Patents

Literature

251results about How to "Increase lifting power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

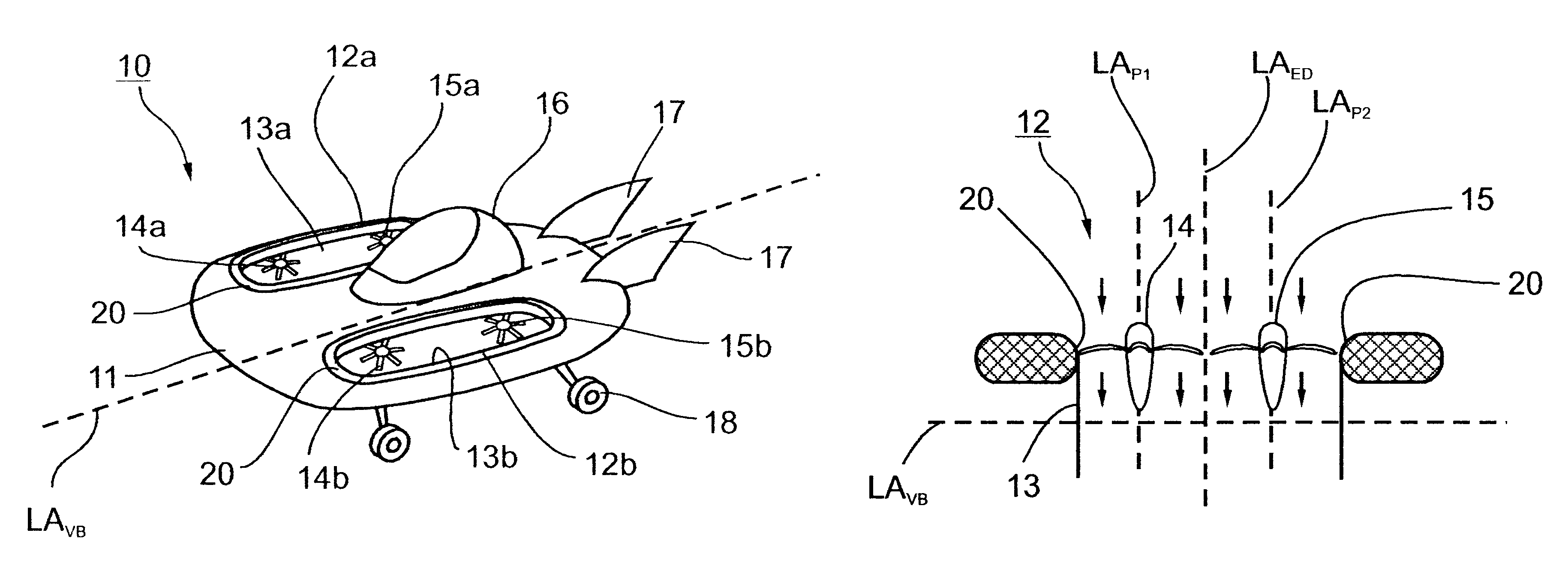

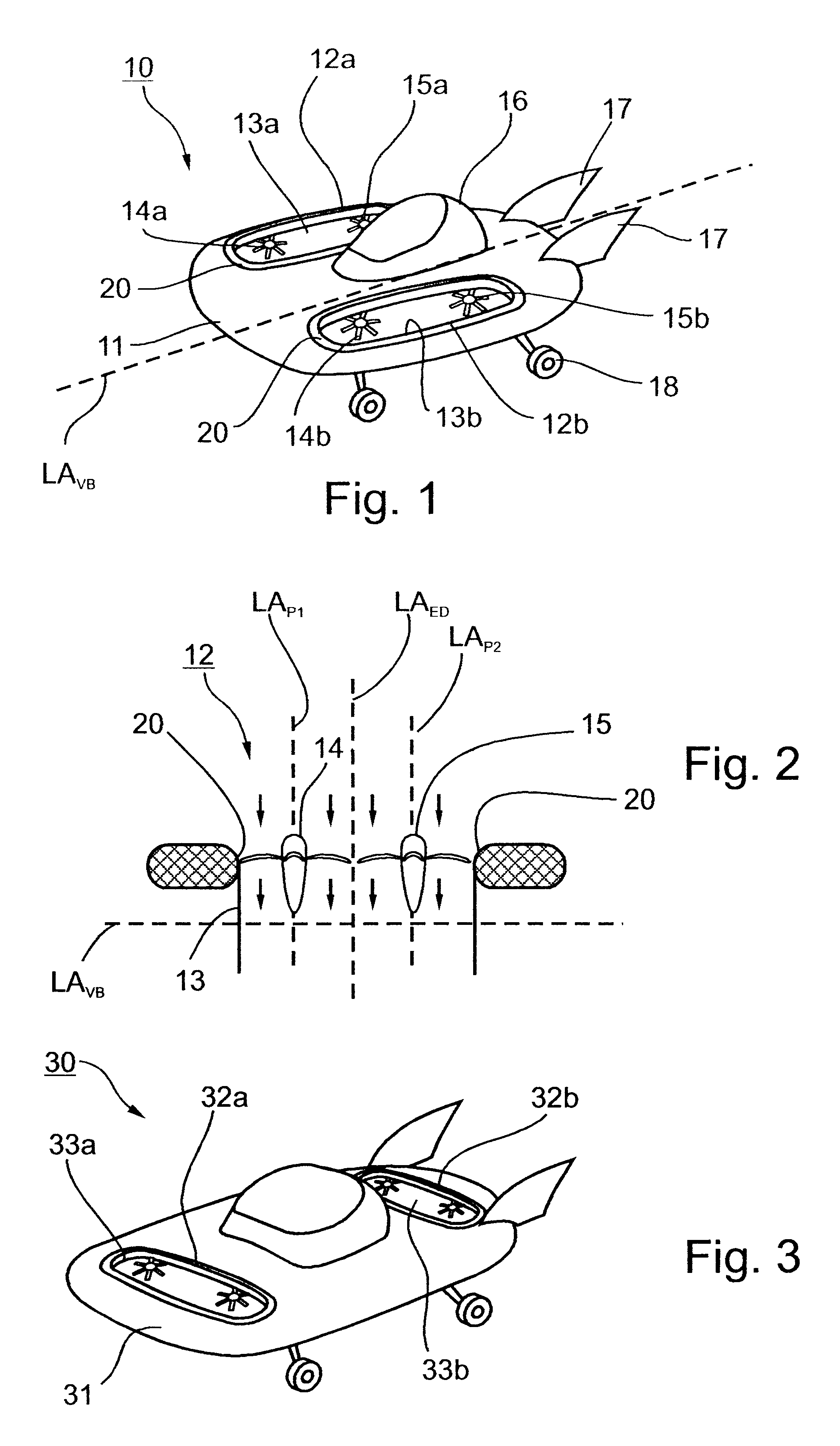

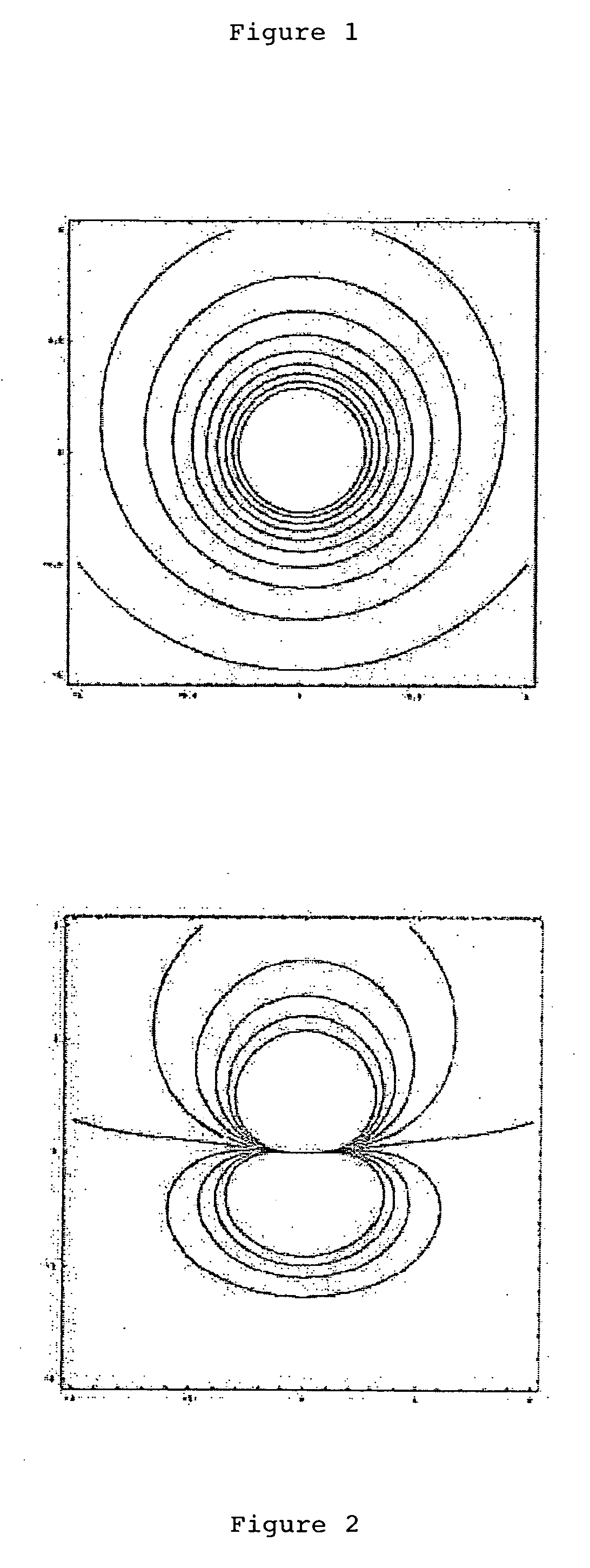

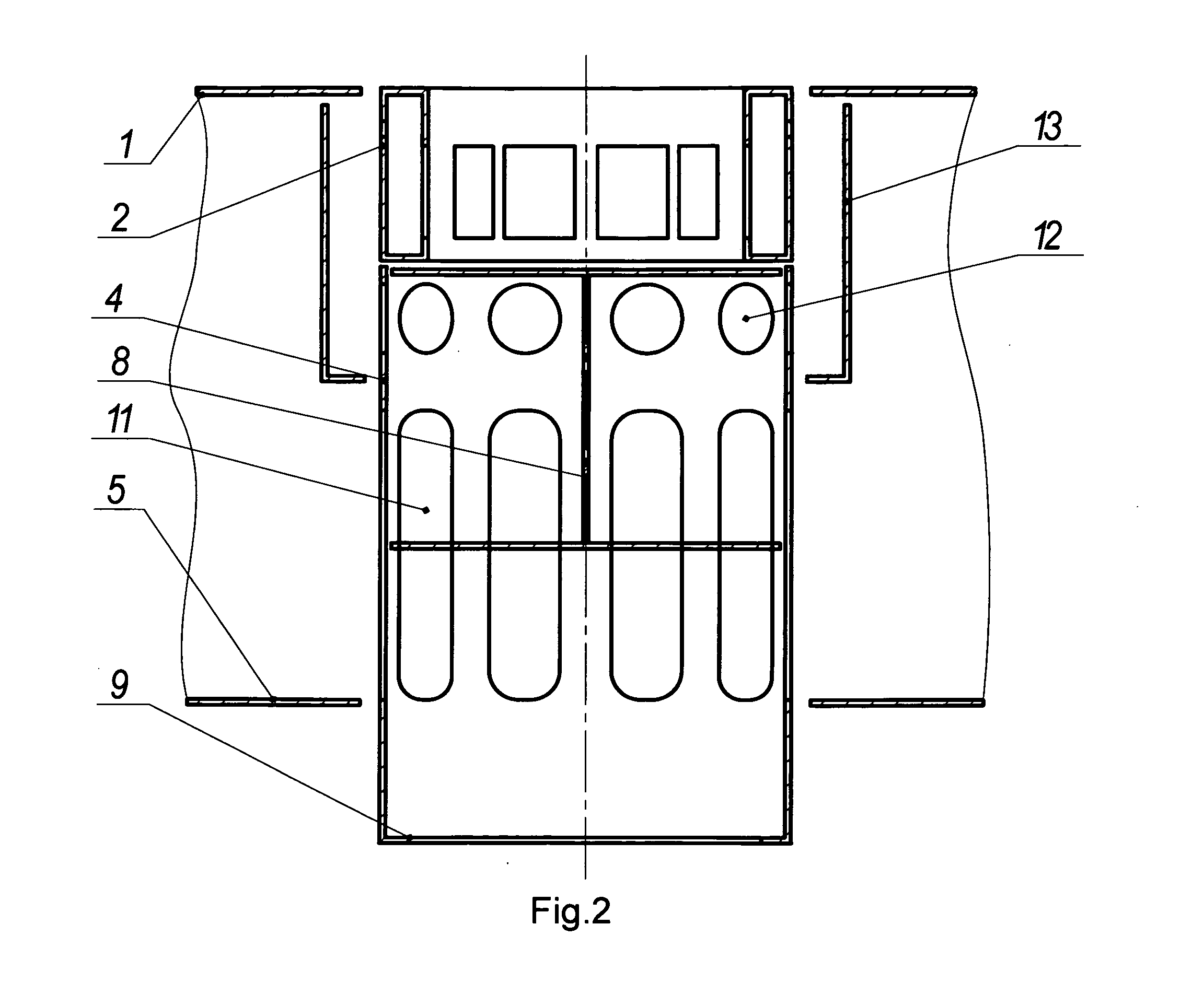

Ducted vehicles particularly useful as VTOL aircraft

InactiveUS6568630B2Easy entryEasy exitAircraft navigation controlFlying saucersJet aeroplaneJet engine

A VTOL aircraft (or other vehicle such as a sea vehicle) includes a pair of elongated ducts on opposite sides of the vehicle body, and a plurality of powered propellers (or other propulsion units such as jet engines) mounted within and enclosed by each of the elongated ducts, such as to produce an upward lift force to the vehicle. Each of the elongated ducts has a short transverse dimension slightly larger than the diameter of the blades of each propeller enclosed thereby, and a large transverse dimension slightly larger than the sum of the diameters of the blades of all the propellers enclosed thereby.

Owner:URBAN AERONAUTICS

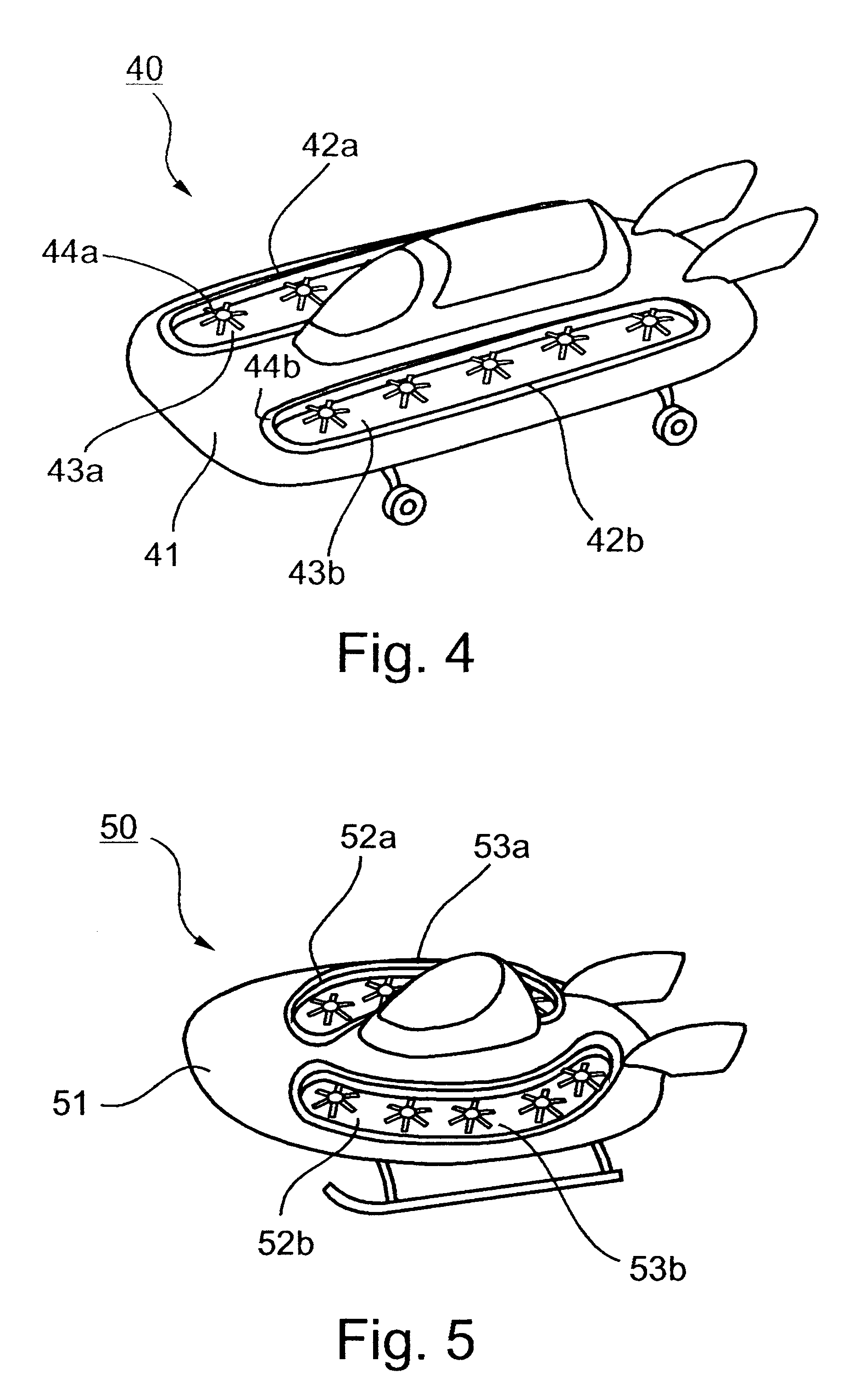

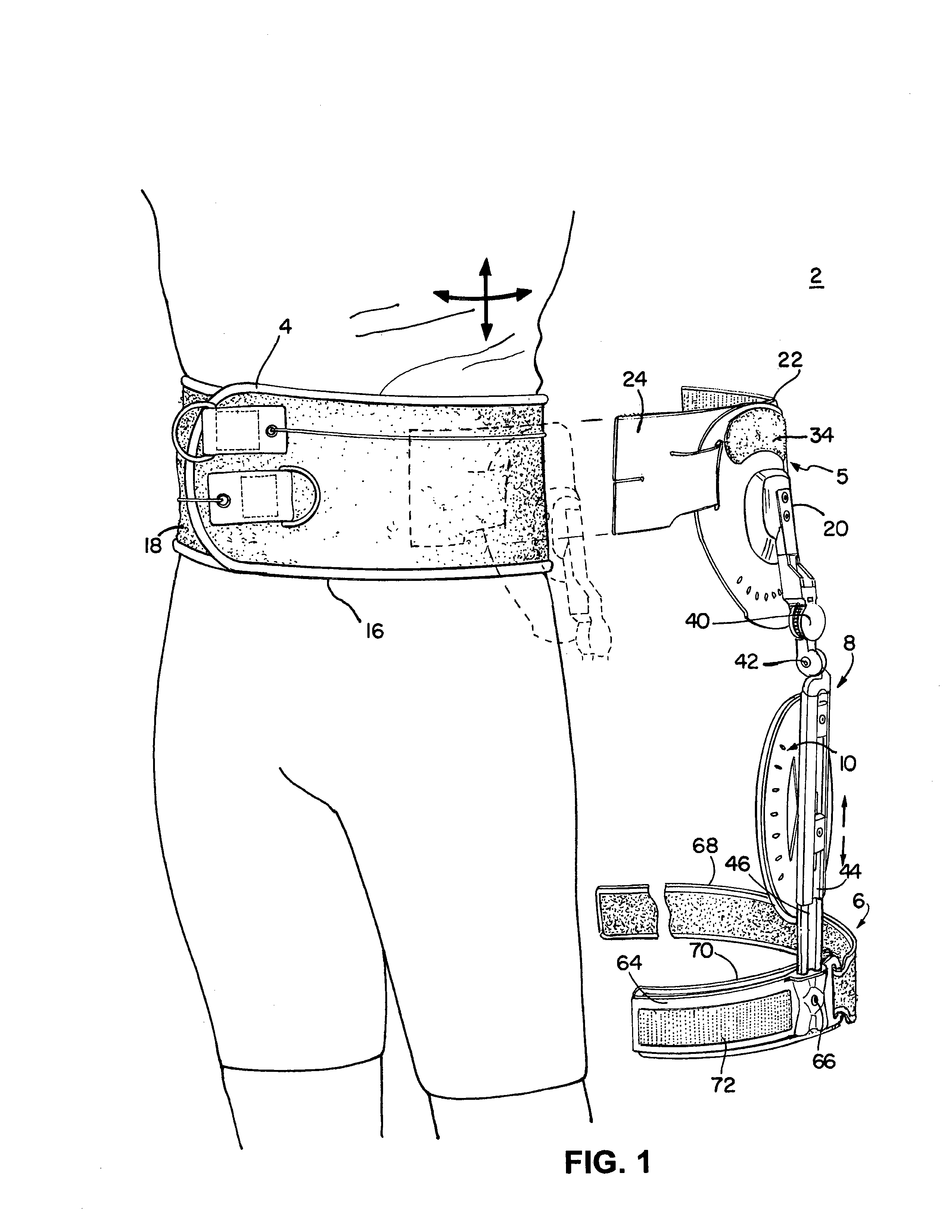

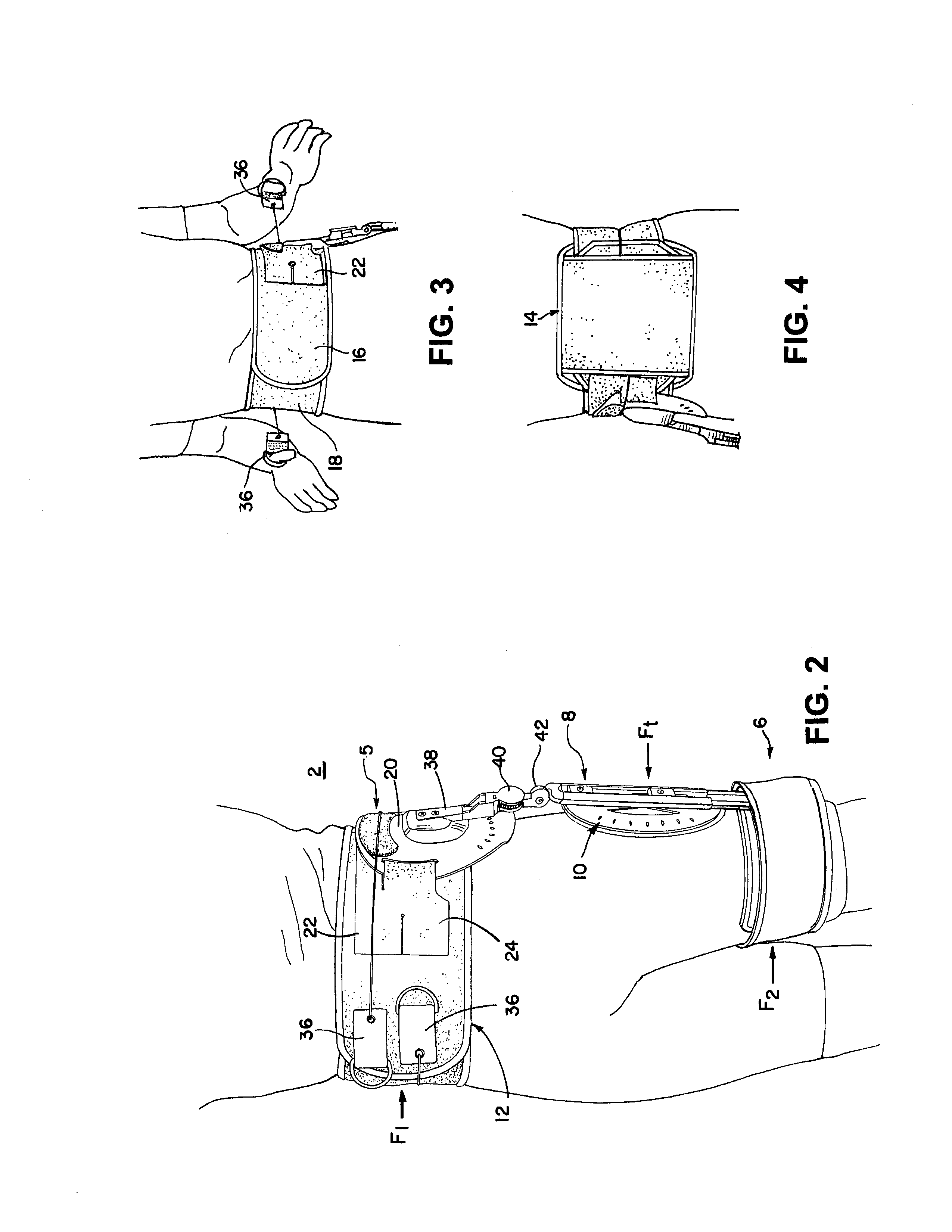

Pelvic support and walking assistance device

InactiveUS6039707APrevent hip dropPrevent pelvis swayNon-surgical orthopedic devicesThighLegs weakness

A pelvic support and walking assistance device is disclosed which includes a trunk support member and a thigh lifting member coupled to each other at a pivot joint positioned opposite a hip joint of a user. The device functions to prevent pelvic sway. With a spring coupled with said pivot joint, the device further provides a thigh lifting torque to partially compensate for proximal leg weakness. The spring assistance pivot device includes a winding device that can be adjusted in use for varying forward torque for varying situations.

Owner:CRAWFORD MICHAEL K +1

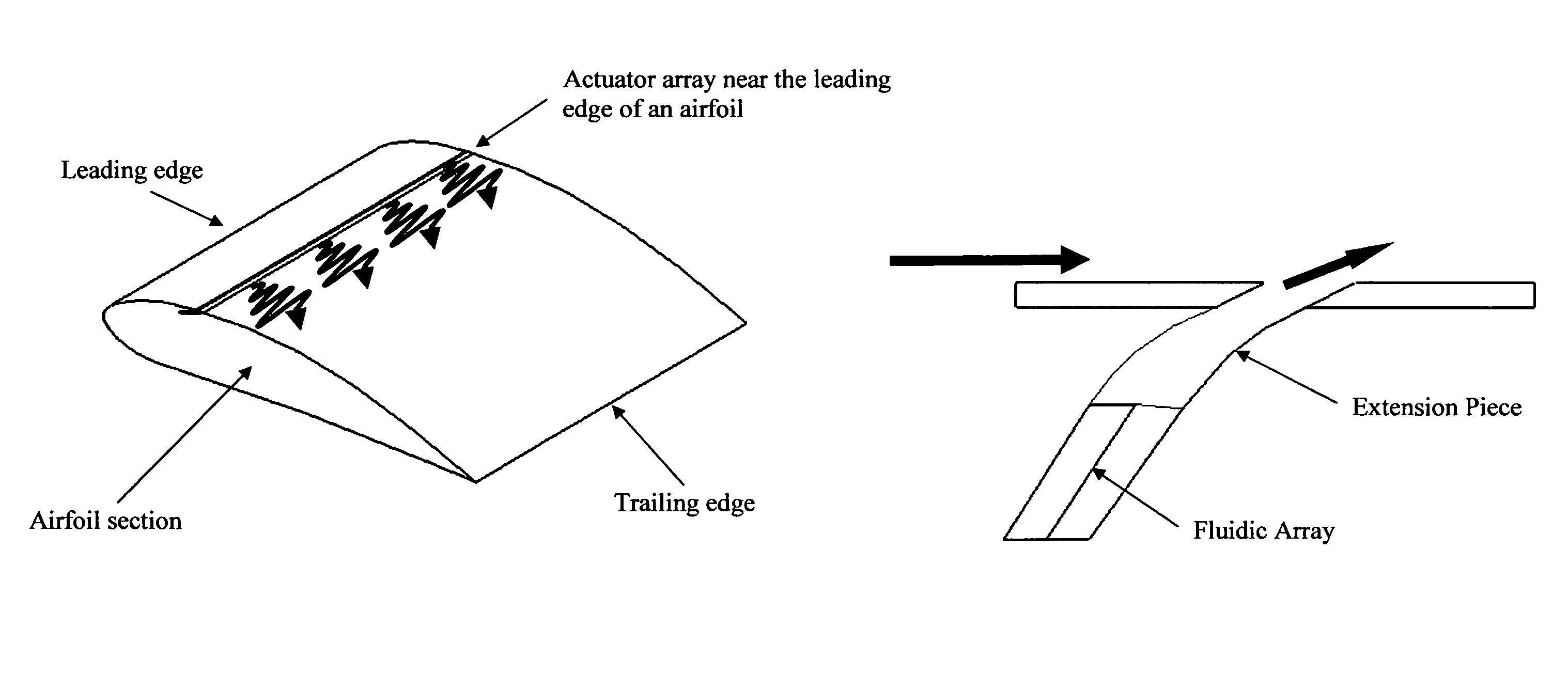

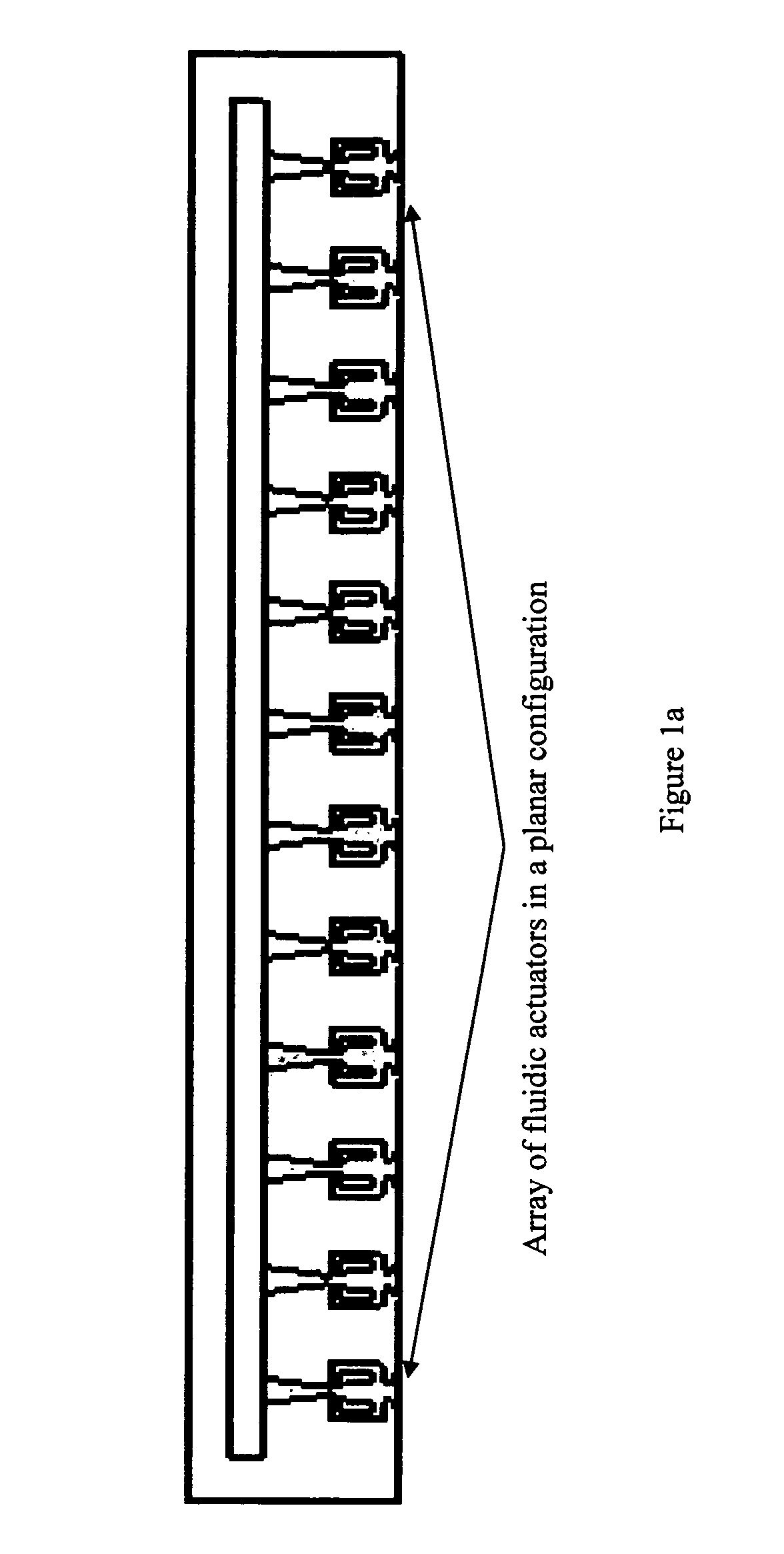

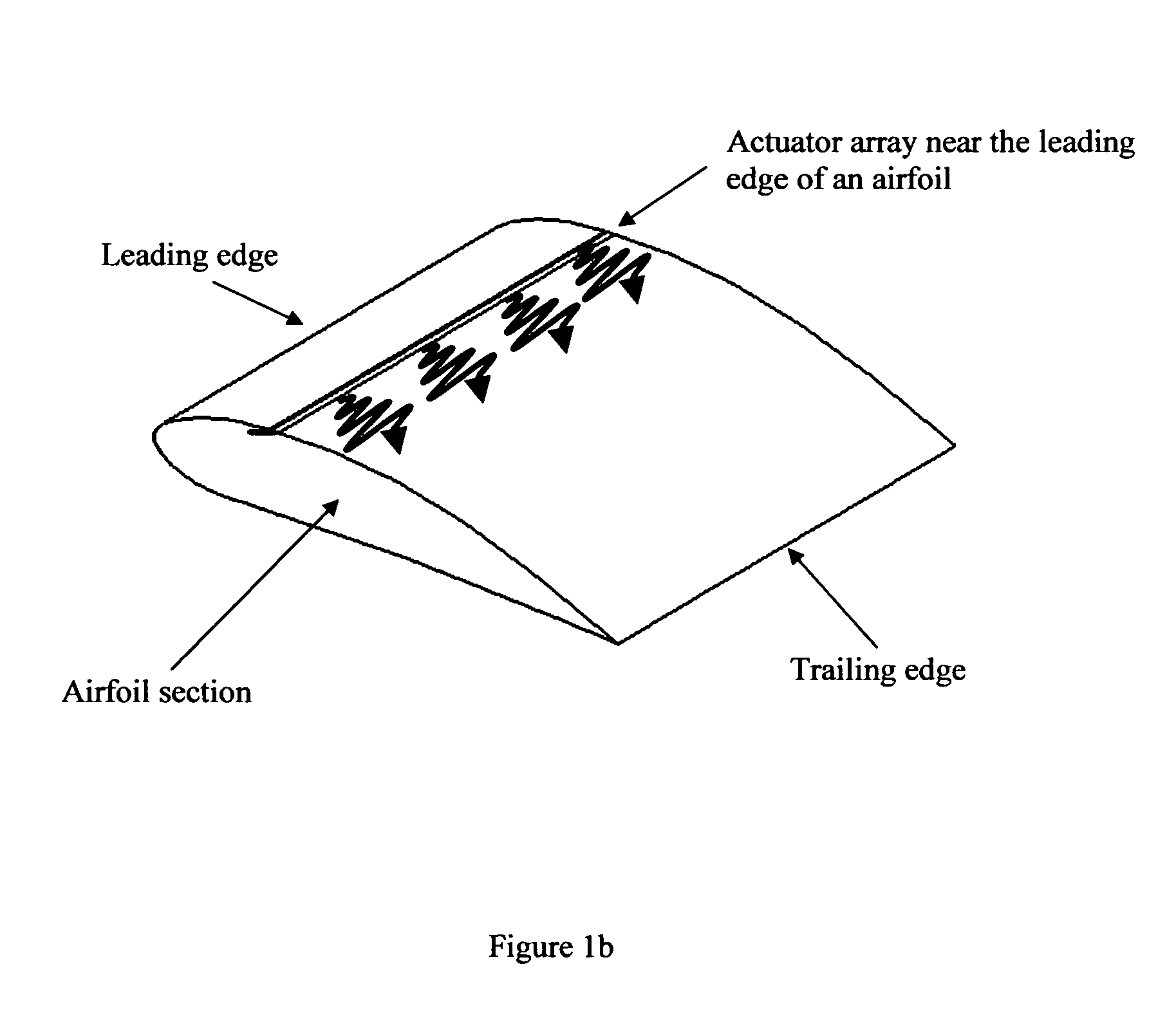

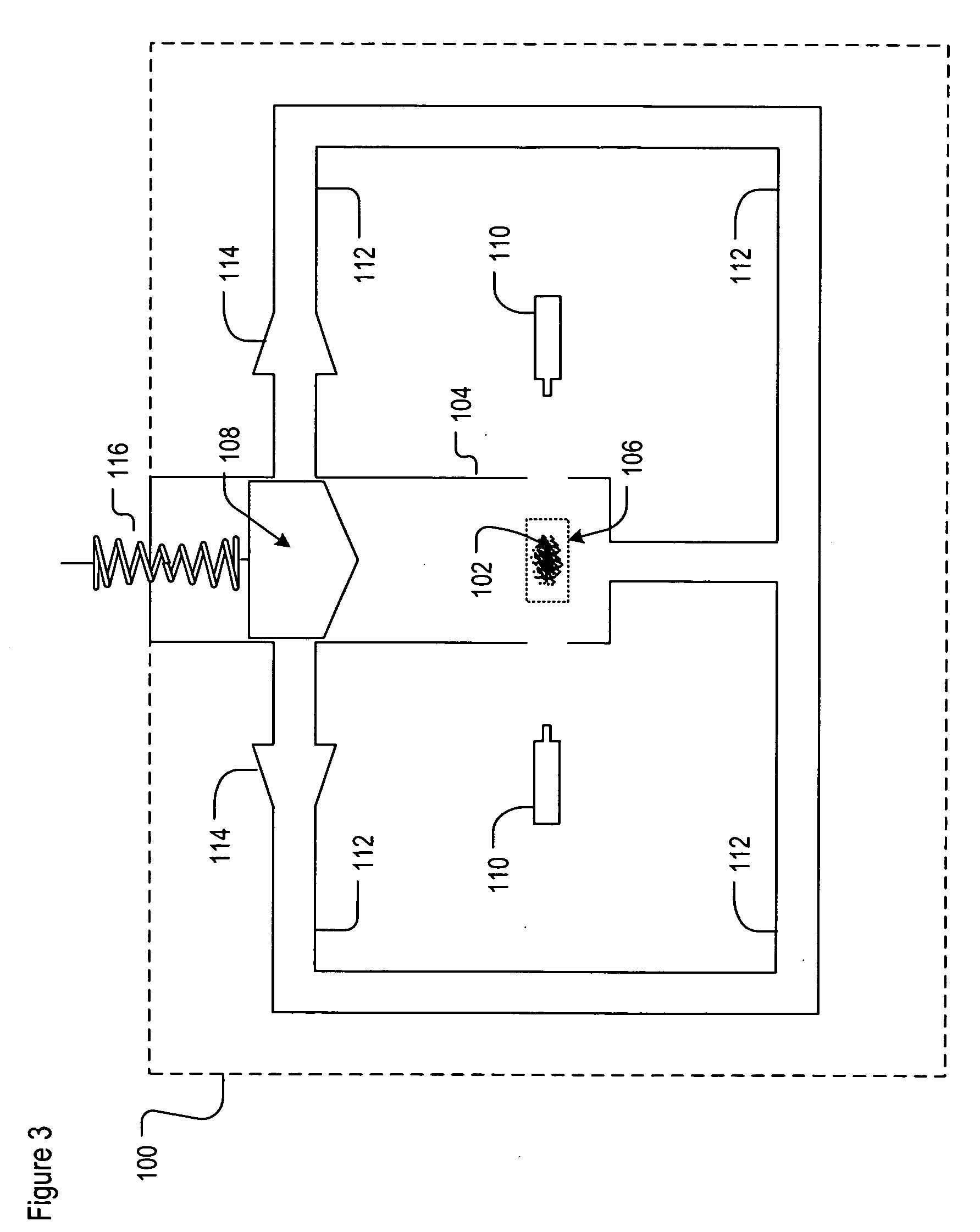

Method and apparatus for aerodynamic flow control using compact high-frequency fluidic actuator arrays

