Insulating sleeve cleaner

A technology for insulating sleeves and cleaners, applied in the field of cleaners, can solve the problems of labor-intensive maintenance costs, time-consuming, and laborious holding of insulating rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

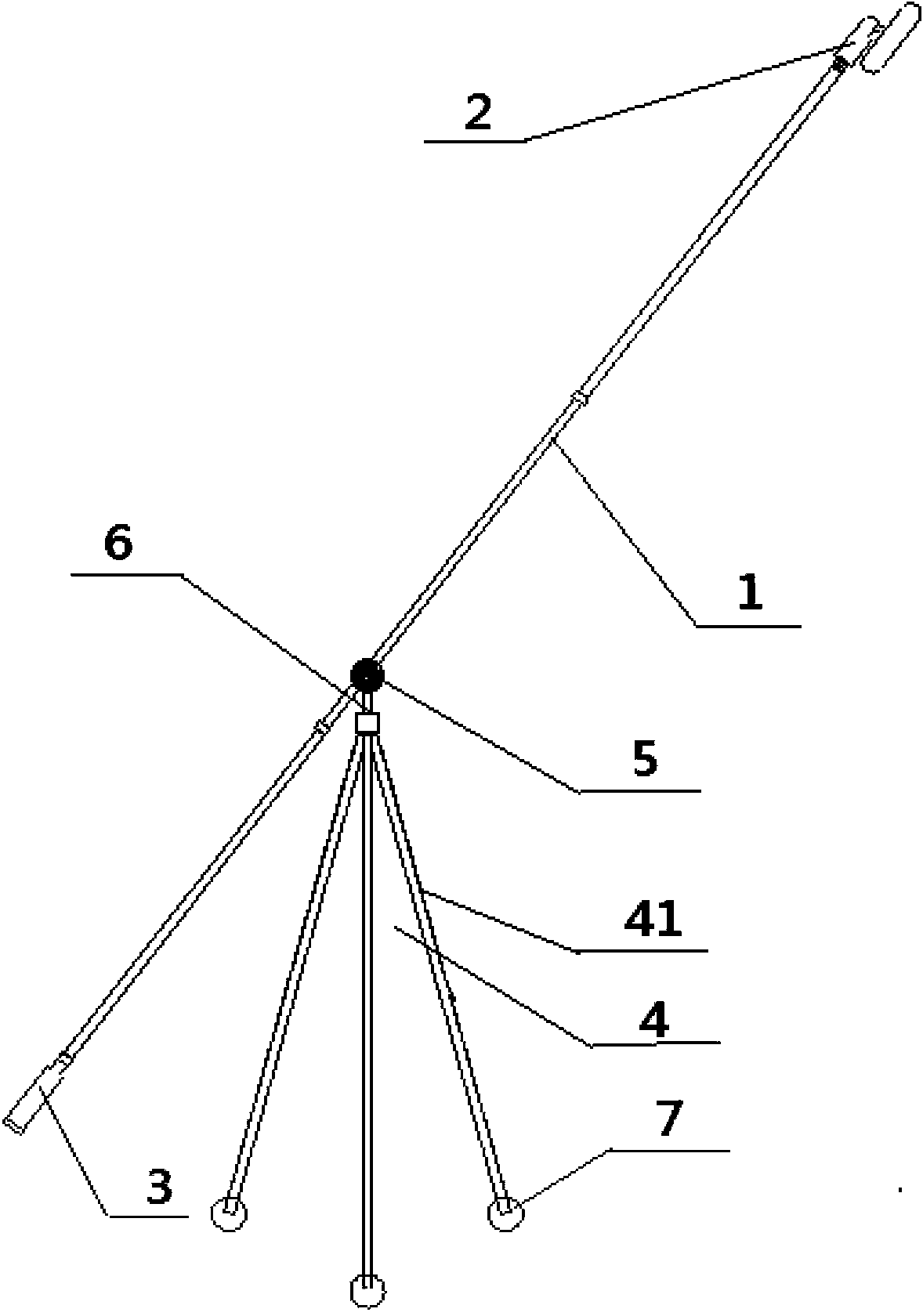

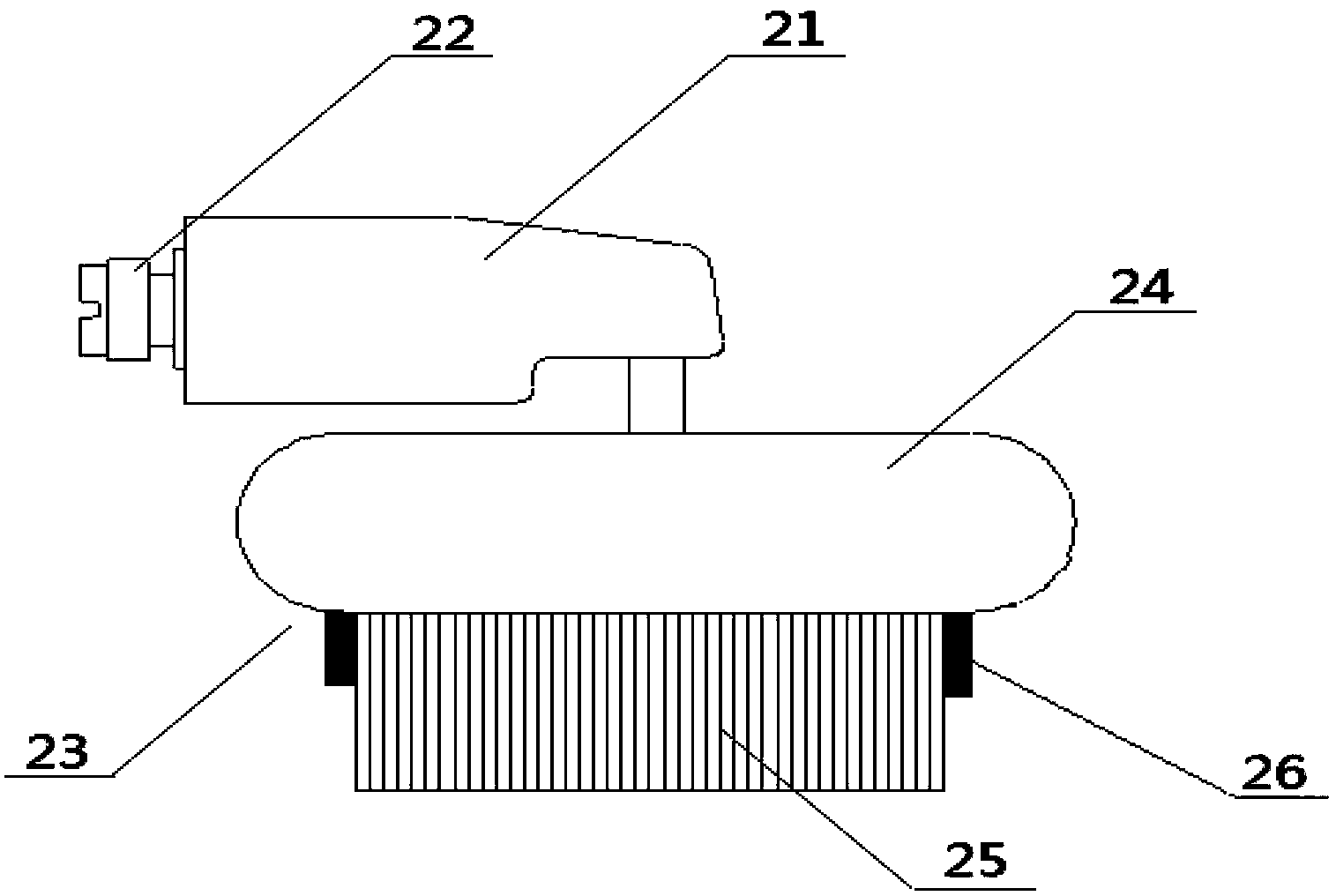

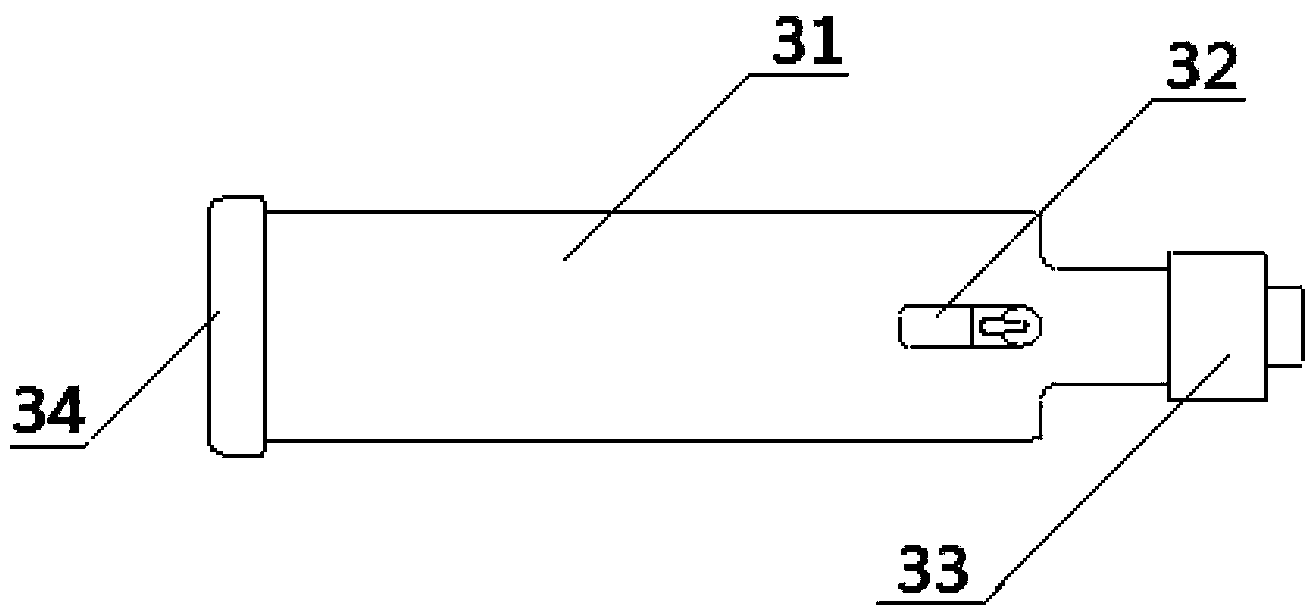

[0019] Such as figure 1 Shown is an embodiment of the present invention, which includes a length-adjustable connecting rod 1. Specifically, a multi-segment plug-in connecting rod can be used. It needs to be pointed out here that the present invention is especially suitable for insulating sleeves located at high places in high-voltage substations. The cleaning of the pipe needs to be carried by the user, so for the convenience of carrying, the present invention can be disassembled. In order to facilitate the disassembly, most of the connection methods of the present invention adopt the plug-in type, which will be introduced in detail below. One end of the connecting rod 1 is connected to the motor brush head 2, and the other end is connected to the controller 3 of the motor brush head, the controller 3 is electrically connected to the motor brush head 2, and the The middle part of the connecting rod 1 is erected on a bracket 4, and the connecting rod 1 and the bracket 4 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com