Patents

Literature

90results about How to "Reduce angle of attack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

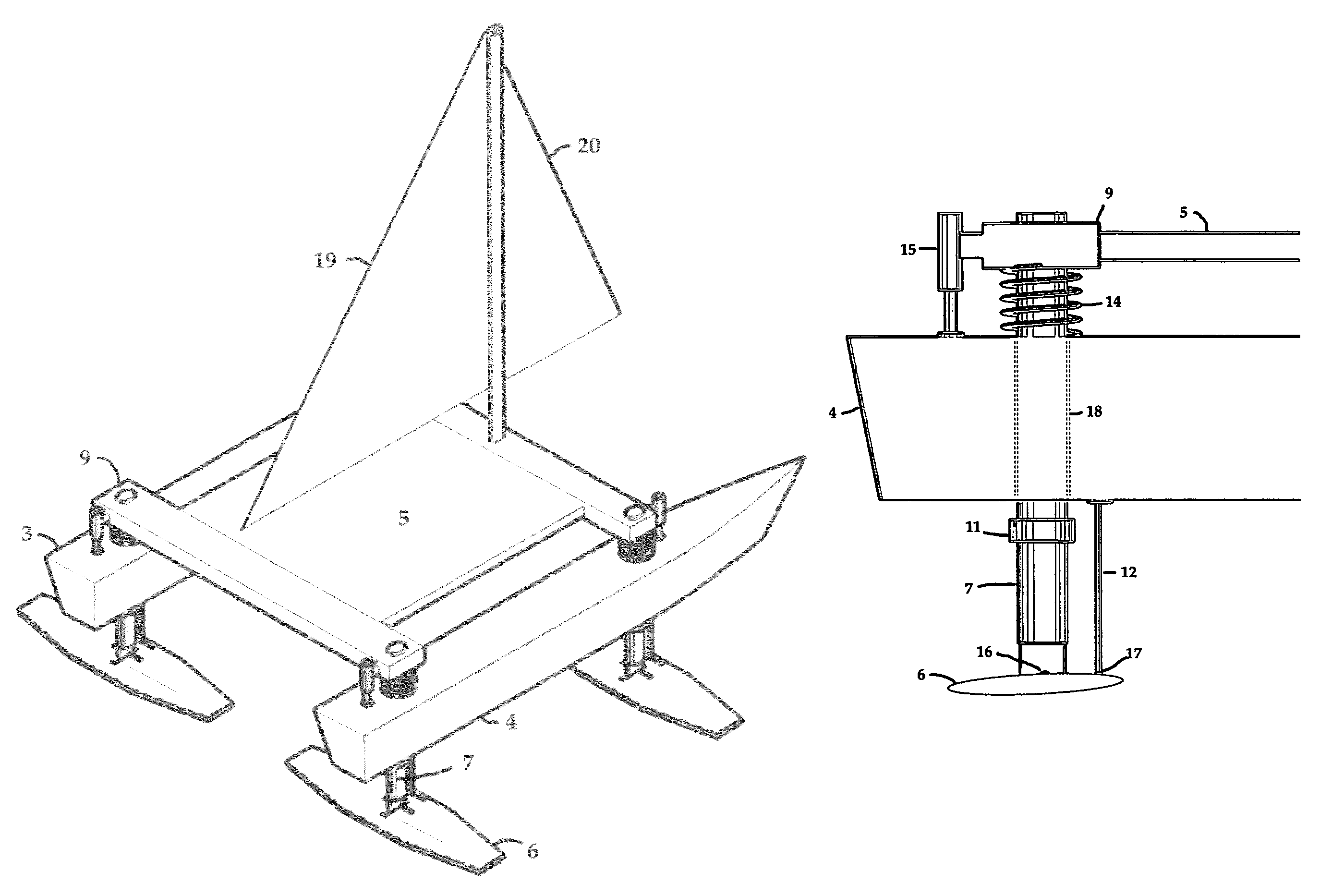

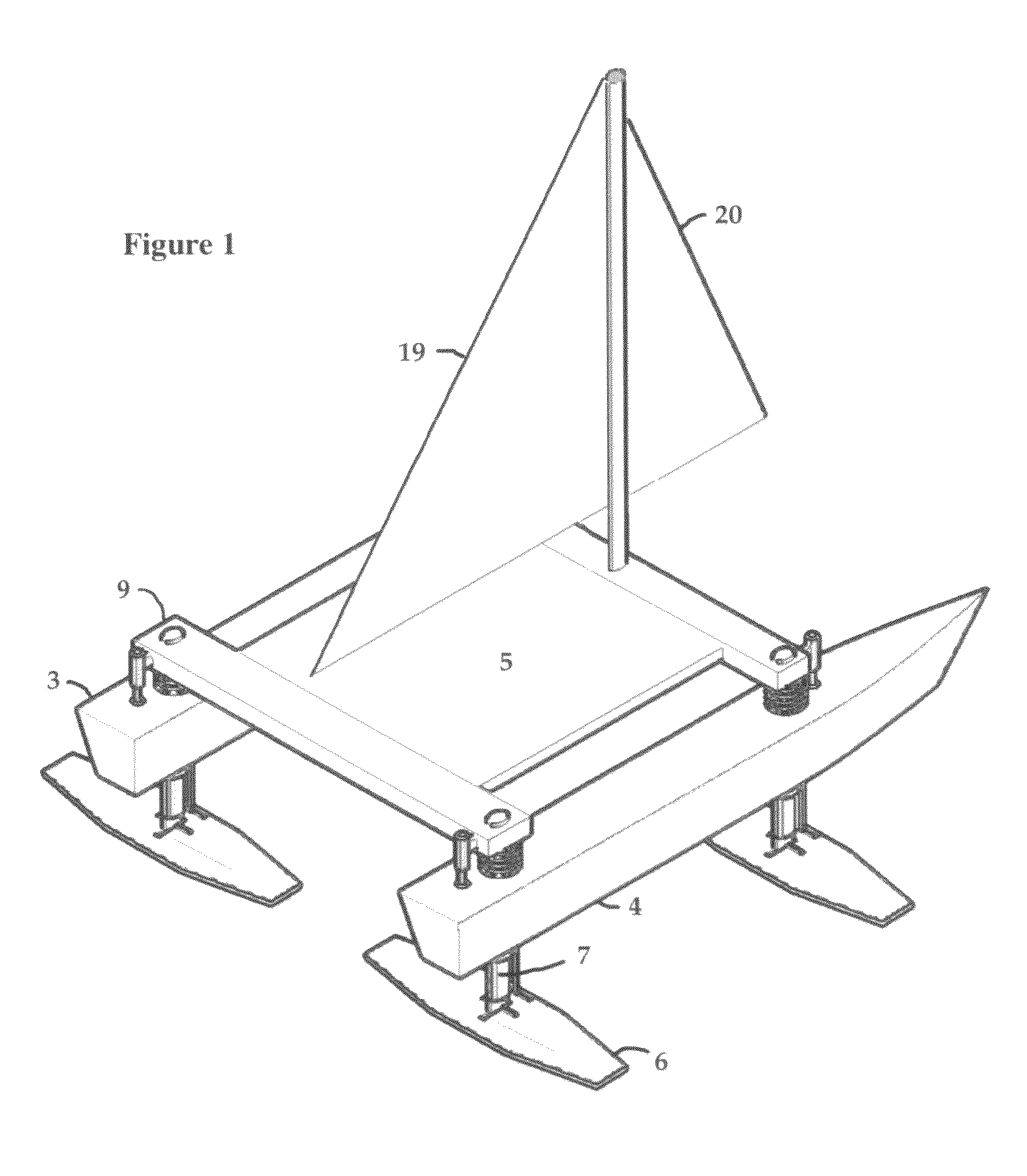

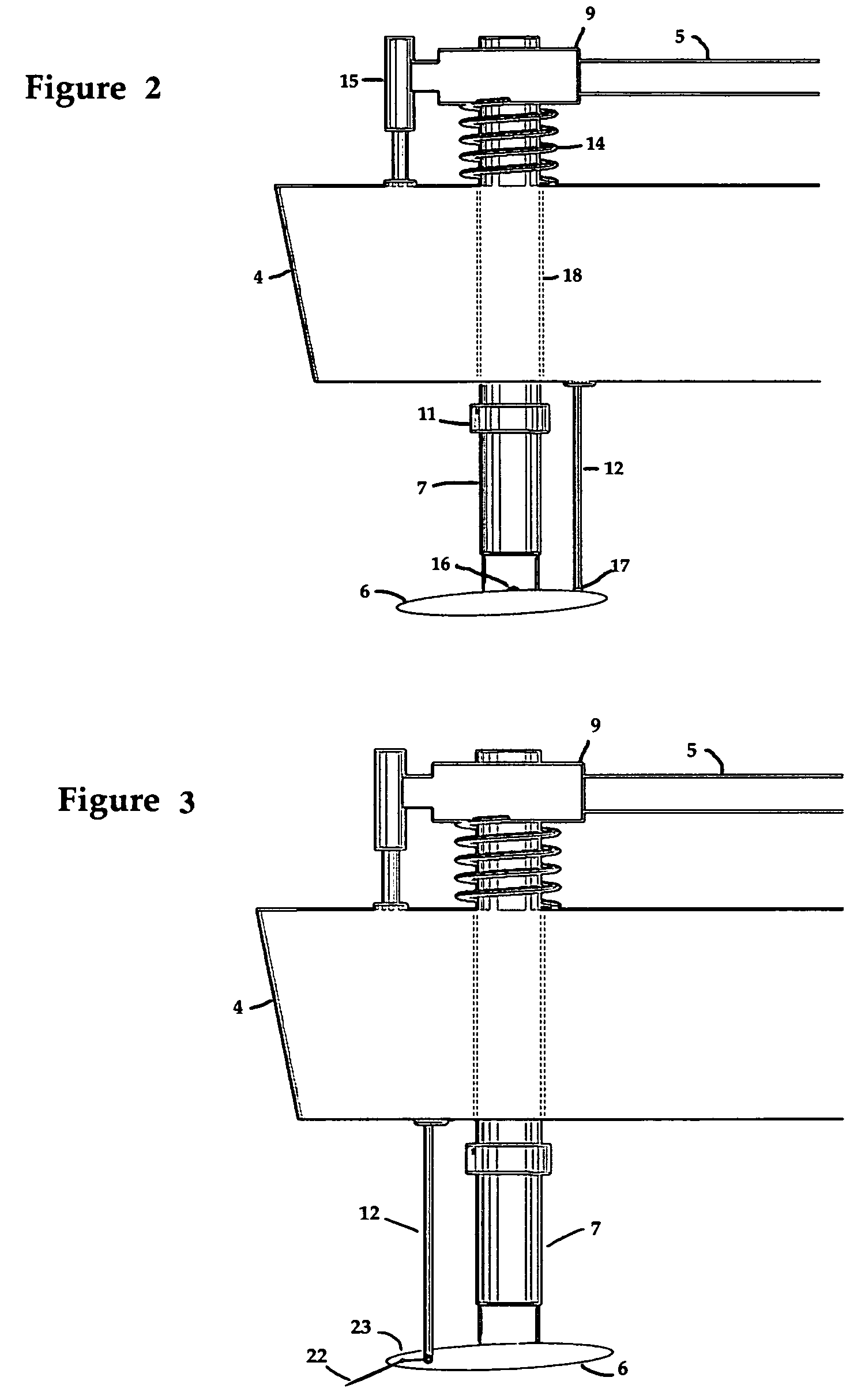

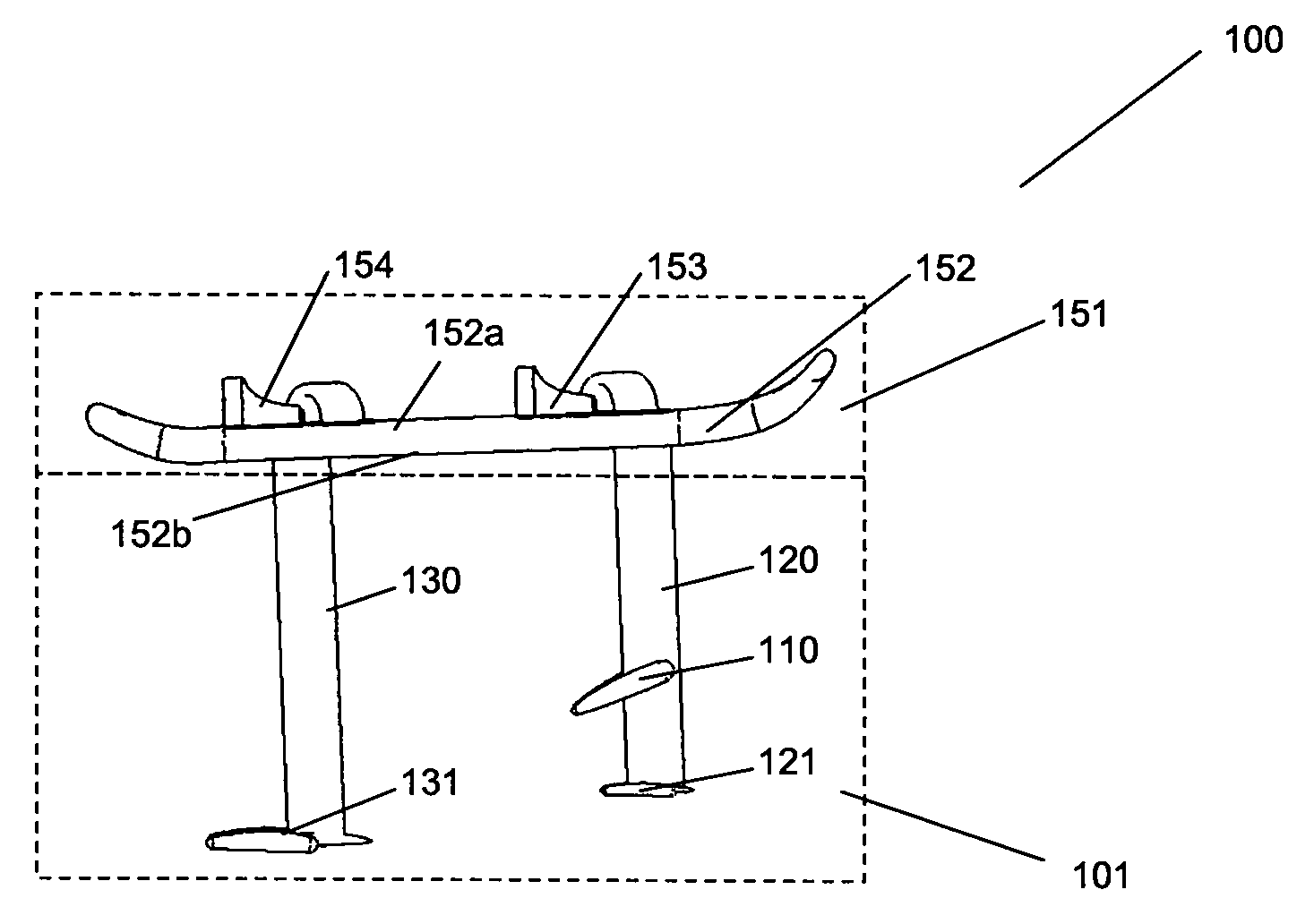

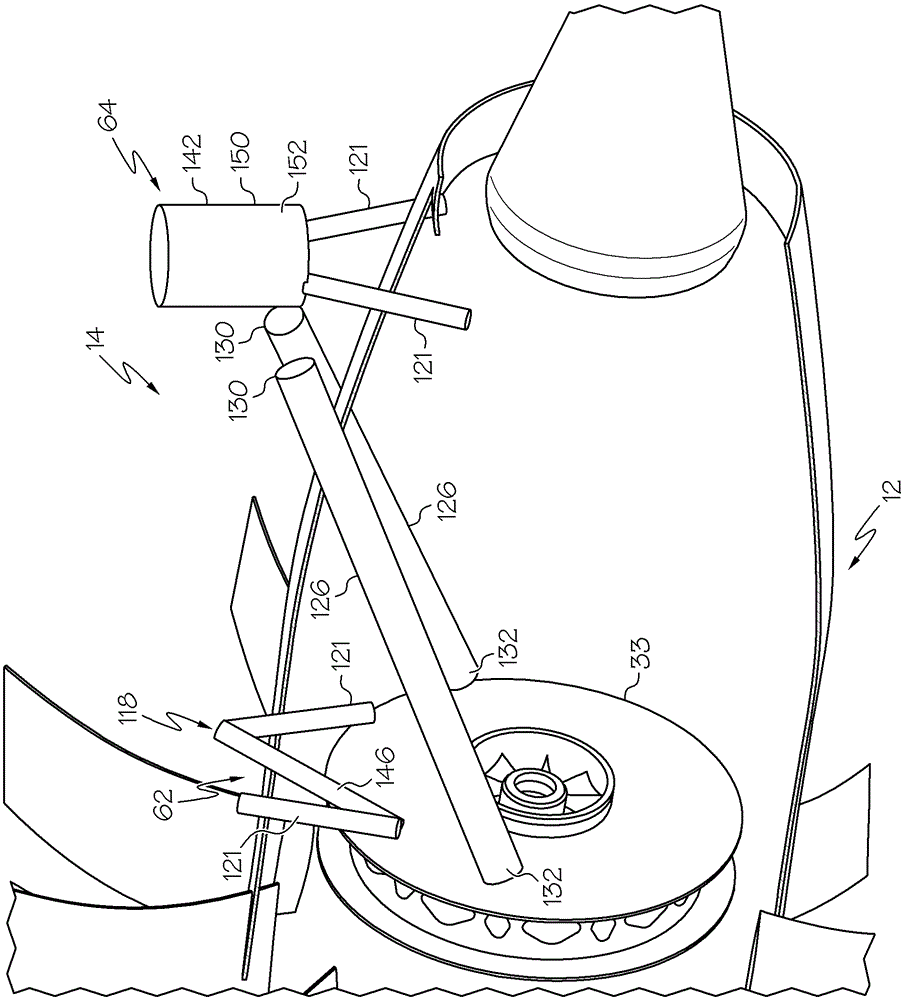

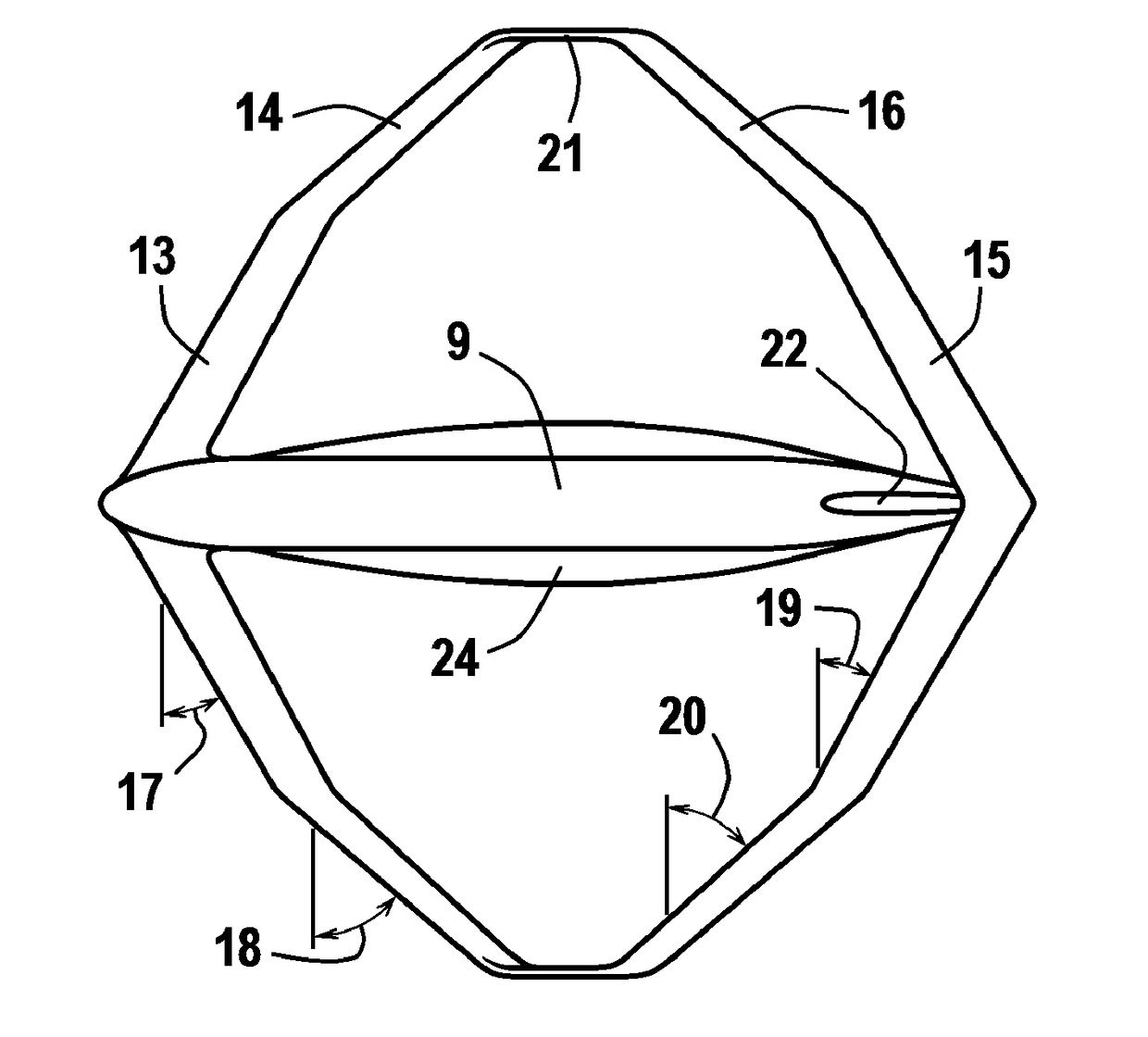

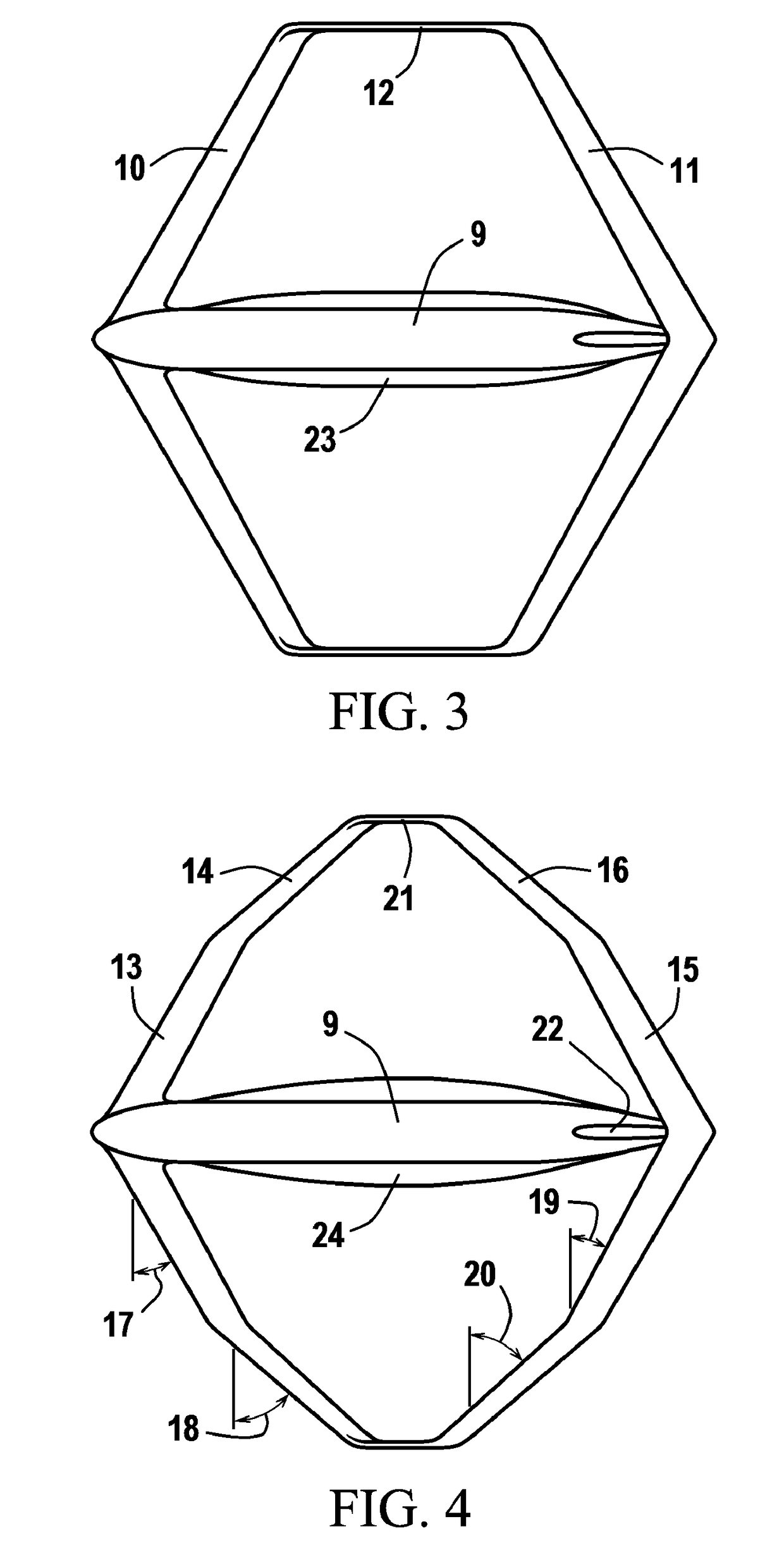

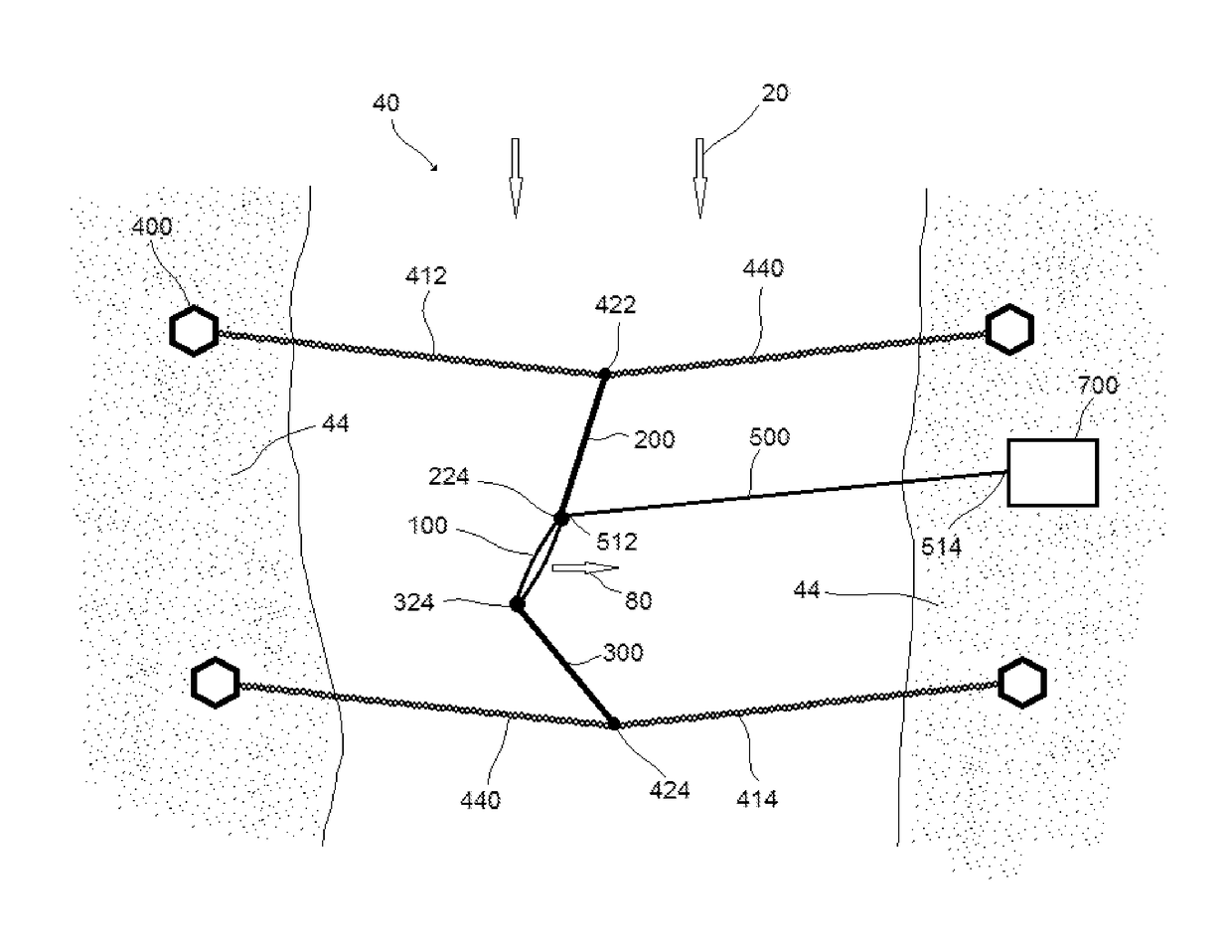

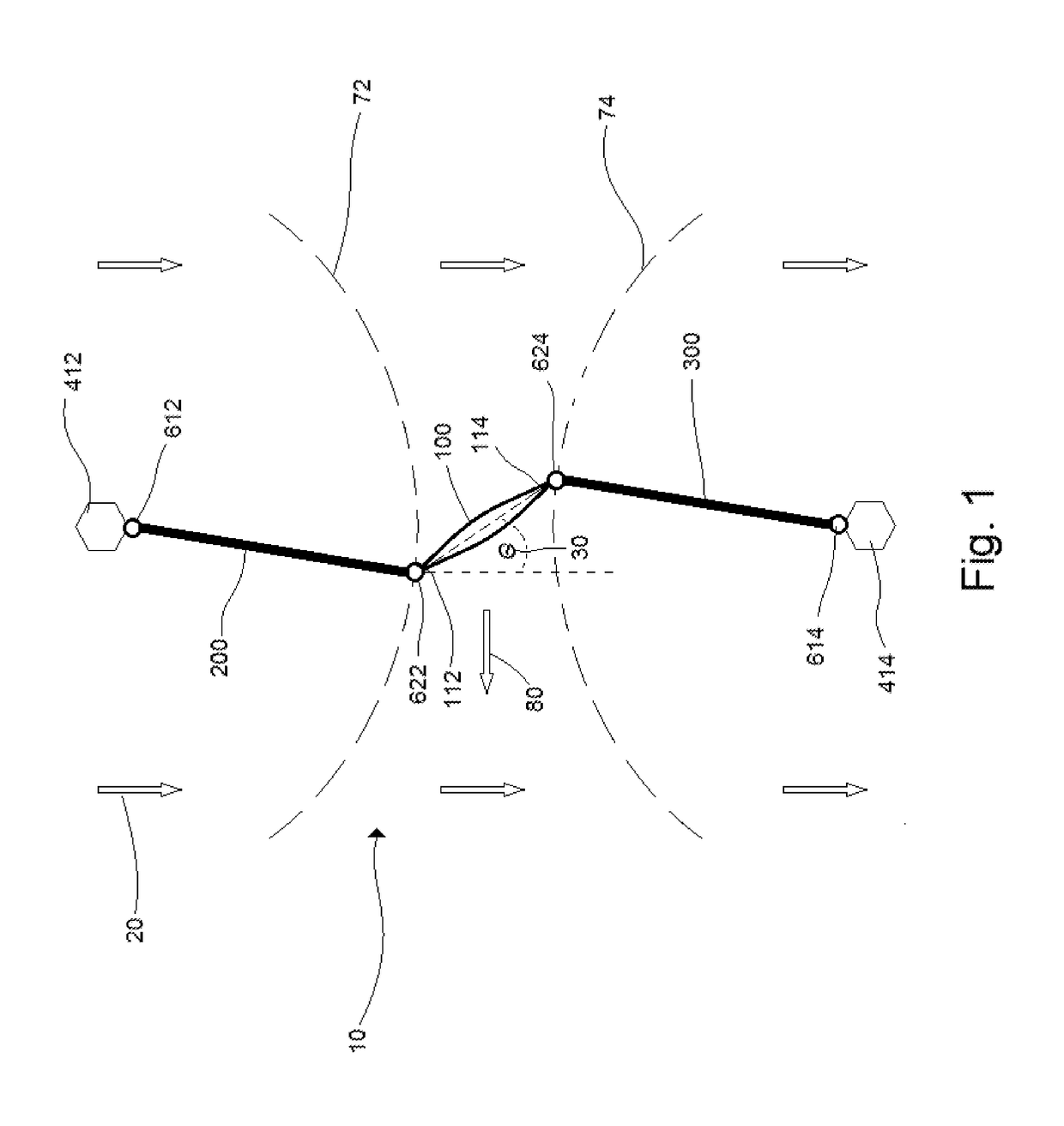

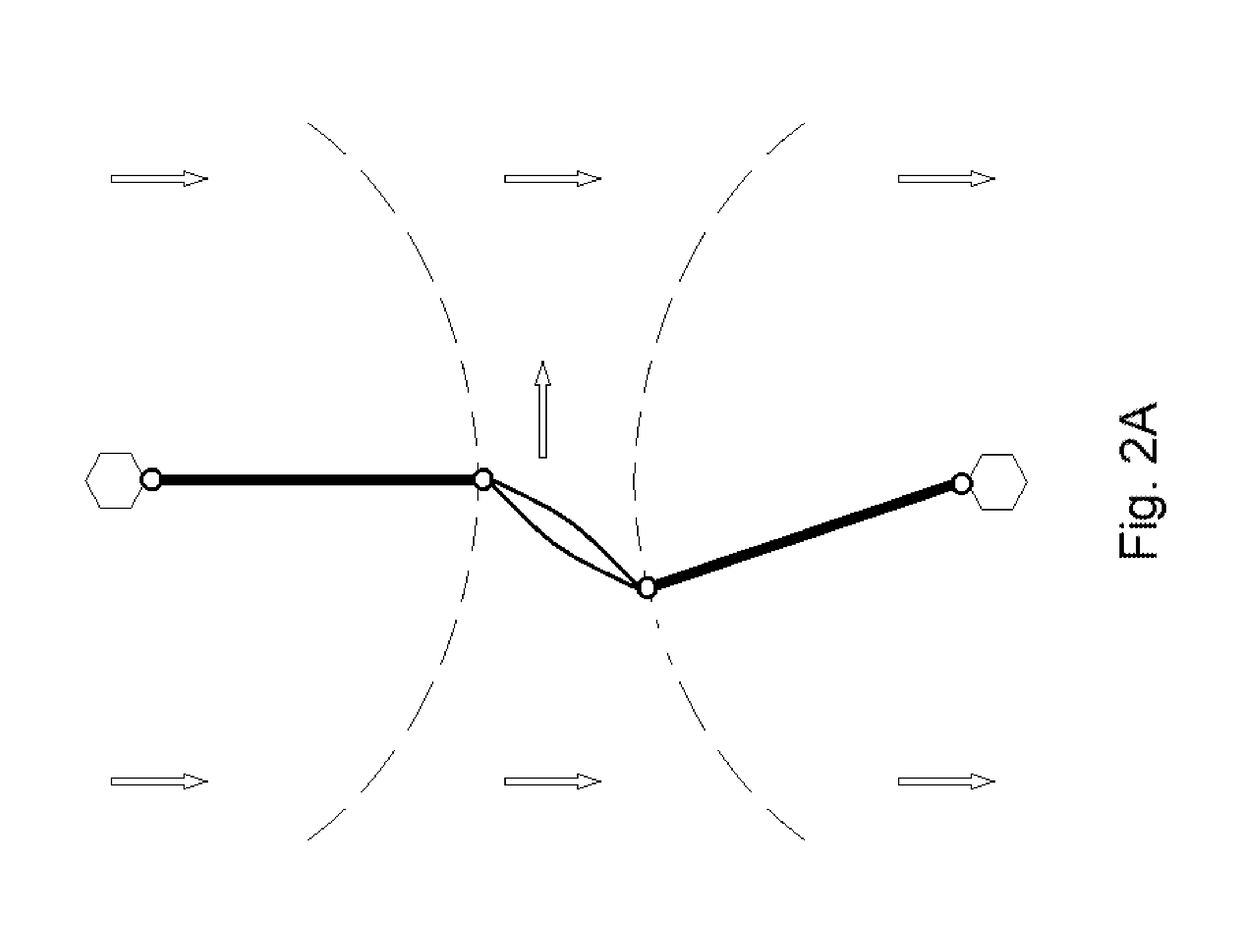

Multihull hydrofoil watercraft

InactiveUS7743720B1Reduce angle of attackReduce lifting forceVessel partsVessel movement reduction by foilsAutomatic controlAutomatic train control

A multihull hydrofoil watercraft incorporates a stabilization system wherein the buoyancy of the hulls is used as a sensing and control mechanism for the hydrofoils. The use of hull buoyancy to adjust the hydrofoil lift provides for automatic control of altitude, pitch and roll, and allows the craft to accommodate varying weather and sea conditions while providing a smooth ride for passengers. The stabilization technique eliminates the need for extraneous sensing mechanisms placed in or on the water surface which are subject to fouling, damage, or disruption by localized surface disturbances.

