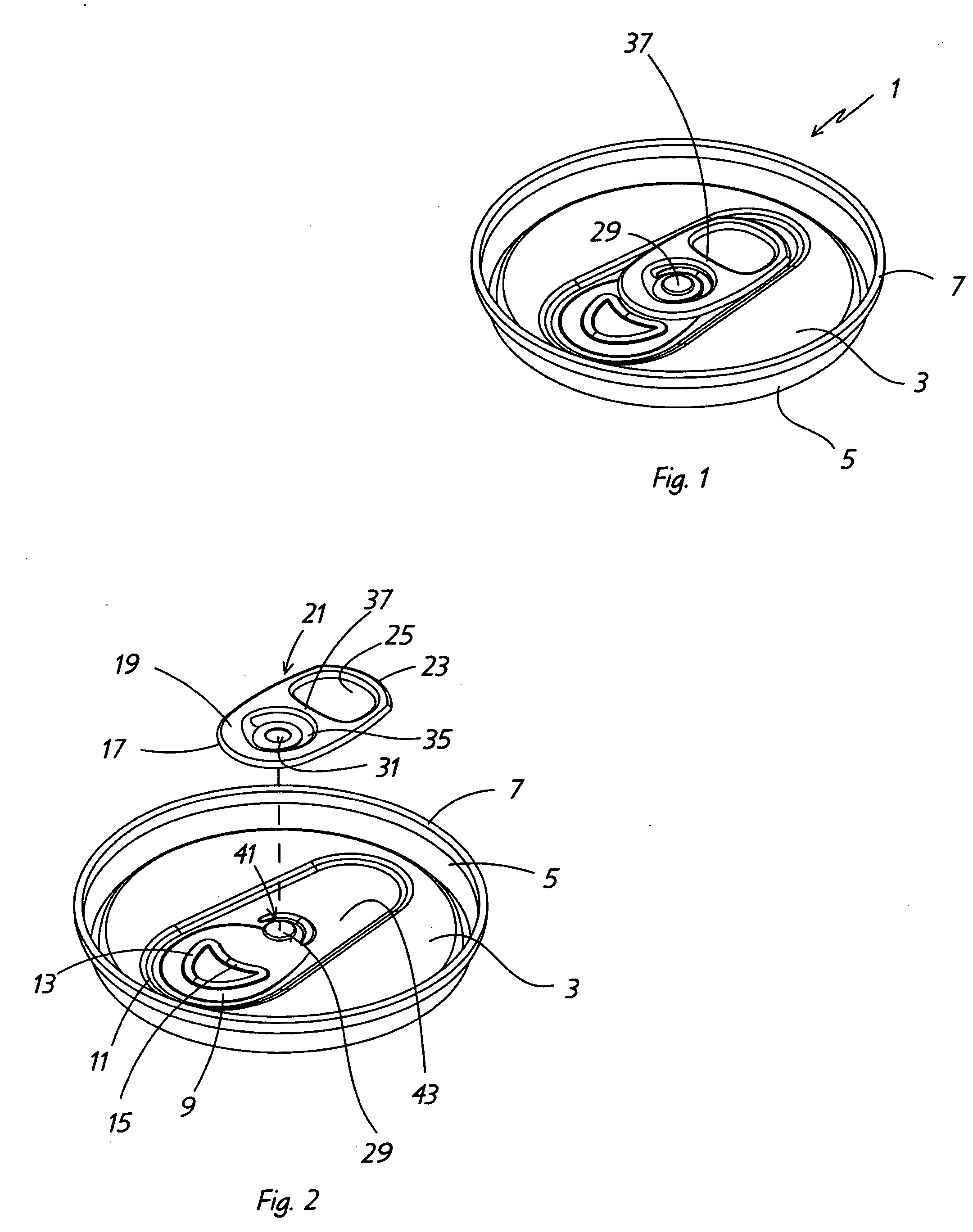

Container end closure with pull tab

InactiveUS20070108208A1Lessen free lift forceReduce lifting forceRigid containersEngineeringFace sheet

An easy opening end closure for a container has a central panel with a tear panel defined by a score line. A pull tab is attached by a rivet to the central panel and has a nose end for engaging the tear panel and an opposite lift end for pivoting the tab about the rivet to fracture the score line. One or a pair of crescent-shaped protrusions are formed on the central panel closely adjacent to and rearwardly of the rivet to reduce the lift force required to initially lift the lift end of the tab to start the fracturing of the score line. The protrusions are concentric to each other and partially circumscribe the rivet and are located beneath the pull tab or within openings of the pull tab to avoid interference with can making equipment and with the pull tab. The protrusions provide greater flexibility to the area of the central panel adjacent the rivet to enable the rivet to pull slightly upwards from the panel at the start lifting the lift end of the tab.

Owner:SPARKTAB

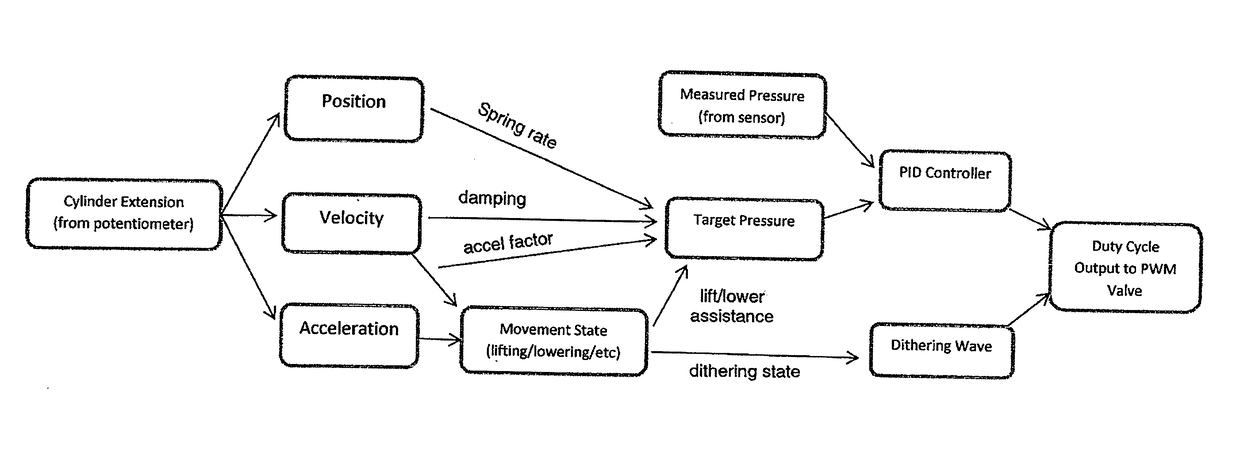

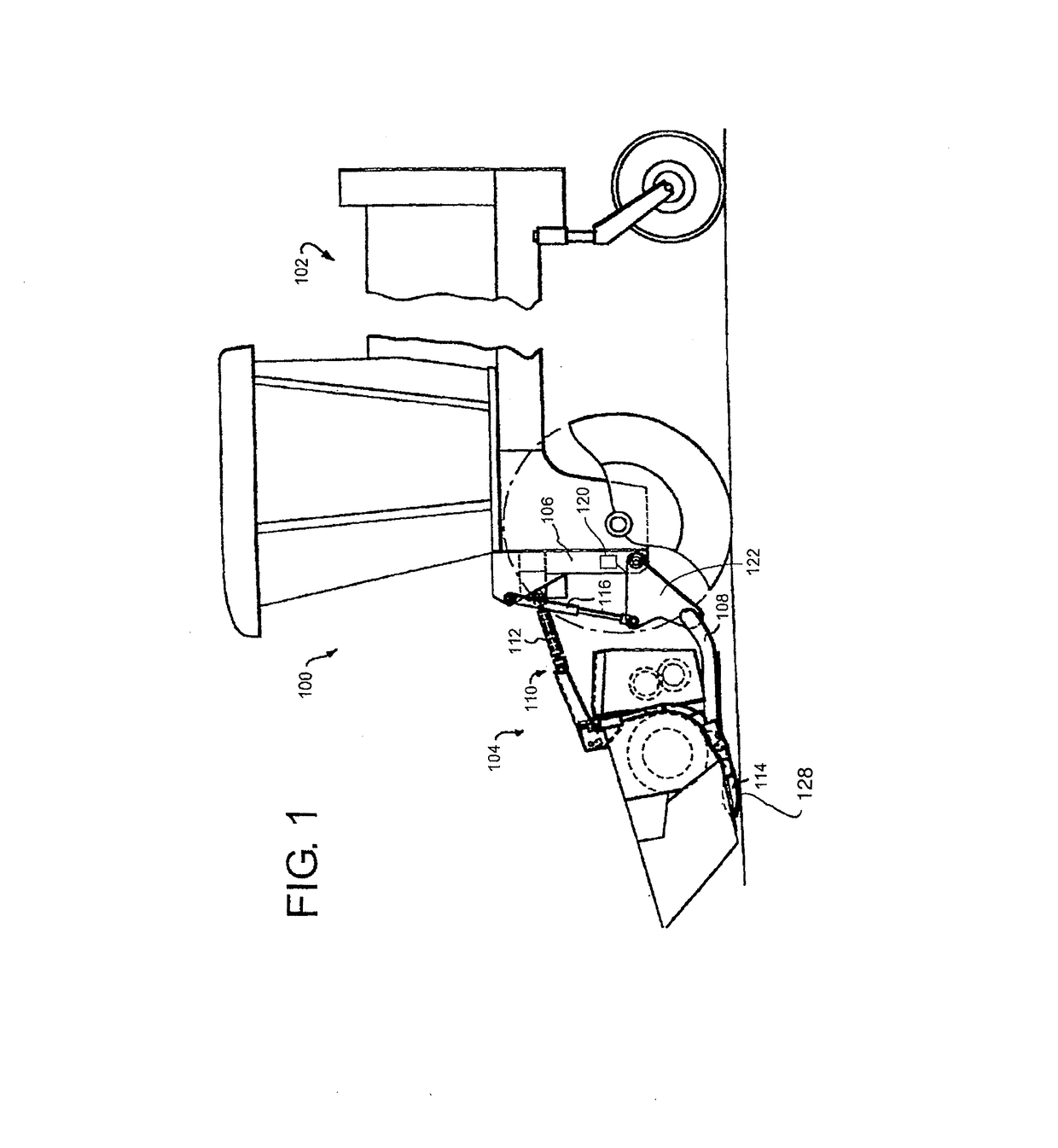

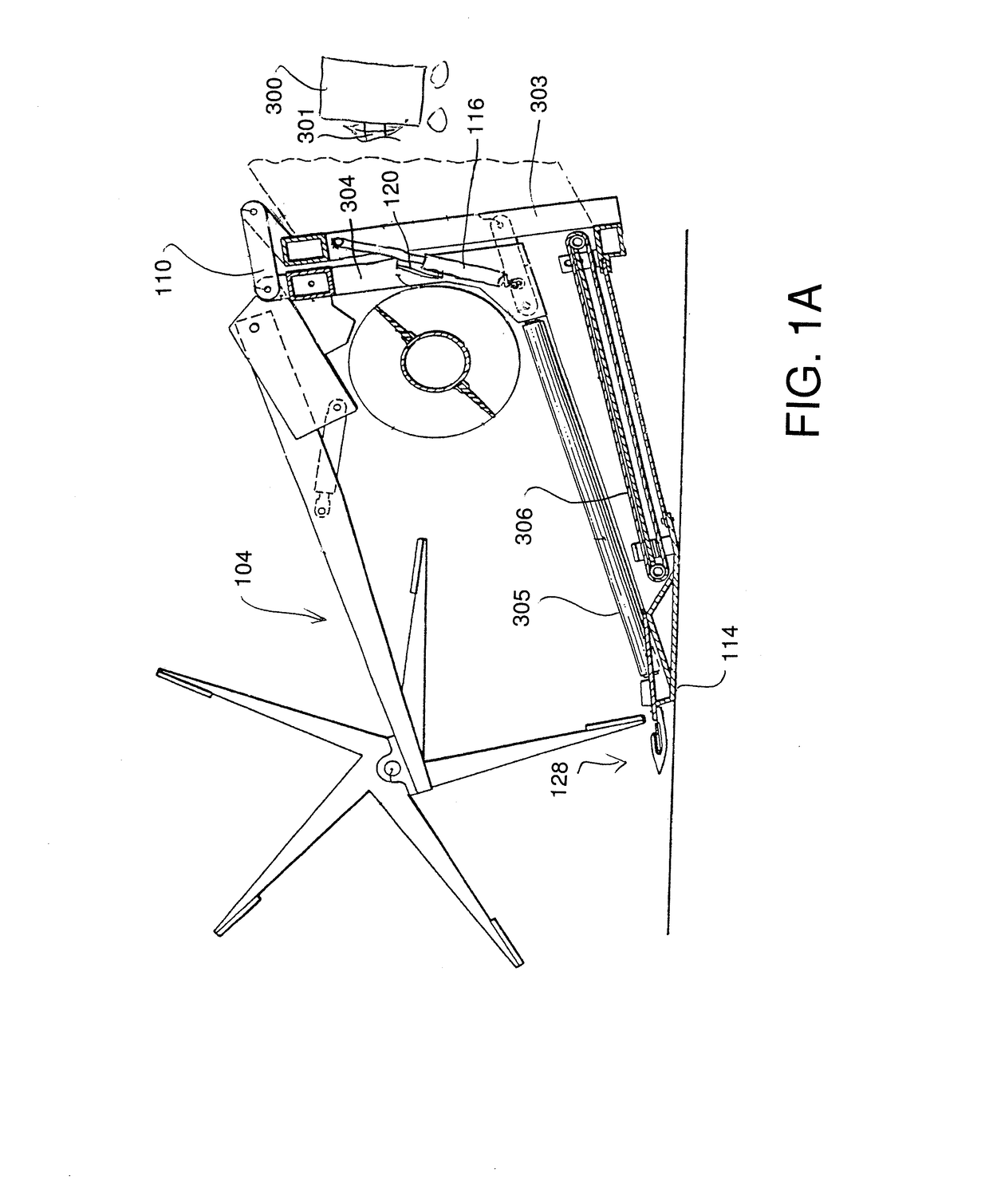

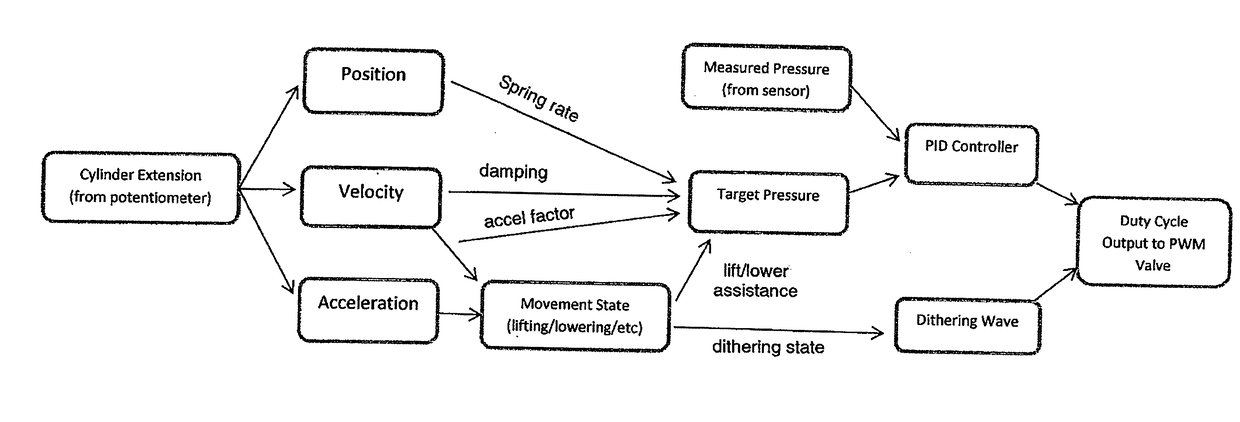

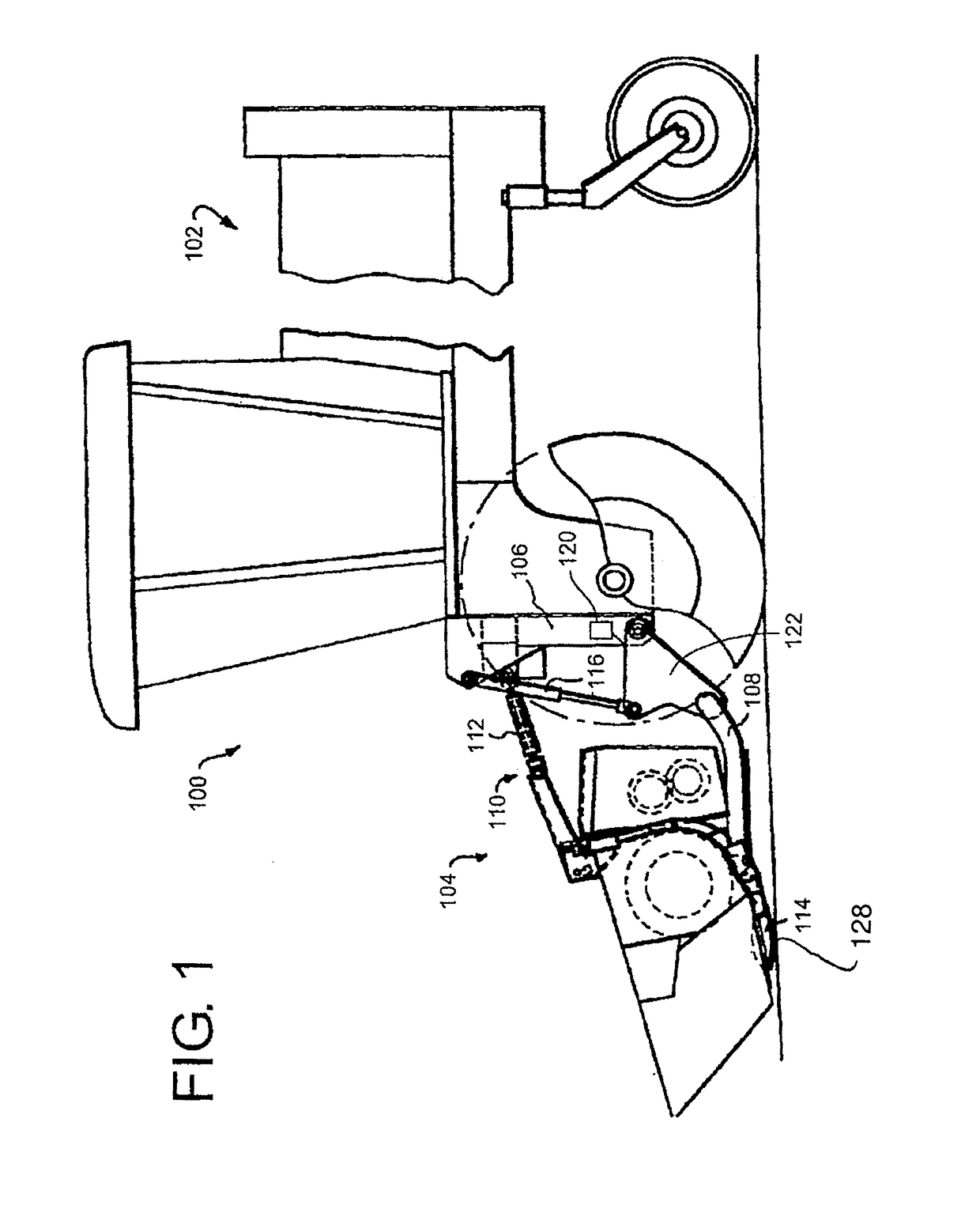

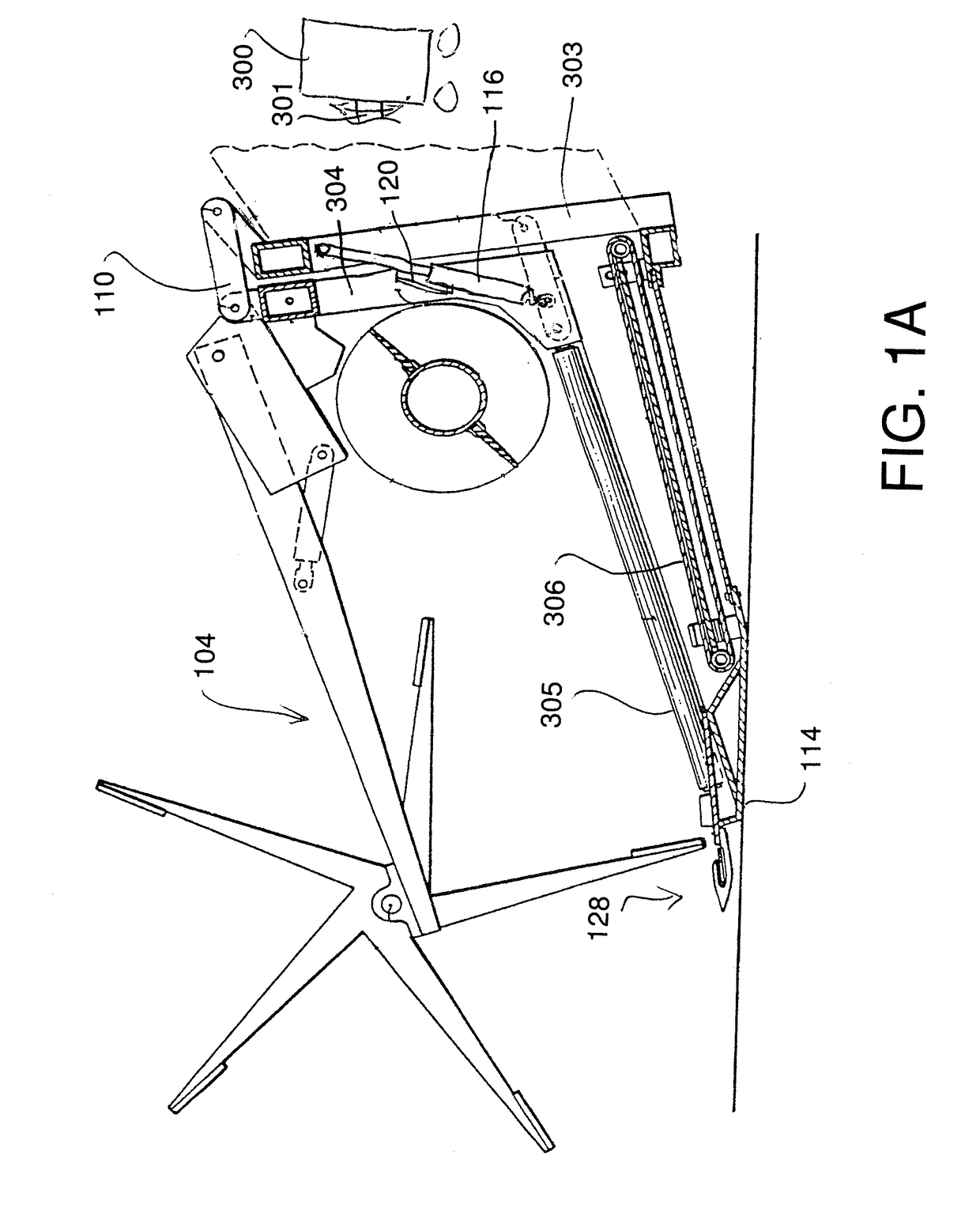

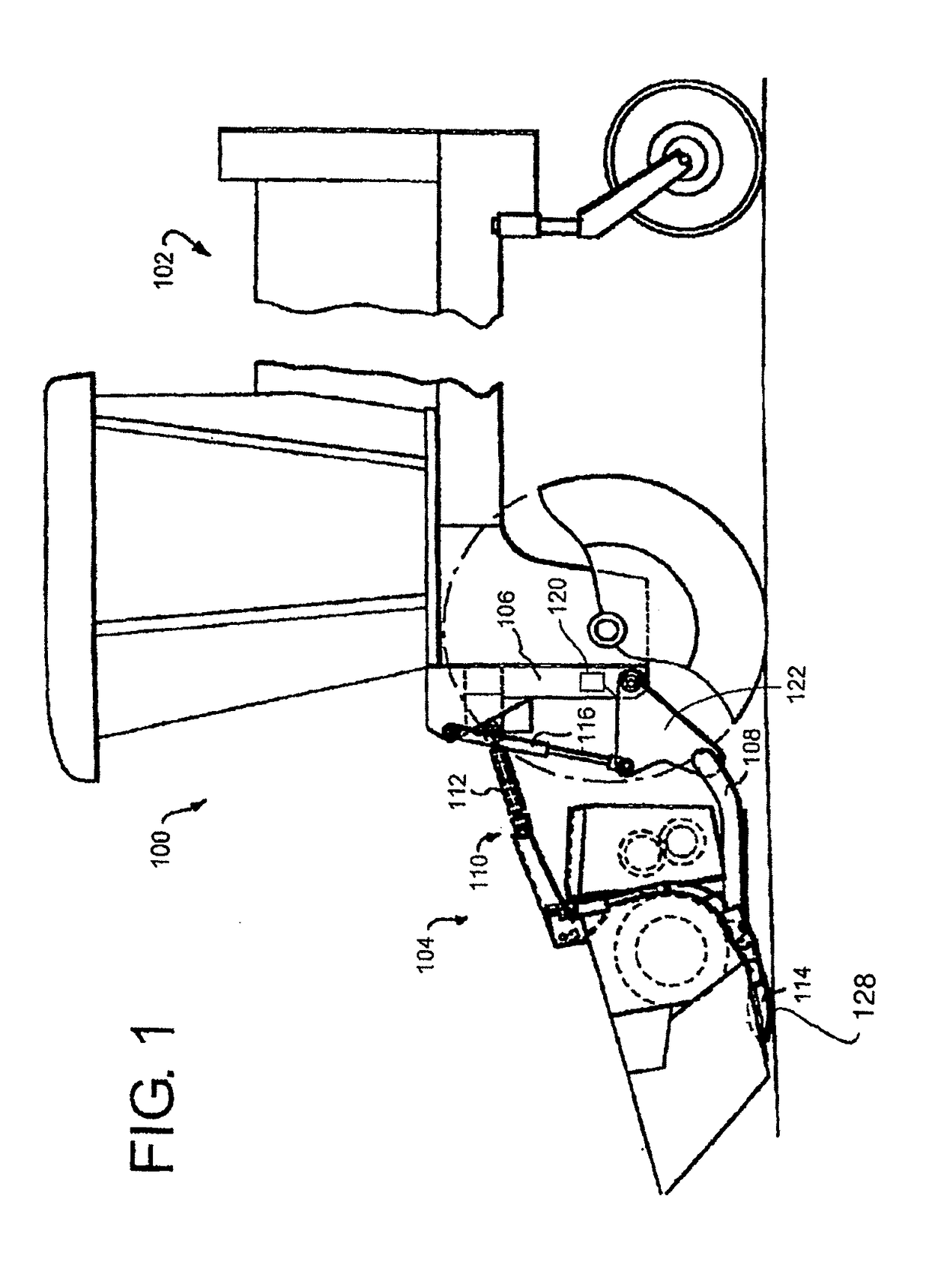

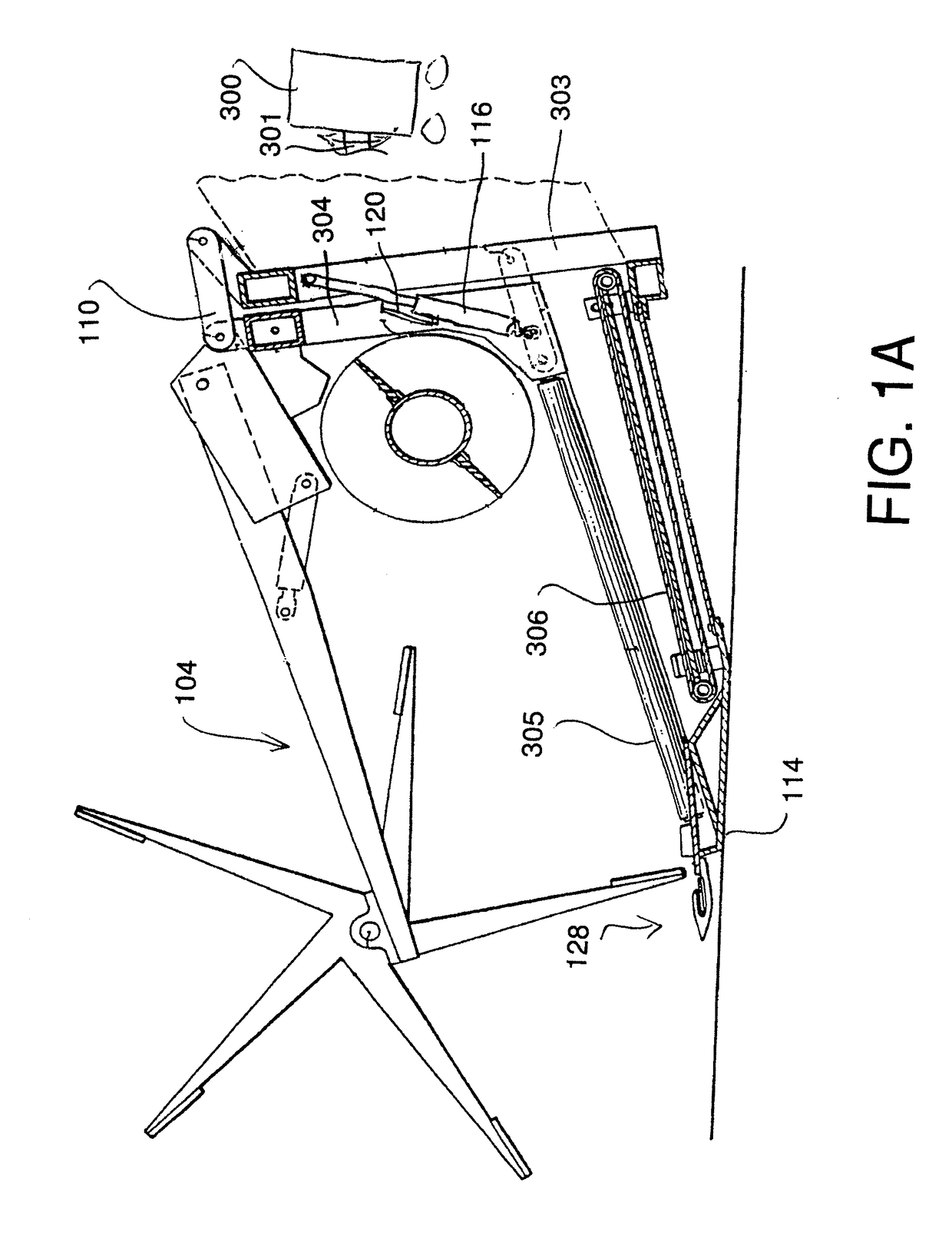

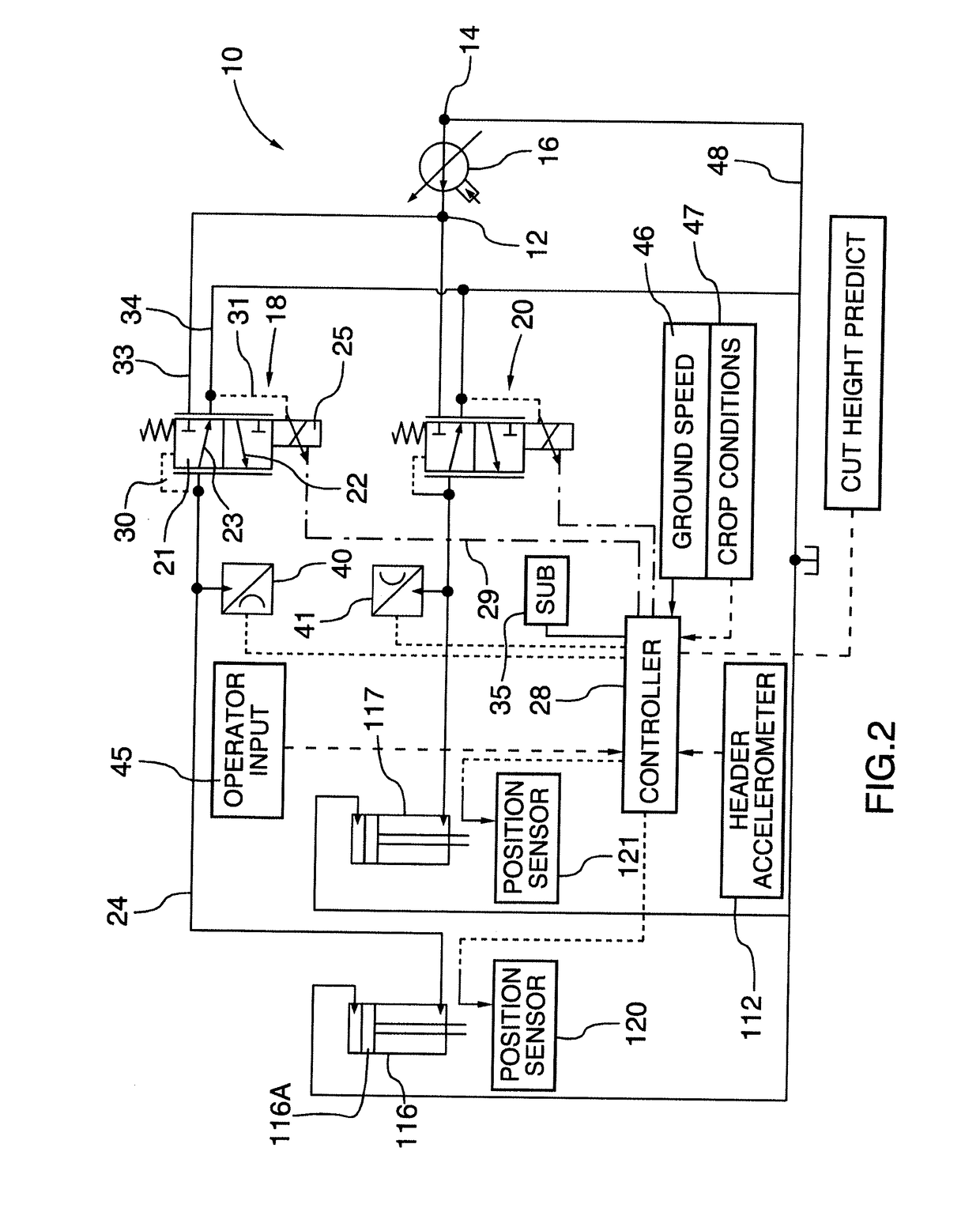

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180153102A1Improve responseReduce lifting forceAgricultural machinesServomotor componentsHydraulic cylinderControl signal

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

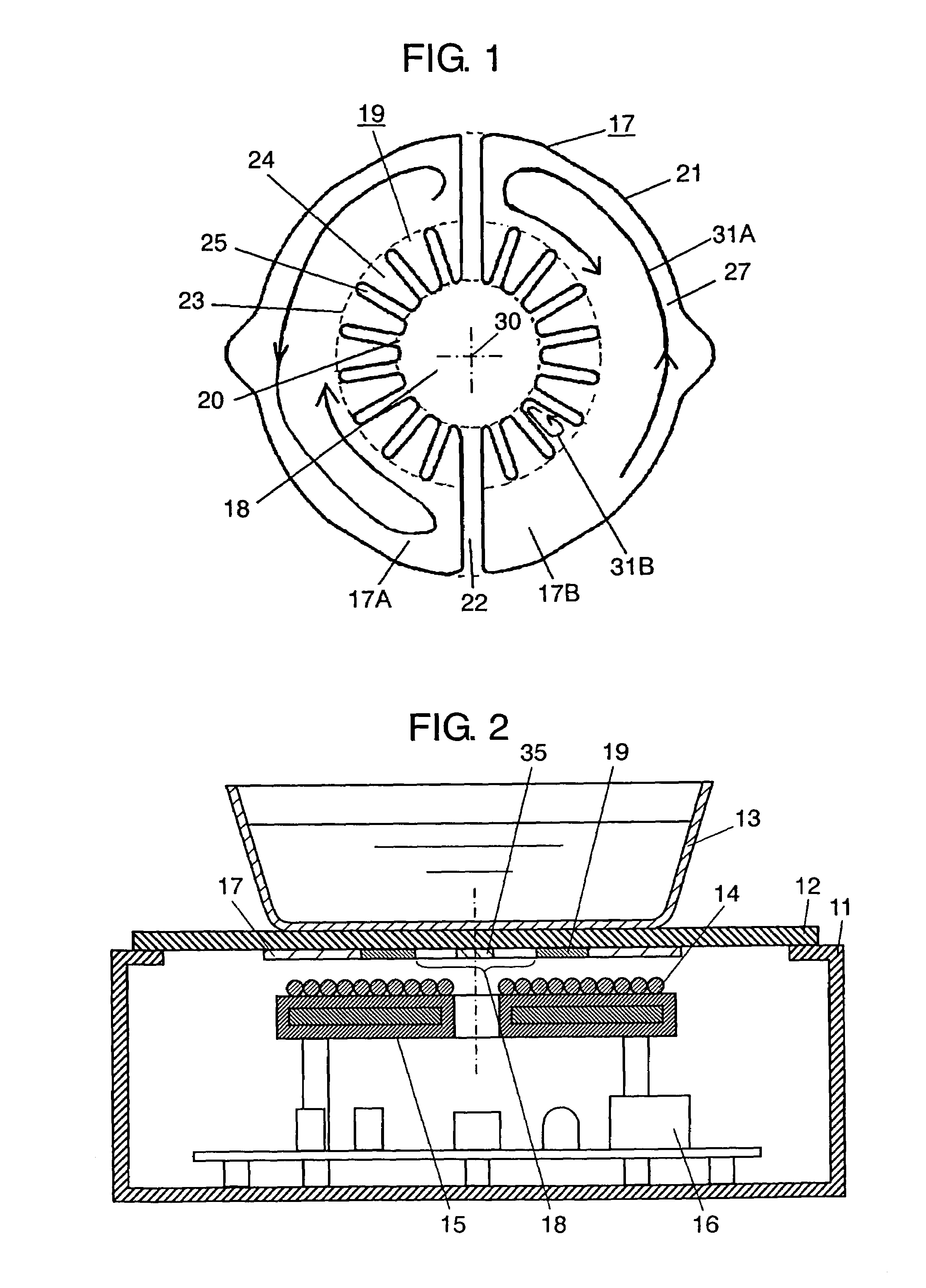

Induction cooker with heating coil and electrical conductor

ActiveUS7049563B2Reduce lifting forceImprove heating efficiencyCoil arrangementsInduction heating apparatusElectrical conductorPassive heating

An electric conductor provided for decreasing a lifting force exerted on an object being heated has an aperture of a small diameter in the center thereof, which leaves a large surface area to enhance reduction of the lifting force. The electric conductor is also provided with a comb section around the aperture for preventing a circling current induced in the electric conductor from flowing into an area around the aperture. This structure can thus alleviate excessive heating around the aperture, and allow the heating coil to produce a high output power for a long duration of time even when an inwardly concaved pan is used.

