Environmentally-friendly mould-proofing wood-plastic composite material and preparation method thereof

A kind of wood-plastic composite material and environment-friendly technology, which is applied in the field of wood-plastic composite material and its preparation, can solve problems such as mildew, and achieve the effects of improving mildew resistance, good mechanical properties, and improving compatibility and interface affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

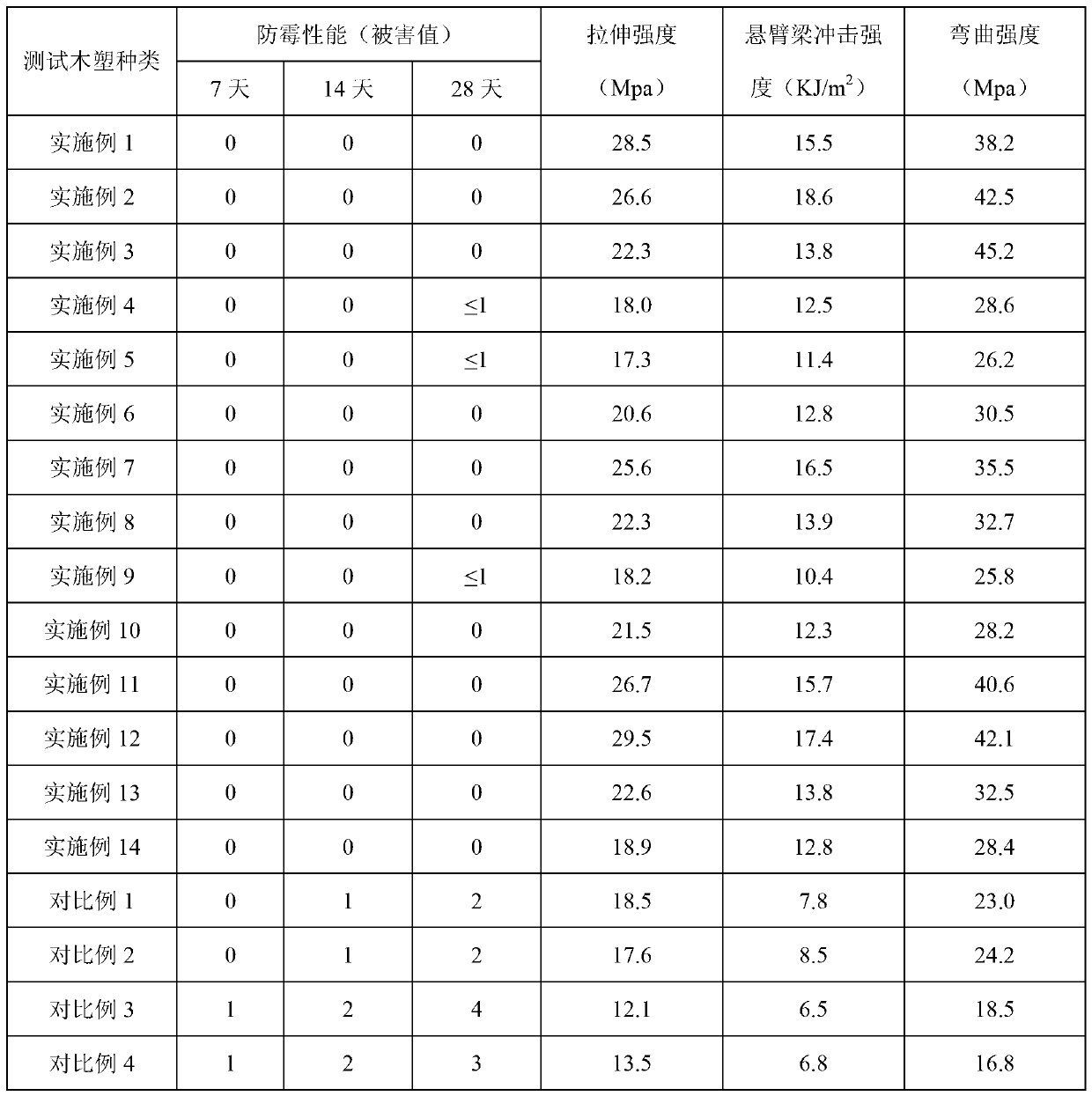

Embodiment 1

[0024] Take a certain amount of pine wood powder with a particle size of 40 mesh, add it to a container filled with a mass fraction concentration of 18% NaOH alkali solution, stir and soak for 24 hours, wash the wood powder with clean water until it is neutral, and then put the wood powder in an oven to dry Dry. Add the wood powder treated and dried with NaOH into the high-speed mixer, heat up while stirring, and then add the titanate coupling agent with 4% wood powder mass in two times, stir for 3 minutes each time, stir well and then low speed Mix and cool to 40°C and discharge to obtain modified pine wood powder.

[0025] Weigh 100 parts of the HDPE plastic matrix prepared above, 100 parts of modified pine wood powder, 15 parts of active calcium carbonate, 3 parts of stearic acid, 7704 parts of light stabilizer, 2 parts of toner, and talcum powder according to the ratio of parts by weight. 1 part, 0.5 part of diatomaceous earth, put the above raw materials into a high-spee...

Embodiment 2

[0027] Take a certain amount of poplar wood powder with a particle size of 80 mesh, add it to a container filled with a mass fraction concentration of 15% NaOH alkali solution, stir and soak for 36 hours, wash the wood powder with clean water until it is neutral, and then put the wood powder in an oven drying. Add the poplar wood powder treated with lye and dried into a small mixer, add toluene diisocyanate with a weight of 1.0% of the wood powder, stir and mix for 30 minutes, and discharge to prepare the modified poplar wood powder.

[0028] Accurately weigh 100 parts of the above prepared PP plastic substrate, 80 parts of modified poplar wood powder, 12 parts of activated calcium carbonate, 3 parts of PE wax, 5404 parts of light stabilizer, 2 parts of toner, and talc according to the ratio of parts by weight. 1 part of powder, 1 part of diatomaceous earth, put the above raw materials into a high-speed mixer, stir and mix at a high speed for 10 minutes under the conditions of...

Embodiment 3

[0030] Take a certain amount of cypress powder with a particle size of 60 mesh, add it to a container filled with a 15% NaOH alkali solution, stir and soak for 36 hours, wash the wood powder with clean water until it is neutral, and then put the wood powder in an oven to dry Dried and set aside. Put the alkali-treated and dried wood flour into a high-speed mixer, add 2% of the mass of wood flour at 60°C and spray the wood flour with vinyltrimethoxysilane diluted to 5% with 95% ethanol solution , After spraying, stir and mix for 30 minutes before discharging, let it air for 12 hours at room temperature, put it into an oven, and dry it at 105°C for 24 hours to obtain modified cedar wood powder.

[0031]Weigh 120 parts of modified cypress powder prepared above, 100 parts of HDPE plastic substrate, 15 parts of activated calcium carbonate, 3 parts of paraffin, 6224 parts of light stabilizer, 1 part of toner, and 2 parts of talcum powder according to the ratio of parts by weight. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com