Owner:SALANI STEVEN JOHN

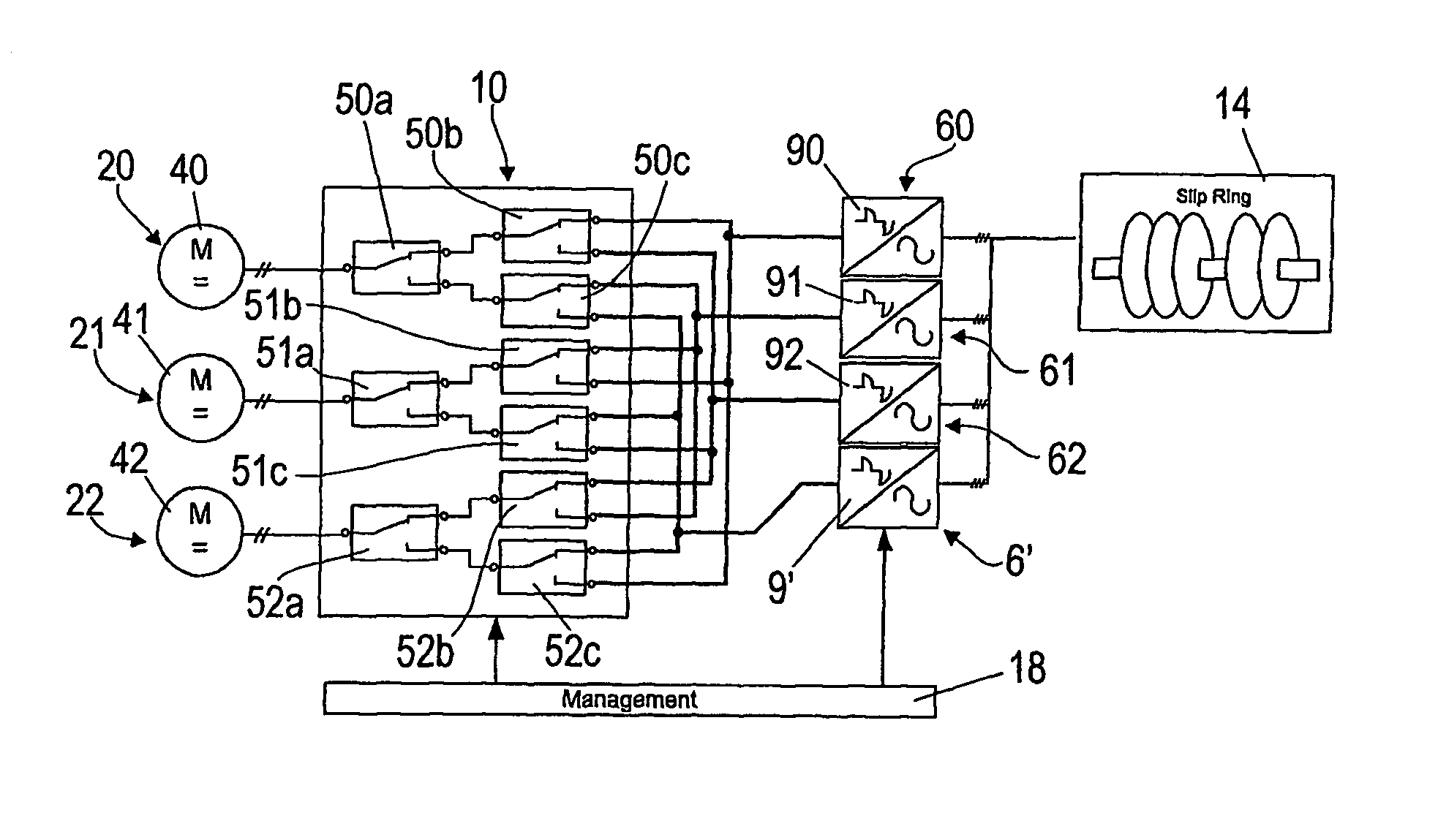

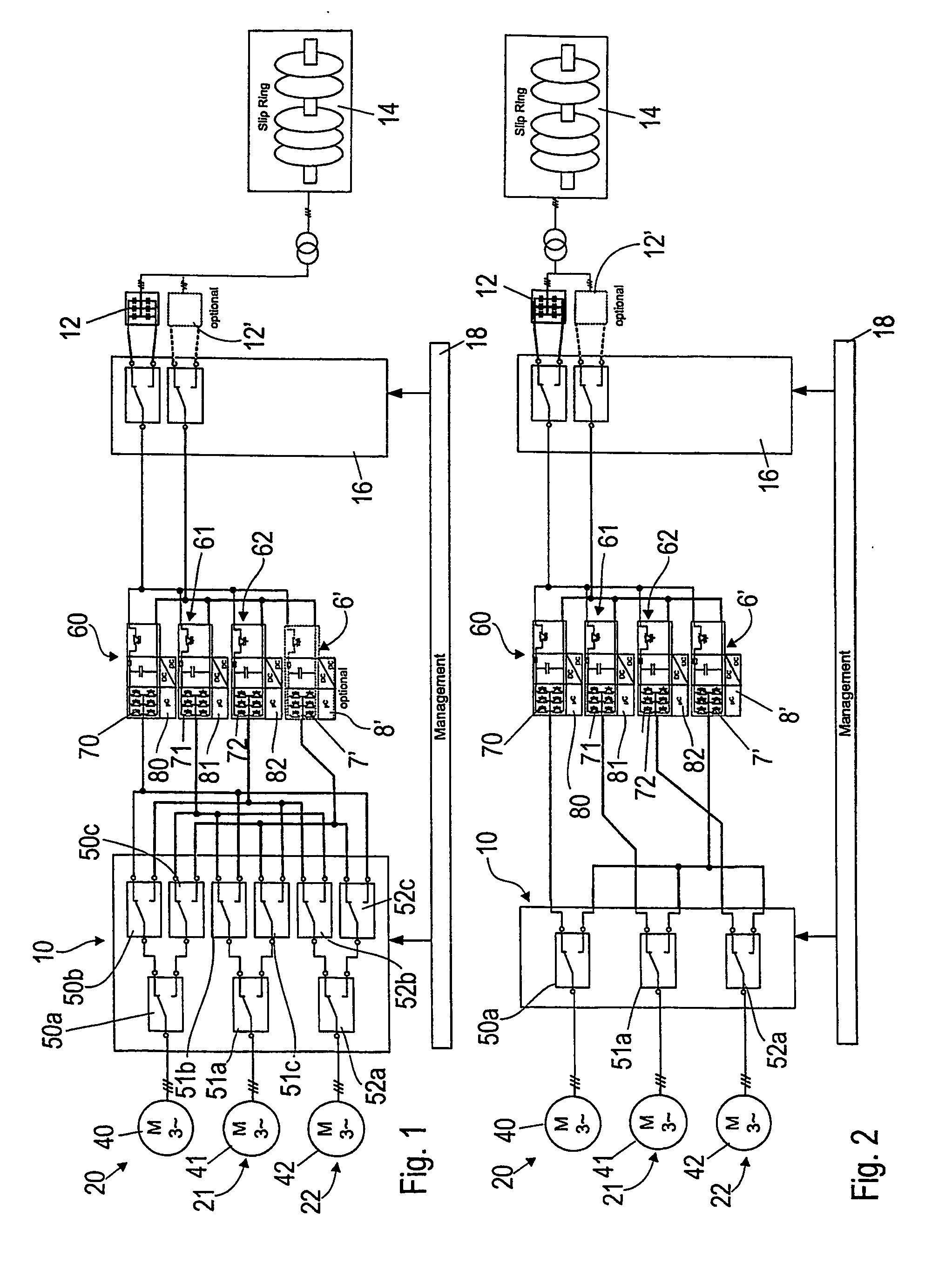

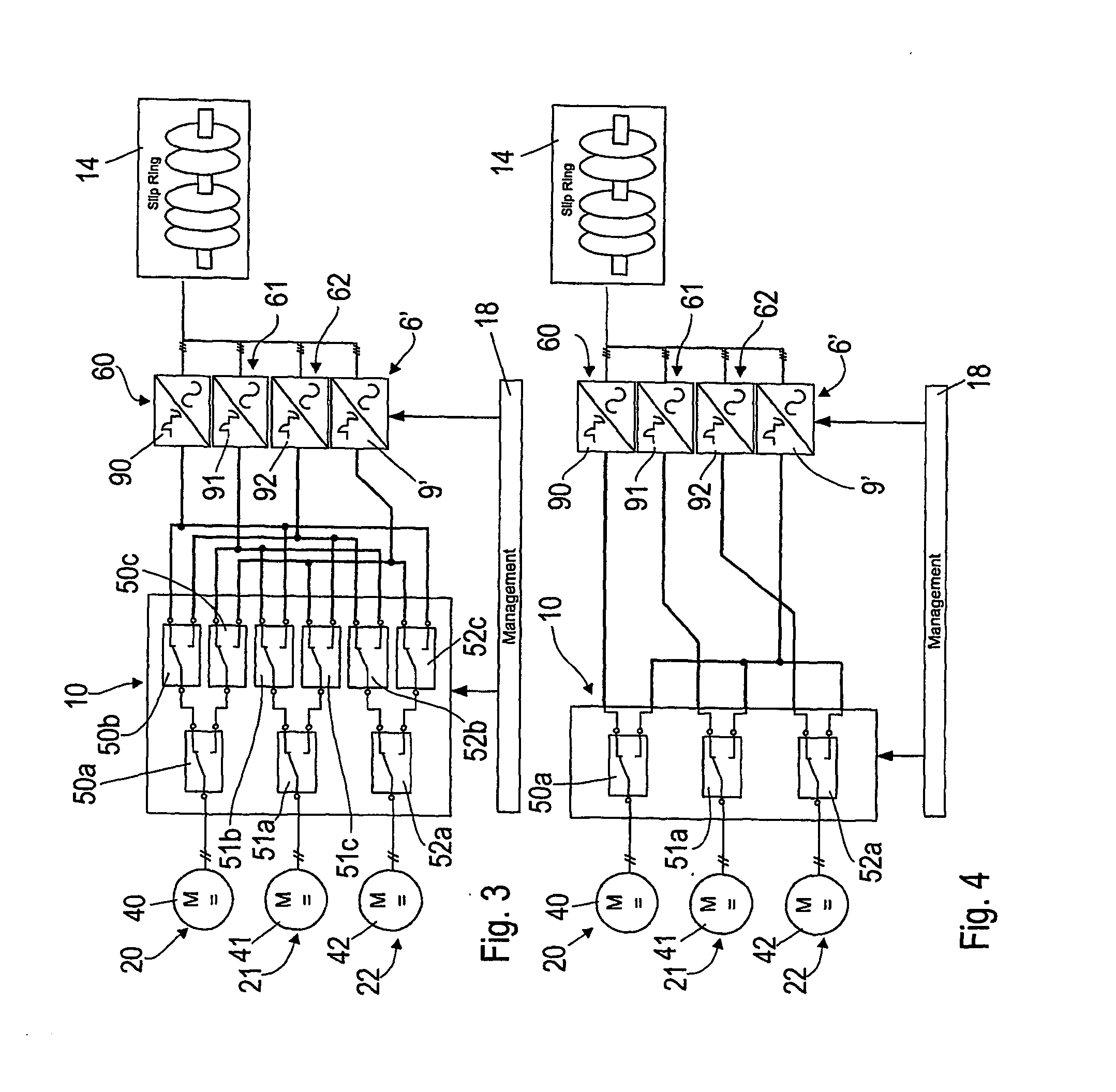

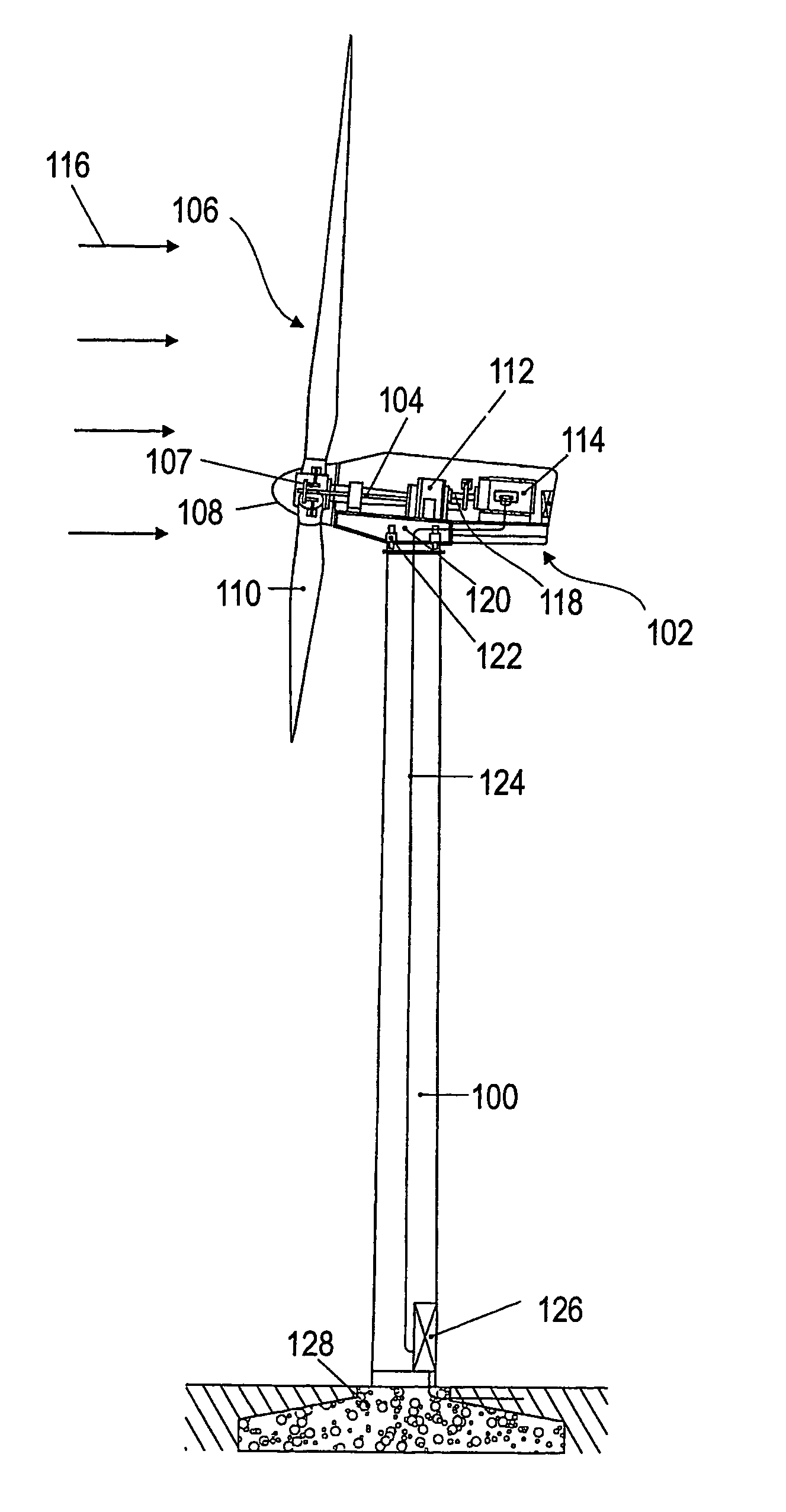

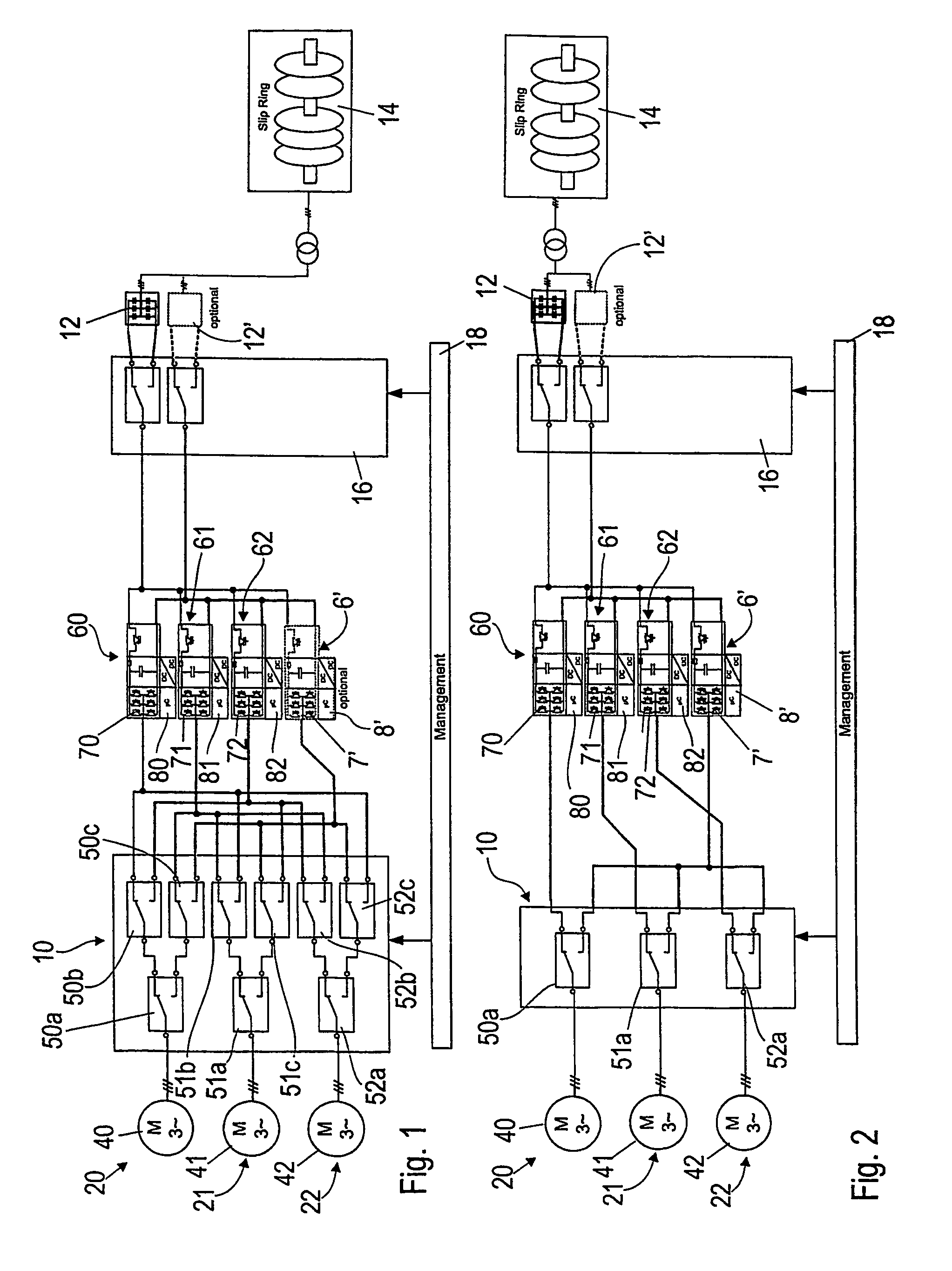

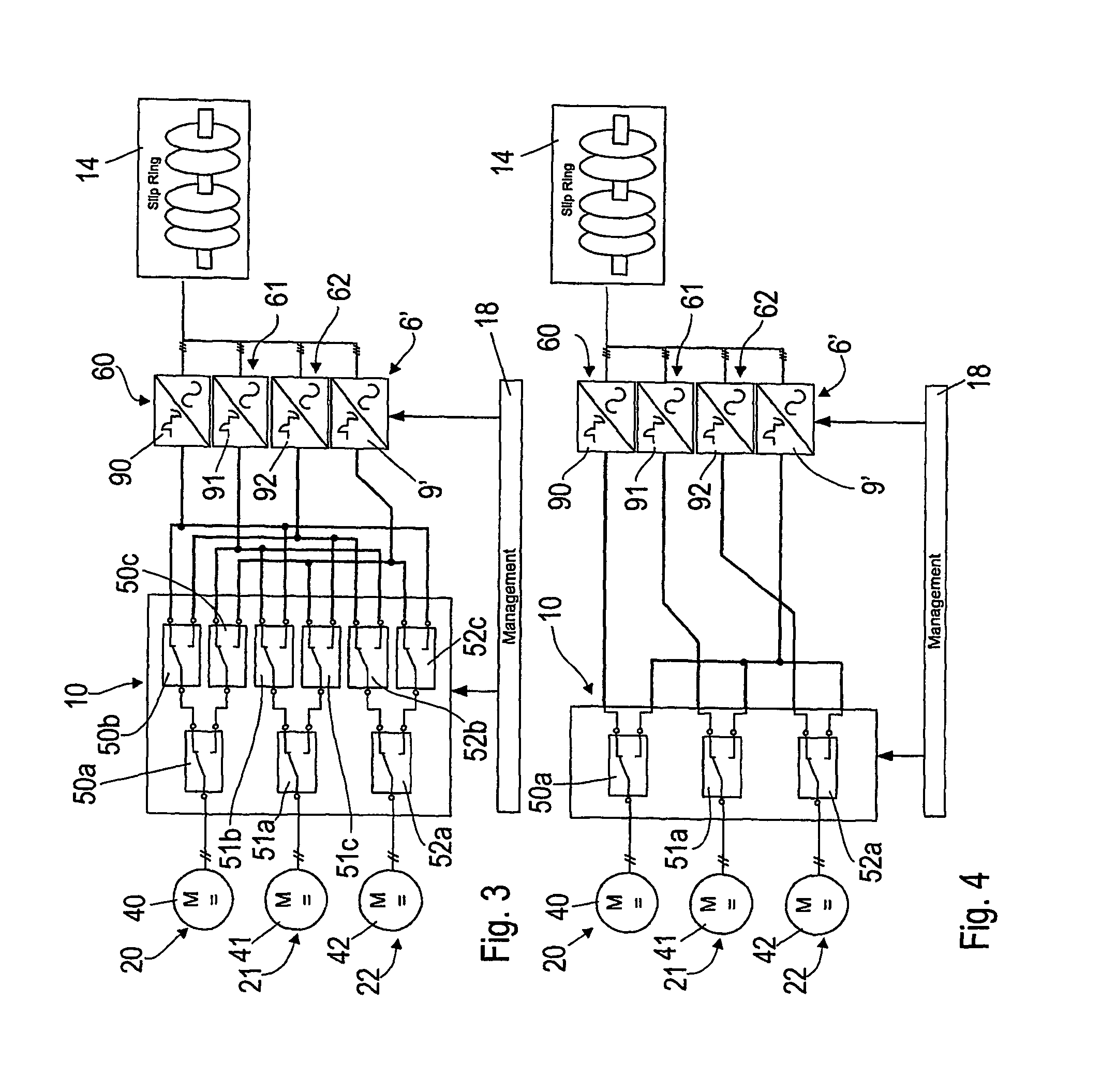

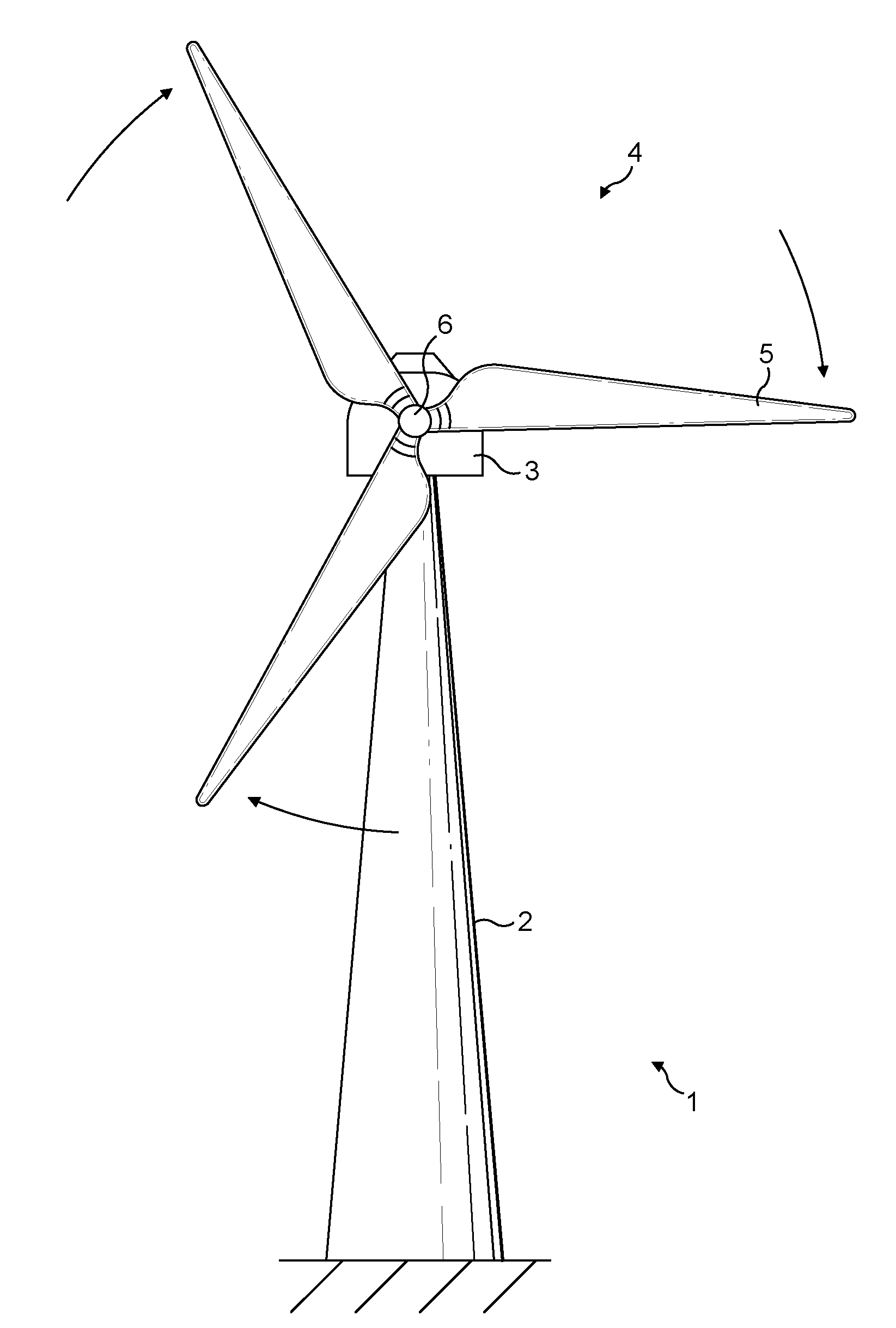

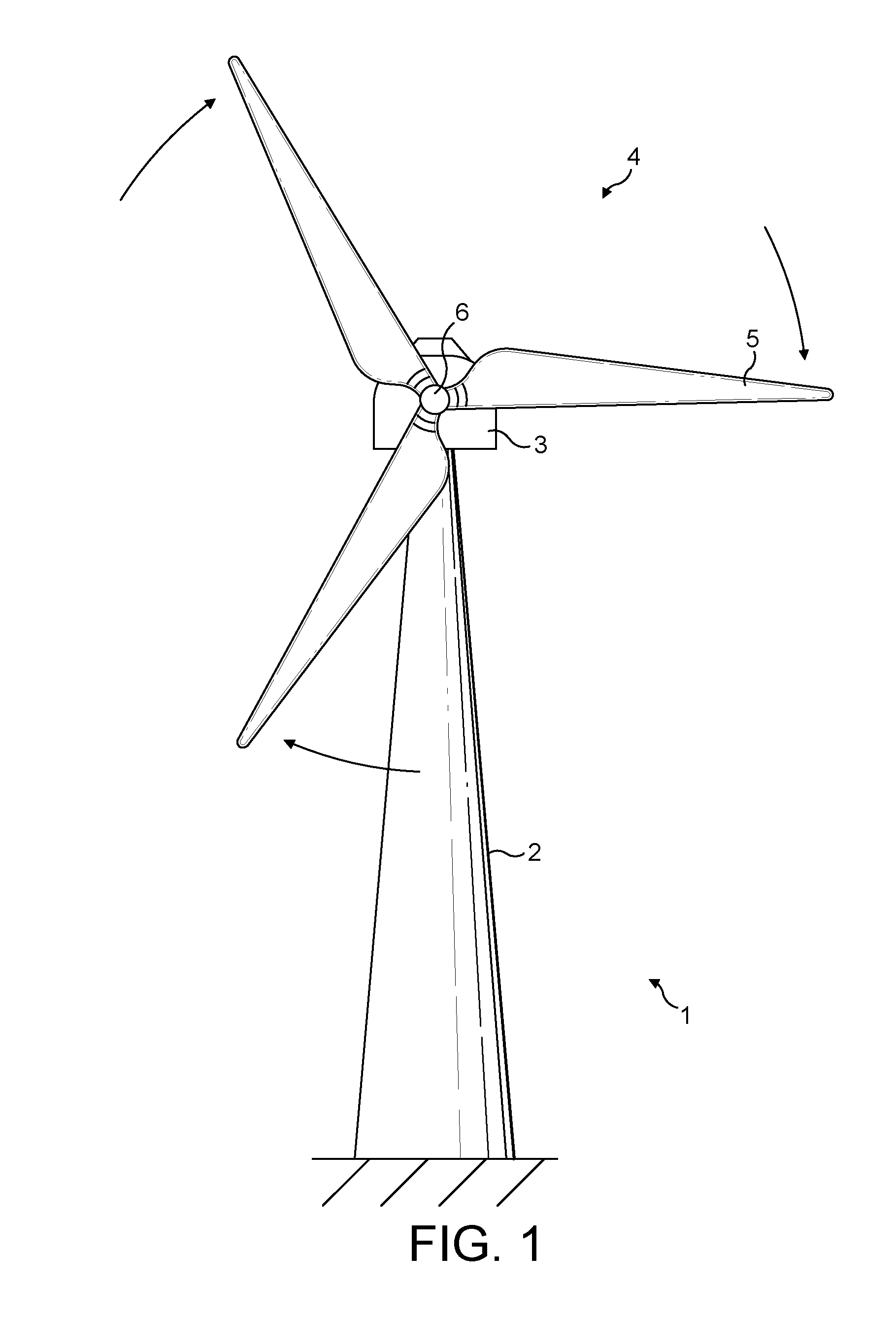

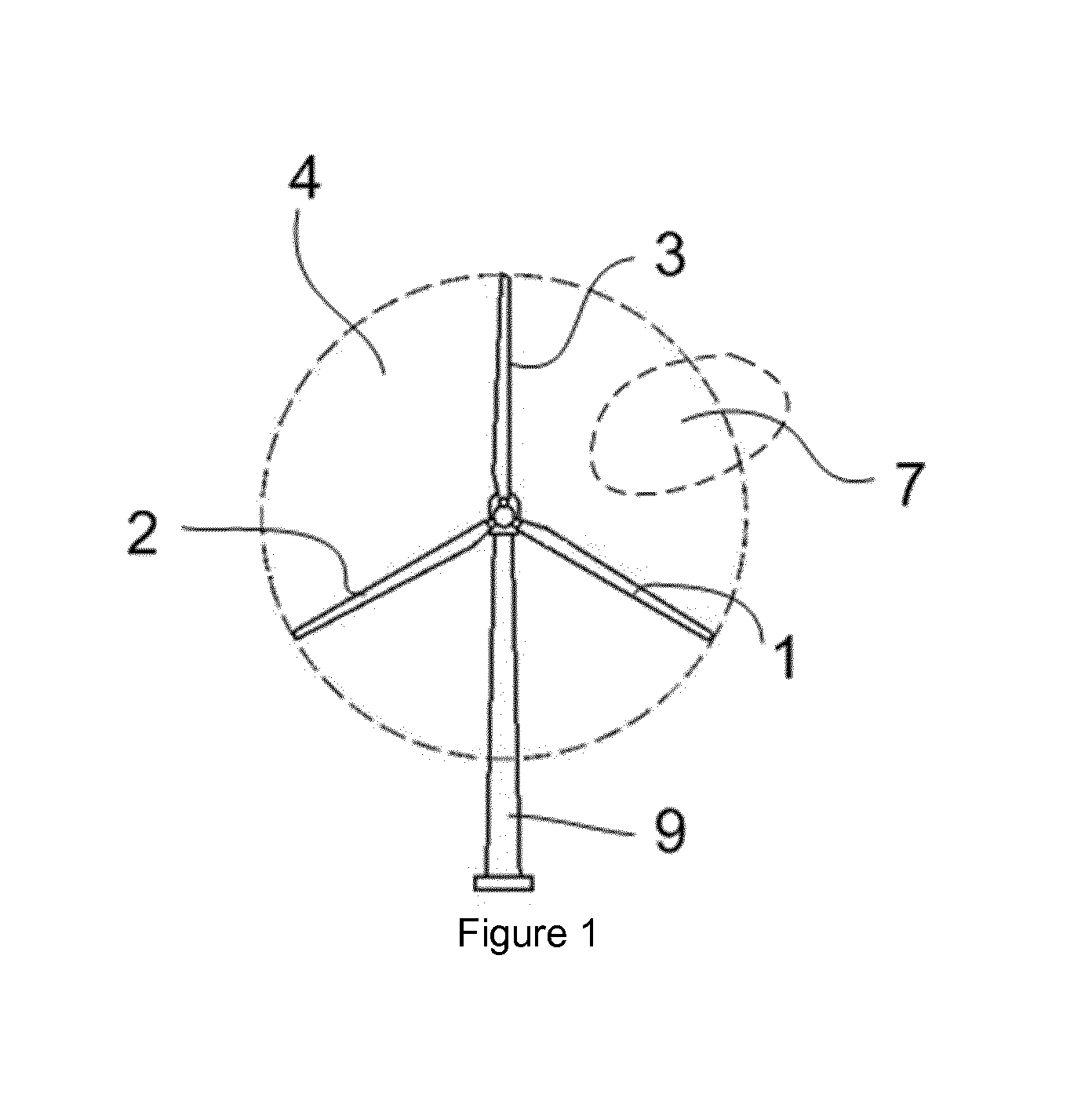

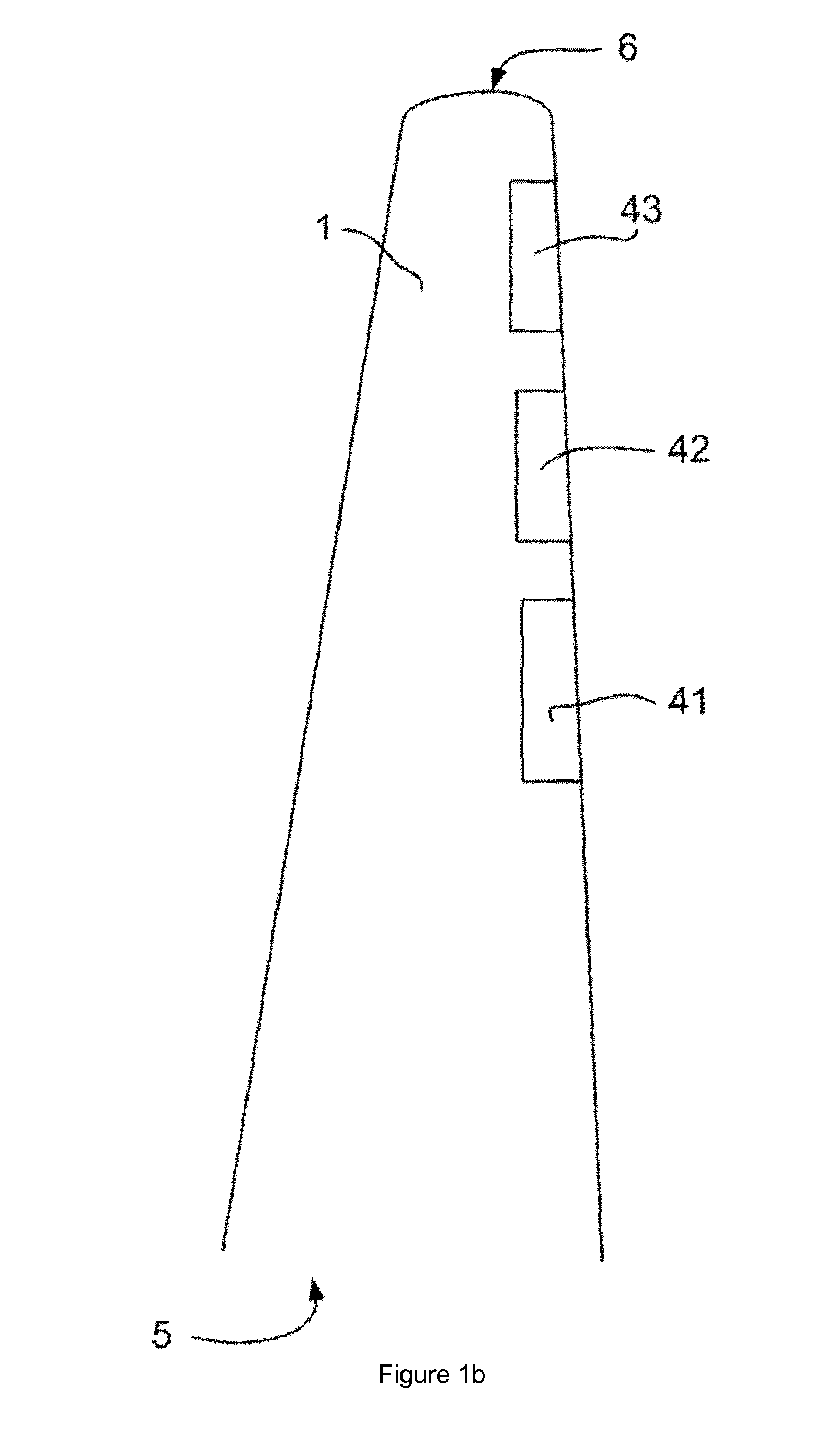

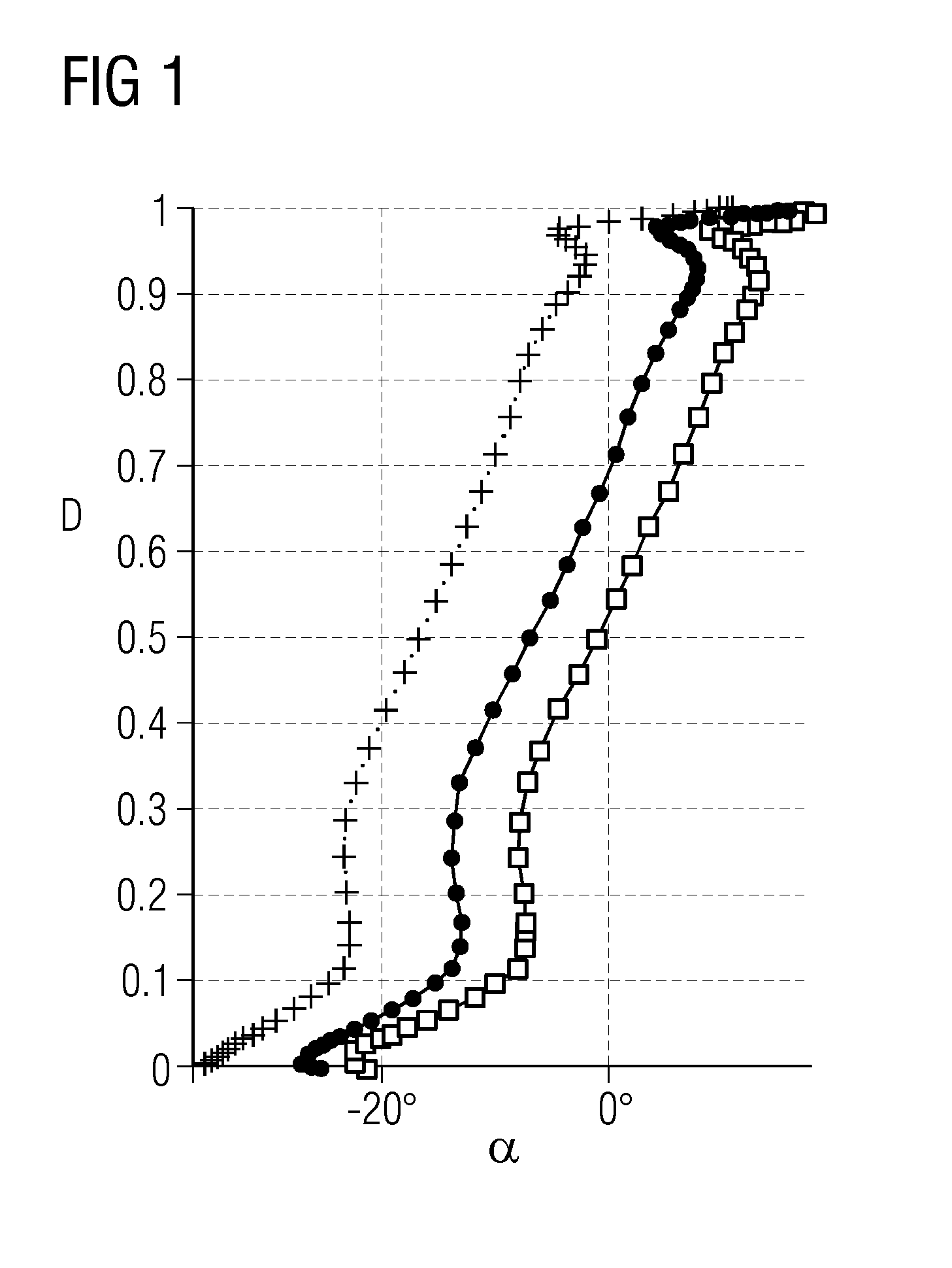

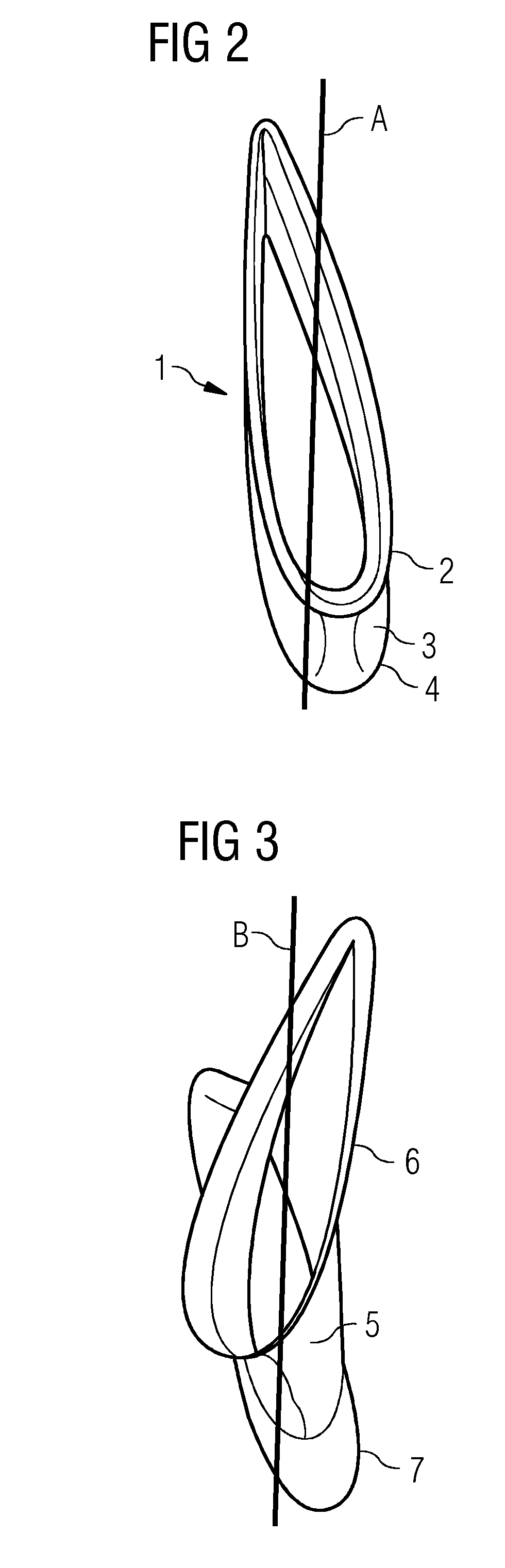

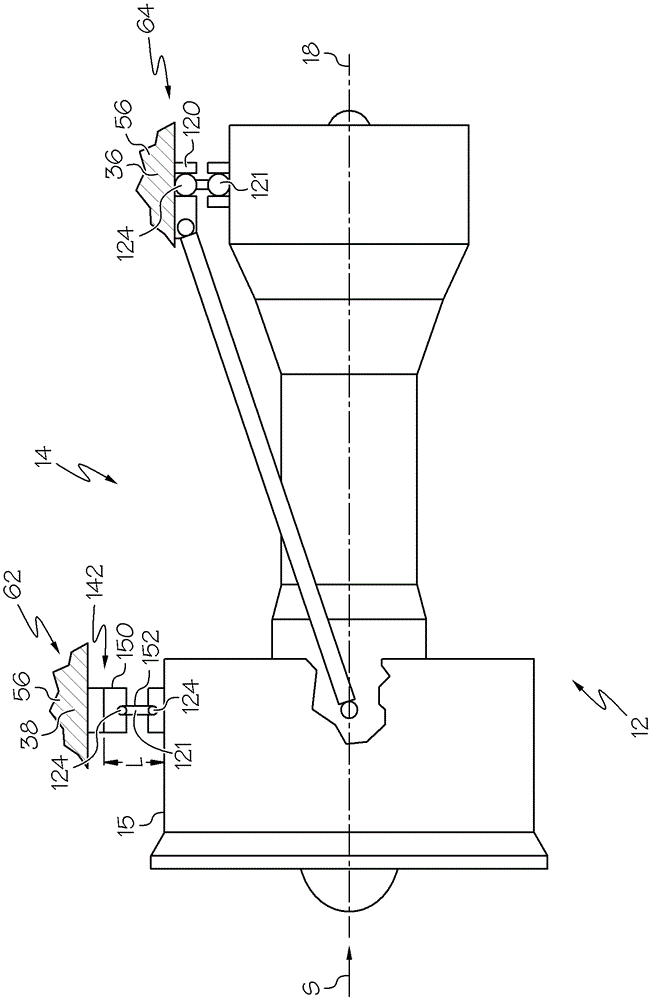

Redundant Blade Pitch Control System for a Wind Turbine and Method for Controlling a Wind Turbine

InactiveUS20070267872A1Avoid damageReliable and fast and safe shut-downPropellersPump componentsPower controlWind force

A redundant and fail-safe blade system of a wind turbine includes at least one blade pitch drive (20, 21, 22) and at least two power control modules (60, 61, 62, 6′) for controlling the blade pitch drive (20, 21, 22). The power control modules (60, 61, 62, 6′) are connected to the blade pitch drive (20, 21, 22) by a switching unit (10) which allows an alternative connection between the blade pitch drive (20, 21, 22) and any of the power control modules (60, 61, 62, 6′). In operation, the blade pitch drive (20, 21, 22) is controlled by only one of the power control modules (60, 61, 62, 6′). If a malfunction of the currently operating power control module (60, 61, 62, 6′) is detected, switching unit (10) provides a connection to the other power control module (60, 61, 62, 6′) to allow an ongoing operation of the wind turbine without an unplanned or forced shut-down.