ActiveUS8382043B1Even air distributionAvoid separationBoundary layer controlsWingsJet engineEngineering

The present invention is directed to the manufacture of and the use of an aerodynamic flow control device having a compact array of a plurality of fluidic actuators in planar, curved, circular and annular configurations. The compact array of fluidic actuators of the invention may be designed to produce oscillating or pulsed jets at the exit ports with frequencies in the range of 1-22 kHz. They may be integrally manufactured along with the wing sections, flaps, tail and rudder of airplane, the inlet or exit geometries of a jet engine. When supplied with a source of fluid such as air, these arrays of actuators produce a set of fluid jets of random phase of high velocity and influence the main stream of air over the subject surface. The beneficial effects of modifying flow using the present invention include increased lift, reduced drag, improved performance and noise reduction in jet engines.

Owner:RAGHU SURYA

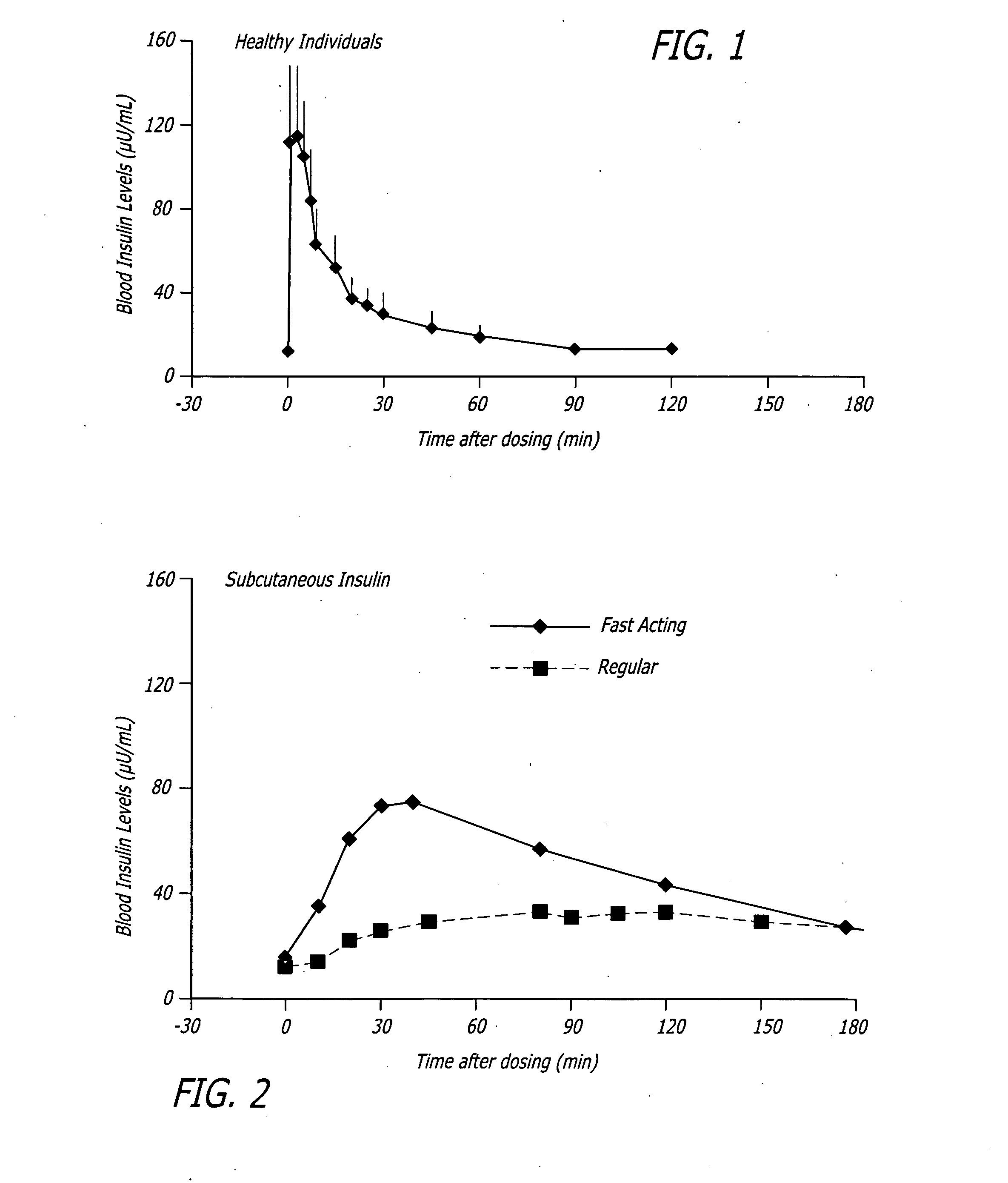

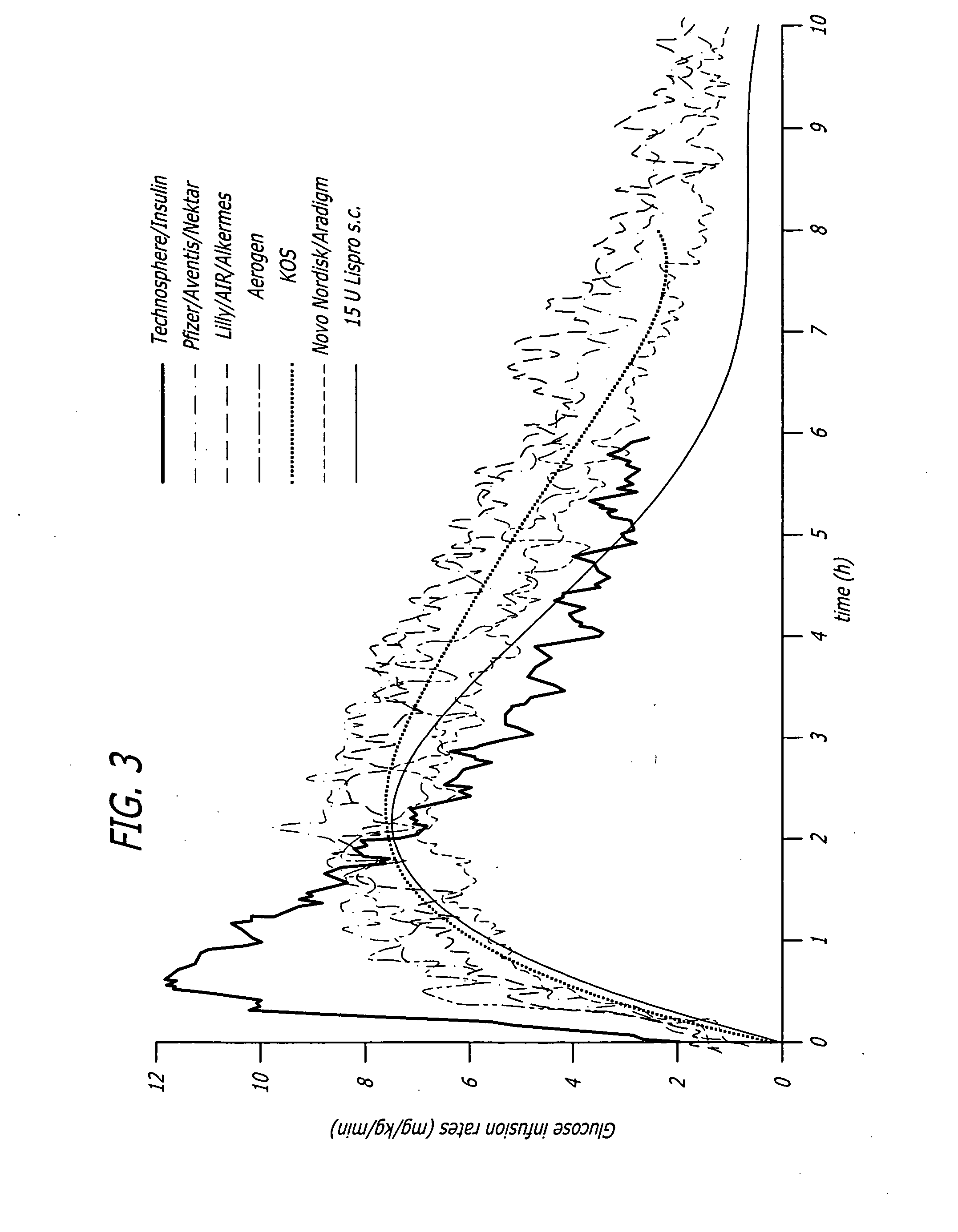

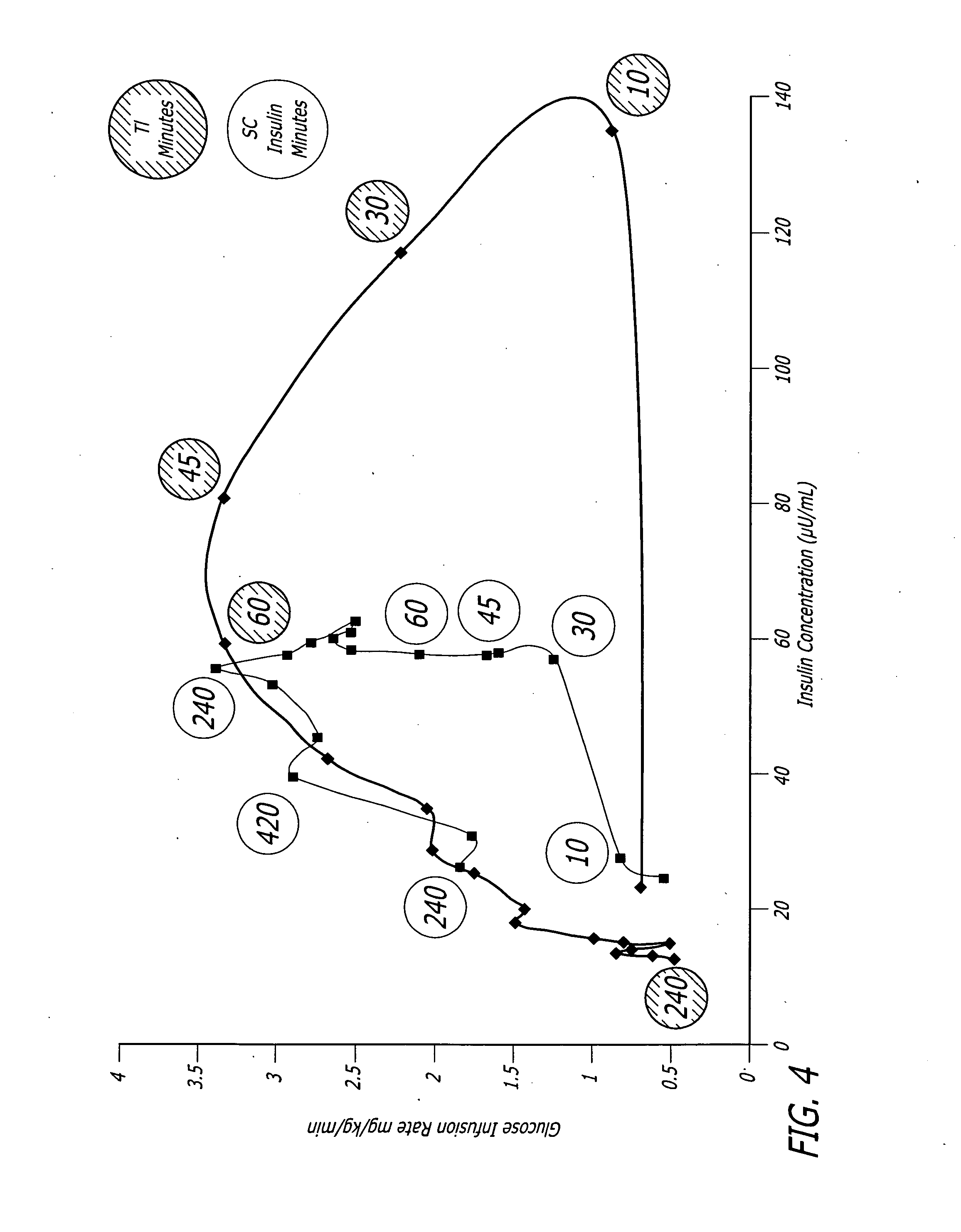

Potentiation of glucose elimination

InactiveUS20070020191A1Improve efficiencyEffective controlPowder deliveryOrganic active ingredientsInsulin activityPostprandial Hypoglycemia

Owner:MANNKIND CORP

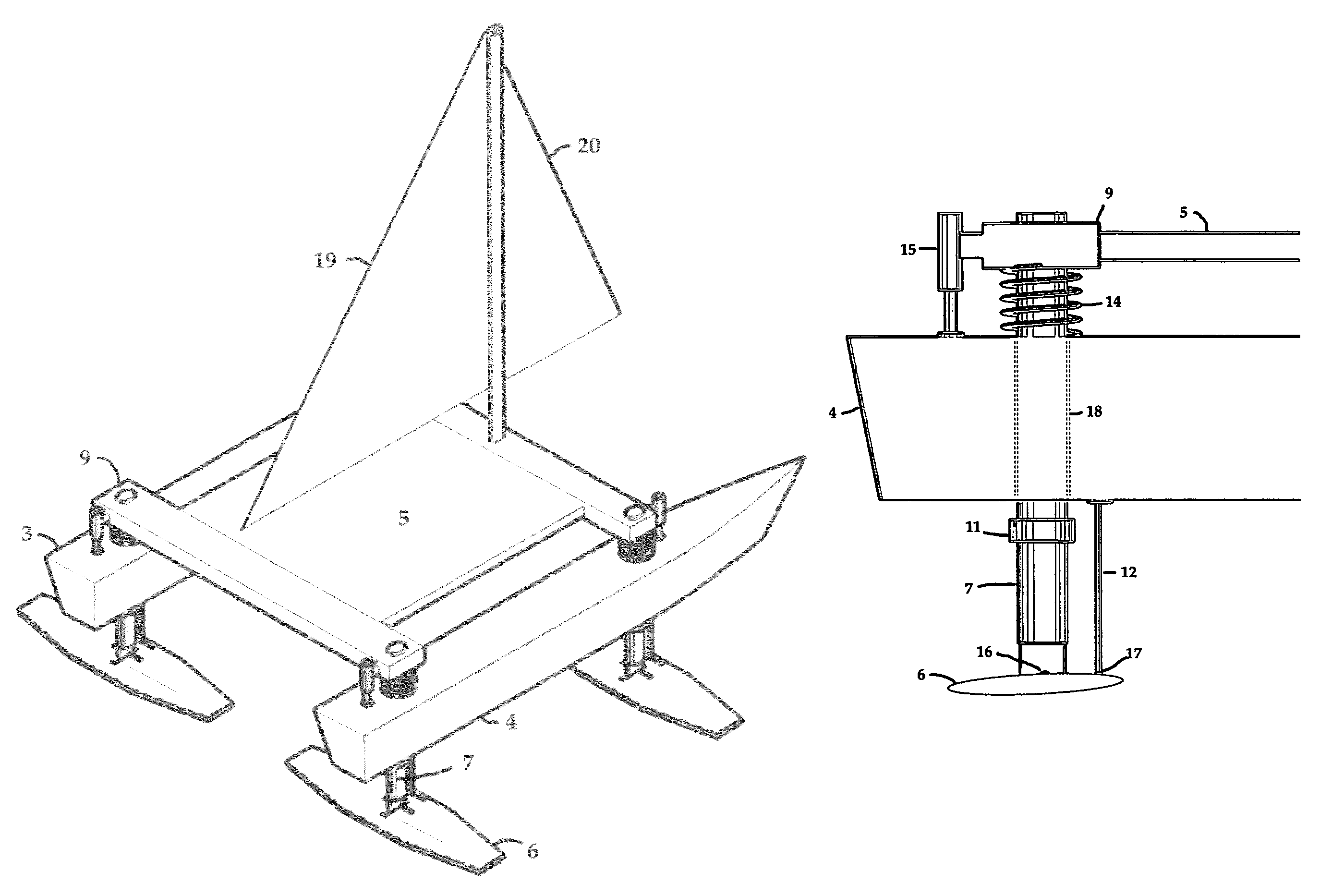

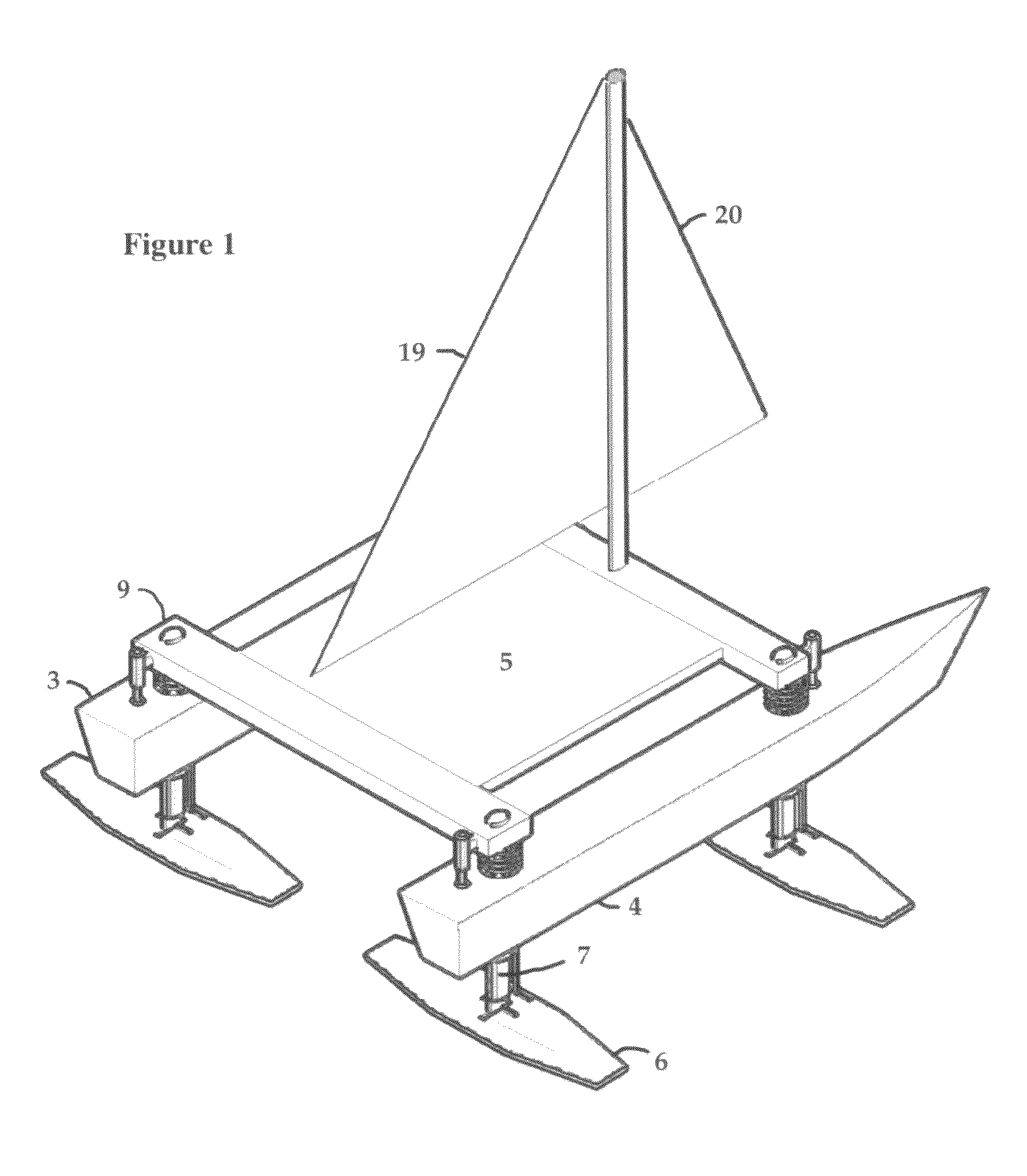

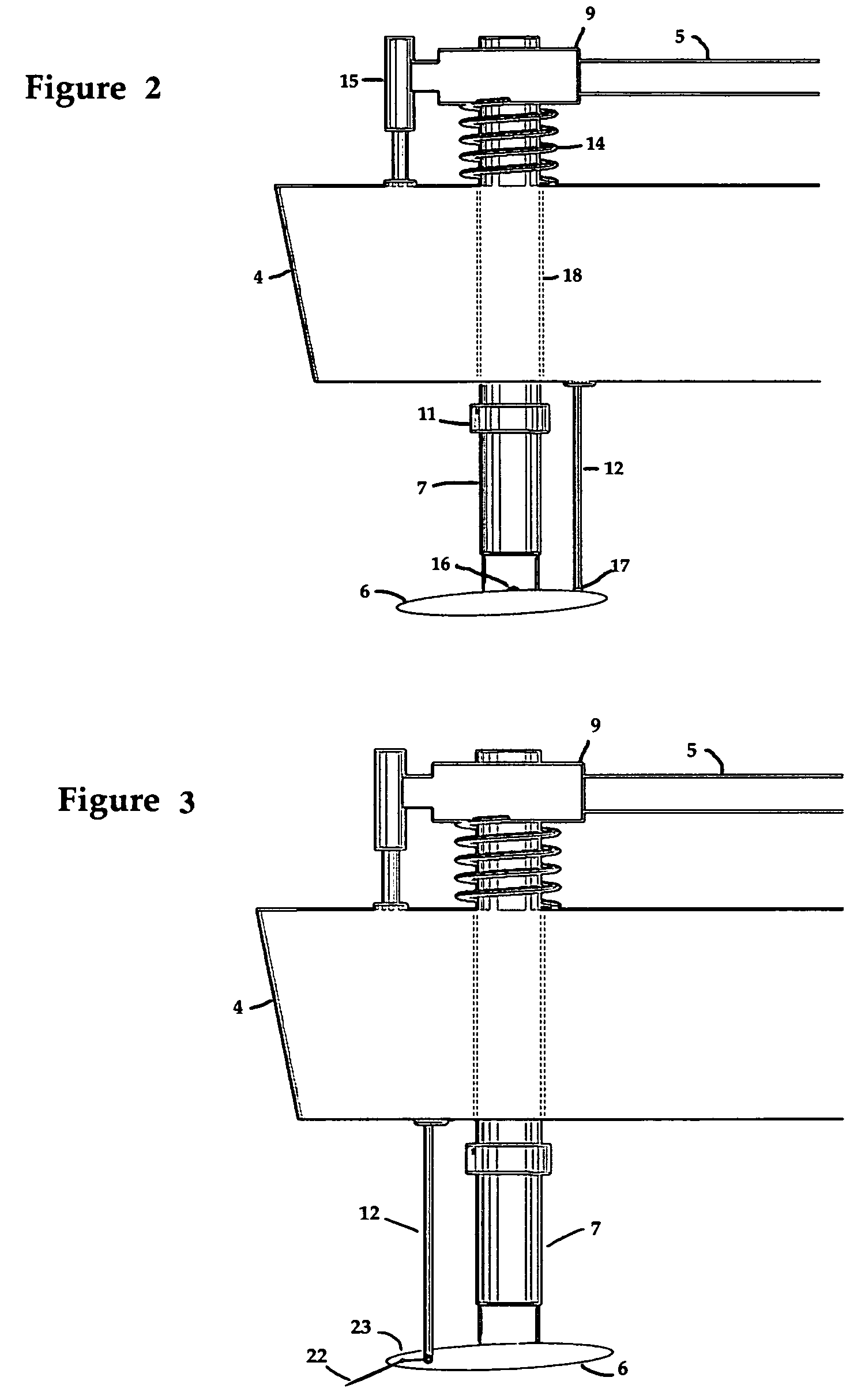

Multihull hydrofoil watercraft

InactiveUS7743720B1Reduce angle of attackReduce lifting forceVessel partsVessel movement reduction by foilsAutomatic controlAutomatic train control

A multihull hydrofoil watercraft incorporates a stabilization system wherein the buoyancy of the hulls is used as a sensing and control mechanism for the hydrofoils. The use of hull buoyancy to adjust the hydrofoil lift provides for automatic control of altitude, pitch and roll, and allows the craft to accommodate varying weather and sea conditions while providing a smooth ride for passengers. The stabilization technique eliminates the need for extraneous sensing mechanisms placed in or on the water surface which are subject to fouling, damage, or disruption by localized surface disturbances.

Owner:SALANI STEVEN JOHN

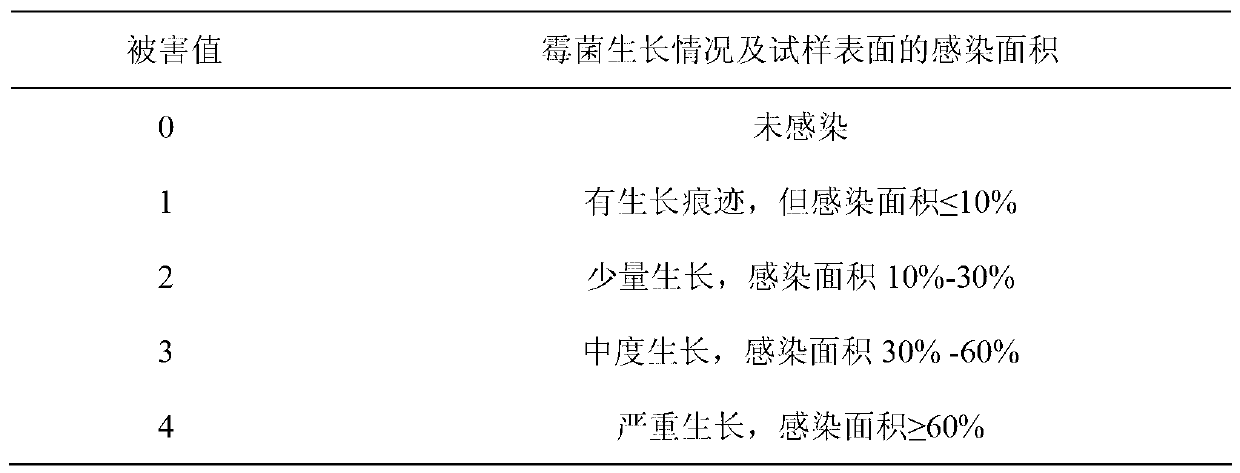

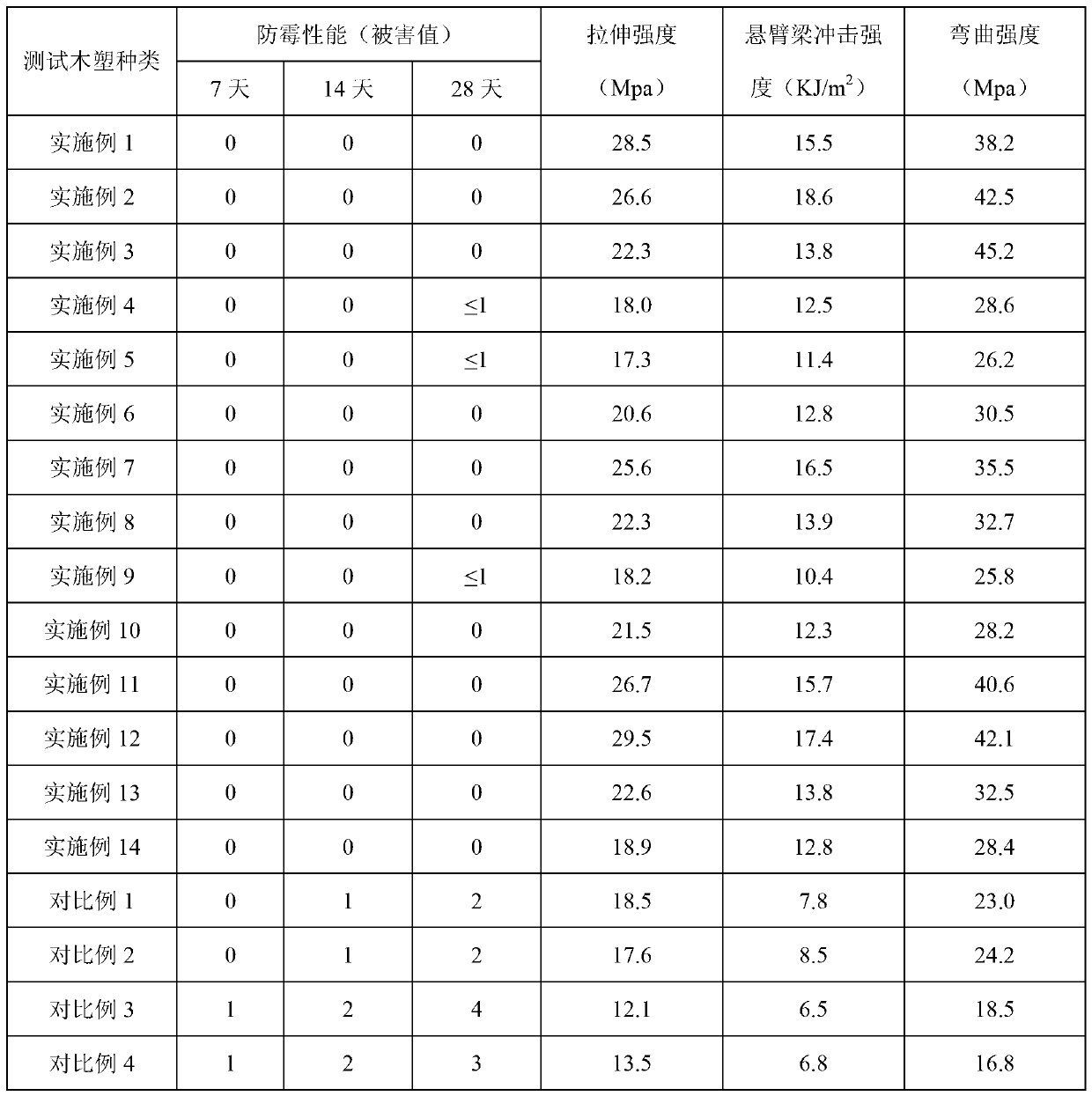

Environmentally-friendly mould-proofing wood-plastic composite material and preparation method thereof

ActiveCN103102591AImprove mildew resistanceImprove compatibility and interface affinityRevolutions per minuteCalcium carbonate

