Multi-degree-of-freedom mechanical arm for automatic welding

An automatic welding technology with degrees of freedom, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reduced welding efficiency, poor versatility, and inability to guarantee welding quality, and achieve improved welding efficiency and simple structure. , easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

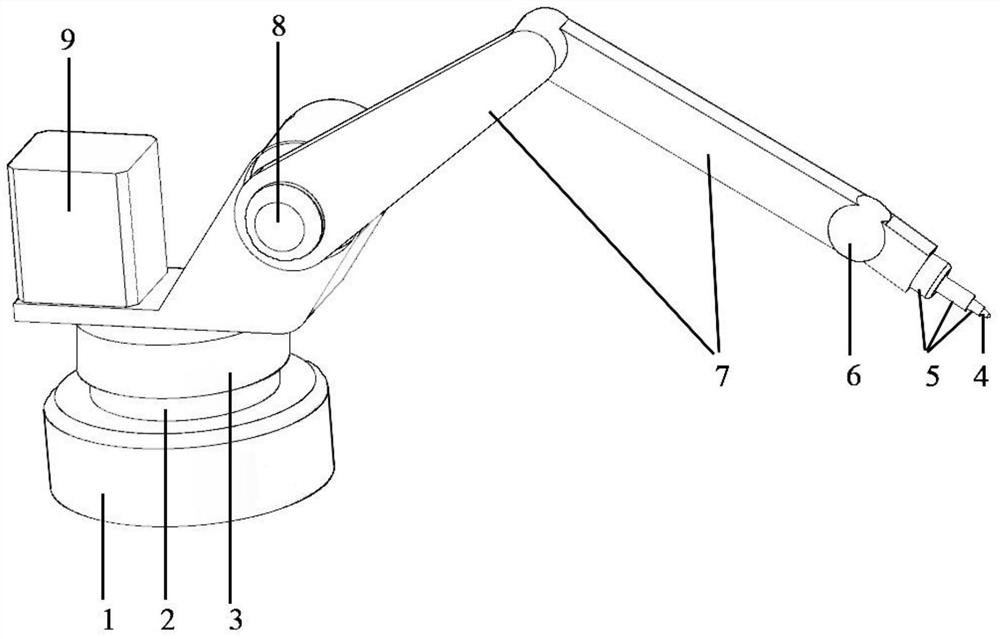

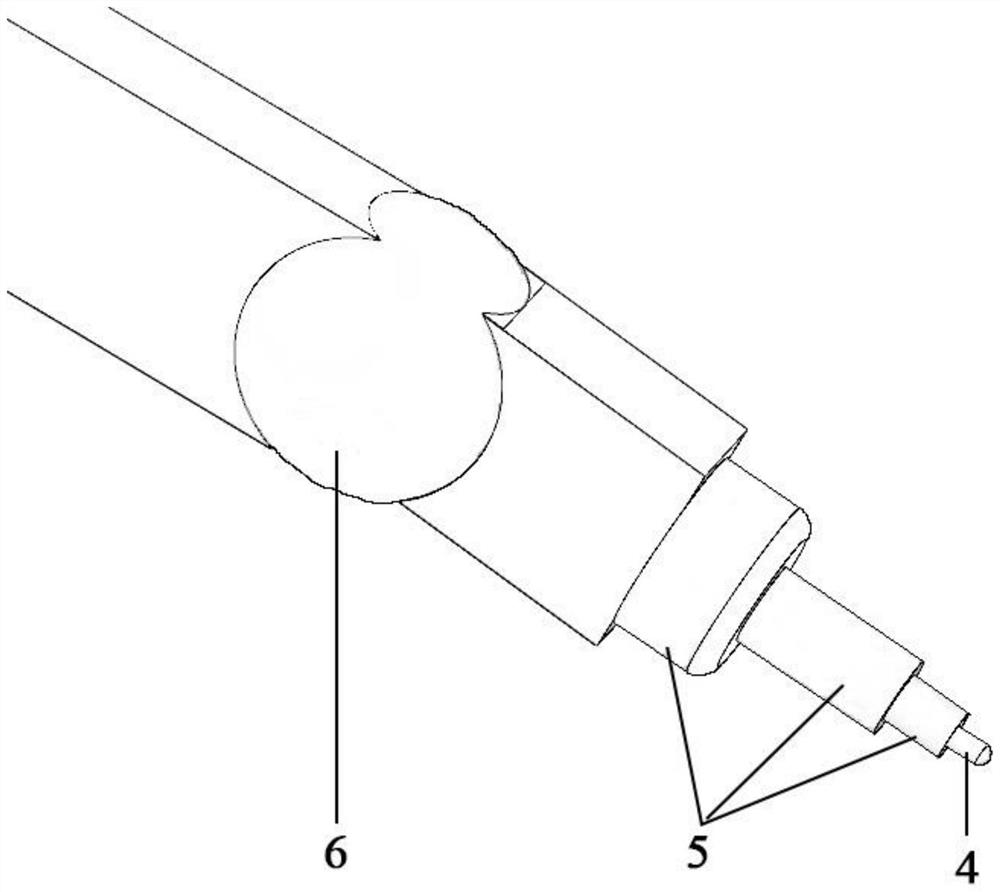

[0021] Such as figure 1 The shown multi-degree-of-freedom mechanical arm for automatic welding includes a base 1, a vertical shaft 2 on the base, a rotating base 3 on the vertical shaft, a horizontal shaft 8 on the rotating base, a The rotating arm 7 on the horizontal rotating shaft, the connecting ball 6 that is located on the end of the rotating arm and the welding torch that is located on the connecting rotating ball; the base and the rotating base are connected by a vertical rotating shaft; The rotating arm is connected, and the connecting ball is used to realize the multi-degree-of-freedom rotation of the welding torch. Wherein, the rotating base drives the horizontal rotating shaft to control the horizontal rotation direction of the welding torch, and the rotating arm is used to control the vertical rotation direction of the welding torch. In addition, the shape of the connecting rotating bead is a sphere, and the shape of the sphere can provide convenience for the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com