Owner:GENERAL ELECTRIC CO

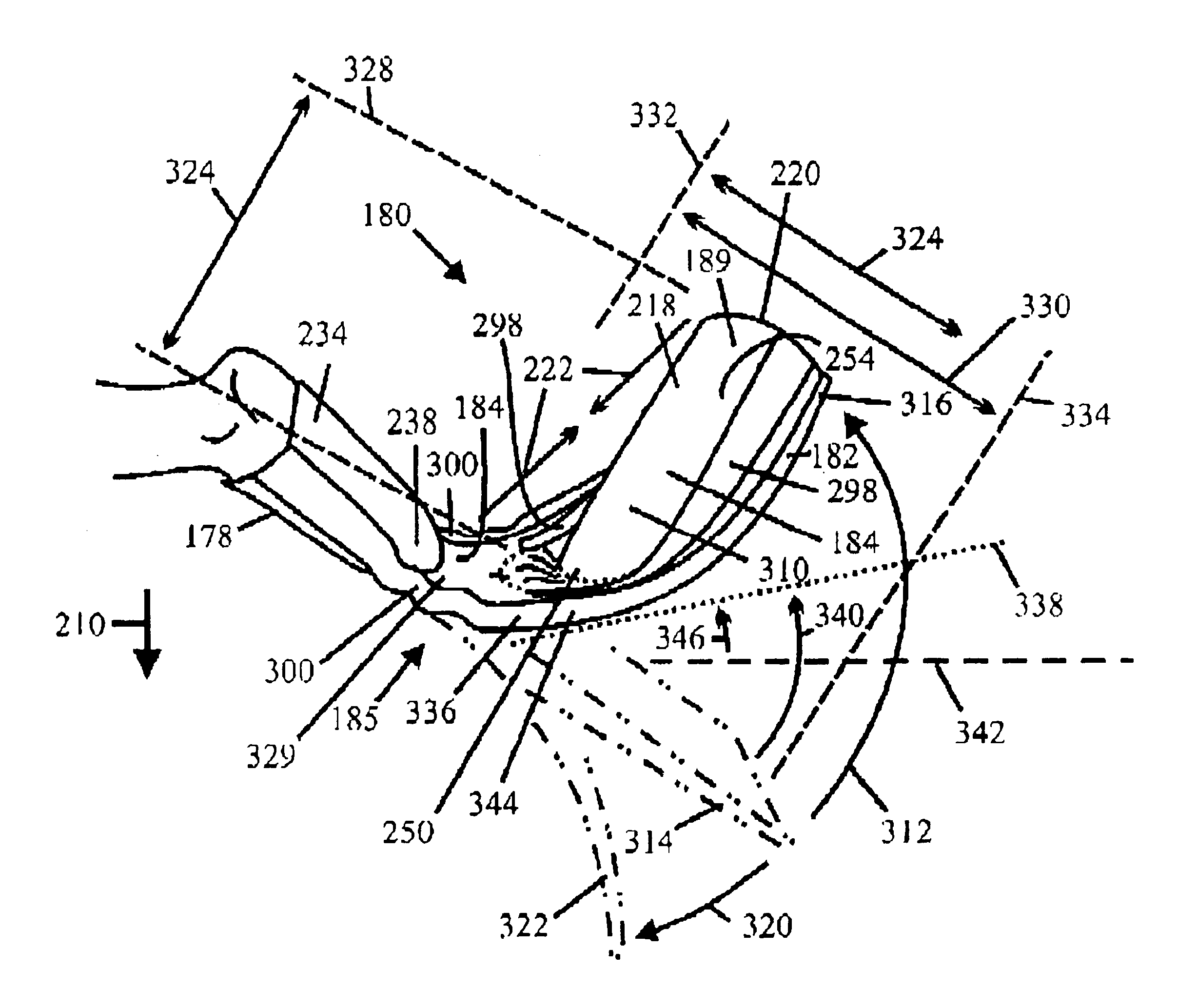

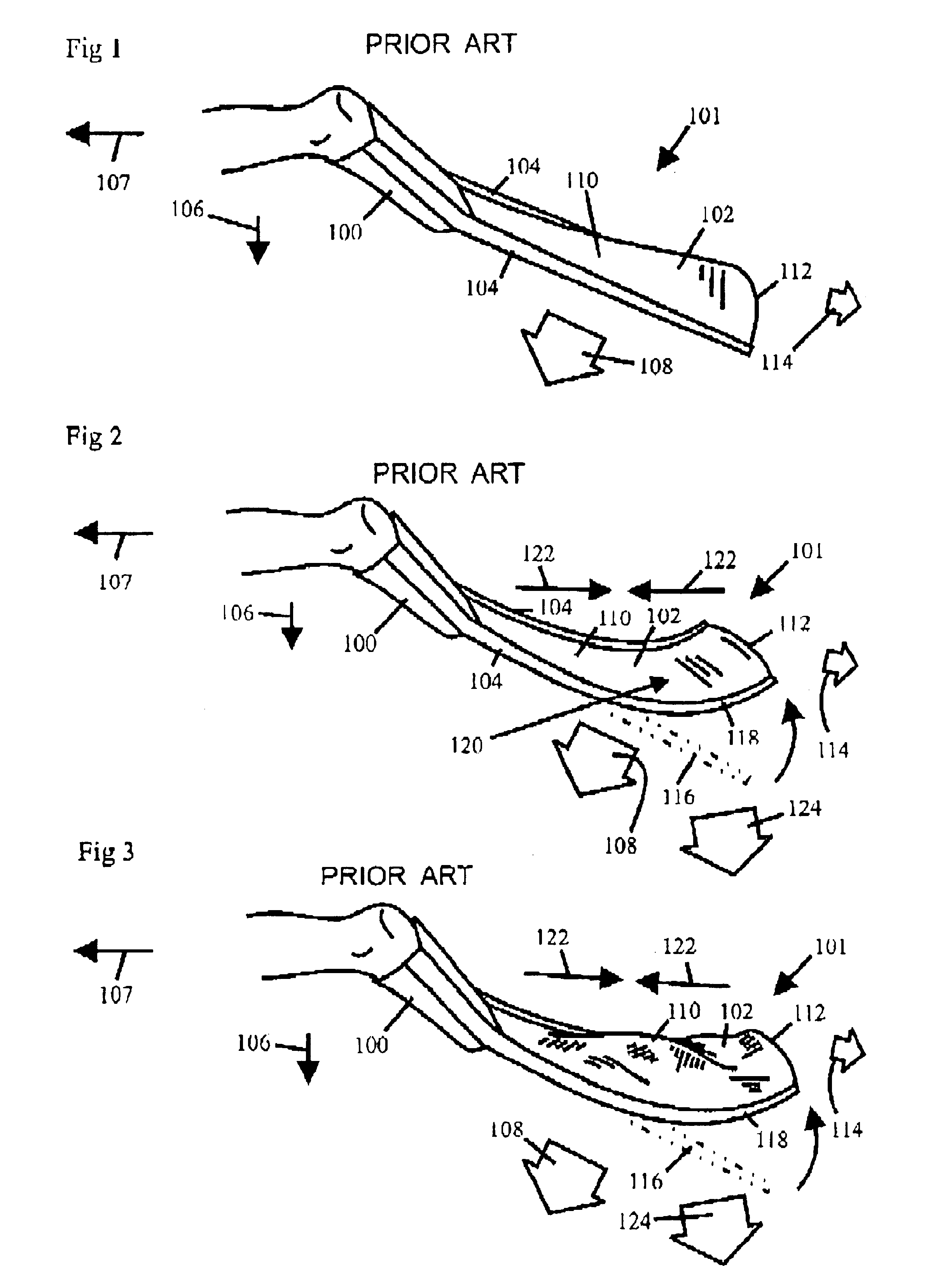

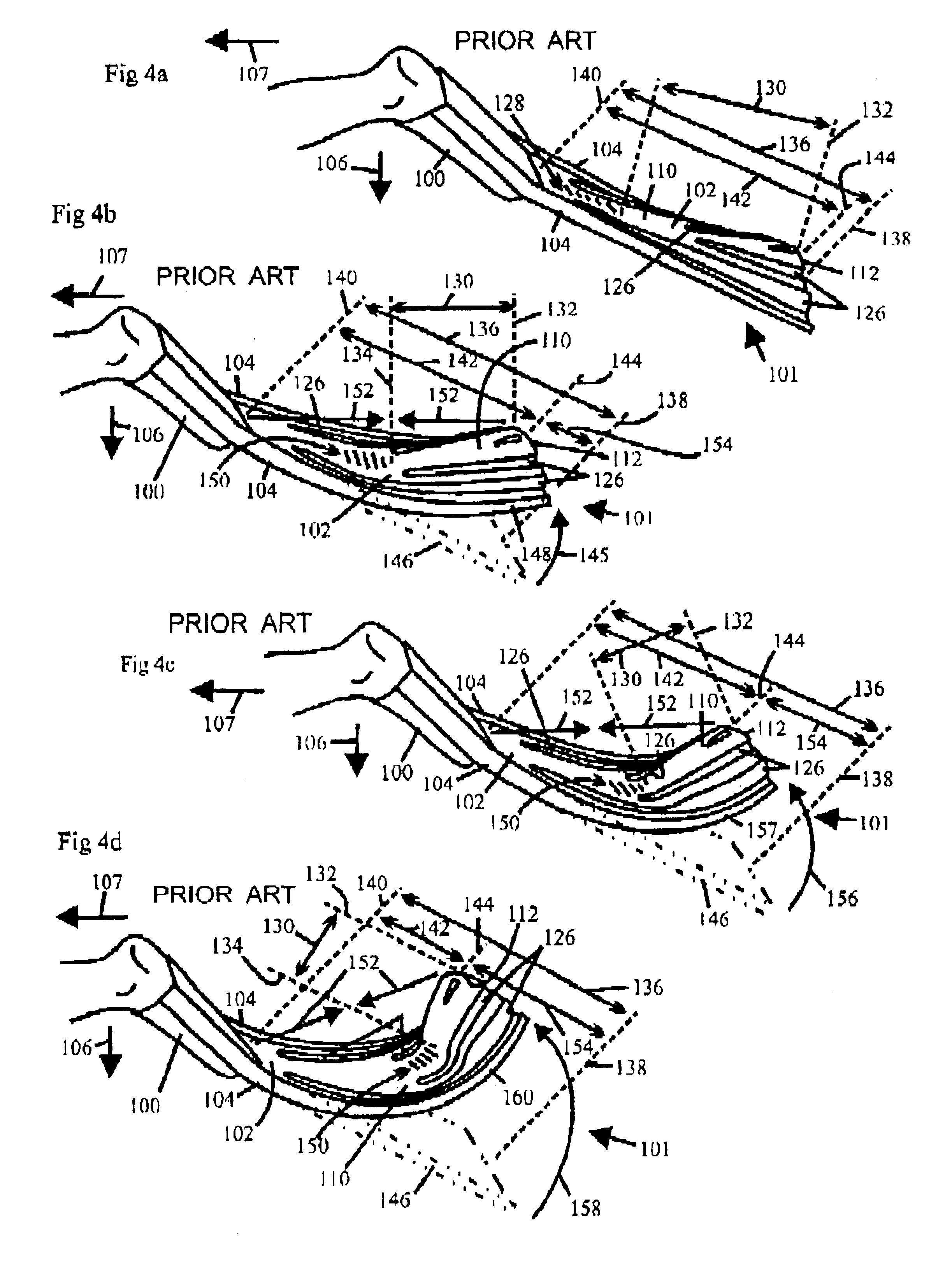

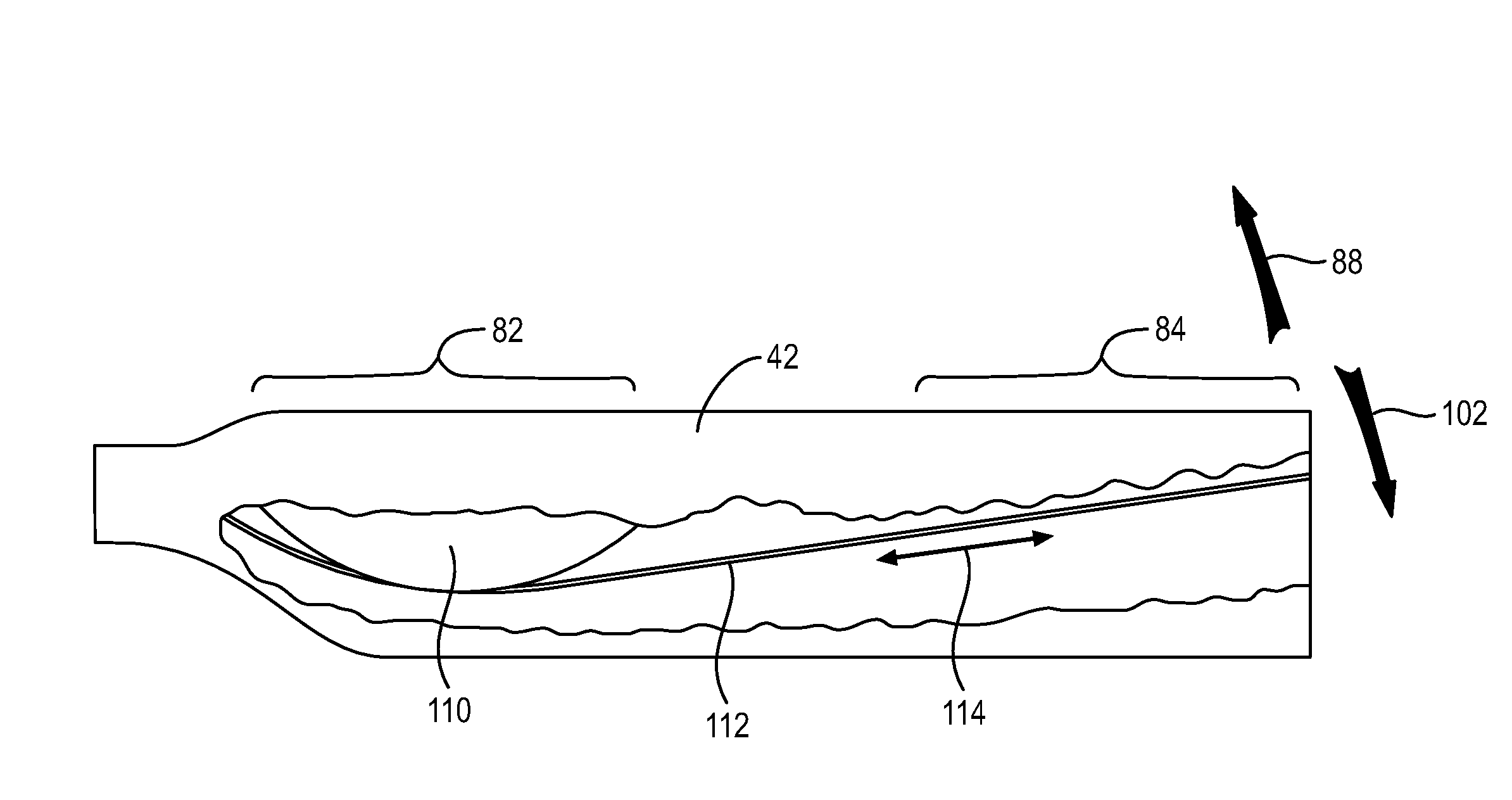

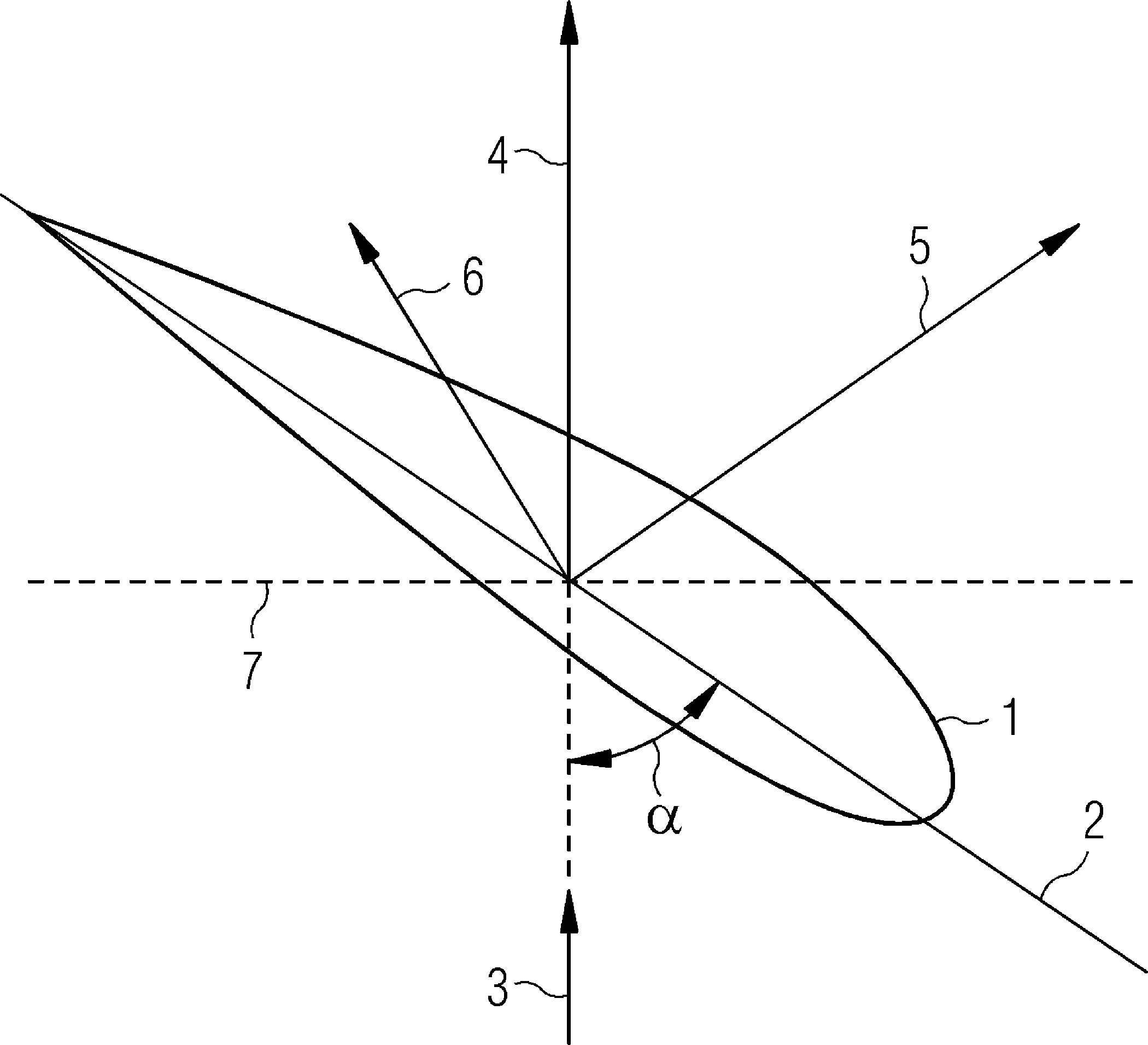

High deflection hydrofoils and swim fins

Designs and methods are disclosed for permitting permit scooped shaped swim fin blades (184) to flex around a transverse axis to a significantly reduced angle of attack while reducing or preventing the scooped blade portion (254) from collapsing or buckling under the longitudinal compression forces (222) exerted on the scooped portion during a large scale blade deflection (212) by strategically alleviating or controlling such compression forces (222). Method are also disclosed for increasing flow capacity, effective scoop length, scoop depth over a greater length of the blade, reducing blade resistance to large scale deflections, reducing bending resistance within scooped blade portions (254) that are experiencing high levels of blade deflection. Methods are also provided for reducing lost motion and increasing propulsion during the inversion phase of a reciprocating kicking stroke cycle while also increasing the formation of a scooped blade region (254) during the inversion phase of the stroke cycle.