The invention discloses an environmentally-friendly mould-proofing wood-plastic composite material and a preparation method thereof. The preparation method comprises the following steps: mixing a plastic substrate, modified wood fiber powder, calcium carbonate, a lubricant, a light stabilizer, a toner and other components in parts by mass; adding the mixture to a high-speed mixer; uniformly stirring; mixing for 6 to 15 minutes at a high speed and at a temperature of 100-120 DEG C and a revolving speed of 700 to 100 revolutions per minute; cooling; discharging to obtain a premix; adding the premix to a parallel twin-screw machine to granulate and extrude, wherein the temperature is controlled to 150-185 DEG C, and screws are at a revolving speed of 280 to 320 revolutions per minute during granulating, the temperature is controlled to 155-190 DEG C, and the screws are at a revolving speed of 10 to 15 revolutions per minute during extruding; thus obtaining the environmentally-friendly mould-proofing wood-plastic composite material. The environmentally-friendly mould-proofing wood-plastic composite material is high in mould proofing performance and mechanical performance, and is environmentally-friendly.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

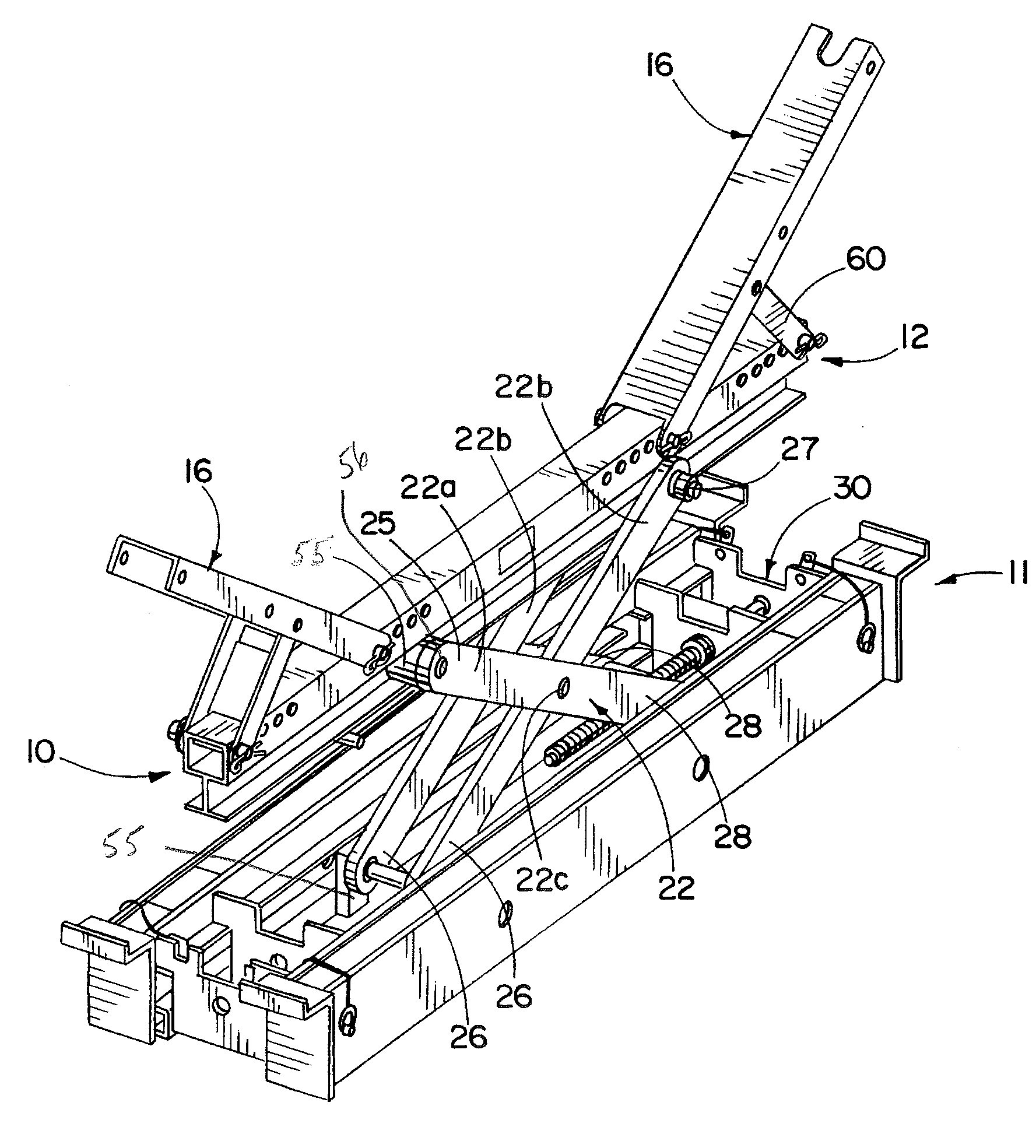

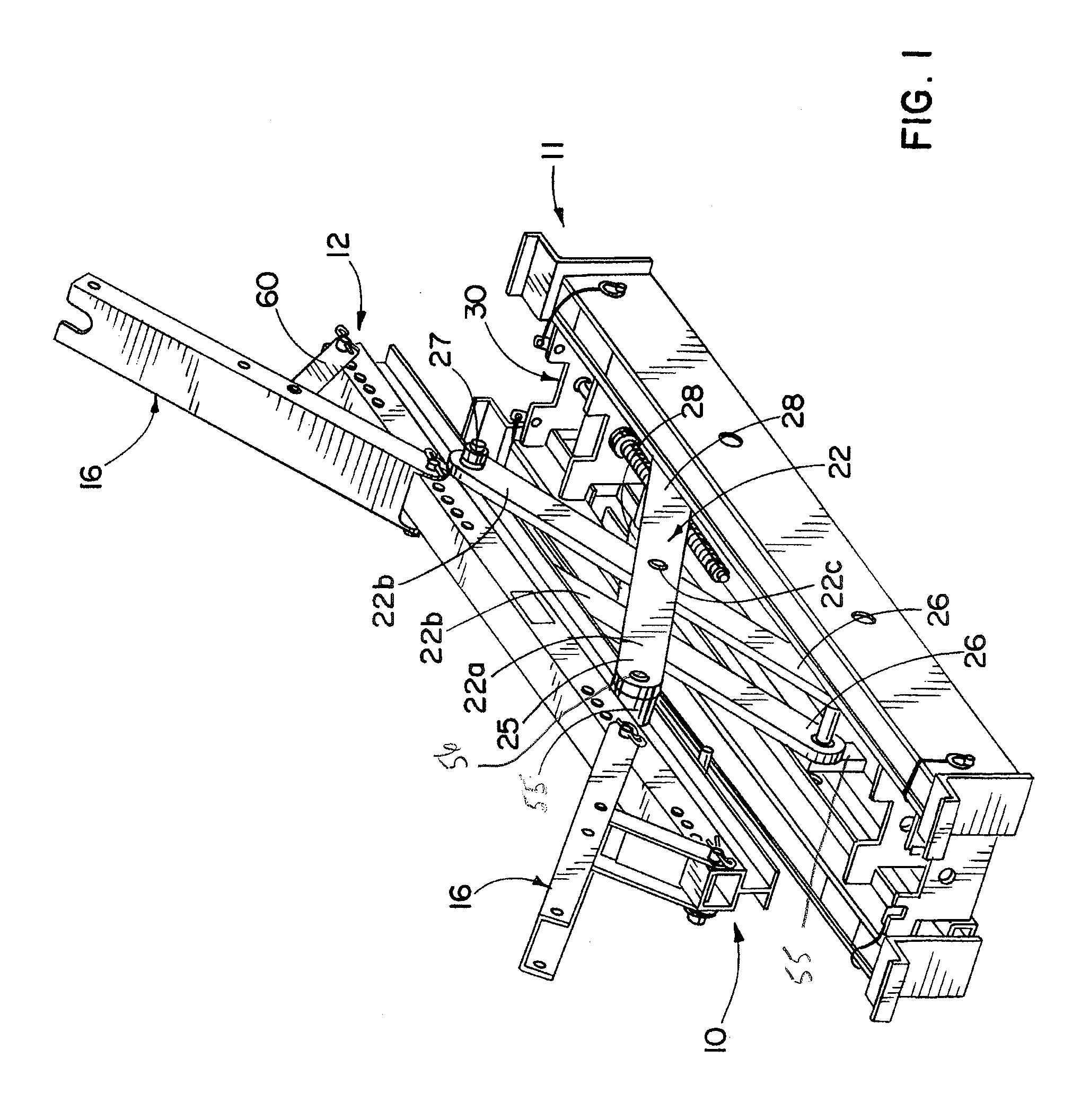

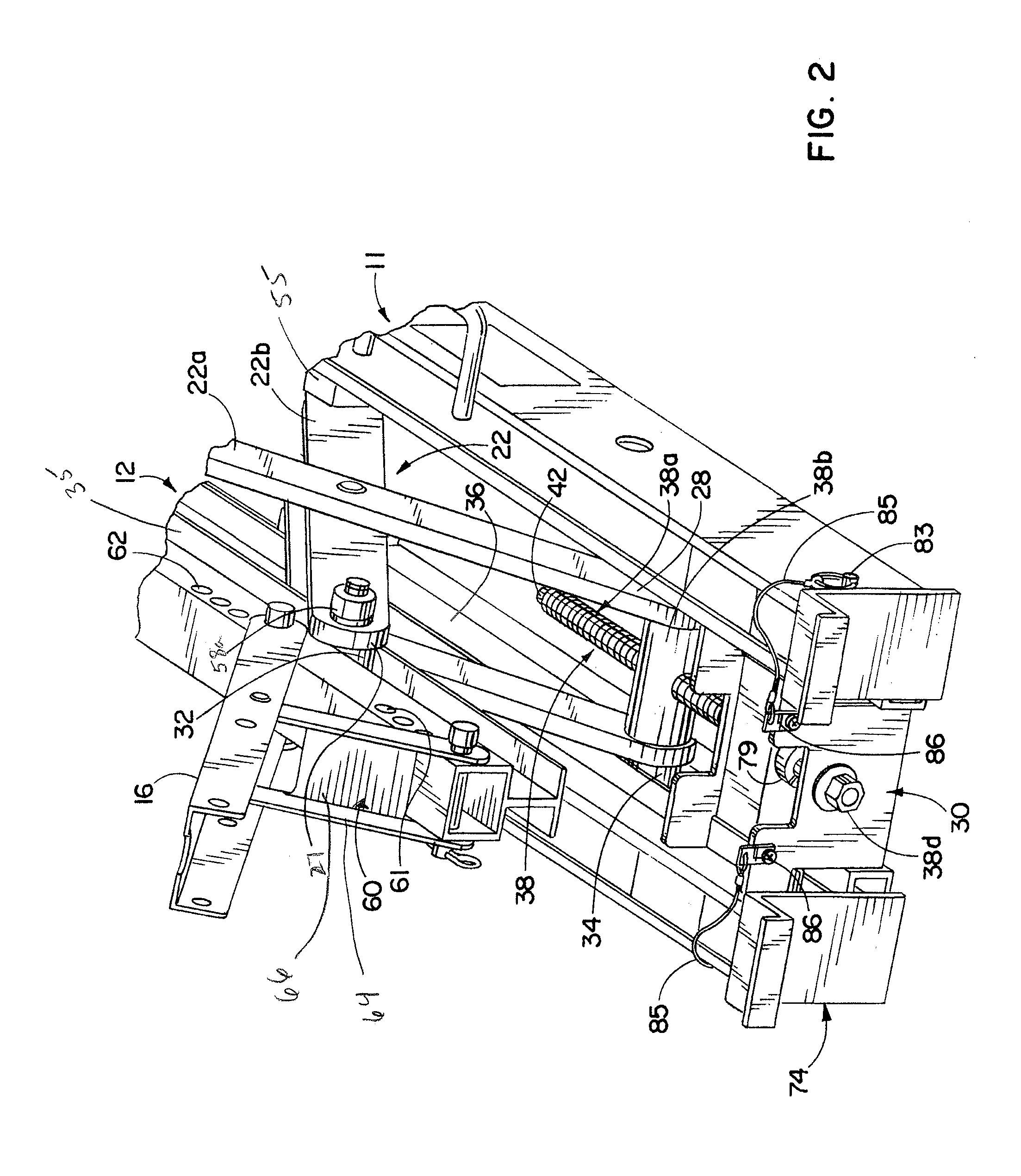

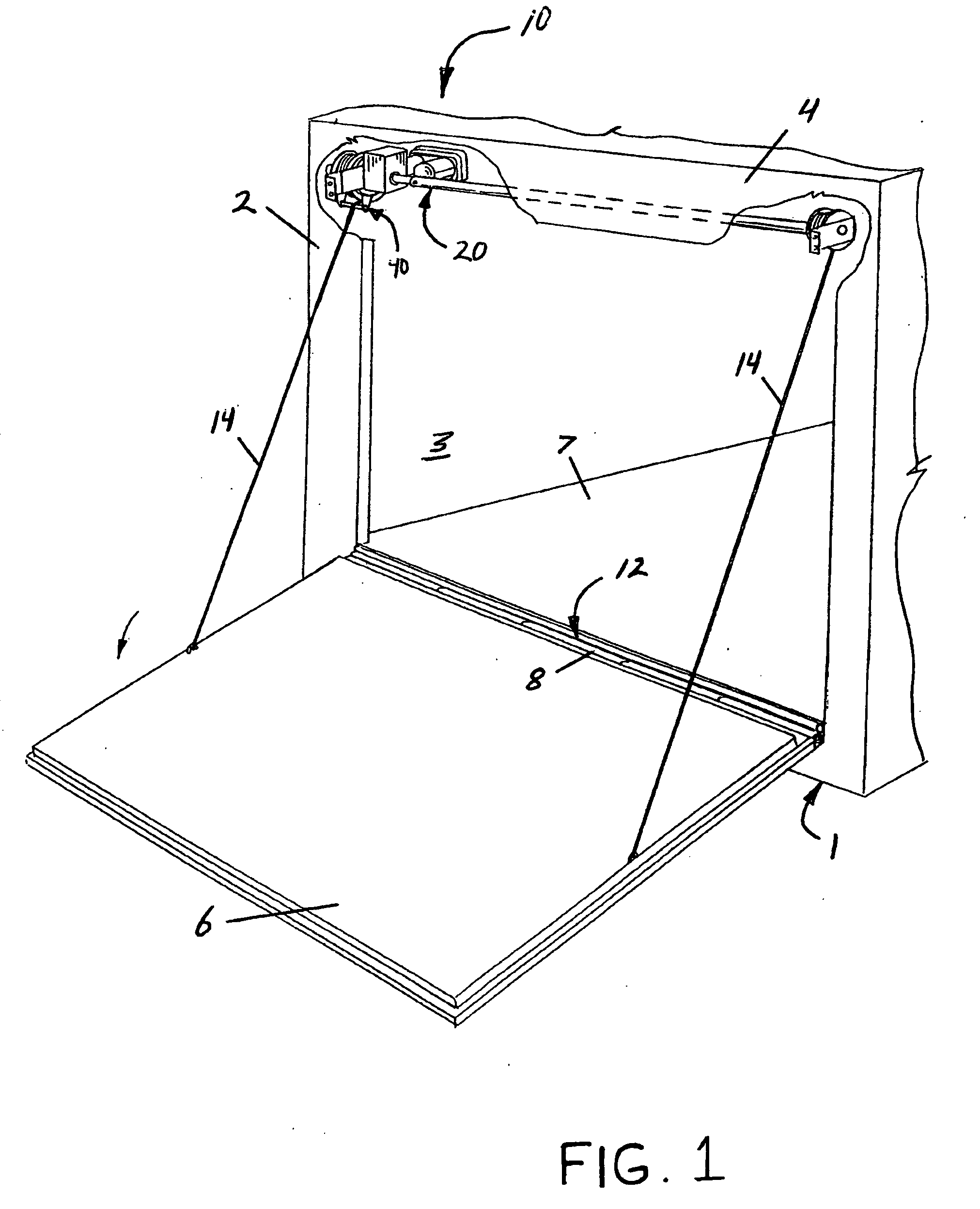

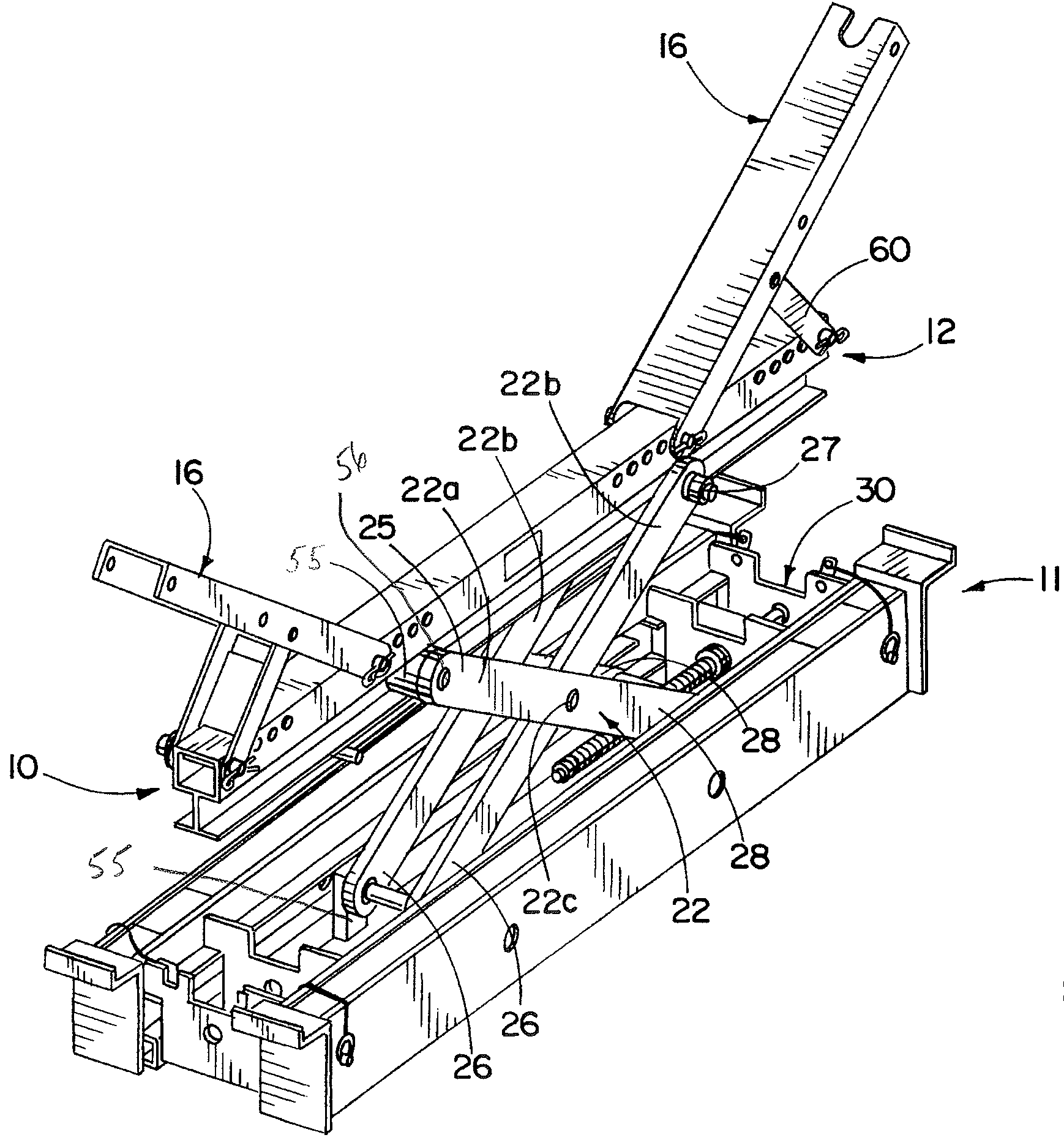

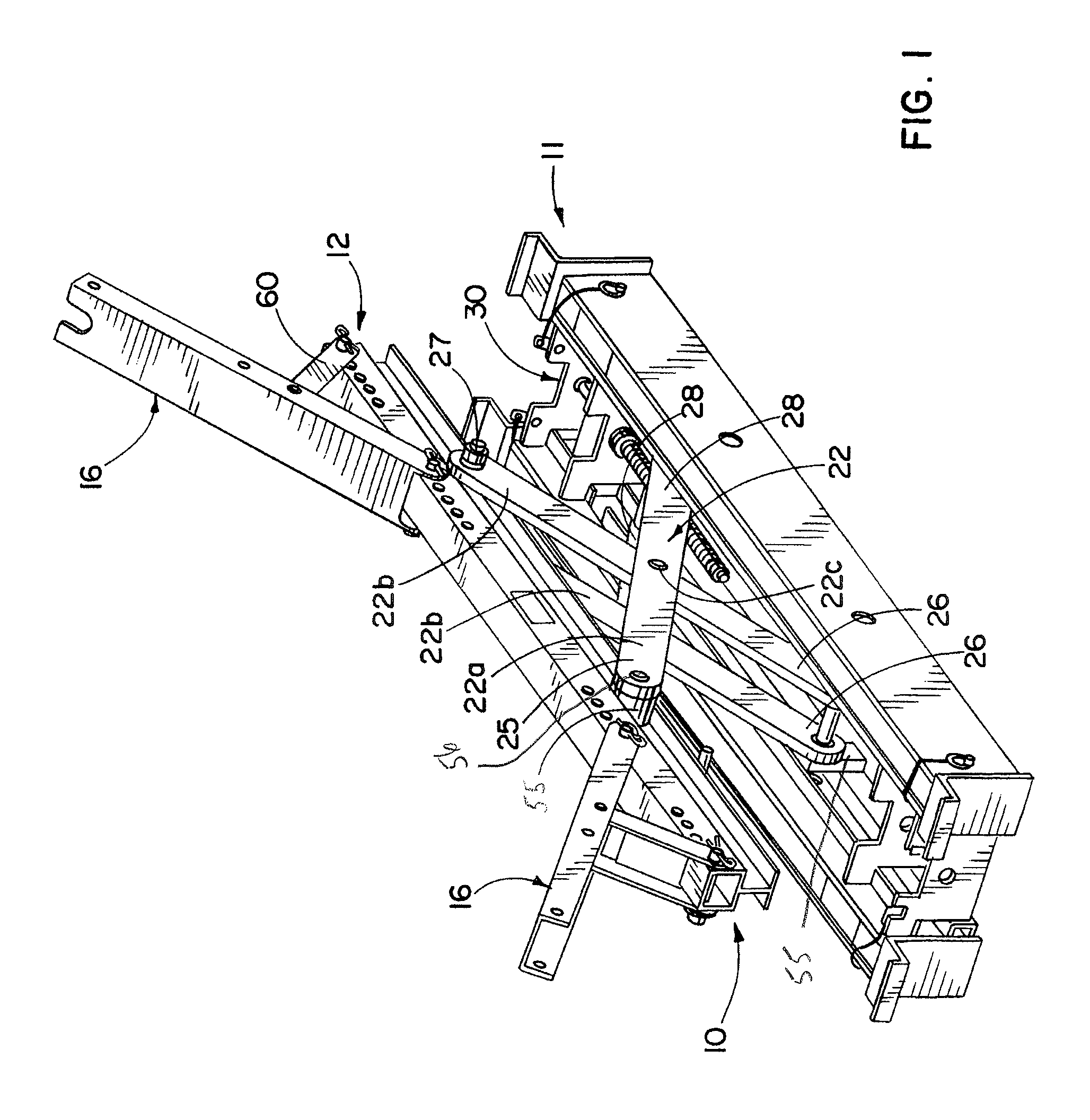

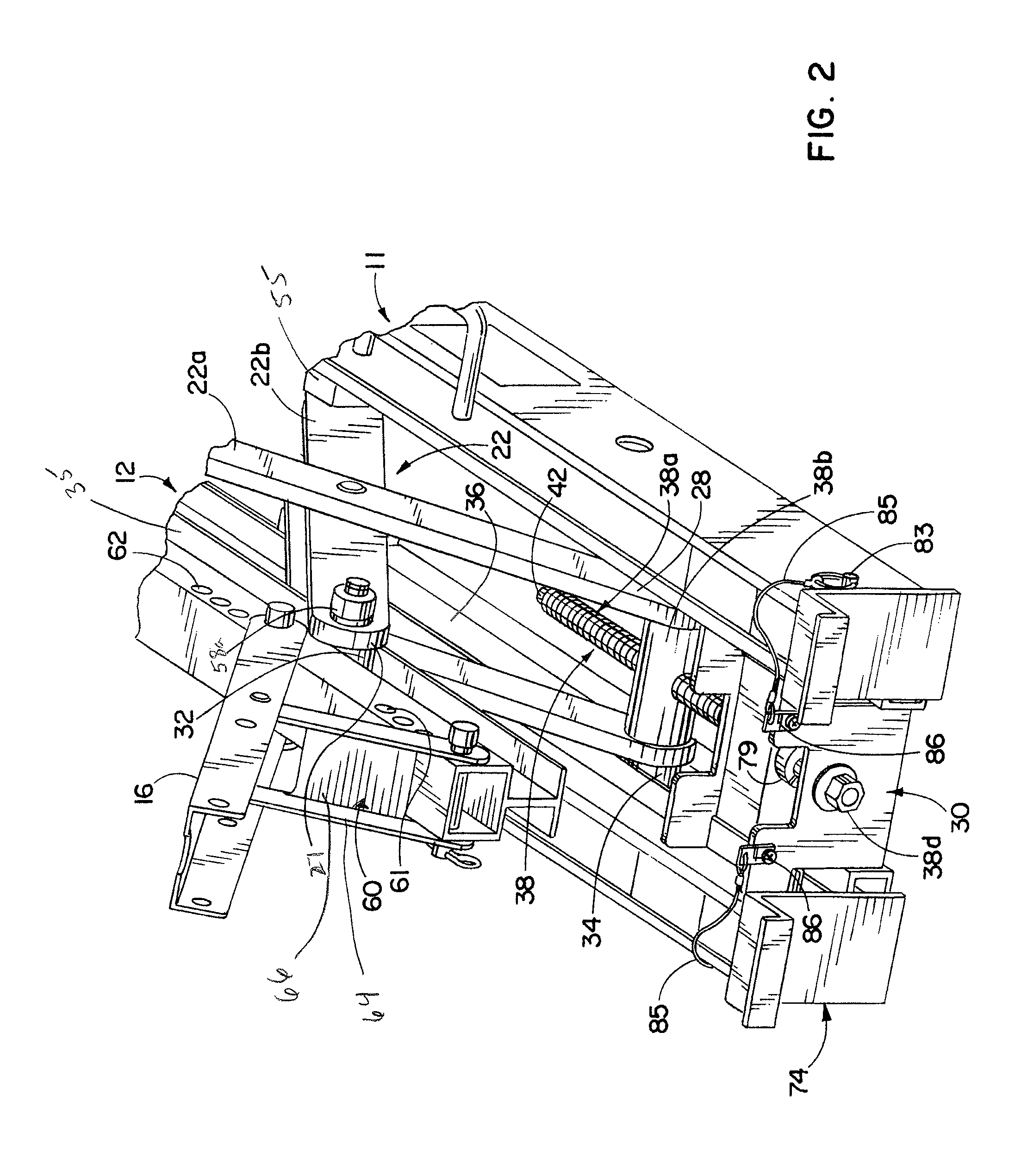

Belt Lifter Apparatus

In one form, a belt lifter apparatus provides increased lifting force and belt lift height by a scissors mechanism having crossed lifting arms each having a translatable end and having a translatable pivot axis between the lifting arms. Preferably, other ends of the lifting arms are fixed to an upper belt lifting member and to a lower support base member at locations such that the pivot axis translates to a position located substantially at the center of the lifted belt when the belt is lifted to the highest lift height. Lightweight, aluminum tubular members are used for the lifting member and the base support and each includes a track for supporting the translatable ends of the lifting arms. The span width of the base member is adjusted by sliding telescoping, tubular legs within the base tubular element. Pivoted wing arms are supported by braces extending to the belt lifting member.

Owner:FLEXIBLE STEEL LACING

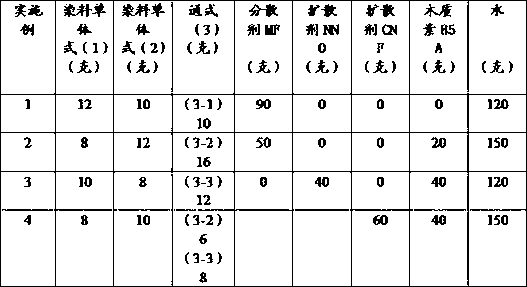

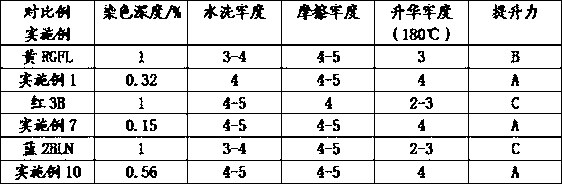

Method for preparing environment-friendly natural fiber printing paste

The invention discloses a method for preparing an environment-friendly natural fiber printing paste, comprising the following steps of: 1) selecting fine diatomaceous earth having a grain size less than or equal to 2 microns; 2) preparing raw printing paste, wherein the raw printing paste is composed of the following components in terms of weight: 6-13% organic printing paste material, 1-8% fine diatomaceous earth and 0.2-0.6% sodium hexametaphosphate, and rest being water; and 3) preparing the printing paste, wherein the printing paste is composed of the following components in terms of weight: 1-4% dye, 1-7% urea, 1-7% urea replacing agent, 1.5-2.5% sodium bicarbonate, 0.2-1% reserve salt S and 50% raw printing paste, and rest being water. The printing paste obtained through the method of the invention is capable of ensuring the printing quality and also capable of greatly reducing the content of organic matters in sewage discharged after printing, thereby reducing pollution.