Owner:PANASONIC CORP

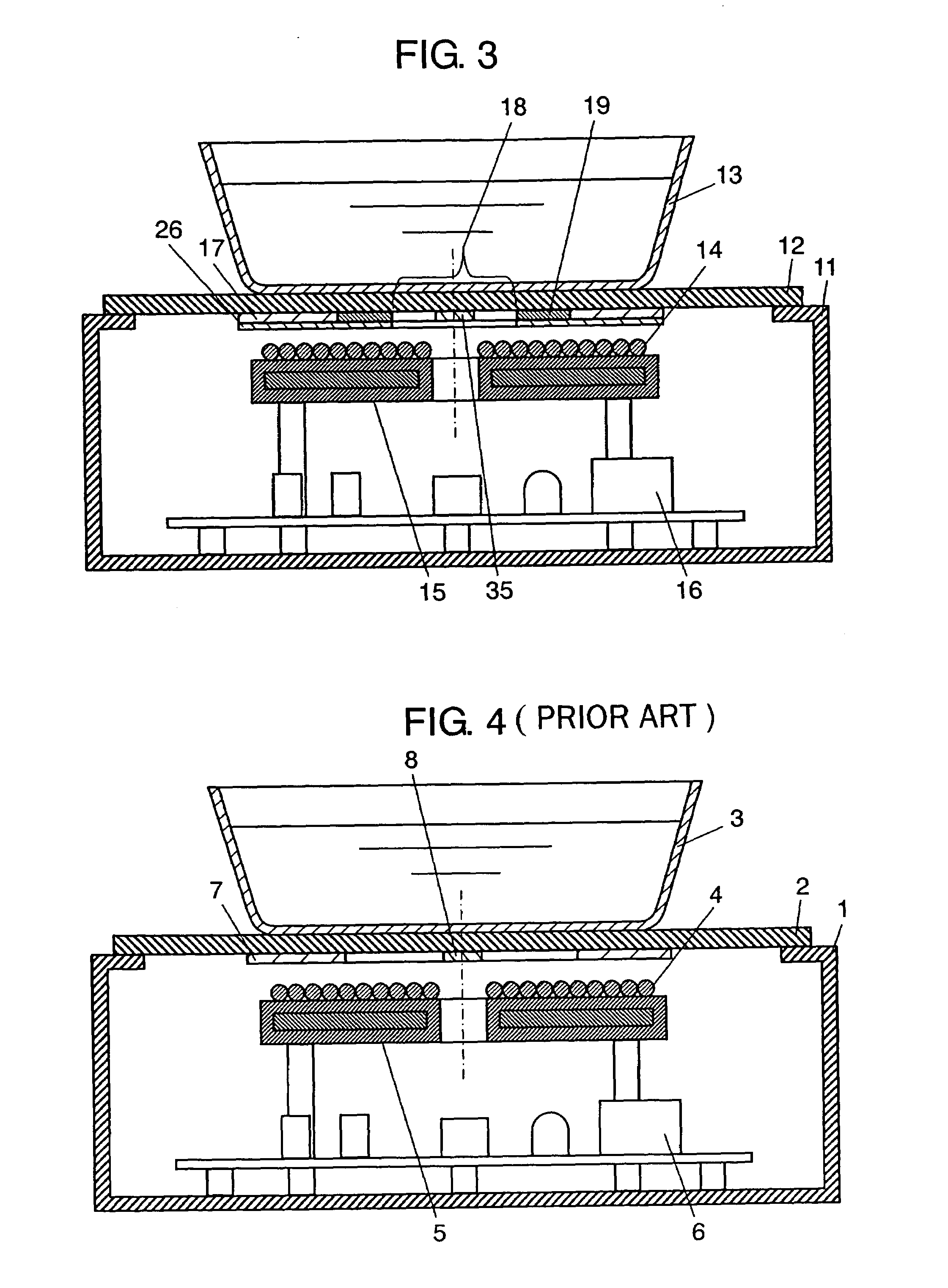

Linear generator

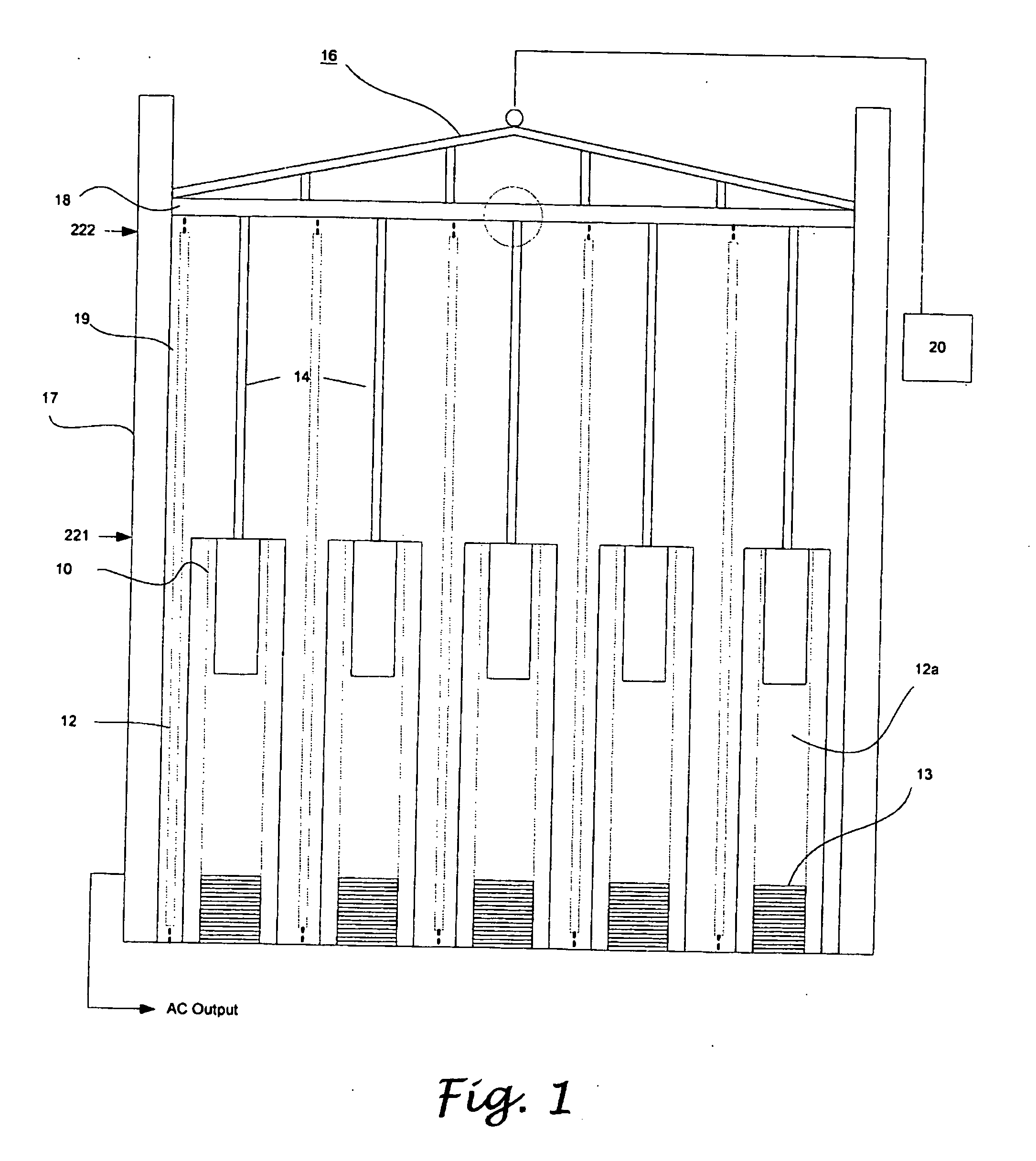

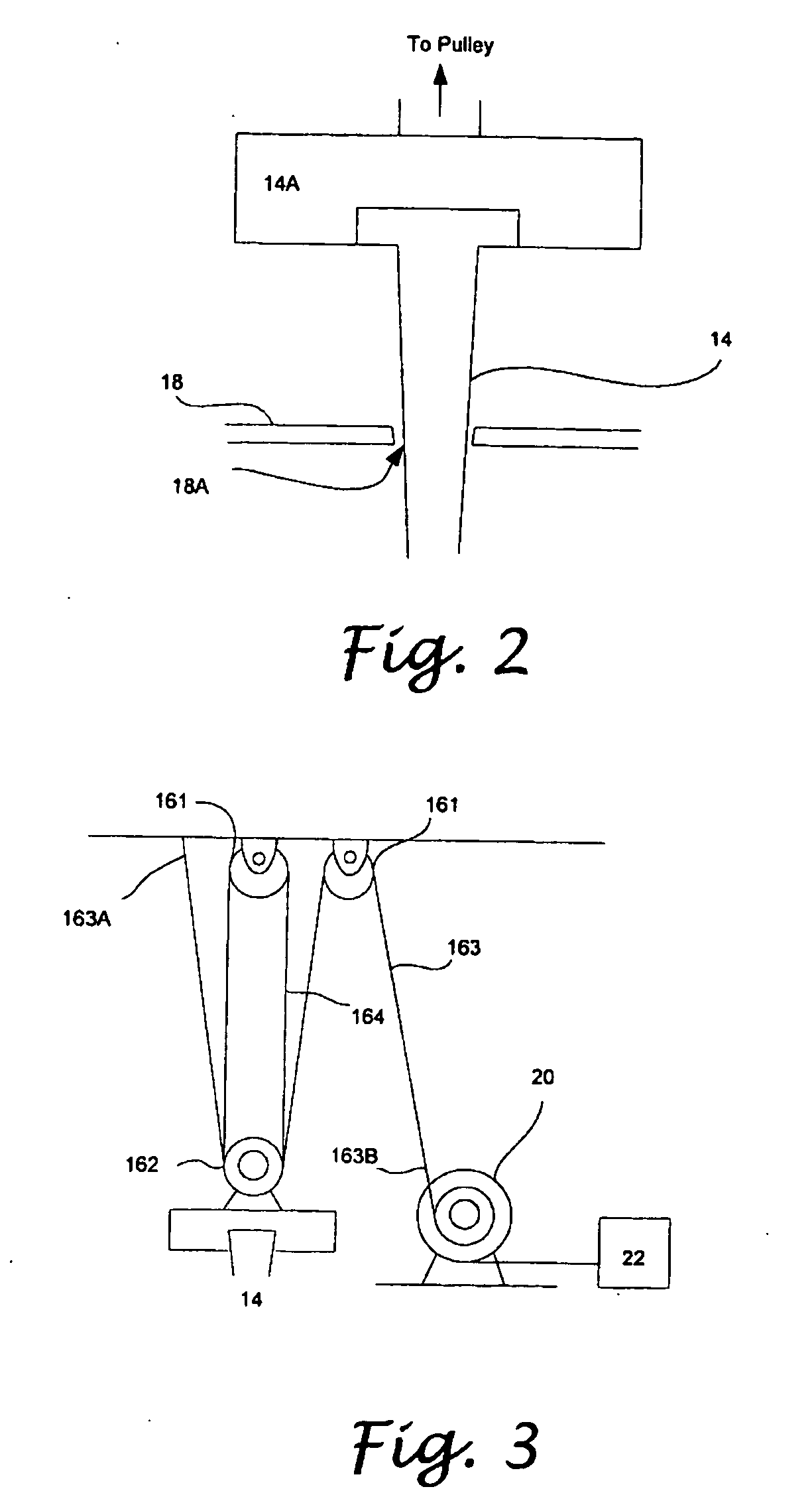

InactiveUS20070278800A1Save spaceSave areaMachines/enginesMechanical energy handlingReciprocating motionEngineering

A linear generator which generates electric energy by reciprocal movement of magnets with inductive coils is provided. The linear generator has a plurality of elongate inductive coils, a plurality of magnets inserted into the respective inductive coils and slidable between two opposing ends of the inductive coils, a pulley assembly connected to top ends of the magnets, and an elevating motor generating and applying a lifting force to the magnets through the pulley assembly. The pulley assembly is operative to provide 1:N mechanical advantage, where N is preferably an even integer larger than 1. The pulley assembly is connected to the magnets by a plurality of rigid cables, rods, or strings, and a cable connected to the elevating motor is reeved through the pulley assembly, so as to exert a lifting force to the magnets via the pulleys.

Owner:GALICH THOMAS P

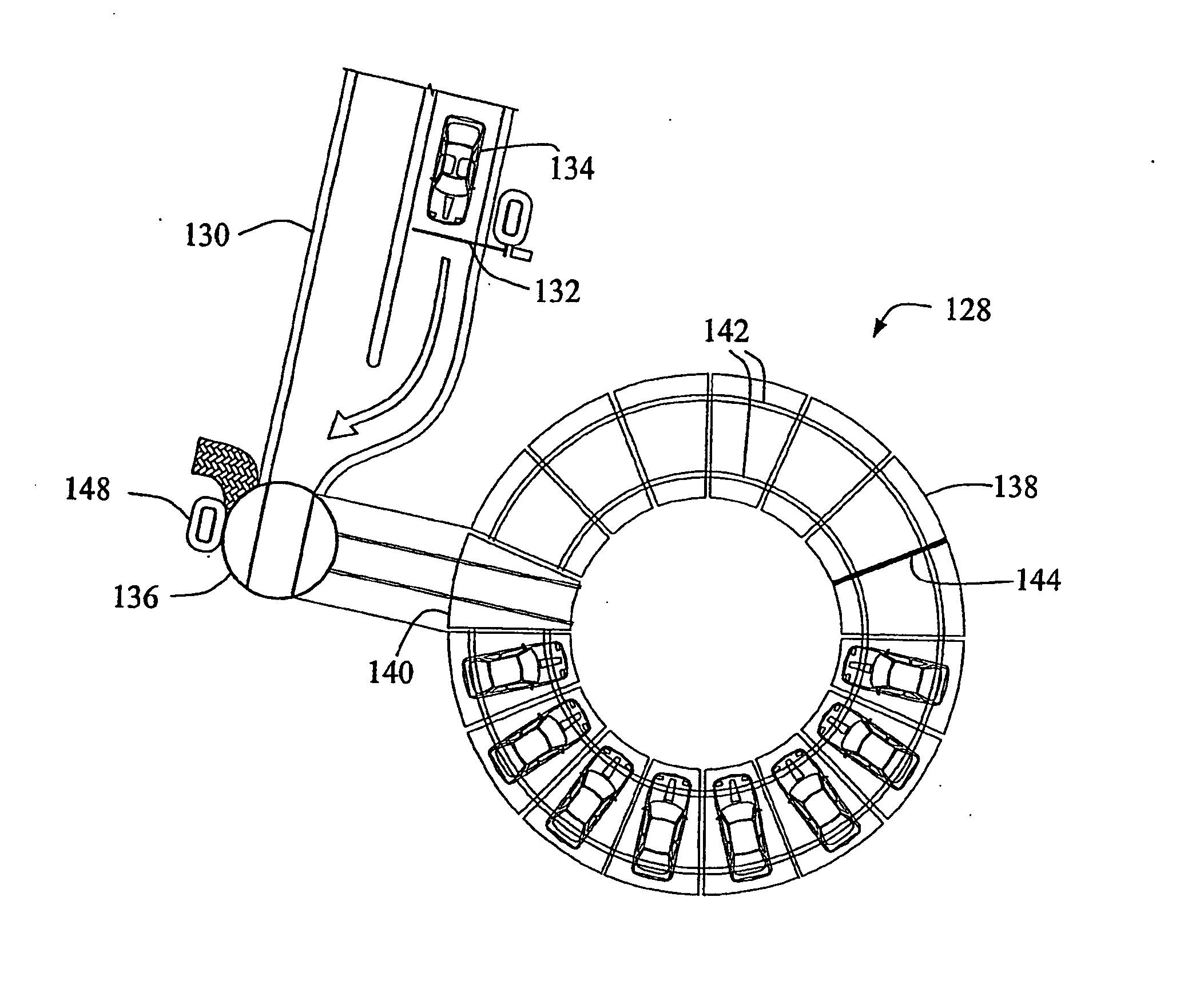

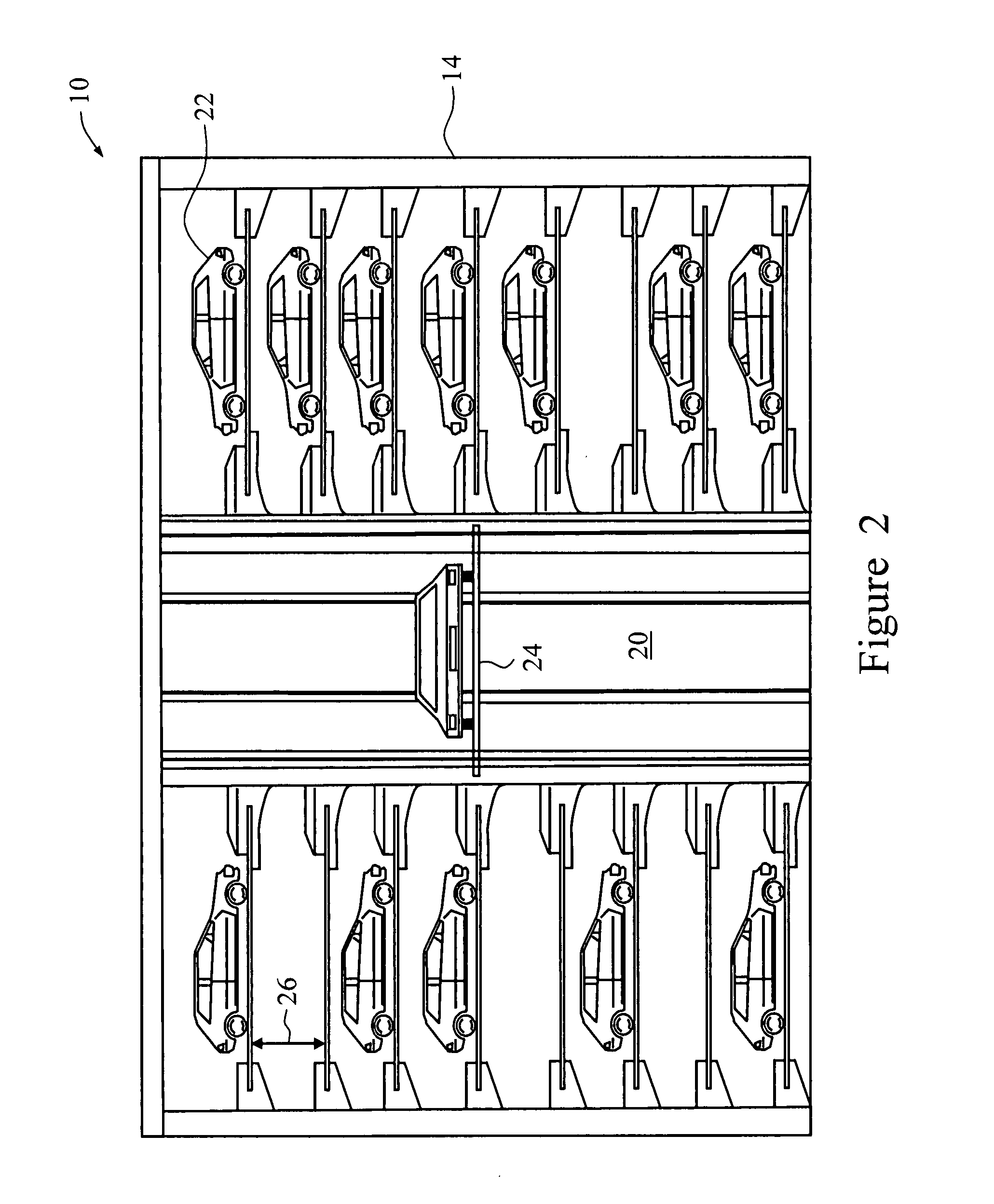

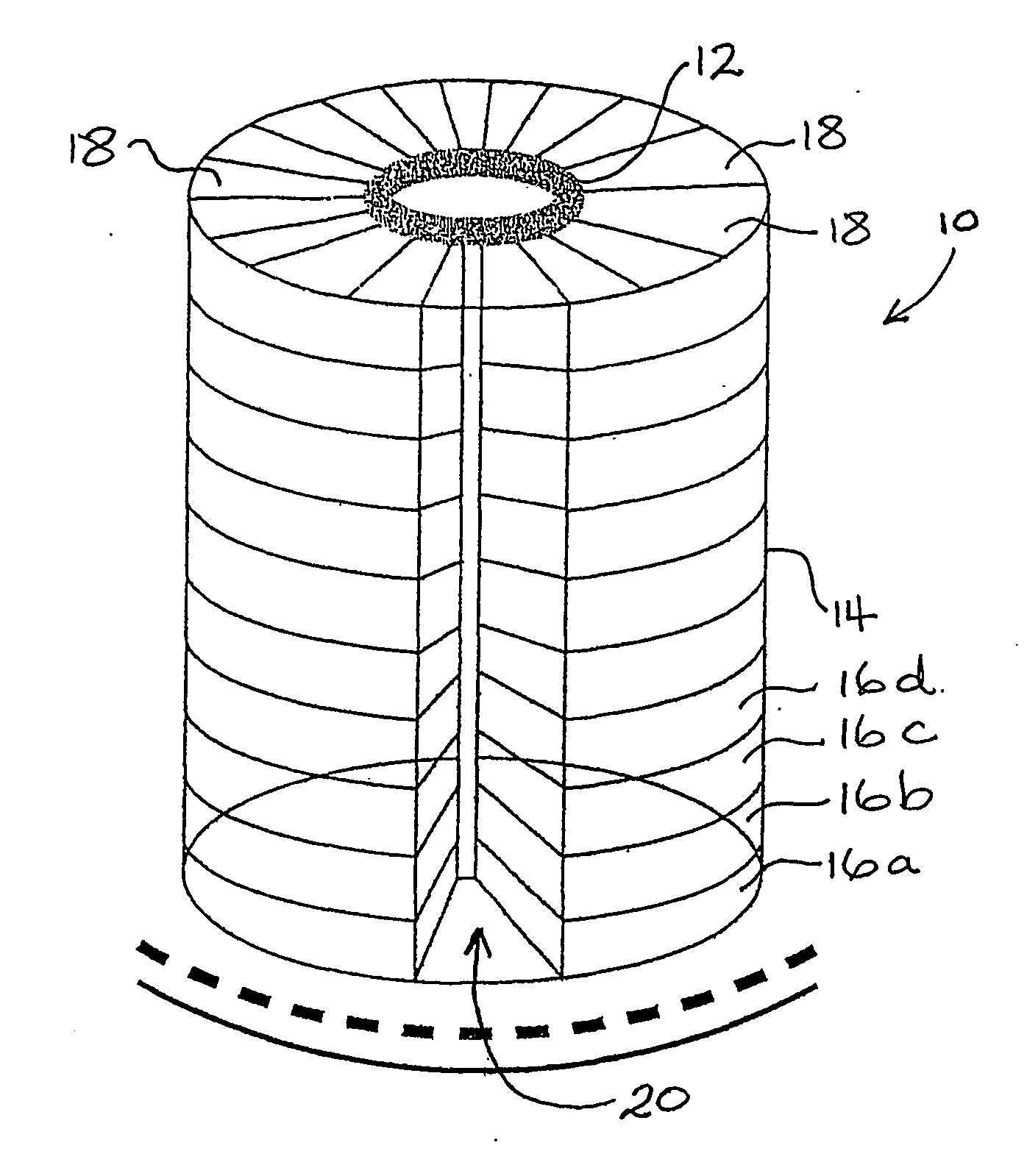

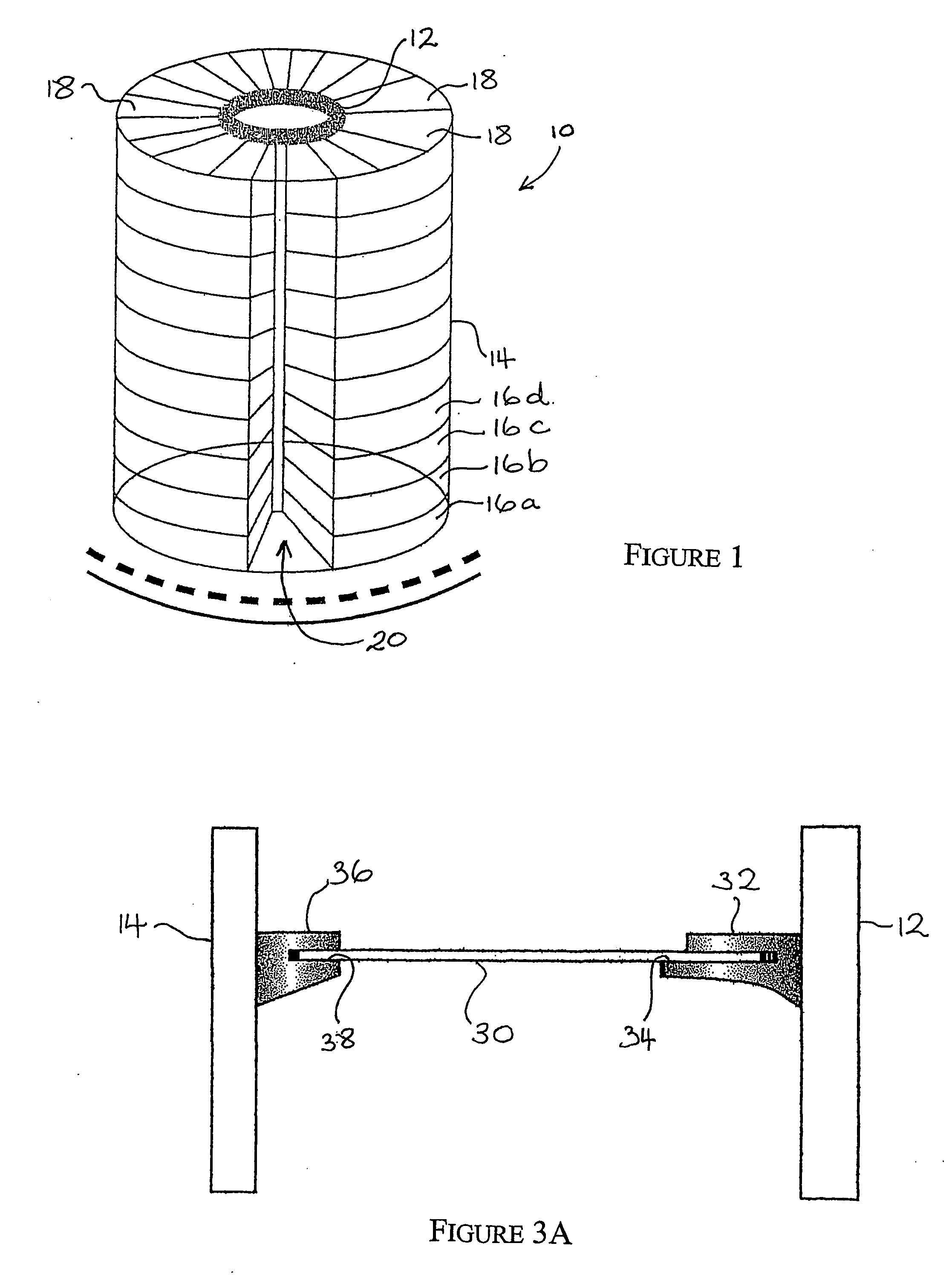

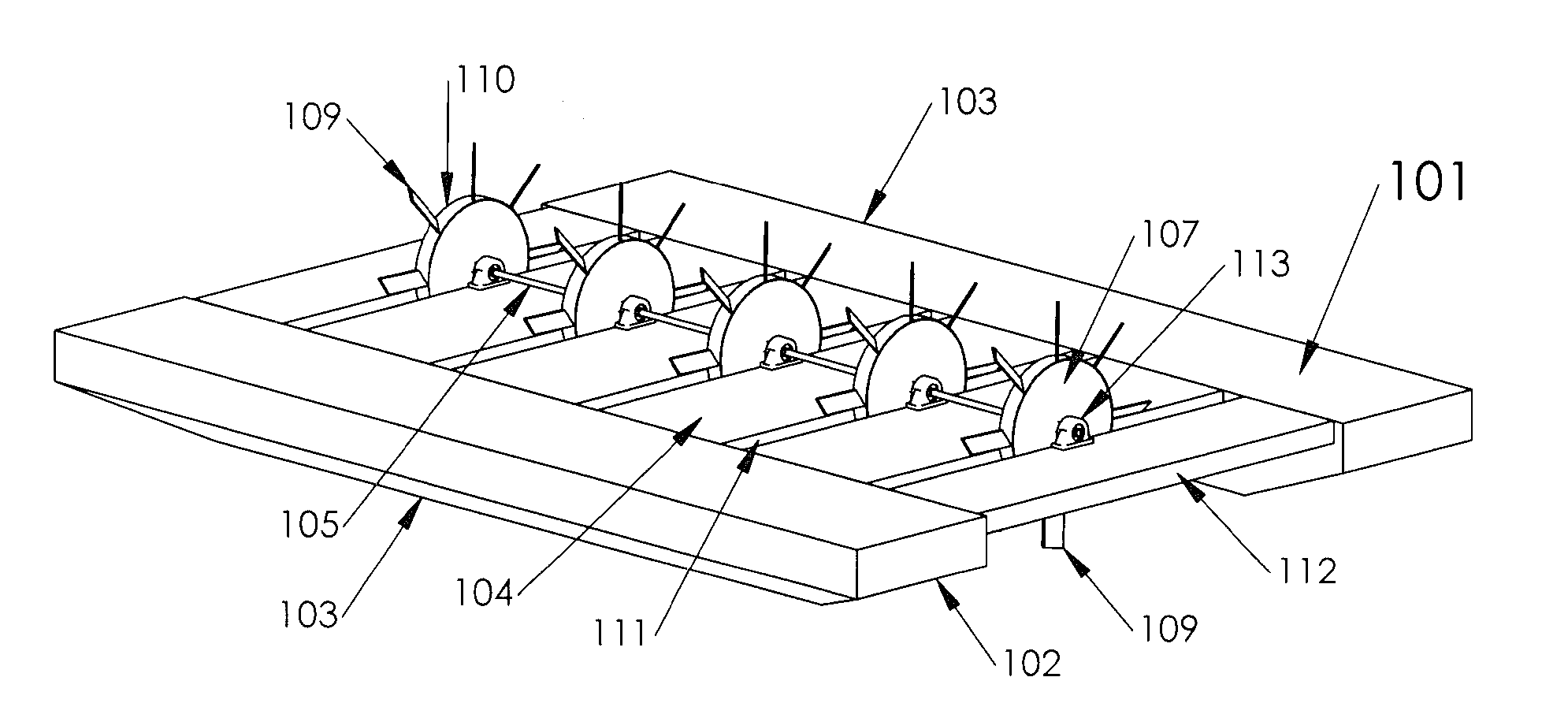

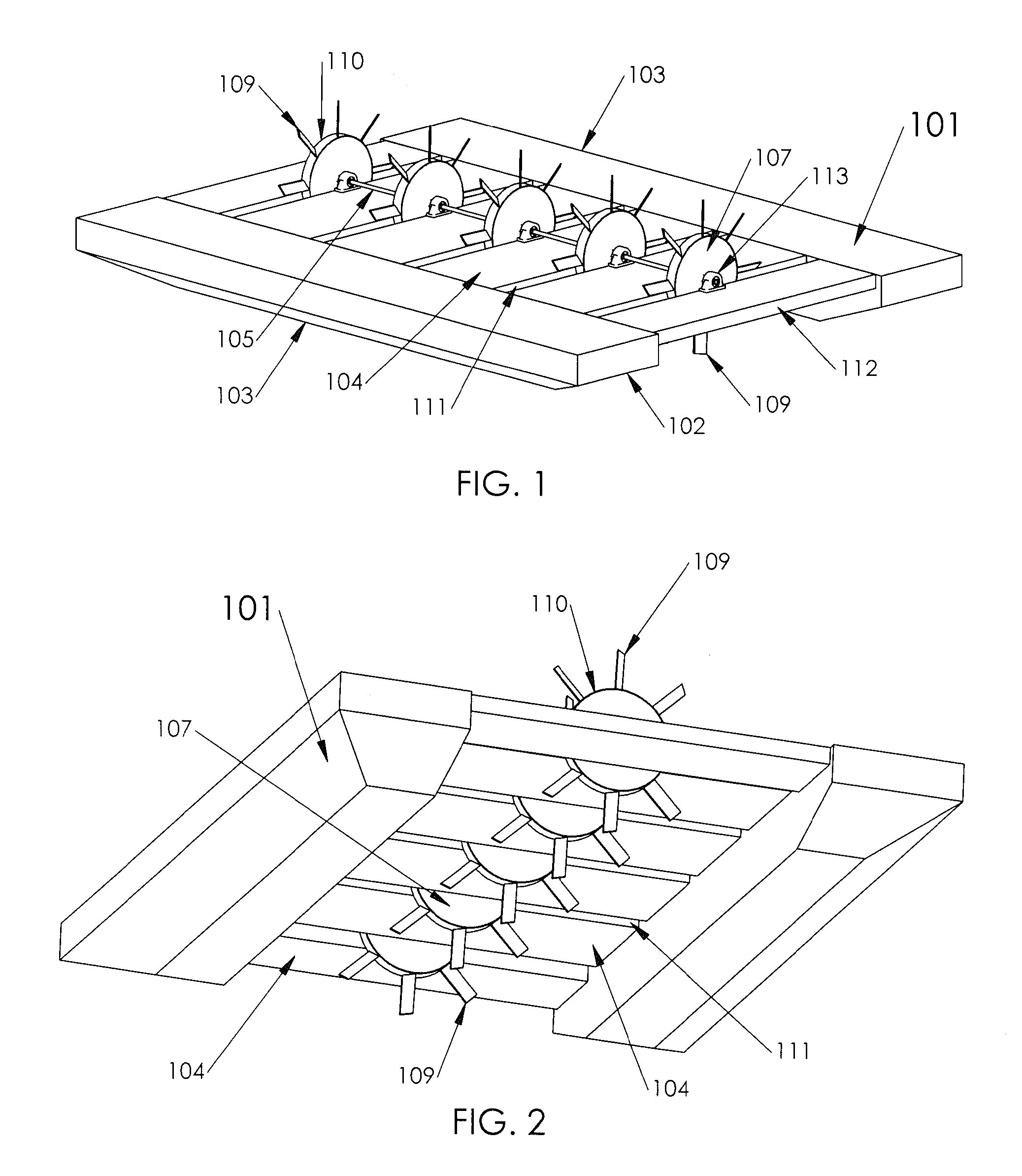

Car park

InactiveUS20070294952A1Increase parking densityHigh densityBuilding liftsParkingsParking spaceEngineering