Owner:MCCARTHY PETER T

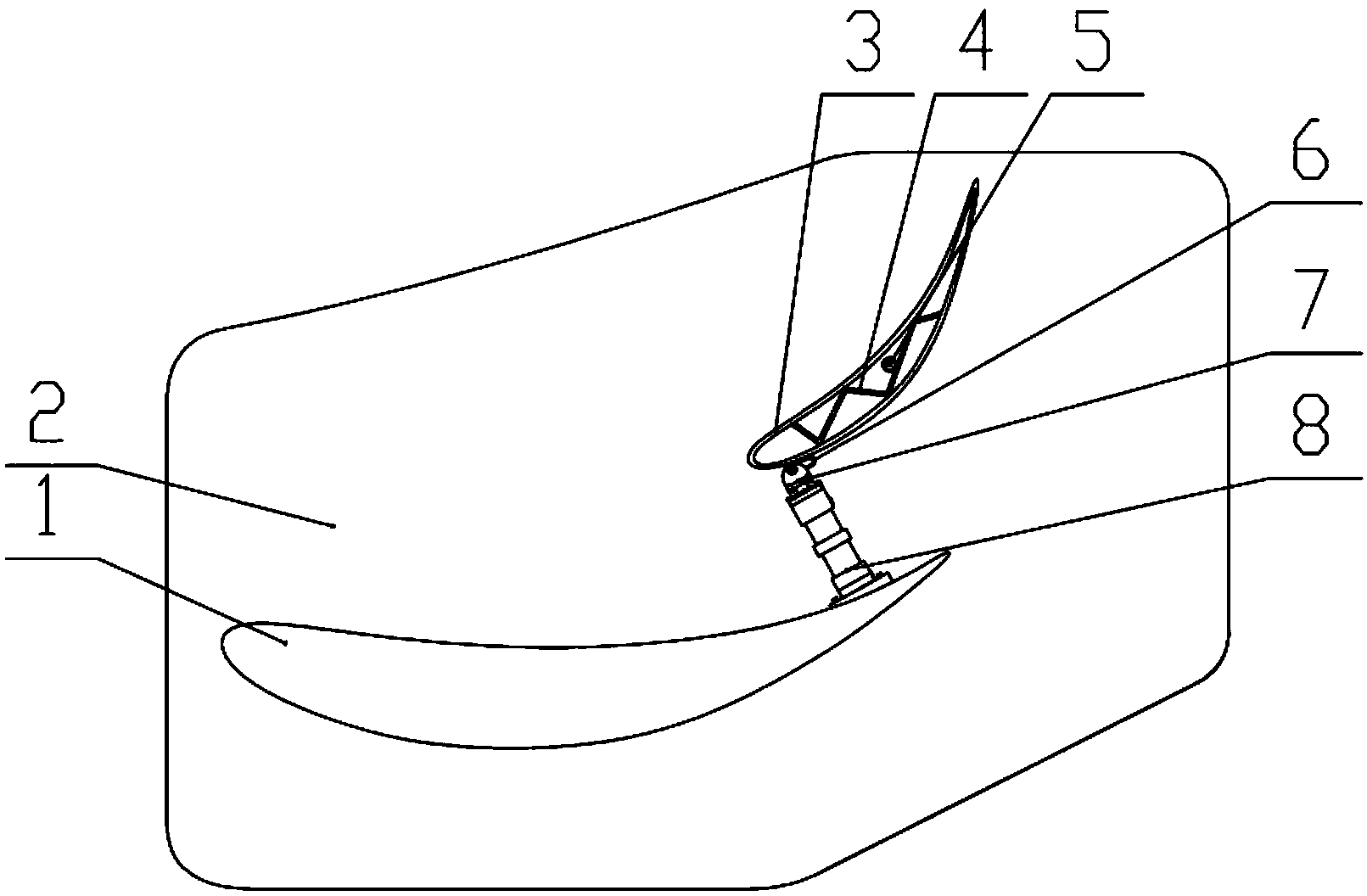

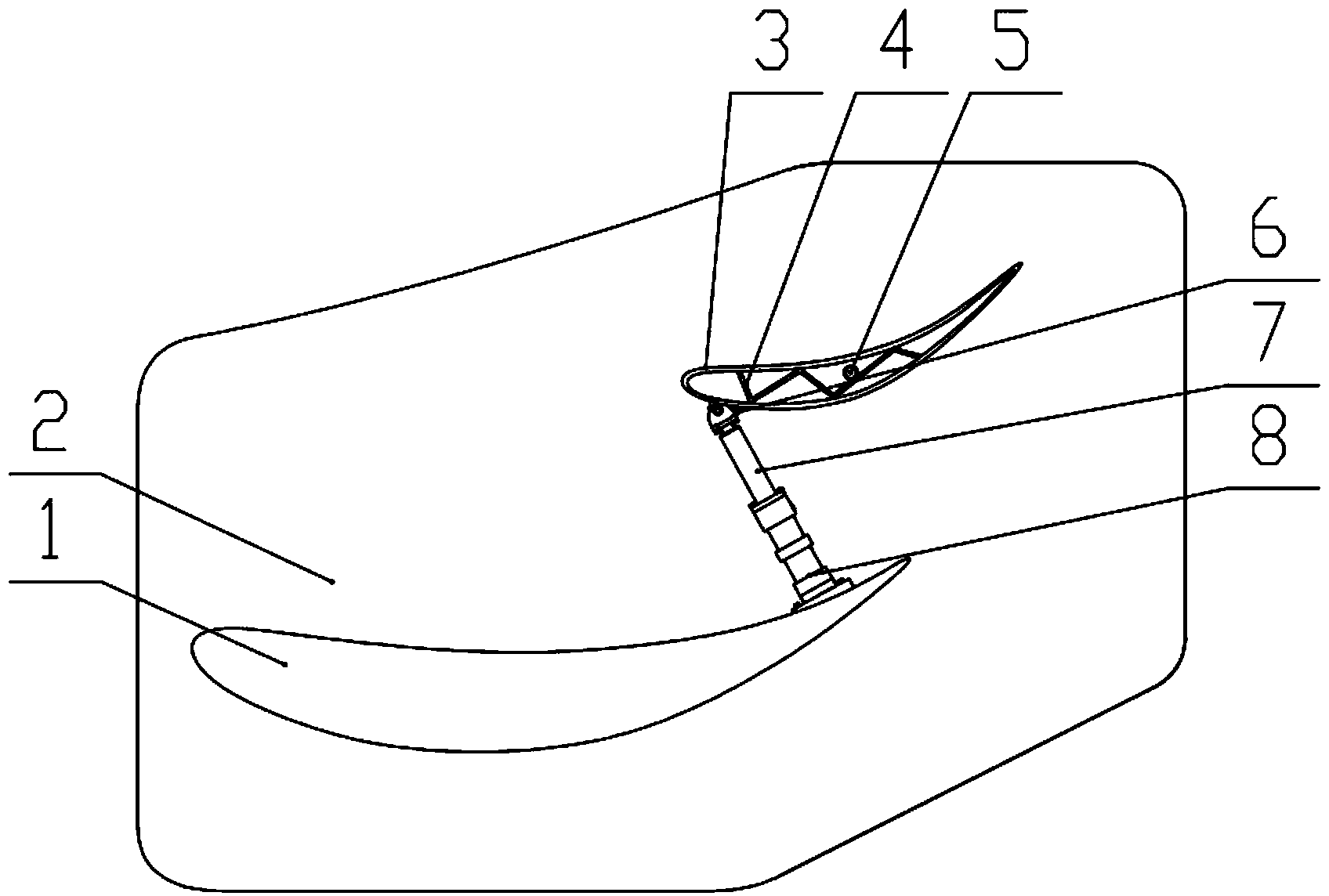

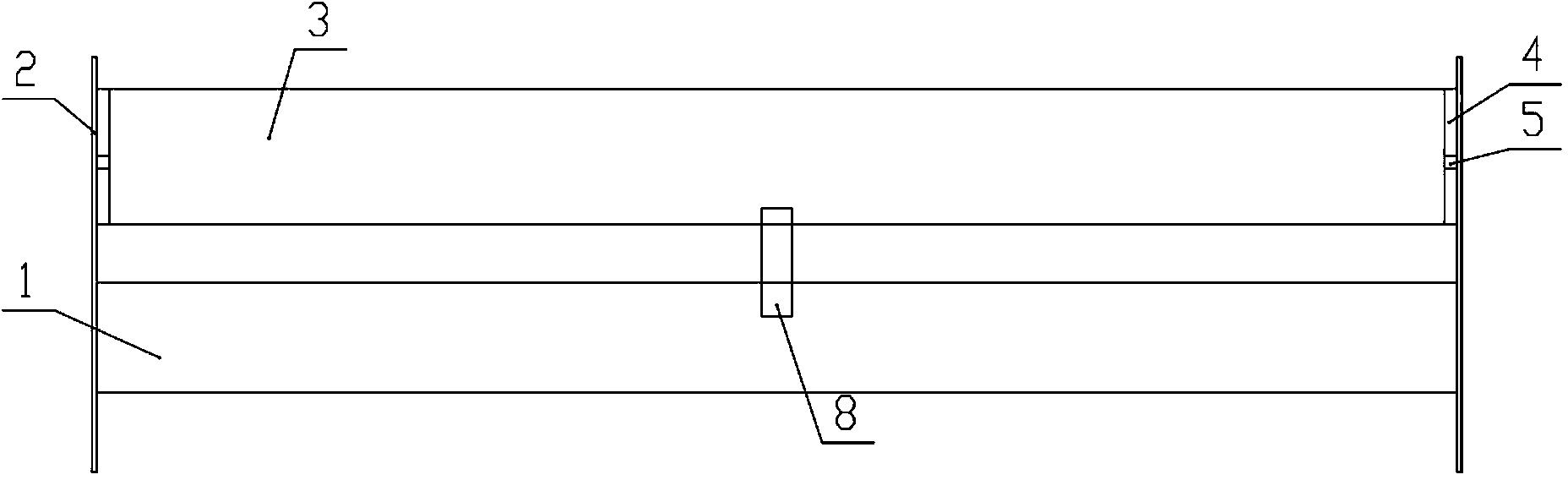

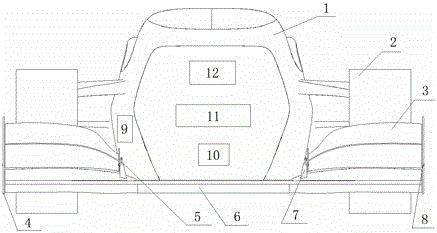

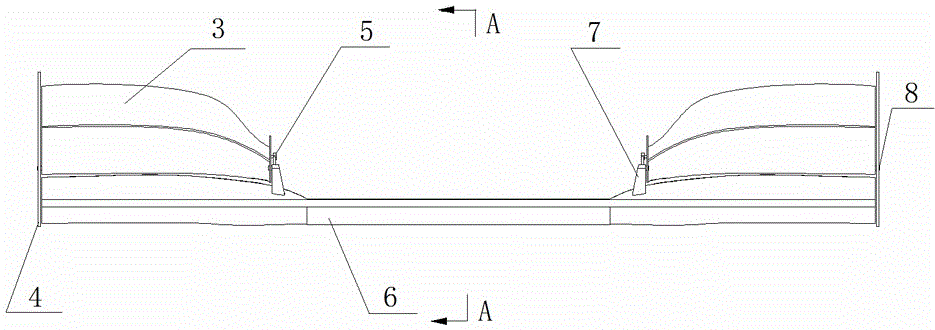

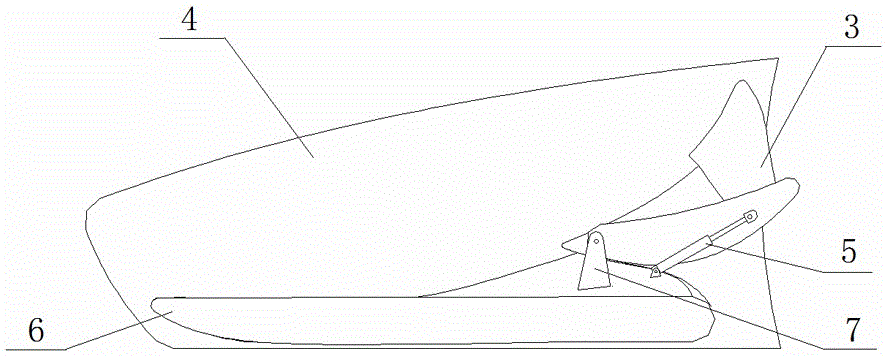

Adjustable spoiler of formula racer

InactiveCN104340285ACompact and reasonable structureSimple structureVehicle body stabilisationAerodynamic dragSteering wheel

The invention discloses an adjustable spoiler of a formula racer. The adjustable spoiler of the formula racer is characterized by mainly comprising a main wing and a flap, wherein the main wing and the flap are arranged at an interval; an end plate is connected to each of two ends of the main wing; the arrangement direction of each end plate is in accordance with the traveling direction of the racer; the flap is arranged on the main wing in a mode of being movably supported by a movable supporting point; two end surfaces of the flap are arranged on the end plates in a mode of being movably supported by a bearing; the axis of the bearing and the movable supporting point are not on the same straight line, so that the flap can be controlled by a button operating mechanism to rotate around the axis of the bearing; the button operating mechanism is mounted on a steering wheel and is manually operated by a racing driver. When the racer turns, the attack angle of the spoiler can be increased under the control of the driver, so that the racer turns at a high speed by virtue of the generated negative lift; when the racer straightly runs, the attack angle of the spoiler can be decreased under the control of the driver, and additional air resistance is avoided.

Owner:WUHAN UNIV OF TECH

Redundant blade pitch control system for a wind turbine and method for controlling a wind turbine

InactiveUS7717673B2Increase the angleDecreases the aerodynamic lift on the rotor bladesPropellersWind motor controlControl systemEngineering

Owner:GENERAL ELECTRIC CO

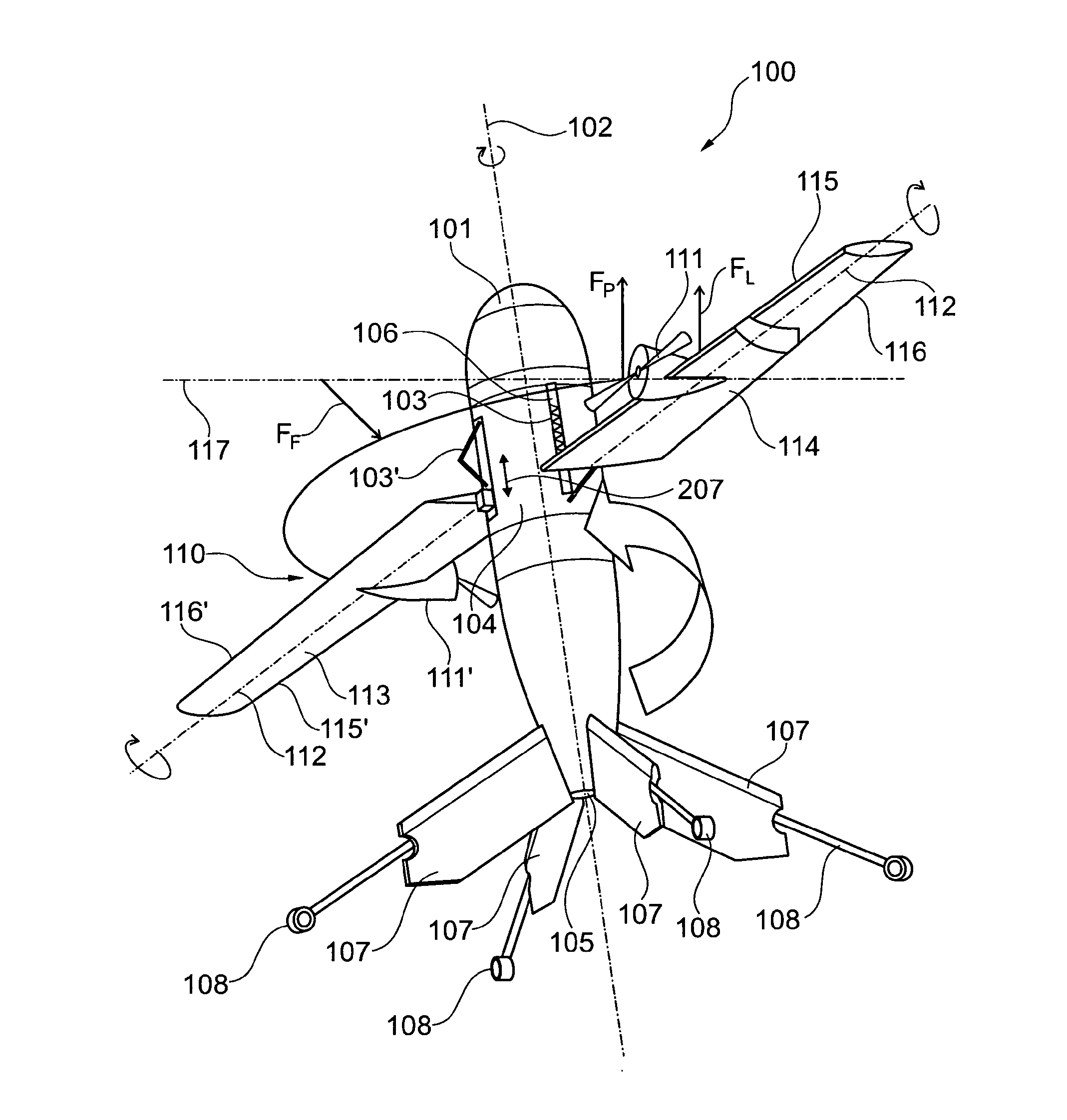

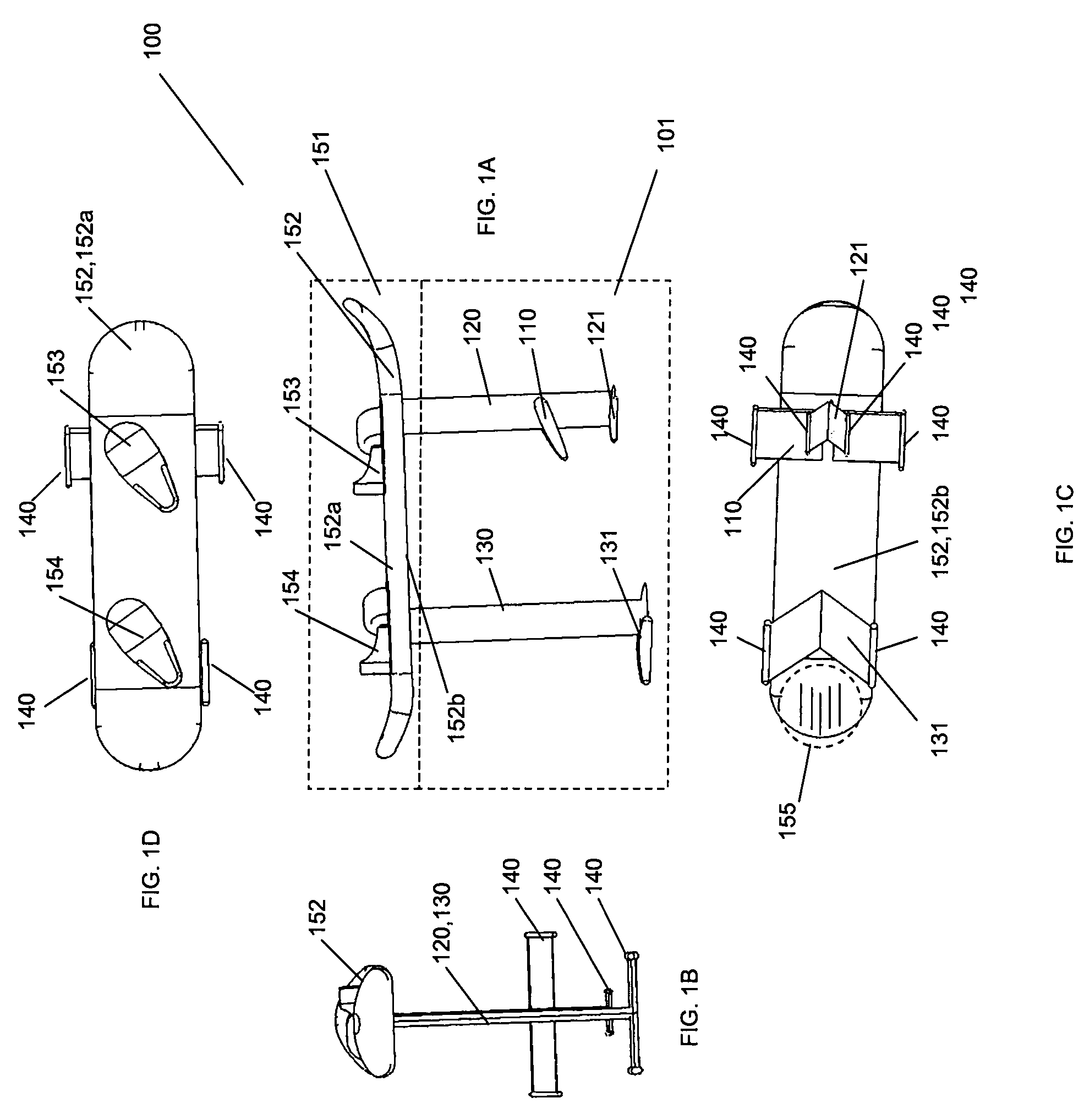

Wing adjusting mechanism

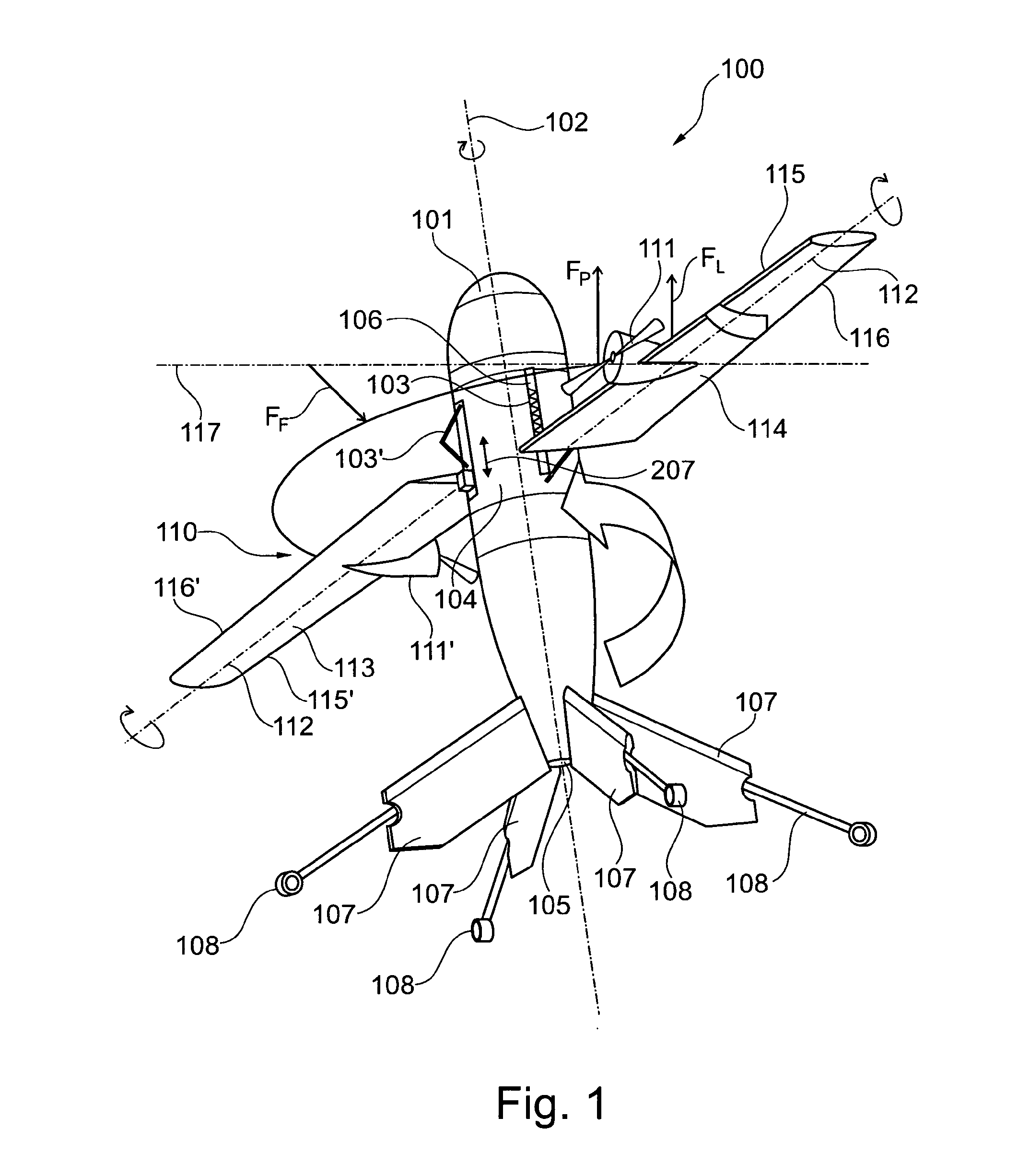

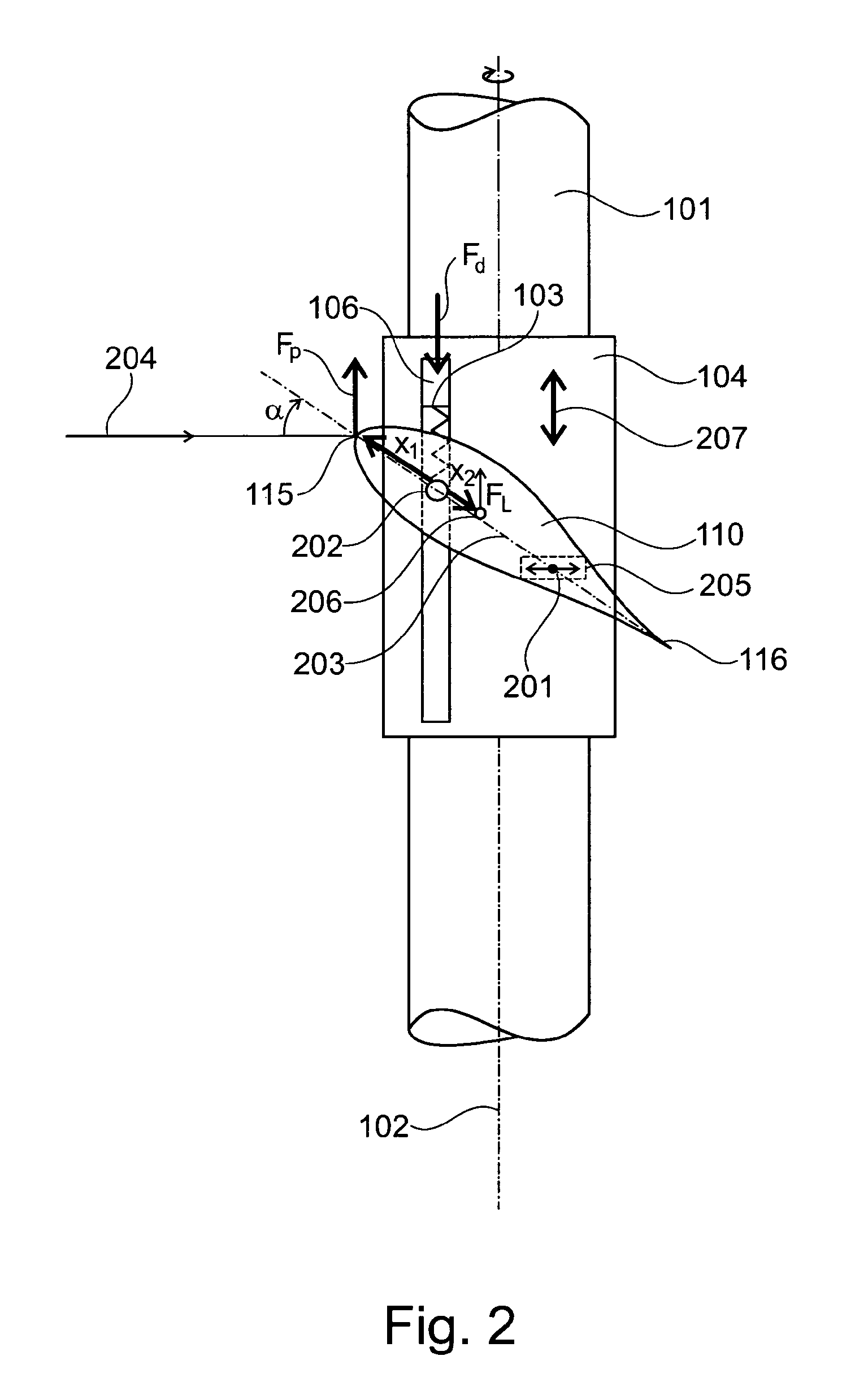

InactiveUS20150028155A1Reduce angle of attackReduce resistanceRemote controlled aircraftWing adjustmentsPrecessionFuselage

The present invention relates to a device for generating aerodynamic lift and in particular an aircraft (100) for vertical take-off and landing. A wing arrangement (110) comprises at least one propulsion unit (111), wherein the propulsion unit (111) comprises a rotating mass which is rotatable around a rotary axis (117). The wing arrangement (110) is mounted to a fuselage (101) such that the wing arrangement (110) is tiltable around a longitudinal wing axis (112) of the wing arrangement (110) and such that the wing arrangement (110) is rotatable with respect to the fuselage (101) around a further rotary axis that differs to the longitudinal wing axis (112). An adjusting mechanism adjusts a tilting angle of the wing arrangement (110) around the longitudinal wing axis (112) under influence of a precession force (Fp) which forces the wing arrangement (110) to tilt around the longitudinal wing axis (112).