Owner:ZHEJIANG SCI-TECH UNIV

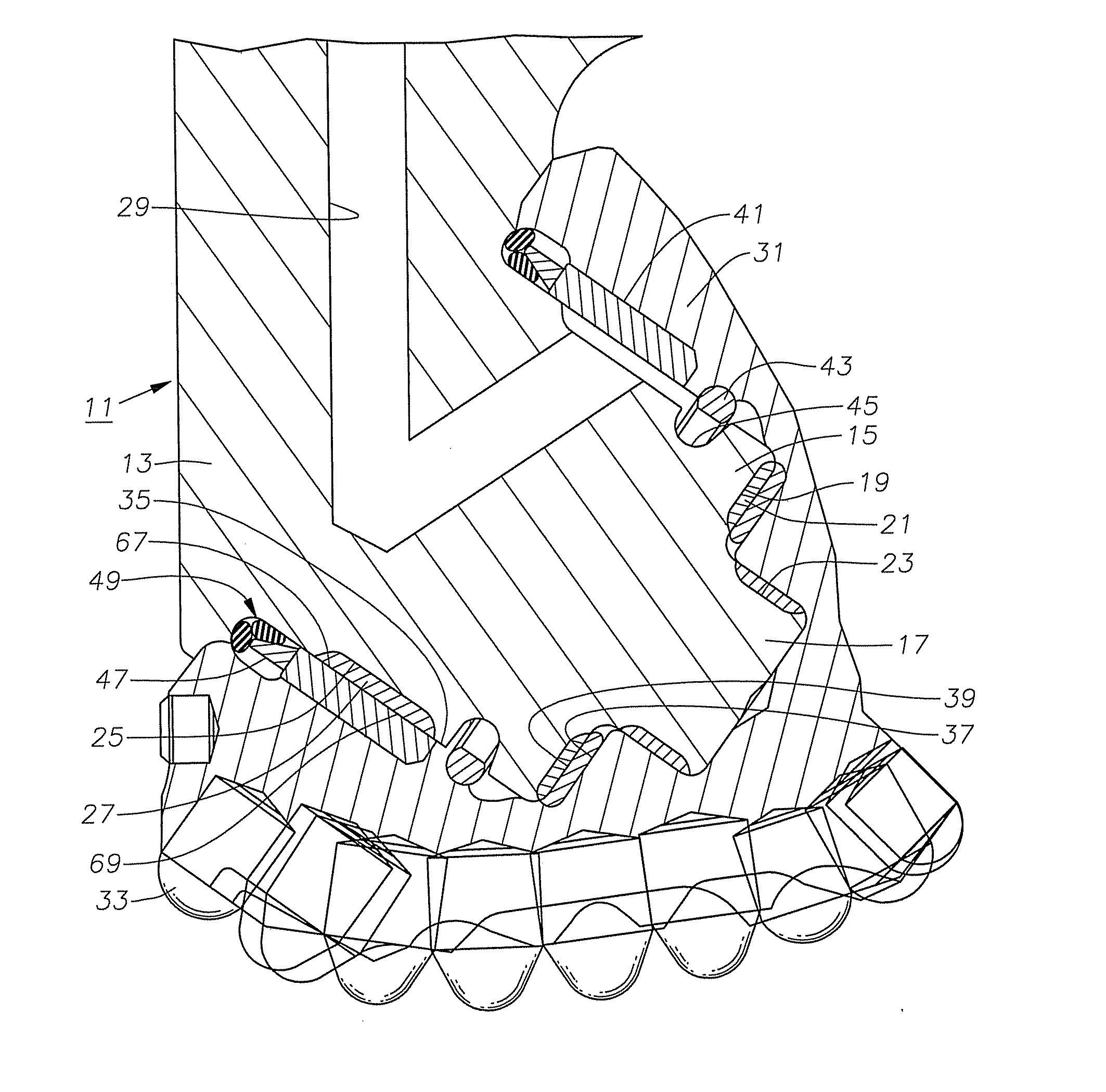

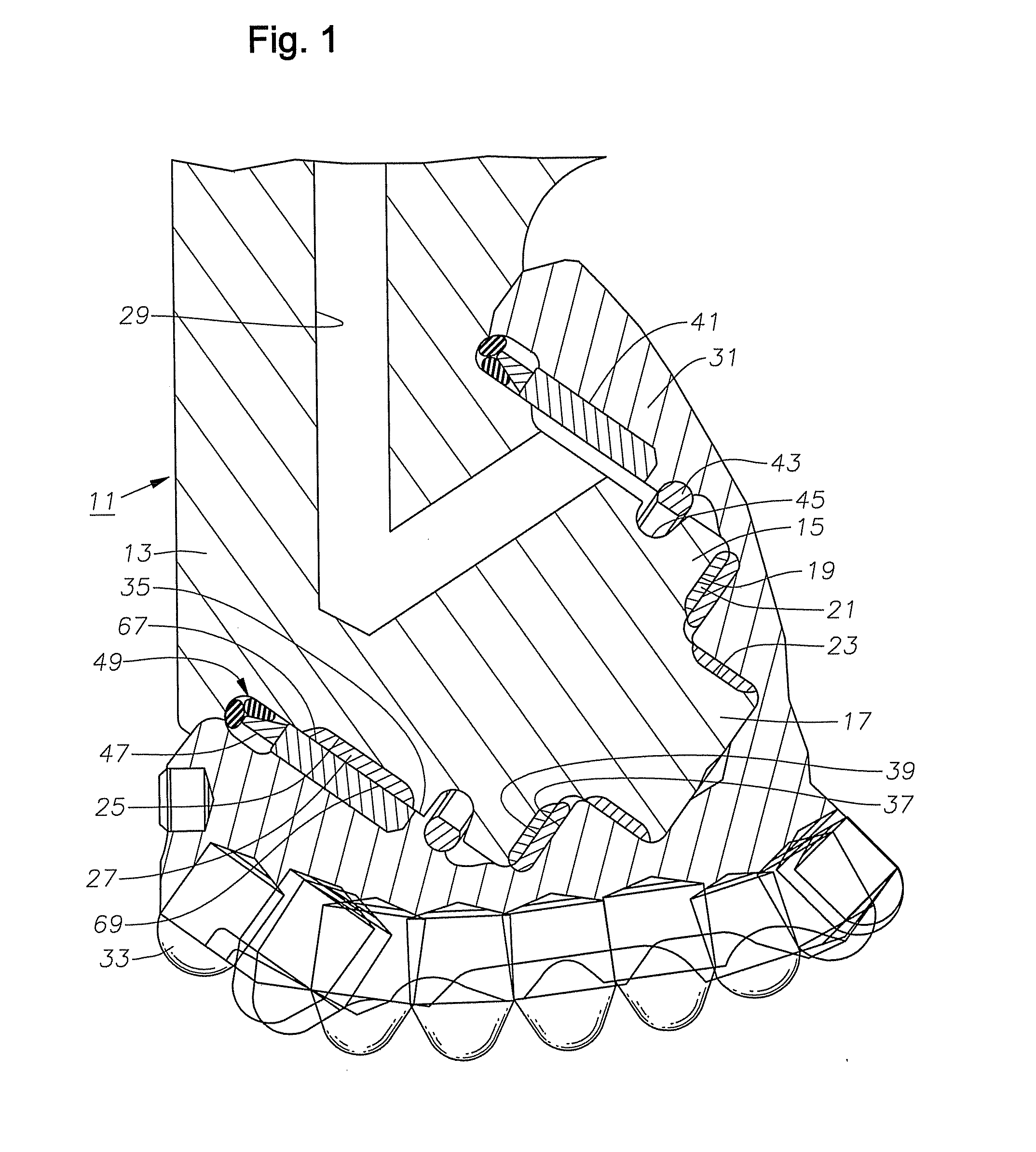

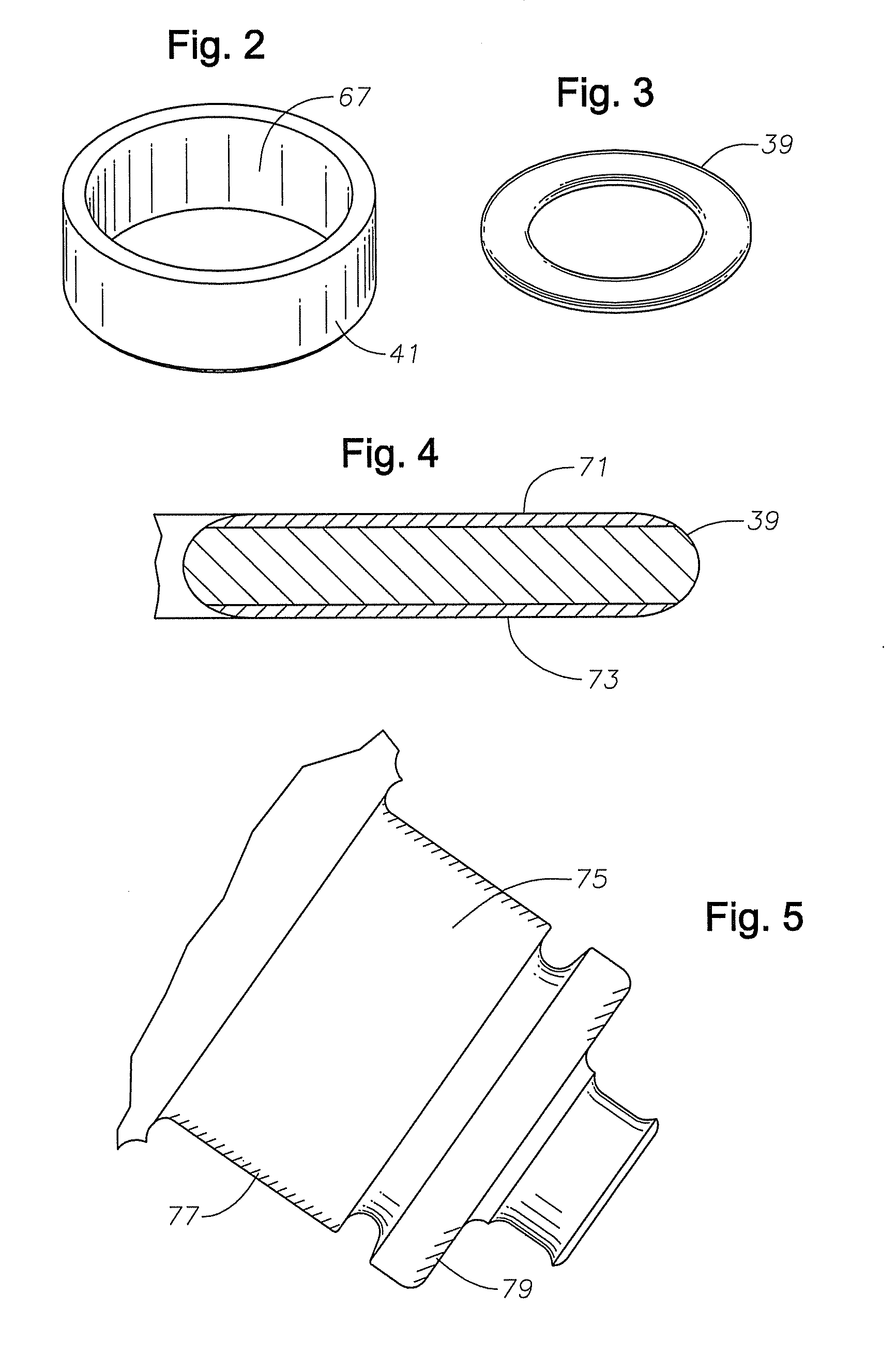

Surface Textures for Earth Boring Bits

ActiveUS20070284150A1Prevent side leakagePromote absorptionDrill bitsBearing componentsEngineeringBearing surface

A texture pattern is applied to bearing surfaces of earth-boring bits, especially the bearings of earth boring bits of the roller cutter variety. The textured surface that may be applied to either or both sides of the thrust washer faces, bearing faces, inlays, or thrust shoulders, or a combination thereof.

Owner:BAKER HUGHES INC

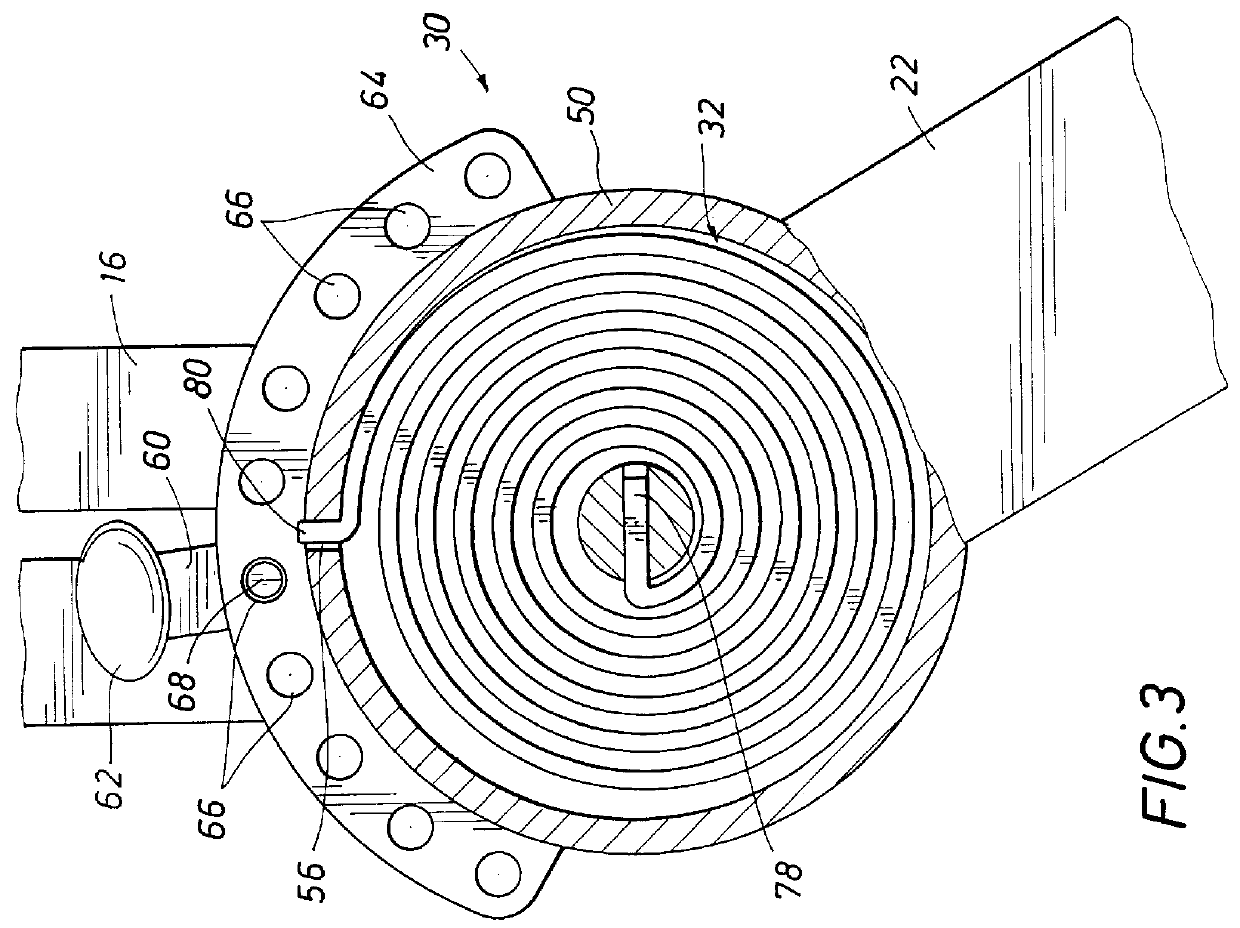

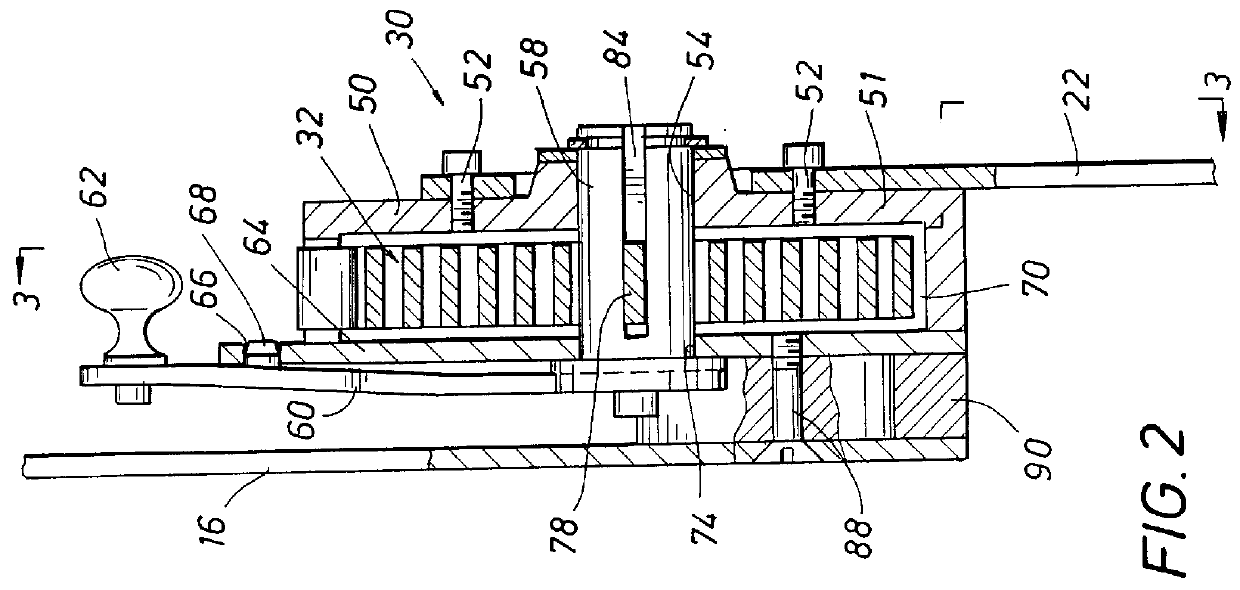

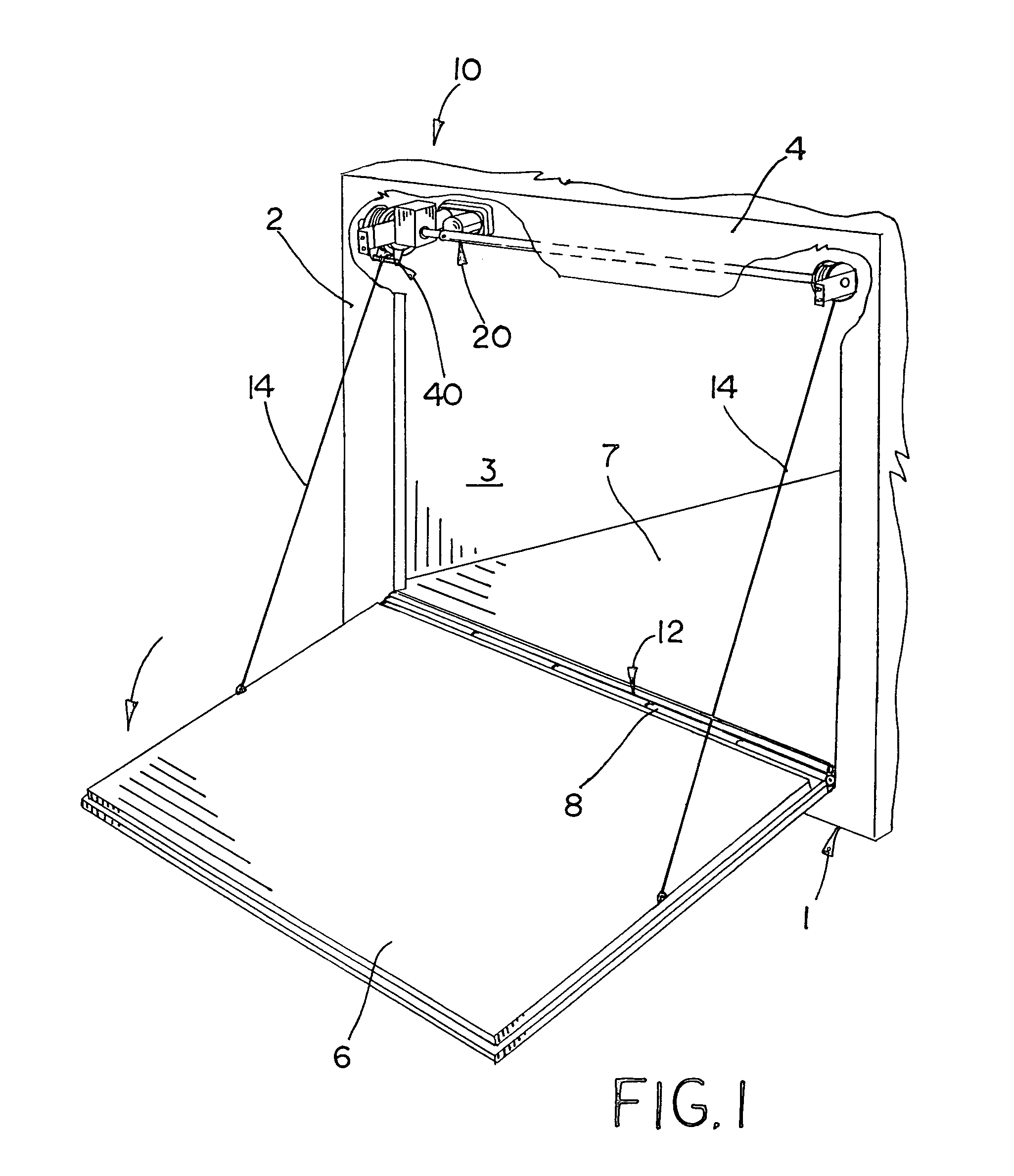

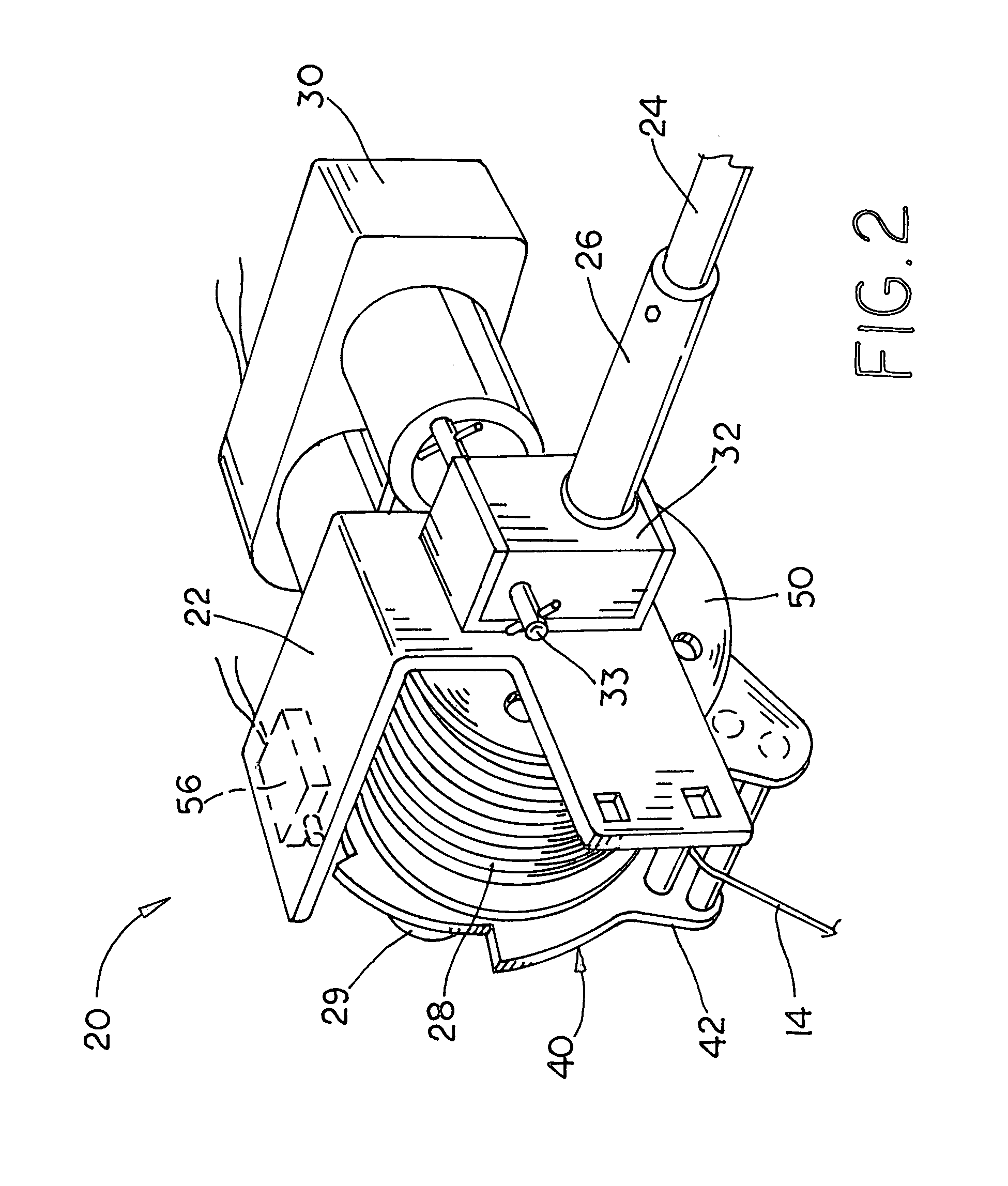

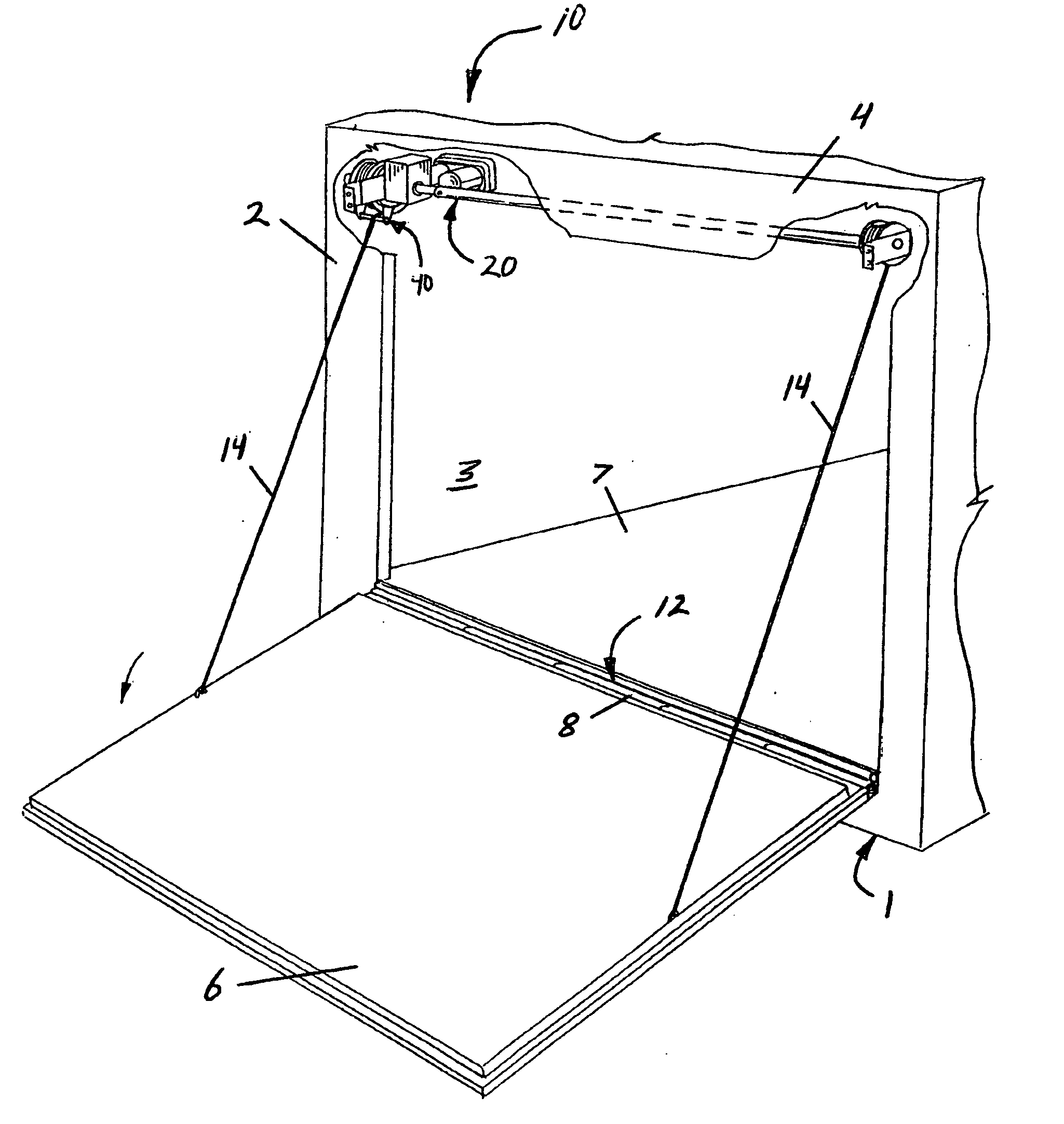

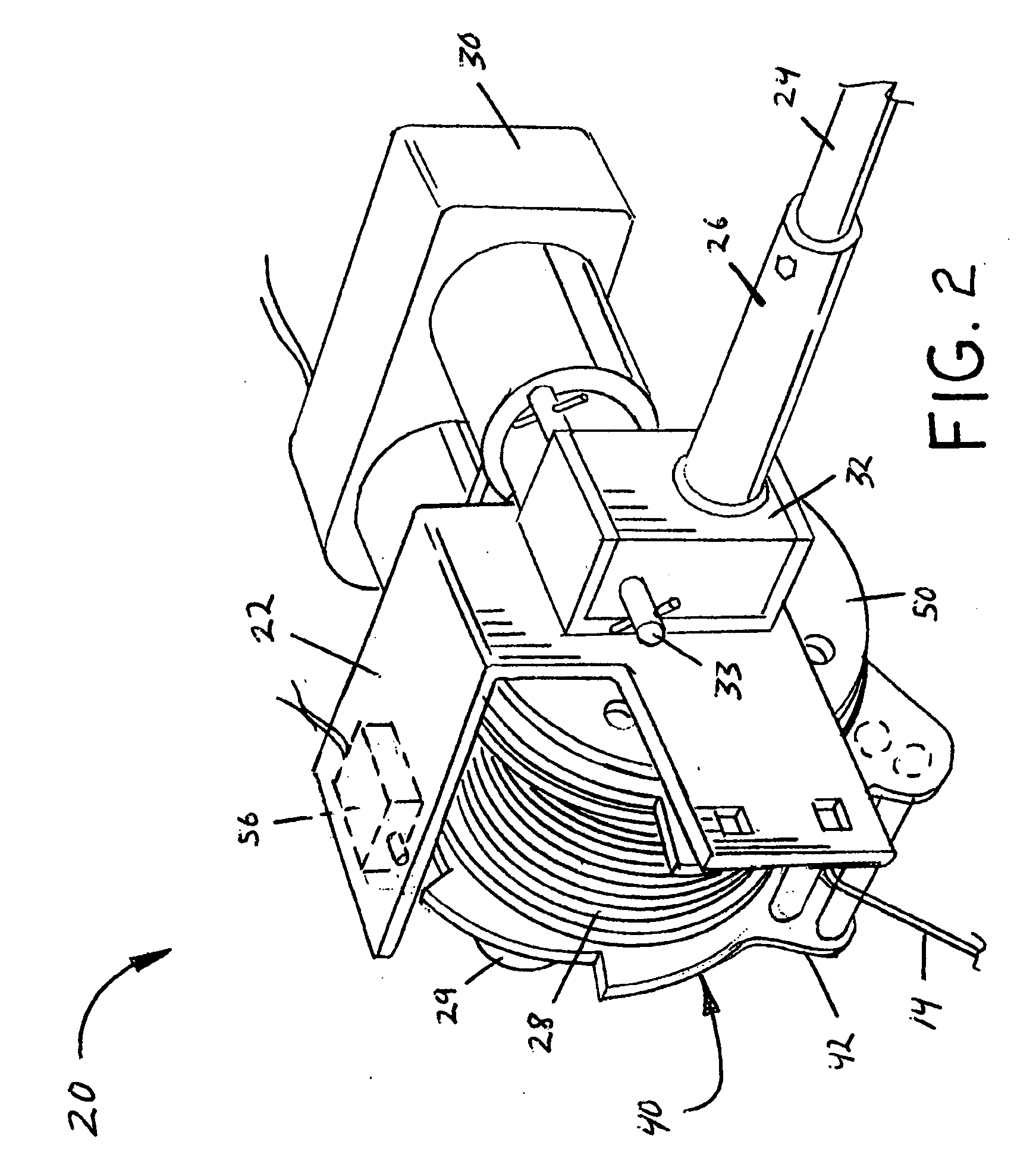

Powered ramp door lift

InactiveUS7419204B2Simple and compact designEasy to installEngine sealsLoading/unloading vehicle arrangmentDrive shaftEngineering

The powered ramp door lift is used in cargo trailers and other ramp door applications and includes a powered winch assembly, a pair of wire cables or nylon straps connecting the winch assembly to the ramp door, and a “pusher” mechanism. The winch assembly mounted to the trailer header winds and unwinds the cables onto a pair of spools mounted to a drive shaft, which is driven by an electric motor. The “pusher” mechanism prevents the “unspooling” problems that effect the operation of winches in automated ramp door applications. The pusher mechanism engages the ramp door in the closed position and applies an outward force to the ramp door over a small portion of its travel to assist in the initial lowering of the ramp door from the closed position. The winch assembly also includes a cable tension winch shut off mechanism, which deactivates the winch motor in the absence of any tension on cables.

Owner:CARGO SYST

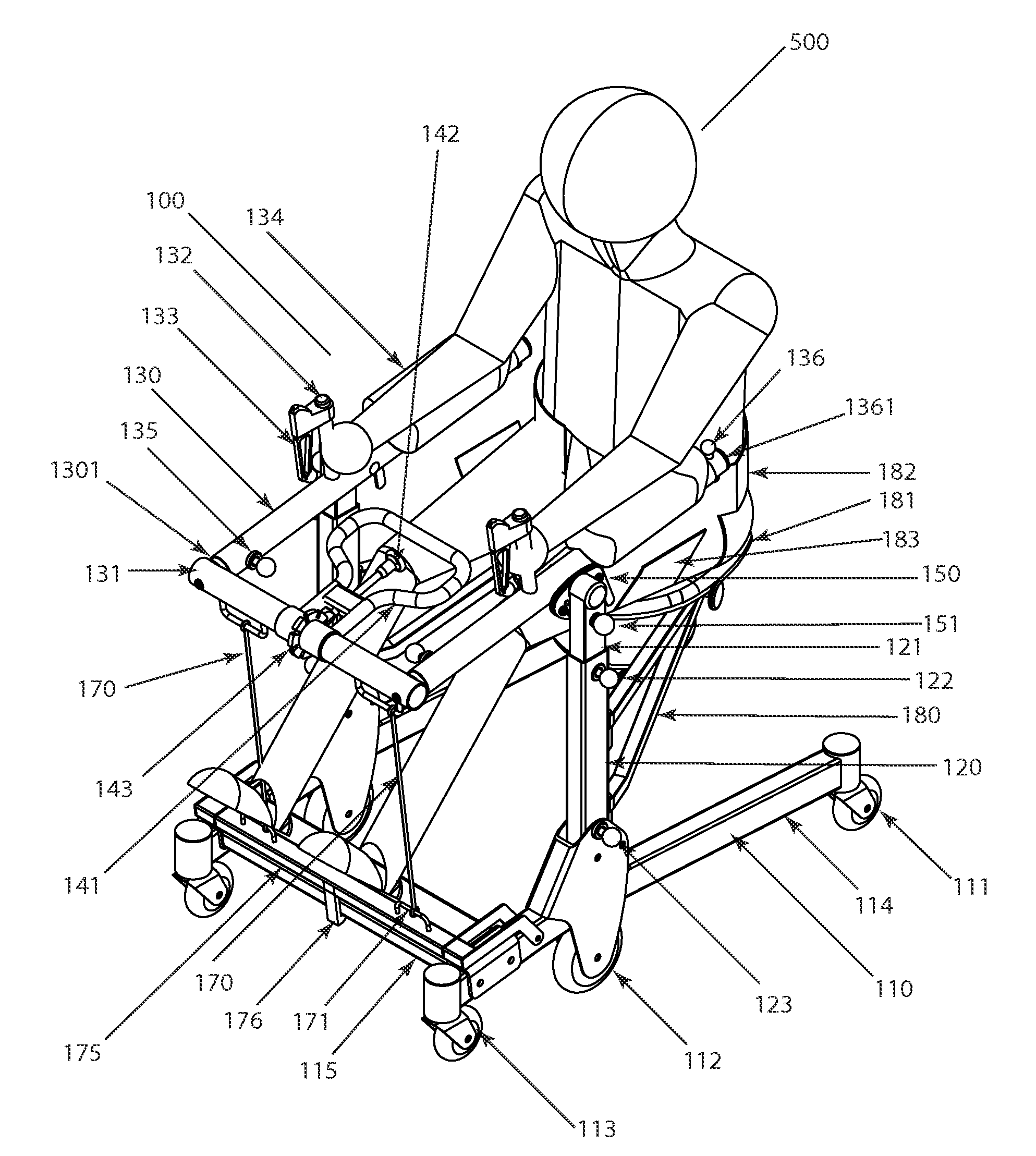

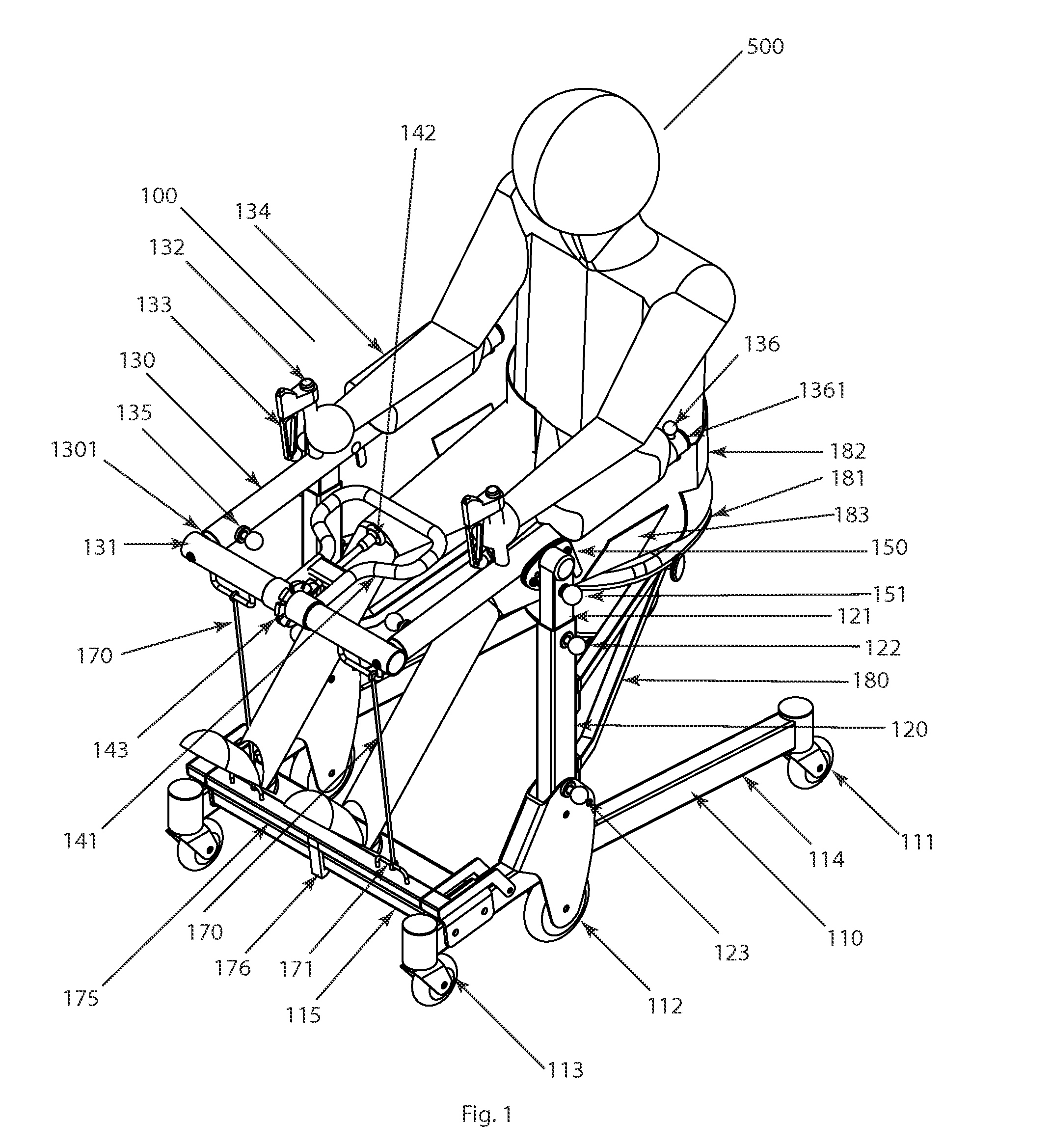

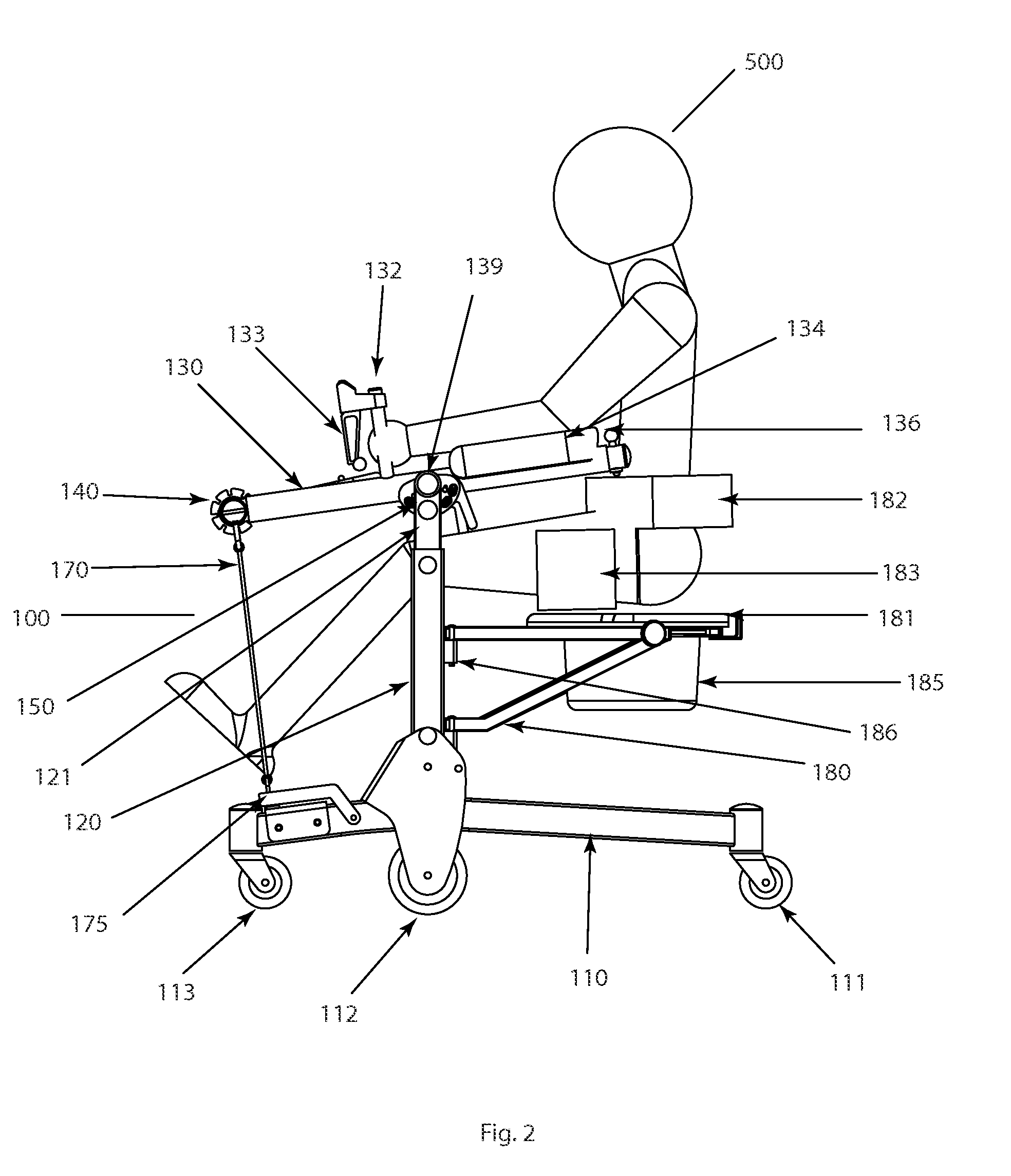

Patient assistance and rehabilitation device and method of use

InactiveUS20160331610A1Eliminate wasteEasy to disassembleWalking aidsWheelchairs/patient conveyancePhysical medicine and rehabilitationMechanical lift

A patient assistance and rehabilitation device or more specifically a patient mechanical lift device that can be utilized as patient walker, a seat, a seated transporter, a toilet, a table and a rehabilitation device. The patient assistance and rehabilitation device including a power band or tension motor to help a patient move from a sitting to a standing position and to supplement an exercise or rehabilitation program.