Owner:EMCP PTD

Car park

InactiveUS20060228196A1Increase parking densityHigh densityStorage devicesParkingsEngineeringParking lot

Owner:EMCP PTY LTD

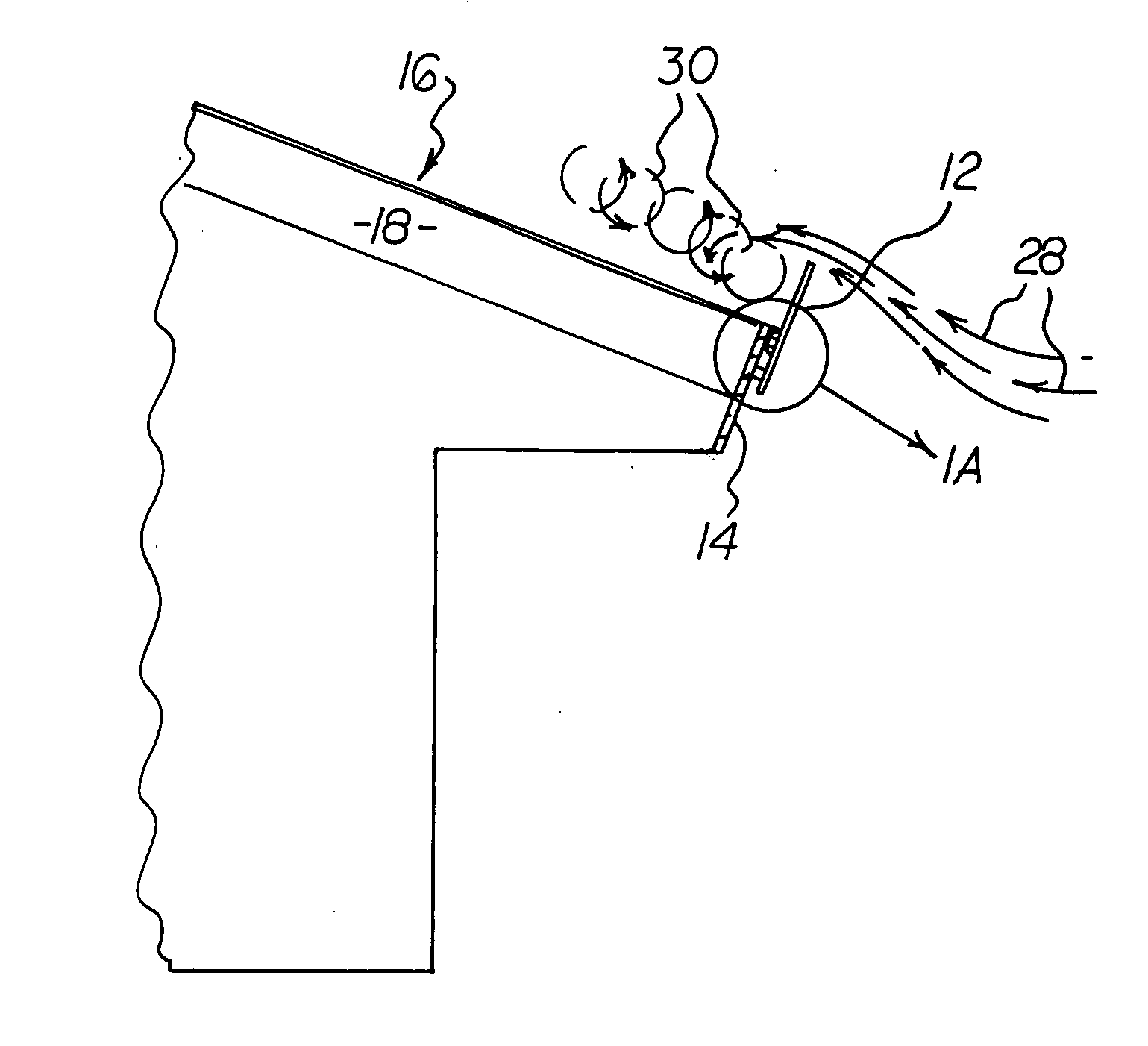

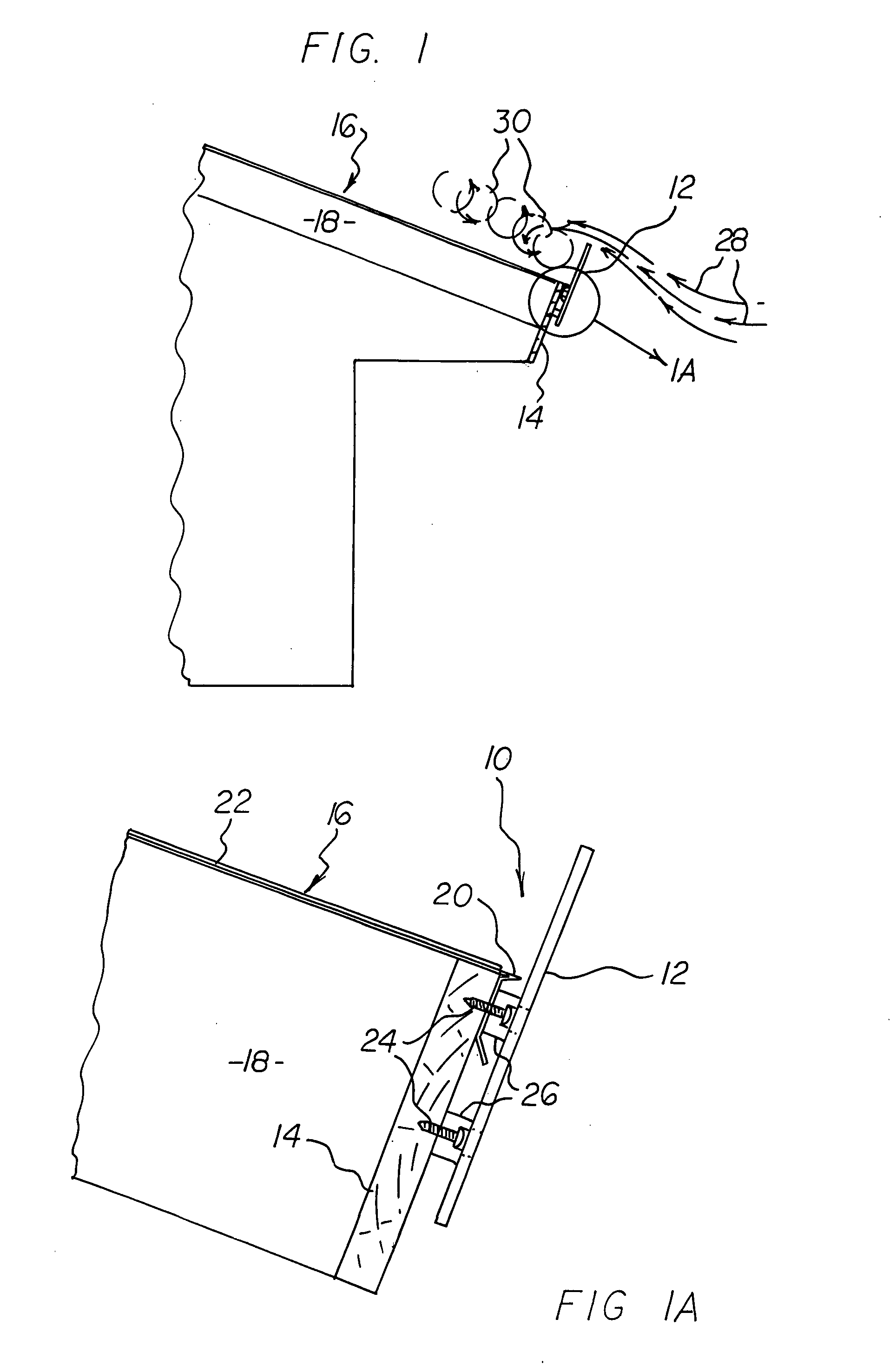

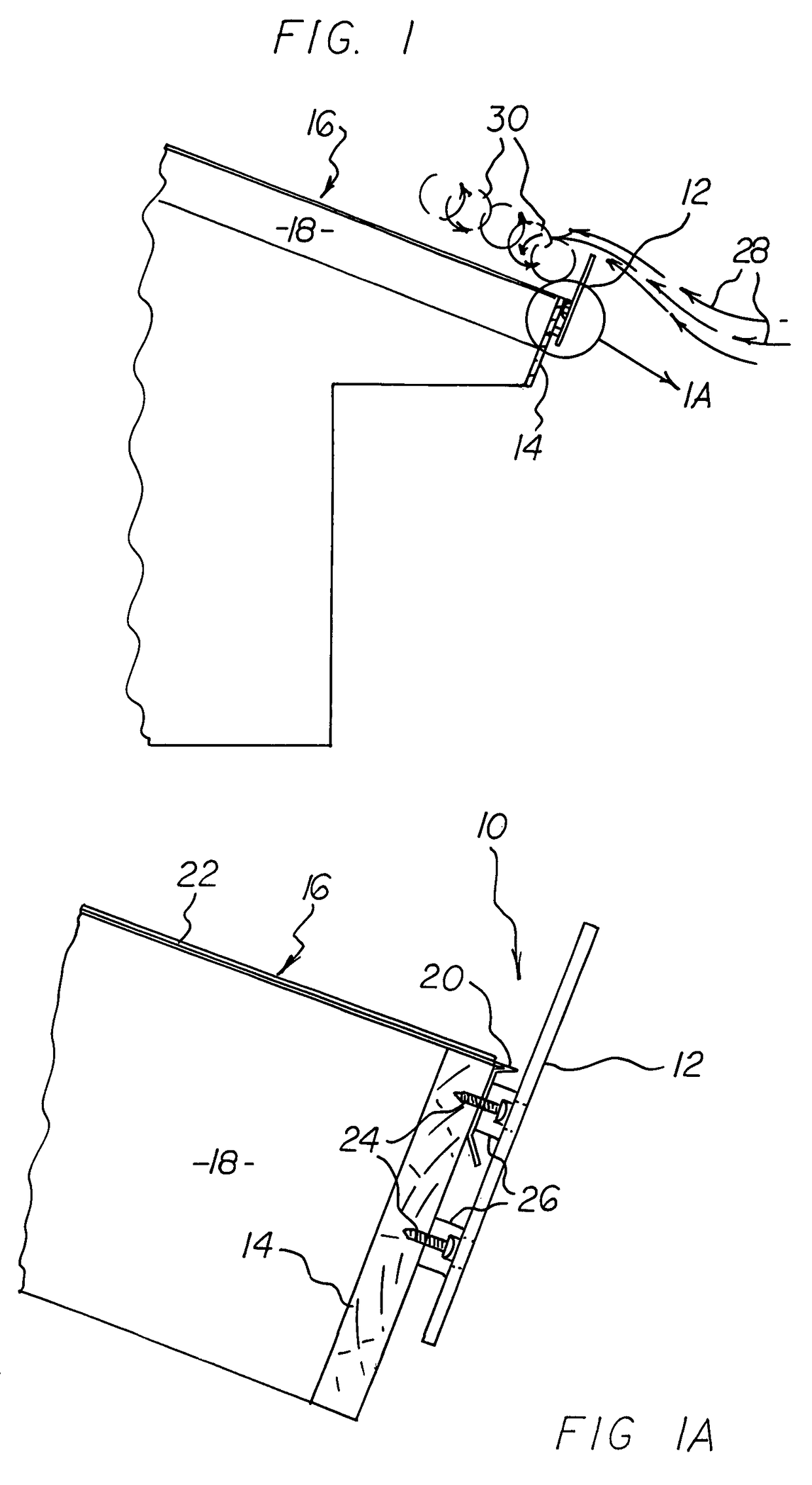

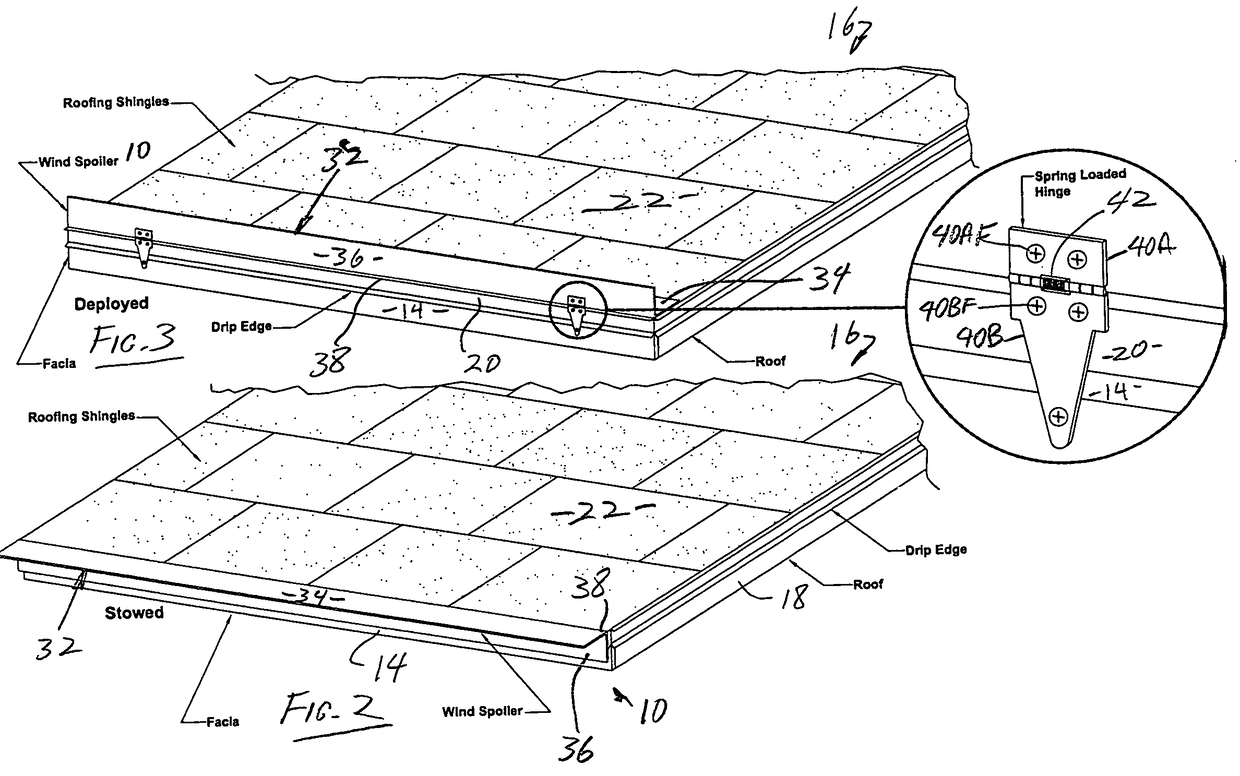

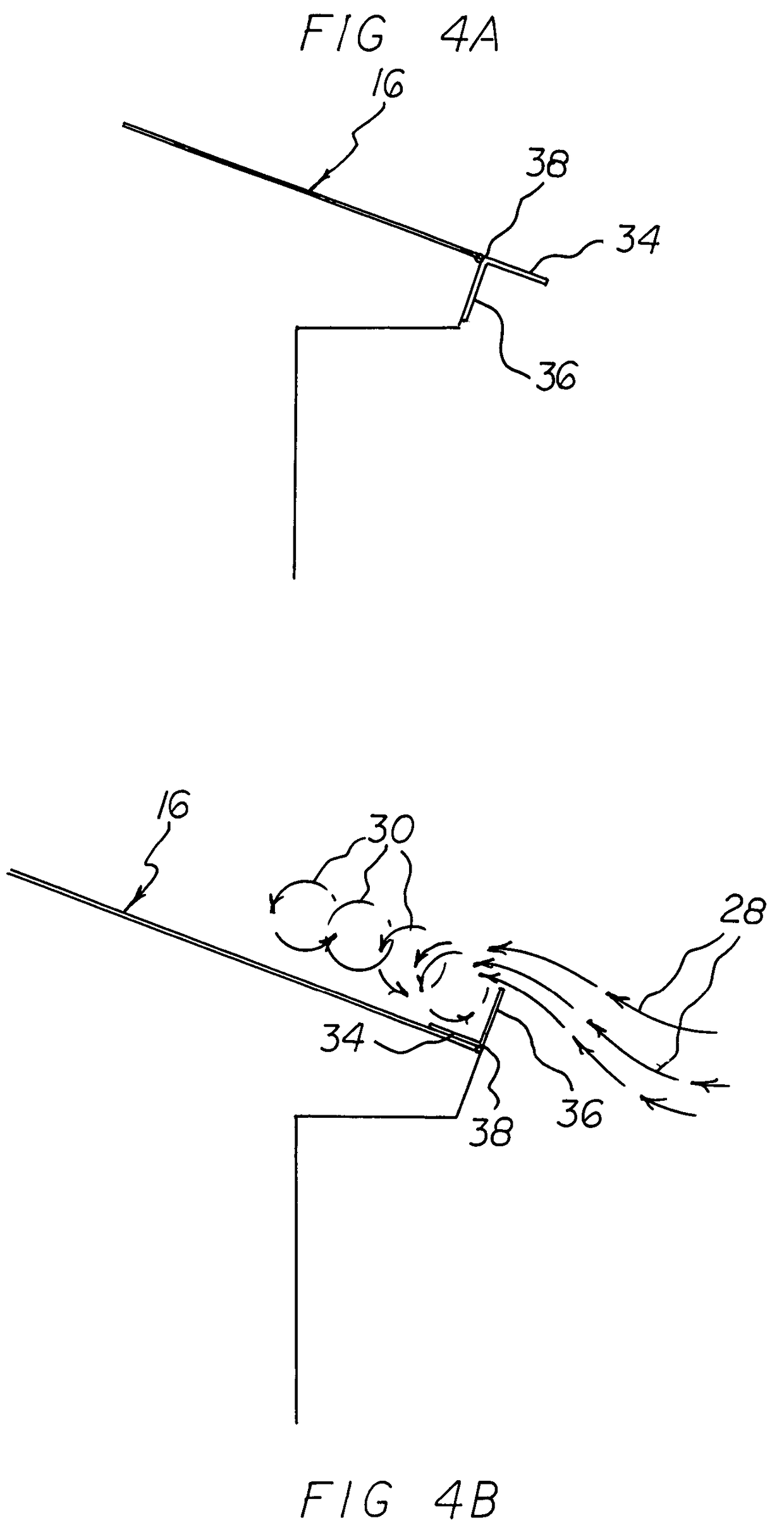

Wind spoiler for roofs

ActiveUS20070113489A1Reduce the possibilityReduce areaRoof covering using slabs/sheetsBuilding roofsEngineeringWind flow

A wind spoiler including a vertical member mounted vertically along a roof of a structure to extend above the plane of the roof for creating turbulence in wind flowing over the roof.

Owner:HOD GINA B +1

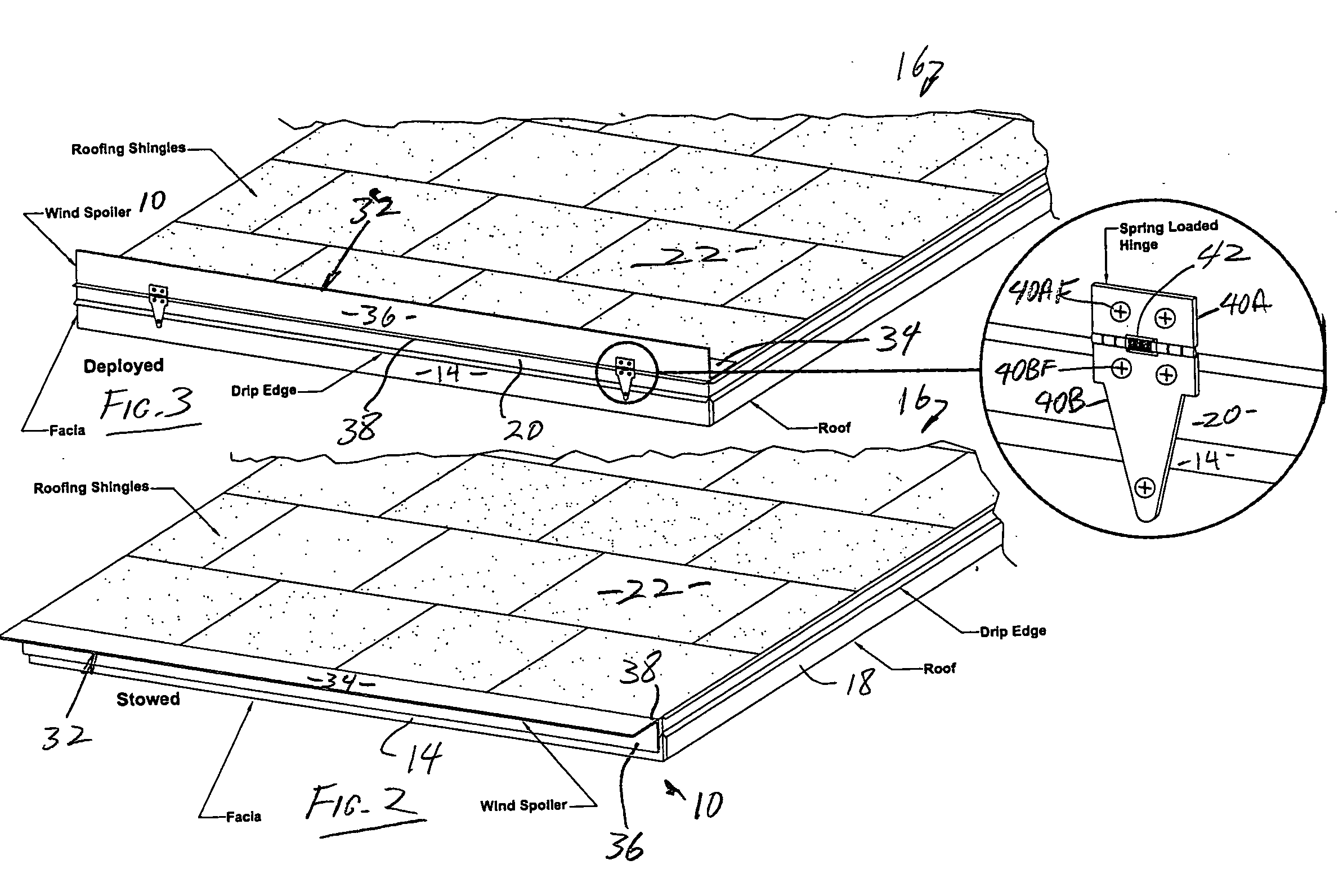

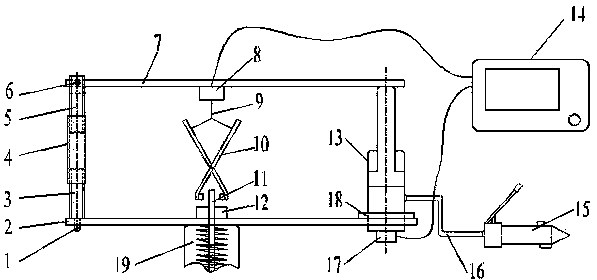

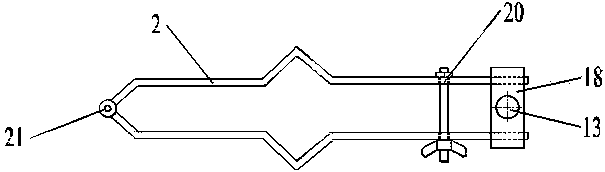

Two-stage scraper type garbage compression and transfer apparatus

InactiveCN1919703AGarbage to reasonableThe mechanism is evenly stressedRefuse transferringLoading/unloadingSewageControl system

The invention discloses a two-grade scraper-typed rubbish compressing rotary device, which comprises the following parts: wagon, rubbish compressor, wagon mobile locating device, hydraulic dynamic system and electric appliance control system, wherein the rubbish elevation mechanism of rubbish compressor possesses certain separation angle of vertical direction for rubbish compressor bulk, the pushing board locking mechanism of rubbish compressor and joint scraper board constitutes rubbish press-loading mechanism with rubbish elevating mechanism and loading mechanism individually, the effluent collecting and draining structure is set on the back door of wagon.

Owner:广西玉柴专用汽车有限公司

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180153101A1Reduce lifting forceEliminate the effects ofAgricultural machinesServomotor componentsHydraulic cylinderControl manner

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

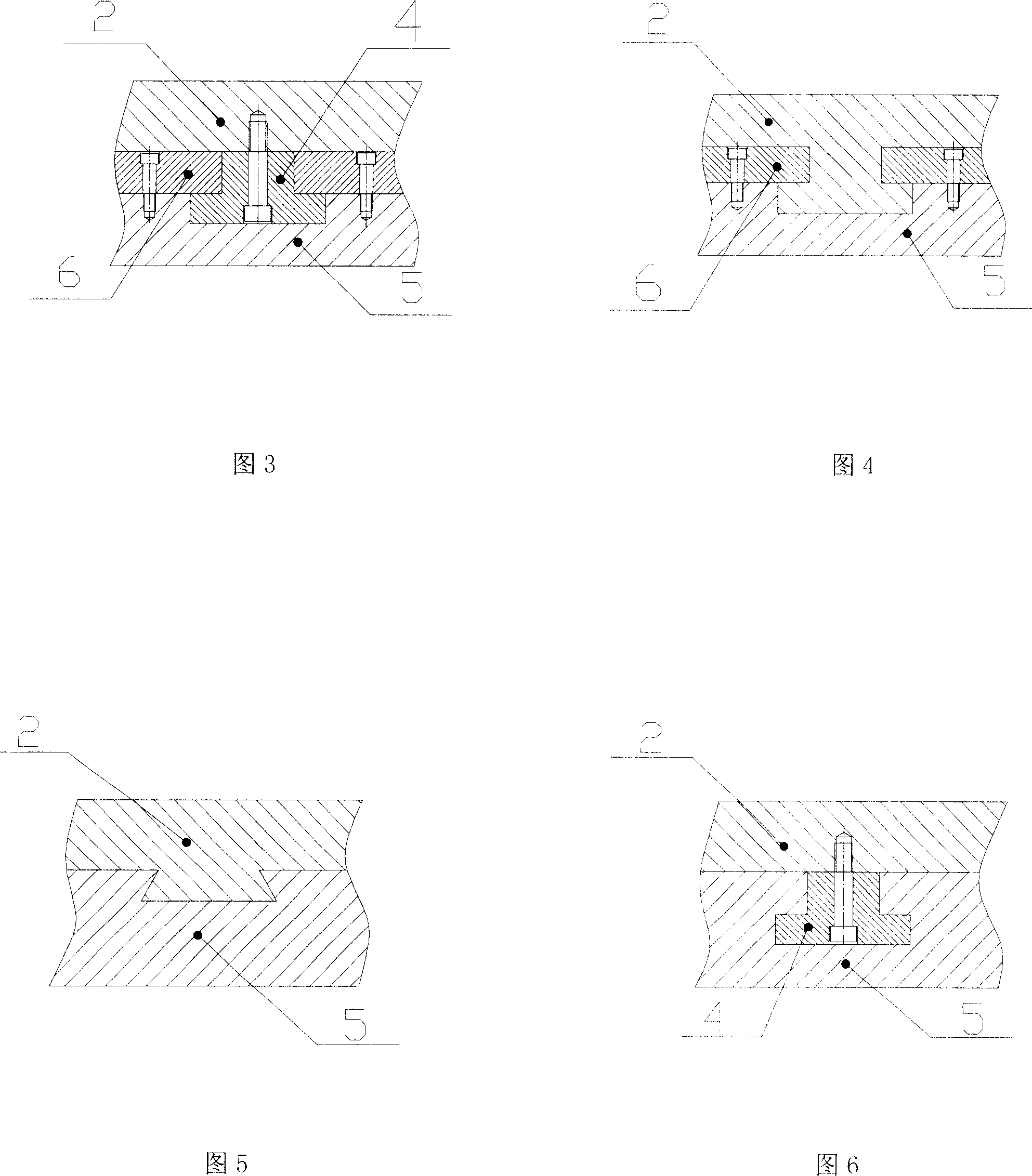

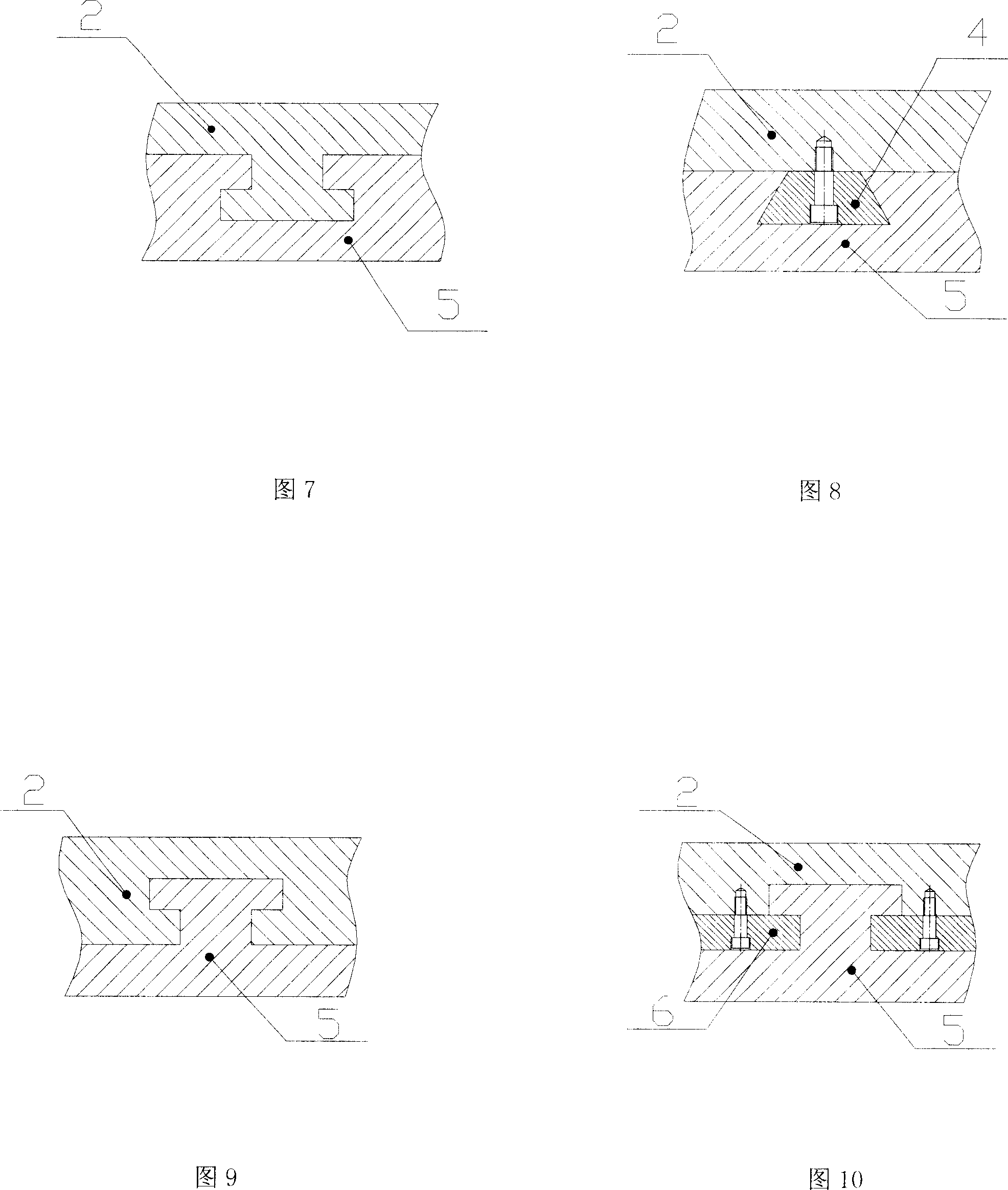

Tyre mould

The present invention relates to a vulcanized radial tire mould. It includes the following several portions: upper side plate, middle mould cover, lower side plate and tread block positioned between upper side plate and lower side plate for forming tire tread face. Said the mould is simple, can greatly reduce tire cost.

