Composite dye composition, composite disperse dye and preparation method thereof

A dye composition, composite dispersion technology, applied in the direction of organic dyes, etc., can solve problems such as insufficient performance, and achieve the effects of improving lifting force and rubbing fastness, good rubbing fastness and washing fastness, and excellent rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

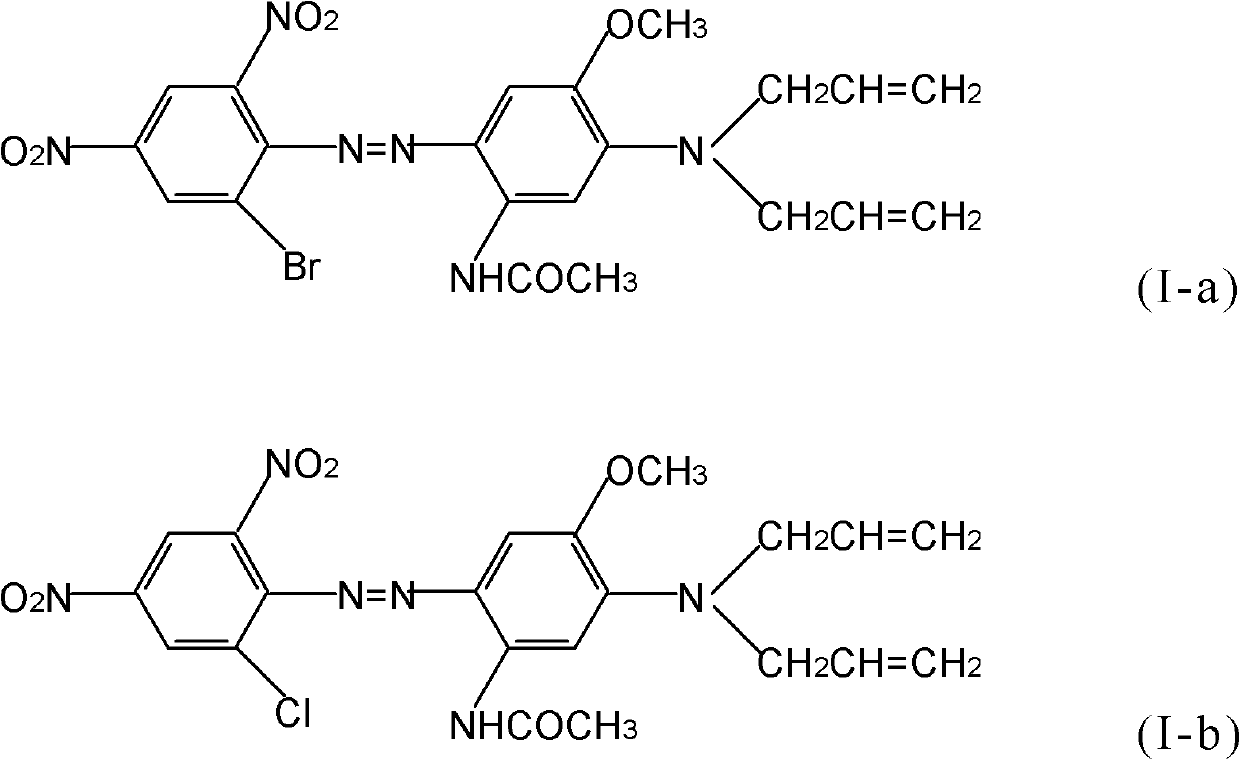

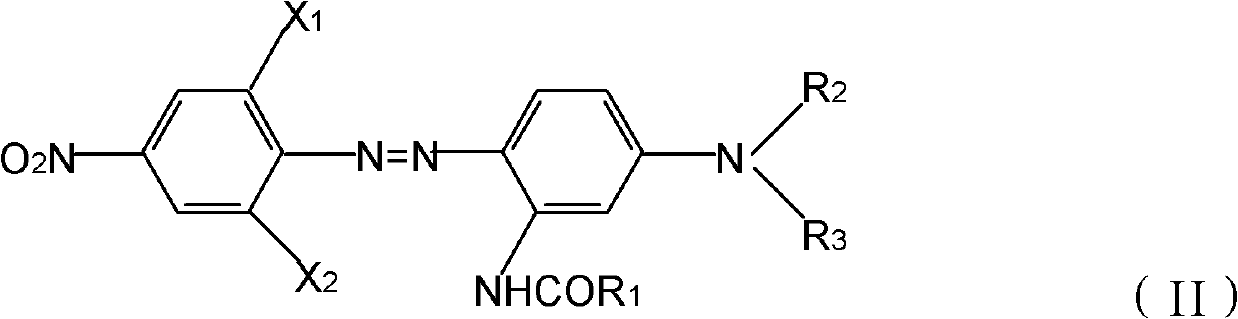

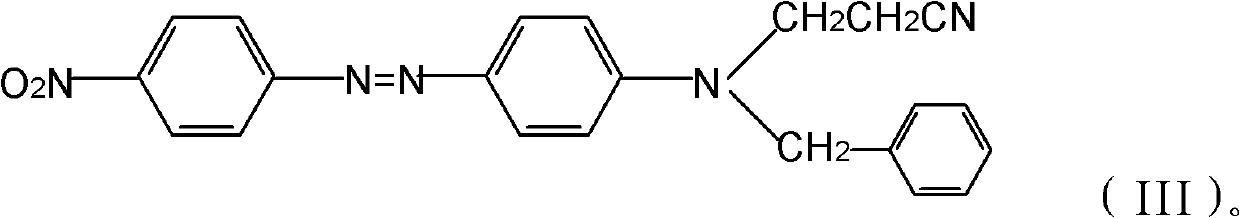

[0032] With the mixture of 17.6 gram formula (I-a) compound and formula (I-b) compound (formula (I-a) compound: formula (I-b) compound=30:70), 9.4 gram formula (II-1) compound, 11 gram formula (III) Compound, and 62 grams of sodium lignosulfonate and 300 grams of water are ground and dried together to make composite disperse dyes.

Embodiment 2

[0041] With the mixture of 17.6 gram formula (I-a) compound and formula (I-b) compound (formula (I-a) compound: formula (I-b) compound=30:70), 9.4 gram formula (II-1) compound, 11 gram formula (III) Compound, and 62 grams of sodium lignosulfonate and 300 grams of water are ground and dried together to make composite disperse dyes.

Embodiment 3

[0050] The mixture of 30 gram formula (I-a) compound and formula (I-b) compound (formula (I-a) compound: formula (I-b) compound=30:70), 10 gram formula (II-1) compound, 10 gram formula (II- 2) The compound, 50 g of the compound of formula (III), and 180 g of the diffusing agent NNO and 420 g of water were ground together and dried to prepare a composite disperse dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com