Socket

A socket and tooth technology, which is applied to electrical components, coupling devices, circuits, etc., can solve the problem of the singleness of the connector installation direction, and achieve the effects of simple and reliable structure, low cost and low manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

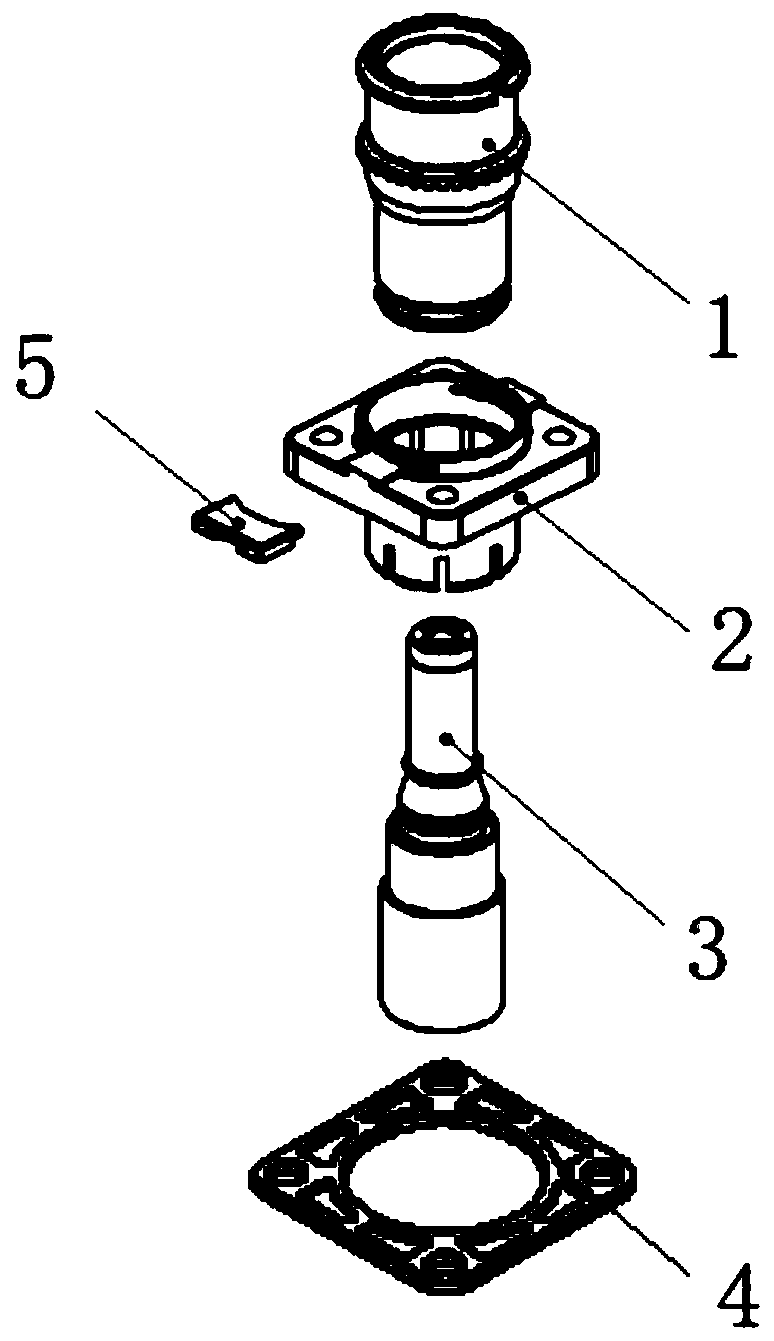

[0025] First, refer to figure 1 , the socket of this application mainly includes three main structures: socket rotating shell 1, socket shell 2 and socket conductor 3; Figure 4 The socket rotating shell has a big end and a small end, the small end of the socket rotating shell runs through the socket shell, and the big end of the socket rotating shell is blocked and fixed by the socket shell. The socket conductor is inserted into the socket rotary shell from the small end of the socket rotary shell, and its conductive end is flush with the big end of the socket rotary shell; a sealing ring 4 is arranged between the socket conductor 3 and the socket shell 2 .