Owner:QINGDAO YUANTONG MACHINERY CO LTD

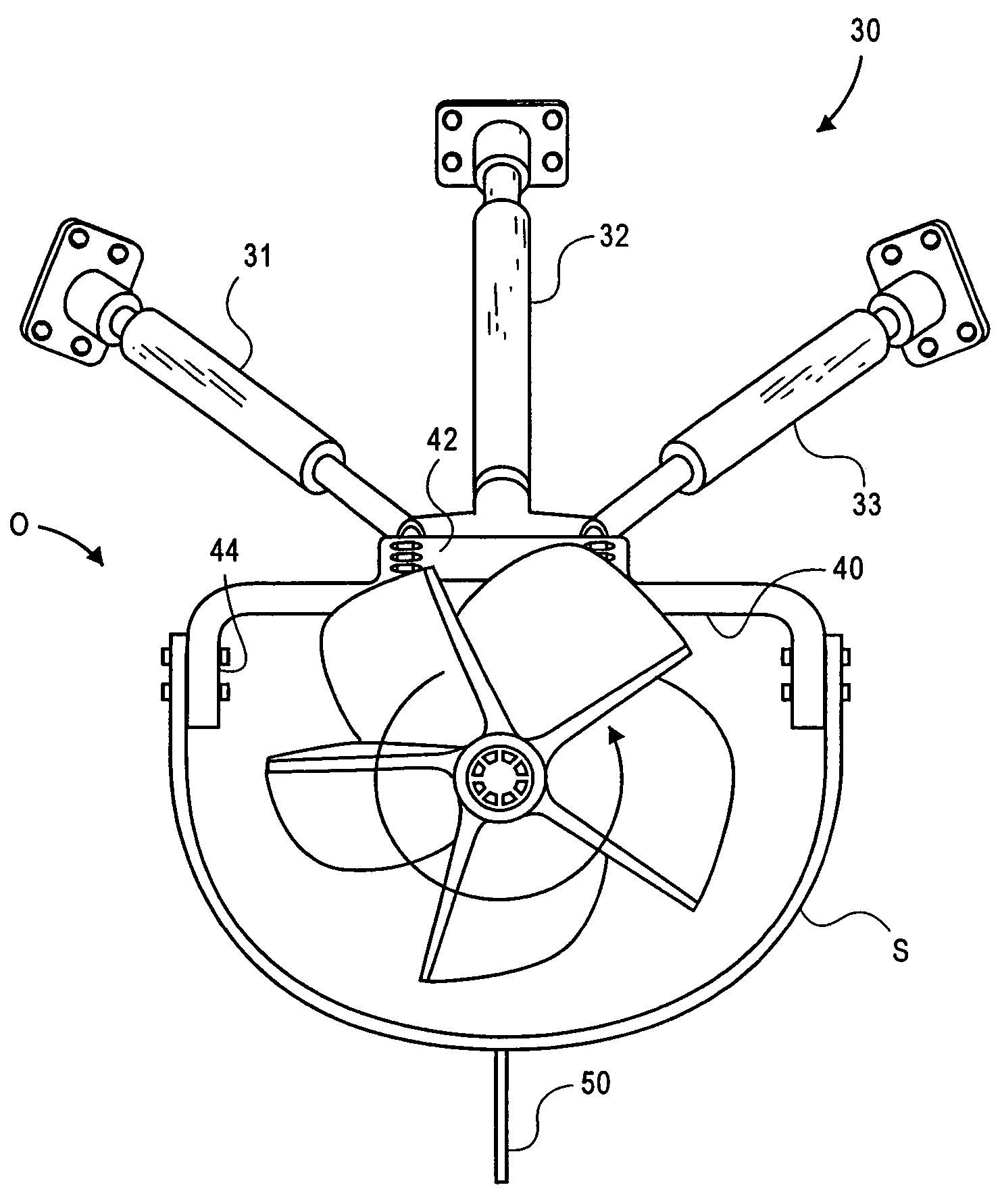

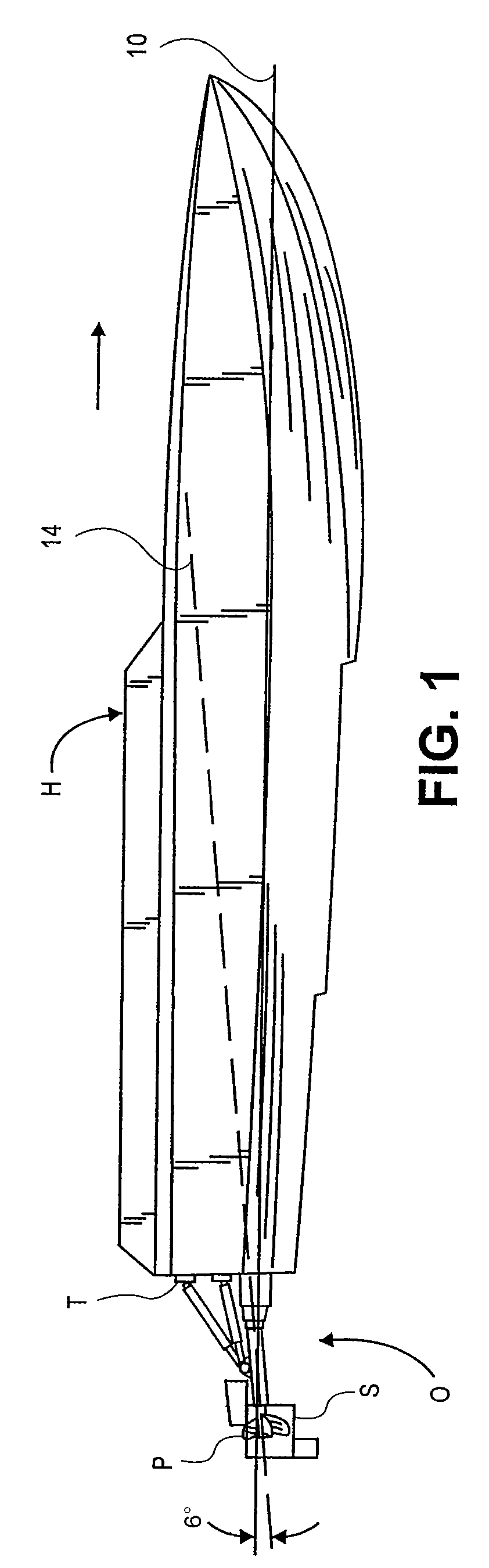

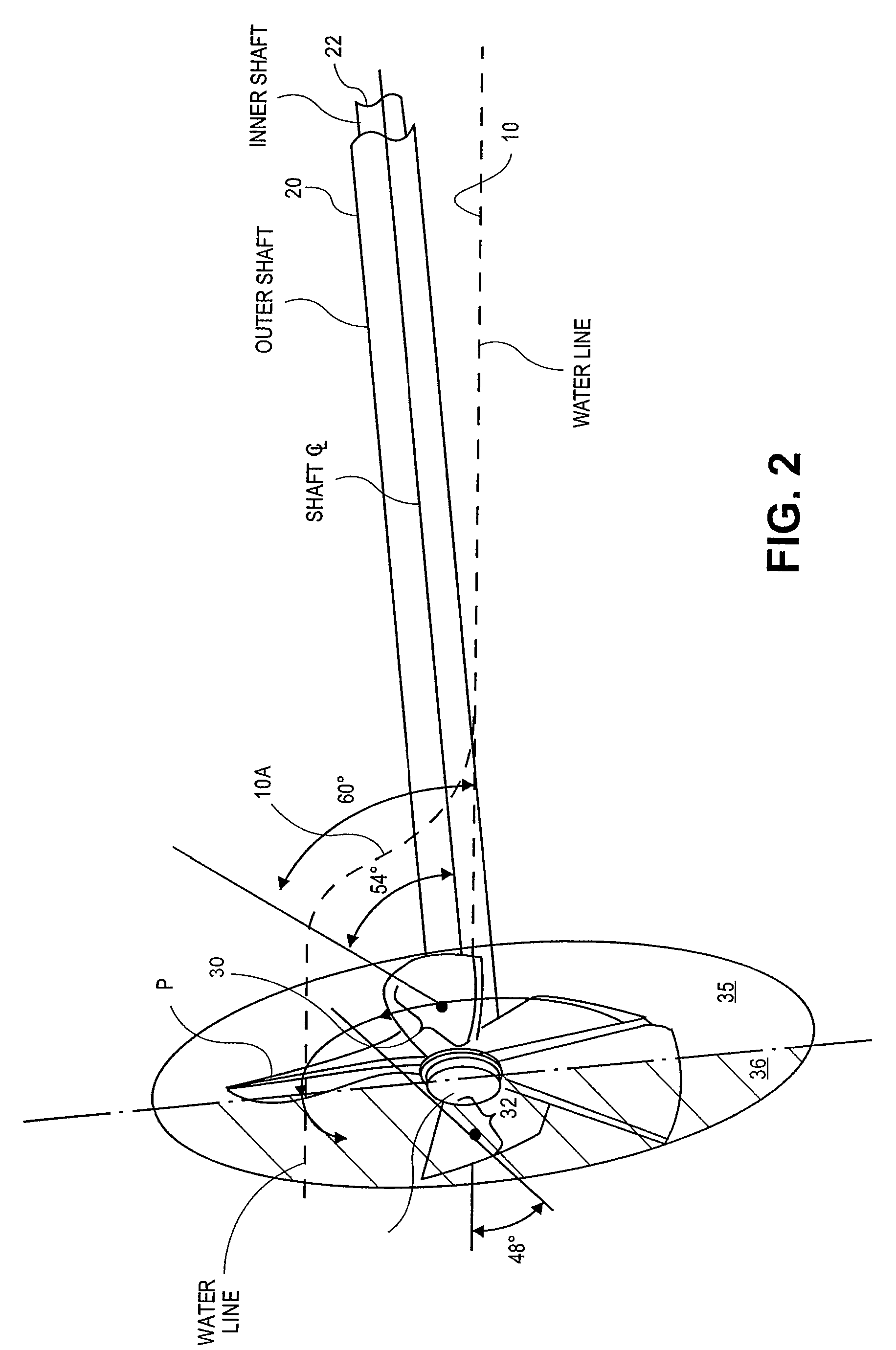

Shroud enclosed inverted surface piercing propeller outdrive

A shrouded outdrive propels a high-speed boat having a hull for high-speed passage through water. The hull has at least one bow at the forward end and at least one transom at the stern. A tubular shaft extends at a small angle (6° to 12°) from the boat transom into the water, and a drive shaft is arranged within the tubular shaft. A propeller is mounted to the drive shaft for partial immersion in the water so that a lower portion of the propeller extends into the water during high-speed floating passage of the boat and a upper portion of the propeller is above the water during high-speed floating passage of the boat. A shroud is arranged about the propeller and is disposed below the water and adjacent the propeller. A mount holds the shroud to form a shroud-enclosed channel during high-speed passage of the boat through the water in which the propeller rotates. A plate horizontal to the undisturbed passing water surface overlies the departure side of the propeller at a radial distance of about two thirds (⅔) of the radius of the propeller. This plate immediately abuts the departure blading of the propeller in the direction of boat movement through the water and assures immersion of the lower pitch departure side of the partially immersed propeller in water for more efficient propulsion. Embodiments are disclosed where the plate is utilized as the necessary support for the shroud. Additionally, both the shroud and the plate can have small angular variations with respect to the surface of the undisturbed surface through which the high-speed hull passes.

Owner:HOWARD M ARNESON TRUSTEE OF THE HOWARD M ARNESON TRUST DATED AUGUST 3 2016

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

ActiveUS20180359920A1Reduce supportReduce lifting forceServomotor componentsMowersHydraulic cylinderControl signal

A header is supported by a pair of hydraulic float cylinders, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration and / or velocity. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. A lift force greater than that required to lift the header can be provided by a lift cylinder and can be opposed in a controlled manner to apply a controlled downforce by the back of the same cylinder or by a separate component.

Owner:MACDON INDS

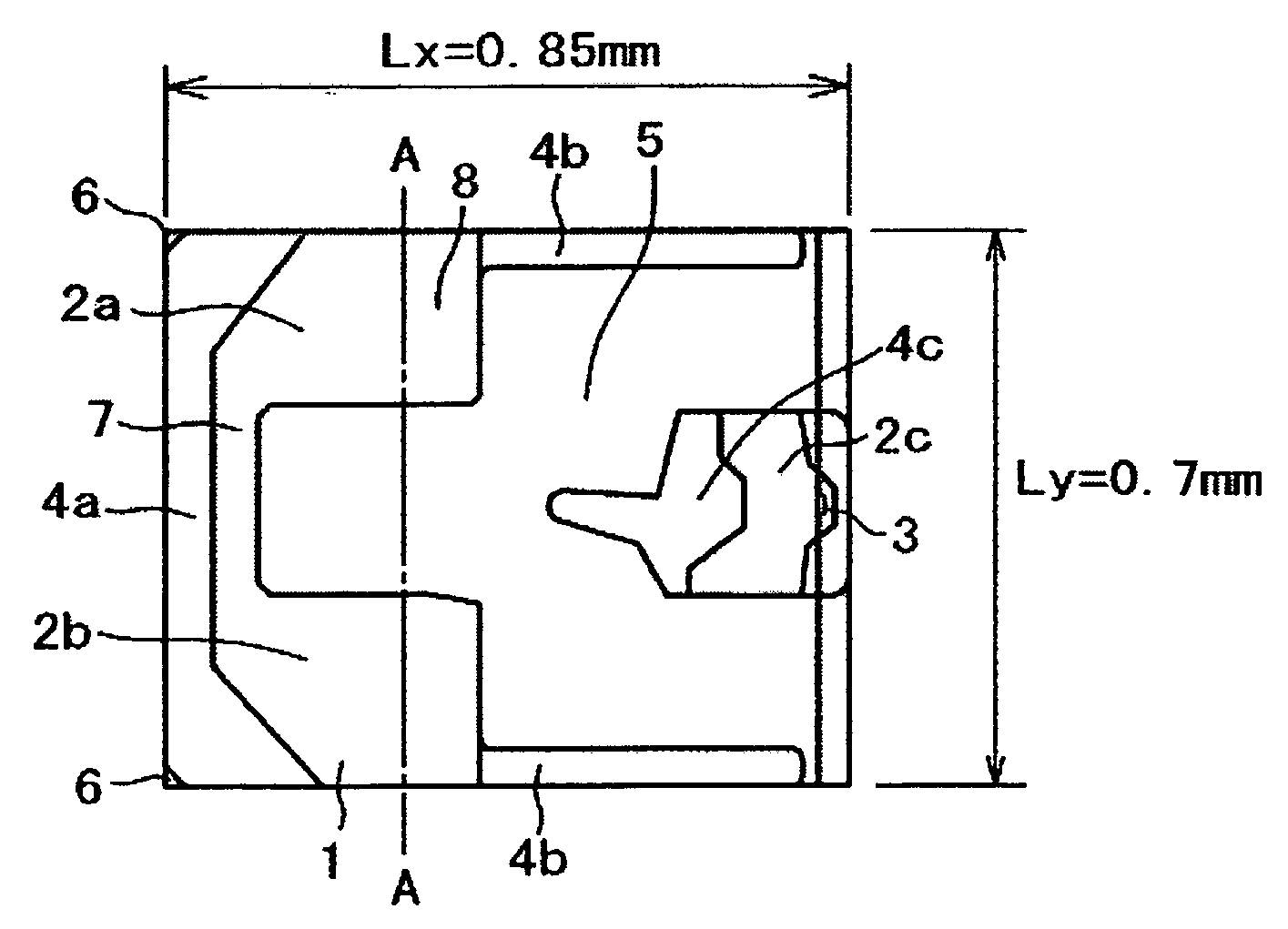

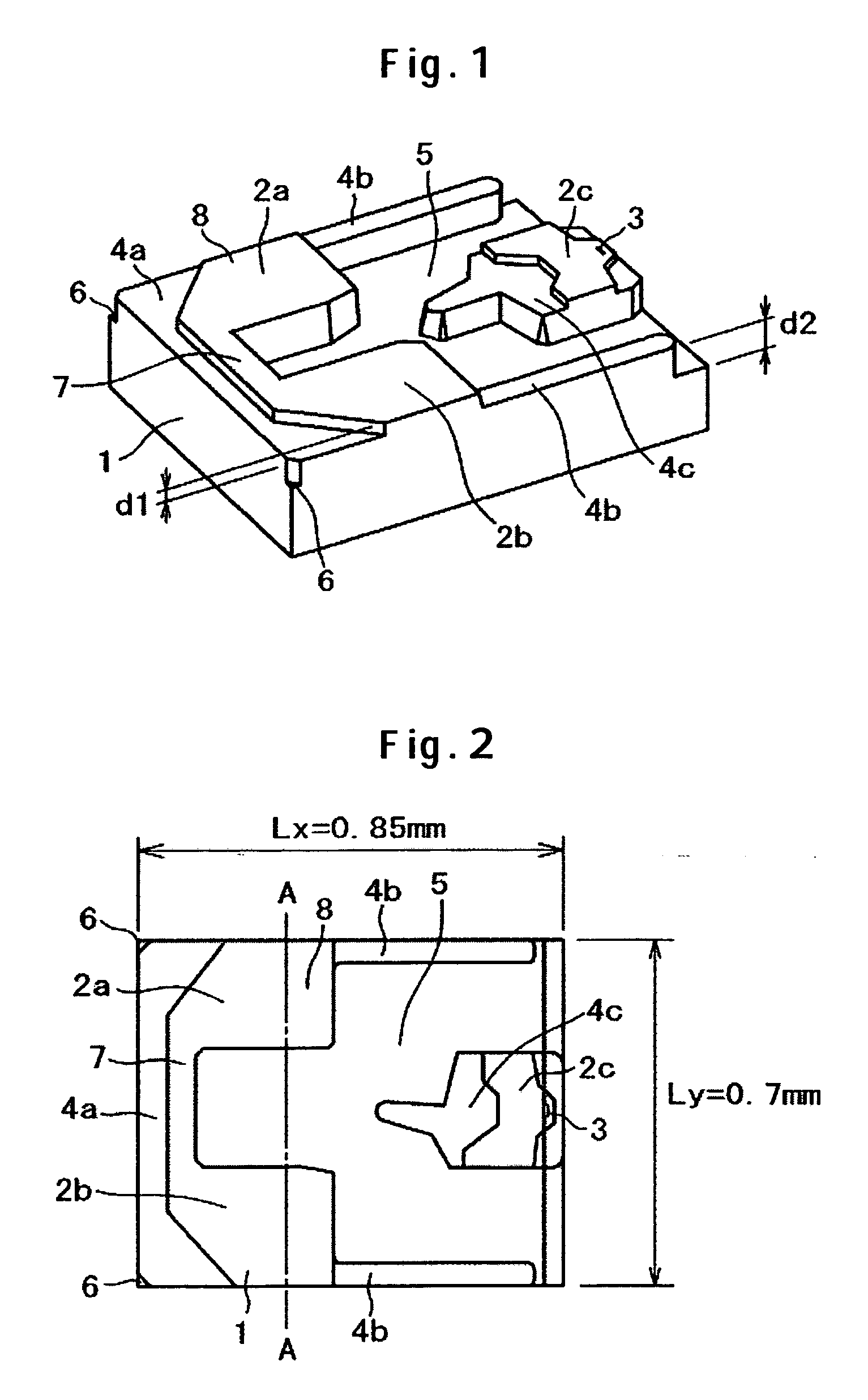

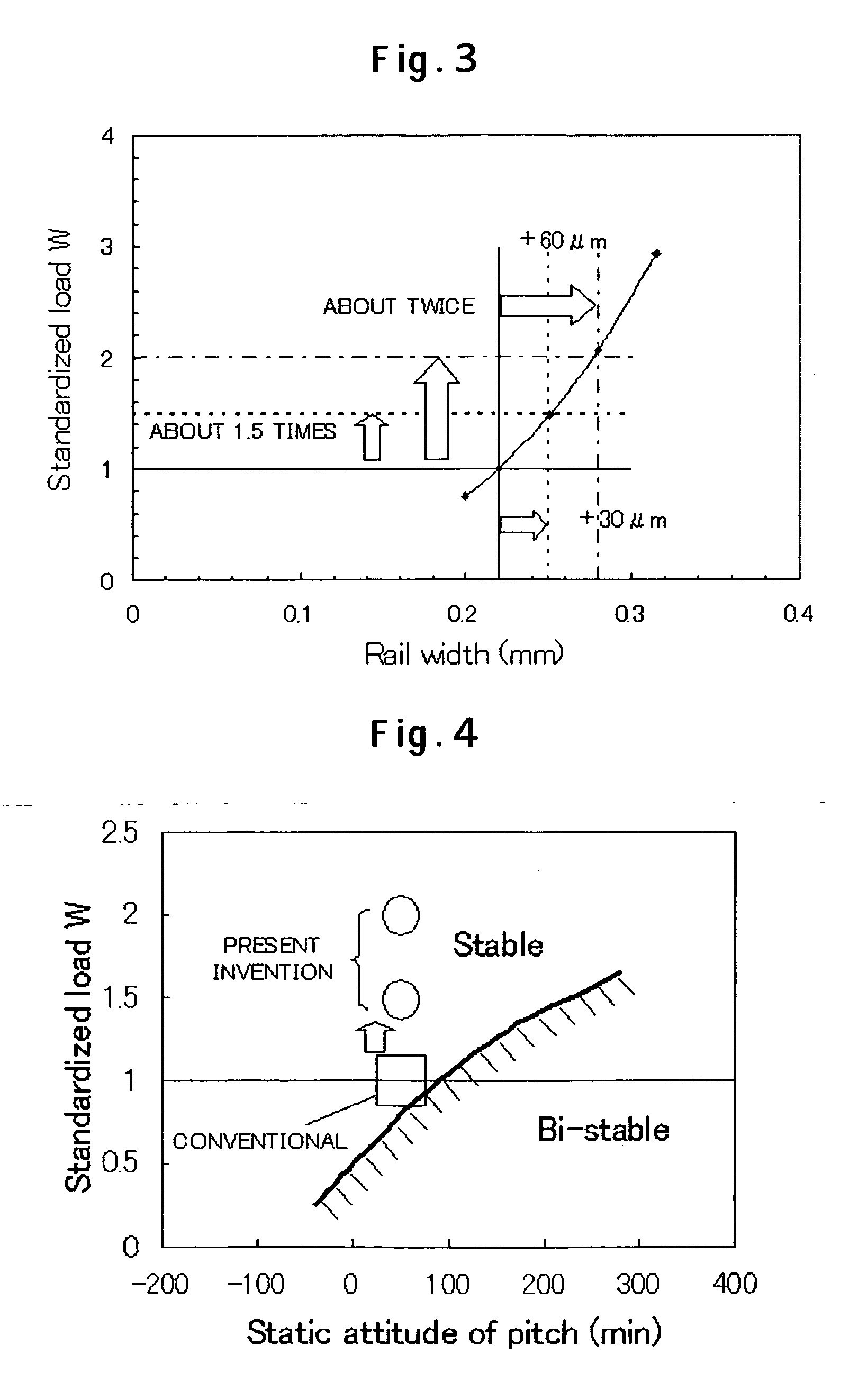

Magnetic head slider with reduced bearing surface area and magnetic disk drive

InactiveUS20060119986A1Pressing load is increasedReduce driving resistanceFluid-dynamic spacing of headsRecord information storageAir bearingEngineering

A compact slider has a reduced area of bearing surfaces, thus substantially decreasing a lifting force obtained through an air bearing characteristic. In one embodiment, a shallowly grooved surface and air bearing surfaces are disposed on an inflow side of a bearing surface of a slider. The air bearing surfaces are connected to each other through a connection air bearing surface. Side shallowly grooved surfaces are respectively disposed rearward of the air bearing surfaces. The side shallowly grooved surface extends up to a point near an outflow end. A center air bearing surface is disposed on the outflow end of the slider. A magnetic head is mounted on the center air bearing surface. A center shallowly grooved surface is disposed on an inflow side of the center air bearing surface. A deeply grooved surface is disposed at a center of the bearing surface. No cutting margins are provided on both sides of the slider. The air bearing surfaces on the inflow side therefore reach end faces in a width direction of the slider.

Owner:WESTERN DIGITAL TECH INC

Lever type online safety valve checking device

InactiveCN103822776AReduce the required powerReduce volumeMachine part testingHydraulic cylinderHydraulic pump

The invention discloses a lever type online safety valve checking device. One end of a V-type lower rod and one end of the other V-type lower rod are hinged to each other, the two ends of a supporting rod adjusting nut are supported by one end of an upper rod and one end of each lower rod, a groove in a supporting rod upper bolt is hinged to one end of the upper rod, a tension sensor is arranged on the middle point of the upper rod, an iron chain and a clamping device with clamping heads provided with transverse tooth-shaped patterns are hung below the upper rod, a manual hydraulic pump is connected with a single-action hydraulic cylinder, the hydraulic cylinder is located on the open end of the lower rods through a hydraulic cylinder holding board, a hydraulic cylinder ejector rod is in contact with the upper rod, a displacement sensor is installed at the bottom of the hydraulic cylinder, a safety valve body is arranged in protruding V shapes of two pressing rods, and a valve neck of a safety valve is clamped by a locking device; the clamping device can clamp a valve rod of the safety valve, the valve rod of the safety valve and the tension sensor are coaxially arranged, and the displacement sensor and the tension sensor are connected with a data processor through data cables. According to the lever type online safety valve adjusting device, the valve rod is lifted according to the lever principle, the power and the size of a lifting mechanism are effectively reduced, checking is rapid and accurate, the application range is wide, and the checking efficiency can be effectively improved.