Owner:BROWN ADAM +1

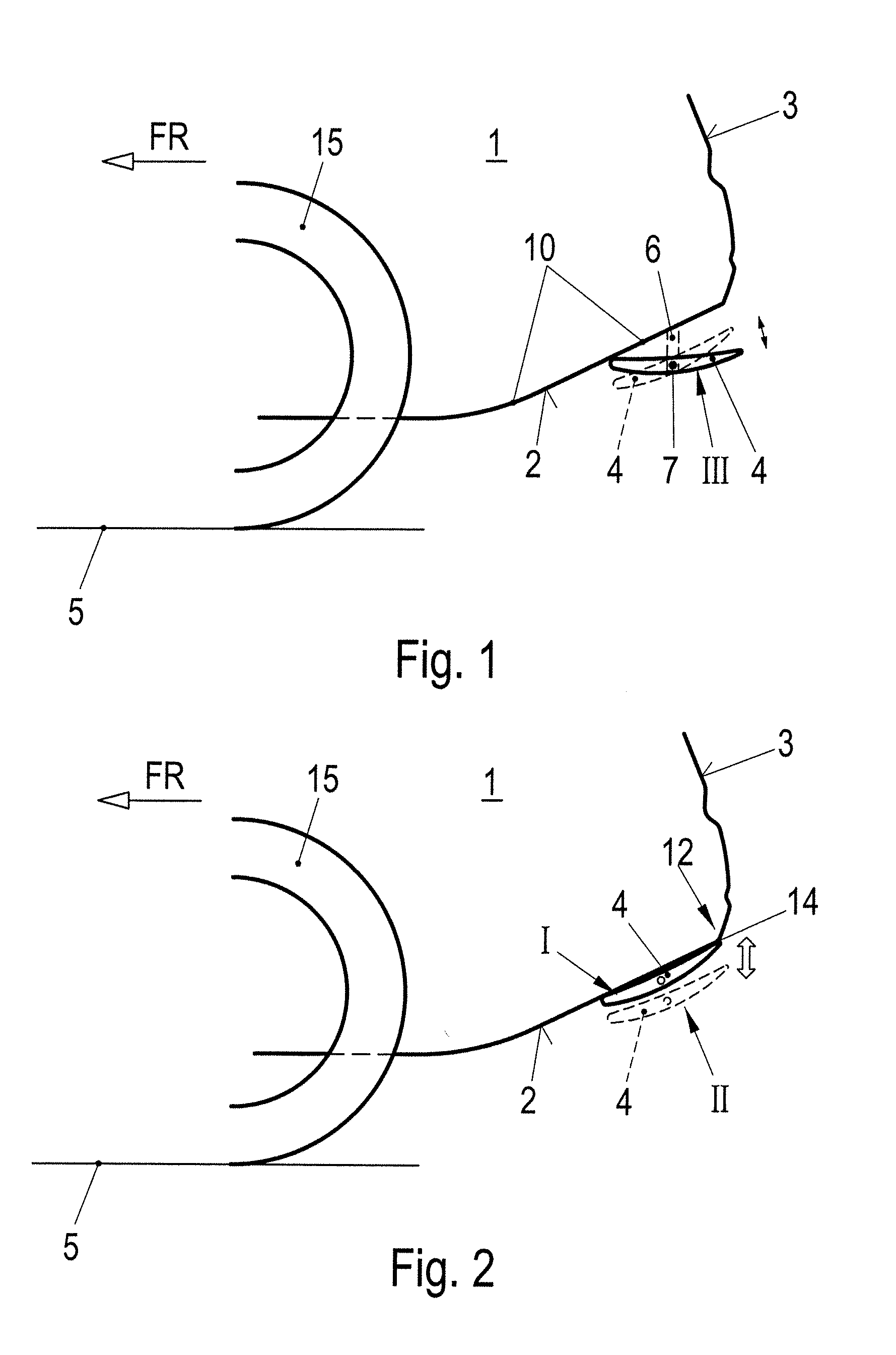

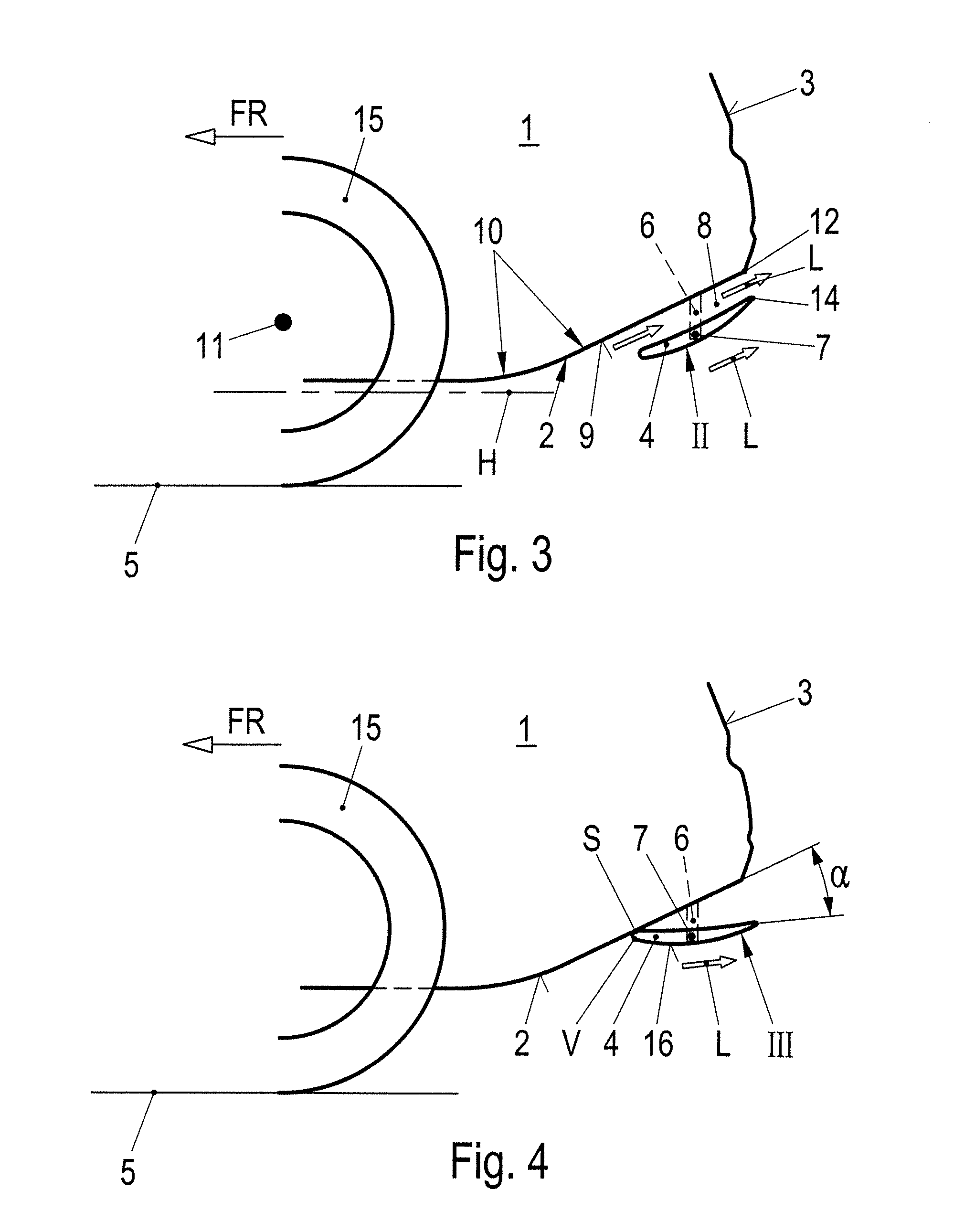

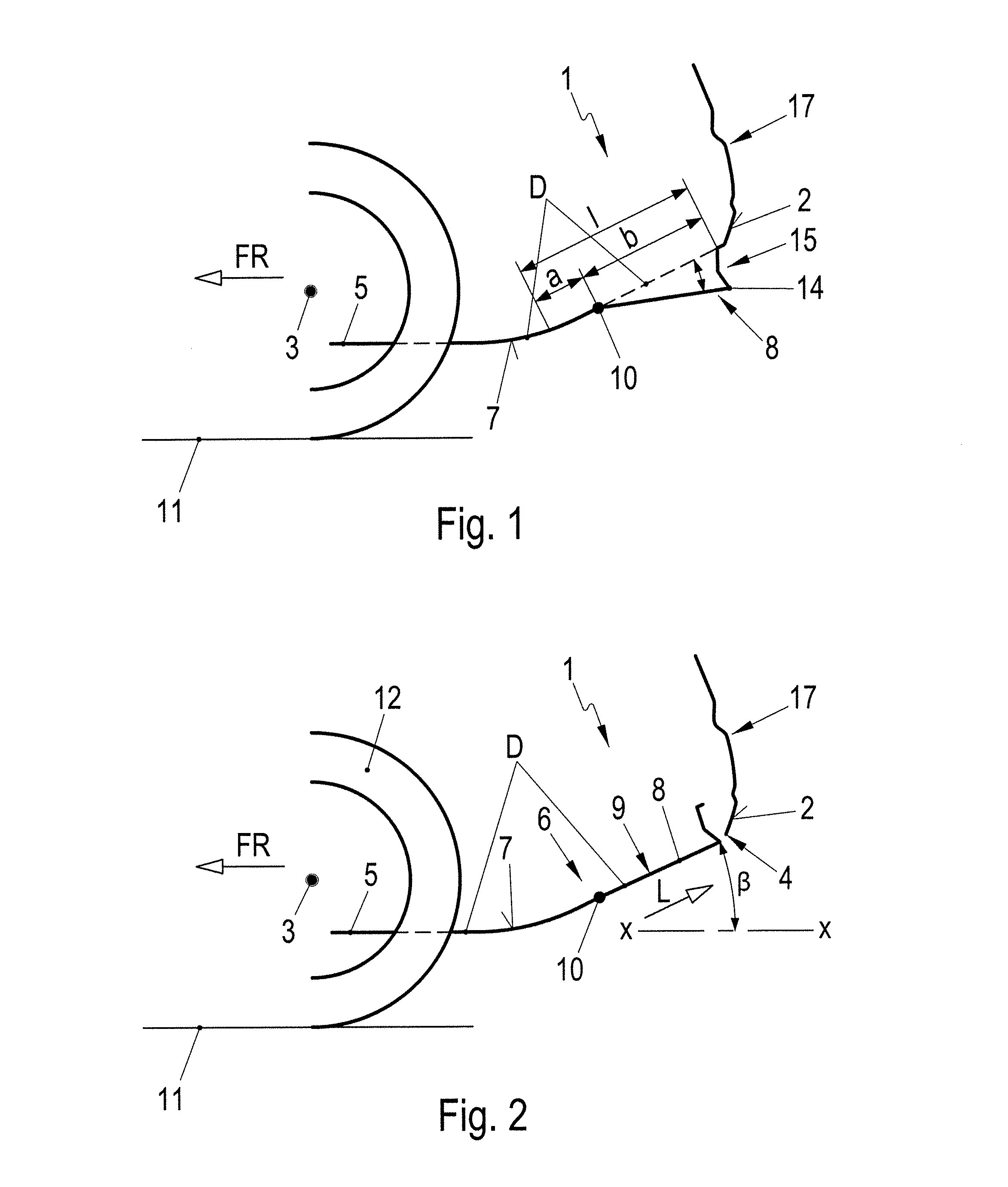

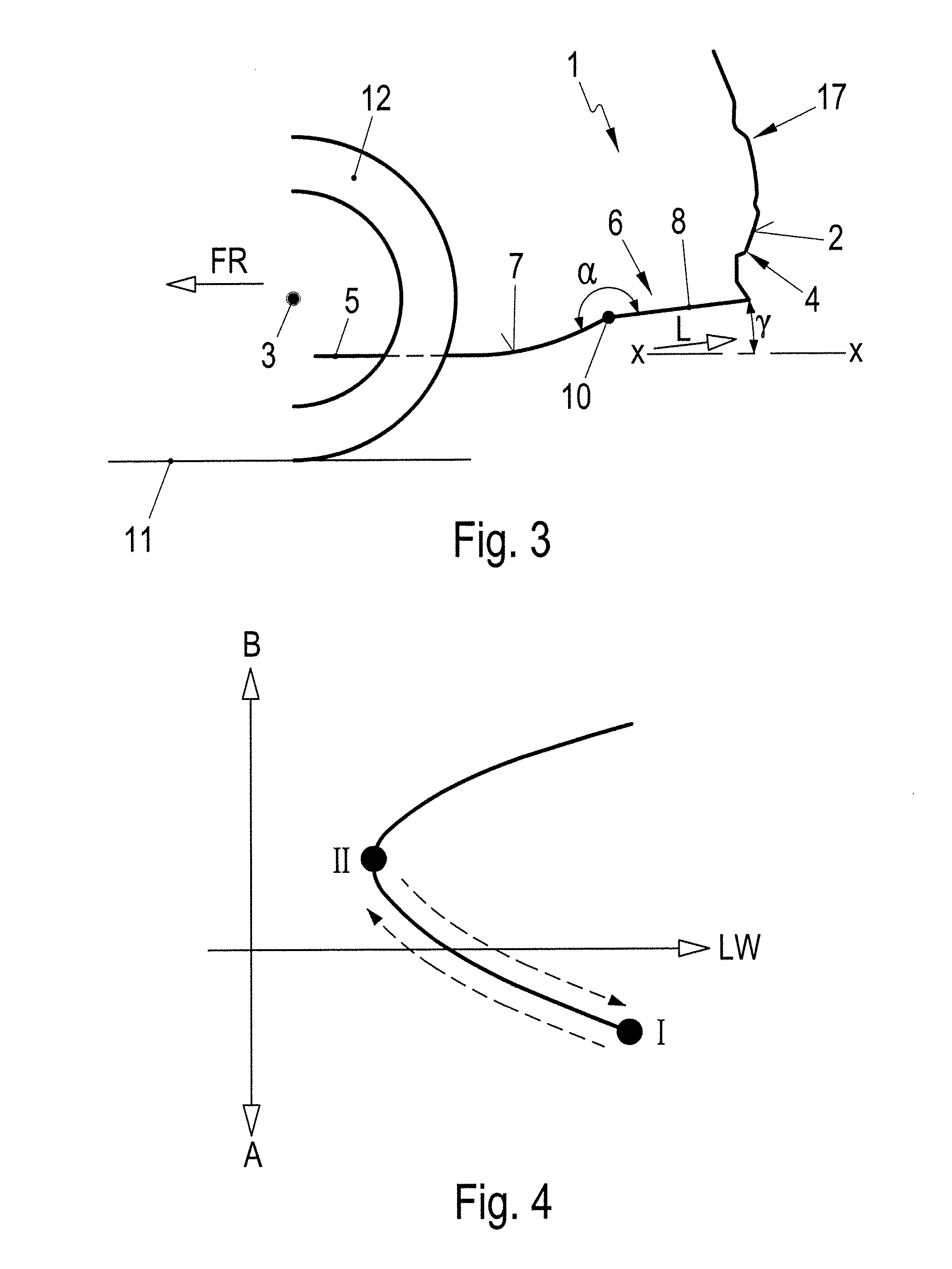

Motor vehicle with an adjustable air-guiding element

ActiveUS20150353149A1Higher negative lift forceEasy to adaptVehicle seatsWindowsRest positionAerodynamic drag

A rear region of a motor vehicle has an underbody with at least one air-guiding element that is adjustable from a rest position into various operative positions. One operative position increases negative lift and another operative position reduces aerodynamic drag. The air-guiding element is adjustable into the individual operative positions via a central, transversely arranged pivot axis.

Owner:DR ING H C F PORSCHE AG

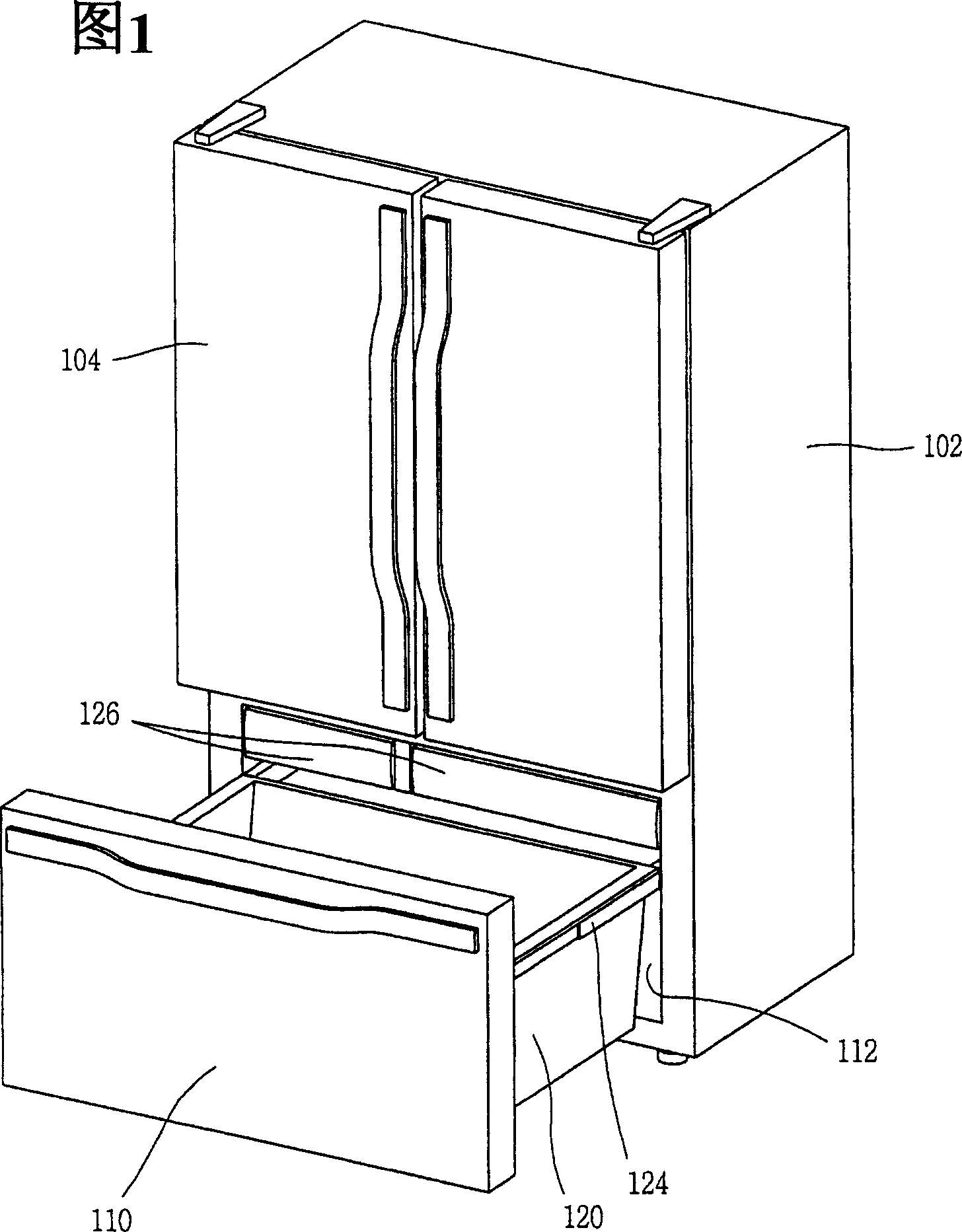

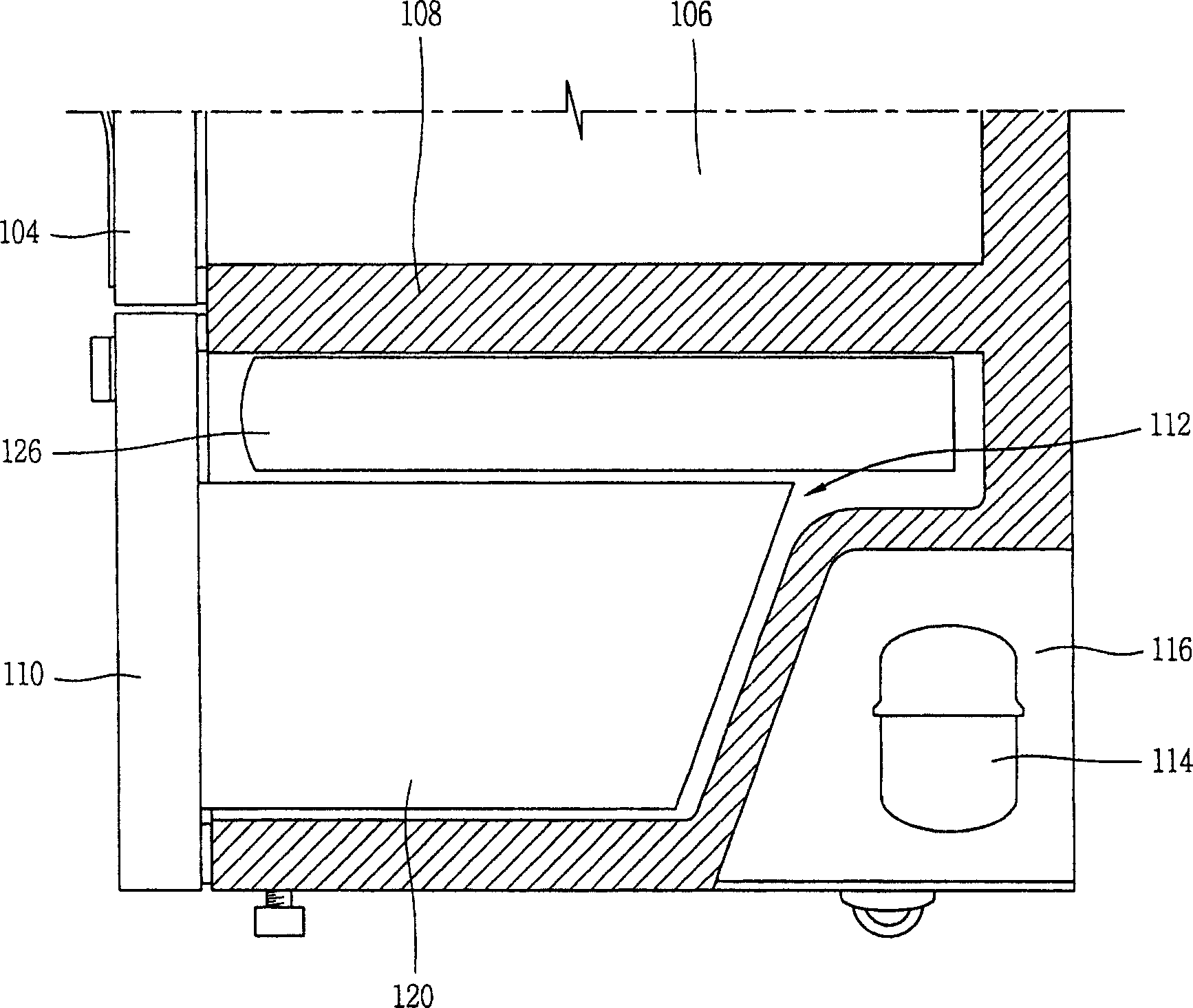

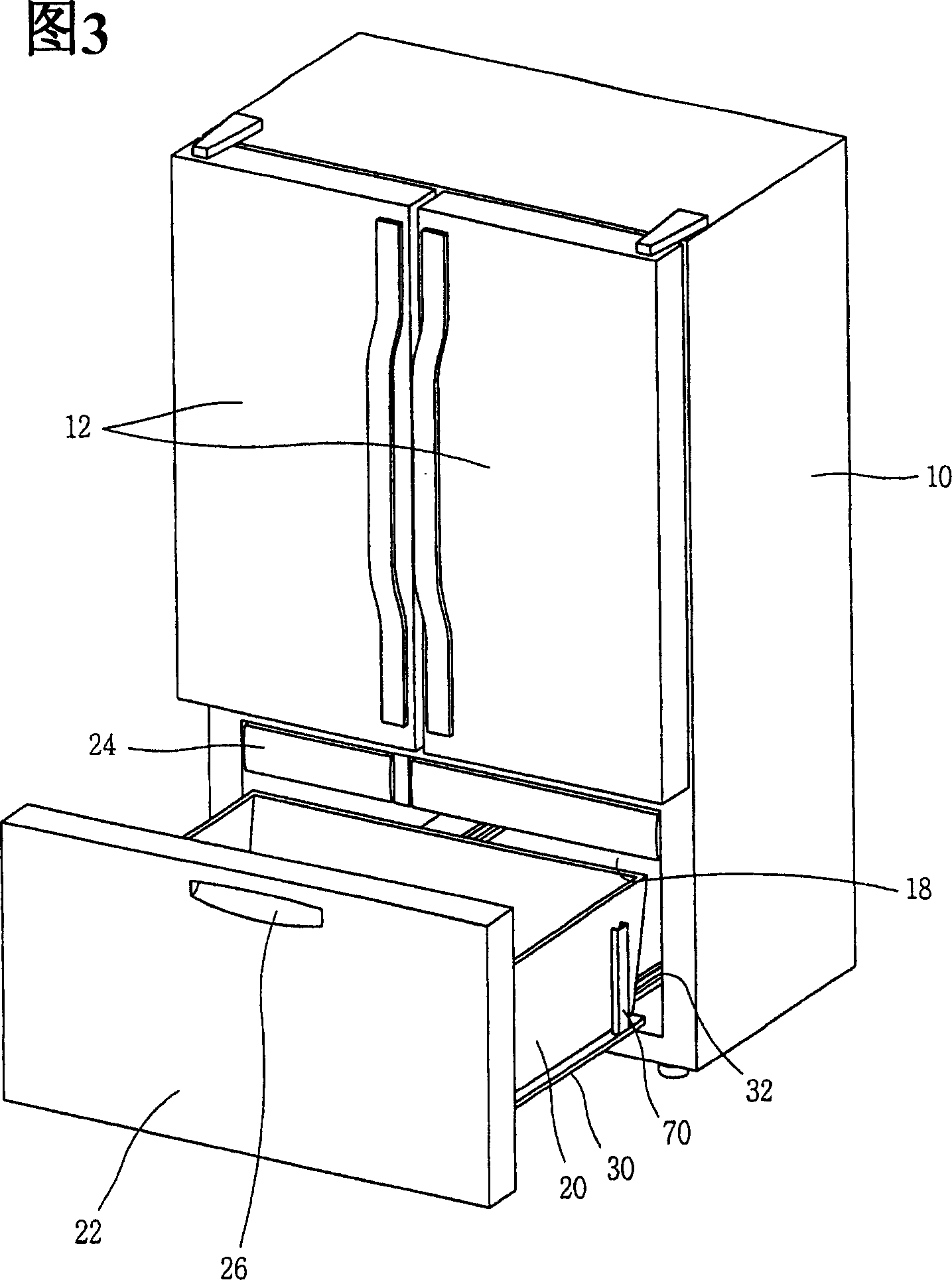

Bottom drawer type refrigerator having basket lift device

InactiveCN1727824AImprove convenienceBasket liftingLighting and heating apparatusChestsAir springGas spring

A refrigerator includes a main body having at least a lower cooling chamber disposed at a lower portion of the main body, a base frame disposed to be movable in inward / outward directions at the lower cooling chamber and having a drawer door at a front side thereof, a lift frame disposed at an upper surface of the base frame, on which a basket is placed, a gas spring mounted vertically at an upper surface of the base frame and connected with the lift frame for lifting the lift frame, and lift rails at a rear side of the drawer door and guiding the lift frame to be moved up and down.