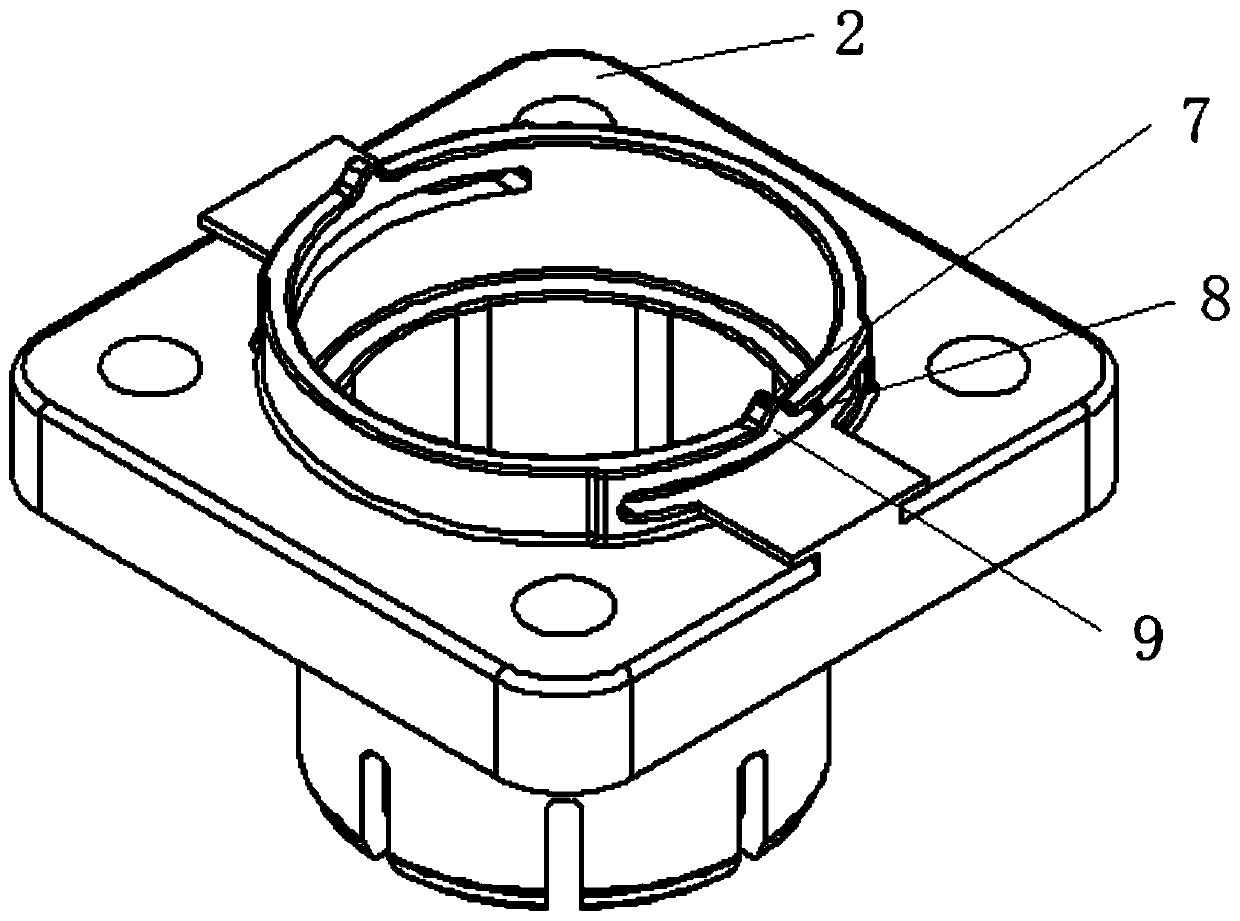

[0026] In order to achieve rotation locking, the present application relates to a two-stage locking structure.

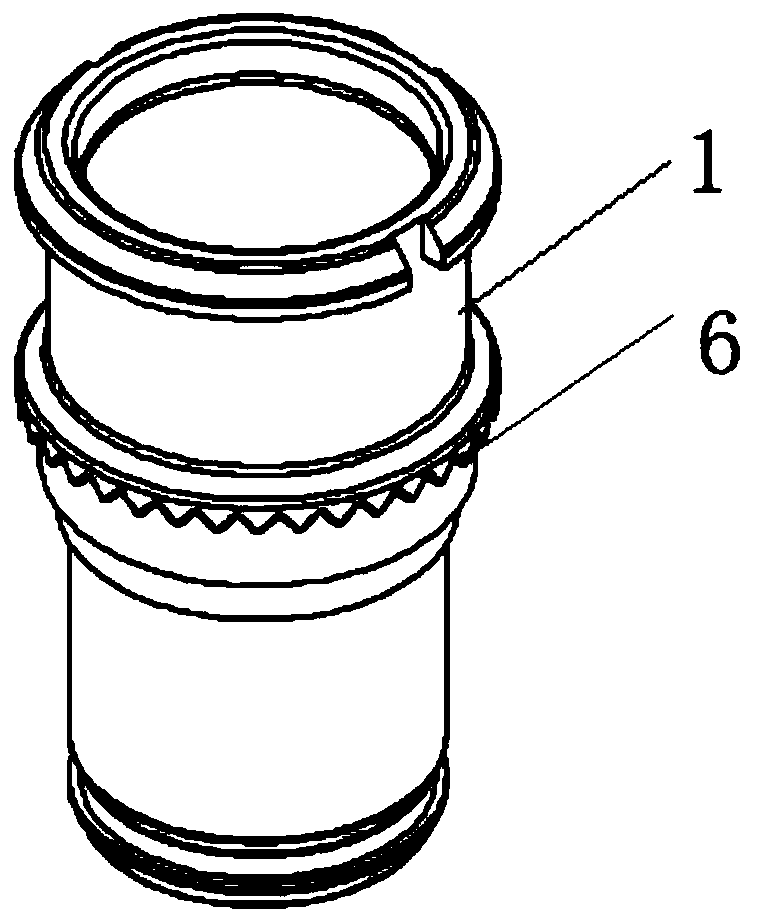

[0027] Such as figure 2 shown with image 3 As shown, the first-level locking structure is mainly composed of a number of first locking teeth 6 arranged on an outer circumference of the socket rotating she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com