Owner:HANGZHOU SPECIAL EQUIP INSPECTION & RES INST

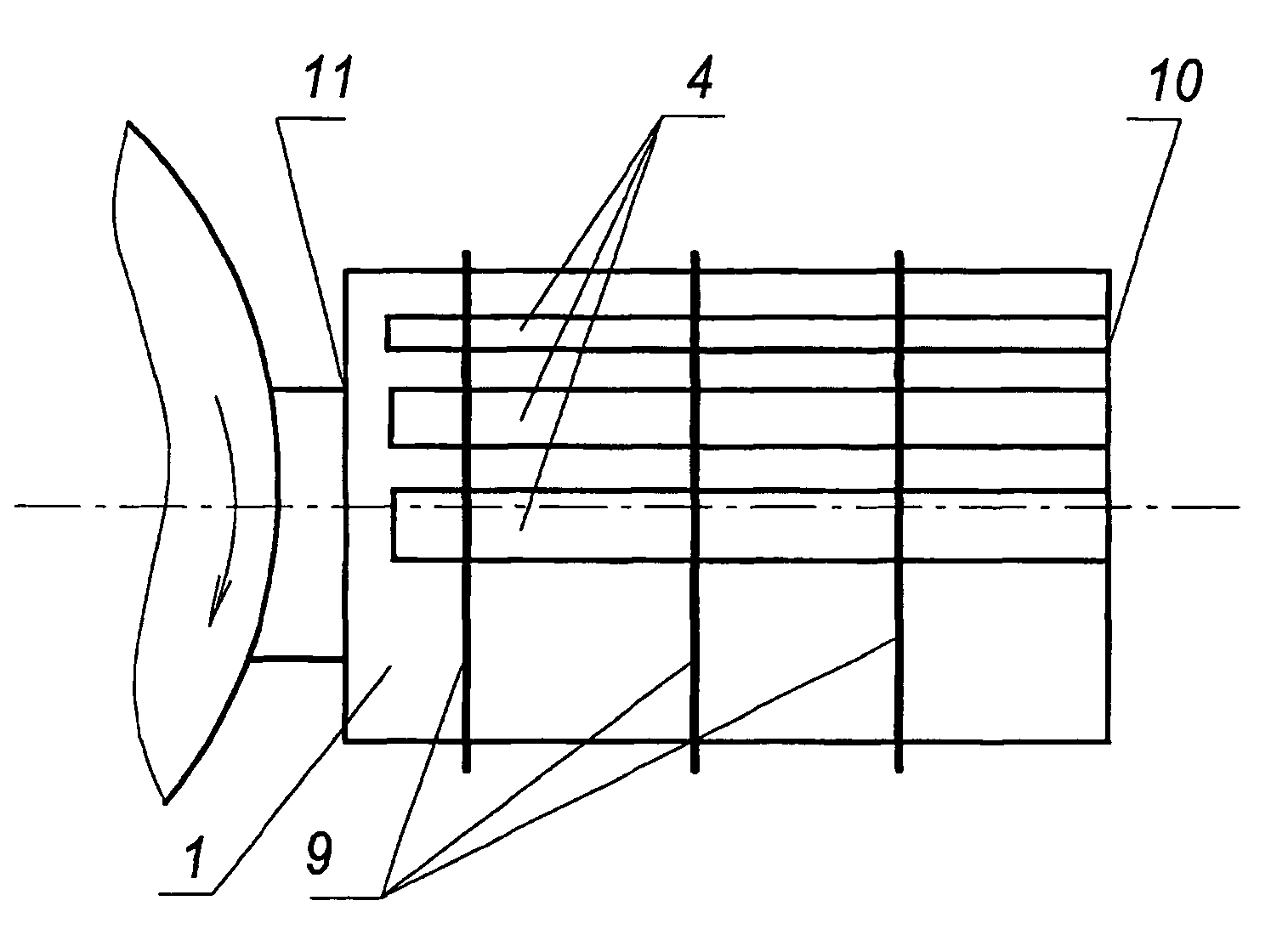

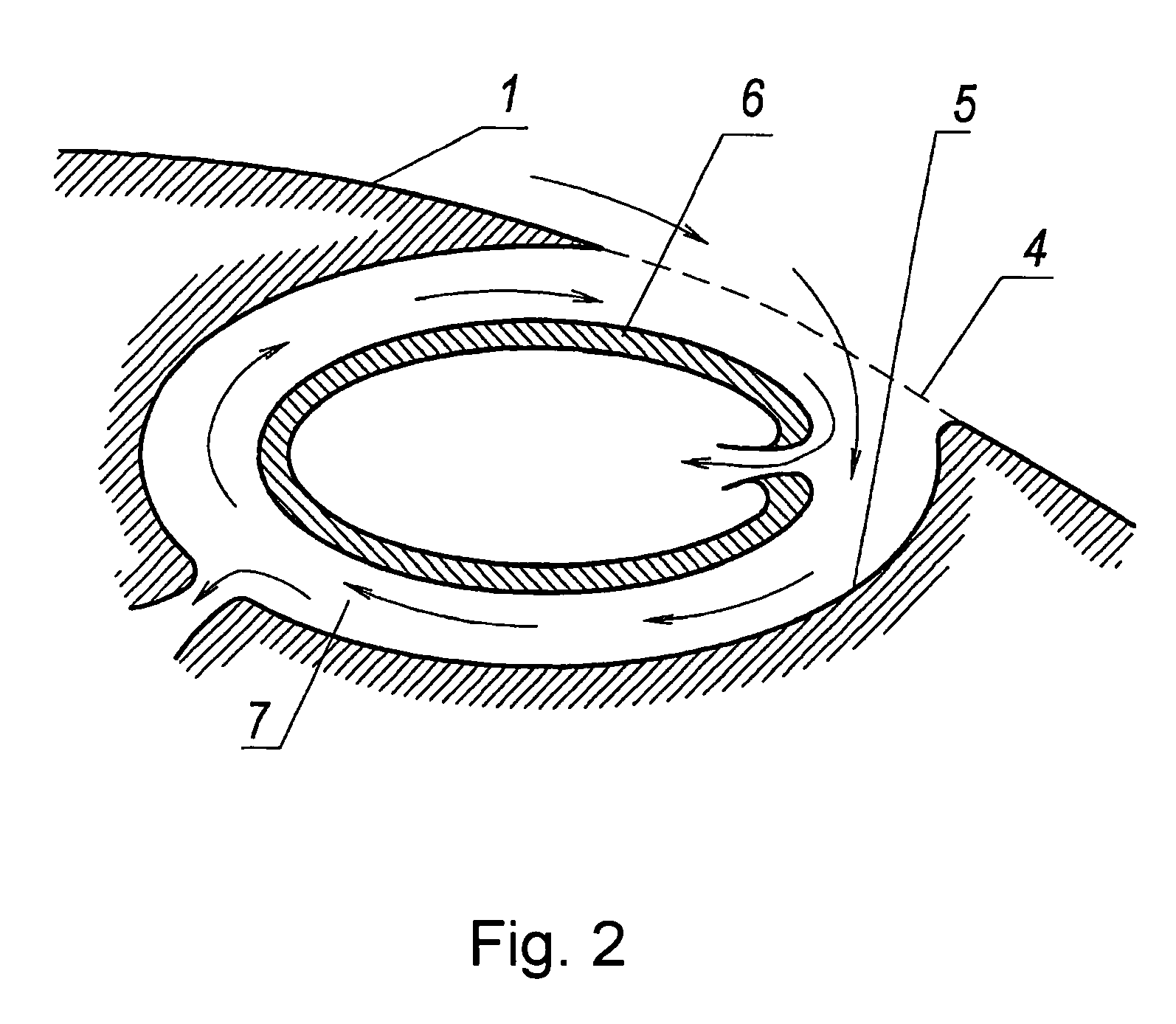

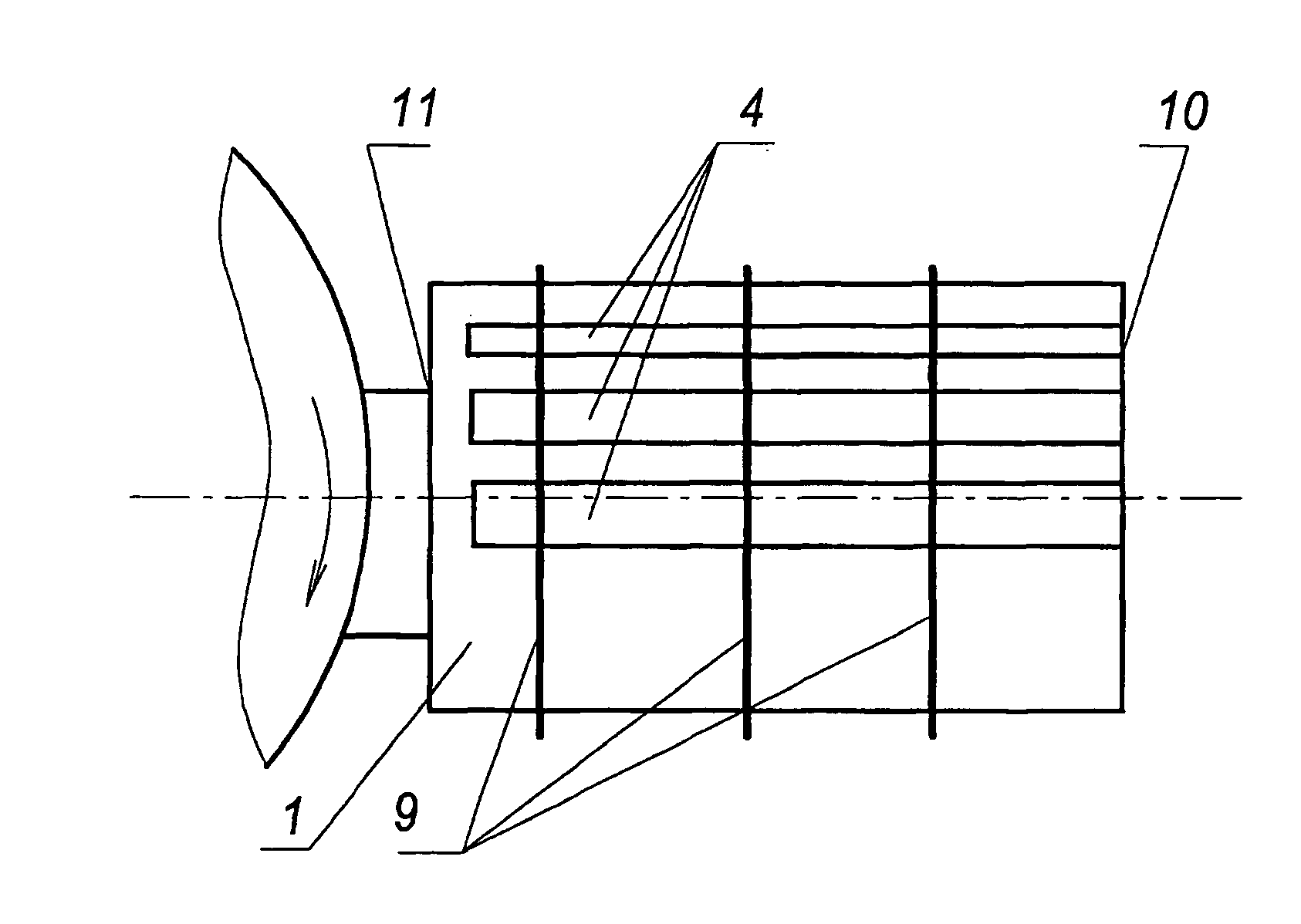

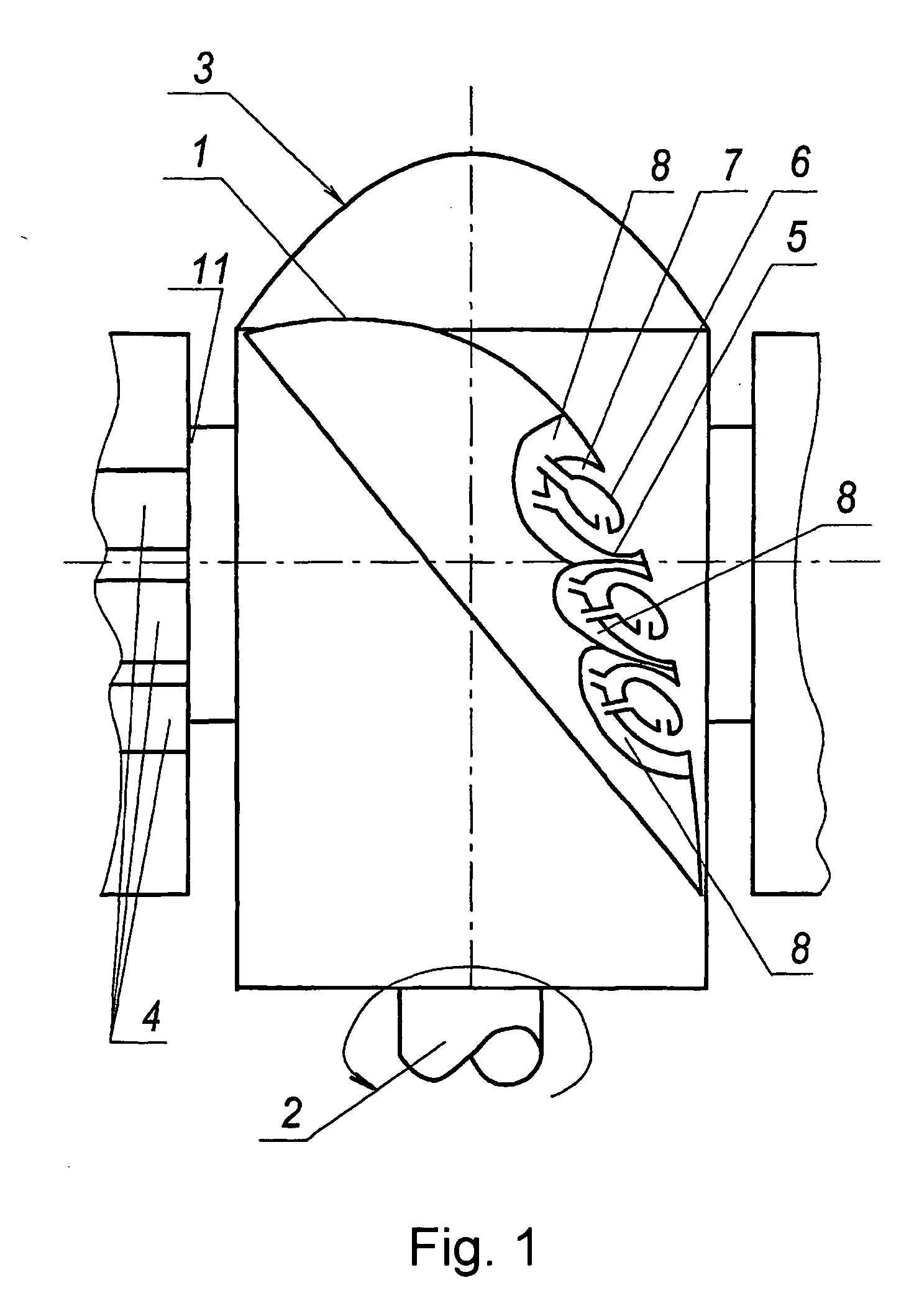

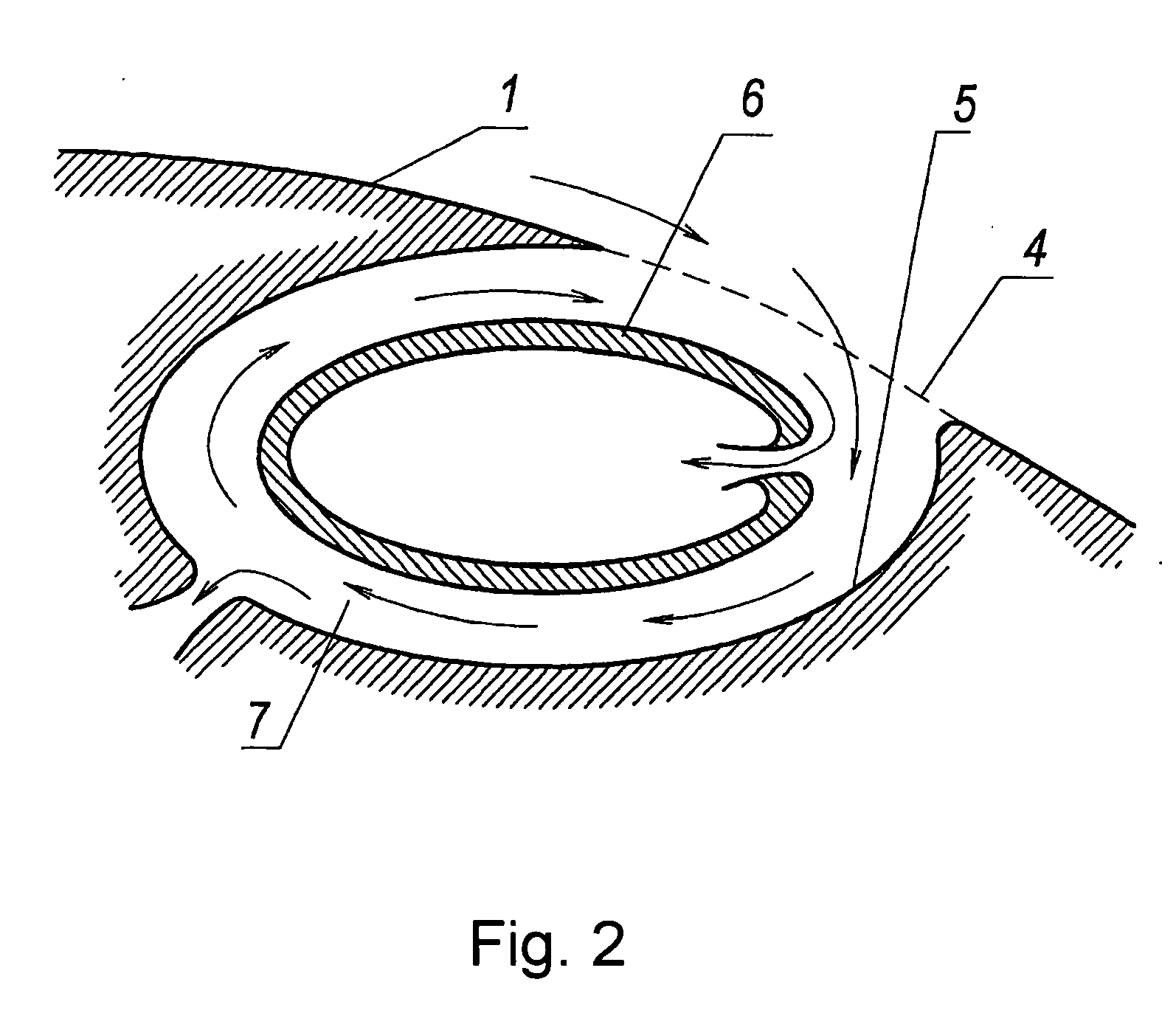

Method for increasing a blade performance (variants)

InactiveUS7520722B2Improve performanceReduce energy consumptionPropellersRotary propellersMachine buildingEngineering

The invention relates to machine building in particular to blade machines for air injection, in particular to fans and air blowers, and also to blades of different propulsion devices. The inventive method for increasing the blade (1) performance consists in producing a blade (1) in the form of a wing and in carrying out the boundary layer suction on the blade 1 surface on the opposite side with respect to the incoming air flow through a system of slotted holes (4). The blade (1) is provided with a thick airfoil profile. The air suction is carried out through the system of slotted holes (4) embodied along the blade (1) and into cavities (5) which are embodied under said holes (4) along the latter and each of which is provided with a central longitudinal hollow body arranged therein, said body forming an annular channel (7) in each cavities (5) in such a way that a vortex-like flow is generated by the incoming air flow in said channel. The air is sucked out from the cavities (5) and the central bodies (6) through branch channels (8). The latter are used to discharge air outside of the blade (1). The air flowing-off along the cavities (5) and along the blade 1 is limited within the cavities (5) by mounting partitions and on an external surface of the blade (1)—by mounting ribs (9). In another embodiment of the method, the cavity is embodied without the central body (6). As a result, the invention makes it possible to increase the blade performance.

Owner:LNS WINDBLADE TECH LLC +1

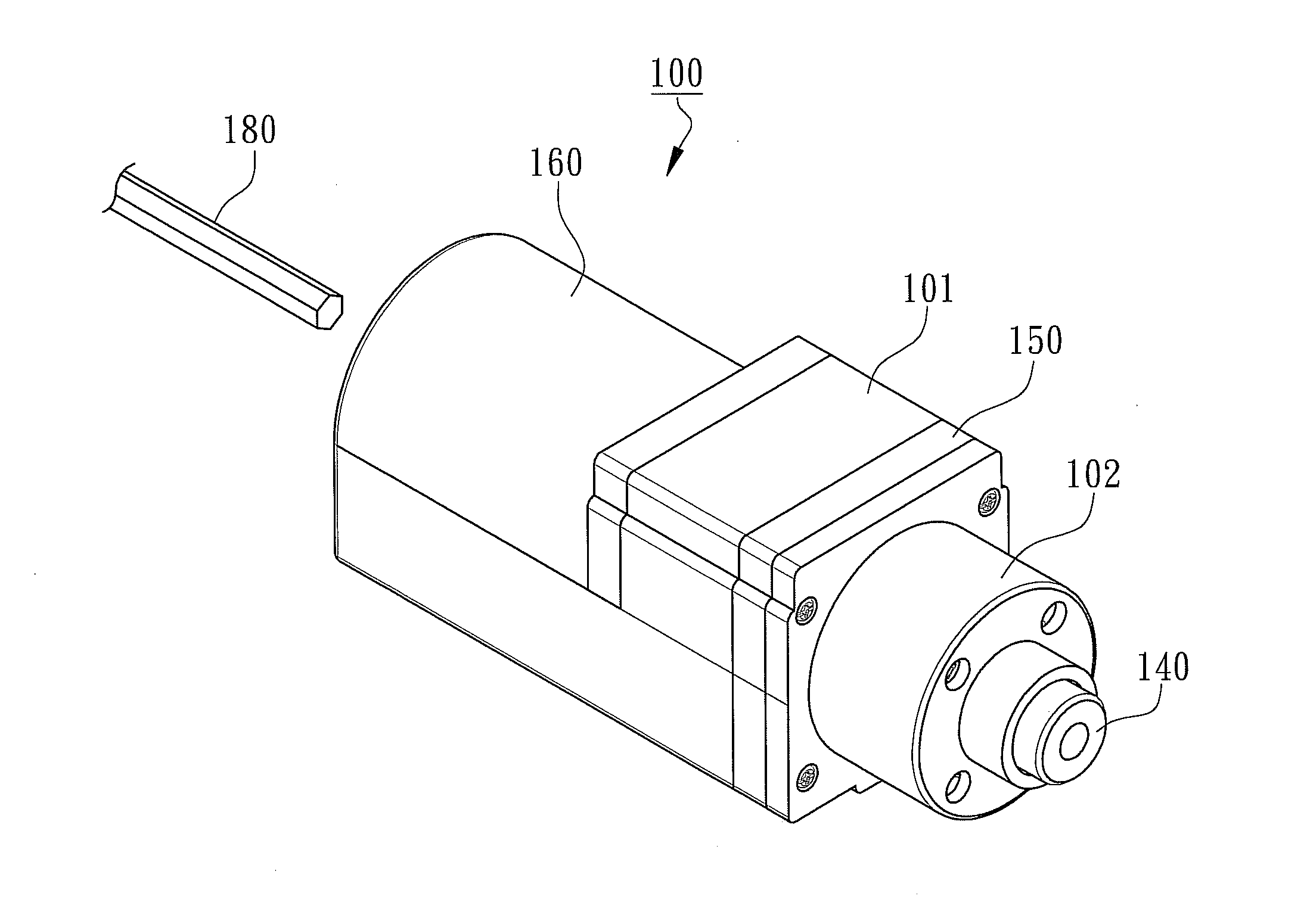

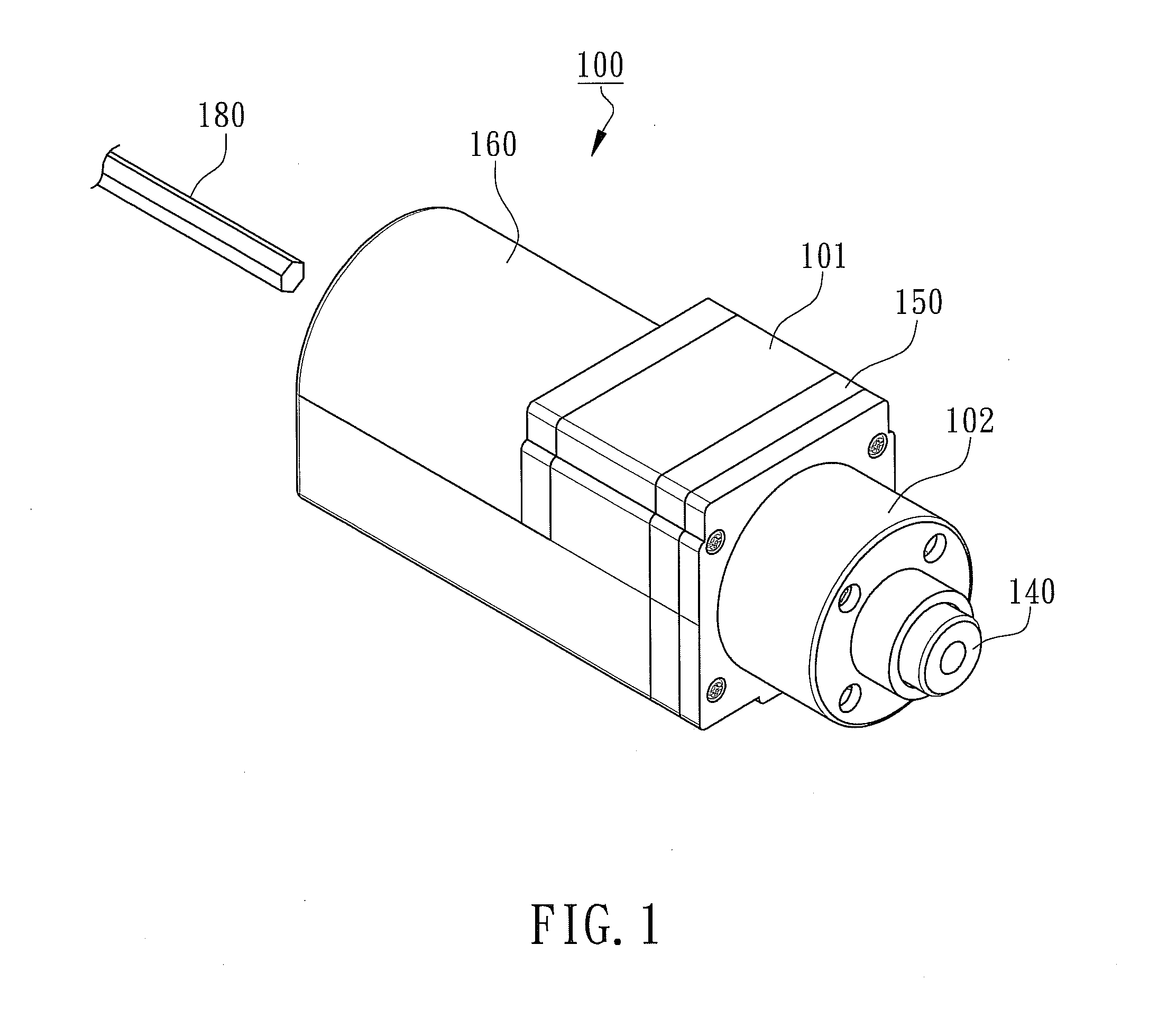

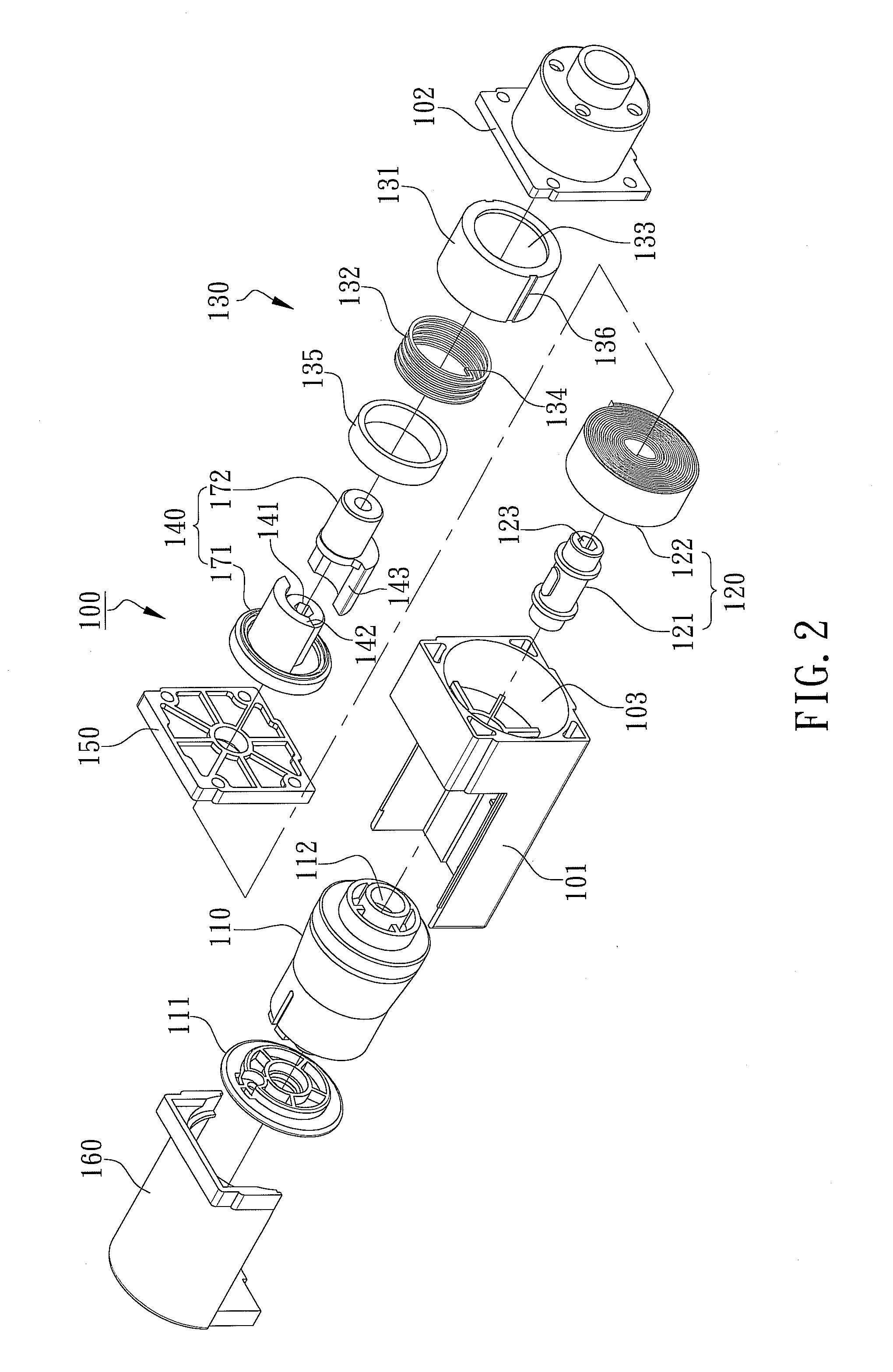

Blind cord winder integrating with stopping control

InactiveUS20140061354A1Easy component integrationEasy to installDoor/window protective devicesFilament handlingEngineeringVolute spring

Disclosed is a blind cord winder integrating with stopping control to allow open / close operation of the cordless blind to lift or lower the cordless blind at any positions according to user's needs. The winder primarily comprises a spool installed inside a first compartment, a force-feedback mechanism, and a braking cushion mechanism installed inside a second compartment where the force-feedback mechanism is installed in a shaft cavity of the first compartment. The force-feedback mechanism includes a shaft sleeve and a volute spring. The braking cushion mechanism includes a friction ring, a friction spring, and a trigger sleeve. The friction ring is immovably installed inside the second compartment. The friction spring is tightly plugged into the friction ring and has an extrusion end for the trigger sleeve to trigger friction variation in a single directional rotation of the trigger sleeve.