Owner:LG ELECTRONICS INC

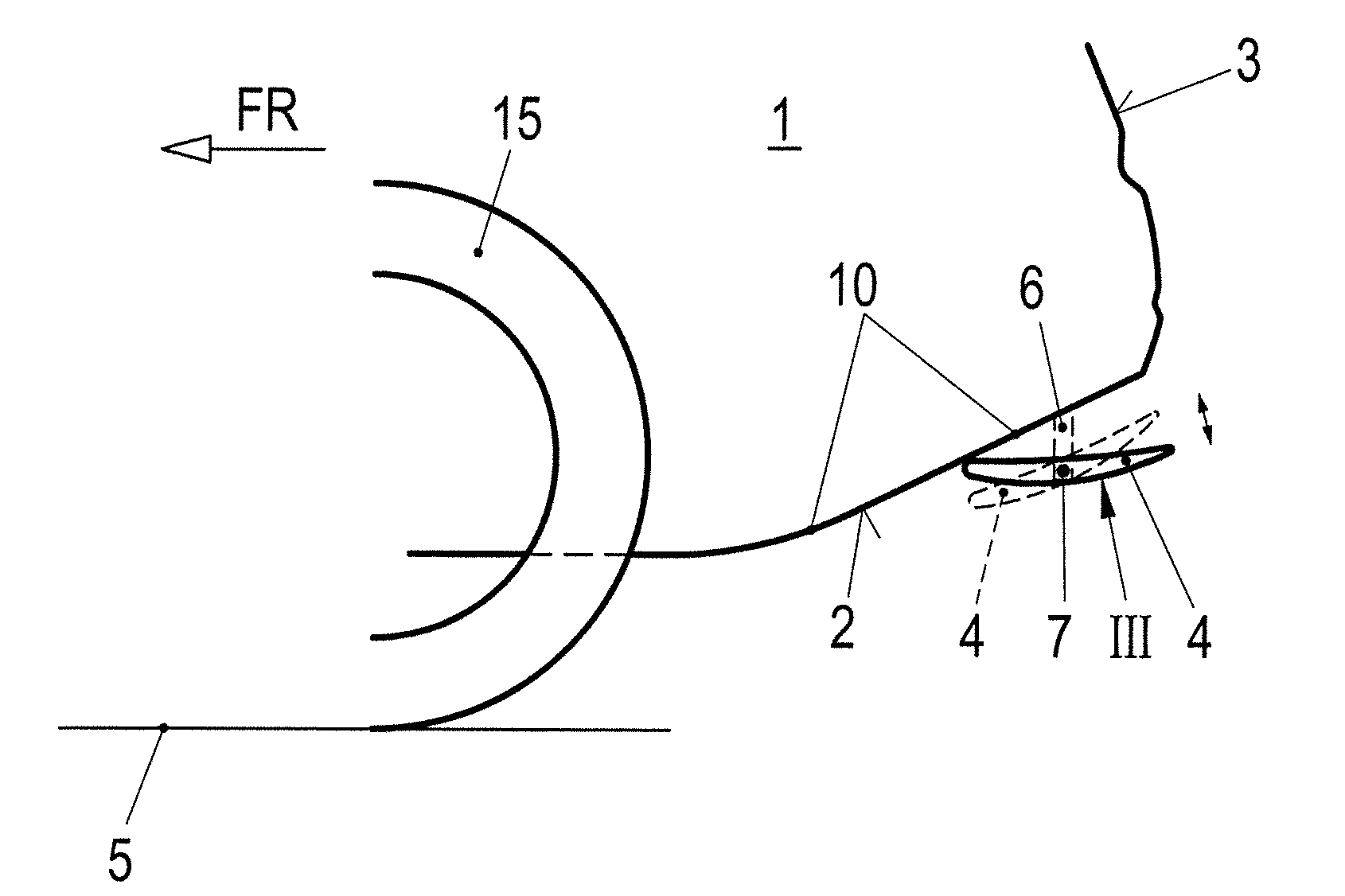

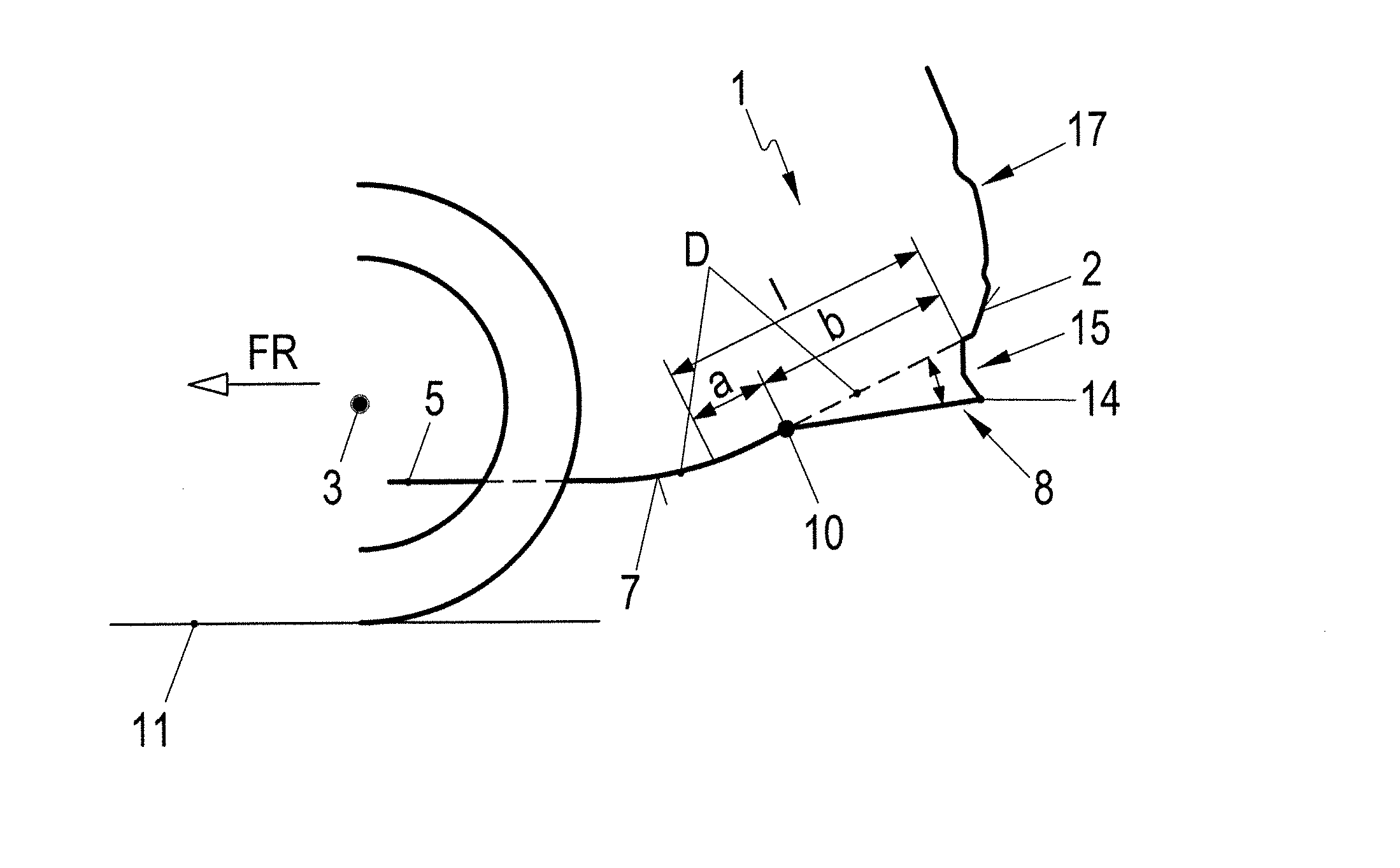

Motor vehicle with a rear diffuser

ActiveUS20150353148A1Reduce aerodynamic dragNegative lift forceVehicle seatsWindowsAerodynamic dragControl theory

A diffuser is arranged at the rear of a vehicle in the region of the underbody and has a fixed front part and an adjoining, pivotable rear part. Negative and positive lift effects and aerodynamic drag effects are obtained by adjusting pivotable rear part between an upwardly pivoted position and a downwardly pivoted position.

Owner:DR ING H C F PORSCHE AG

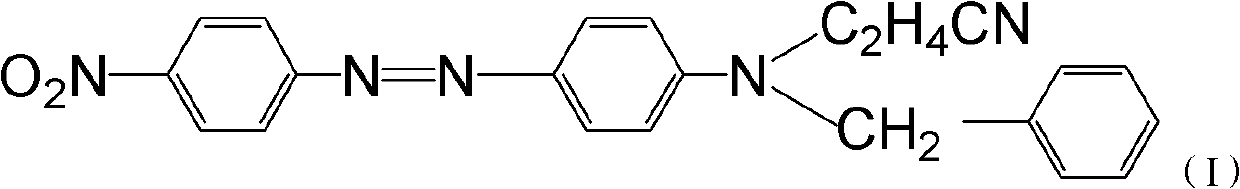

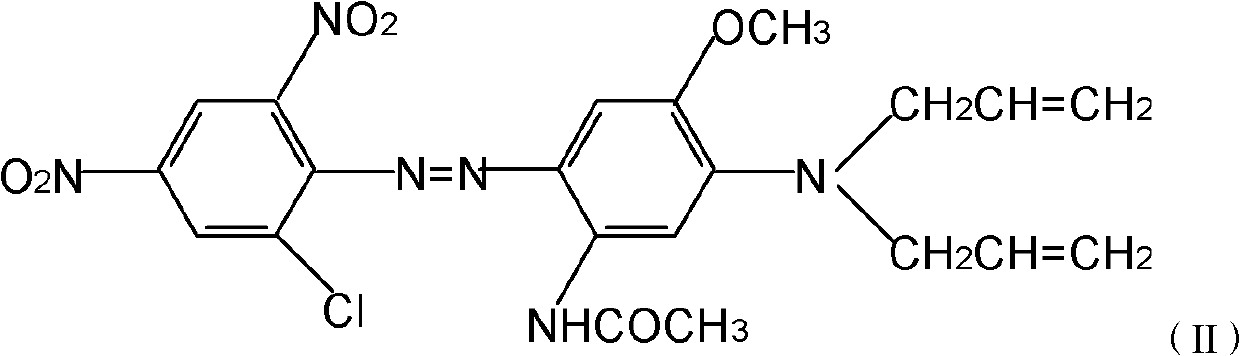

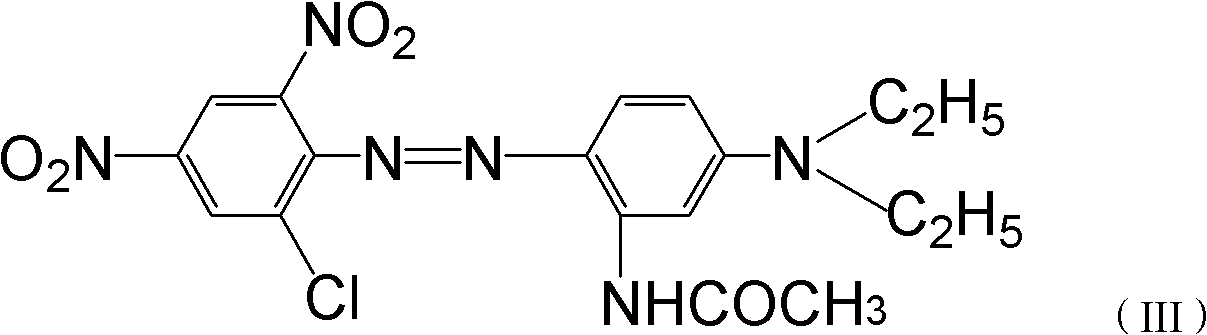

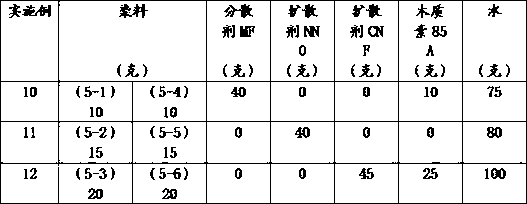

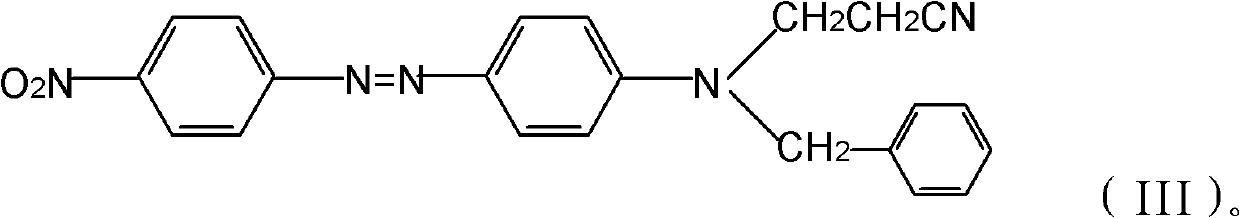

Composite dye composition, composite disperse dye and preparation method thereof

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of a formula (I), a formula (II), a formula (III) and an optional formula (IV). The composite disperse dye prepared from the composite dye composition has high intensity and lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

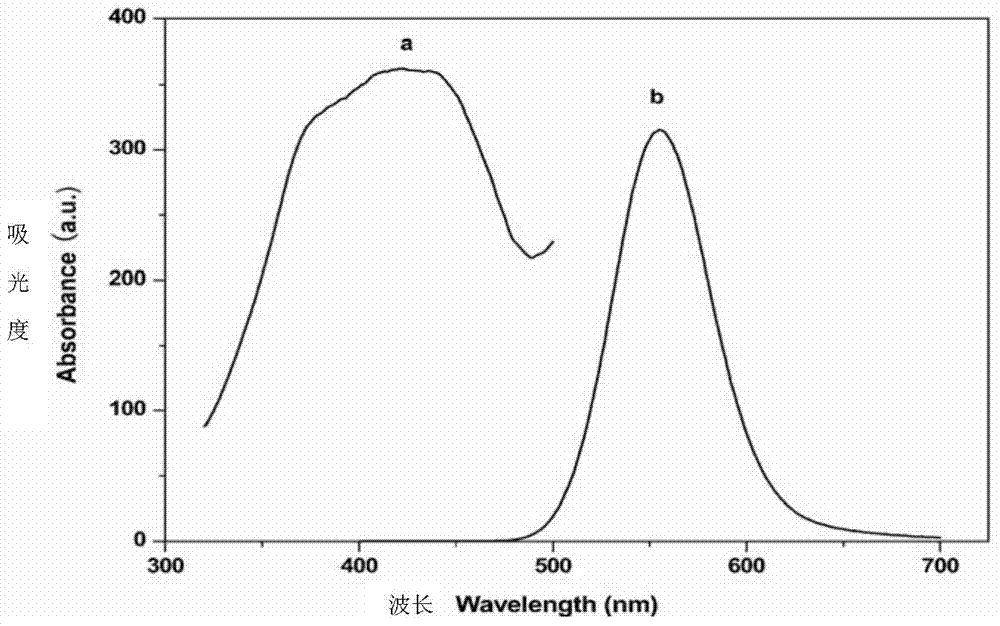

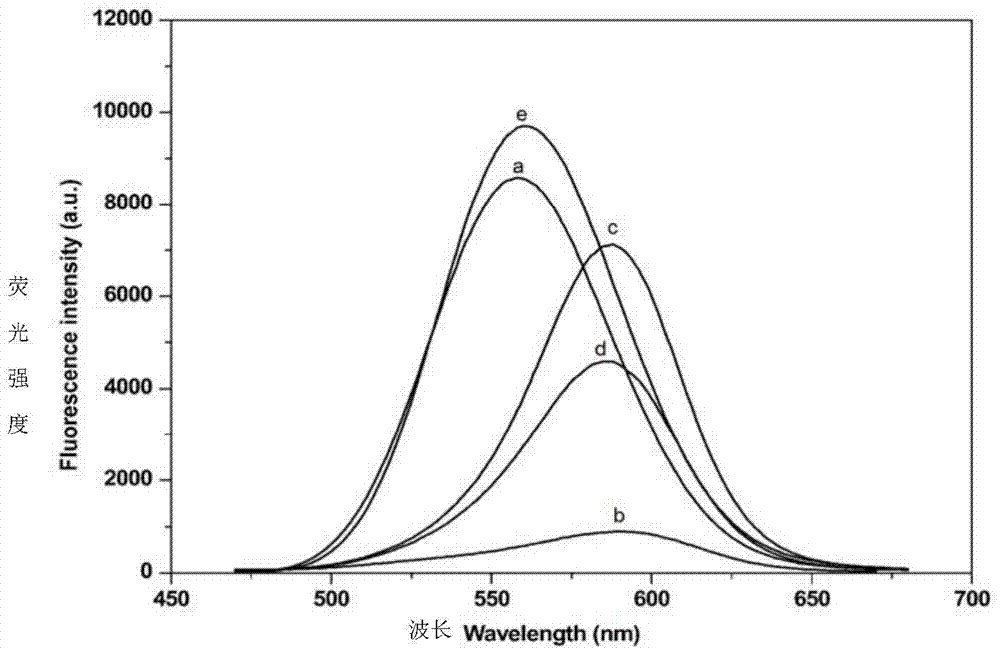

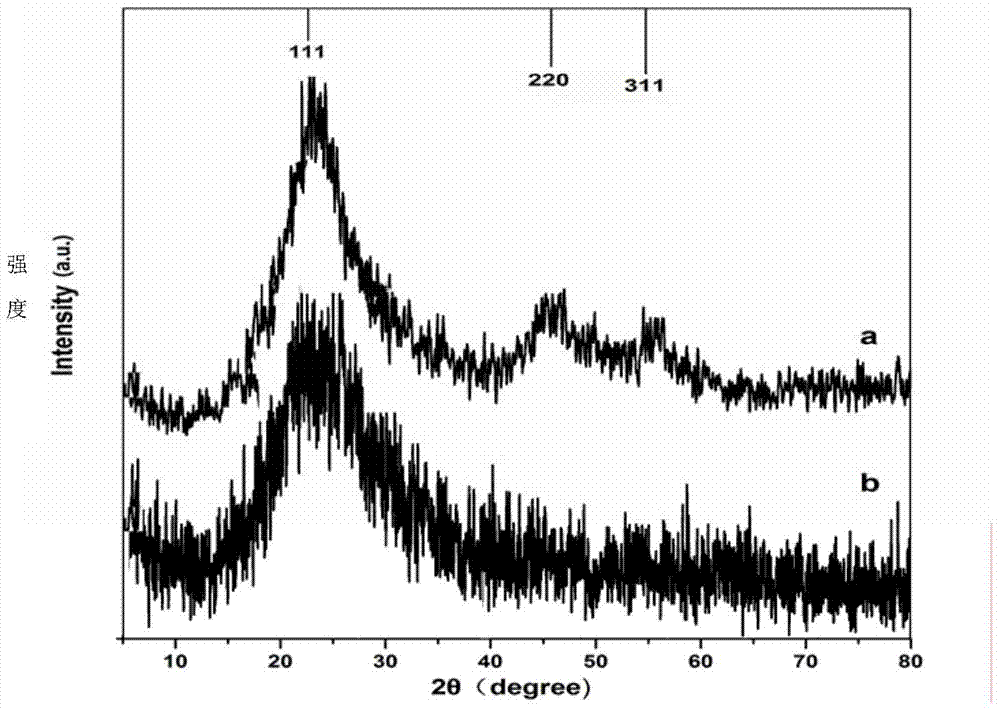

P-aminophenol imprinted polymer on surface of cadmium telluride quantum dot as well as preparation method and application thereof

InactiveCN103539945AHigh selectivityIncrease heightOther chemical processesFluorescence/phosphorescenceCadmium zinc tellurideMaterials science

The invention relates to a p-aminophenol imprinted polymer on the surface of a cadmium telluride quantum dot as well as a preparation method and application thereof. The preparation method comprises the following steps: I, synthesizing the cadmium telluride quantum dot CdTeQDs with a fluorescence characteristic and carrying out silanized modification on the surface; II, preparing the p-aminophenol imprinted polymer on the surface of the cadmium telluride quantum dot; and III, removing template molecules to obtain the p-aminophenol imprinted polymer on the surface of the cadmium telluride quantum dot CdTe@SiO2@MIP. Test results show that the limit of detection of CdTe@SiO2@MIPsQDs synthesized by the method to template molecules can reach 0.02 mu m. Fluorescence detection is quickly and simply carried out by using a fluorospectro photometer in a time-saving manner.

Owner:NANJING MEDICAL UNIV

Medium temperature type three-primary-color disperse dyes

ActiveCN103073918AGood sublimation fastnessEasy to liftOrganic dyesDyeing processDisperse dyeDistillation

The invention discloses a group of medium temperature type three-primary-color disperse dyes. A yellow disperse dye is a mixture formed by 5-20 % of compound shown by a chemical formula (1), 5-40 % of compound shown by a chemical formula (2) and 5-40 % of compound shown by a chemical general formula (3) in percentage by weight; a red disperse dye comprises one or more monomers in a compound shown by a chemical general formula (4); and a blue disperse dye comprises one or more monomers in a compound shown by a chemical general formula (5). The medium temperature type three-primary-color disperse dyes disclosed by the invention have the advantages as follows: medium temperature type three primary colors beautiful in colored lights and high in intensities; the colored lights of the medium temperature type three primary colors are similar to the original three primary colors; the medium temperature type three-primary-color disperse dyes have the advantages of perfect compatibility, high lifting force, distillation, excellent fastness and the like during dyeing and are a group of medium temperature type three-primary-color disperse dyes with excellent comprehensive performances.

Owner:JIANGSU YABANG DYE

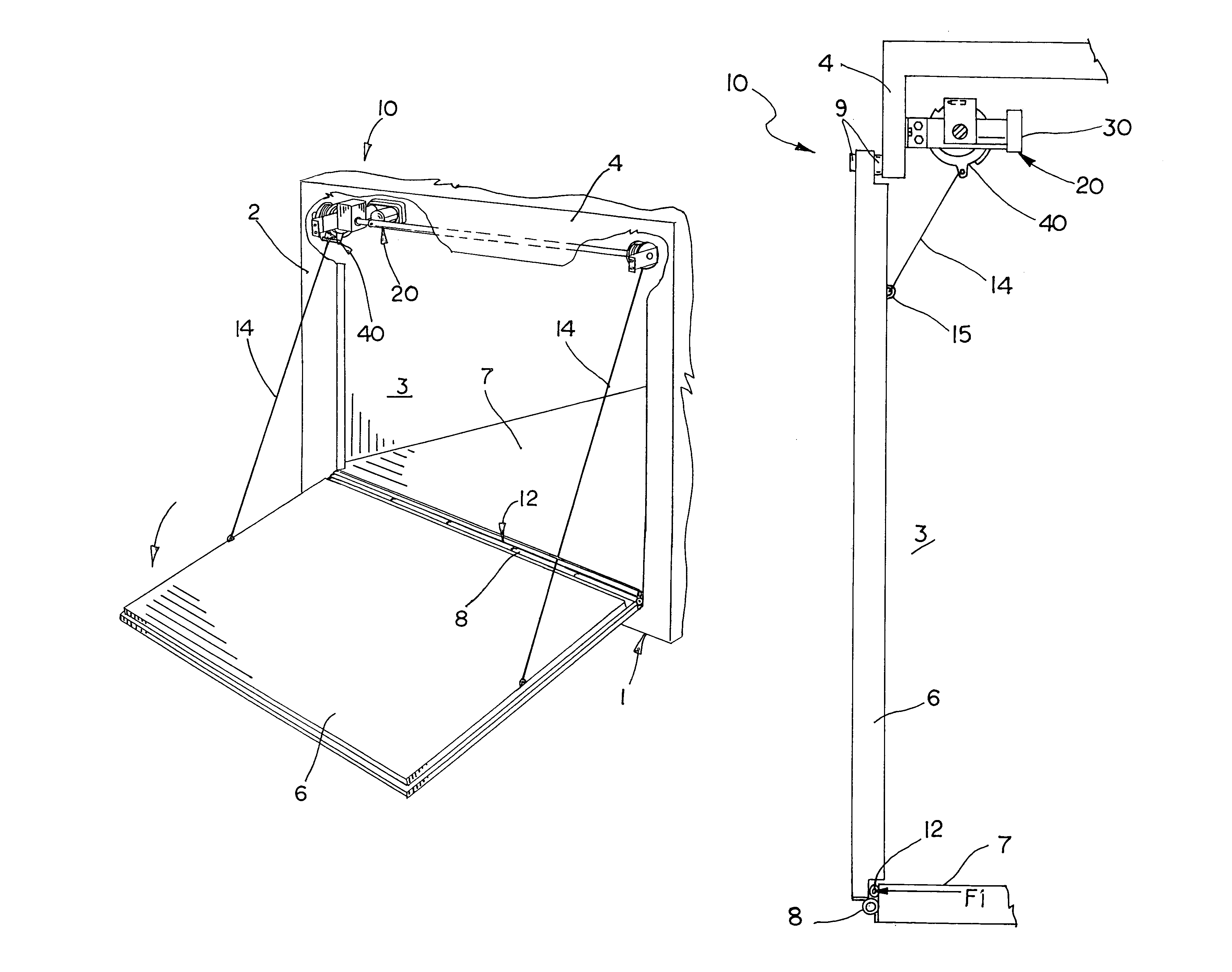

Powered ramp door lift

InactiveUS20070040405A1Avoid problemsSimple and compact designEngine sealsSuperstructure subunitsDrive shaftElectric machinery

The powered ramp door lift is used in cargo trailers and other ramp door applications and includes a powered winch assembly, a pair of wire cables or nylon straps connecting the winch assembly to the ramp door, and a “pusher” mechanism. The winch assembly mounted to the trailer header winds and unwinds the cables onto a pair of spools mounted to a drive shaft, which is driven by an electric motor. The “pusher” mechanism prevents the “unspooling” problems that effect the operation of winches in automated ramp door applications. The pusher mechanism engages the ramp door in the closed position and applies an outward force to the ramp door over a small portion of its travel to assist in the initial lowering of the ramp door from the closed position. The winch assembly also includes a cable tension winch shut off mechanism, which deactivates the winch motor in the absence of any tension on cables.

Owner:CARGO SYST

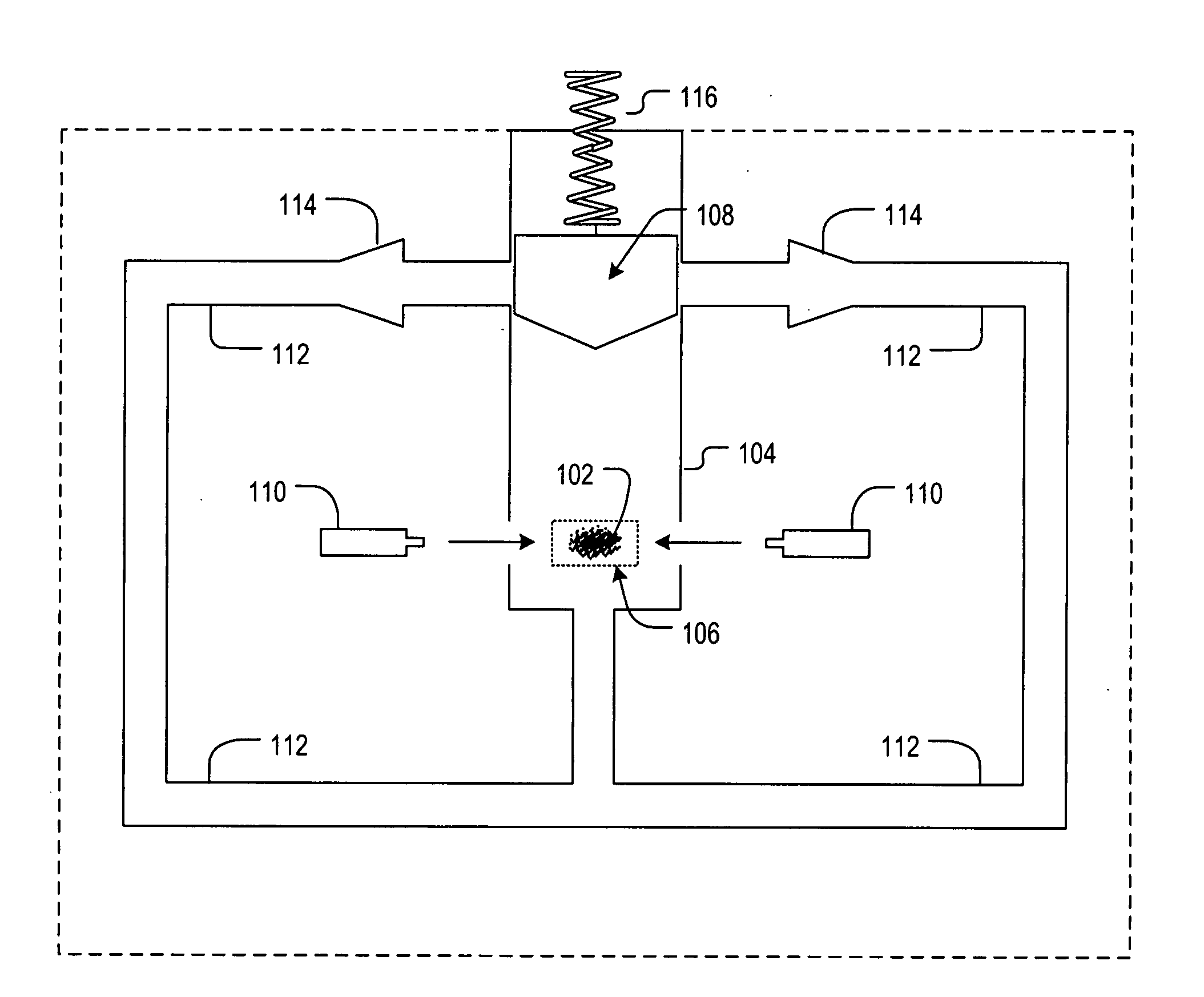

Apparatus comprising of propulsion system

InactiveUS20060027709A1Facilitate phase-inReduce the total massCosmonautic vehiclesCosmonautic propulsion system apparatusPistonEngineering

A propulsion system that does not consume fuel. The system operates to modify the dispersion force (i.e., van der Waals) that arises between particles, such as neutral atoms. A lifting force is generated as a result of this modification of the dispersion force. In the illustrative embodiment, the propulsion system includes particles, a particle trap, a source of electromagnetic energy, and a piston.

Owner:INTERSTELLAR TECH CORP

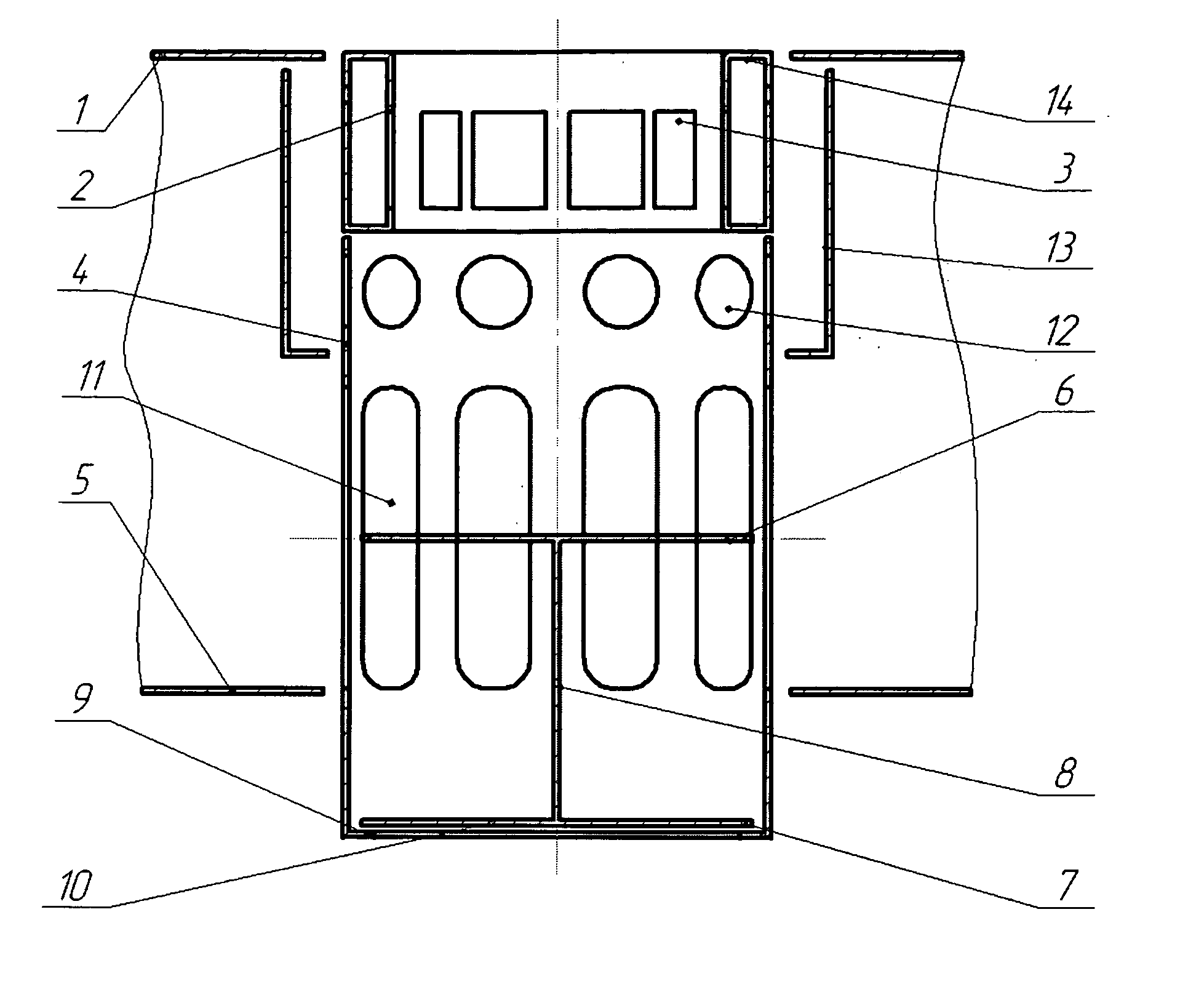

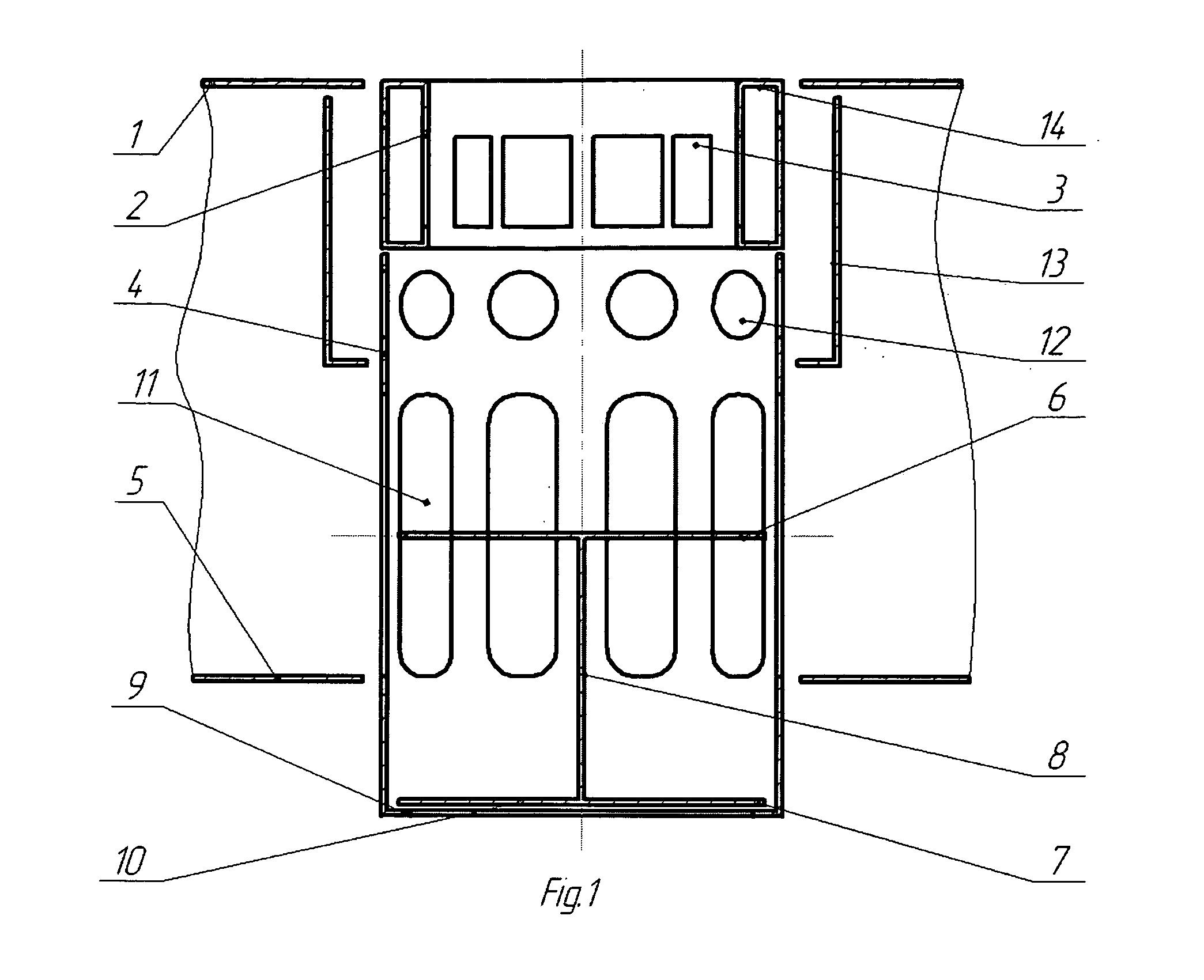

Mass exchange contact device

ActiveUS20100221156A1Increasing reliability and durabilityReduce metal contentUsing liquid separation agentMachines/enginesGratingCatalytic distillation

A mass-exchange contact device is proposed, comprising an upper tray, contact element including a barbotage unit configured as an inner cap with strips tangently bent out, a lower tray, a casing including a ring-shaped descending limiter, windows circumferentially disposed on the casing's walls (lower row), orifices circumferentially disposed on the casing's walls (upper row) above the windows, a double-acting valve composed of an upper and lower plates fixedly attached to a distance rod, and a cover bushing disposed coaxially to and around the upper region of casing embracing the contact element. Embodiments comprise a number of rows of the proposed devices situated one above the other, and separated by multi-layer packing fittings. In catalytic distillation columns, the fittings can be filled with catalytic material. Alternatively, the fitting is substituted with a grating that supports a catalytic granular layer. The device allows improving operation, reliability, durability, reducing its weight and costs.