Owner:REITER JOHANNES

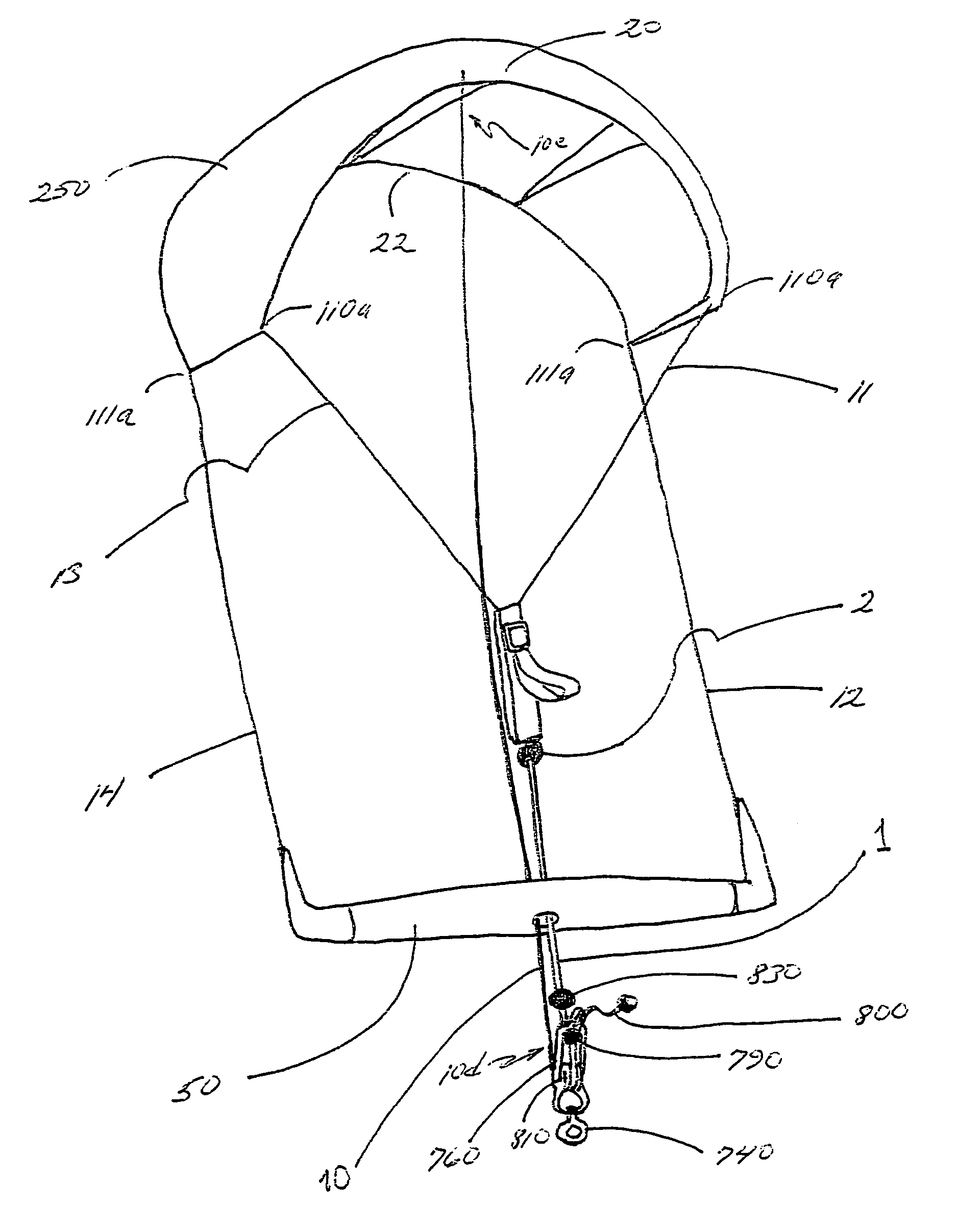

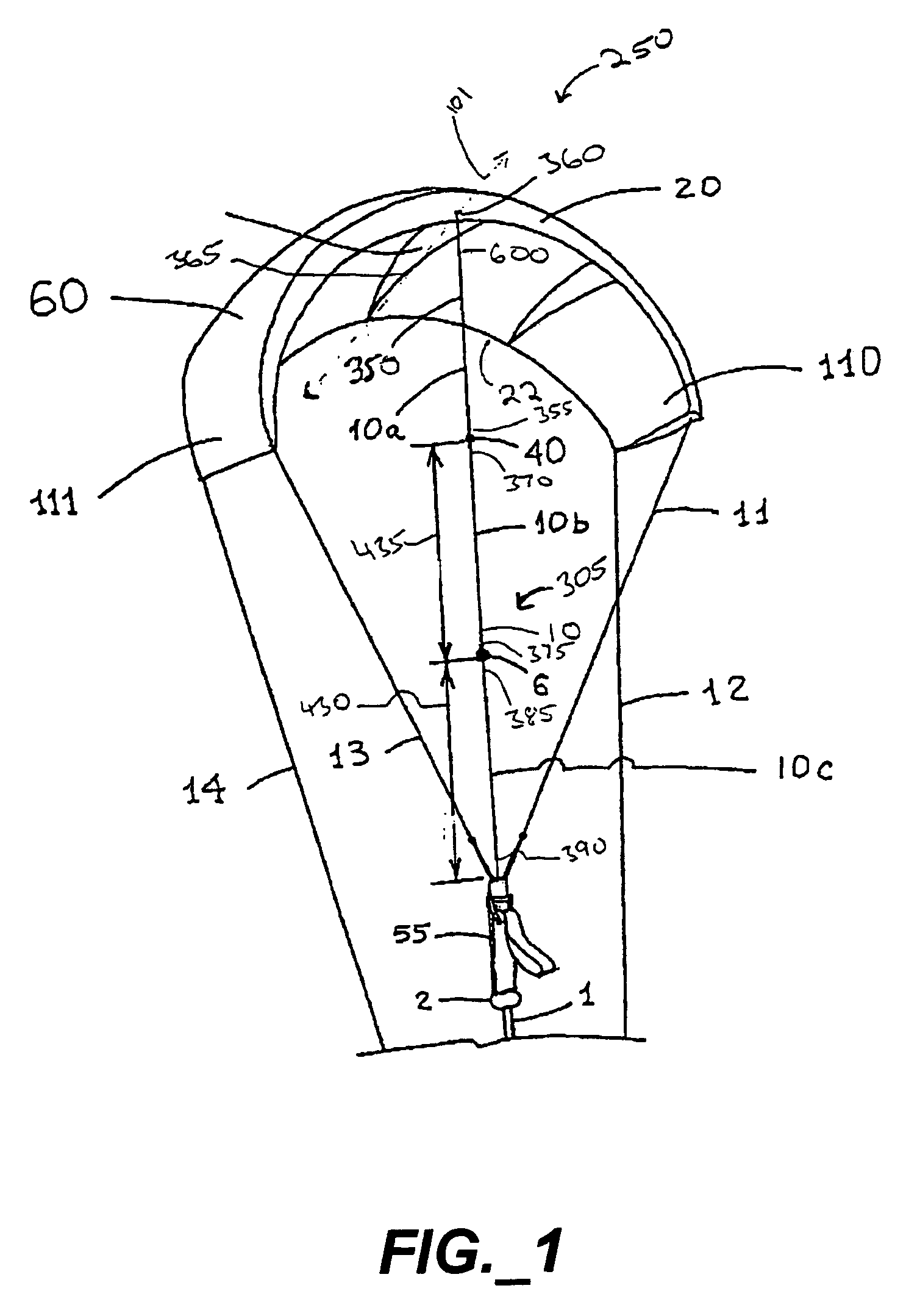

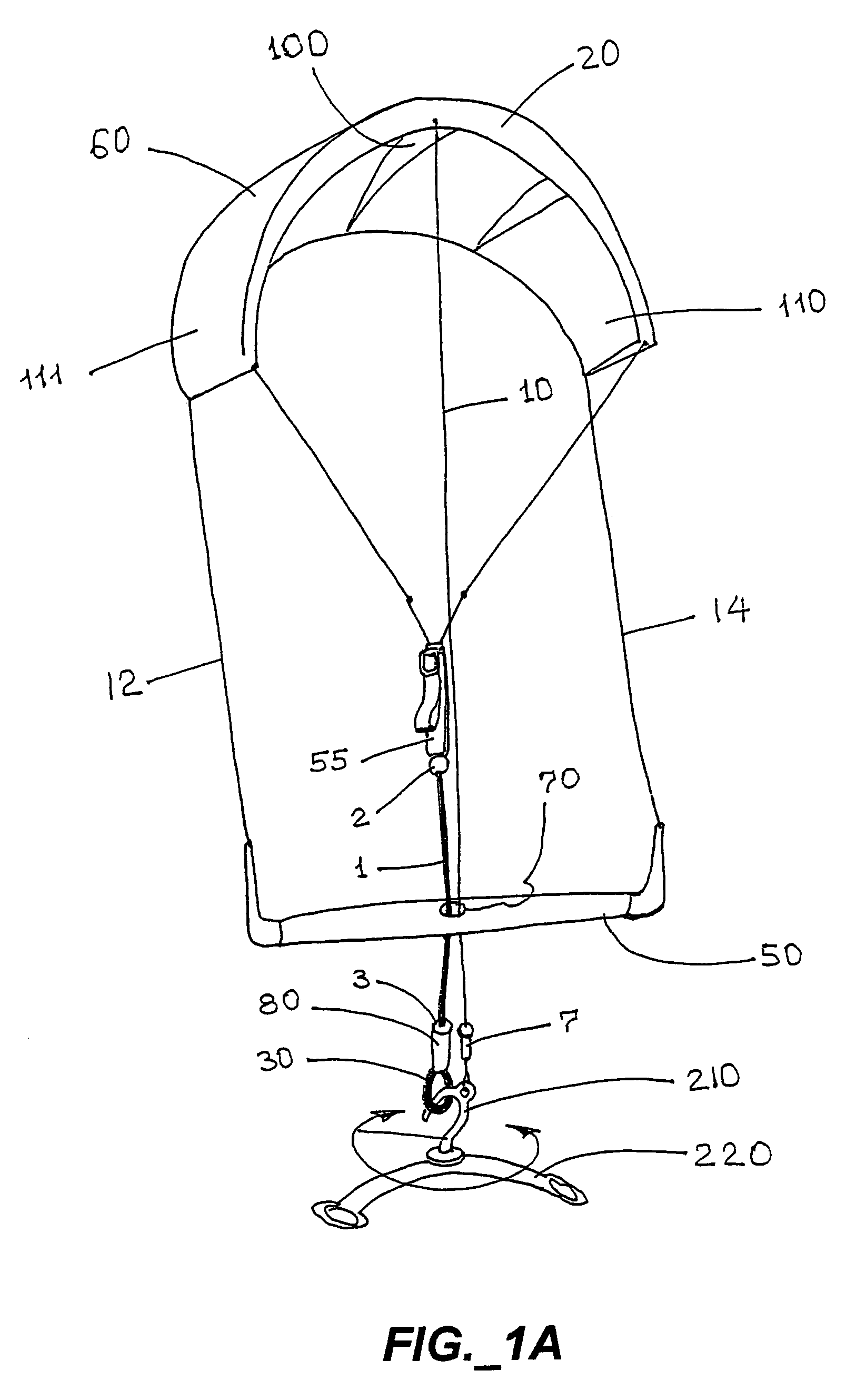

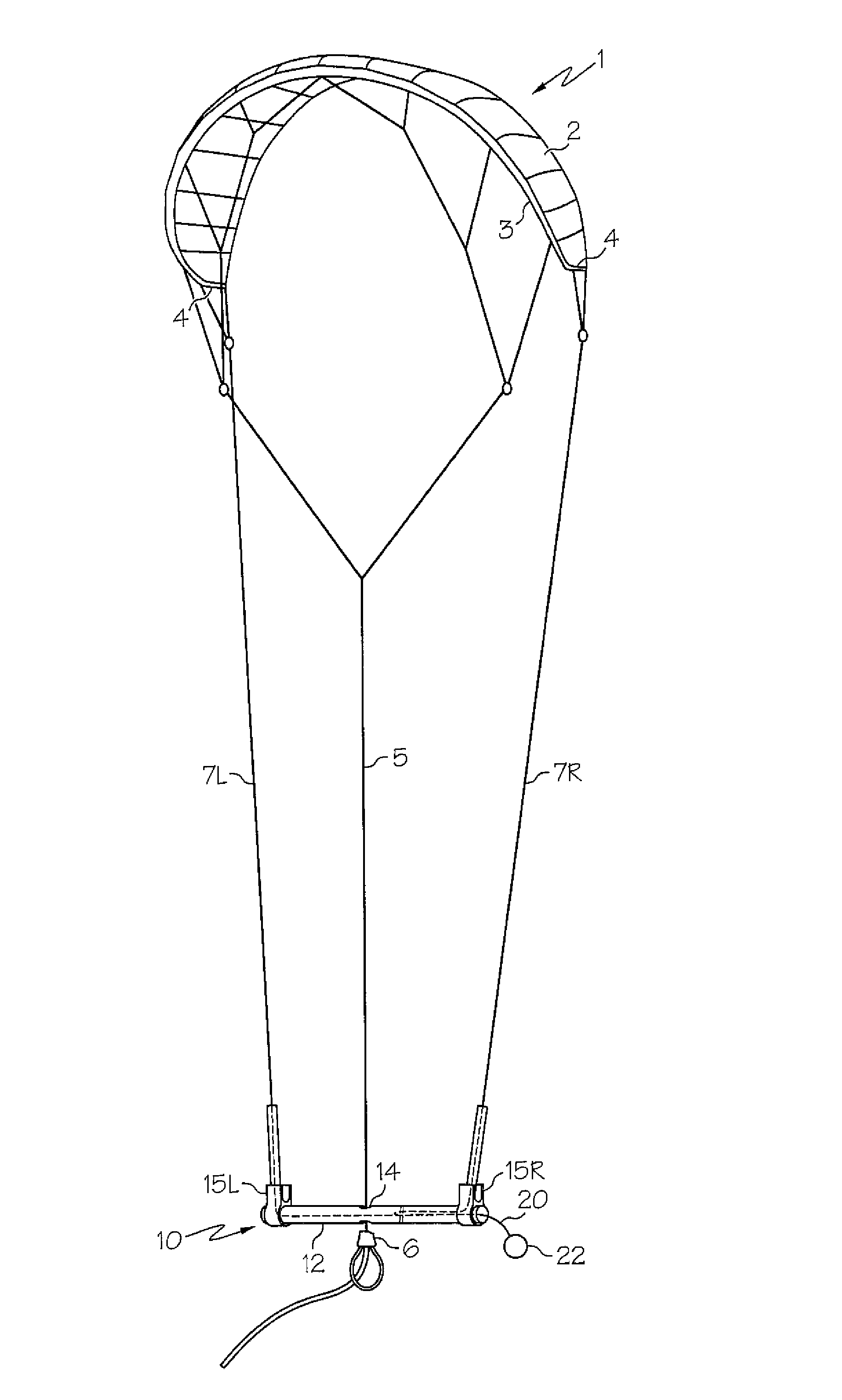

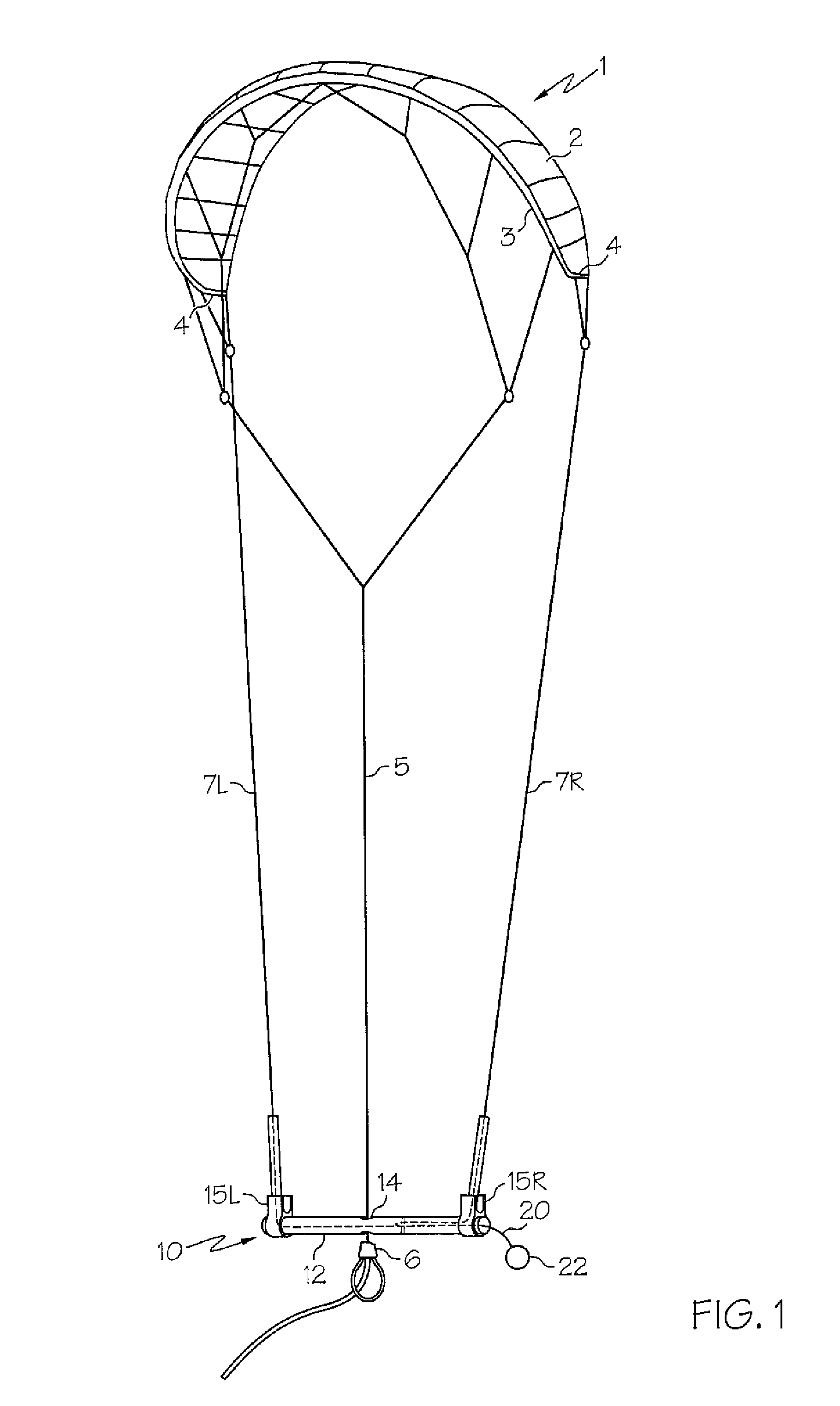

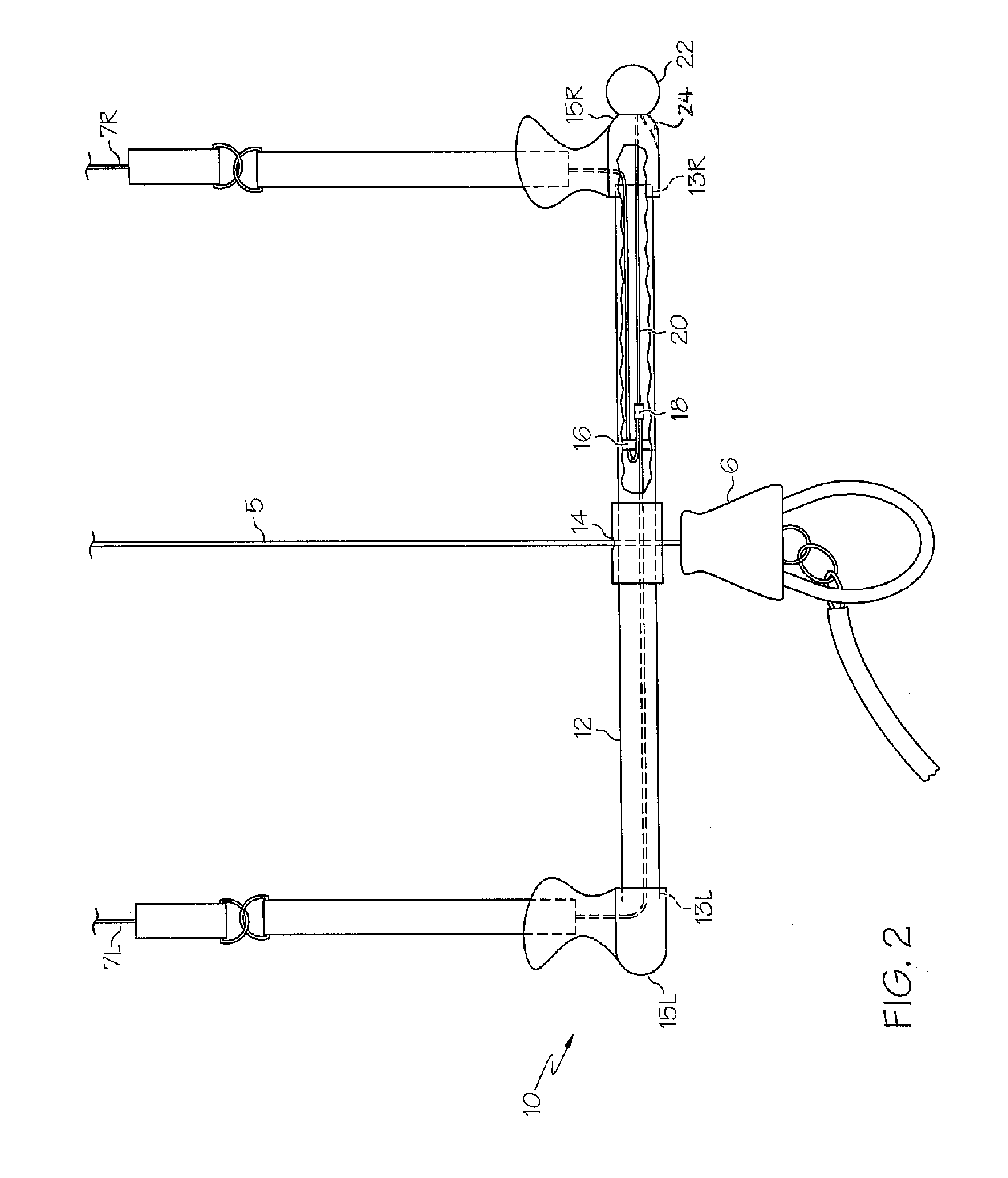

Kite safety, control, and rapid depowering apparatus

InactiveUS7036771B1Safely and quickly de-poweringEasy to controlMarine propulsionParachutesLeading edgeFast release

A kite safety, control, and depowering device for a kite having an airfoil with leading and trailing edges, at least two control lines attached to the airfoil and a control flying bar attached to at least two of the control lines. The device features a continuous trim and safety flying line disposed at their lower ends over a rapid depowering apparatus. The depowering apparatus includes means for capturing and rapidly releasing an expansion disposed on the trim line, such that when rapid depowering is required, a simply release mechanism may be actuated to change the angle of attack of the airfoil rapidly.

Owner:POUCHKAREV ALEXANDER S

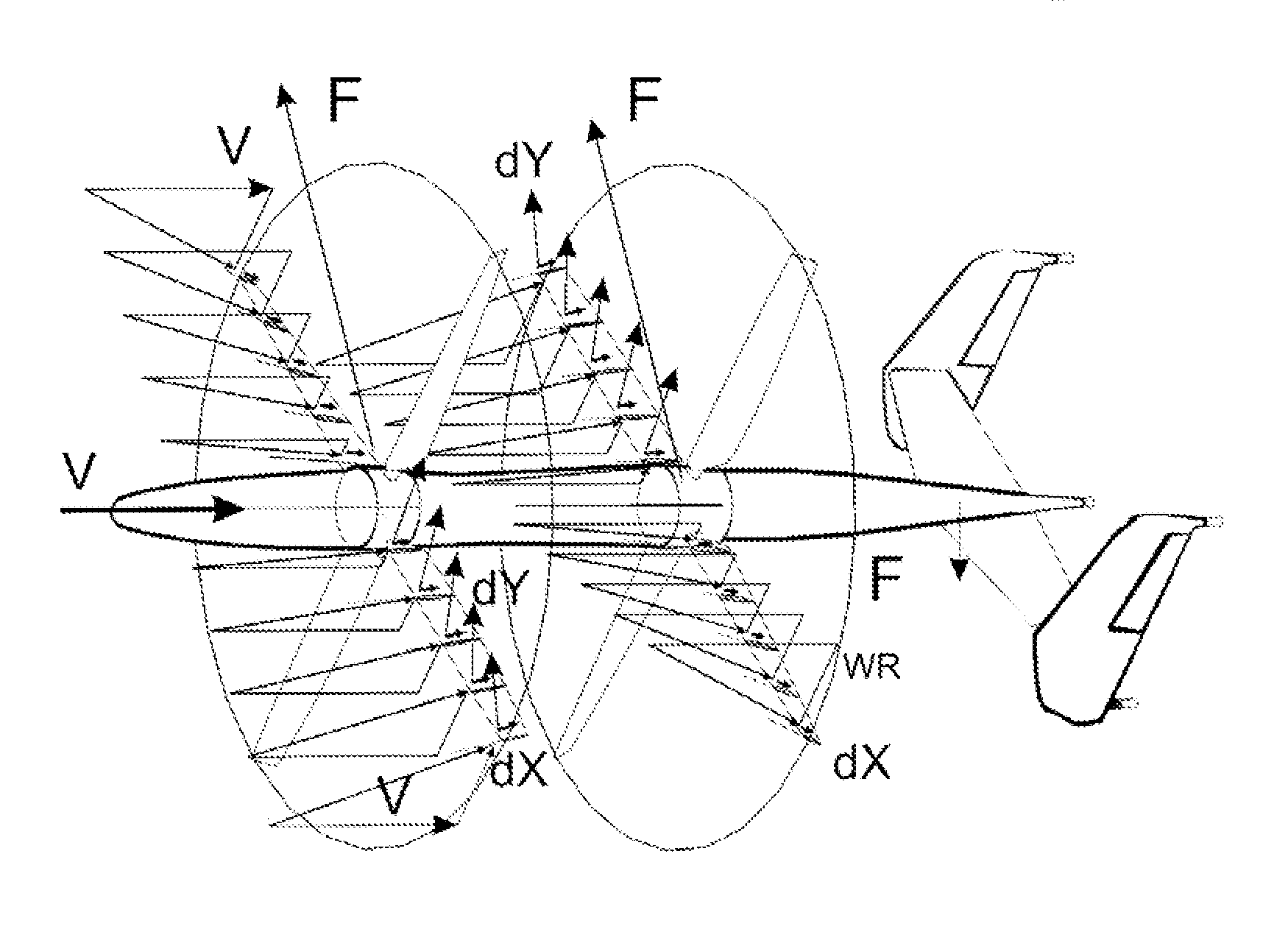

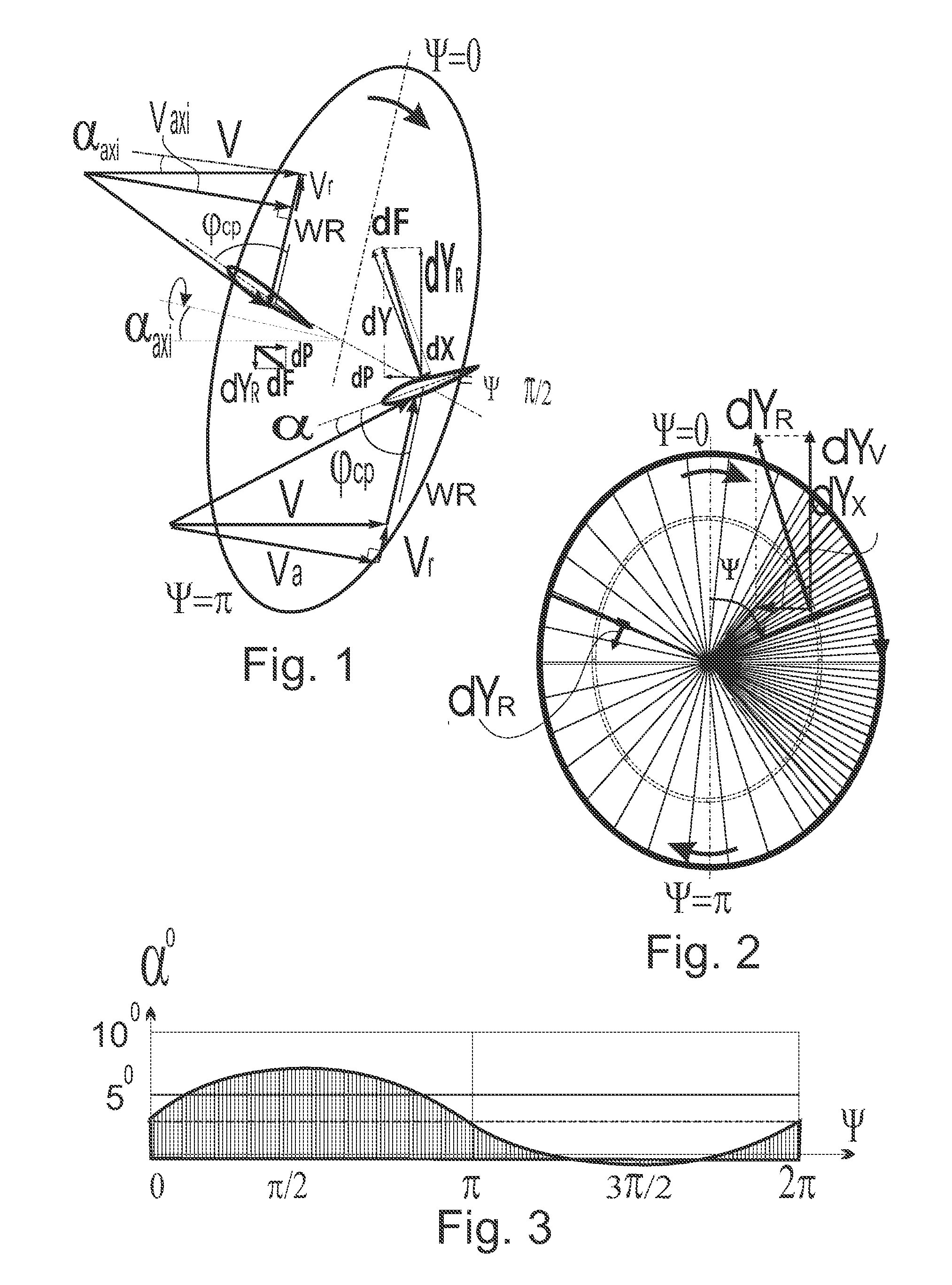

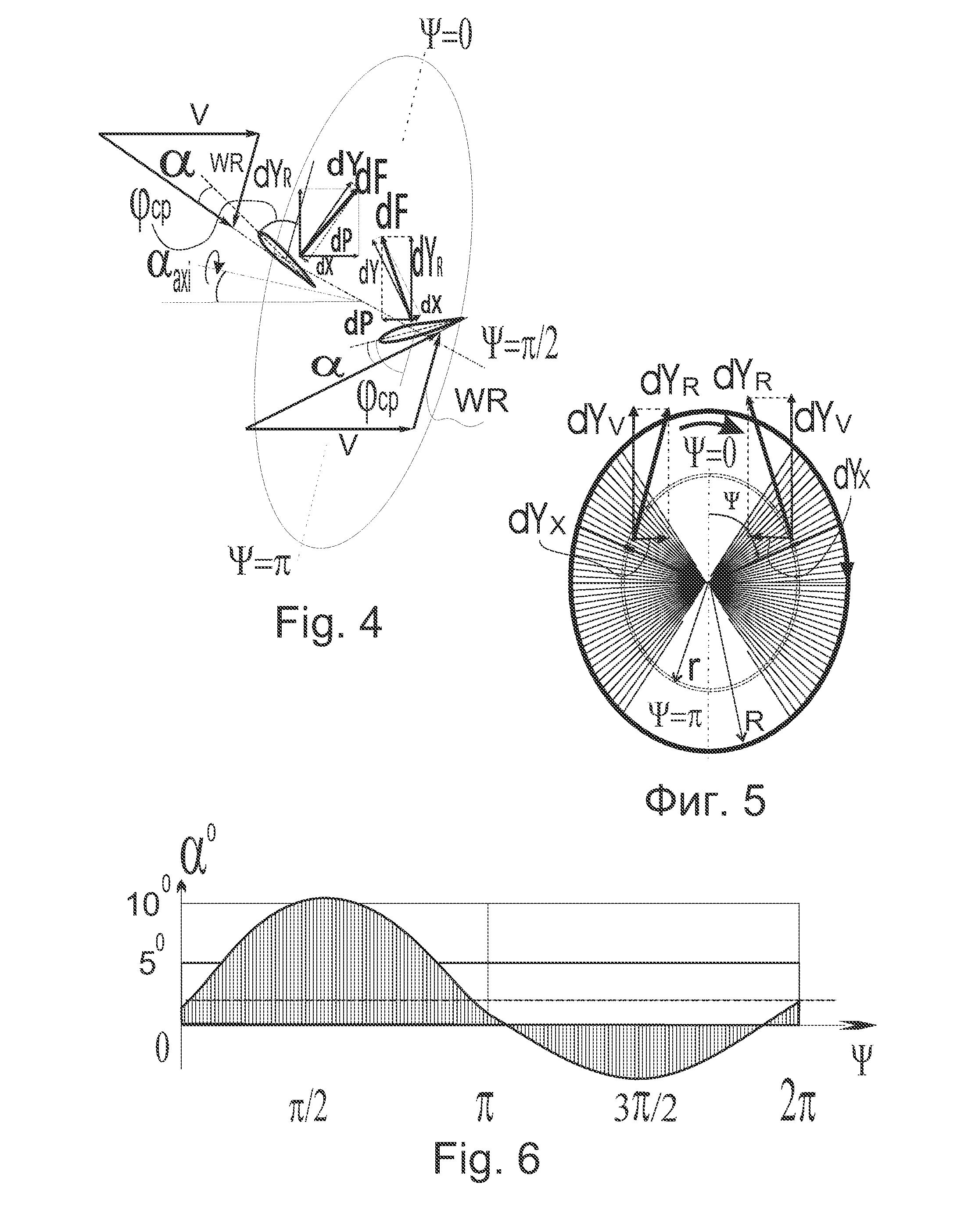

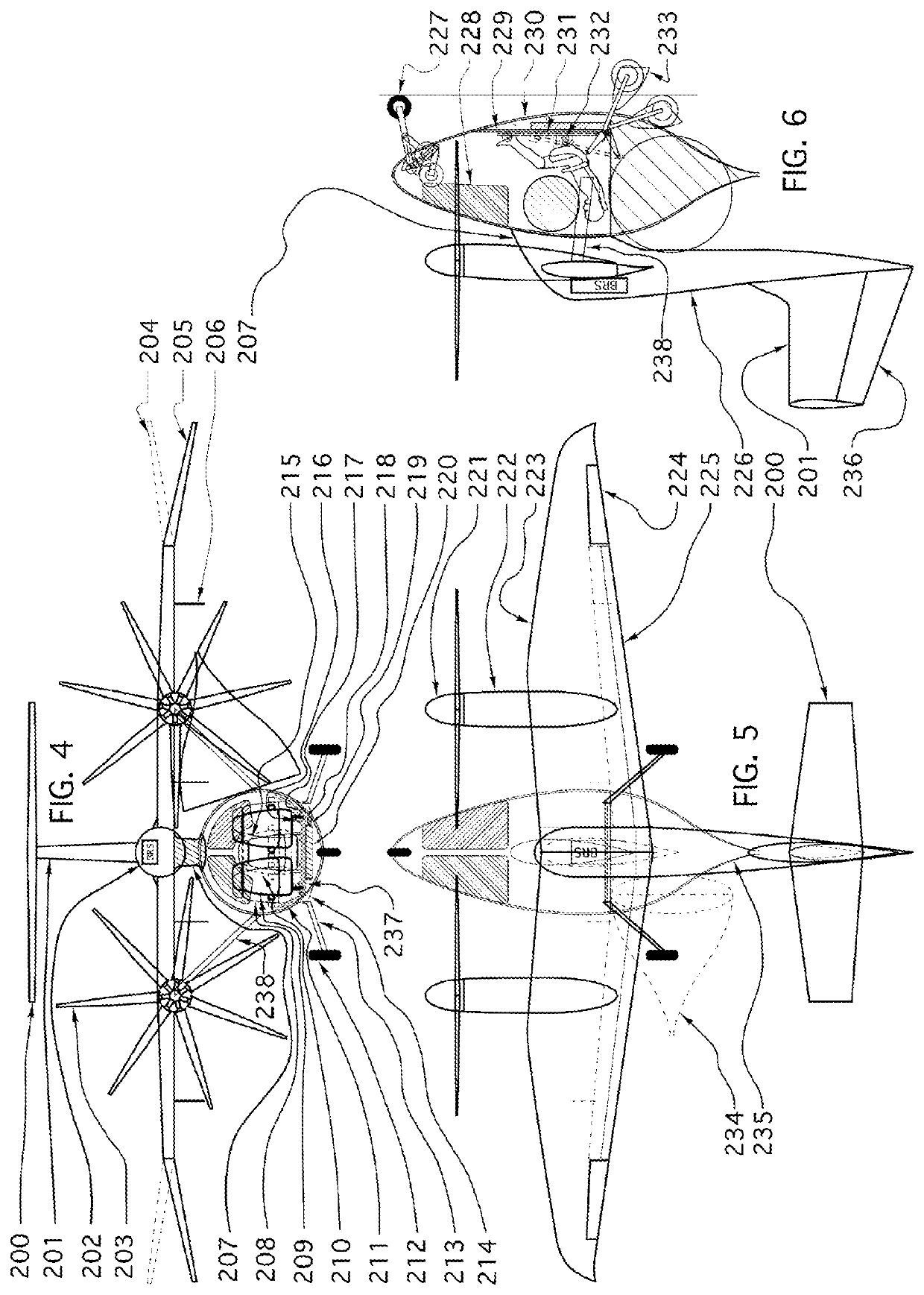

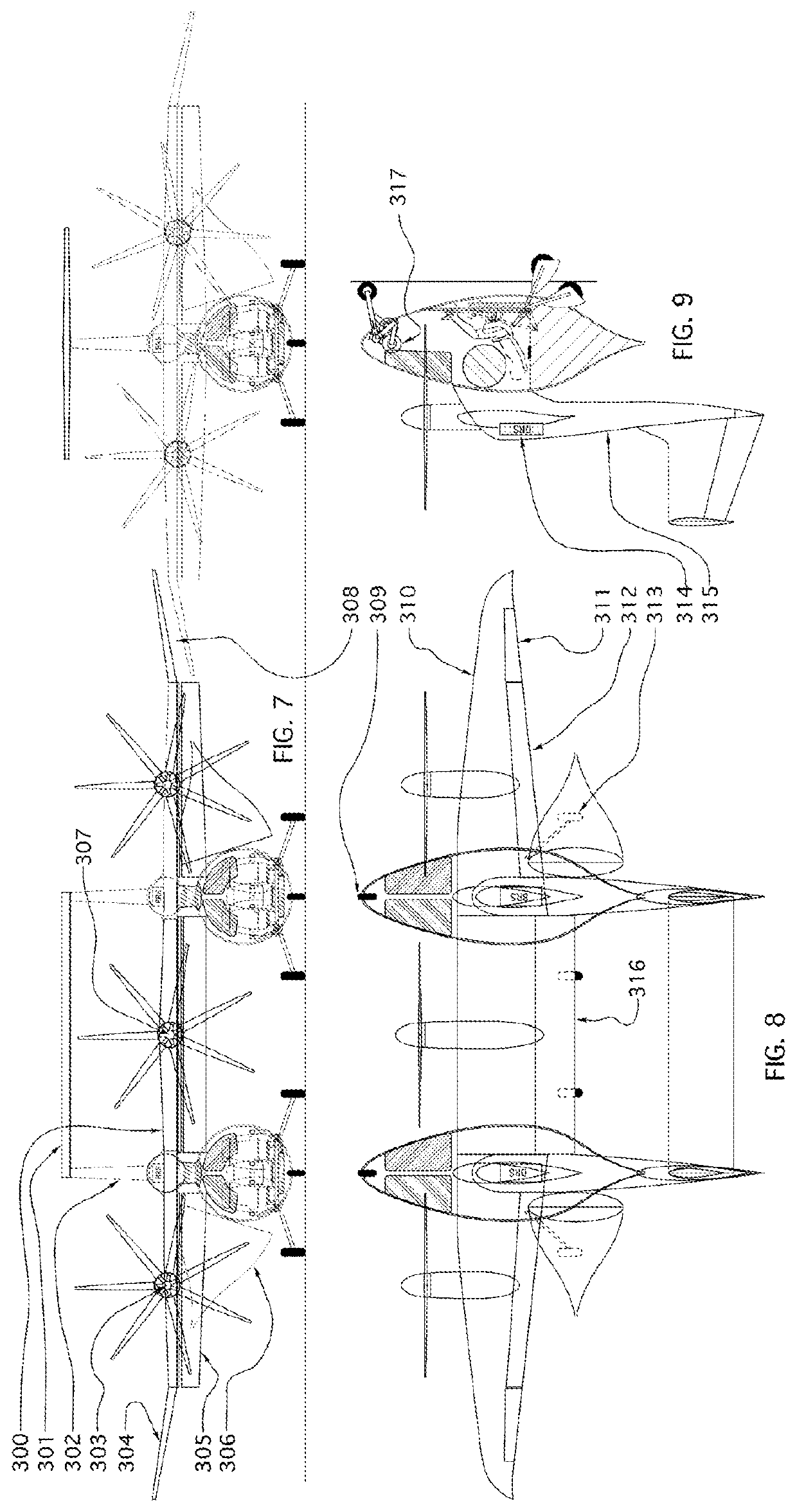

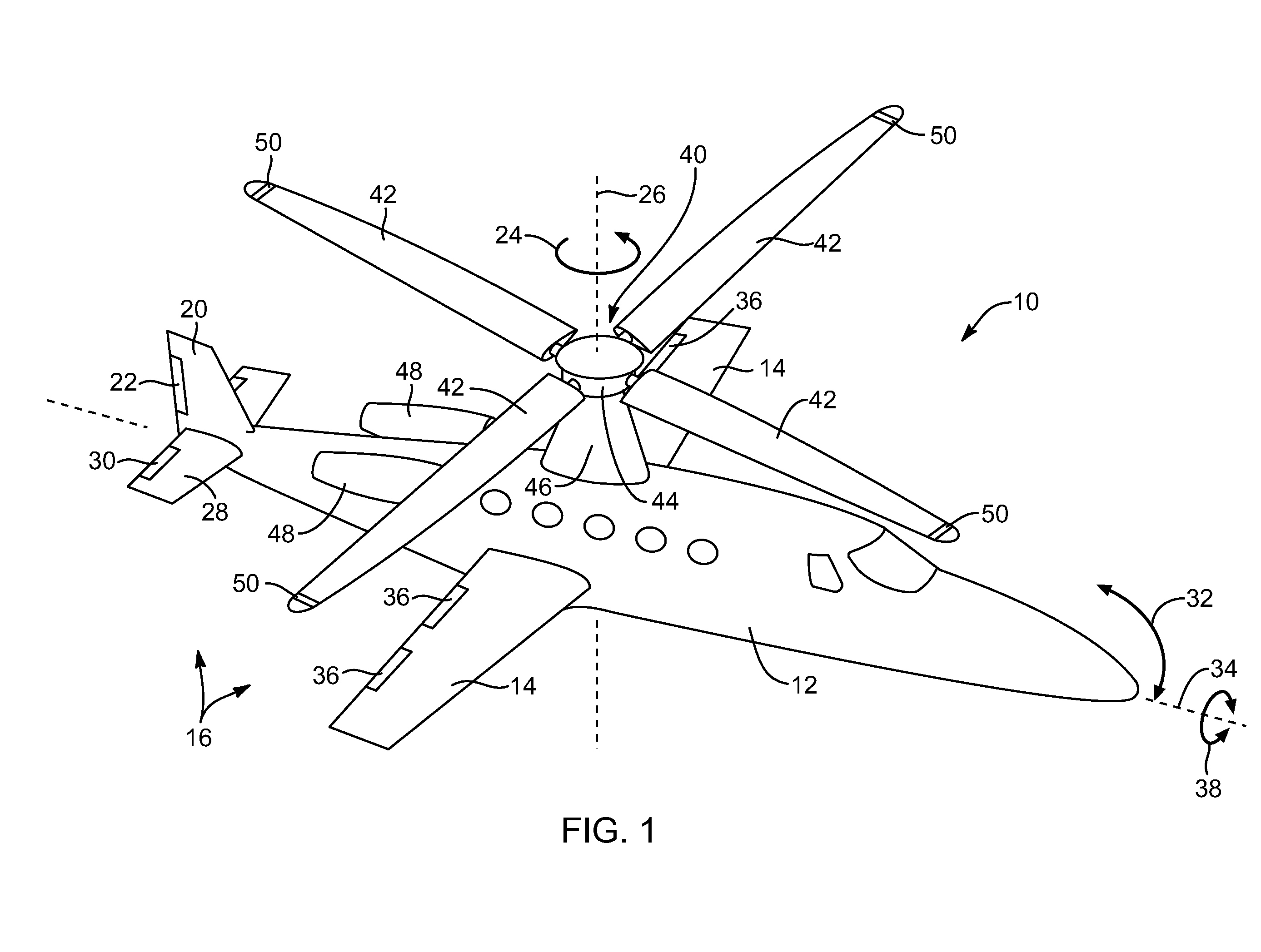

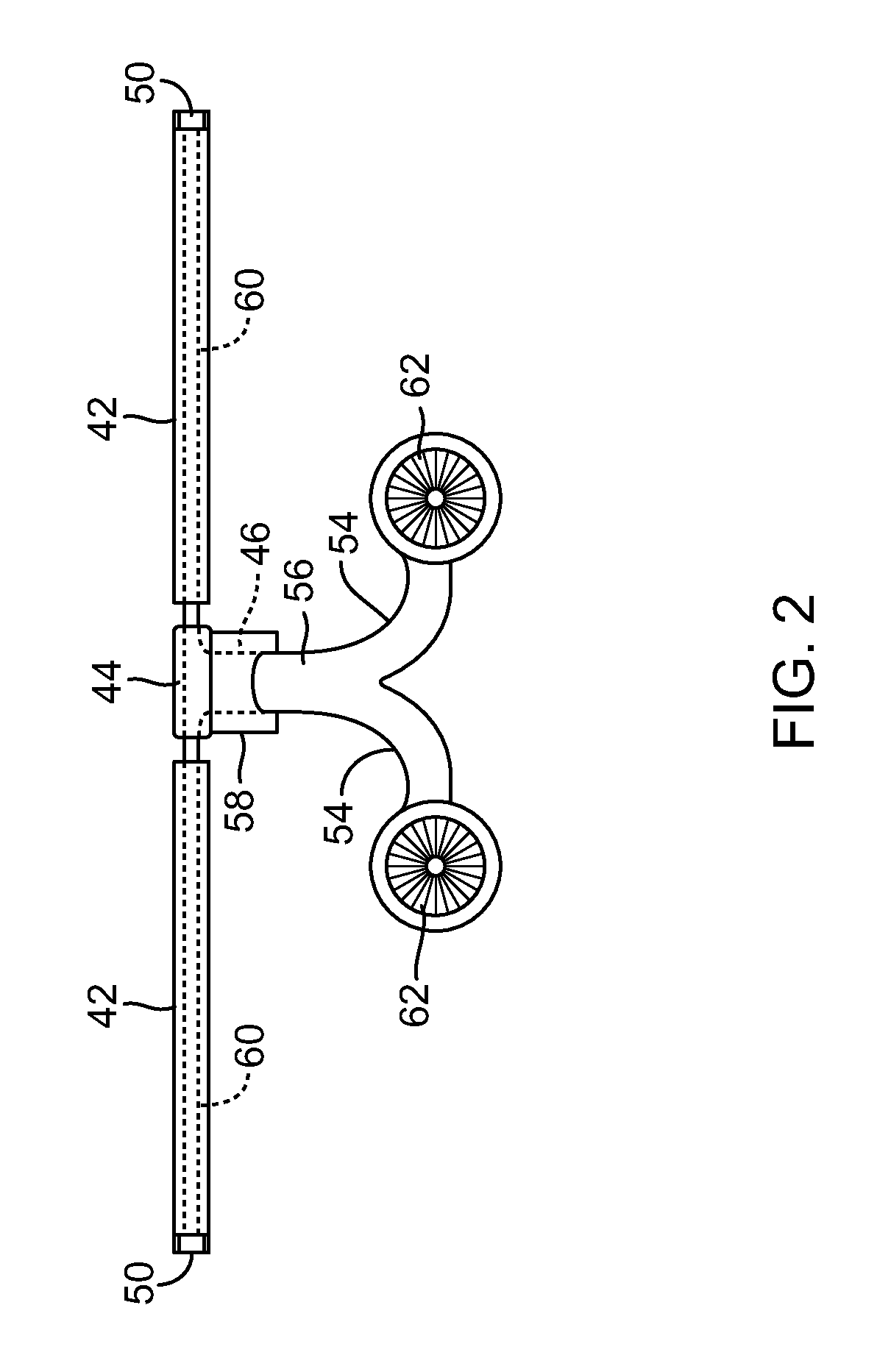

Method of flight in an expanded speed range using thrust vectoring propellers

InactiveUS20110052392A1Add supportIncreasing angle of attackPropellersPump componentsPropellerAirplane

The invention relates to aeronautical engineering, in particular to methods of flight due to creating of forces on air propellers, namely using thrust vectoring of direction and amount of force created by air propellers of opposite rotation with the axis, mainly in the direction of flight, in the expanded range of speeds, from 50 m / s to high near-sonic speed of flight. The invention may be applied for horizontal flight and maneuvering in flight on vertical take-off aircrafts using rotation of main rotors from the vertical stand of rotor axes during the take-off to almost horizontal position of rotor axes in horizontal flight, thus both the rotation of rotors and the change of position of an aircraft together with its rotors may be applied, and it may be also used in the horizontal take-off aircrafts with almost horizontal position of axes during the horizontal flight, including the planes with airscrew propellers.