Owner:WU WEN YU

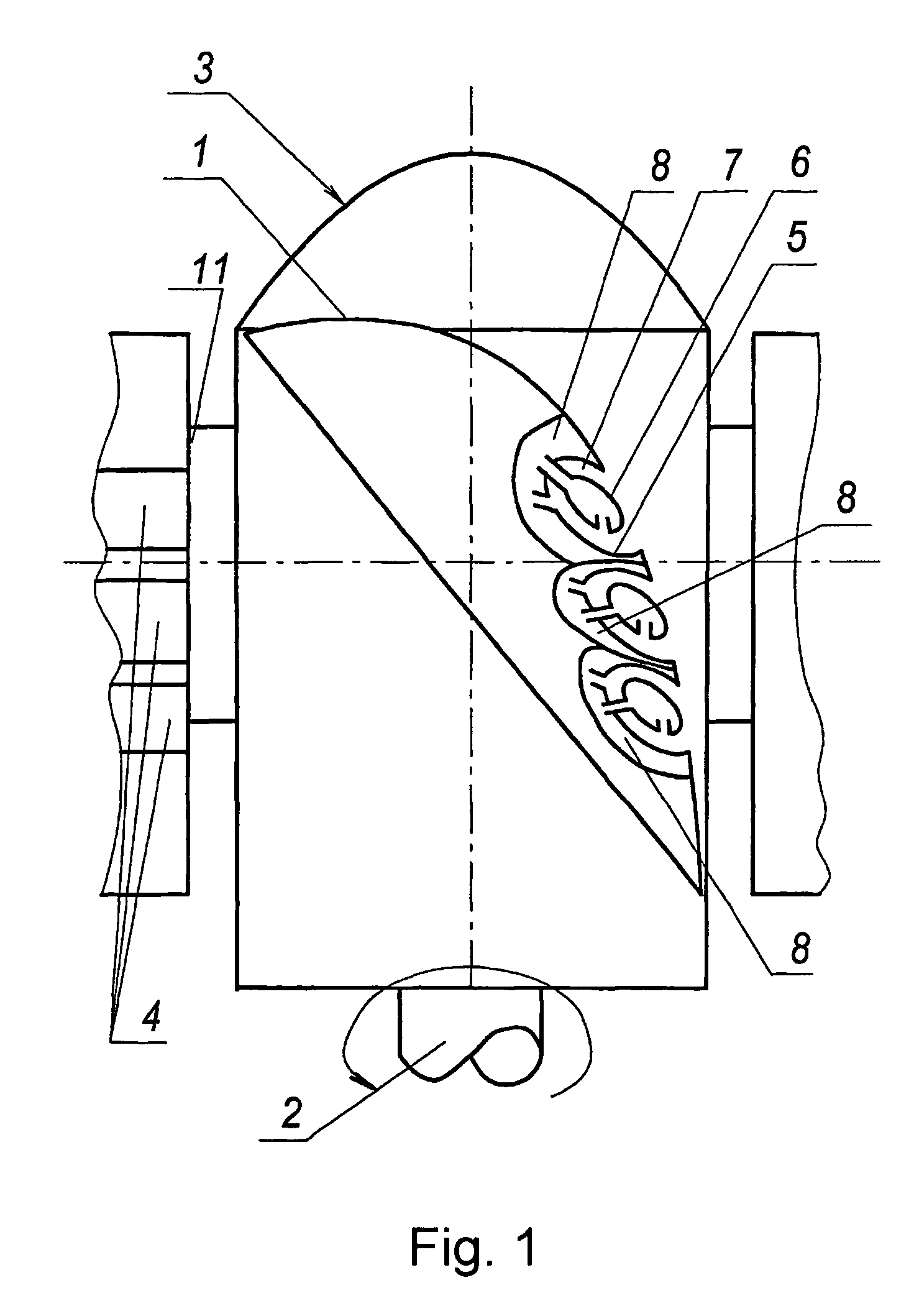

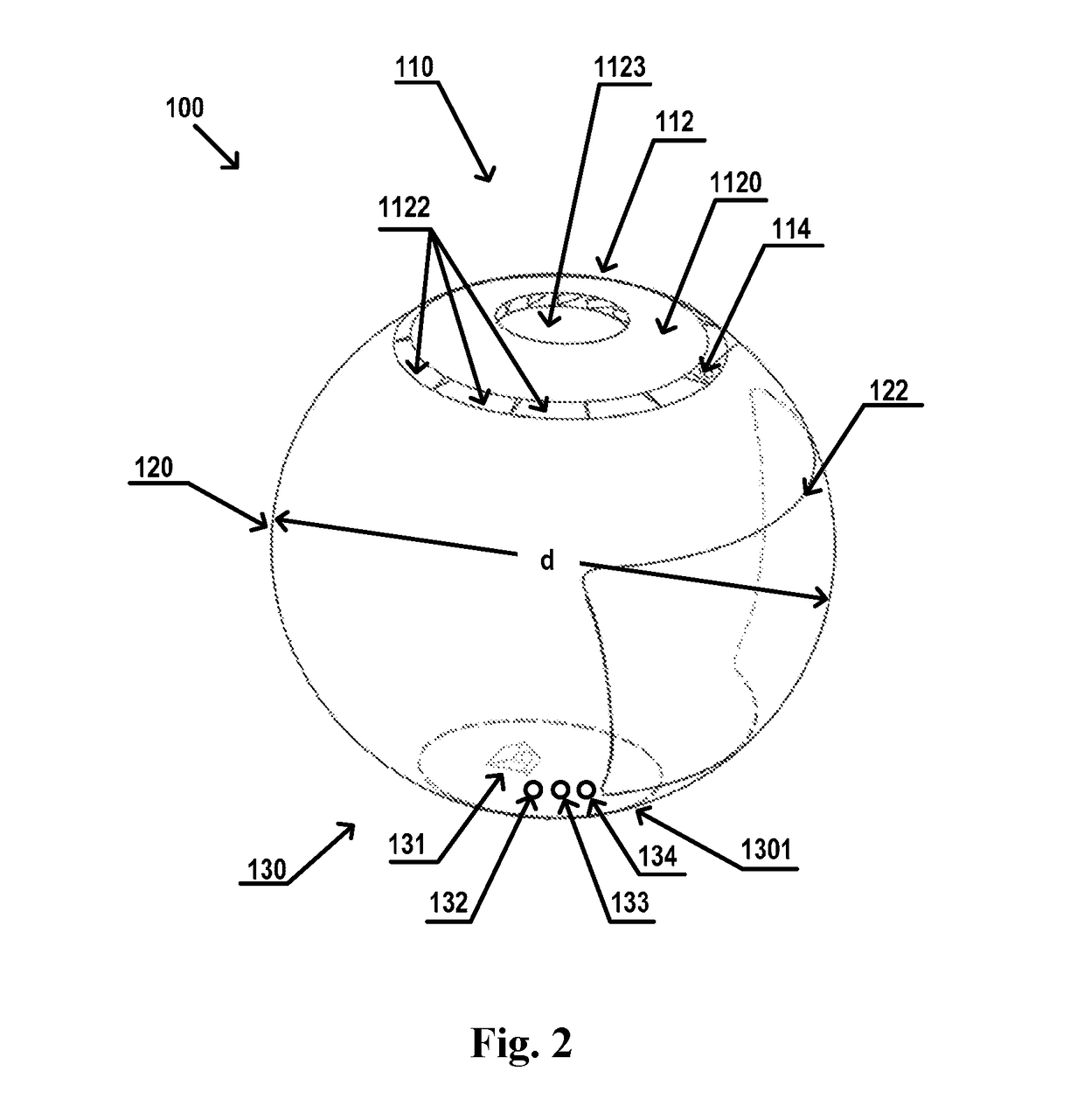

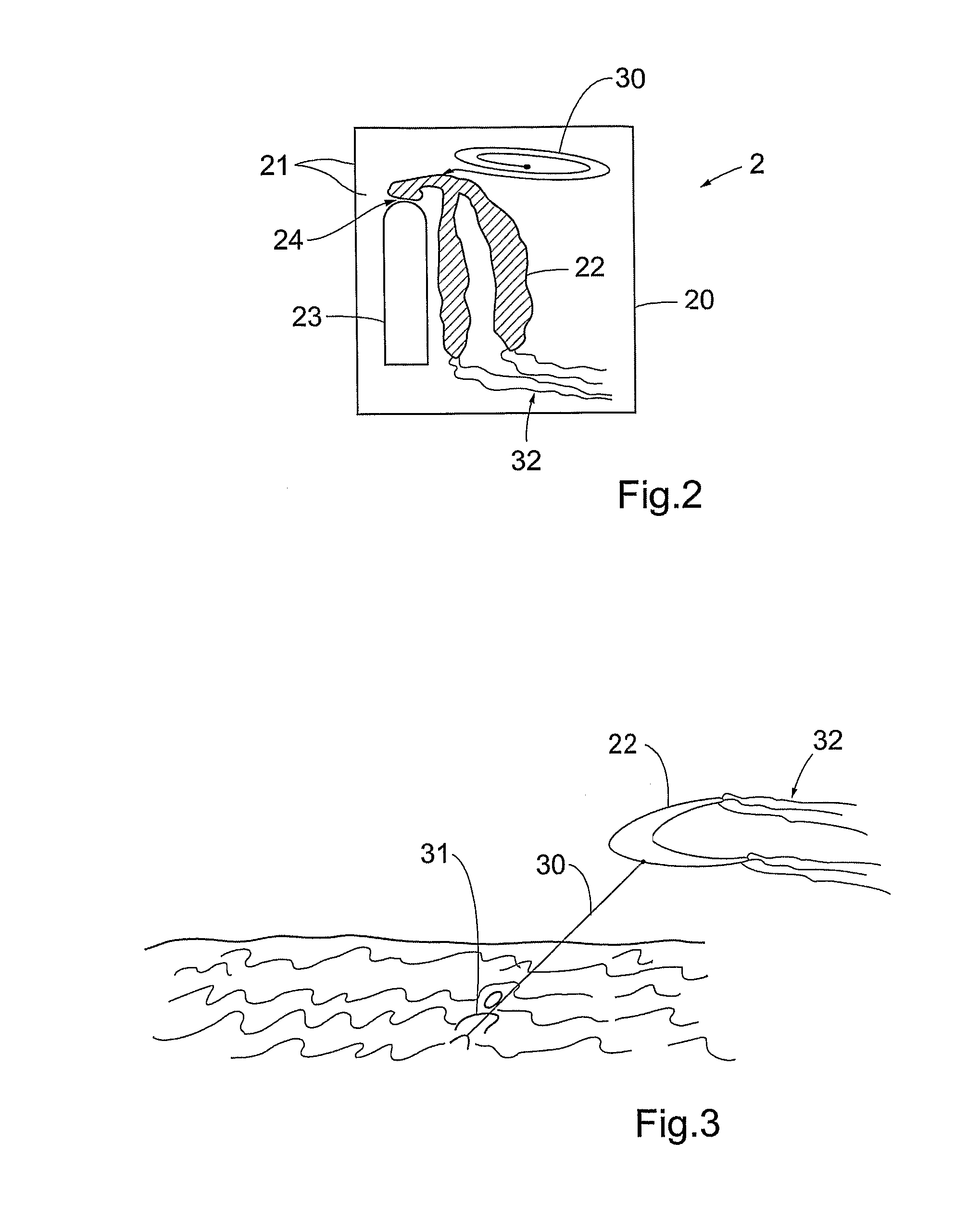

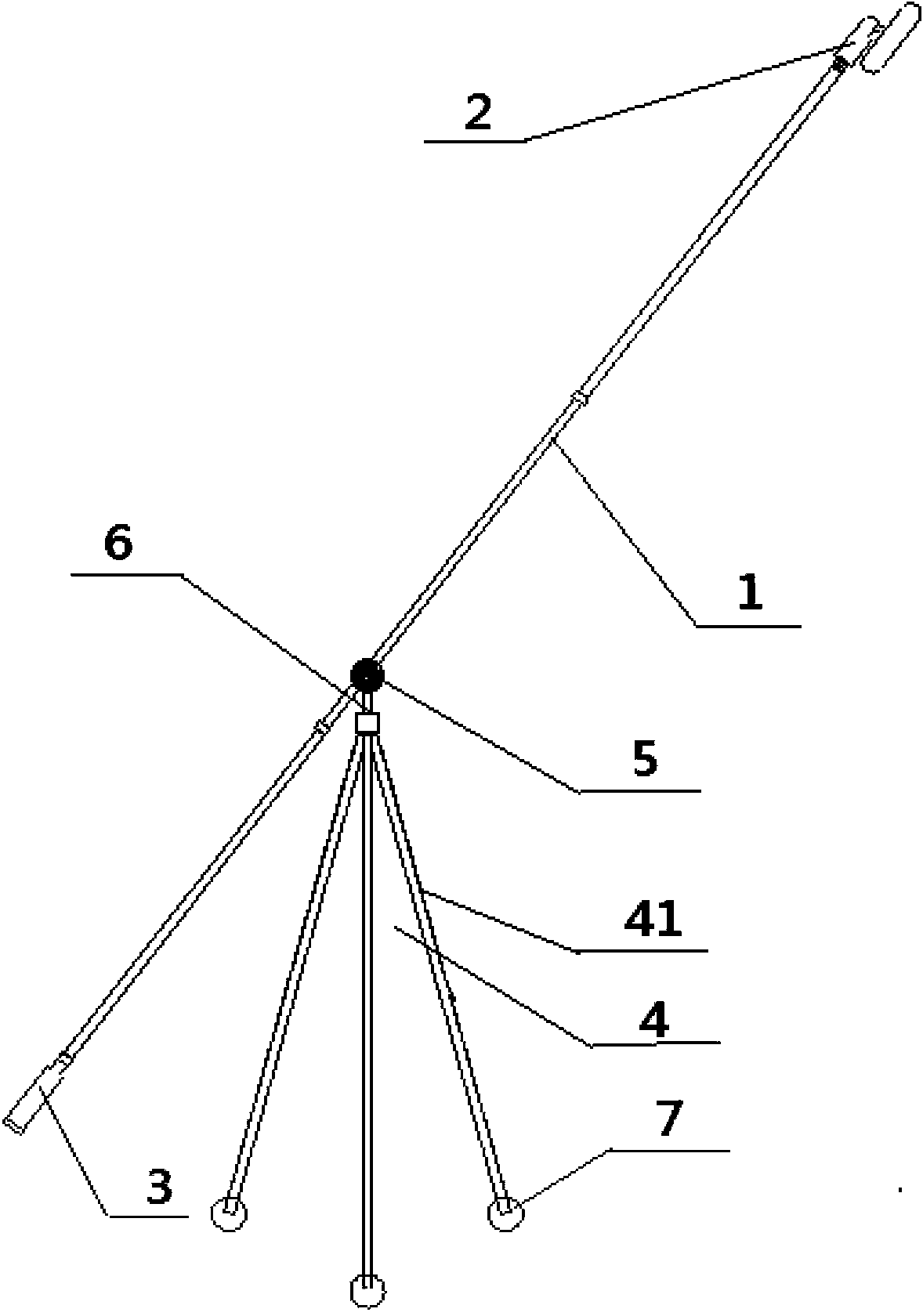

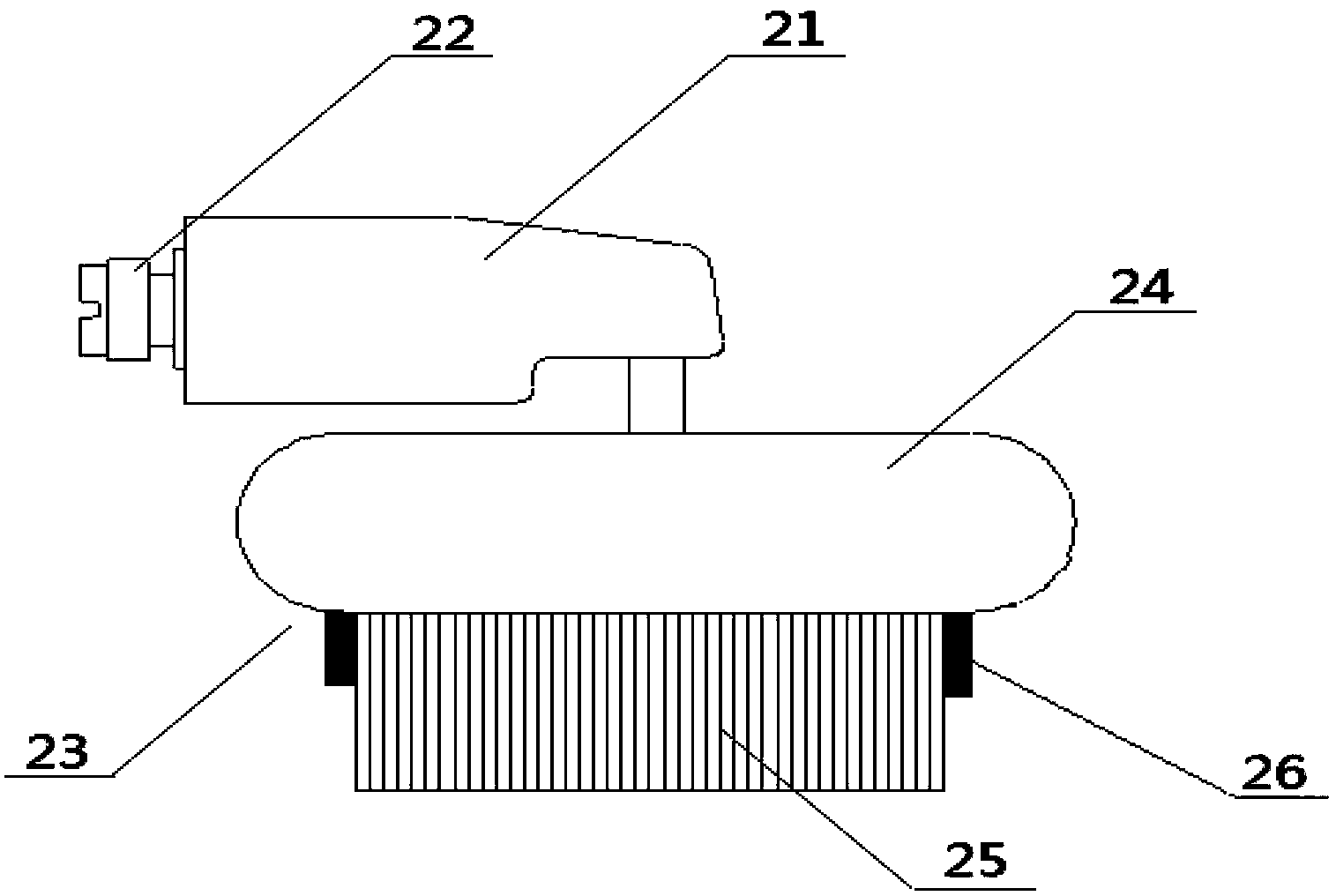

Flying robot provided with projector

ActiveUS20180229828A1Long flight durationFacilitating human-machine interactionPrintersUnmanned aerial vehiclesFilm materialLift system

The present invention provides a flying robot (10) with projector, including a movable end (100) and a fixed end (200). A distributed working mode is used on the movable end (100) and the fixed end (200). The movable end (100) includes a top (110), a main body (120) and a bottom (130). The top (110) includes a lift system (112) and one or more proximity sensors (114); the main body (120) is a sealed hollow spherical body or spheroid body made of a film material capable of being used as a rear projection screen, and is filled with a gas of which the density is less than that of the air. The bottom (130) includes one or more rear projectors (131), a wireless communication module (132), a microcontroller (133), a battery (134), a direction and steering controlling device (135), a camera device (136), a sound capturing and reproduction device (137), a height sensor (138) and other sensors, etc. The fixed end (200) includes a wireless communication module (220), a control apparatus (240), a charging port (260), and other data interfaces, etc. The flying robot (10) with projector according to the present invention facilitates human-machine interaction and is suitable for being used in both indoor and outdoor environments.

Owner:X CONTROL SYST CO LTD

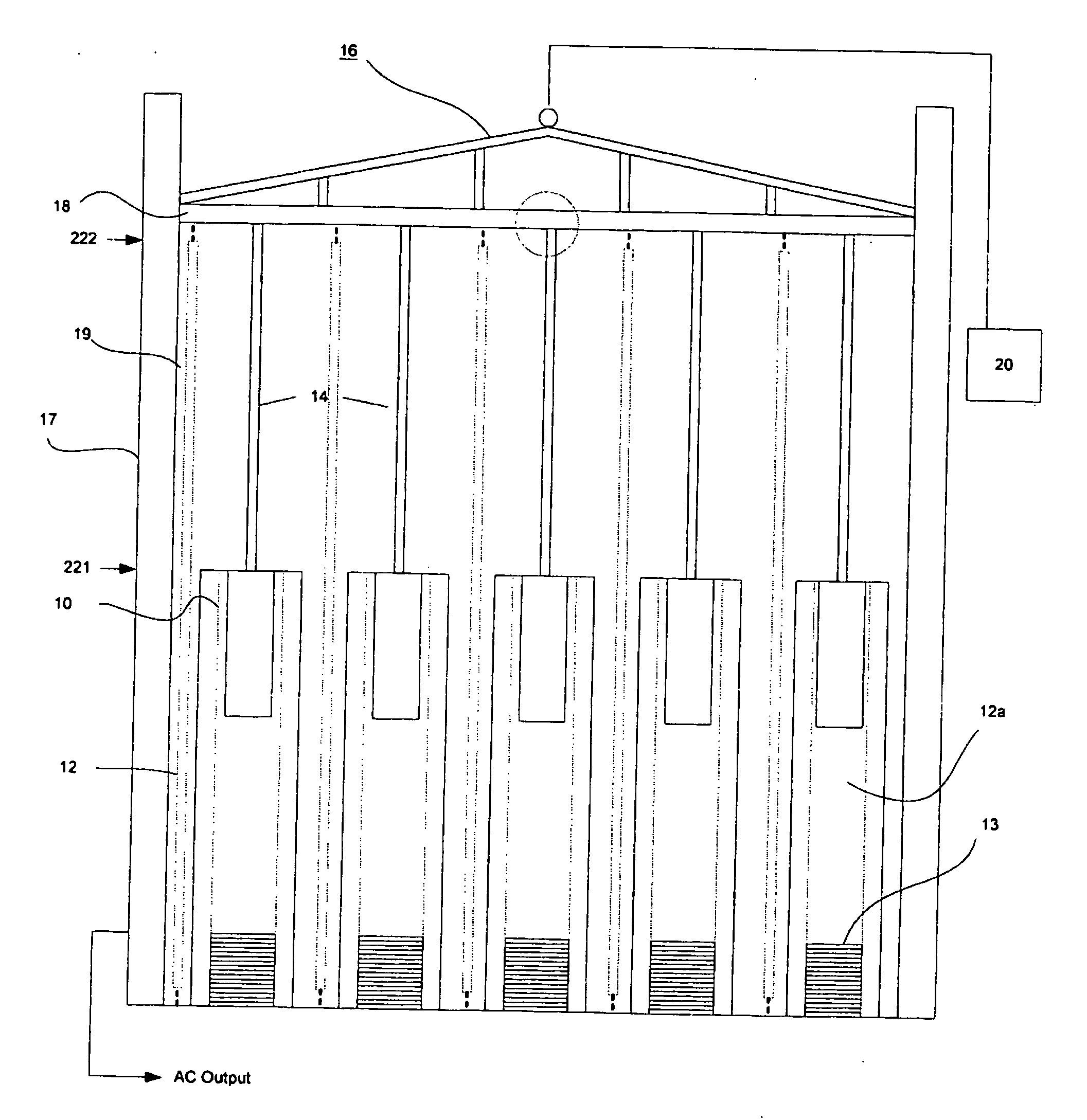

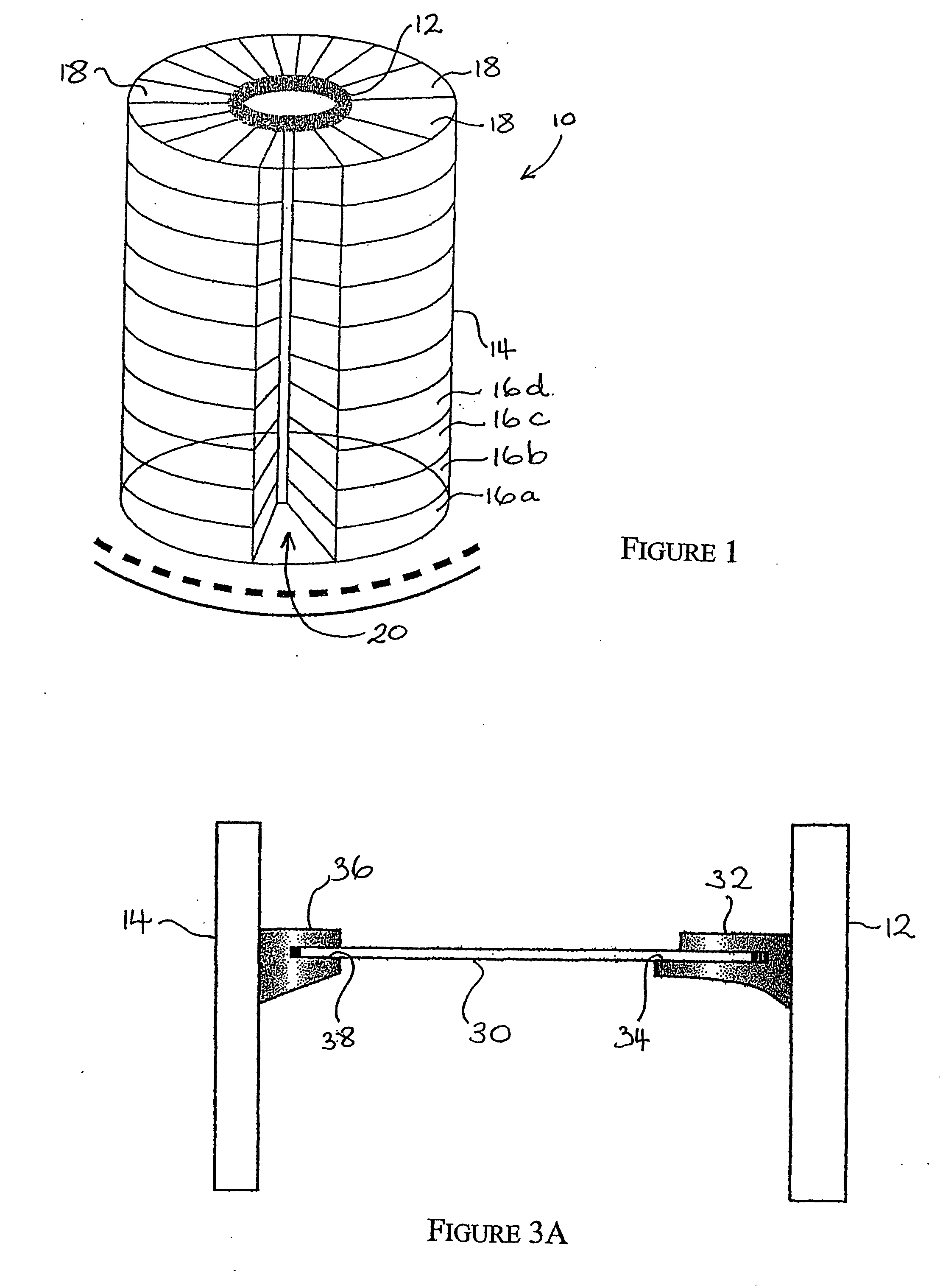

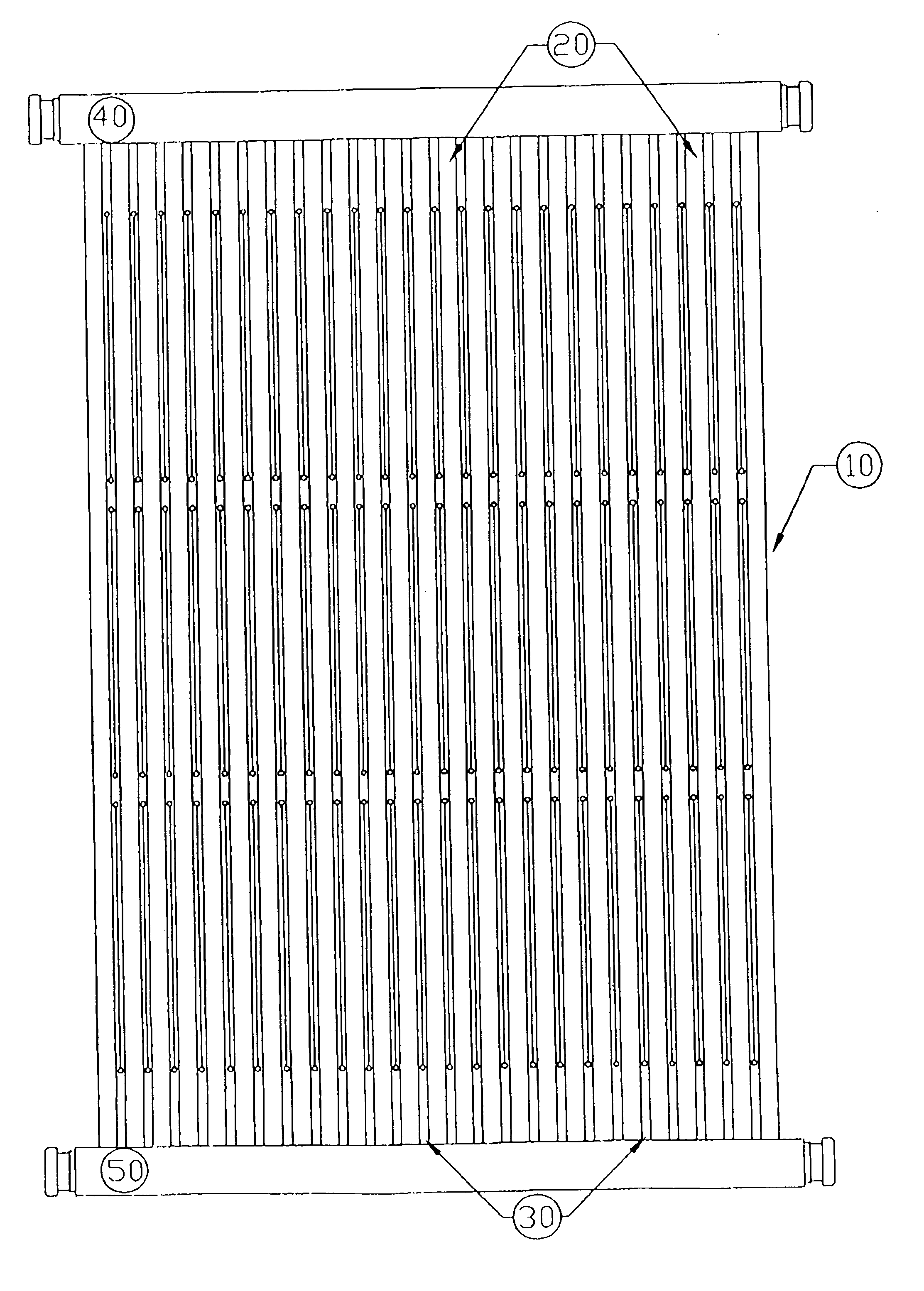

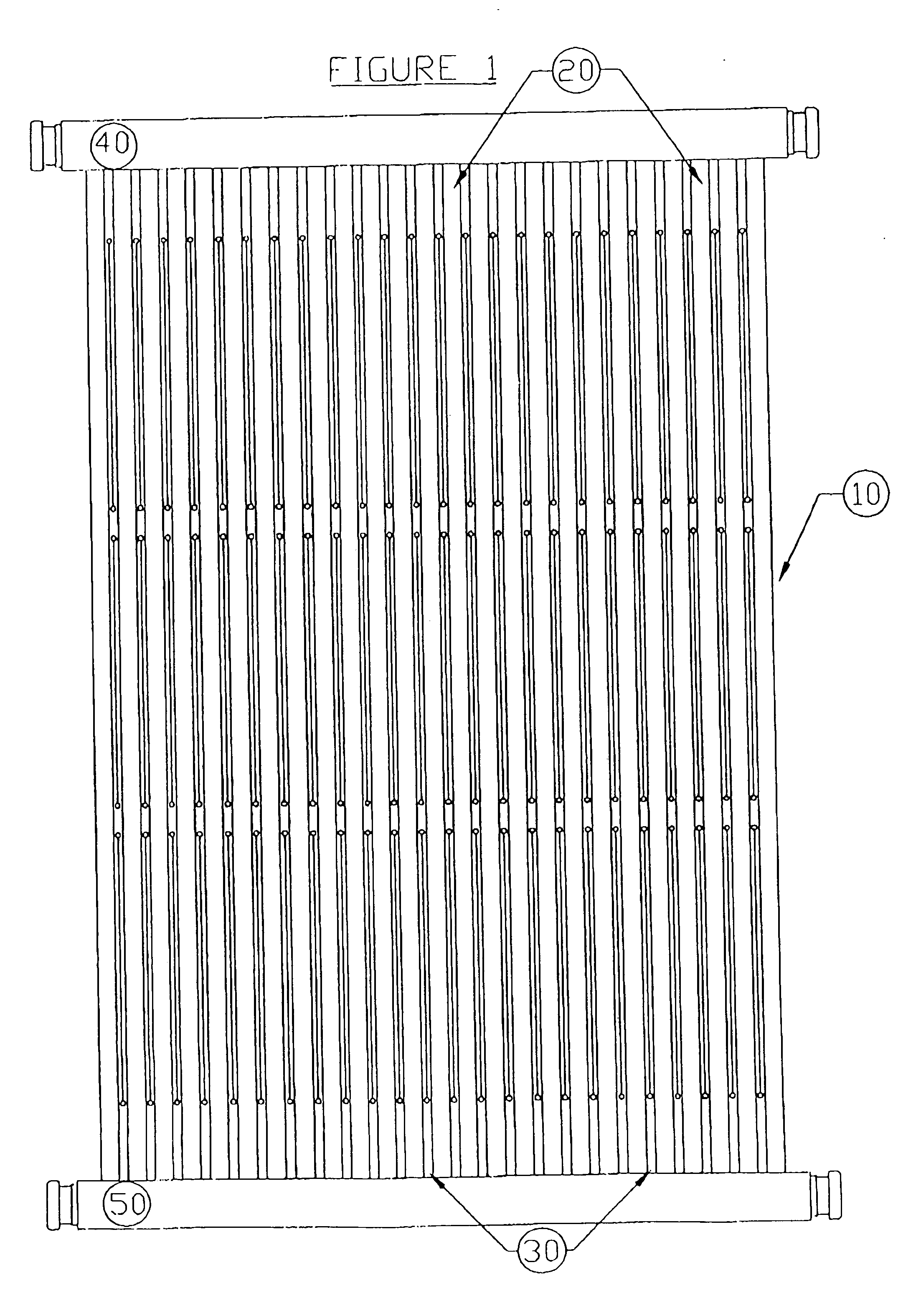

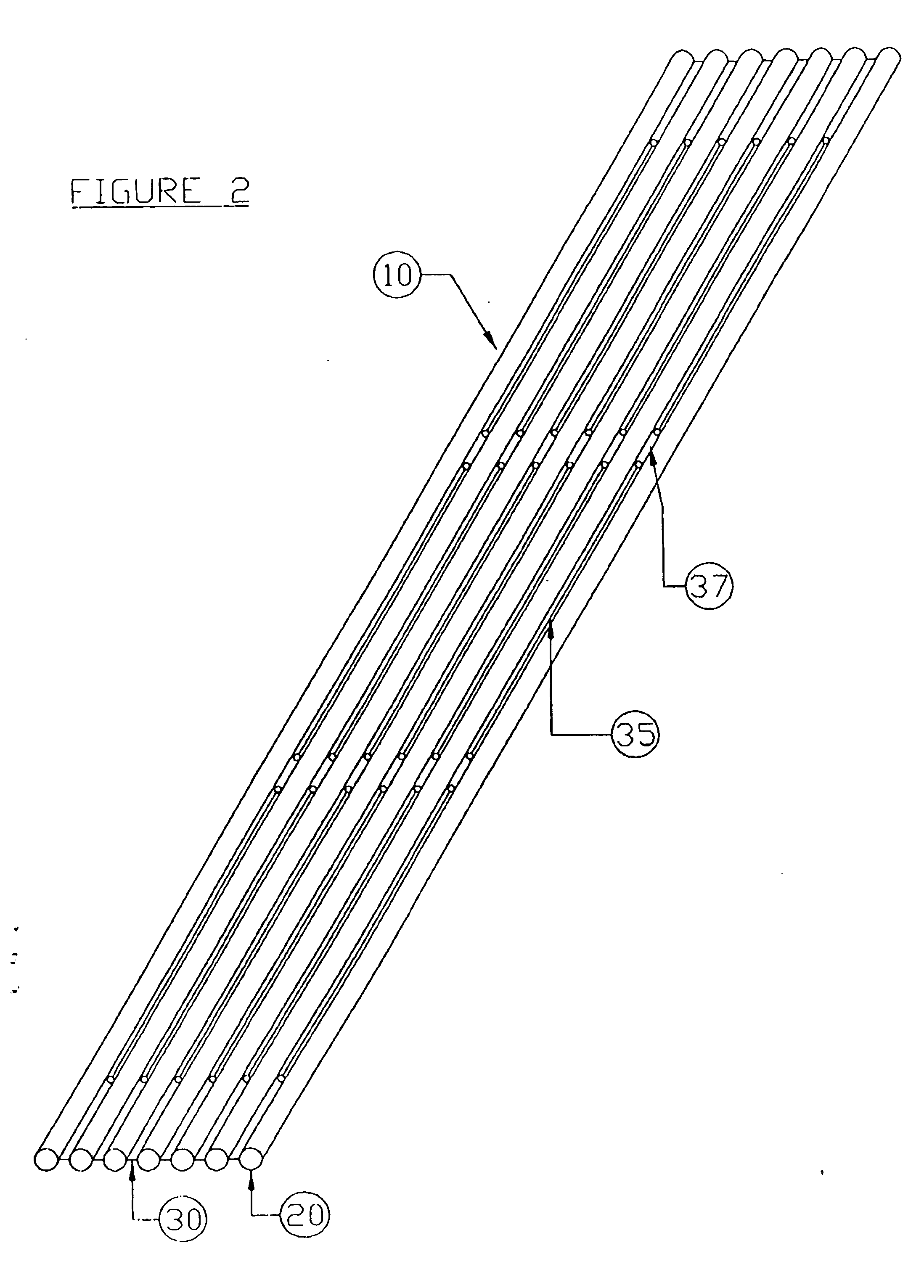

High efficiency tube mat solar collector having intermittently separated tubes and method for preventing damage to a solar collector

ActiveUS20060048771A1Reduce lifting forceSolar heating energySolar heat devicesEngineeringSolar energy harvesting

A solar collector including a plurality of hollow tubes, each tube directly joined, or indirectly joined by a web, to an adjacent tube; a first manifold connected to a first end of each tube; a second manifold connected to a second end of each tube; where at least two adjacent tubes are separated along a portion of their length so as to form a first section in which adjacent tubes are separated from one another and a second segment in which adjacent tubes are joined to one another. Also disclosed is a method for preventing damage to a tube mat solar collector which includes maintaining the hollow tubes of a solar collector in a substantially coplanar relationship in the absence of high wind conditions; permitting individual tubes to move about their longitudinal axis in response to high wind conditions; and returning the tubes to their longitudinal axis as the high wind conditions subside, the high wind conditions being wind of at least 15 miles per hour.

Owner:AQUATHERM INDS

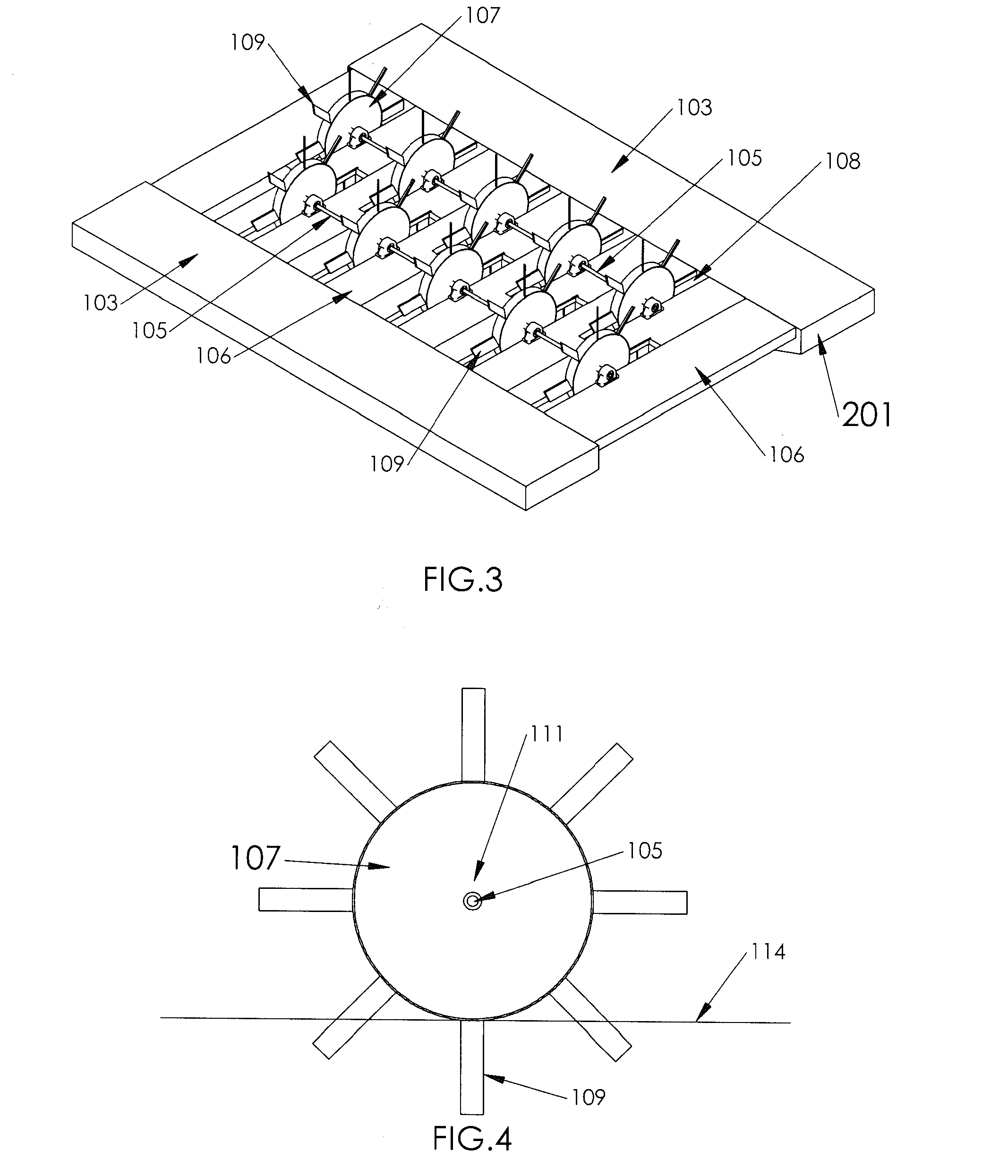

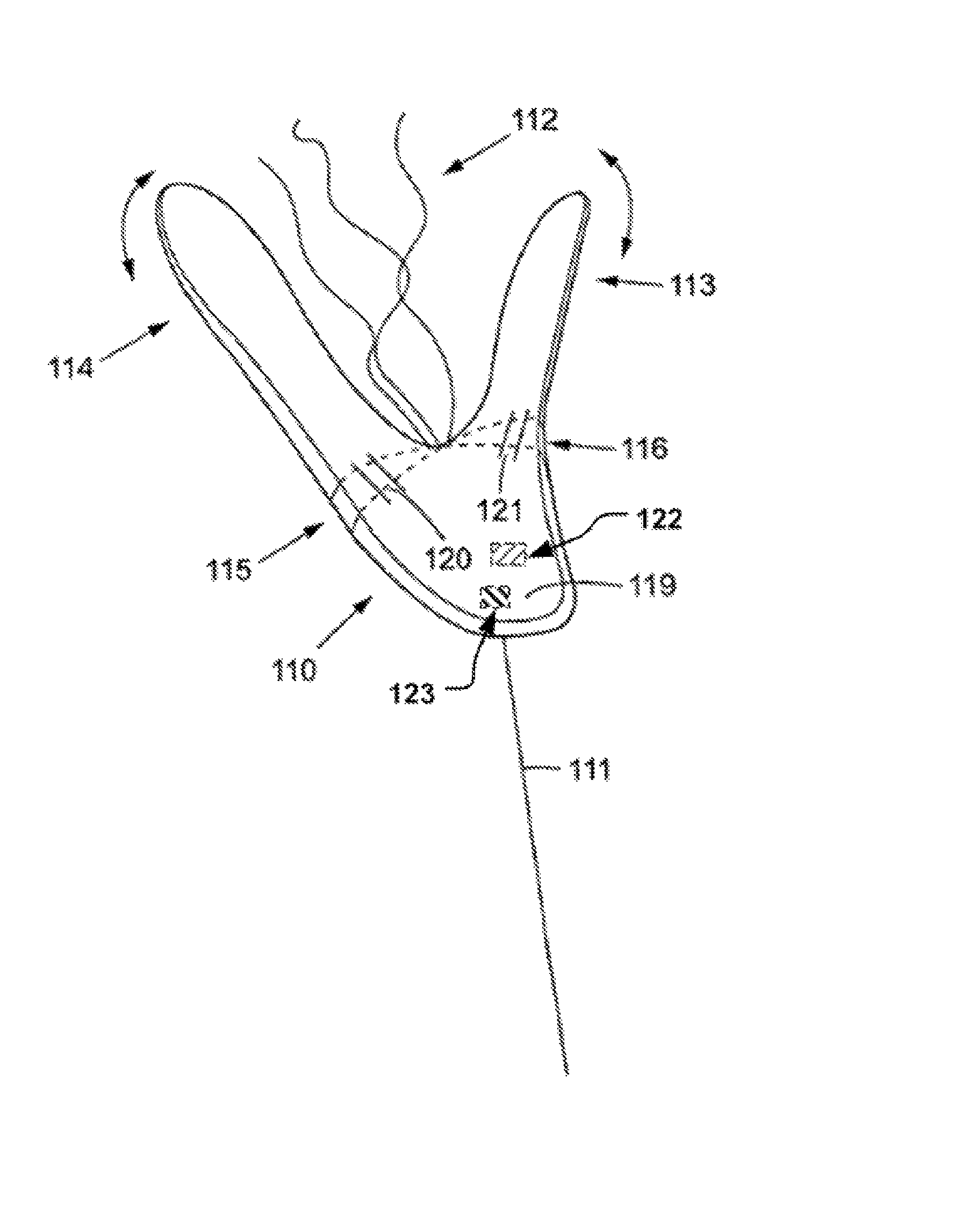

Surface piercing tidal generator

InactiveUS20100013228A1Alter attack angleIncrease attack angleMachines/enginesEngine componentsMarine engineeringMoving body

A tidal generator includes a floating structure and a shaft that is supported over a moving body of water. The shaft is coupled to multiple rotors that have pitched blades that extend radially from the center of the rotor. Portions of the lower blades are submerged in the moving water. The movement of the water relative to the tidal generator causes the rotors and shaft to rotate. The shaft is coupled to an electrical generator.

Owner:DUGGLEBY TONY +2

Location signaling device

InactiveUS8356569B2Effective surface is reducedReduce lifting forceVessel signalling devicesLife-savingLighter than airAirbag deployment

A location signalling device comprising a wing balloon for signalling a location. The wing balloon is fixed to a tether line that itself is fixed to the location to be signalled. The wing balloon has an inflatable aerodynamically shaped hollow body to be at least partly be filled with a lighter-than-air gas and having a wing attack surface for air flowing relative to said wing balloon. The floating aloft of said wing balloon is supported by said air flow. When the wing balloon is inflated, a flexible wing portion is passively variable. The stronger the wind, the less attack is given. Thus, the dragging force on the tether line is generally static.