Owner:MALETA BOGDAN +1

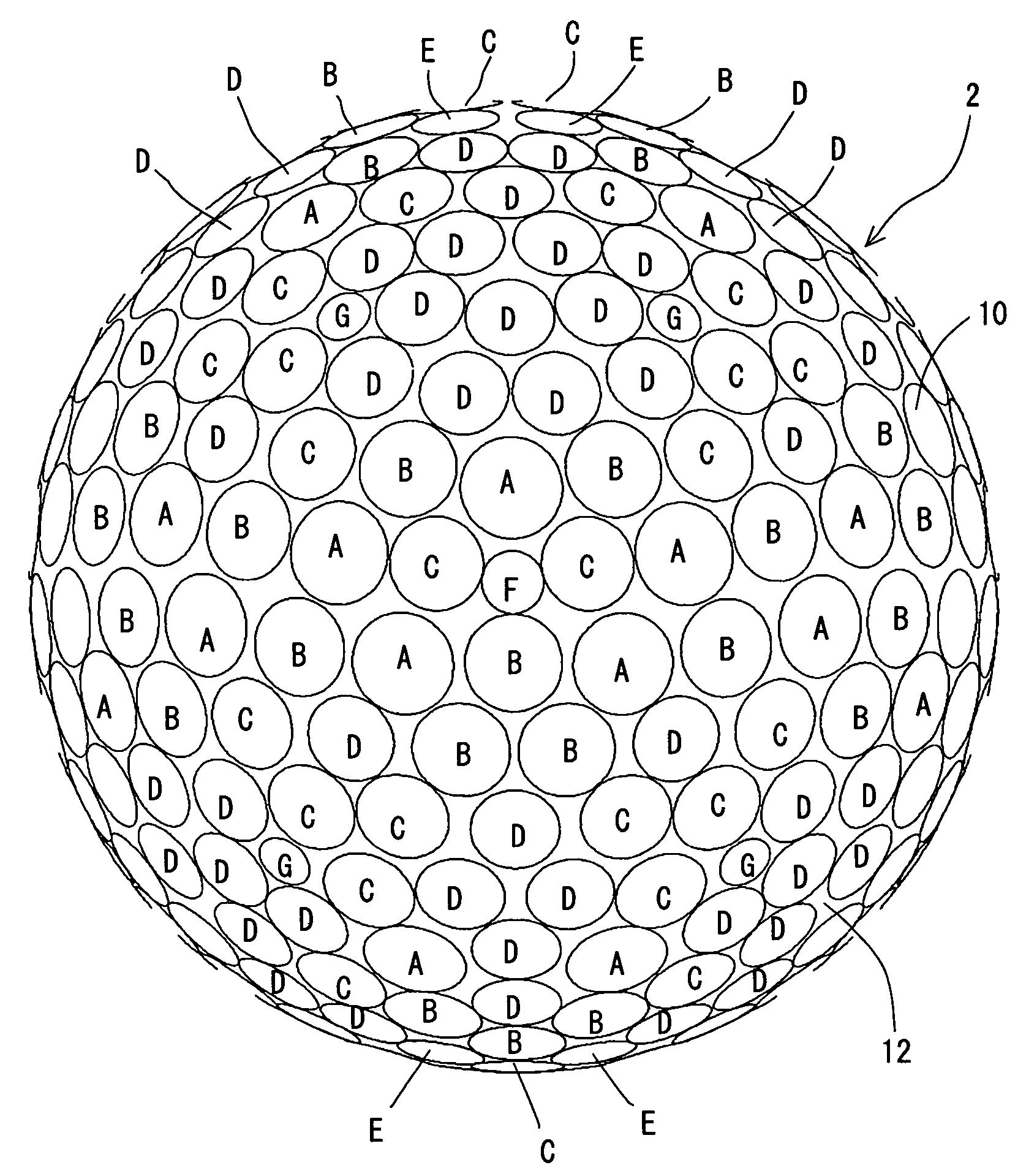

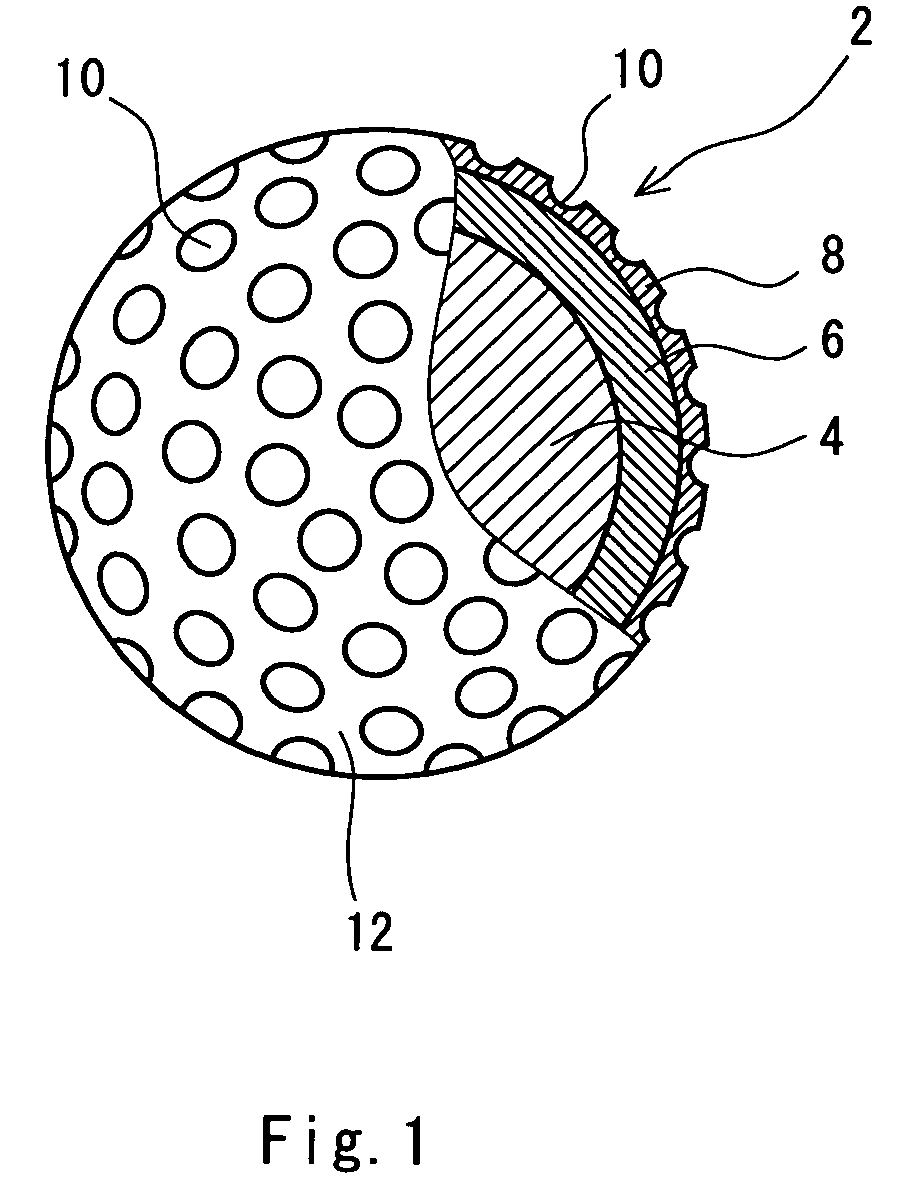

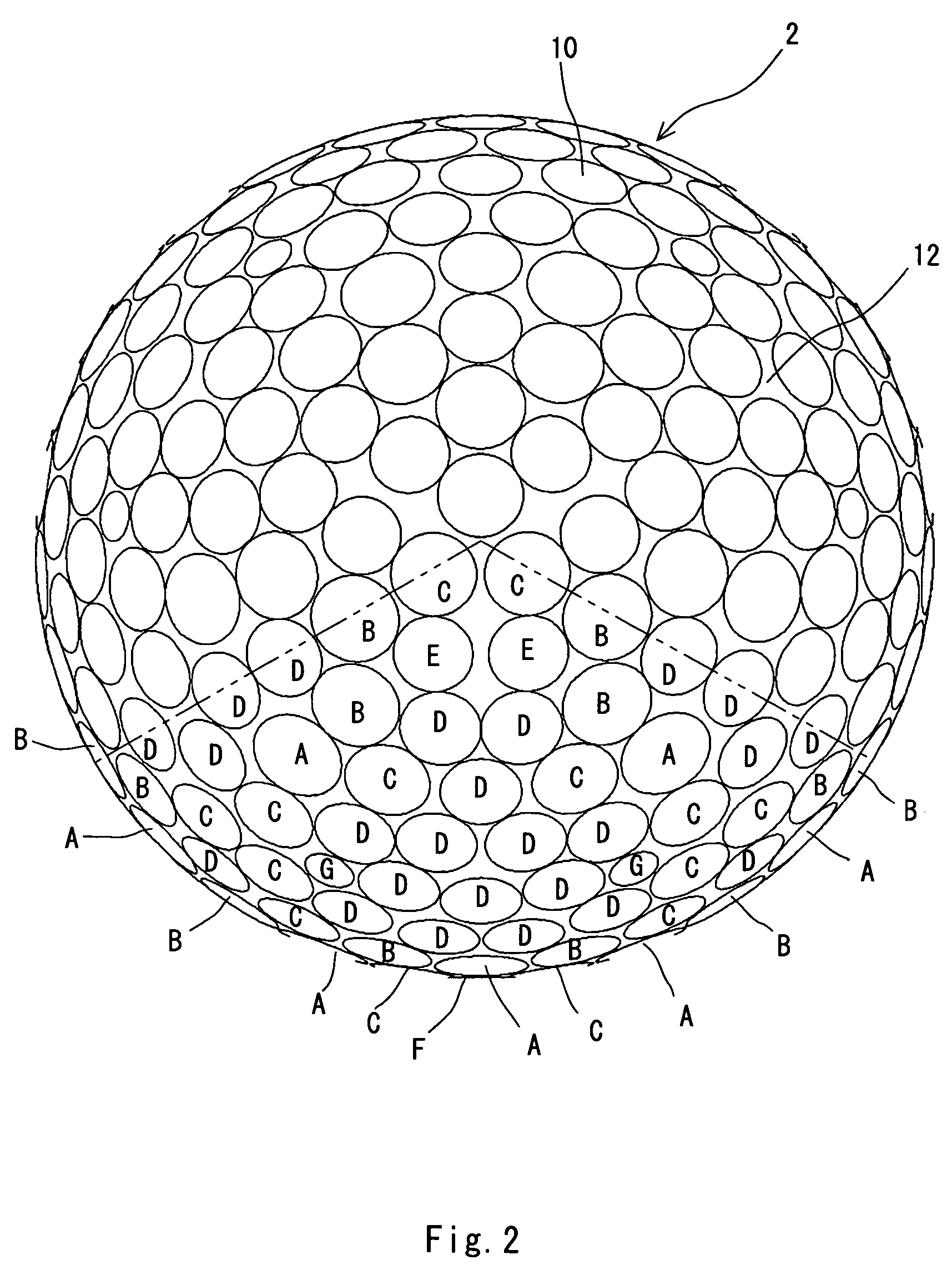

Golf ball

A golf ball 2 has a core, a mid layer and a cover. This mid layer comprises 10 parts by weight or greater and 70 parts by weight or less of a thermoplastic elastomer containing a styrene block having a material hardness of less than 10, and 30 parts by weight or greater and 90 parts by weight or less of an ethylene-(meth)acrylic acid copolymer based ionomer resin having a material hardness of 50 or greater and 70 or less. Hardness of this mid layer is less than 40, and the thickness is equal to or less than 1.2 mm. This golf ball 2 has seven kinds of dimples (A to G), each having a different diameter. When all the dimples are arranged in decreasing order of the diameter Di, ratio (Dx / Dn) of the mean diameter Dx of the dimples ranking in the top 10% to the mean diameter Dn of the dimples ranking in the bottom 10% is equal to or greater than 1.30. Standard deviation η of diameters of all the dimples is equal to or less than 0.52.

Owner:SUMITOMO RUBBER IND LTD

Belt lifter apparatus

In one form, a belt lifter apparatus provides increased lifting force and belt lift height by a scissors mechanism having crossed lifting arms each having a translatable end and having a translatable pivot axis between the lifting arms. Preferably, other ends of the lifting arms are fixed to an upper belt lifting member and to a lower support base member at locations such that the pivot axis translates to a position located substantially at the center of the lifted belt when the belt is lifted to the highest lift height. Lightweight, aluminum tubular members are used for the lifting member and the base support and each includes a track for supporting the translatable ends of the lifting arms. The span width of the base member is adjusted by sliding telescoping, tubular legs within the base tubular element. Pivoted wing arms are supported by braces extending to the belt lifting member.

Owner:FLEXIBLE STEEL LACING

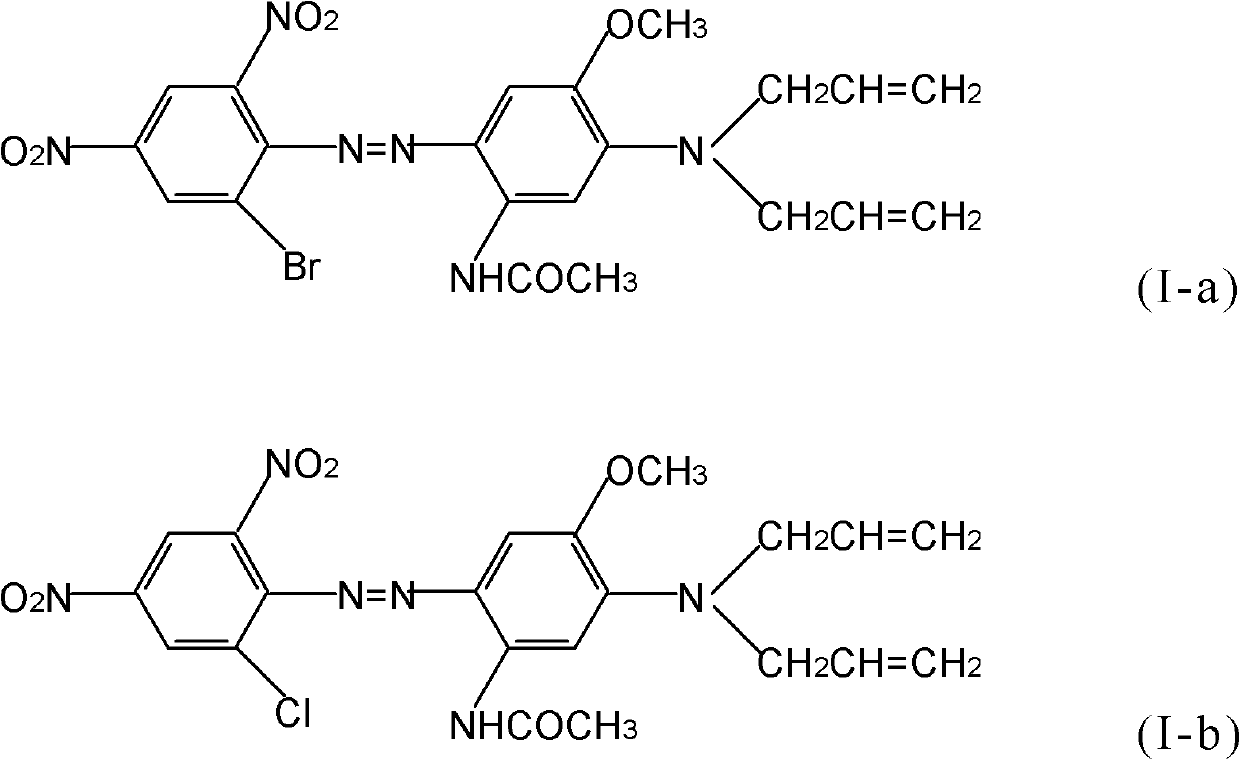

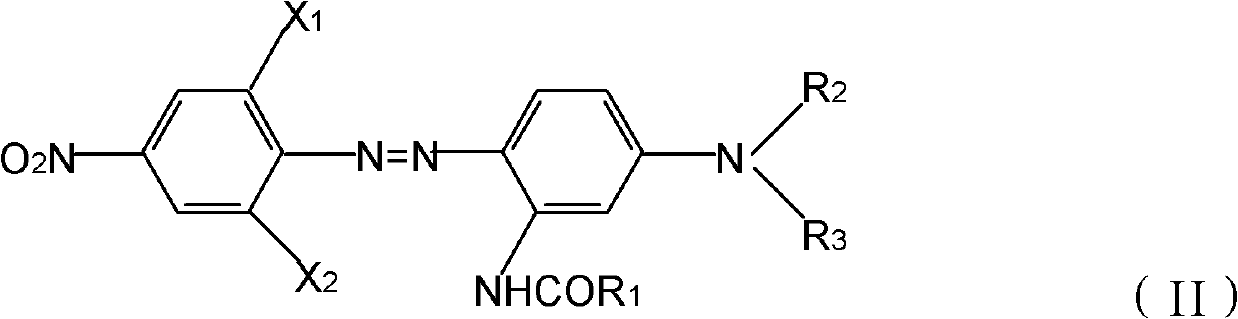

Composite dye composition, composite disperse dye and preparation method thereof

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of compounds as shown in a formula (I-a), a formula (I-b), a formula (II) and a formula (III). The composite disperse dye prepared from the composite dye composition has good comprehensive fastness property and high lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

Method for propulsion

InactiveUS20070007393A1Facilitate phase-inReduce the total massCosmonautic vehiclesCosmonautic propulsion system apparatusMomentumEngineering

A method for propulsion that does not consume fuel. The method involves the modification of the dispersion force (i.e., van der Waals) that arises between particles, such as neutral atoms. The method comprises generating a lifting force by subjecting a plurality of confined particles to a trigger acceleration, exposing the particles to an amount of electromagnetic radiation that is sufficient to induce the lifting force to (1) exhibit relatively long-range interactions and (2) increase the momentum of the particles, and then transferring at least a portion of the increase in momentum to a vehicle.

Owner:INTERSTELLAR TECH CORP

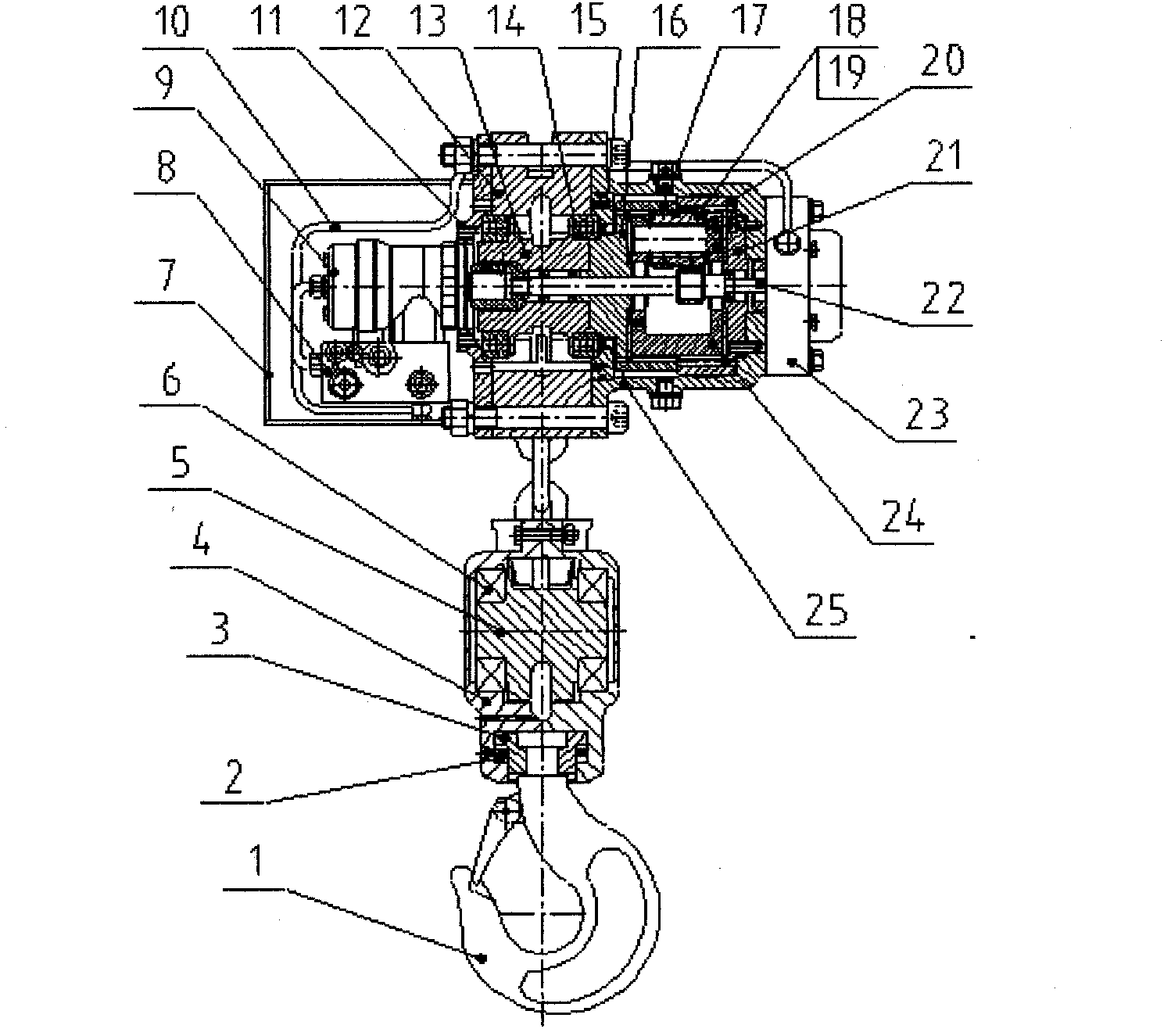

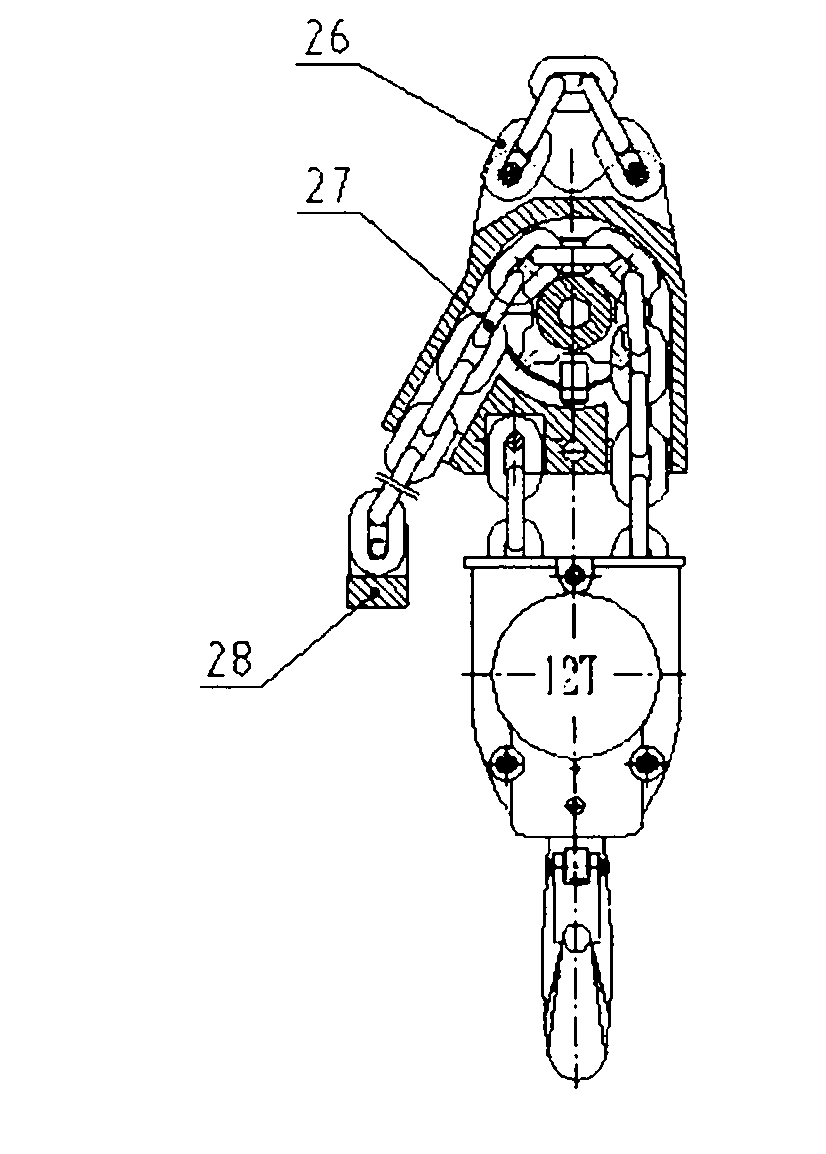

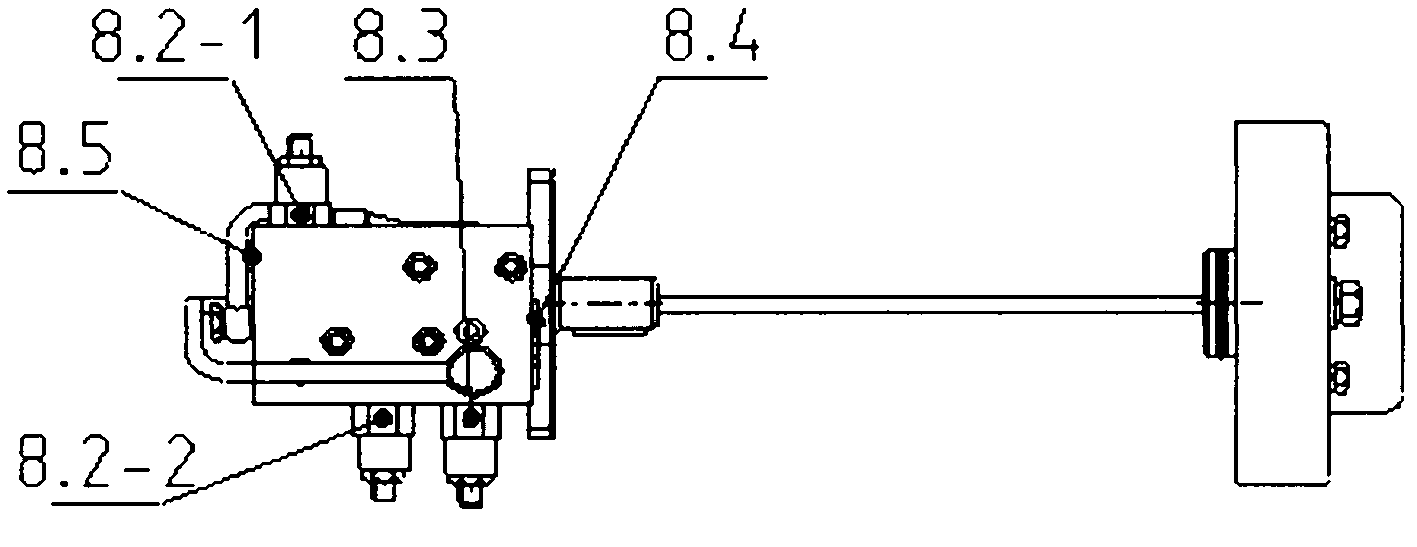

Chain-type hydraulic hoist for lifting

ActiveCN102838049ACompact structureReduce volumePortable liftingToothed gearingsHydraulic motorControl engineering

The invention discloses a chain-type hydraulic hoist for lifting, which comprises a lifting hook, a hydraulic drive control part, a lifting part, a planetary reducer and a high-strength lifting chain; the hydraulic drive control part comprises a valve block, a hydraulic motor, a non-brake oil tube and a hydraulic brake; the lifting part comprises an end cover, a housing, a driving chain wheel, a locating bearing and a primary drive gear; the planetary reducer comprises a sun wheel shaft, a planetary gear, a planetary gear shaft, a planetary gear rack, a primary gear ring, a fixed gear, a secondary gear ring and a planetary reducer shell; the hydraulic hoist provides a control oil tube by a matched hydraulic system on mining machinery, and drives the planetary reducer by the hydraulic motor; the planetary reducer outputs a torque to drive a lifting driving chain wheel, and drives an annular lifting chain and a lifting hook device to lift and put down heavy objects, and also can be used for horizontally dragging the heavy objects (namely used as a hydraulic winch). The chain-type hydraulic hoist is suitable for downhole operation of coal mine, and has the advantages of being reasonable in structure, large in lifting ratio in equal volume, simple and convenient to operate, high in work efficiency, safe and reliable.

Owner:BEIJING JINXUANYE TECH

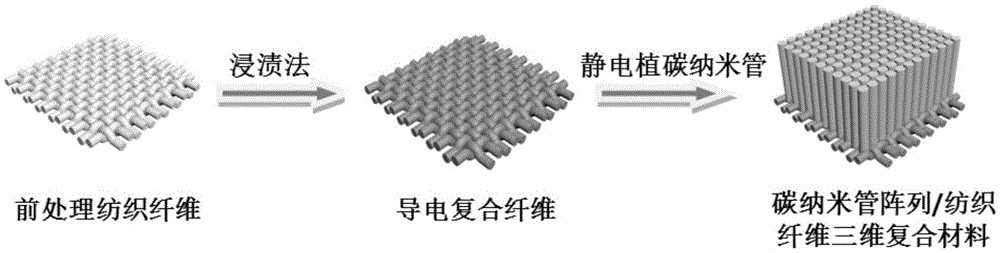

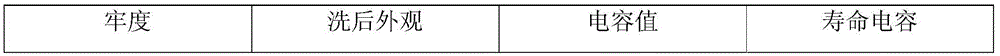

Preparation method for three-dimensional aminated carbon nanotube array/stretchable textile fiber electrode material

ActiveCN105679555AGood stretchabilityImprove mechanical propertiesHybrid capacitor electrodesHybrid/EDL manufactureTextile fiberCooking & baking

The invention relates to a preparation method for a three-dimensional aminated carbon nonotube array / stretchable textile fiber electrode material. The preparation method comprises the following steps of placing textile fiber subjected to pre-treatment in a composite agent containing a dispersing agent and an aminated carbon nanotube in a room temperature, carrying out immersion and drying to obtain a conductive and stretchable textile substrate; placing the aminated carbon nanotube in an electricity processing liquid to obtain aminated carbon nanotube subjected to electricity processing; and uniformly coating the conductive and stretchable textile substrate with a graphene conductive adhesive, implanting the aminated carbon nanotube subjected to electricity processing into the surface of the substrate through single-surface static electricity to obtain the three-dimensional conductive electrode material, carrying out pre-baking and baking, and absorbing the aminated carbon nanotube floated on the surface to obtain the three-dimensional aminated carbon nanotube array / stretchable textile fiber electrode material. The method disclosed by the invention is simple in process, the cost can be substantially reduced, and meanwhile, mass production of a high-capacitance electrode is achieved.

Owner:DONGHUA UNIV

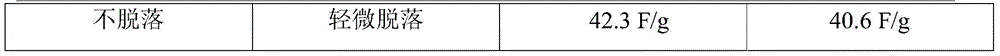

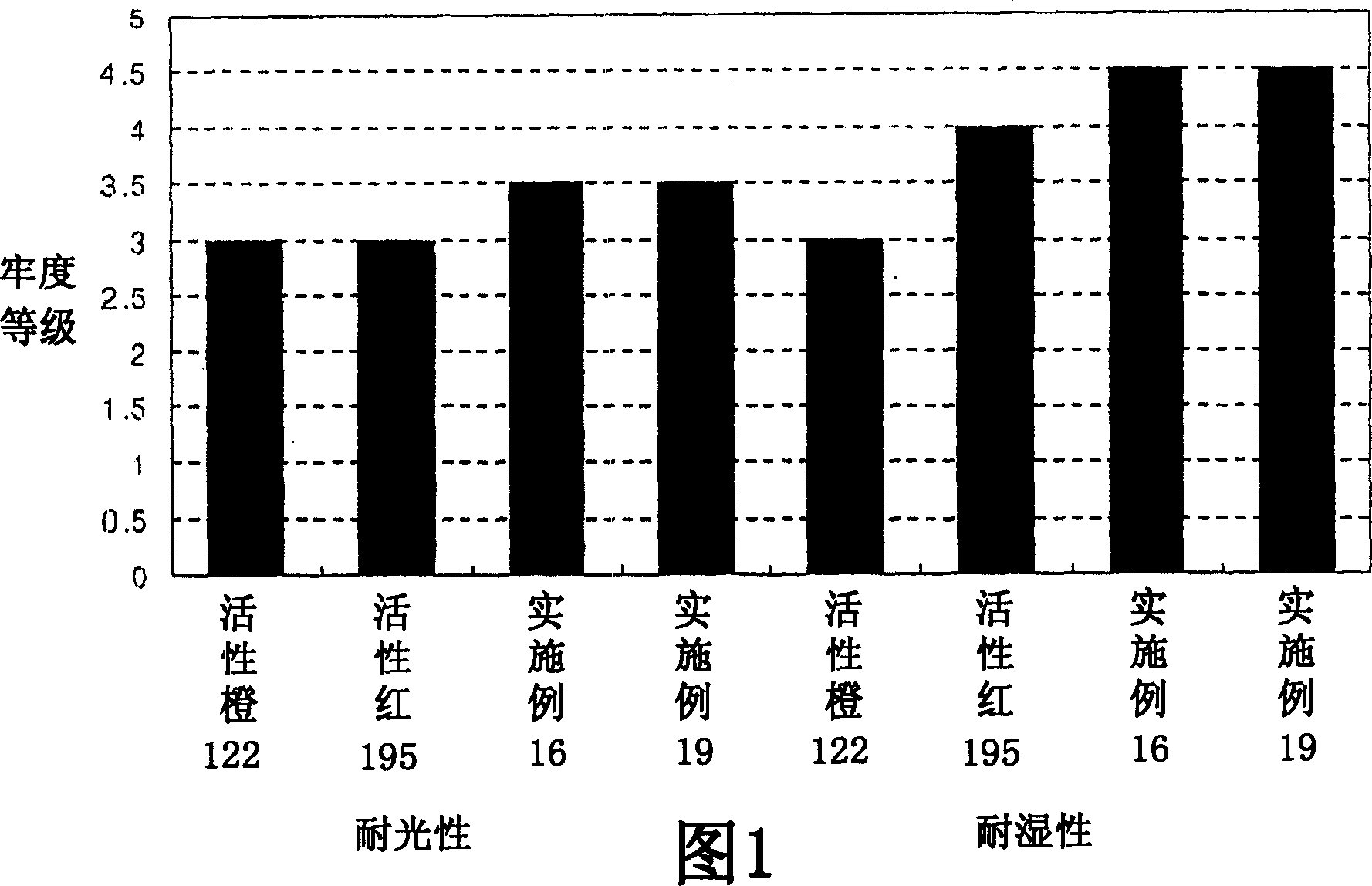

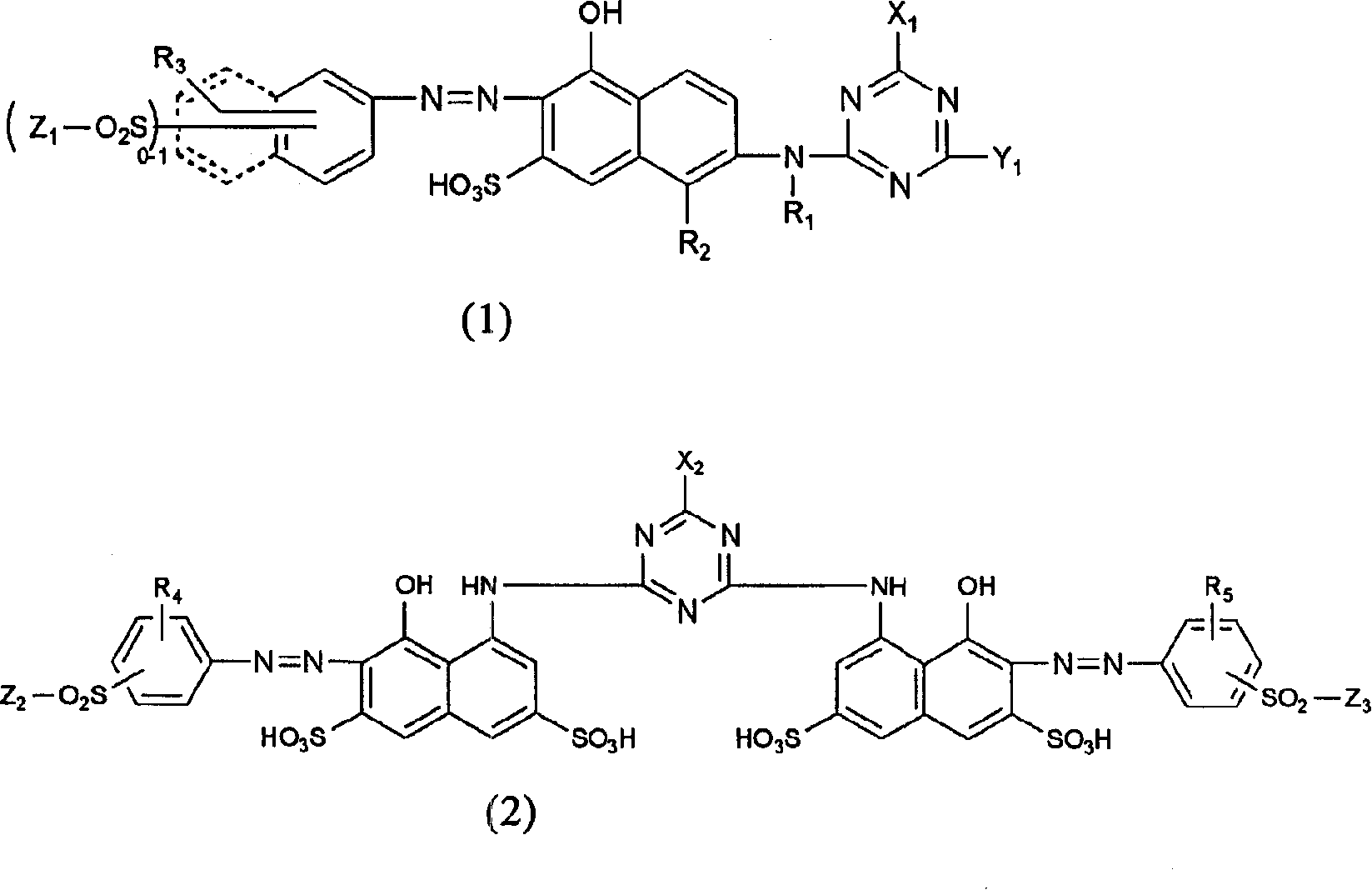

Mixture of fiber reactive dye compounds and dyeing method using the same

InactiveCN1810893AGood light fastnessIncrease lifting powerOrganic dyesDyeing processNitrogenCellulose fiber

Provided is a fiber-reactive dye mixture, comprising (i) one or more reactive dyes represented by Formula 1, and (ii) one or more reactive dyes represented by Formula 2: and a dyeing method using the same. The dye mixture of the present invention exhibits superior adsorptivity and fixability when dyeing a fiber material containing nitrogen or hydroxyl group, particularly a cellulose fiber material, and particularly very high light fastness and wet fastness, and thus provides a variety of balanced physical properties which are required in dyeing.