Owner:KHMEL DMITRY SERGEEVICH

Towed personal watercraft

InactiveUS20080305698A1Reduce resistanceReduce surface roughnessWater sport boardsHydrodynamic/hydrostatic featuresWatercraftTorsion spring

A towed personal watercraft apparatus includes a submergible unit and a platform. The submergible unit comprises at least two independent vertical stabilizers and one or more hydrofoil units mounted to at least one of the vertical stabilizers. One or more of the hydrofoil units is pivotally attached to the vertical stabilizers. Pivotal attachment can include a torsion spring or roller bearing to allow the hydrofoil units to pivot or rotate about the pitch axis of the platform, thereby improving stability of the towed personal watercraft. Rotation of the hydrofoil units can be limited for functional concerns and performance. For example, rotation of the hydrofoils about the pivot can be allowed in a first direction to prevent a nose dive, while being restricted in a second direction to facilitate a launch of the watercraft out of the water. The platform includes a user mount, such as foot holds or equivalents.

Owner:ROSIELLO KEITH M

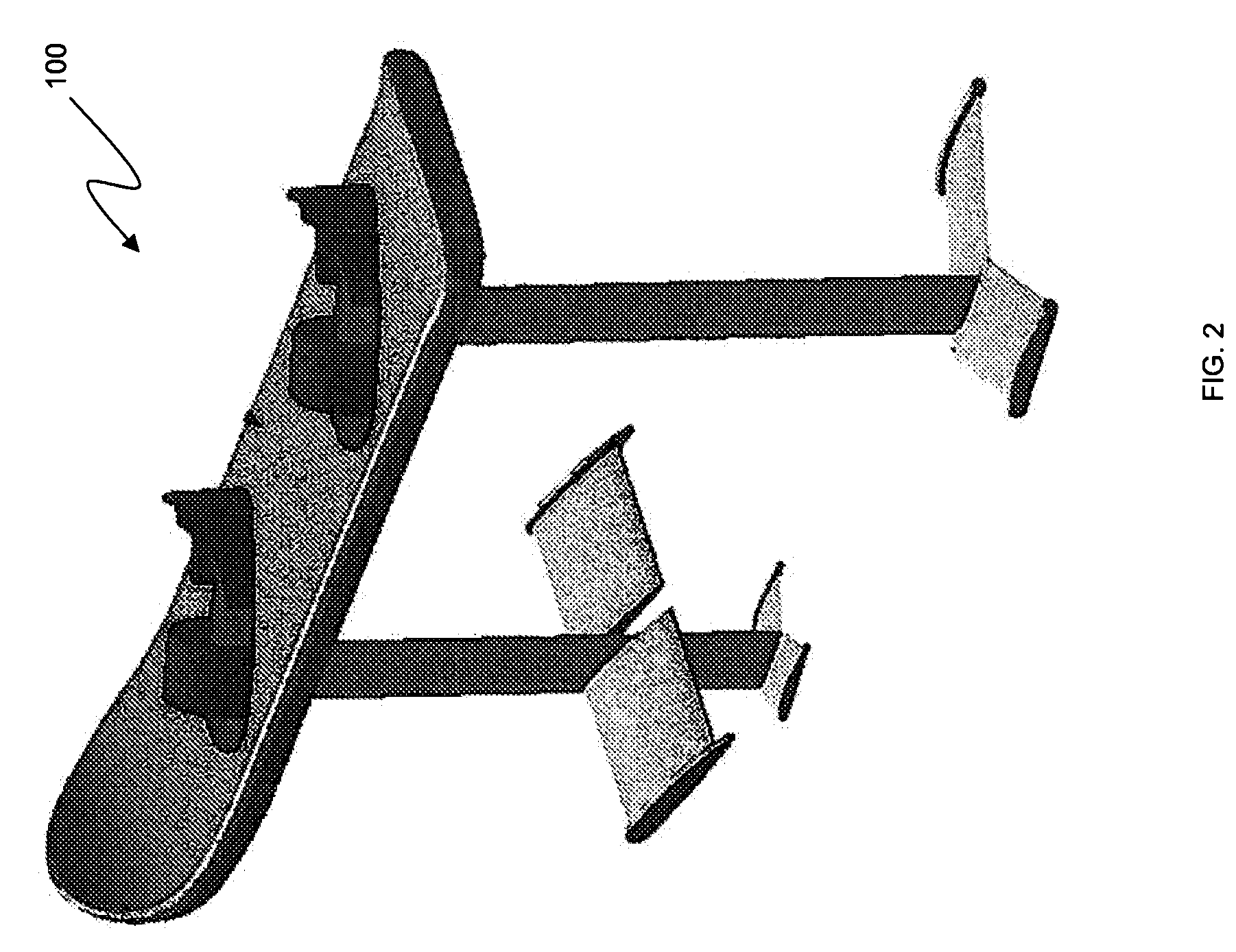

Quiet urban air delivery system

ActiveUS11198519B1Manageable wing weightManageable ride qualityPropellersArresting gearElectric carsEmbedded system

A public transportation system combines a unique combination of components that includes interoperable electric-powered vehicles, facilities, hardware and software having specifications, standards, processes, capabilities, nomenclature, and concepts of operations that together include a concerted, comprehensive, multi-modal, future system for moving people and goods that is herein named Quiet Urban Air Delivery (QUAD) and in which uniquely-capable, ultra-quiet, one to six-seat, electrically-powered, autonomous aircraft (SkyQarts) fly sub-193 kilometer trips on precise trajectories with negligible control latency and perform extremely short take-offs and landings (ESTOL) with curved traffic patterns at a highly-distributed network of very small, airports (“SkyNests”) that themselves have standardized compatible facilities that interoperate with SkyQarts as well as with versatile, autonomous electric-powered payload carts (EPCs) and robotic delivery carts (RDCs) to provide safe, fast, on-demand, community-acceptable, environmentally friendly, high-capacity, affordable door-to-door delivery of both passengers and cargo across urban, suburban and rural settings across the globe.

Owner:SEELEY BRIEN AVEN

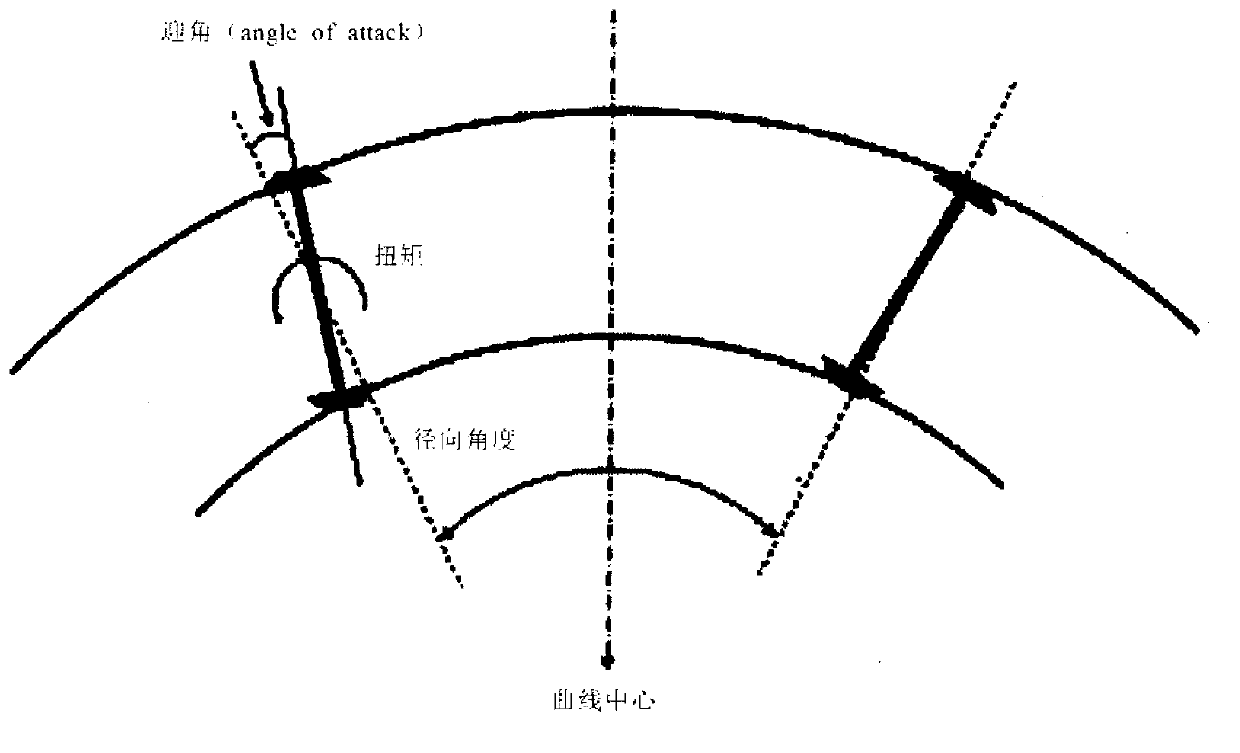

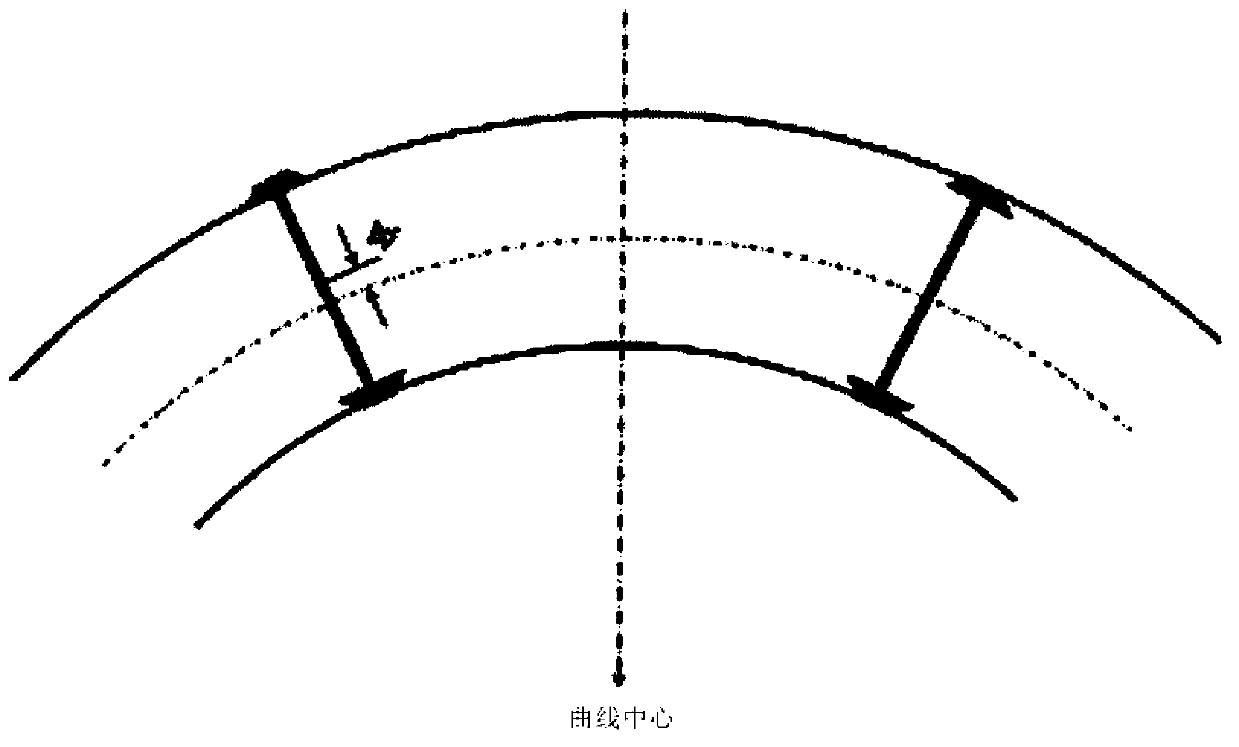

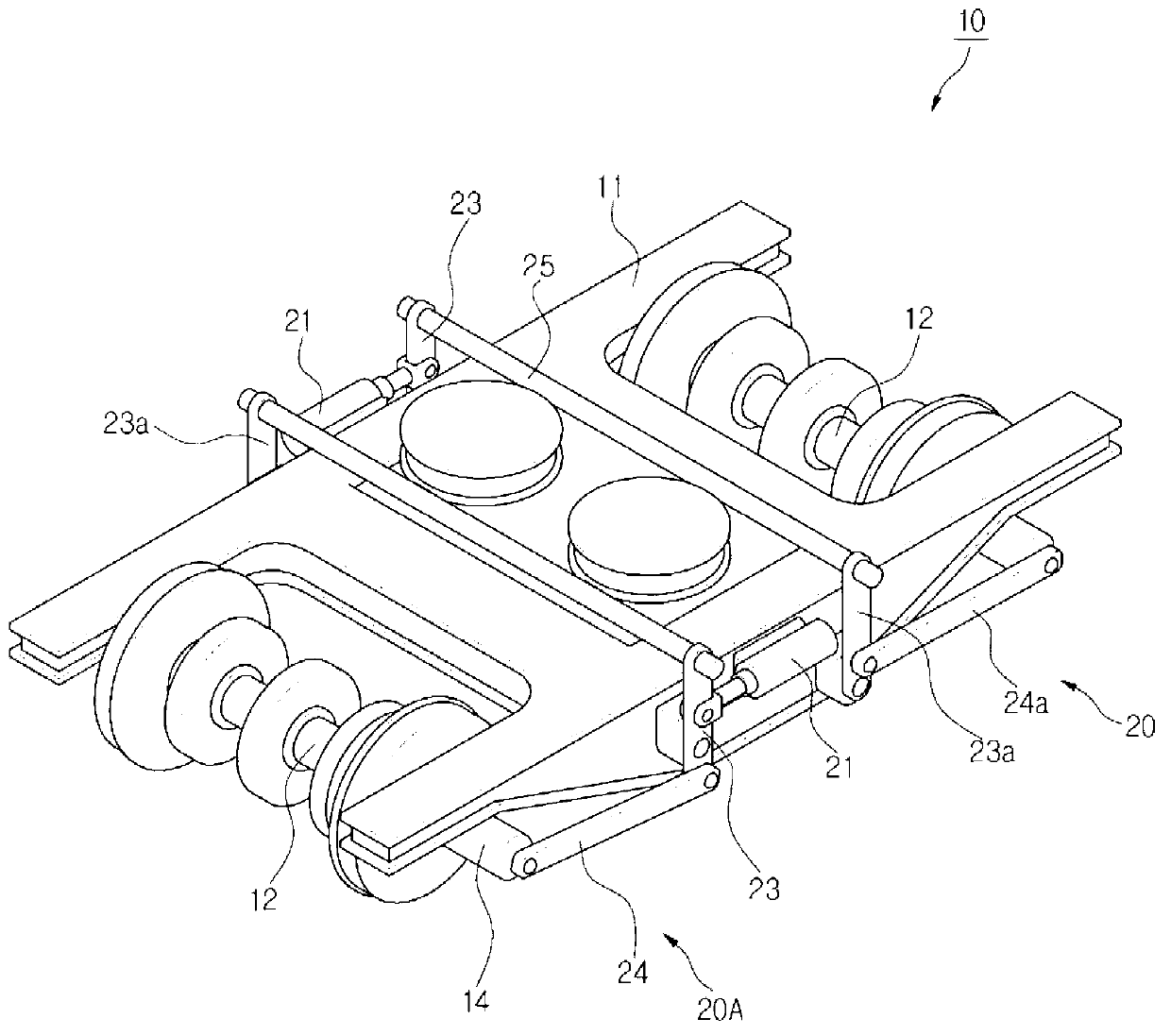

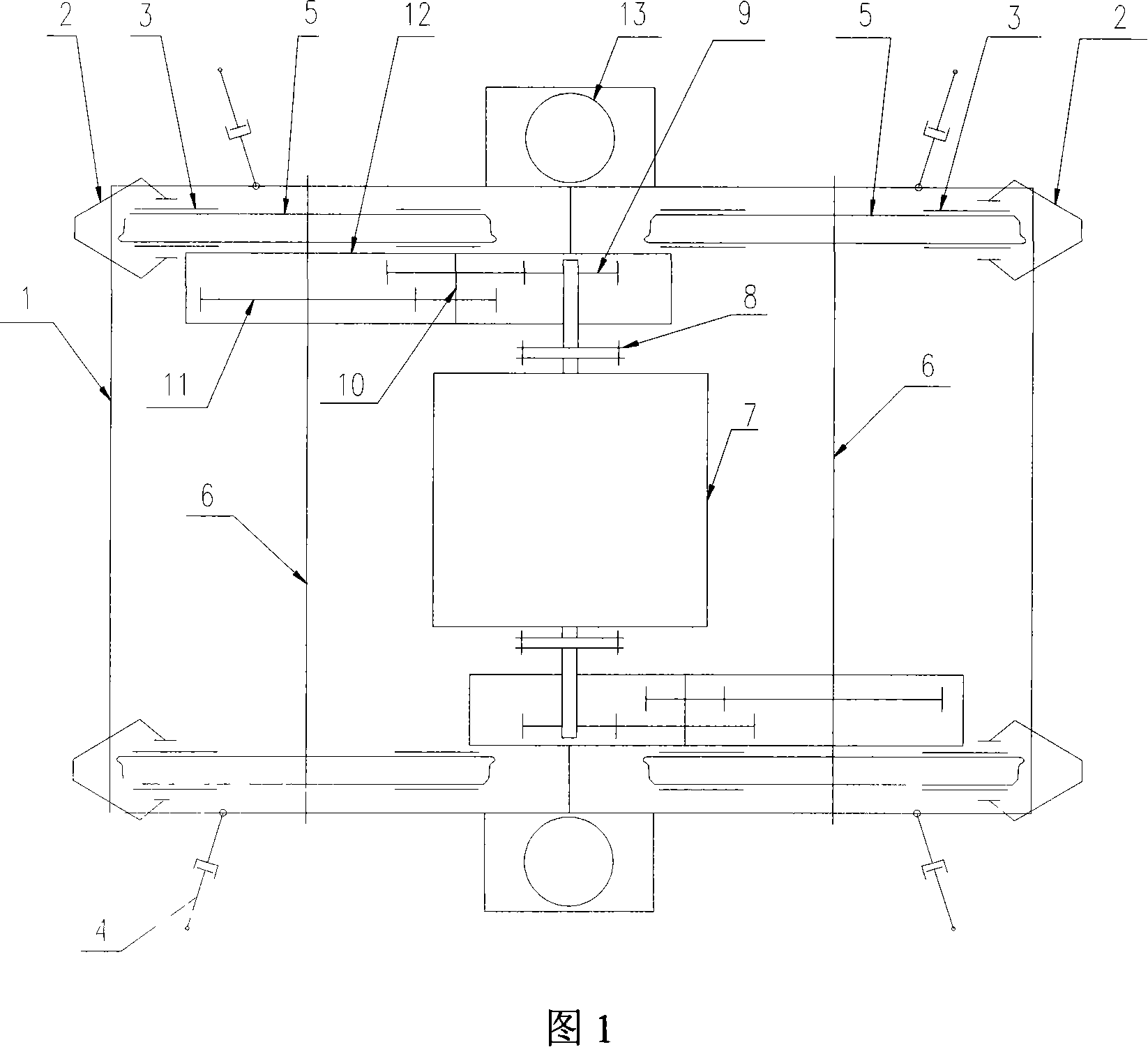

Active steering control device and method for railroad vehicle

ActiveCN102712326AOptimum axle steering angleReduce angle of attackBogiesMechanical measuring arrangementsSteering angleSignal on

The present invention relates to an active steering control device and method for a railroad vehicle, and more specifically, to an active steering control device and method for a railroad vehicle, which can smoothly steer a running railroad vehicle by estimating the radius of curvature of a curved line in real time when the train runs on the curved line and controlling an optimal steering angle on the wheel and axle according to the estimated radius of curvature, and can remarkably reduce an angle of attack which exists between the curved line and the wheel and axle. The invention comprises: a measurer that measures drive data of the running railroad vehicle,an estimator that estimates the radius of curvature of the curved line on which the railroad vehicle is running, by using the data measured in the measuring unit,a calculator that sets a target value of the steering angle on the wheel and axle of the running railroad vehicle, by using the radius of curvature estimated in the estimator,a controller that generates a steering control signal on the wheel and axle by comparing an actual steering angle on the wheel and axle with the target value of the steering angle on the wheel and axle, which is set in the calculator,and an actuator that steers the wheel and axle by the steering signal of the controller.

Owner:KOREA RAILROAD RES INST

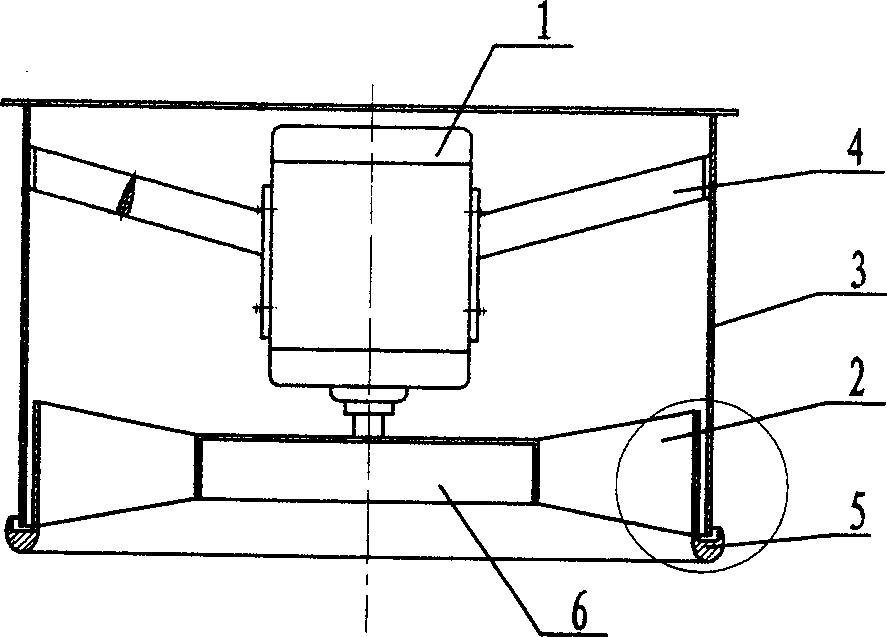

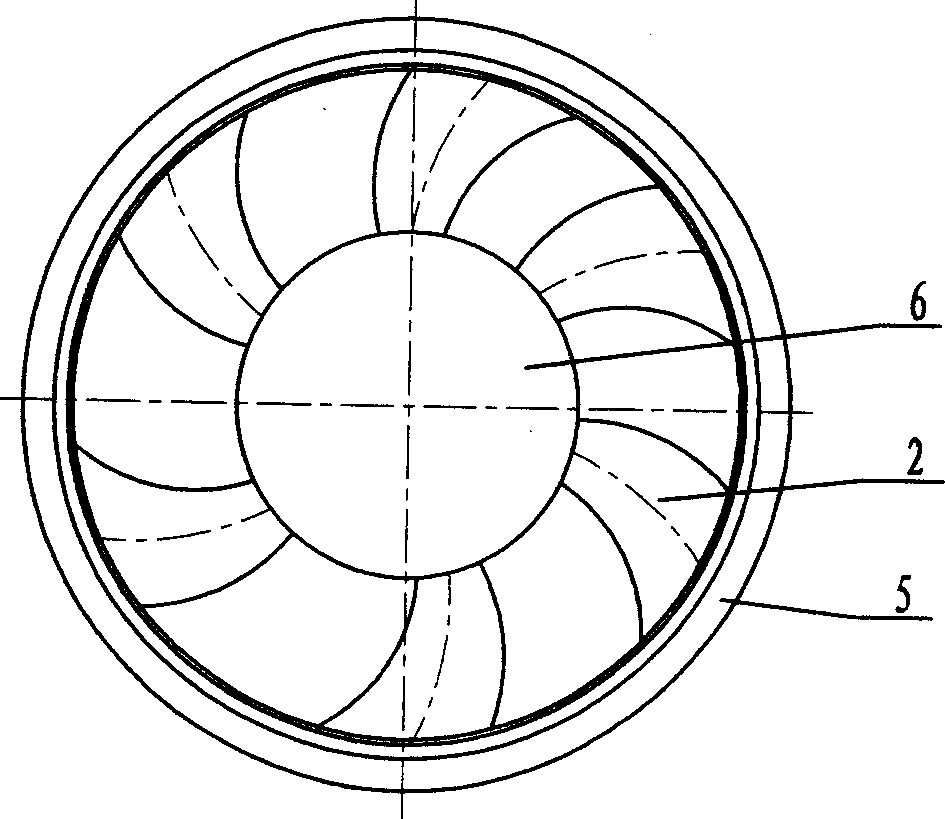

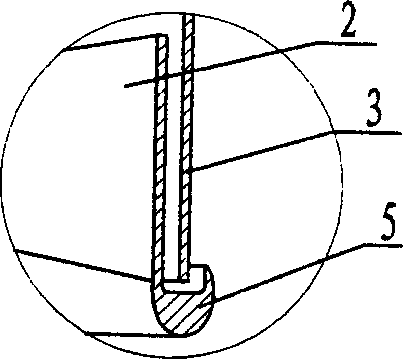

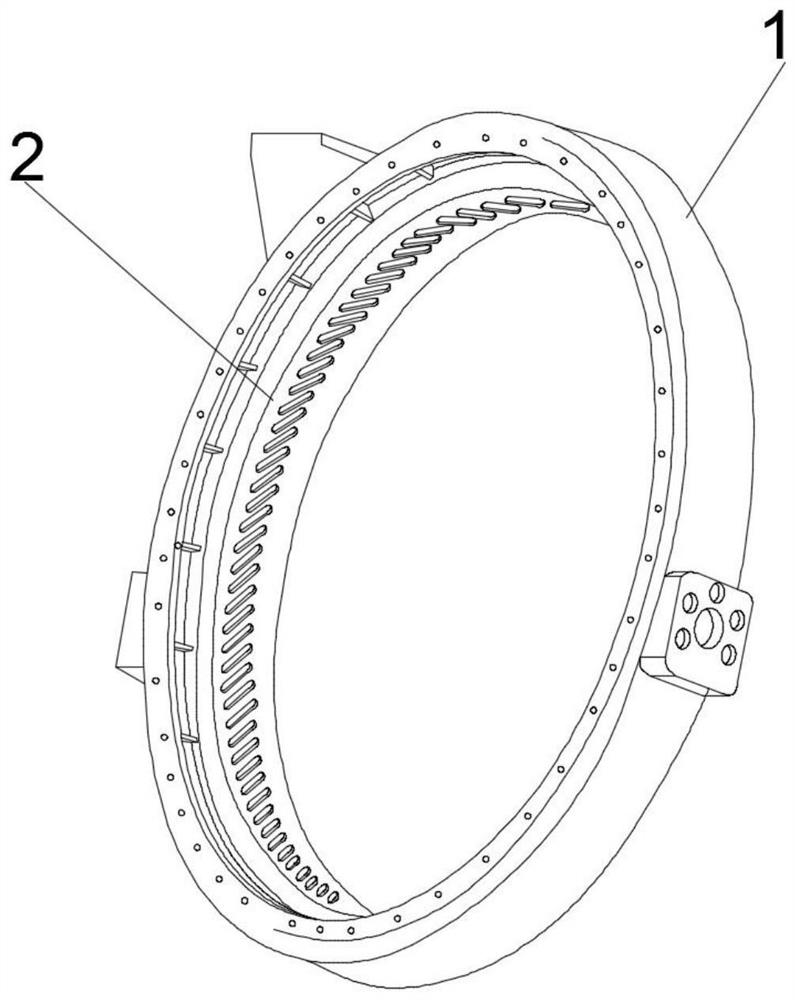

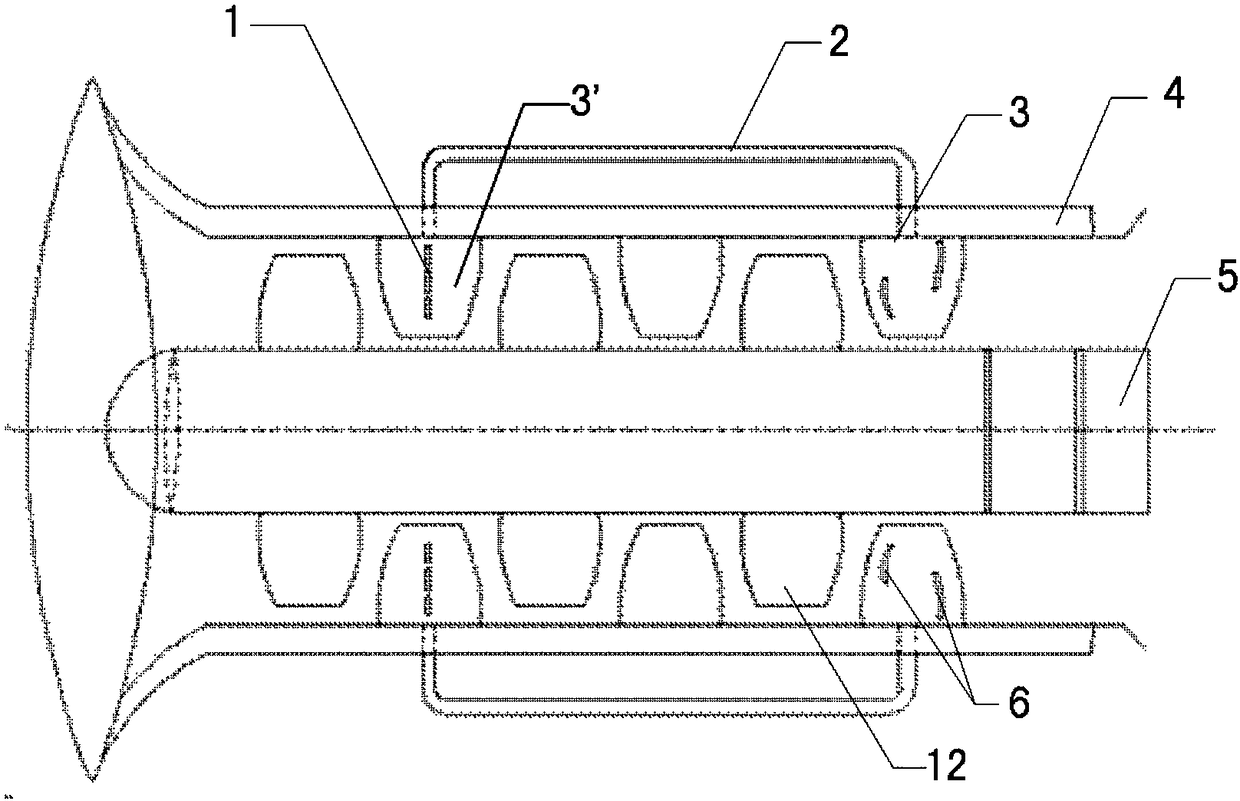

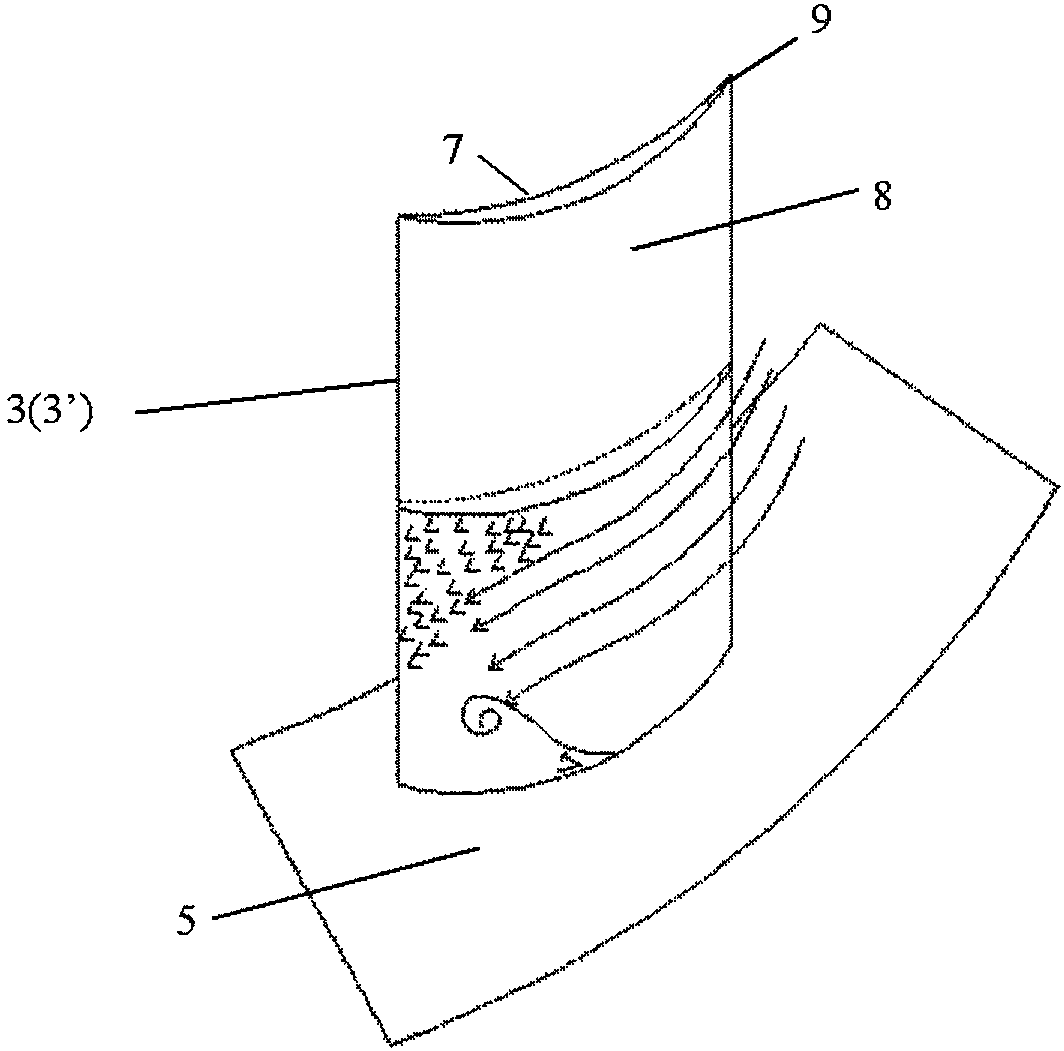

Low noise axial fan with rotary deflecting ring

InactiveCN1793665AEliminate vortexImprove the suction flow fieldPump componentsAxial flow pumpsEllipseImpeller

The invention relates to a low noise axial fan with rotating flow guide ring, comprising electric machine, vane, machine casing, bracket and wheel hub, where the wheel hub is arranged at the lower part of the machine casing, the electric machine is arranged above the wheel hub and coaxially connected with the wheel hub and fixed on the inner surface of the machine casing, the section of the bracket is streamlined, the vane is of an integral fixed vane angle profile and of a forward-swept shape, wide outside and narrow inside, and these vanes are not equidistantly arranged, and the link line of gravity centers of various sections of the vane forms an included angle <=30 deg. with its radial straight line. The lower inlet end of the machine casing is provided with rotating flow guide ring rotating with the vanes, the upper cylinder body of the flow guide ring is integrated with the vane circumference, and keeps a rotating gap from the inner diameter of the machine casing, a bottom circular arc flow guide ring is of a 1 / 4 ellipse in shape, and the lower annular end surface of the machine casing is arranged in the flow guide ring and forms an axial gap from a platform in the flow guide ring to be good for relatively rotating. The invention has remarkable noise-reducing and energy-saving effects.