Owner:SJOBLOM HANS

Wind spoiler for roofs

ActiveUS7905061B2Reduce the possibilityReduce areaBuilding roofsRoof covering using slabs/sheetsEngineeringWind flow

A wind spoiler including a vertical member mounted vertically along a roof of a structure to extend above the plane of the roof for creating turbulence in wind flowing over the roof.

Owner:HOD GINA B +1

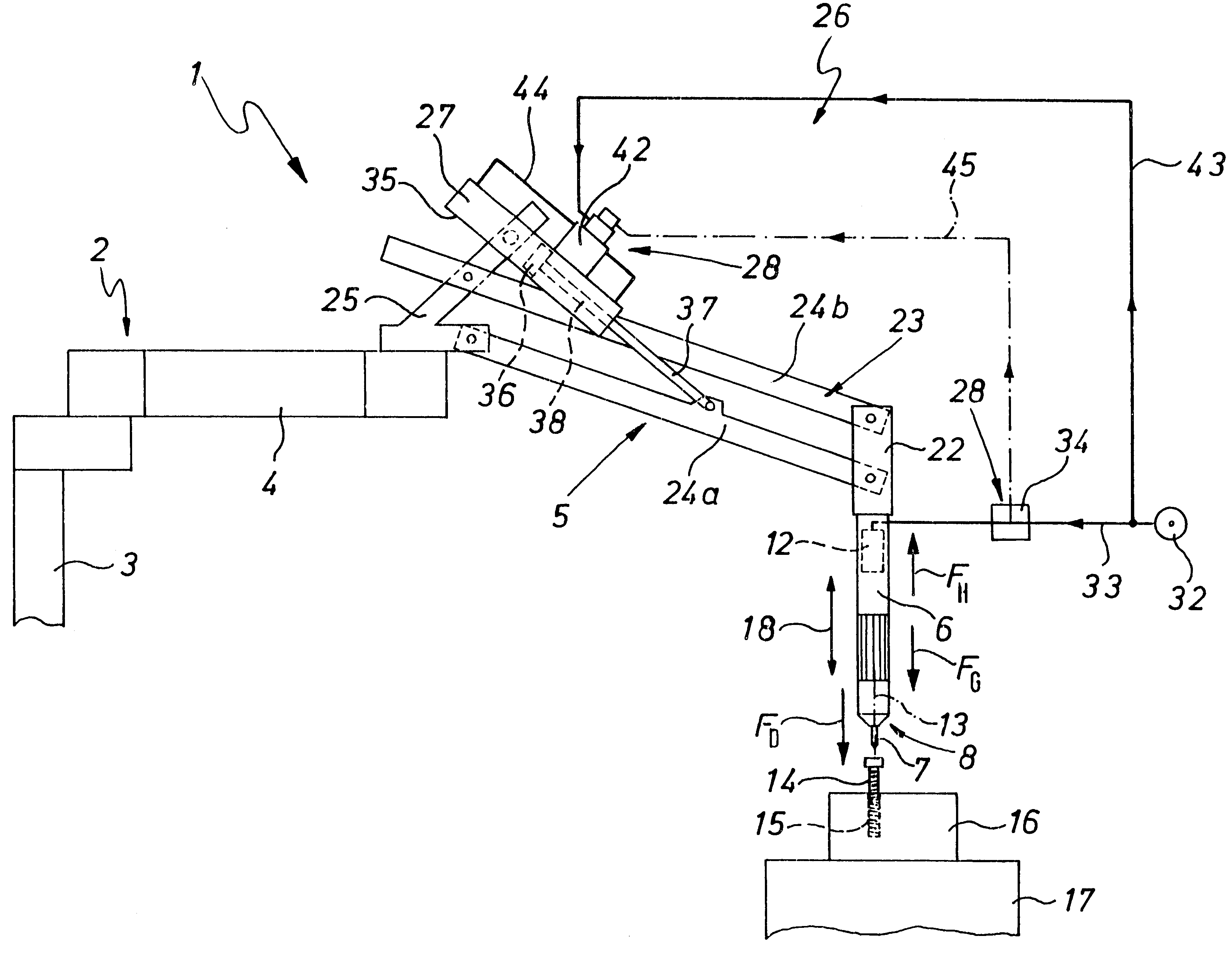

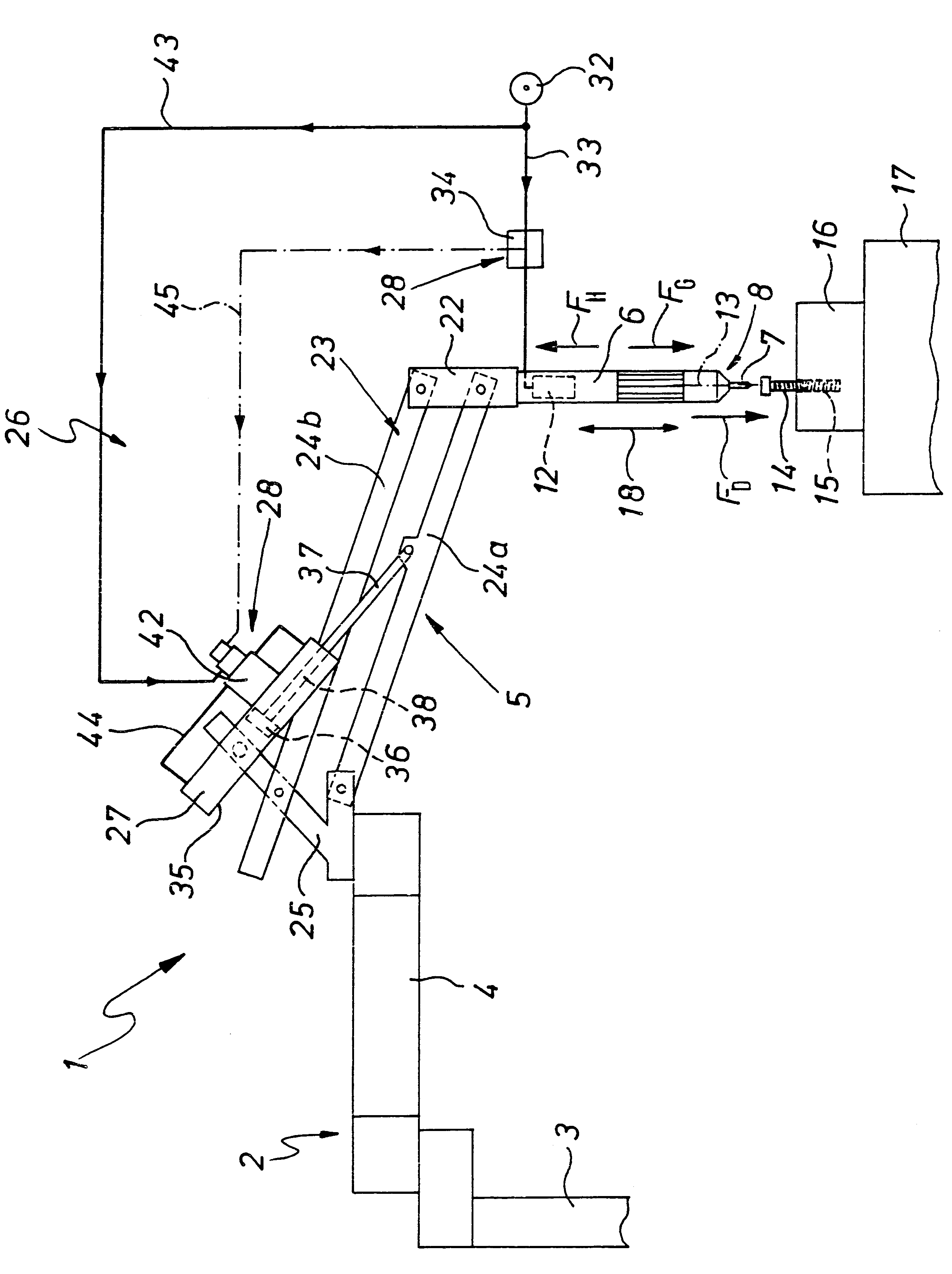

Device for the control of the thrust force of a manually operated pneumatic screw driver

InactiveUS6736033B2Facilitate and simplify handlingQuality improvementWrenchesWork benchesLine tubingPneumatic tool

A device for controlling the vertical translation of a pneumatic tool includes a drive means and a control means. The pneumatic tool is supported by a holding device which configured to allow the pneumatic tool to be translated in a vertical direction. The pneumatic tool is connected to an air supply line having a pressure associated therewith. The drive means exerts a lifting force on the holding device to support the pneumatic tool. The control means adjusts the lifting force delivered by the drive means and is configured to monitor the pressure in the air supply line.

Owner:FESTO AG & CO KG

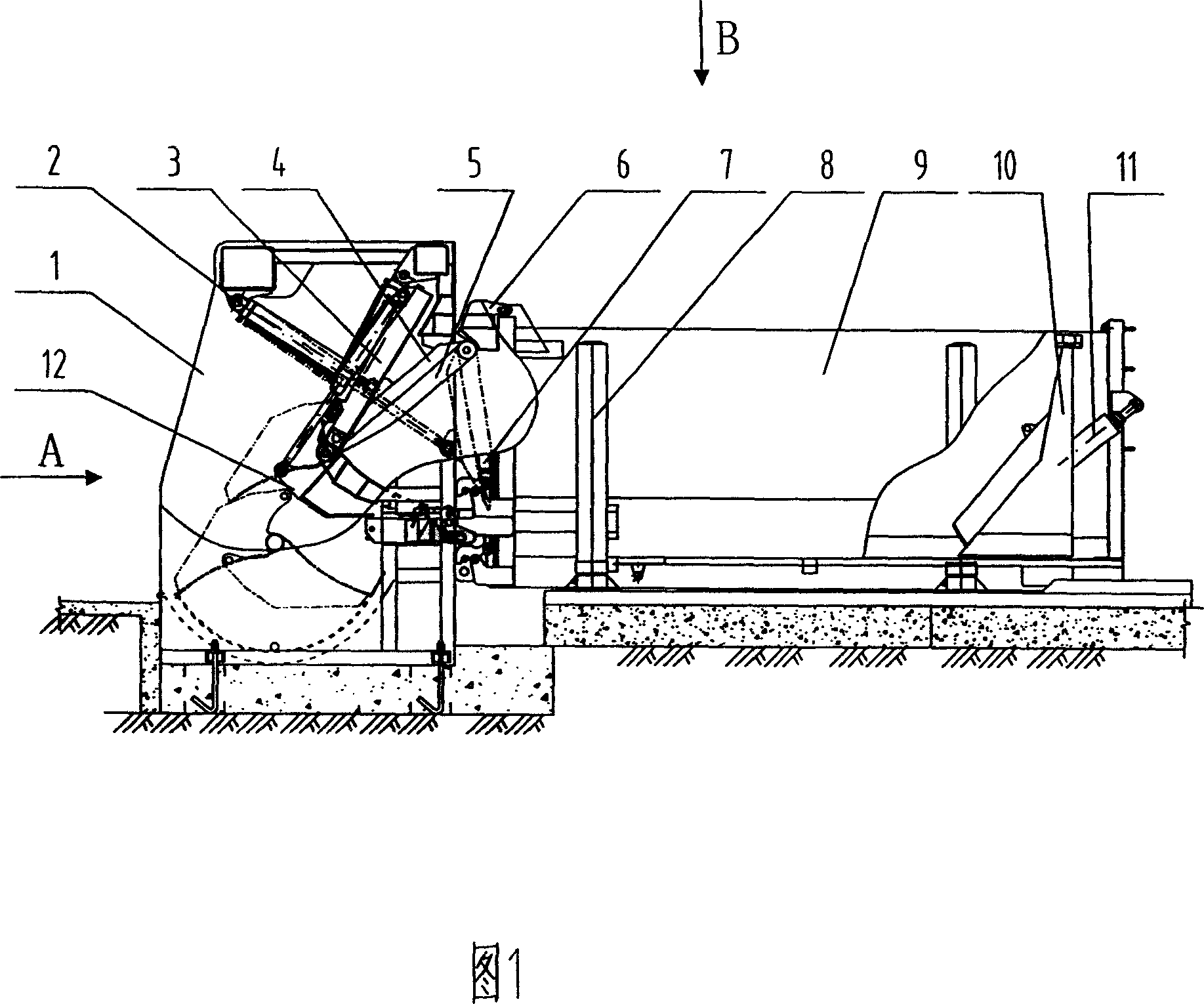

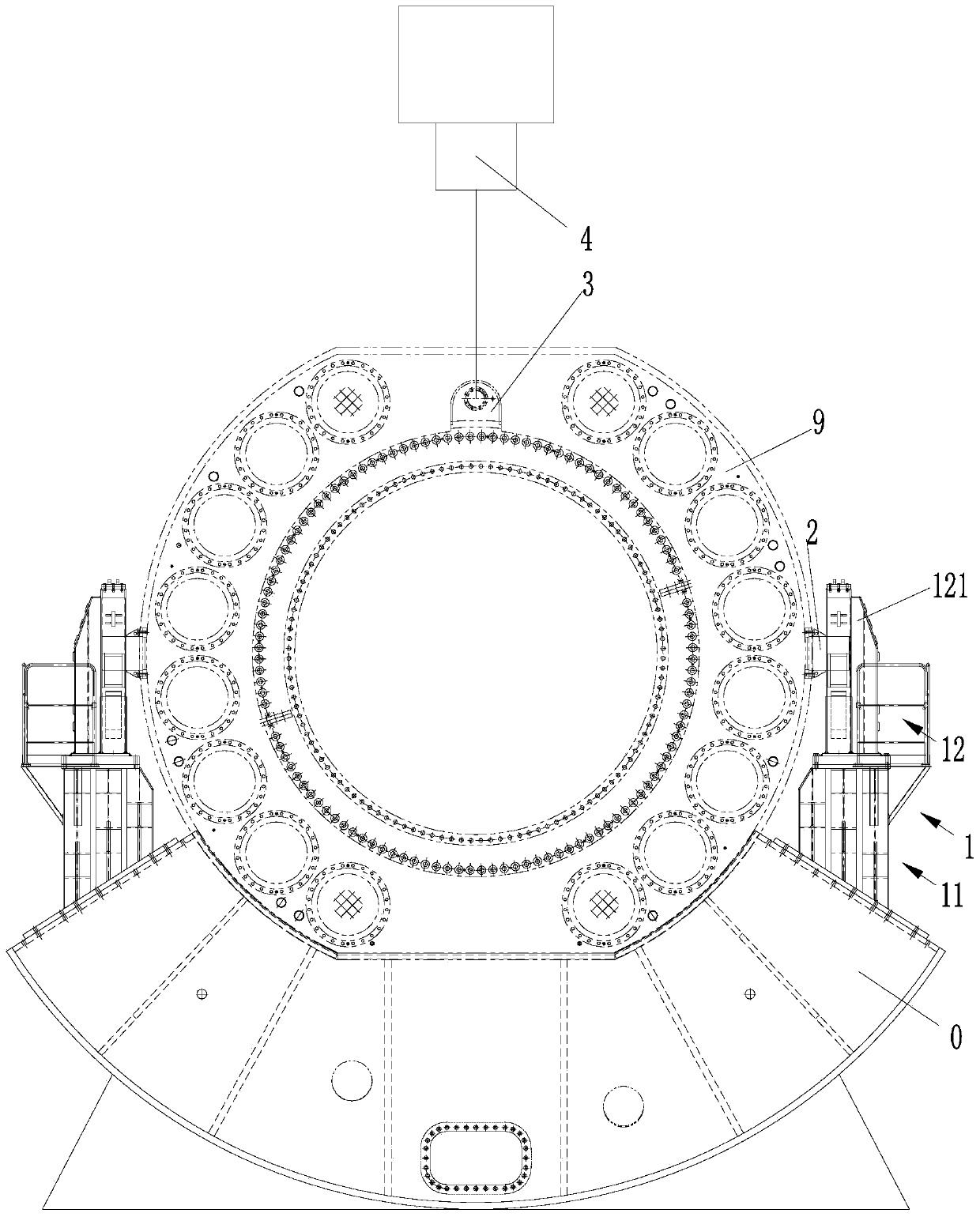

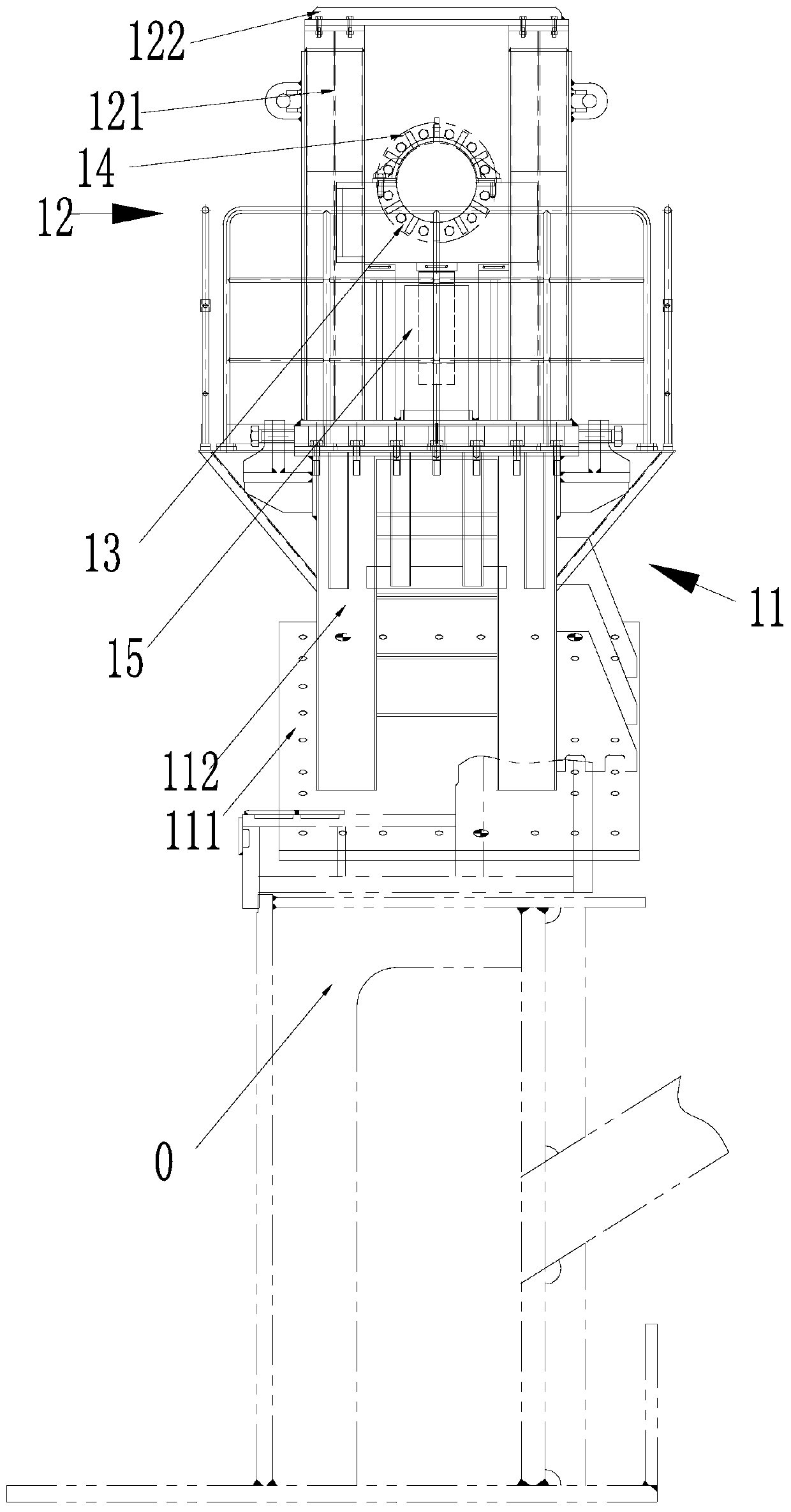

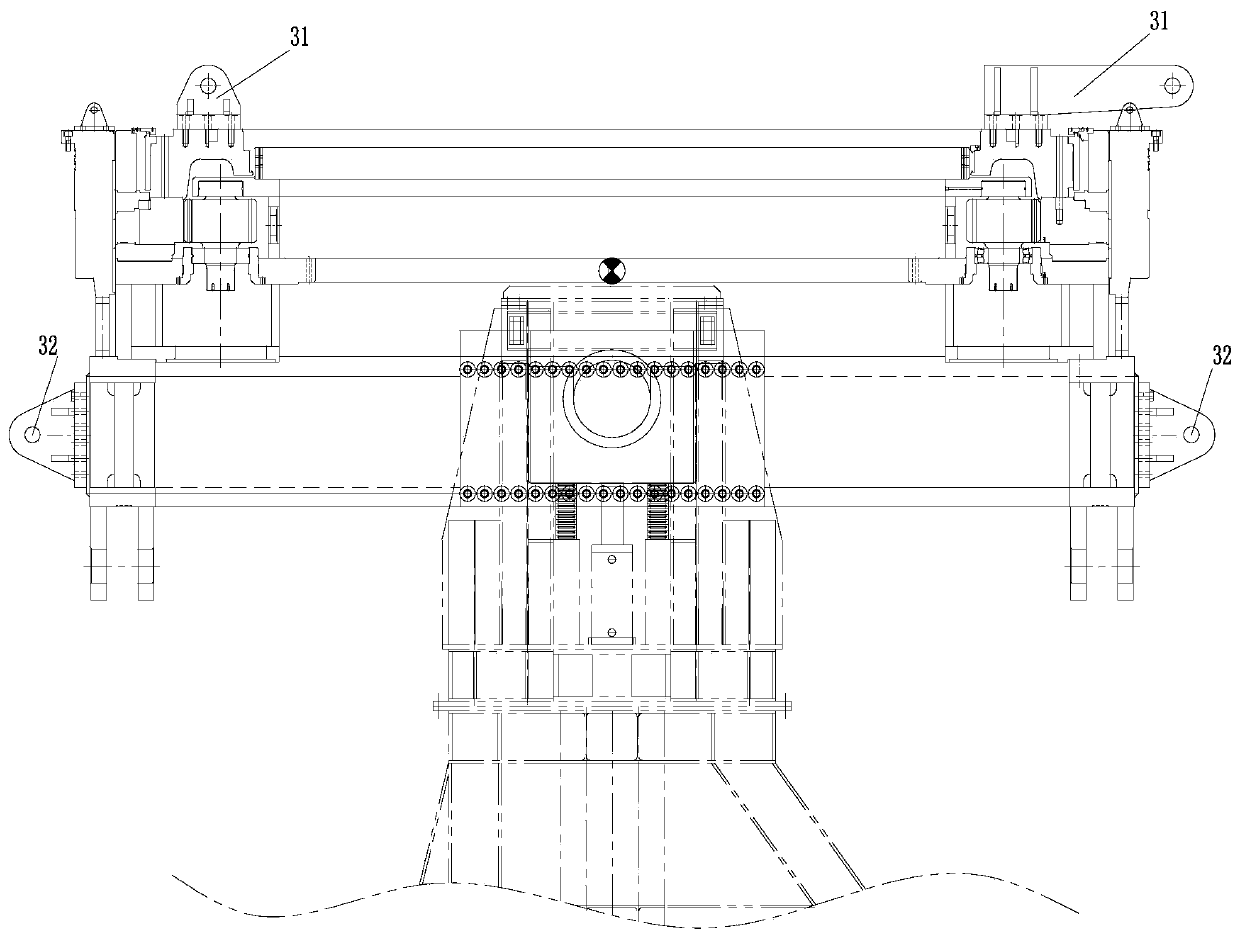

Main drive turn-over device and method for super-large-diameter shield tunneling machine

PendingCN110950242AReduce lifting forceRealize the purpose of overturning heavy objectsLoad-engaging elementsControl engineeringElectric machinery

The invention discloses a main drive turn-over device and method for a super-large-diameter shield tunneling machine. The main drive turn-over device comprises an arc-shaped turn-over base, and turn-over parts mounted at the two ends of the turn-over base. The main drive turn-over method comprises the following steps: the lower part of a shield body block serves as the turn-over base; an upward turning part is lifted; lifting lugs are connected for turning over; after a main drive rotates by 90 degrees, hook replacing operation is conducted; after hook replacing is successful, turning over continues; when the main drive rotates by 180 degrees, after a motor and a speed reducer are mounted, lifting hooks are connected, and two lifting parts reversely act till the main drive is located in the vertical position; and the main drive is lowered through hydraulic oil cylinders on the two sides. Previous overall lifting turning-over operation of the main drive is cleverly converted into rotation turning-over operation, when the main drive turns over through the mode, rotation lifting force provided by a crane only needs to overcome rolling friction resistance generated by the self-weight of the main drive, thus the lifting force of the crane can be decreased by about 10 times or above, and the purpose that large heavy objects are turned over by the small crane is achieved.

Owner:TIANHE MECHANICAL EQUIP MFG

Method for increasing a blade performance (variants)

InactiveUS20070113403A1Improve performanceReduce energy consumptionPropellersPump componentsMachine buildingInjection air

The invention relates to machine building in particular to blade machines for air injection, in particular to fans and air blowers, and also to blades of different propulsion devices. The inventive method for increasing the blade (1) performance consists in producing a blade (1) in the form of a wing and in carrying out the boundary layer suction on the blade 1 surface on the opposite side with respect to the incoming air flow through a system of slotted holes (4). The blade (1) is provided with a thick airfoil profile. The air suction is carried out through the system of slotted holes (4) embodied along the blade (1) and into cavities (5) which are embodied under said holes (4) along the latter and each of which is provided with a central longitudinal hollow body arranged therein, said body forming an annular channel (7) in each cavities (5) in such a way that a vortex-like flow is generated by the incoming air flow in said channel. The air is sucked out from the cavities (5) and the central bodies (6) through branch channels (8). The latter are used to discharge air outside of the blade (1). The air flowing-off along the cavities (5) and along the blade 1 is limited within the cavities (5) by mounting partitions and on an external surface of the blade (1)—by mounting ribs (9). In another embodiment of the method, the cavity is embodied without the central body (6). As a result, the invention makes it possible to increase the blade performance.