Owner:京仁洋行

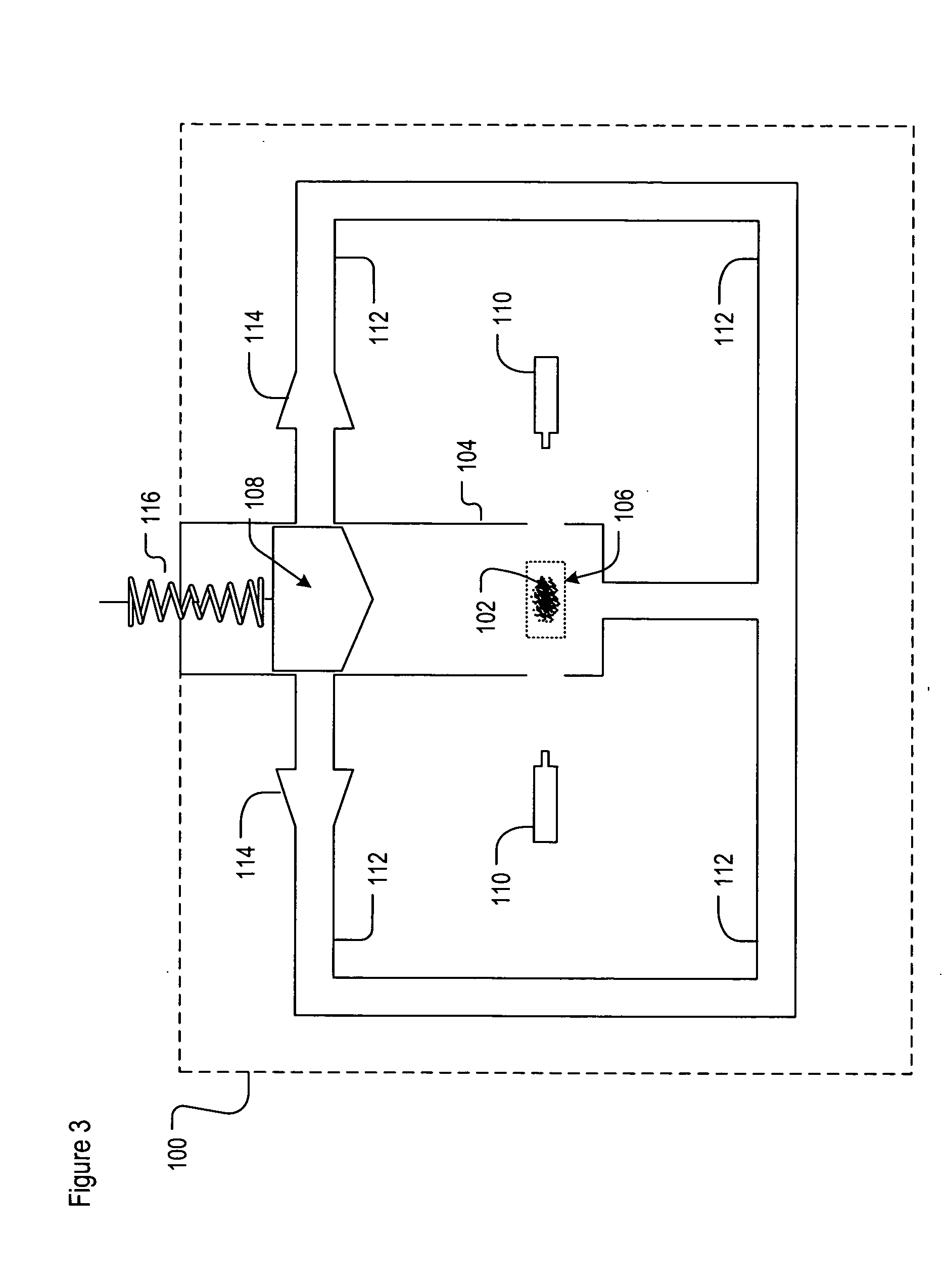

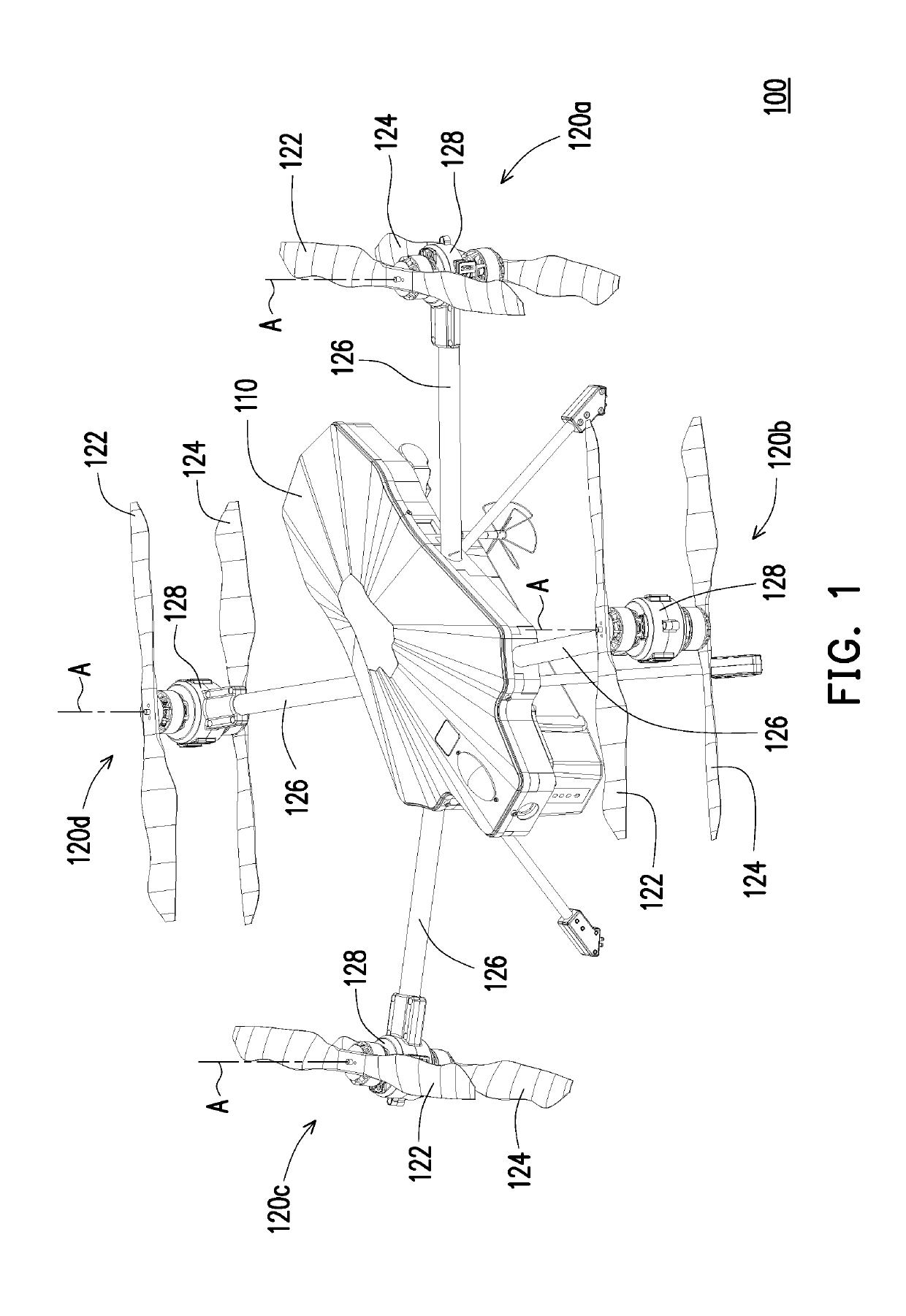

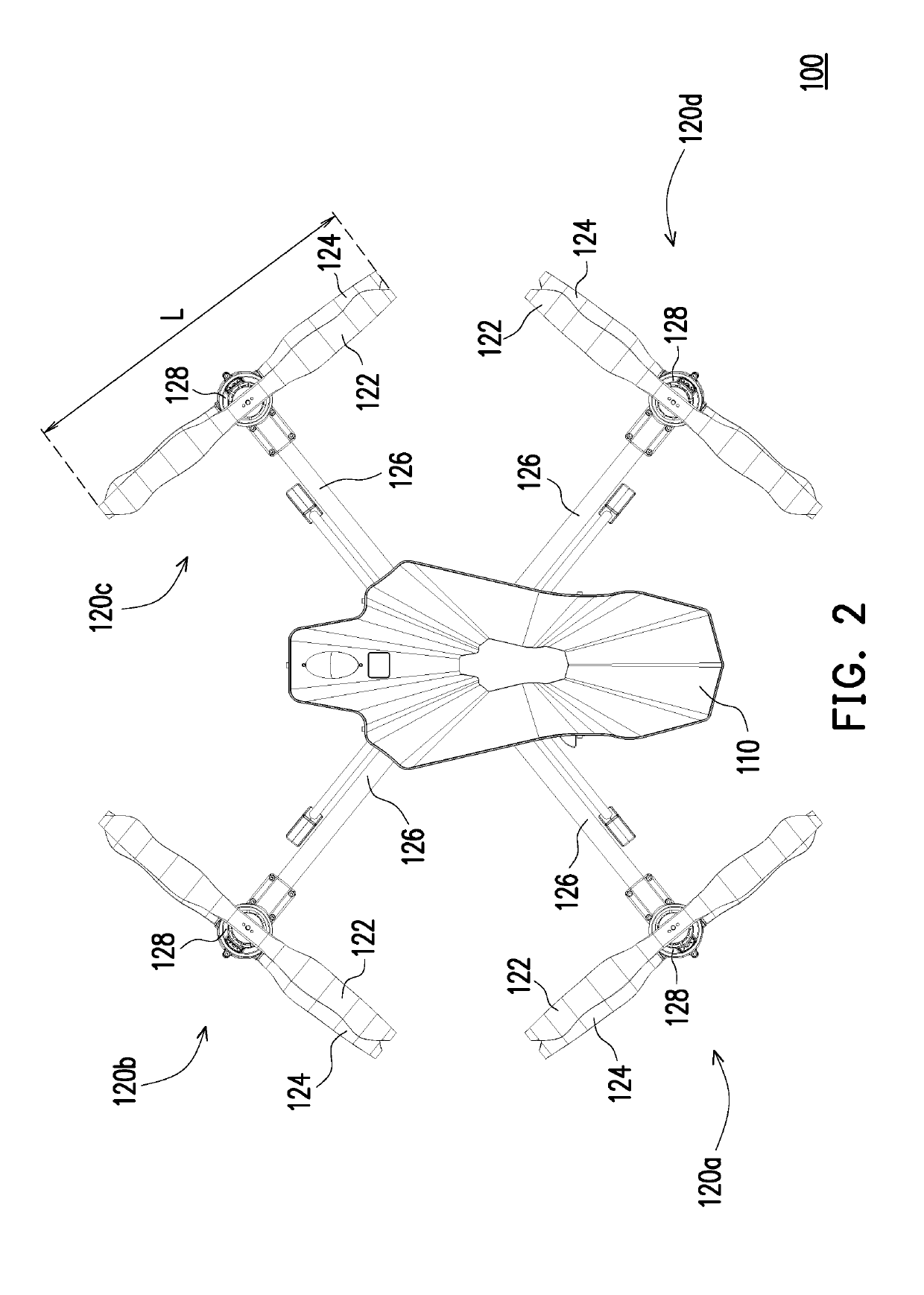

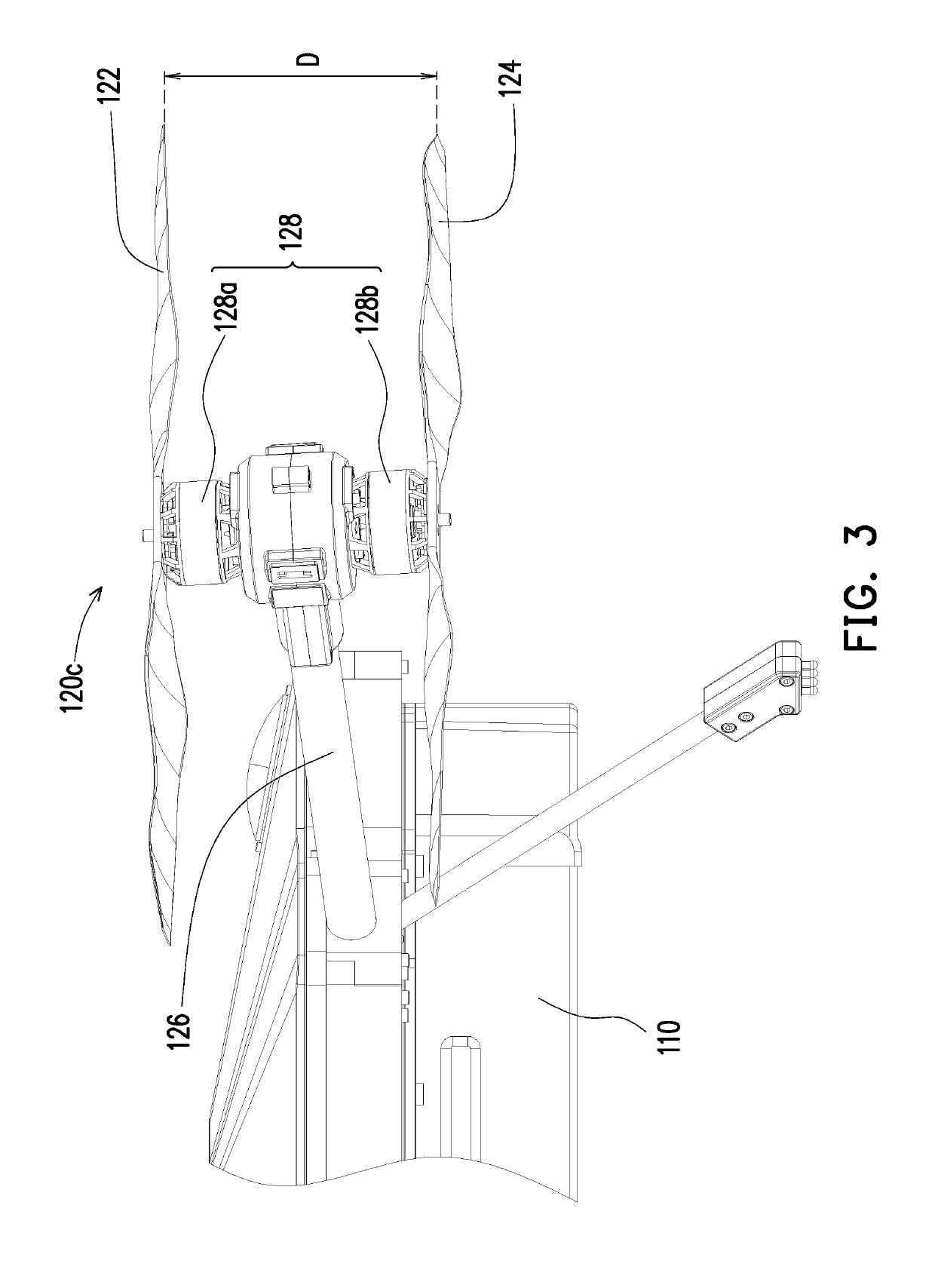

Flight device

InactiveUS20190248486A1Increase lifting powerImprove efficiencyUnmanned aerial vehiclesRemote controlled aircraftComputer modulePropeller

Owner:CORETRONIC INTELLIGENT ROBOTICS CORP

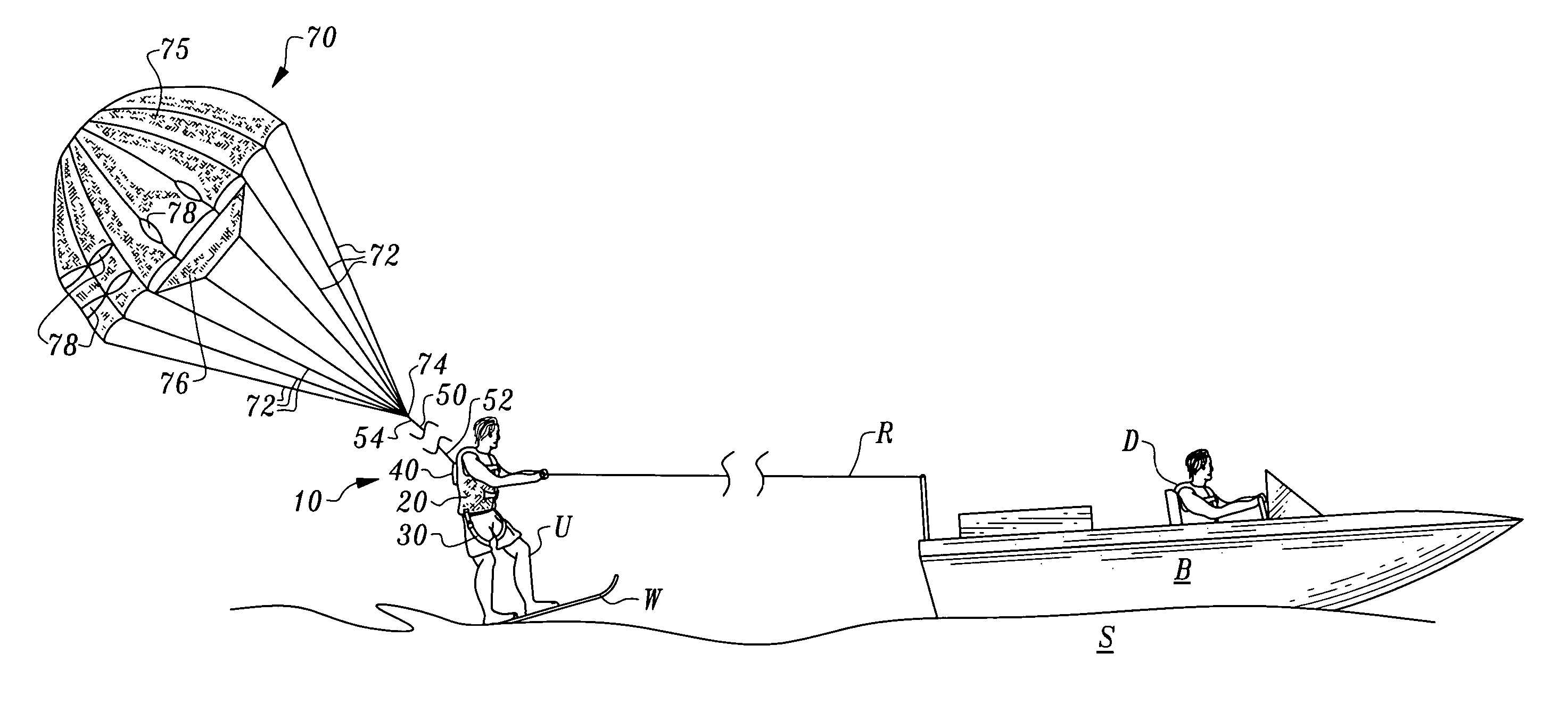

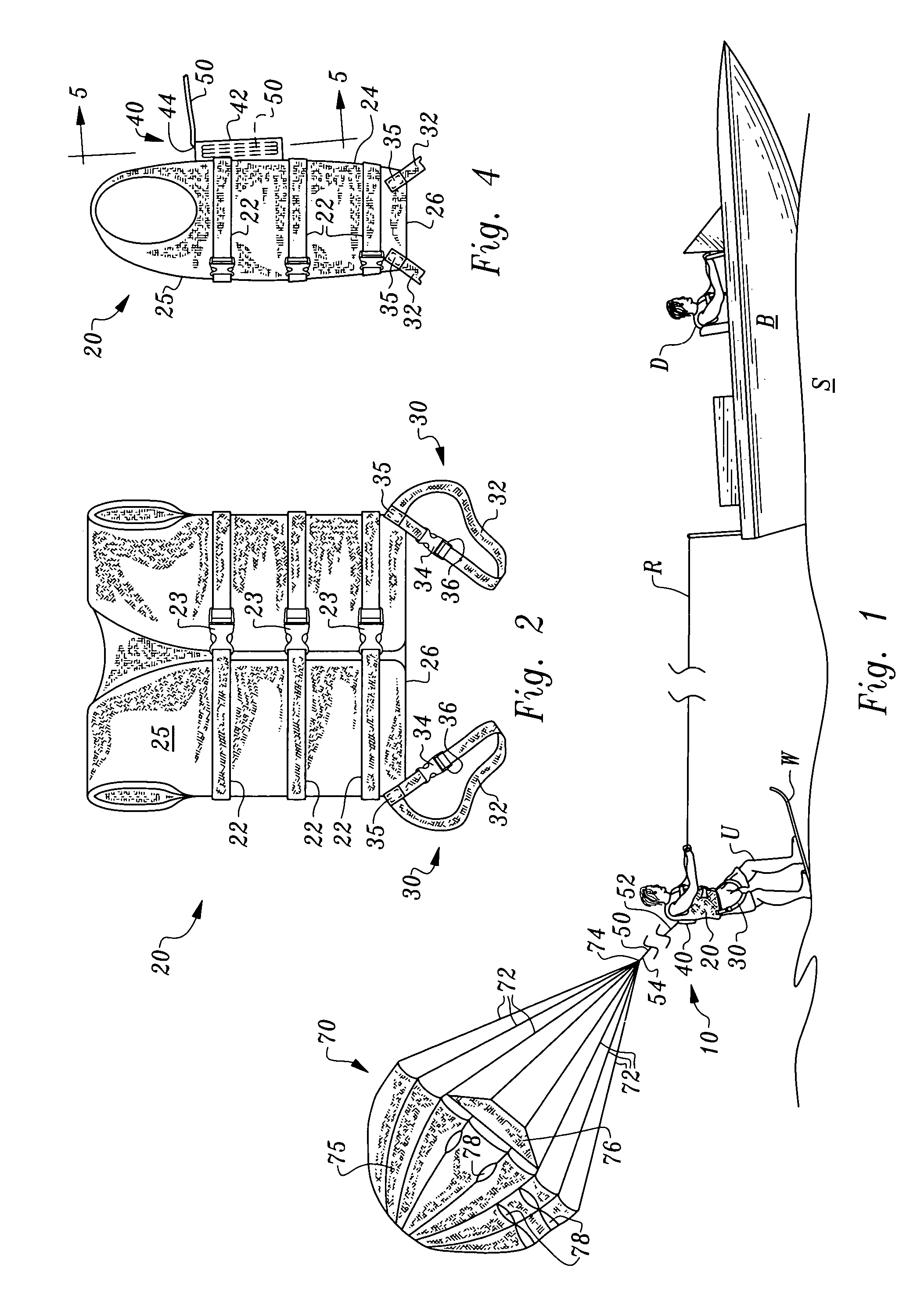

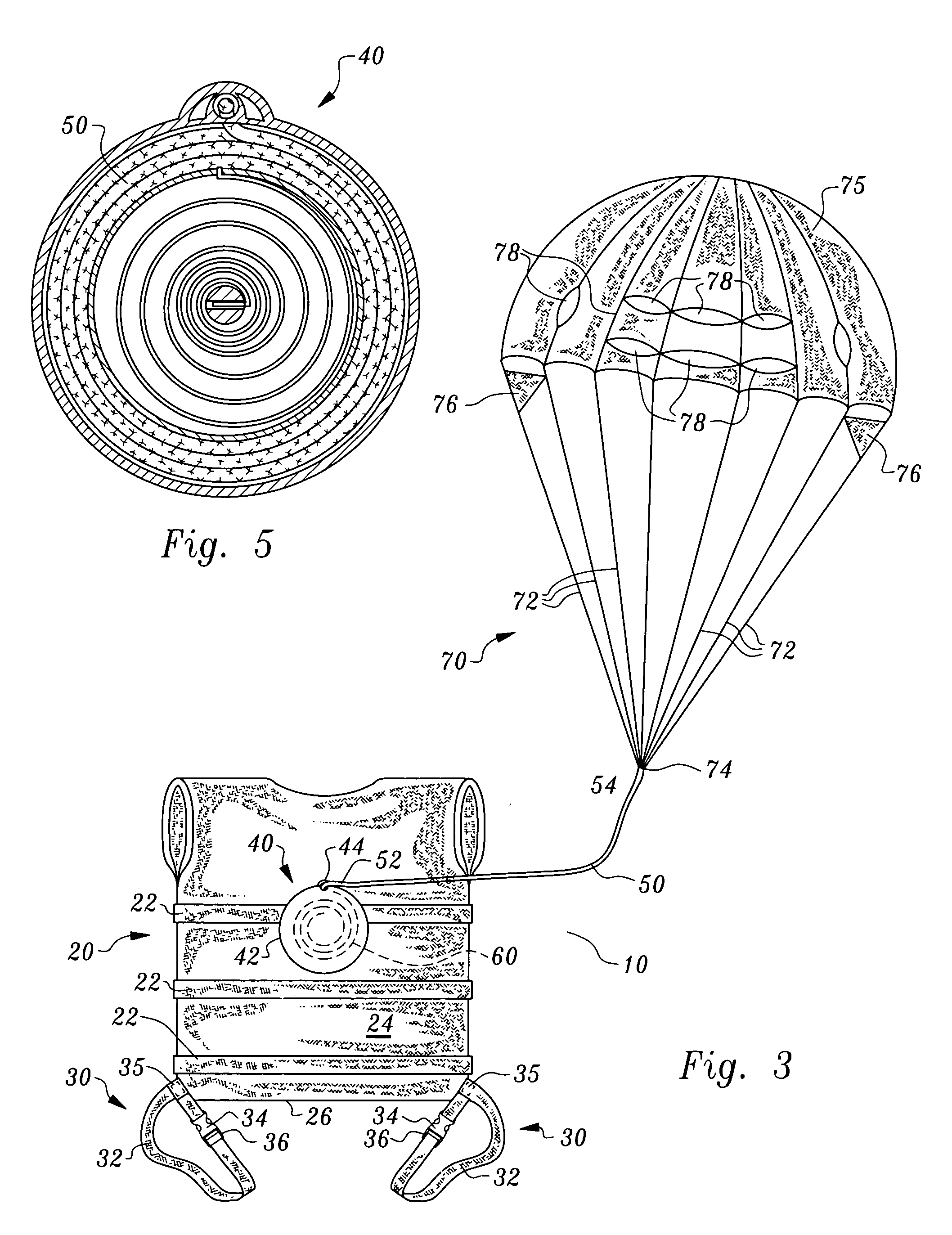

Wakeboard jump enhancement system

InactiveUS7114457B1Great height and durationIncrease lifting powerTowing/pushing equipmentWater sport boardsEngineeringBelt safety

A jump enhancement system is provided for use while riding upon a water or snow planing apparatus towed behind a boat or snowmobile. The system includes an aerodynamic lift generator, such as a parachute, coupled to the user. Most preferably, a flotation or padded / insulated vest is provided which includes leg harnesses and which can be worn by the user with a cord collector coupled to the flotation vest and securing a cord to the flotation or padded / insulated vest which also extends to the parachute. The cord collector is biased to cause the cord to be collected adjacent the user when no drag forces are exerted upon the parachute. When any such drag forces are experienced, the cord is deployed out of the cord collector so that the parachute is deployed. The parachute is thus in position to enhance a height and duration of jumps off of the surface.

Owner:STIERS LUKE D

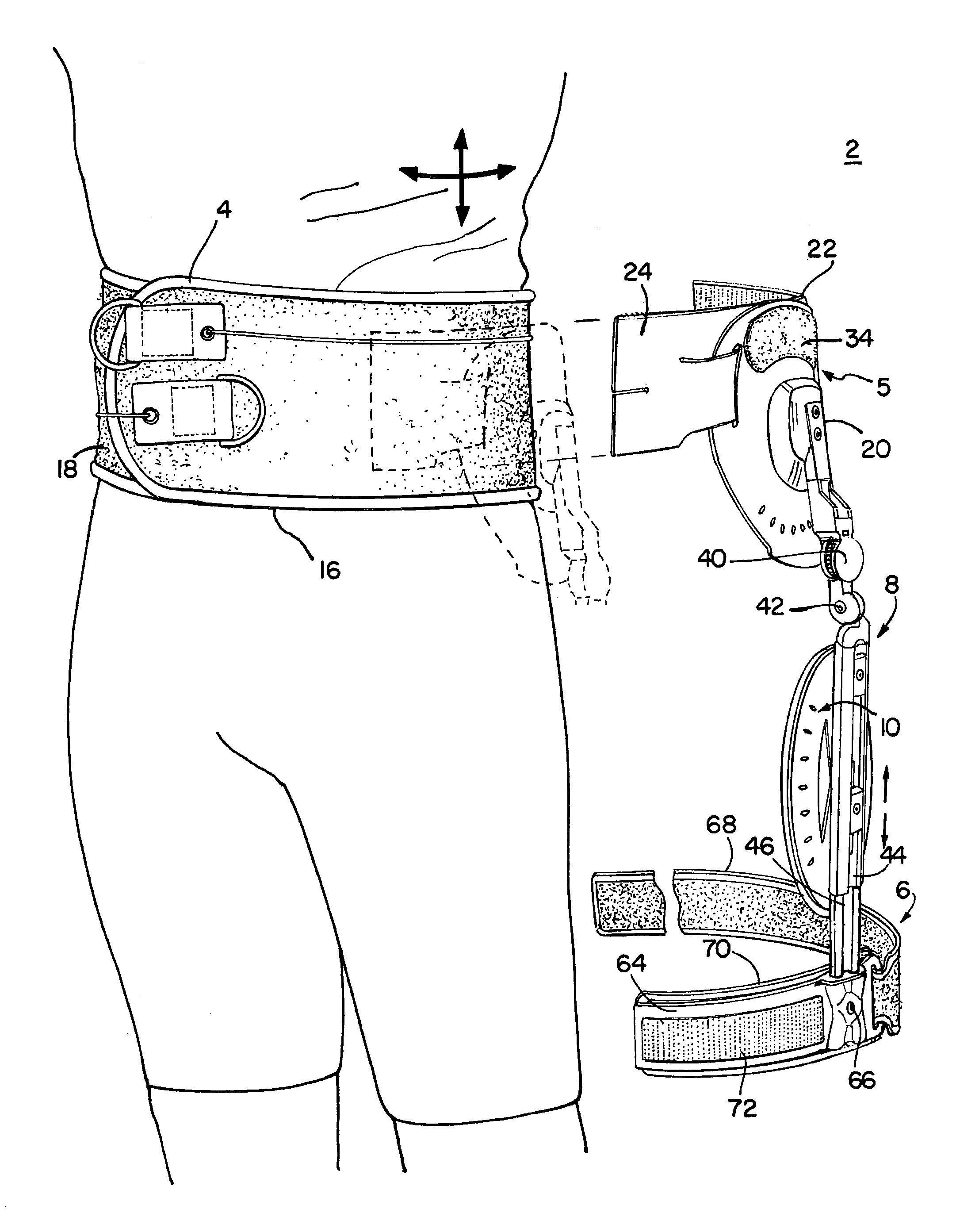

Adjustable multi-component hip orthosis

ActiveUS20130178775A1Increase lifting powerNon-surgical orthopedic devicesMachines/enginesThighKnee orthosis

A hip orthosis having a flexible waist band for conforming to the waist of a user can be attached at any position on the exterior of the waist band with adjustments in a vertical circumferential and rotational position for connecting a hip support unit at a desired position to maintain the head of a femur into the acetabulum of a user. The hip support unit is connected to a hinge member and an extension unit that is secured at a lower portion of the thigh wherein a thigh support unit can be adjusted so that a three point force system can be applied to the user.

Owner:ORTHOMERICA PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com