Owner:SHANGHAI JIAO TONG UNIV

Mission-adaptive rotor blade

ActiveUS20120153073A1Easy to controlIncrease centrifugal forcePropellersPump componentsRotary wingFuselage

A rotorcraft may include an airframe and a rotor connected to the airframe. The rotor may include a hub and a rotor blade connected to the hub to extend radially away therefrom. The rotor blade may include biasing fibers, oriented to increase the twist of the rotor blade in response to an increase in the speed of rotation of the rotor corresponding to a mission, task, or maneuver.

Owner:SKYWORKS GLOBAL INC +1

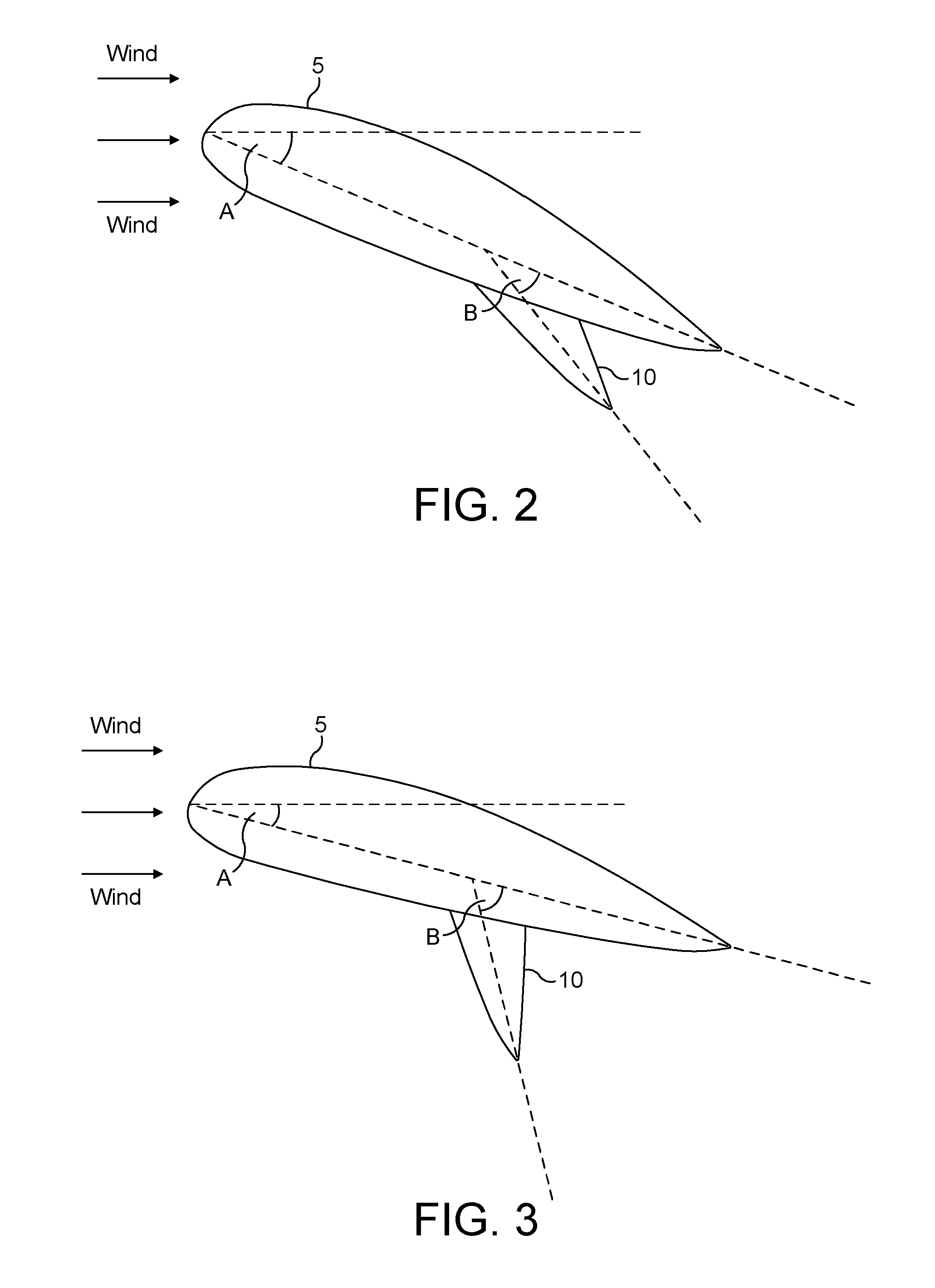

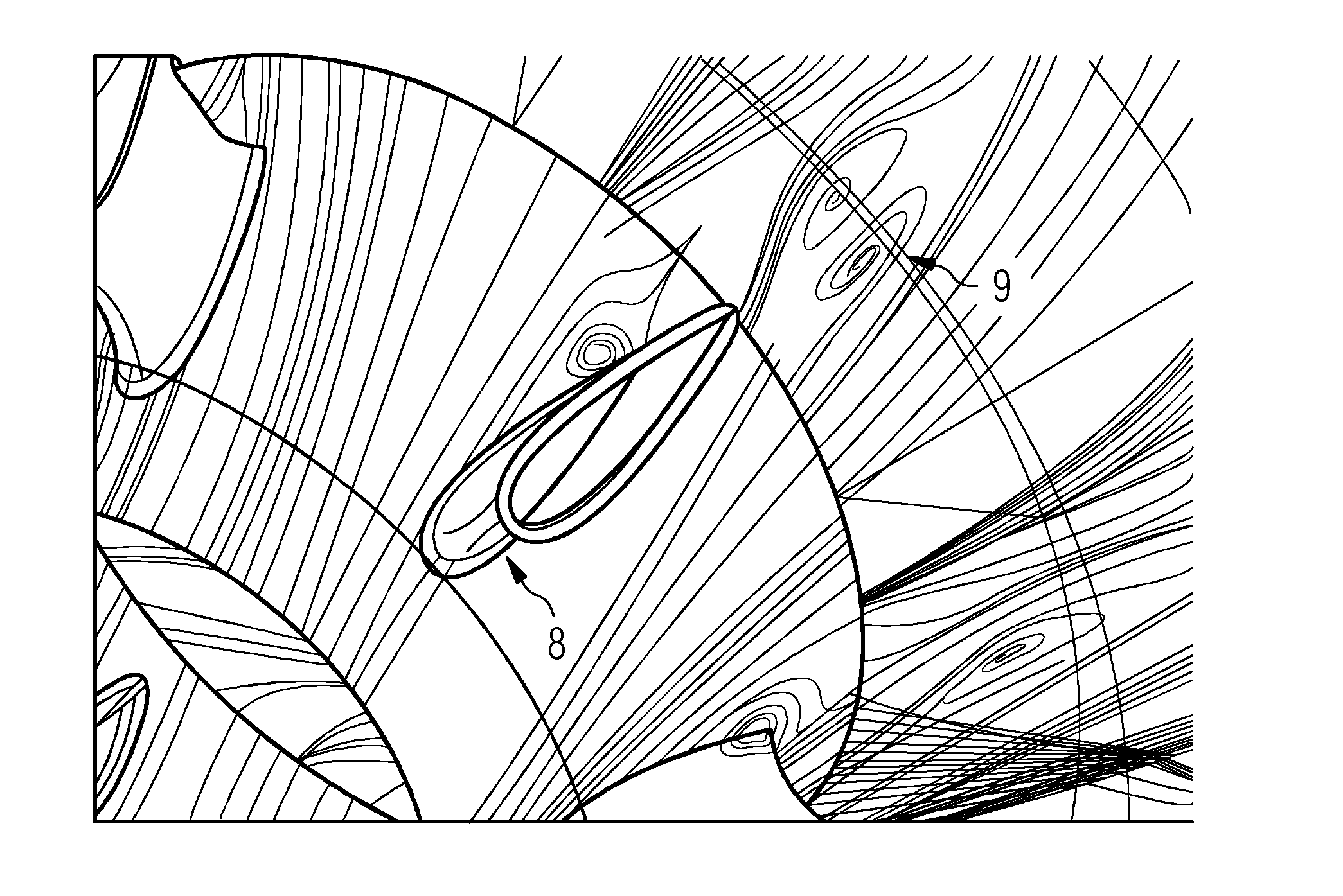

Wind turbine noise control methods

InactiveUS20140248148A1Reduce impact of noiseMaximise power outputPropellersPump componentsWind forceTrailing edge

A wind turbine having at least one trailing edge control surface (10) on at least one rotor blade (5) is operated in a first mode, in which a rotor blade angle of attack and a trailing edge control surface deflection are set according to one or more wind turbine control parameters. The turbine is selectively operated in a second, noise reduced, mode, in which for a given set of wind turbine control parameters, the trailing edge control surface deflection is increased towards the pressure side and the rotor blade angle of attack is decreased with respect to the first mode. In the second mode, for a given set of control parameters, the loading on the blade (5) is on average closer to a hub than in the first operating mode.

Owner:VESTAS WIND SYST AS

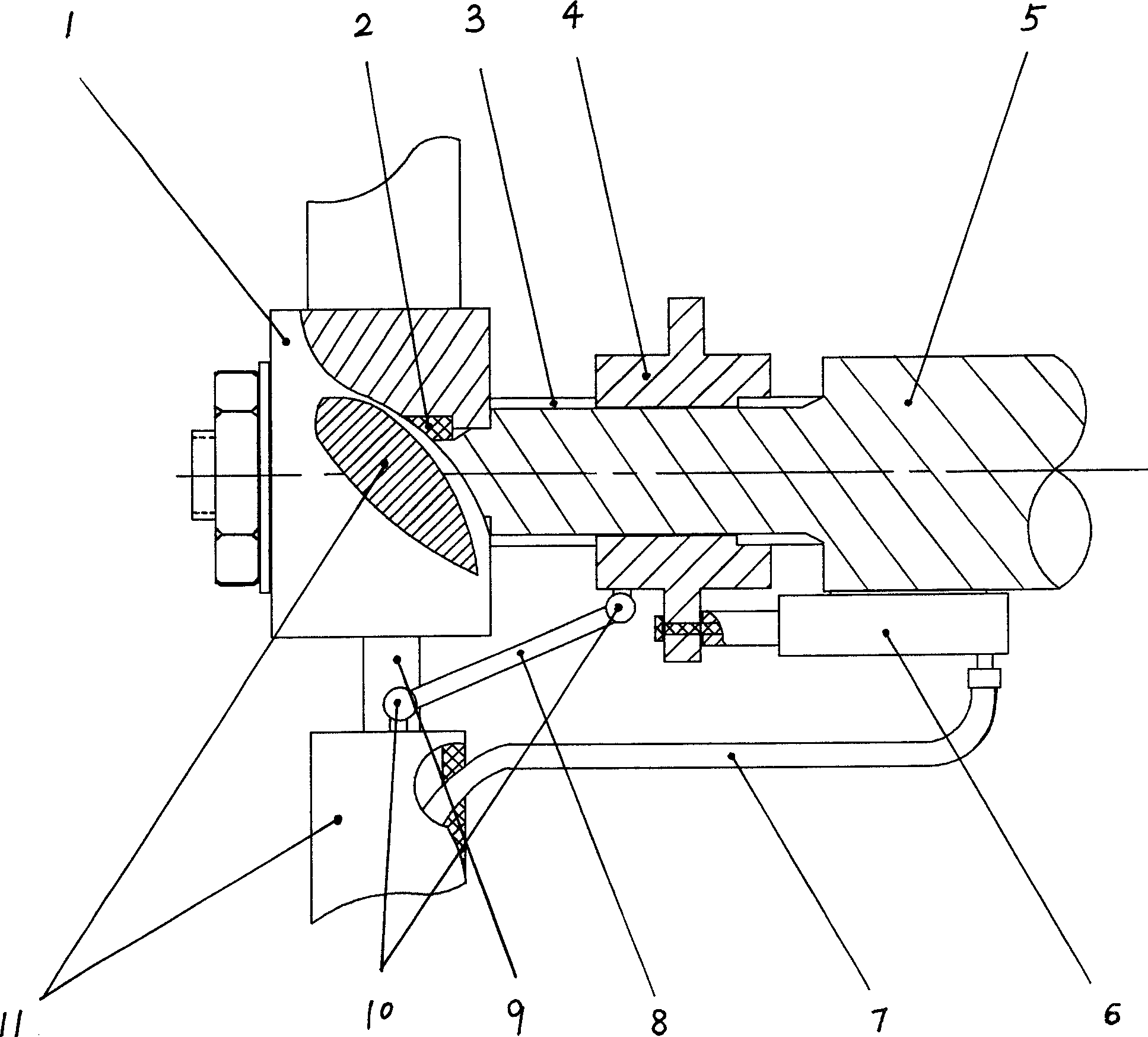

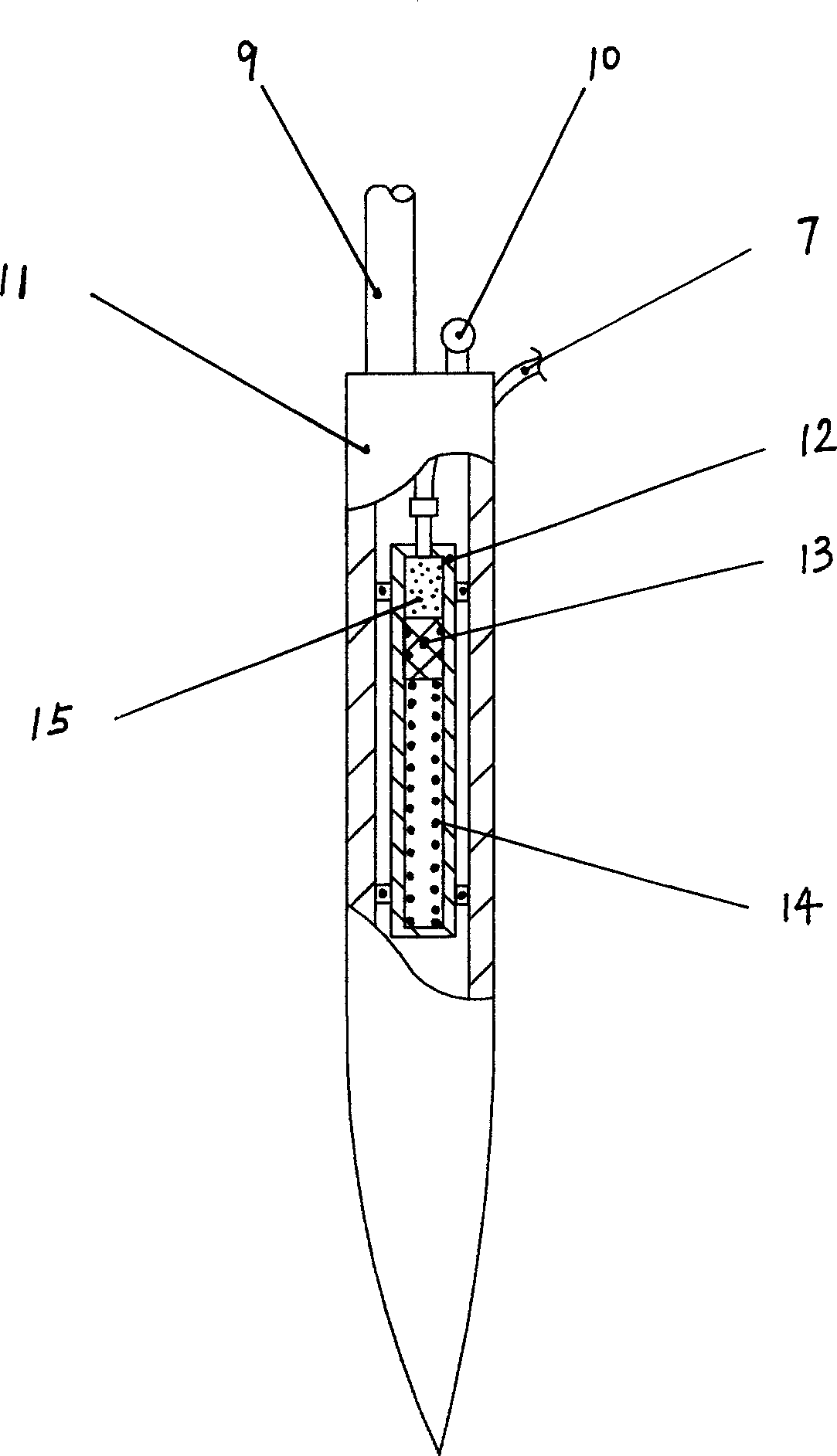

Hydraulic vane change device for wind-driven generator

InactiveCN1752439AReduce angle of attackTo achieve the purpose of automatic adjustmentWind motor controlMachines/enginesWind drivenHydraulic cylinder

In the invention, at least two rotary paddle shafts perpendicular to the main shaft is set on the propeller hub fixed on the main shaft. The paddle is mounted on the paddle shaft one by one. A slide-sleeve is disposed on the main shaft. The connecting heads are disposed beside of the paddle shafts on the paddles and on the slide-sleeve. Between the connecting heads are connected by the connecting-rods. The hydraulic cylinders with the same numbers as the paddles are mounted on the main shaft. The plunger of the hydraulic cylinder is connected on the slide-sleeve. The pressure liquid-storage tank is disposed in the paddle. The pressure liquid-storage tank is connected with the hydraulic cylinder via the pipeline.

Owner:朱汪逸

Method of operating a wind turbine

Method of operating a wind turbine comprising a plurality of blades rotatable along their longitudinal axes using a pitch mechanism, and comprising one or more movable trailing edge surfaces. The method includes predicting, at a first moment in time, a high load for one or more of the blades at a second moment in time. The method further comprises actuating on one or more of the movable trailing edge surfaces of these blades such that the trailing edge surfaces have a wider range of control to counteract the predicted high loads before the second moment in time, and simultaneously pitching the blades such as not to negatively affect the operation of the wind turbine. The method furthermore comprises, at the second moment in time, actuating the one or more movable trailing edge surfaces of the at least one or more blades to counteract the high loads.

Owner:GE RENEWABLE TECH WIND BV

Exhaust diffuser and method for manufacturing an exhaust diffuser

ActiveUS20140174052A1Extended angle rangeImprove pressure recoveryBlade accessoriesEfficient propulsion technologiesAngle of incidenceTurbine

An exhaust diffuser and method for manufacturing an exhaust diffuser is provided. An exhaust diffuser for a torque-generating turbine, in particular a torque-generating gas turbine is provided, the exhaust diffuser having an inner member, and the inner member having an outer surface. The outer member having an inner surface, and the inner member and the outer member forming an annular channel at least a first supporting strut connecting the inner member and the outer member, the supporting strut extending essentially radially from the inner surface to the outer surface, the supporting strut having a middle section, the middle section having a first airfoil and an outer section having a second airfoil, and the second airfoil having a higher angle of incidence than the first airfoil. Furthermore, it is described a method for manufacturing an exhaust diffuser.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

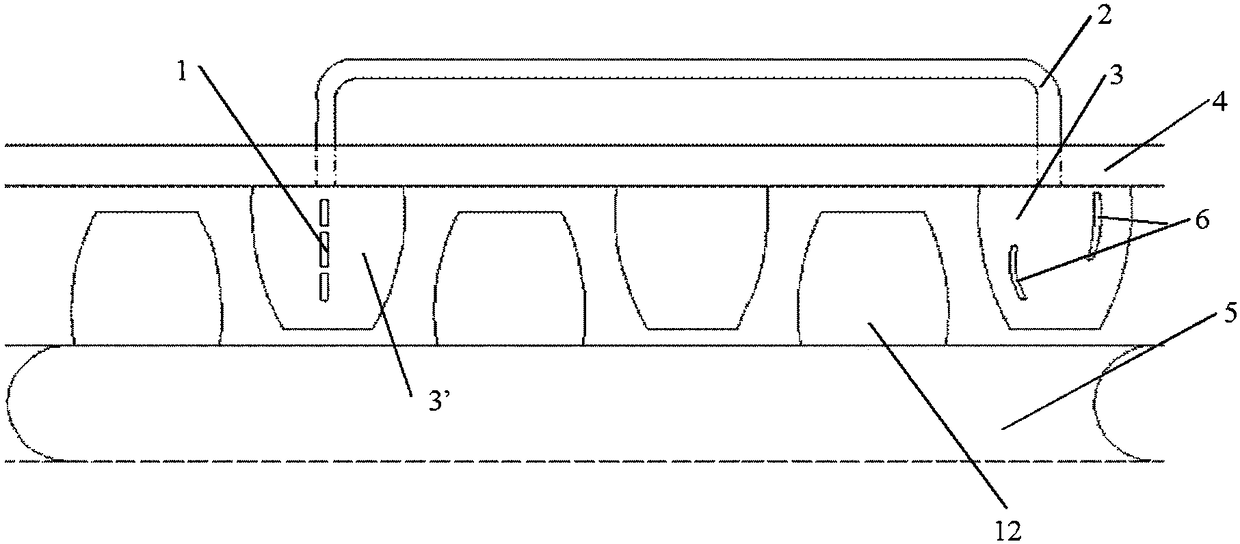

Gas turbine compressor casing anti-surge structure and surge margin evaluation method thereof

InactiveCN112160943AImprove flow statusReduce angle of attackPump componentsDesign optimisation/simulationEngineeringInlet flow

The invention discloses a gas turbine compressor casing anti-surge structure and a surge margin evaluation method thereof. The gas turbine compressor casing anti-surge structure comprises a compressorcasing, wherein a casing treatment section is arranged on the front portion of the compressor casing, the casing treatment section comprises an anti-flow-loss section inner cavity, an anti-flow-losssection inner ring is arranged on the inner side of the anti-flow-loss section inner cavity, an axial chute is formed in the anti-flow-loss section inner ring and communicates with a backflow cavity in the anti-flow-loss section inner cavity, and a radial baffle is arranged in the anti-flow-loss section inner cavity; the axial chute rotates by 90 degrees along the radius line of the circle where the axial chute is located, is parallel to the blade chord line of a rotor blade, and rotates by 45 degrees along the axis of the circle where the axial chute is located; by changing the structure of the axial chute, the air inlet amount and the air inlet flowing condition are changed; and meanwhile, an exhaust section is optimized, the axial speed is increased, the flow coefficient is increased, the flowing state with the too large top attack angle is improved, stability expansion is effectively carried out, and the beneficial effects of effectively reducing the increased air amount, reducingthe attack angle at the blade tip of a movable blade and reducing the flow of a stall point are achieved.

Owner:NAVAL UNIV OF ENG PLA

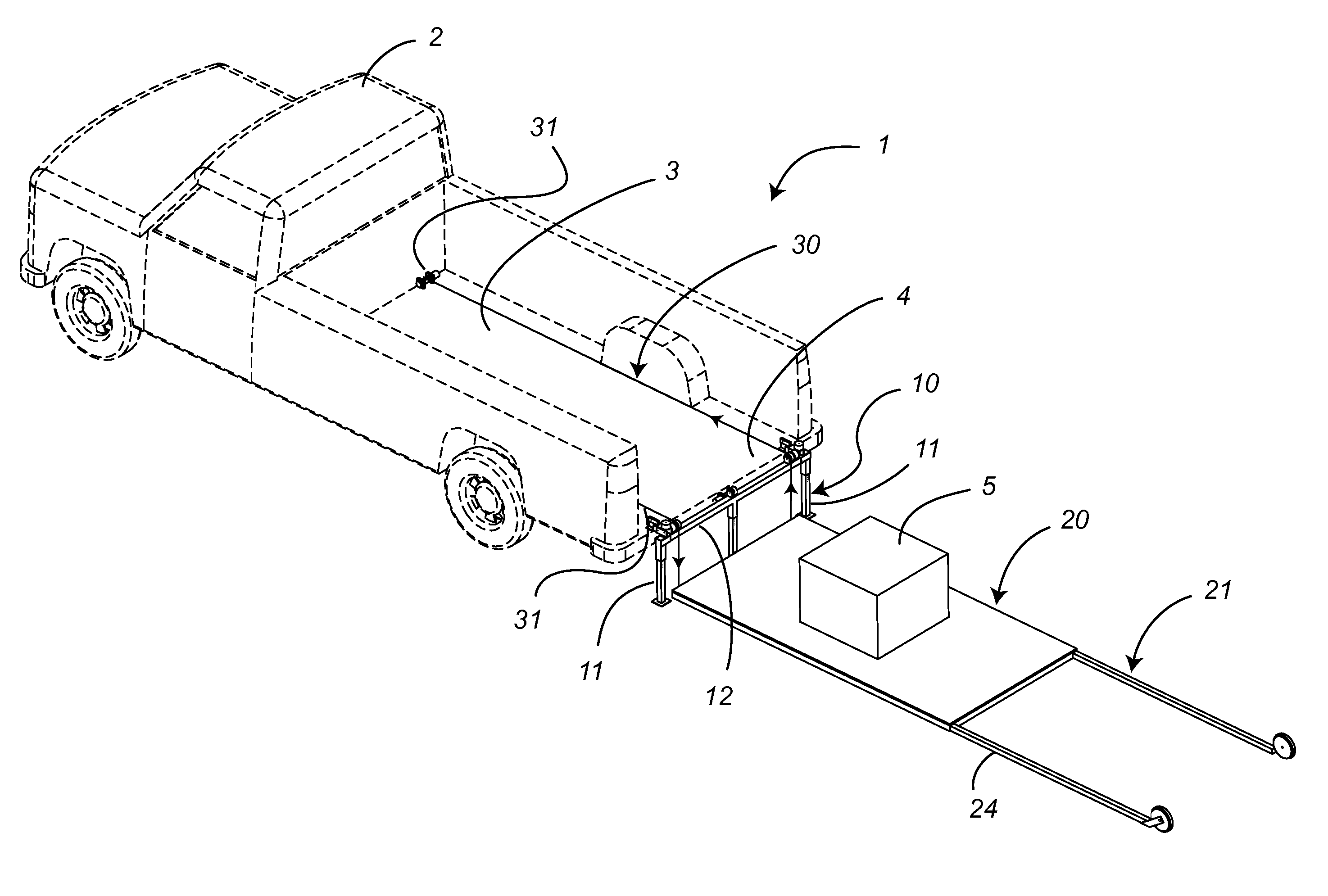

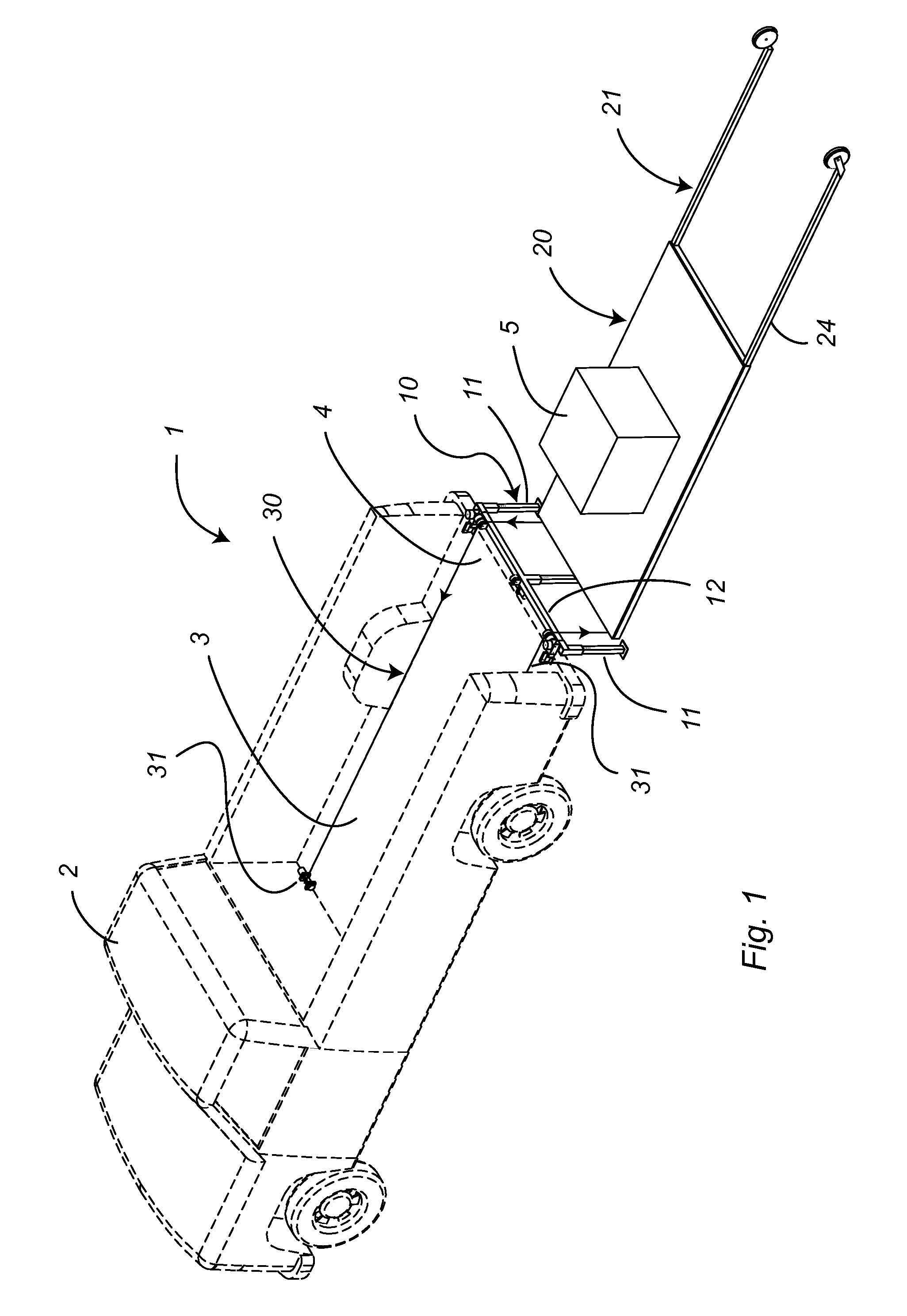

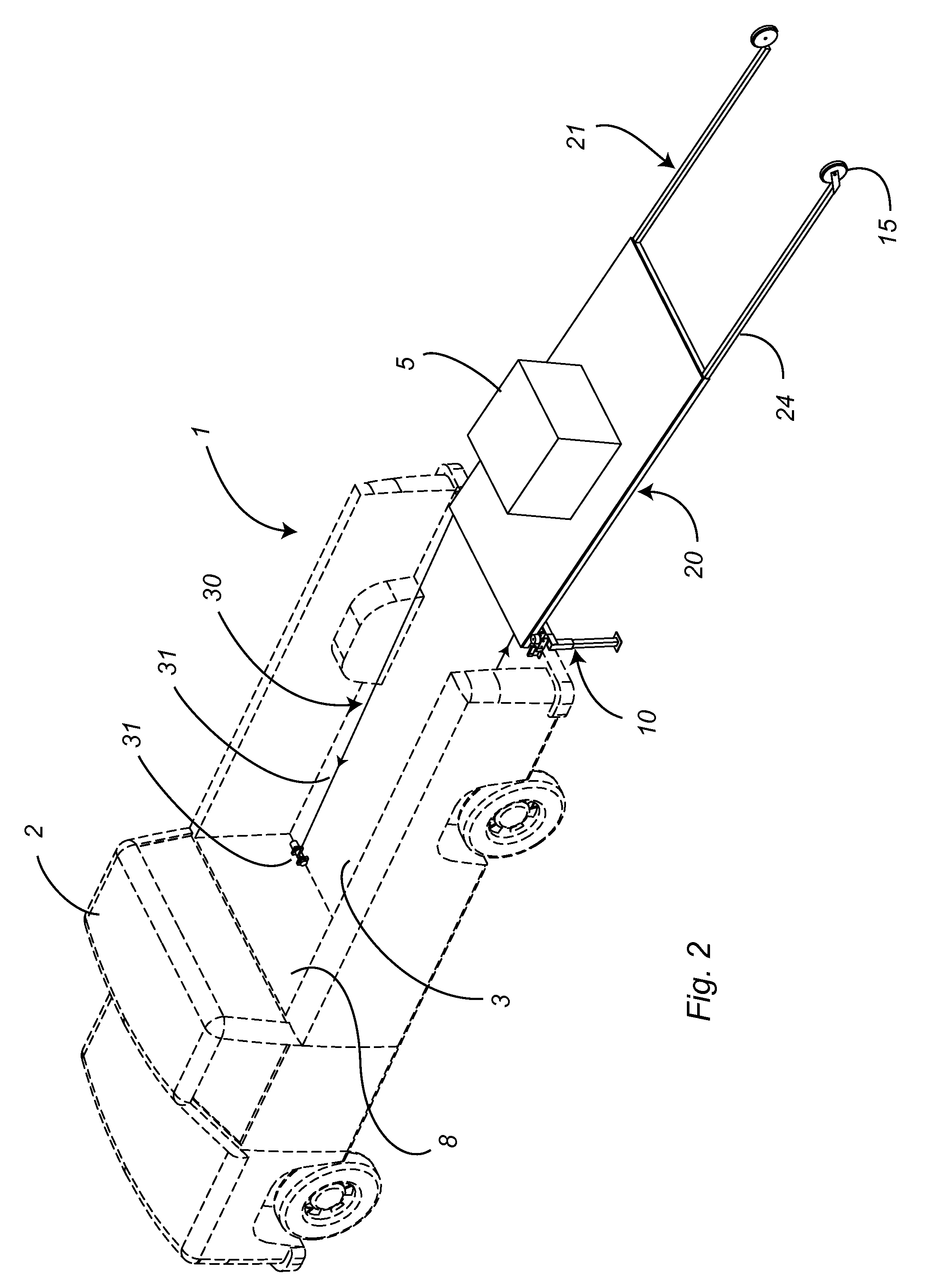

Truck loading device

InactiveUS9011073B2Minimized pitchRigid enoughVehicle with removable loadingRefuse receptaclesPickup truckControl theory

Owner:DIEZIGER HELEN IRENE

Control bar with outer steering line trim and sheeting system for sport kite

InactiveUS8398030B2Shorten the effective lengthIncreasing angle of attackAircraft componentsMarine propulsionJoystickControl system

A kite control system having a control bar adapted with an internal sheeting system that provides trim / sheeting control by adjustment of outer steering lines which are attached at or near the rear corners of the kite. A tubular control bar is adapted such that the outer steering lines are routed through the interior of the control bar through openings at each opposing end. The outer steering lines are each joined to a sheeting control line which extends back out one of the opposing ends in either a left hand actuated or right hand actuated embodiment. A fixed pin located approximately mid-length within the control bar provides a fixed structure about which one of the outer lines and / or sheeting control line is routed in U-turn fashion. By pulling the sheeting control line from the end of the control bar, the rider can shorten the effective length of the outer steering lines thereby increasing the angle of attack so as to power up the kite. By releasing the sheeting control line such that it is drawn into the control bar, the ride can allow the outer steering lines to fully deploy thereby reducing the angle of attack so as to depower the kite. The control bar is equipped with means for selectively fixing the sheeting control line so as to achieve a desired angle of attack.