Owner:LNS WINDBLADE TECH LLC +1

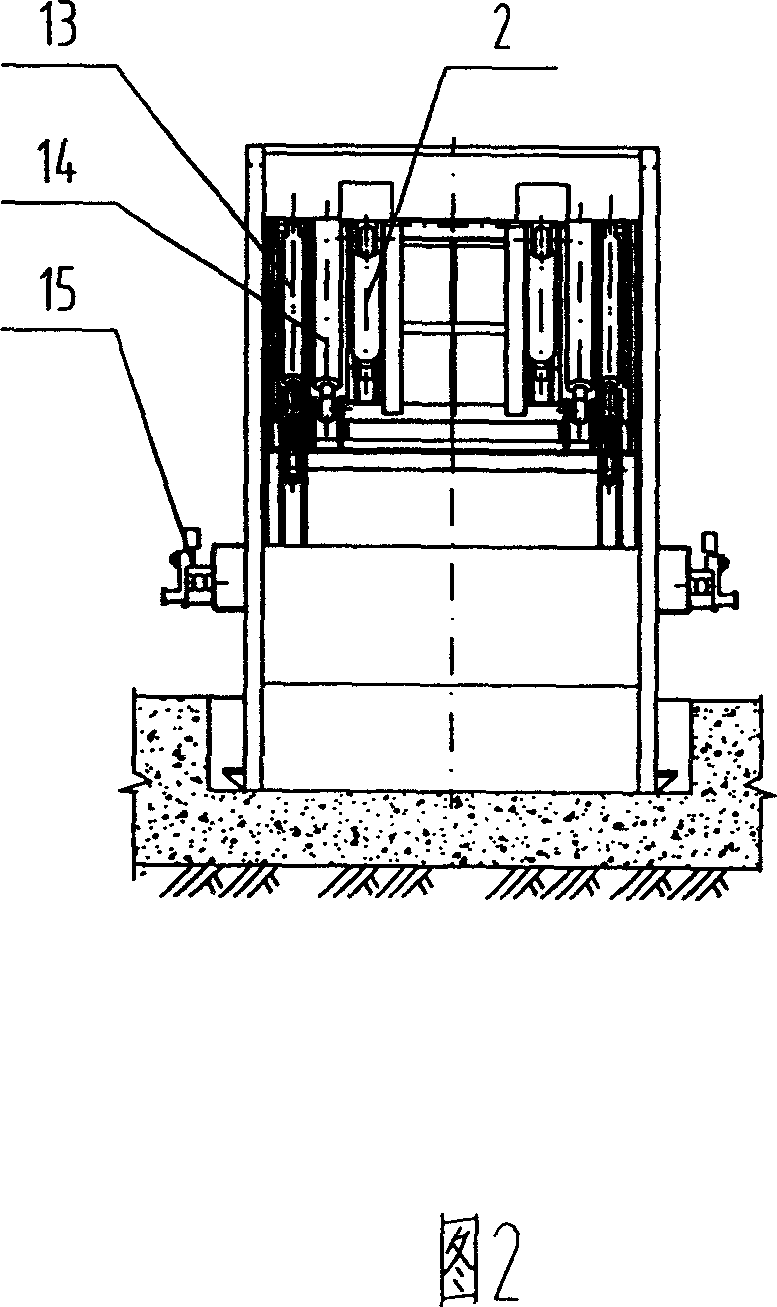

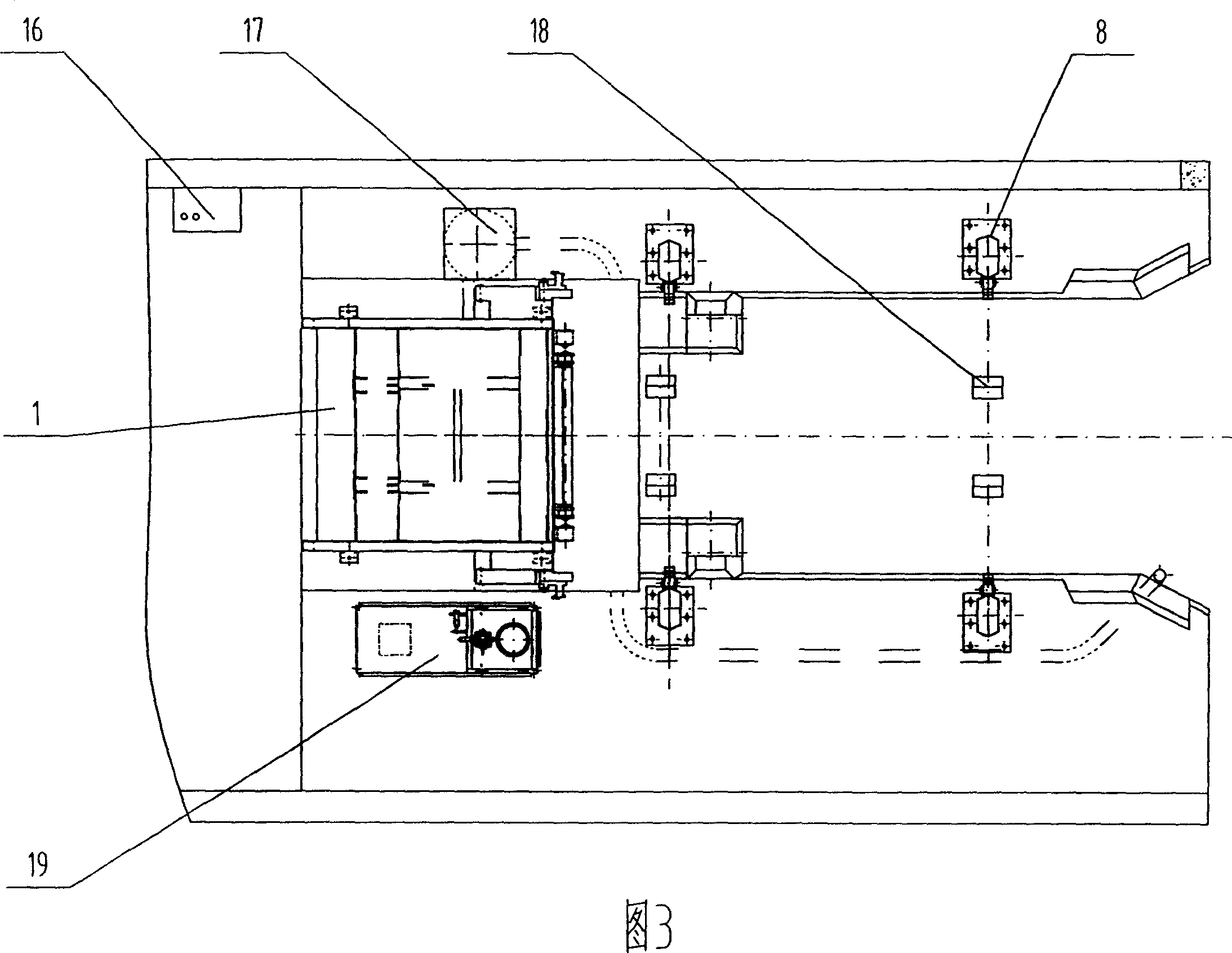

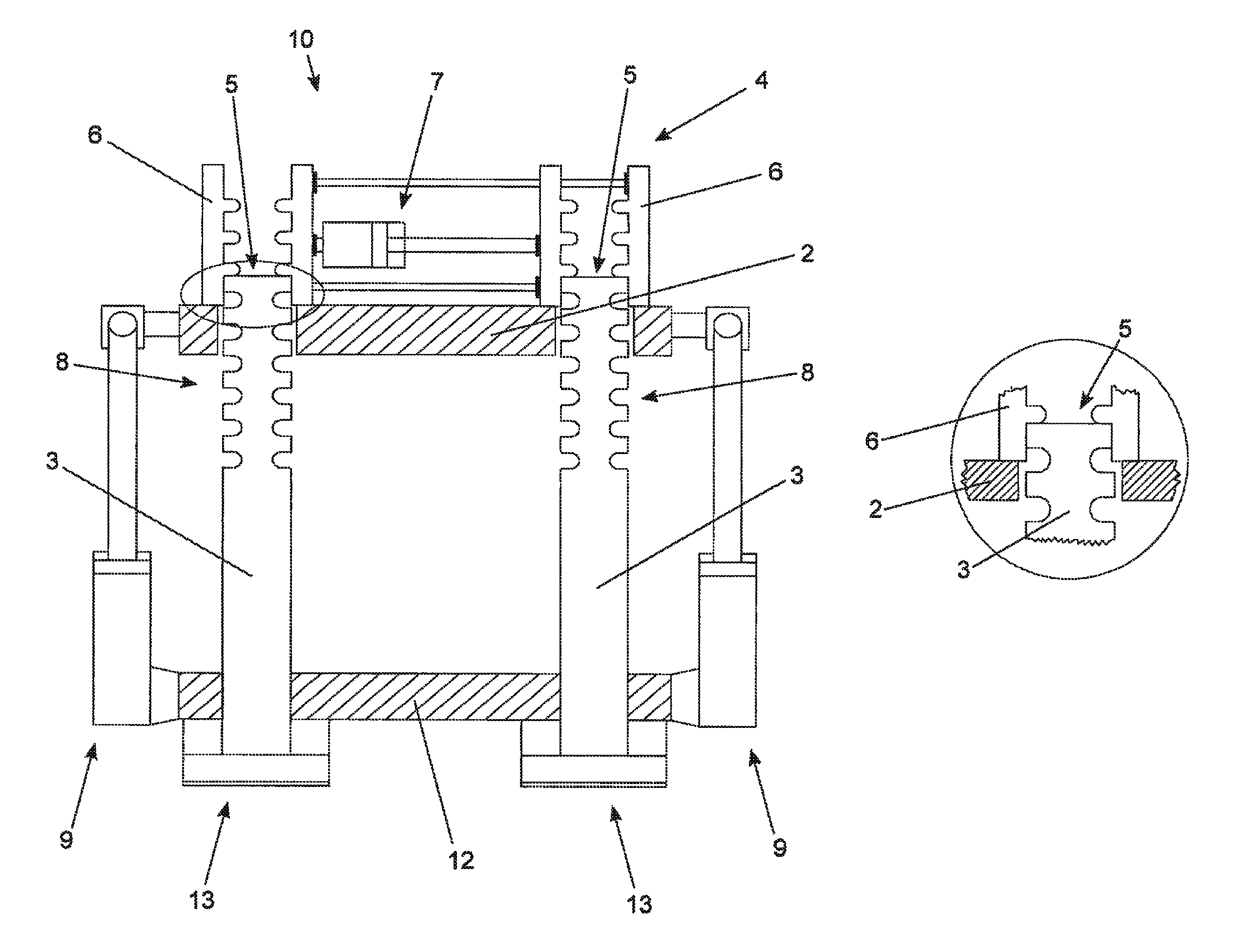

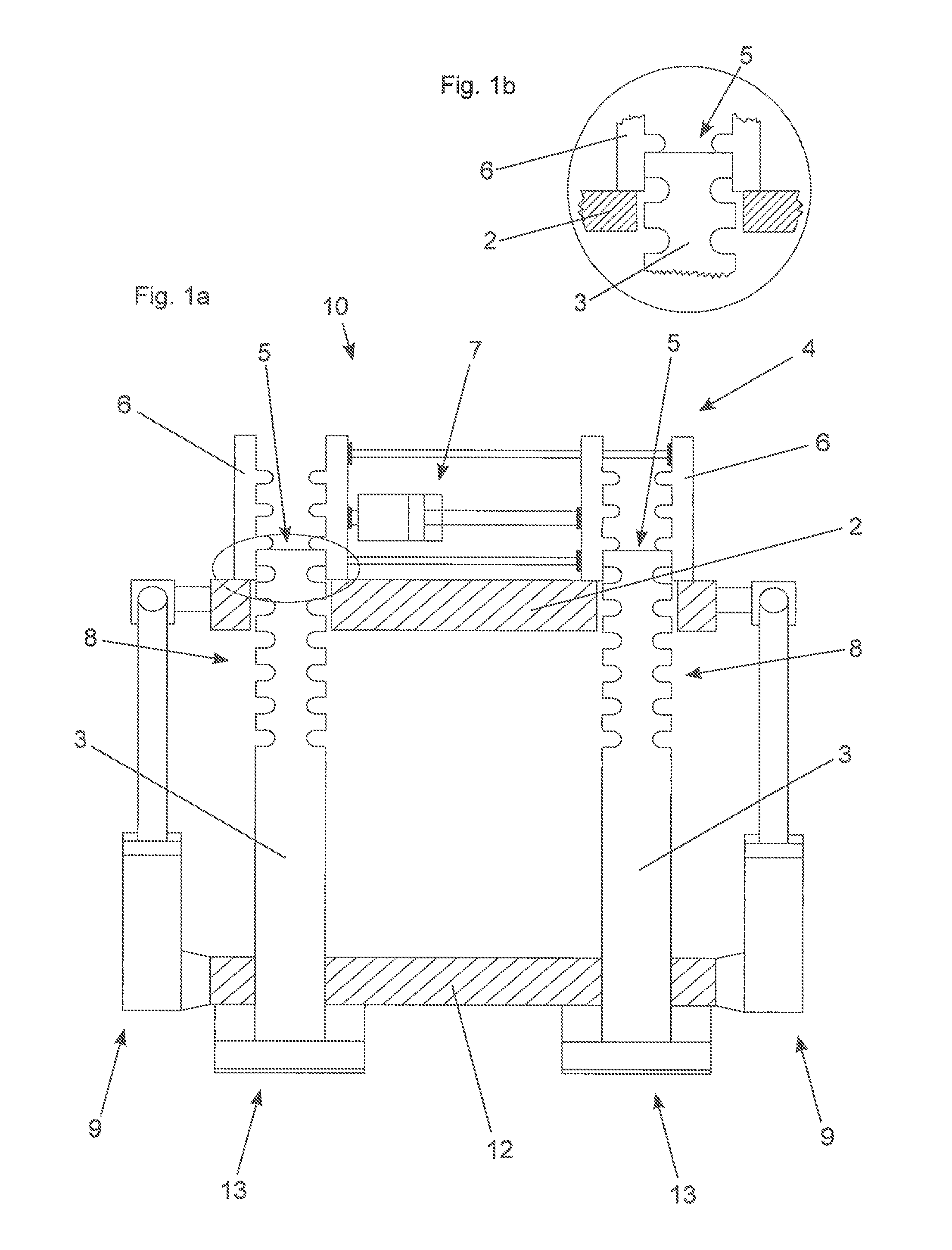

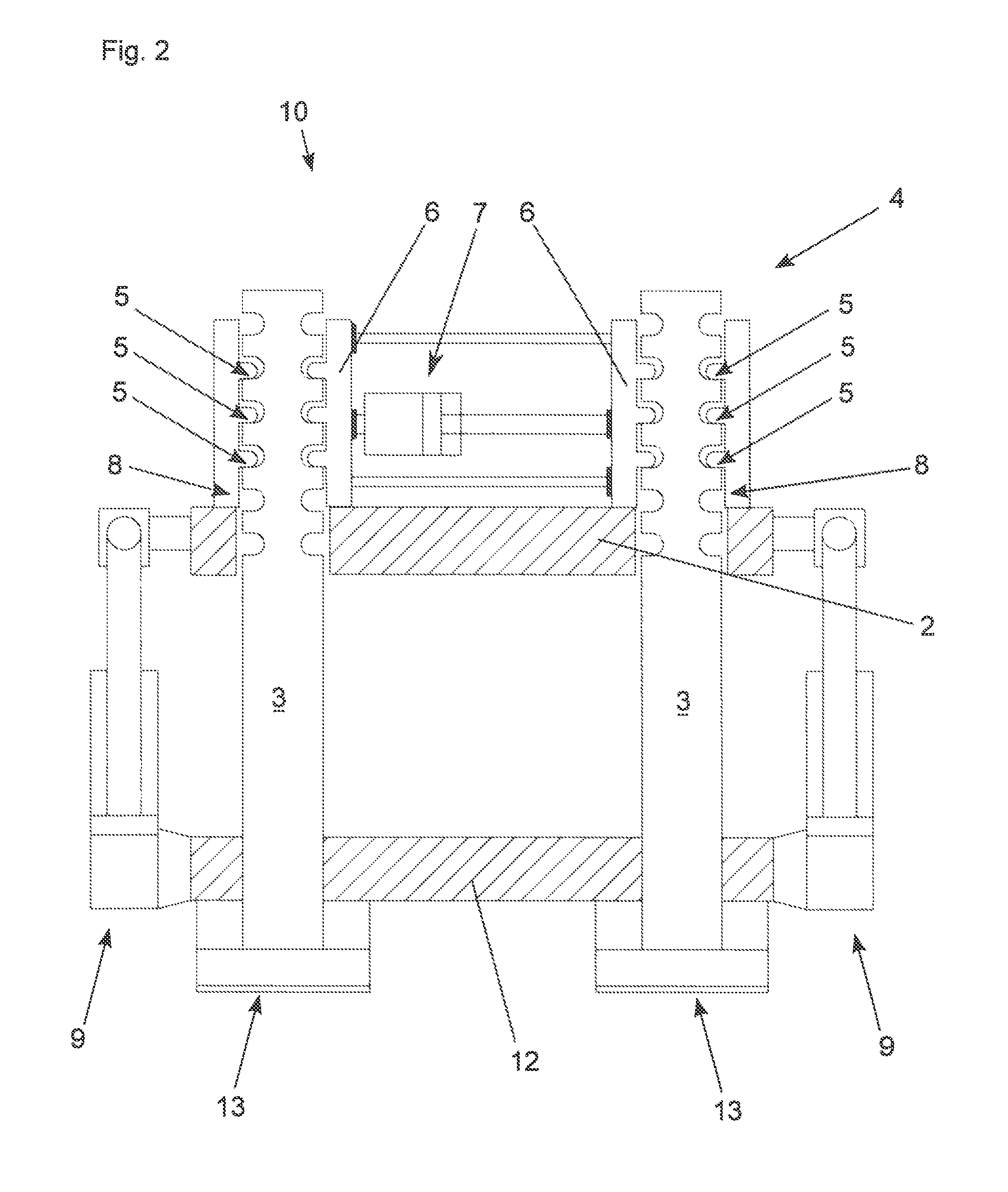

Closure unit

A vertically closing closure unit for an injection molding machine includes a moveable mold mounting plate, and at least one frame bar for guiding the moveable mold mounting plate. A vertical restraint device holds and locks the moveable mold mounting plate to the at least one frame bar.

Owner:ENGEL AUSTRIA

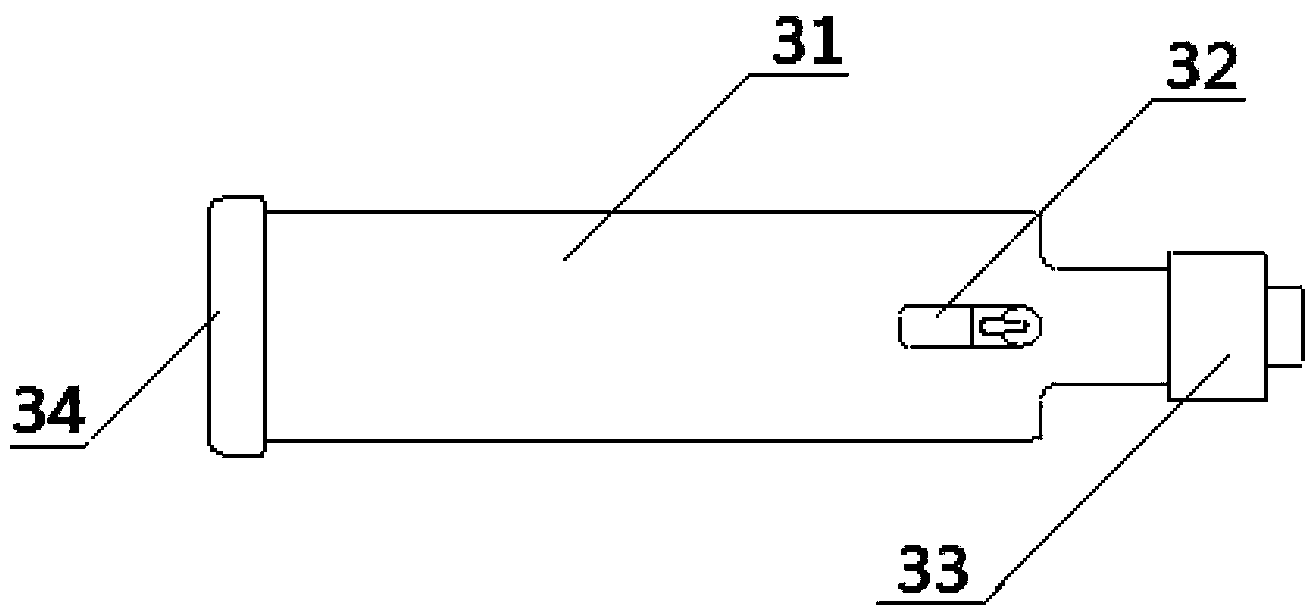

Insulating sleeve cleaner

The invention discloses an insulating sleeve cleaner which comprises a length-adjustable connecting rod. One end of the length-adjustable connecting rod is connected with a motor brush head, and the other end thereof is connected with a controller of the motor brush head. The controller is electrically connected with the motor brush head. The middle of the connecting rod is rested on a support. The connecting rod and the support are connected through a universal ball joint. Main weight of the cleaner is borne by the support, an operator can control actions of the motor easily by holding the controller, any angle and positions of an insulating sleeve can be cleaned by rotating the connecting rod under the action of the universal ball joint, the motor brush head is flexible and convenient, and cleaning of insulating sleeves in a substation is facilitated.

Owner:STATE GRID CORP OF CHINA +1

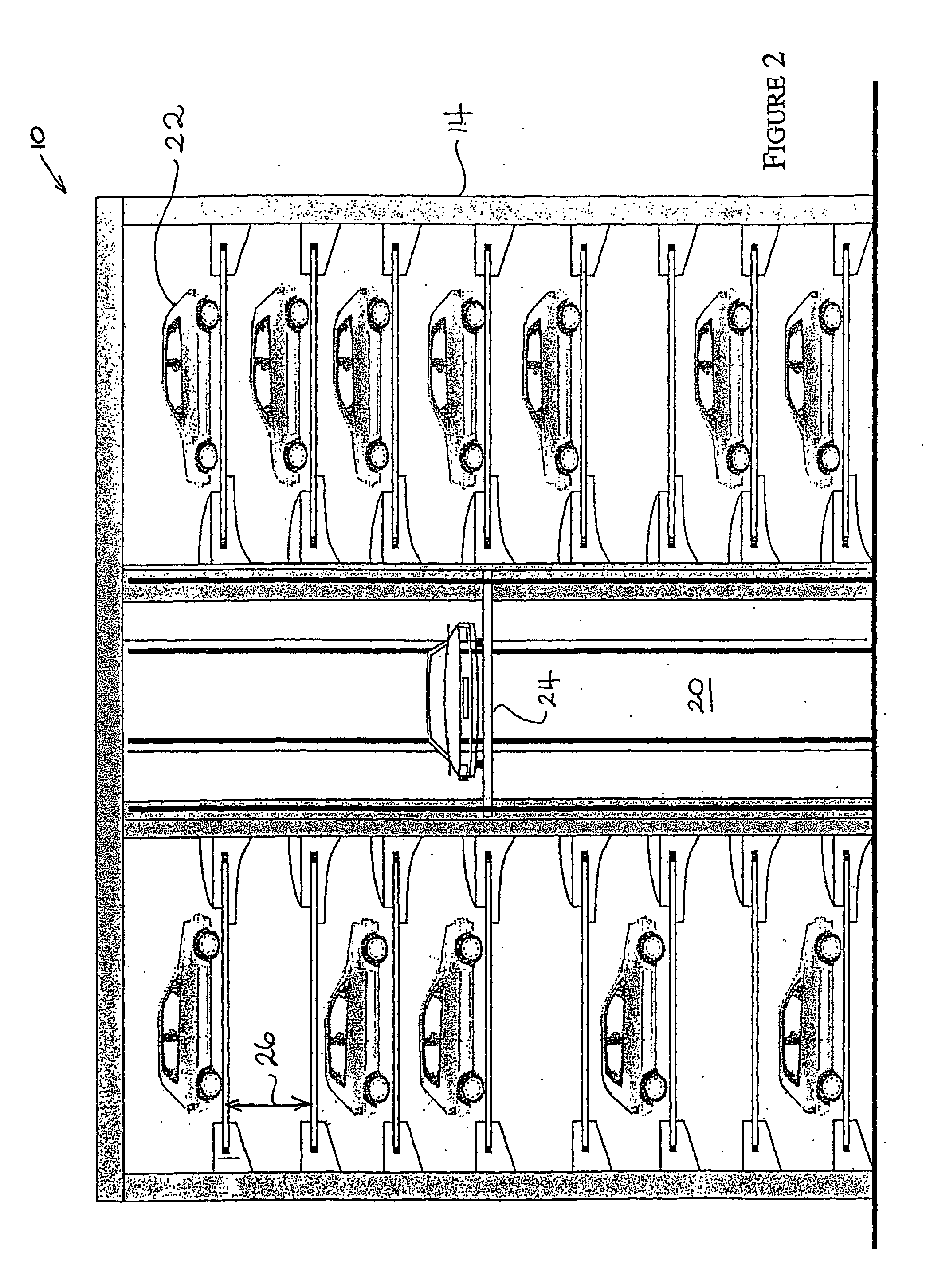

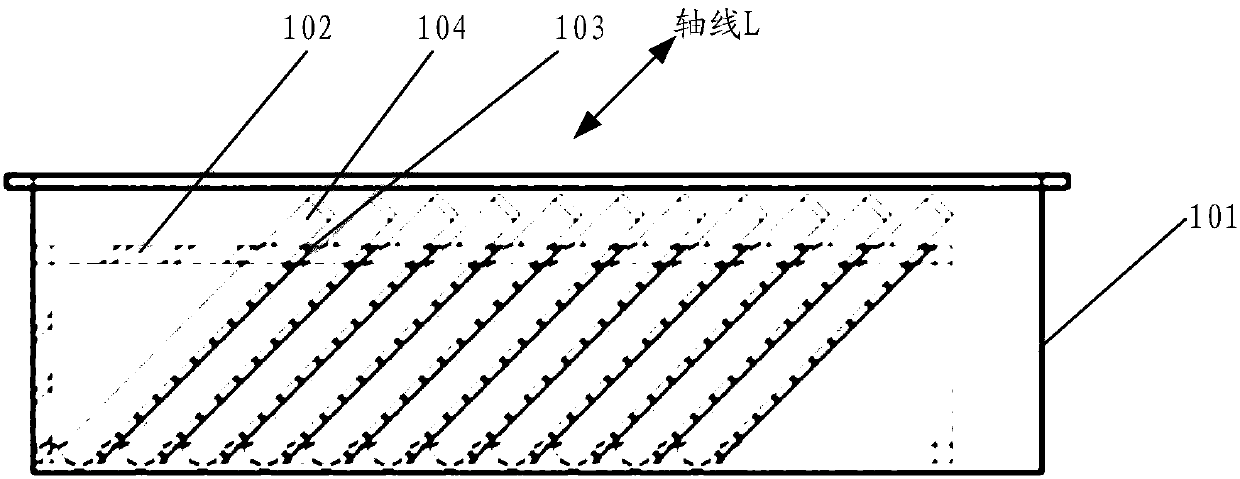

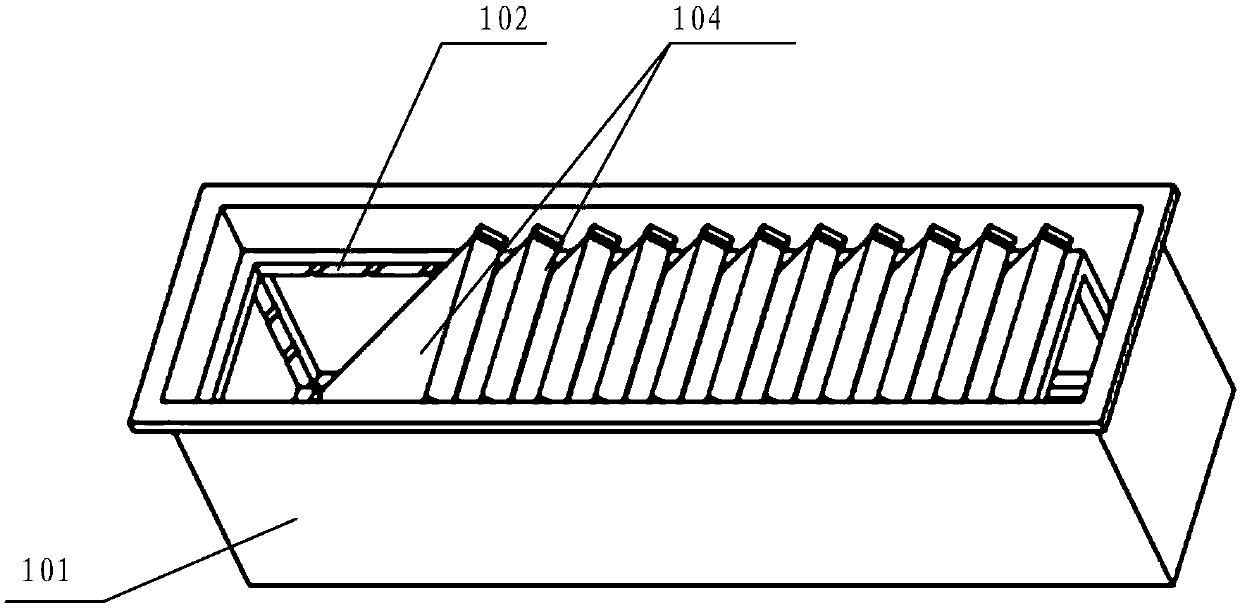

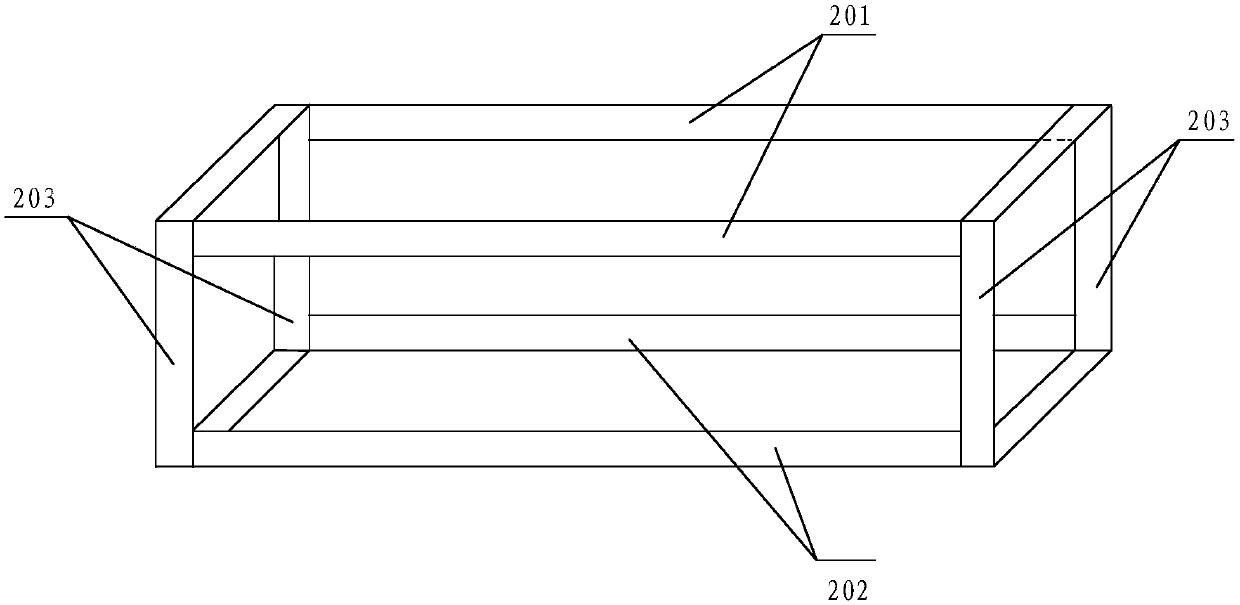

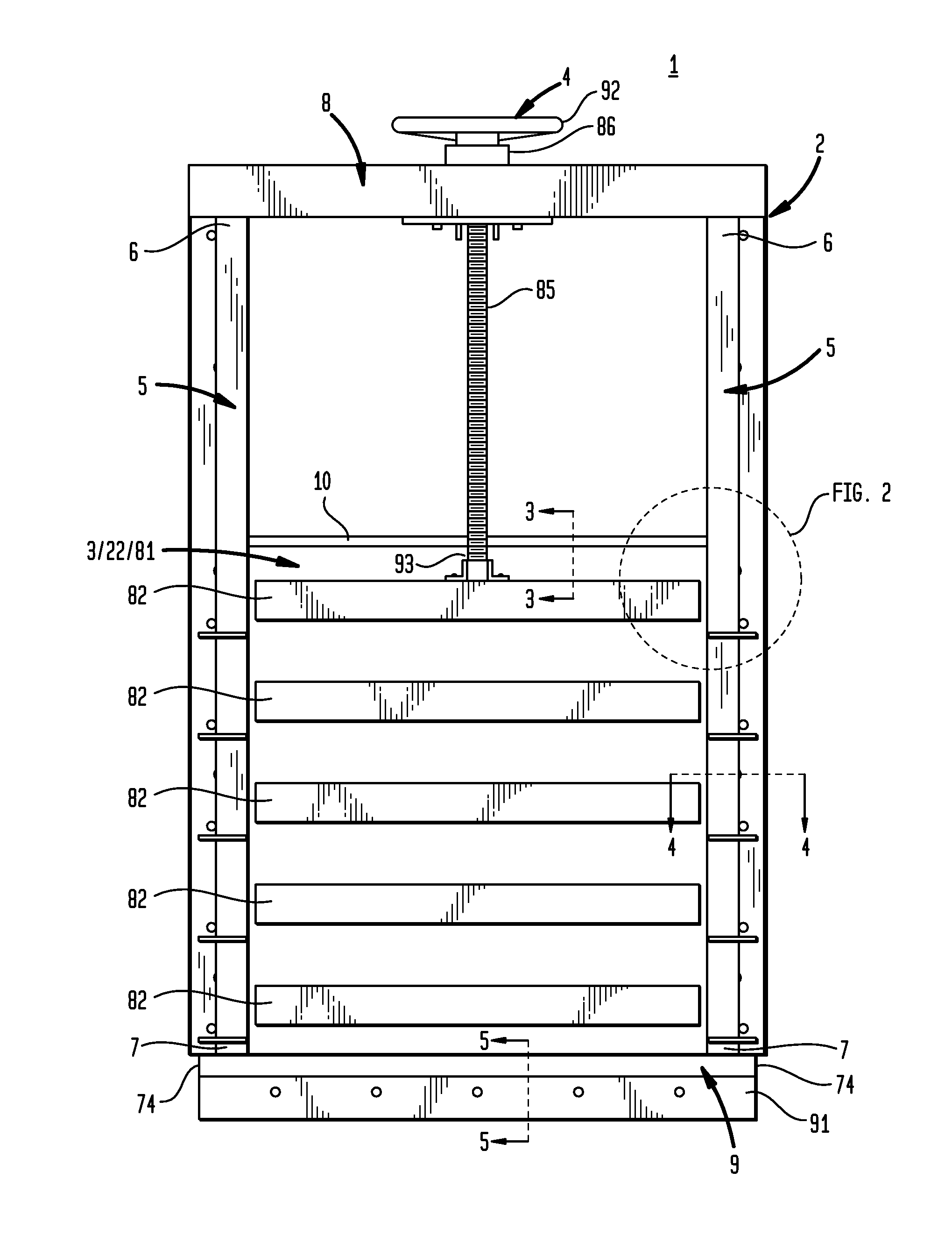

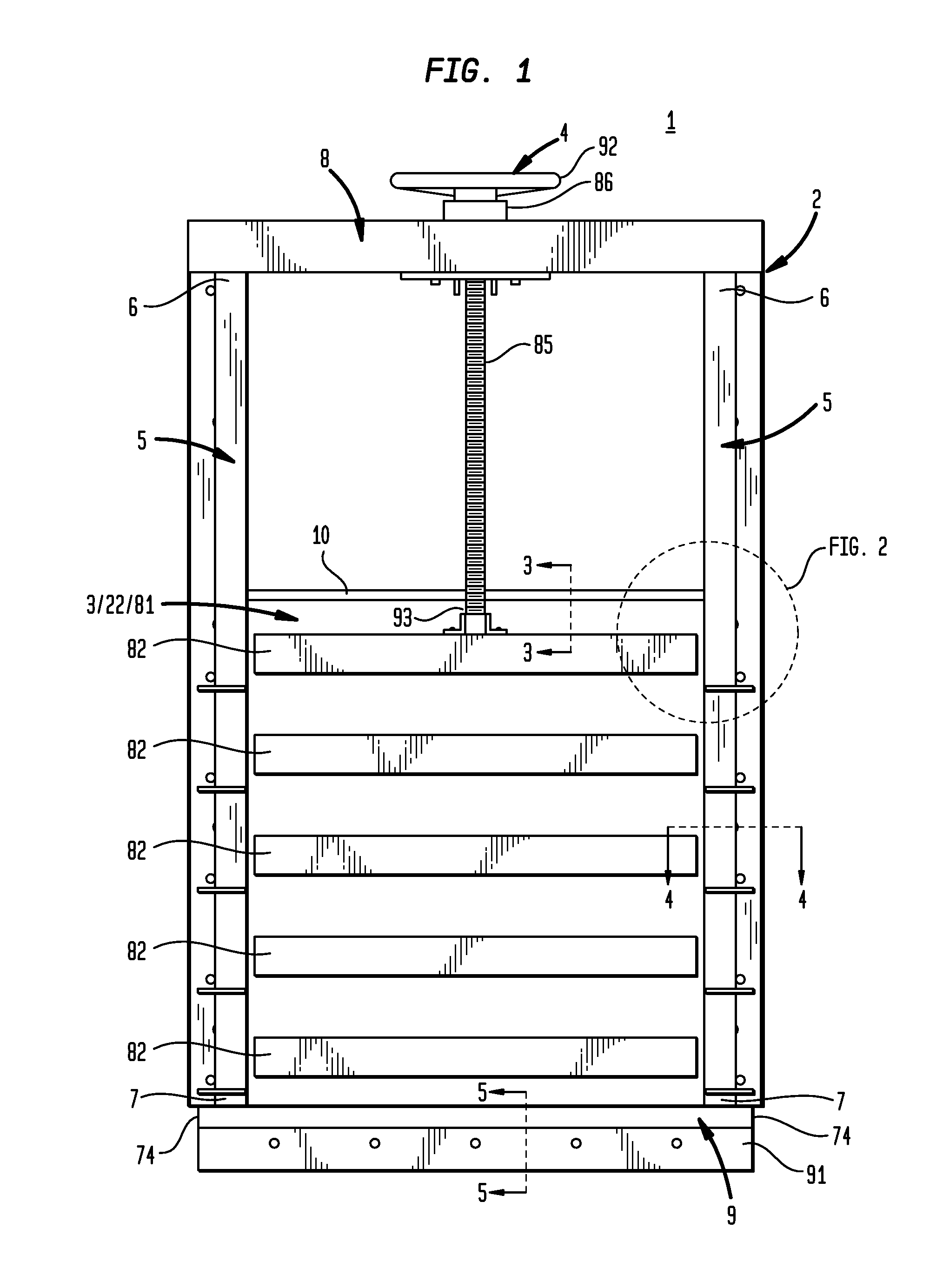

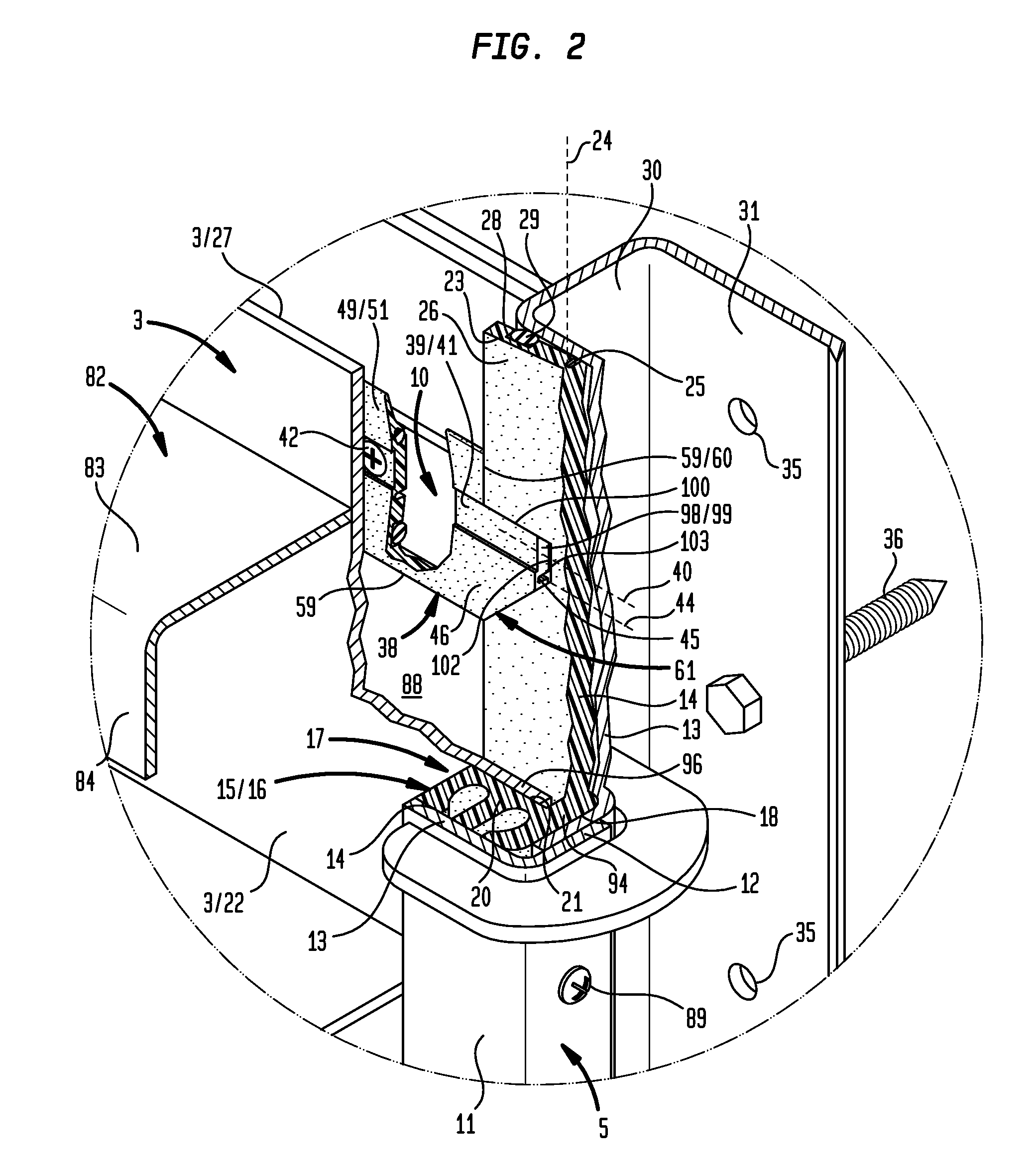

Cabinet

PendingCN107911965AEasy to take outReduce lifting forceCasings/cabinets/drawers detailsInsertion stentEngineering

The invention discloses a cabinet which comprises a cabinet body, a bracket and a number of positioning structures. The bracket is located inside the cabinet body. Each positioning structure is slantly arranged on the bracket, and a server is slantly placed on each positioning structure. According to the invention, the bracket and the positioning structures are arranged inside the cabinet body, and the servers are slantly placed on the positioning structures; the lifting force of server removal can be reduced; the efficiency of server maintenance can be effectively improved; the operation steps of server maintenance can be simplified; and the servers can be easily taken out without an auxiliary lifting device.

Owner:ECO ATLAS SHENZHEN CO LTD

Seal System

ActiveUS20130092862A1Eliminate manual adjustmentAvoid problemsSoldering apparatusSlide valveMechanical engineering

Owner:WATERMAN IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com