Owner:RIDE BEST

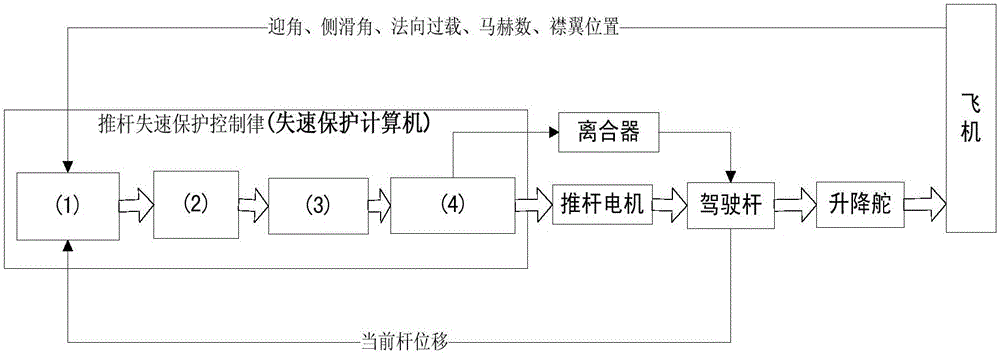

Push rod stalling protection control method

ActiveCN106347636AAvoid stallDoes not affect flight qualityActuated automaticallyActuated personallyLower limitEngineering

The invention belongs to a flight control technology and provides a push rod stalling protection control method. The push rod stalling protection control method comprises the following steps: calculating a final rod displacement instruction of push rod stalling protection, wherein the final rod displacement instruction is zero during initialization and is resolved by a push rod instruction during real-time operation, the output displacement instruction is equal to the push rod instruction plus the upper limit of the velocity threshold if the push rod instruction minus the current rod displacement instruction is more than the upper limit of a preset velocity threshold, the output instruction is equal to an input instruction plus the lower limit of the velocity threshold if the push rod instruction minus the current rod displacement instruction is less than the lower limit of the preset velocity threshold, and the final rod displacement instruction is equal to the push rod instruction under other conditions; finally, outputting the final rod displacement instruction if the final rod displacement does not exceed the preset upper limit and lower limit values, outputting the upper limit value if the final rod displacement exceeds the upper limit value, and outputting the lower limiting value if the final rod displacement exceeds the lower limit value.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC +1

Active variable front wing of formula car

InactiveCN106428257AIncrease air intakeImprove combustion efficiencyAerodynamics improvementVehicle body streamliningFixed wingCar controls

The invention discloses an active variable front wing of formula car which compromises a fixed wing piece arranged on the inner side of a front wing end plate, a connection device for forming a rotation between the fixed wing and the end plate, a driving mechanism for driving the fixed wind piece to rotate a certain angle, a speed detector and an acceleration detector which are arranged on a car and used for detecting the car running state, a water temperature detector arranged at a cooling system. The water temperature detector and the driving mechanism are respectively connected with a car control unit. The active variable front wing of formula car can adjust the angle of the front fixed wing piece according to the car running state and the temperature of the engine, thus, the air resistance is reduced in acceleration, the amount of air input in the side box of the formula car is increased, the efficiency of the engine is improved,and the dynamic performance of the car is improved.

Owner:JILIN UNIV

Arable pitch mounting for aircraft gas turbine engine

ActiveCN105691623AReduce angle of attackGas turbine type power plantsPower plant constructionAviationTemporal information

The light source control apparatus controls drive of multiple light sources included in a light source unit to be used in a state where the multiple light sources are lit. The multiple light sources each include multiple light-emitting elements. The light source control apparatus includes an acquirer acquiring temporal information relating to a temporal change of each of the light sources, an estimator acquiring an estimated lifetime of each of the multiple light sources by using the temporal information, and a controller decreasing, when the multiple light sources include a first light source whose estimated lifetime is shorter than a target lifetime set for the light source unit, a light emission amount of the first light source.

Owner:GENERAL ELECTRIC CO

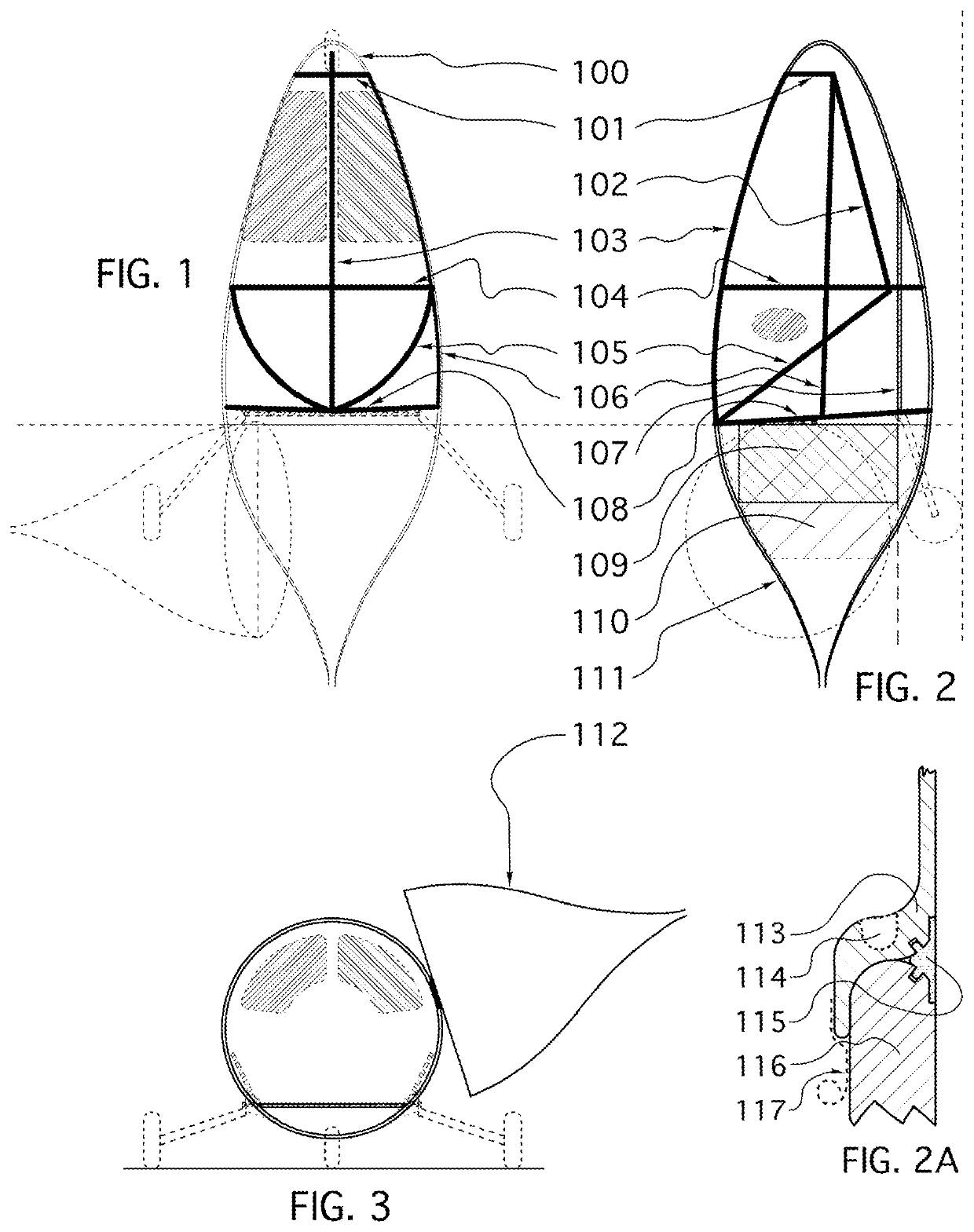

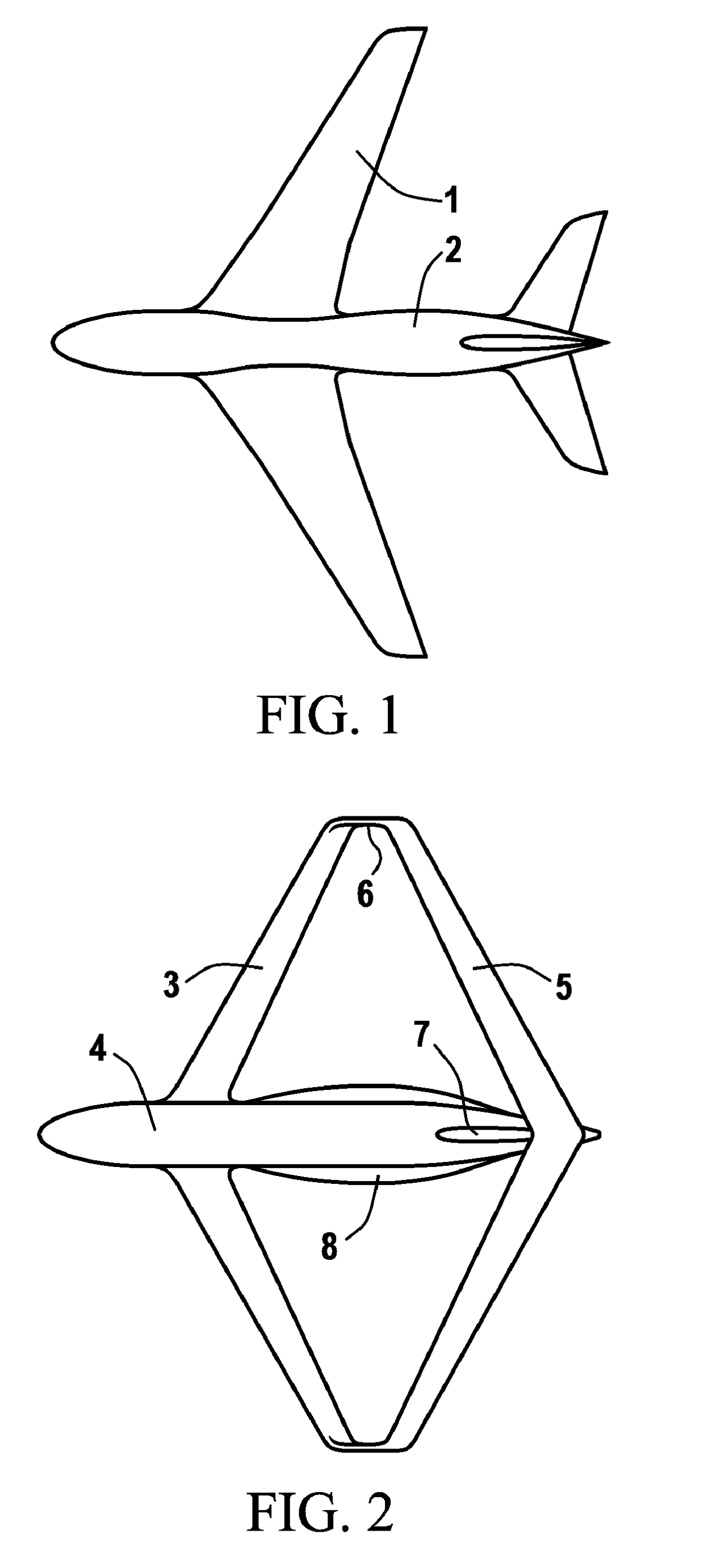

Methods for improvements of the box wing aircraft concept and corresponding aircraft configuration

ActiveUS20170297708A1Good maneuverability and stabilityReduce speedAircraft stabilisationWing shapesAirplaneStream flow

Aircraft configuration by applying the following method steps for improving the conventional box wing aircraft concept: dividing both the backward swept front and the forward swept rear wings into root and tip sections, wherein the tip sections (34) of the front wings are more backward swept than the root sections (37), and the tip sections (35) of the rear wings are more forward swept than the root sections (38). Preferred embodiments comprise moving the front wing to the nose and the rear wing towards the rear end of a long fuselage; adding a middle wing and thereby decreasing the wingspan by one third; dividing the middle wing into a backward swept root section (28) and two tip sections (29,30), one forward and another backward swept. The four wingtips on each side are interconnected by a wingtip fence (26), obtaining seven closed frame structures, as well as seven aerodynamic channels for the stream flow.

Owner:HERNADI ANDRAS

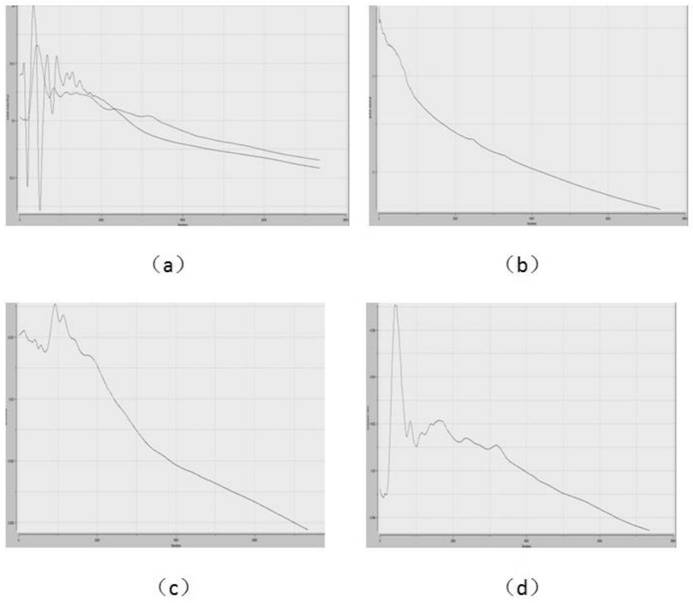

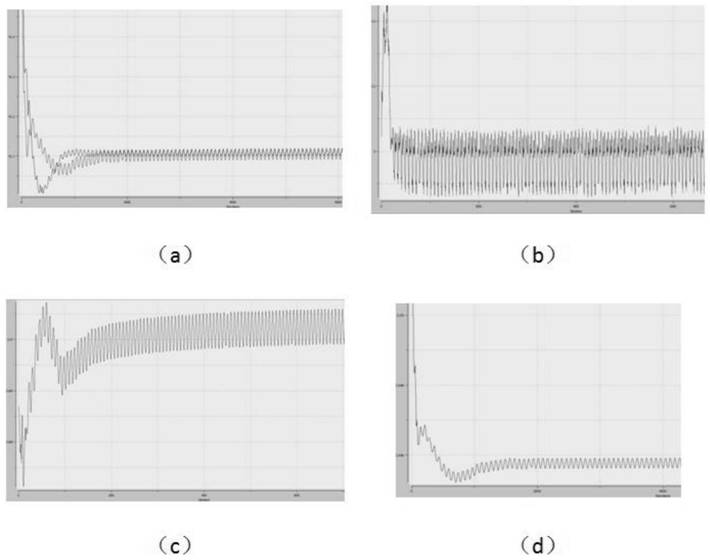

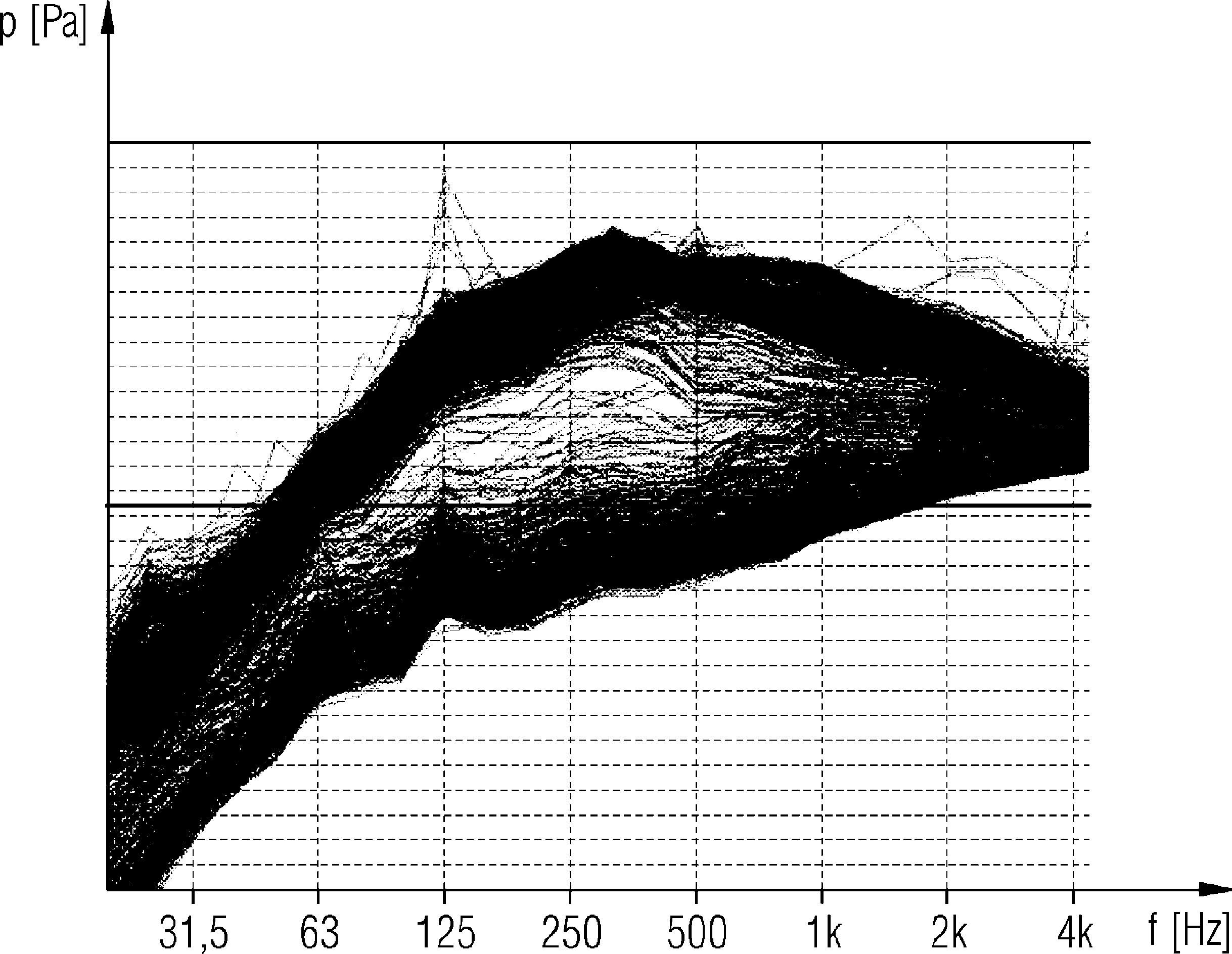

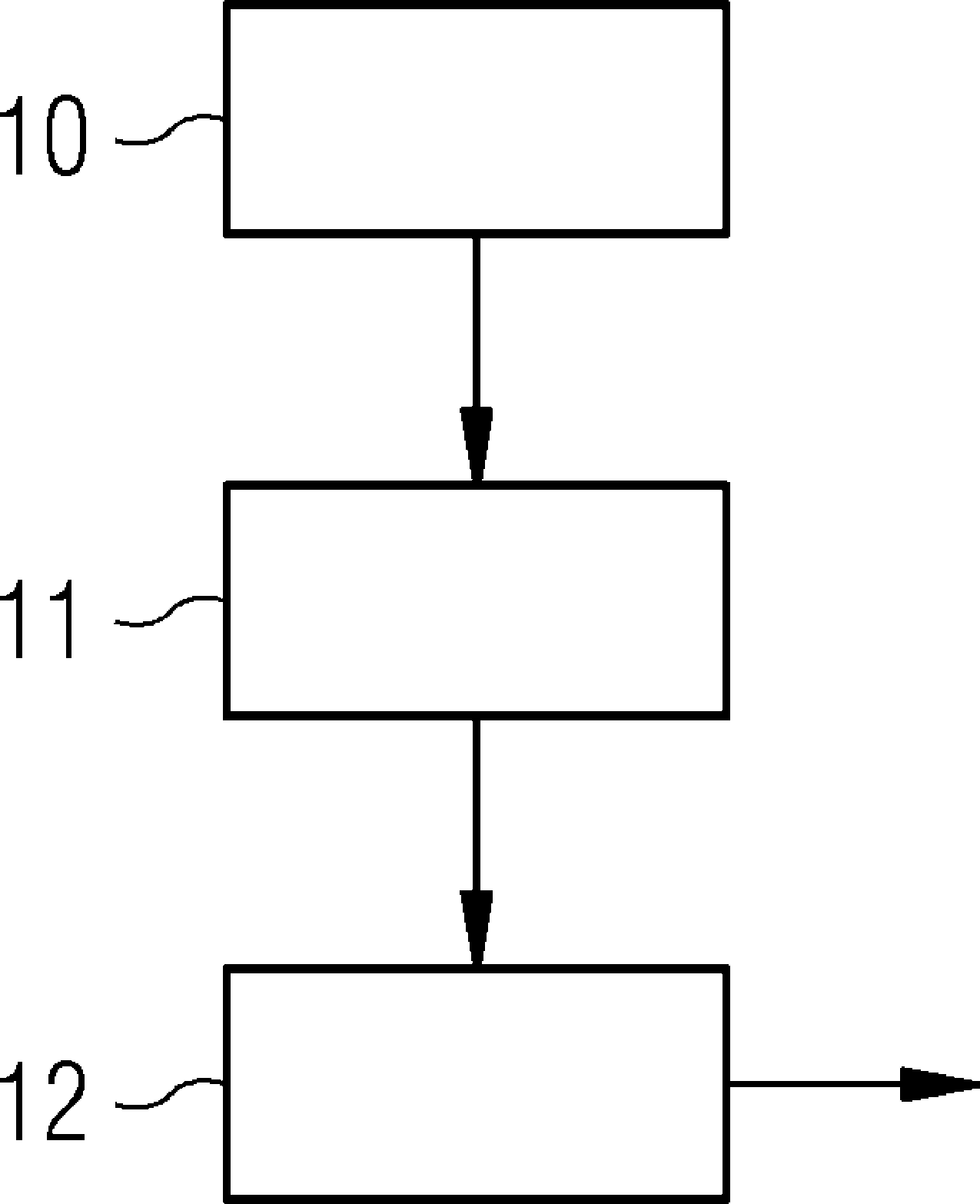

Stall detection of wind turbine blades

InactiveCN103528670AExtend your lifeIncreased power productionSubsonic/sonic/ultrasonic wave measurementWind motor controlFrequency spectrumTurbine blade

The invention provides a stall sensor for a wind turbine, a wind turbine comprising such a stall sensor and a method of operating such a wind turbine. The stall sensor comprises detector means (10) adapted to measure vibration of a rotor blade of the wind turbine and to output a vibration signal representative of the vibration of the rotor blade, conversion means (11) connected to the detector means (10) and adapted to determine a noise figure representative of a spectral signal content within a frequency band of the vibration signal received from the detector means (10) and arbiter means (12) connected to the conversion means (11) and adapted to signal a presence or an absence of stall based on the noise figure received from the conversion means (11).

Owner:SIEMENS AG

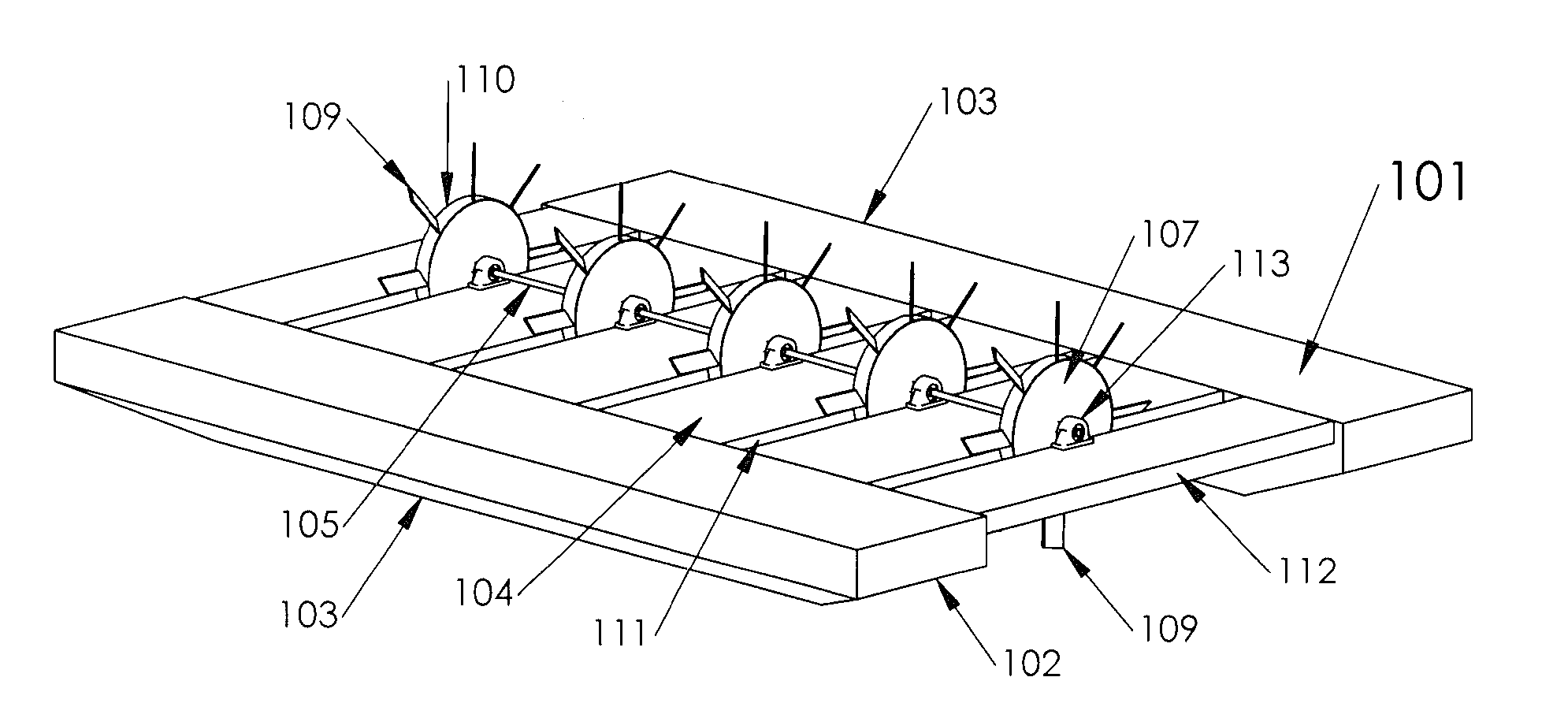

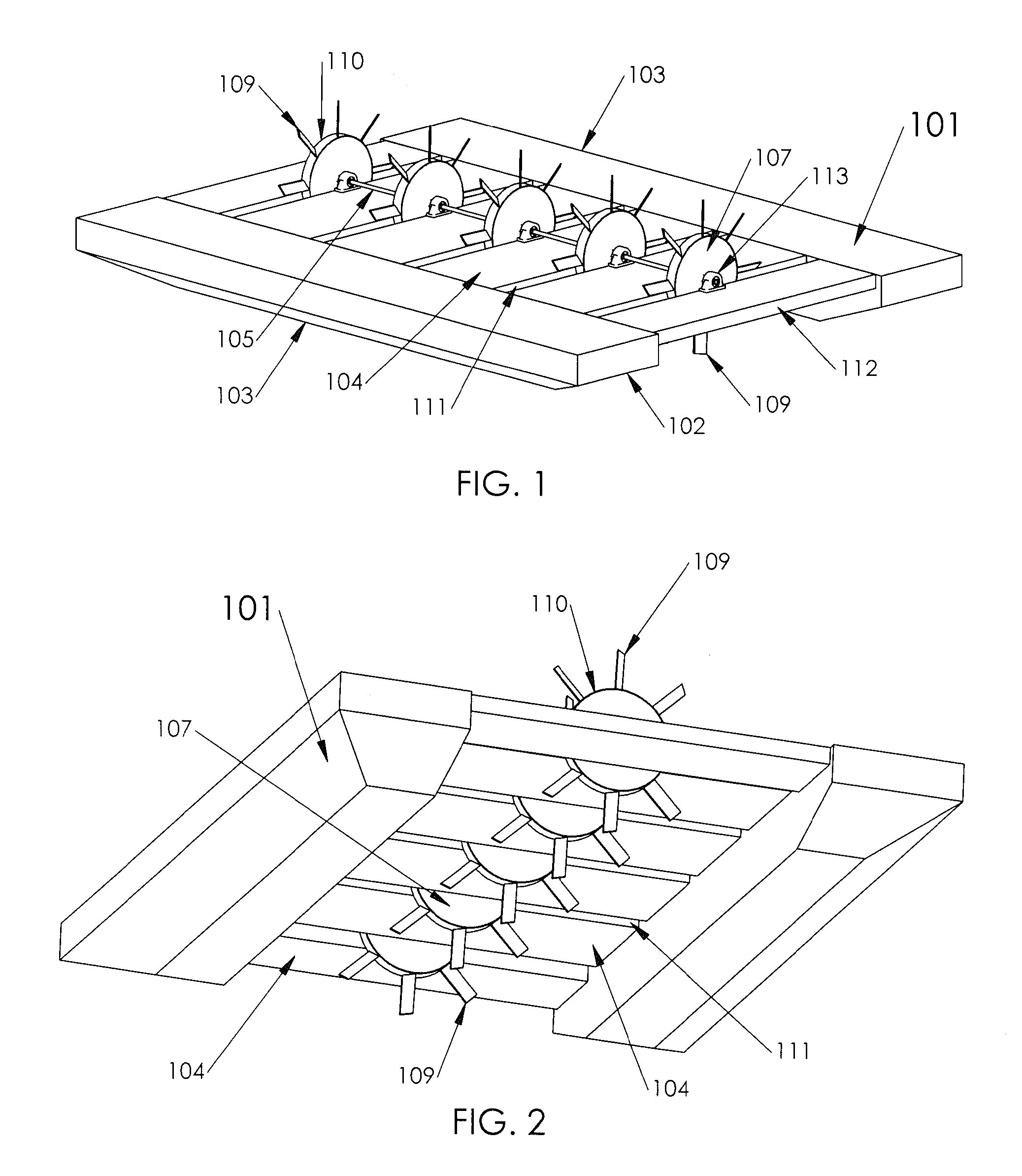

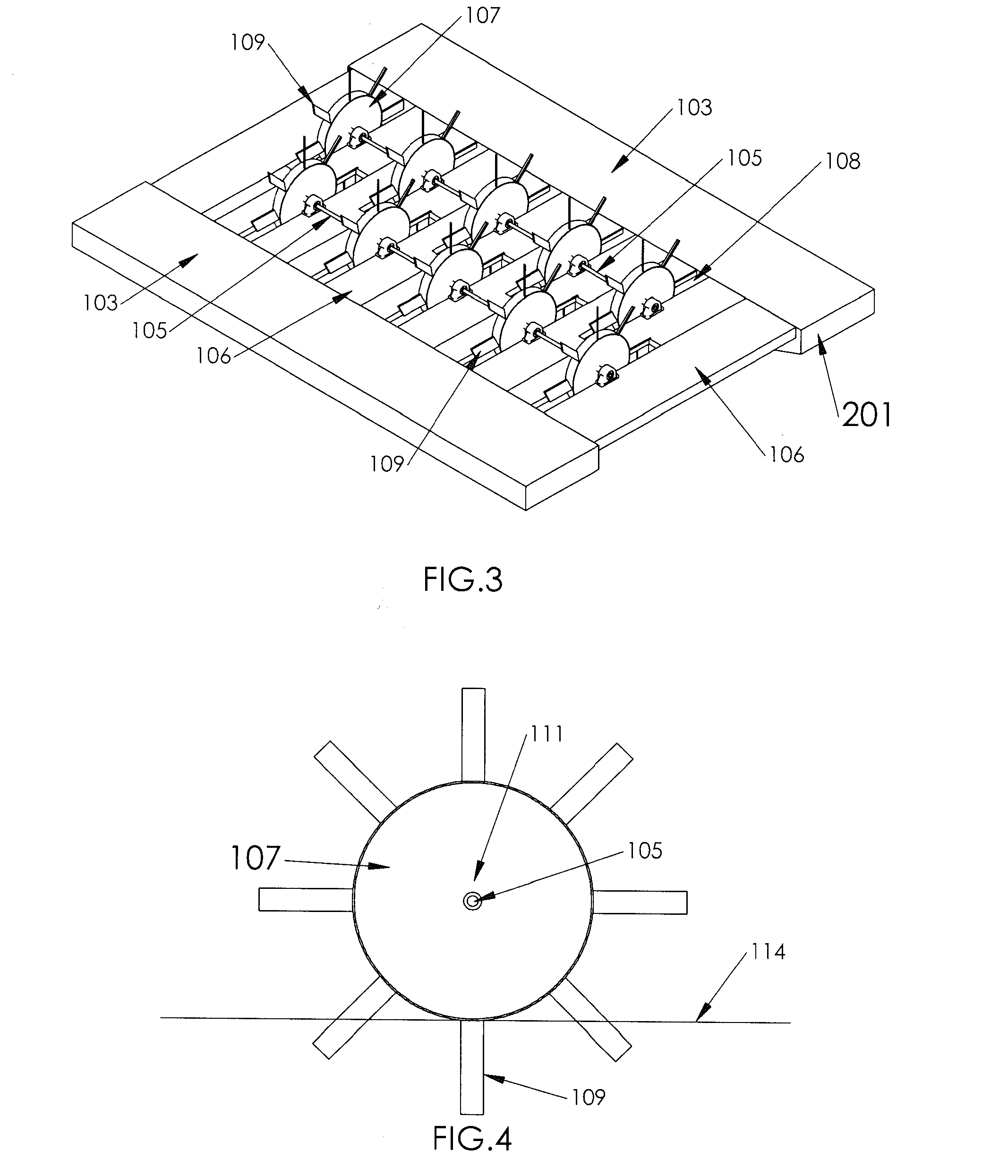

Surface piercing tidal generator

InactiveUS20100013228A1Alter attack angleIncrease attack angleMachines/enginesEngine componentsMarine engineeringMoving body

A tidal generator includes a floating structure and a shaft that is supported over a moving body of water. The shaft is coupled to multiple rotors that have pitched blades that extend radially from the center of the rotor. Portions of the lower blades are submerged in the moving water. The movement of the water relative to the tidal generator causes the rotors and shaft to rotate. The shaft is coupled to an electrical generator.

Owner:DUGGLEBY TONY +2

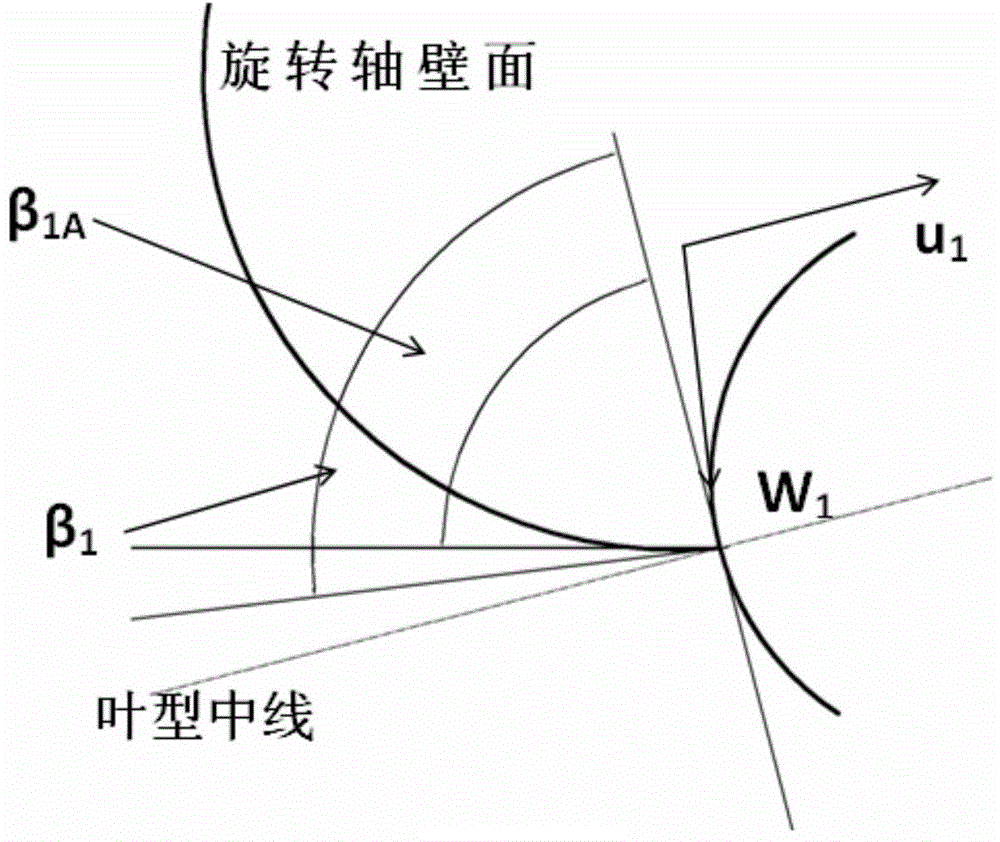

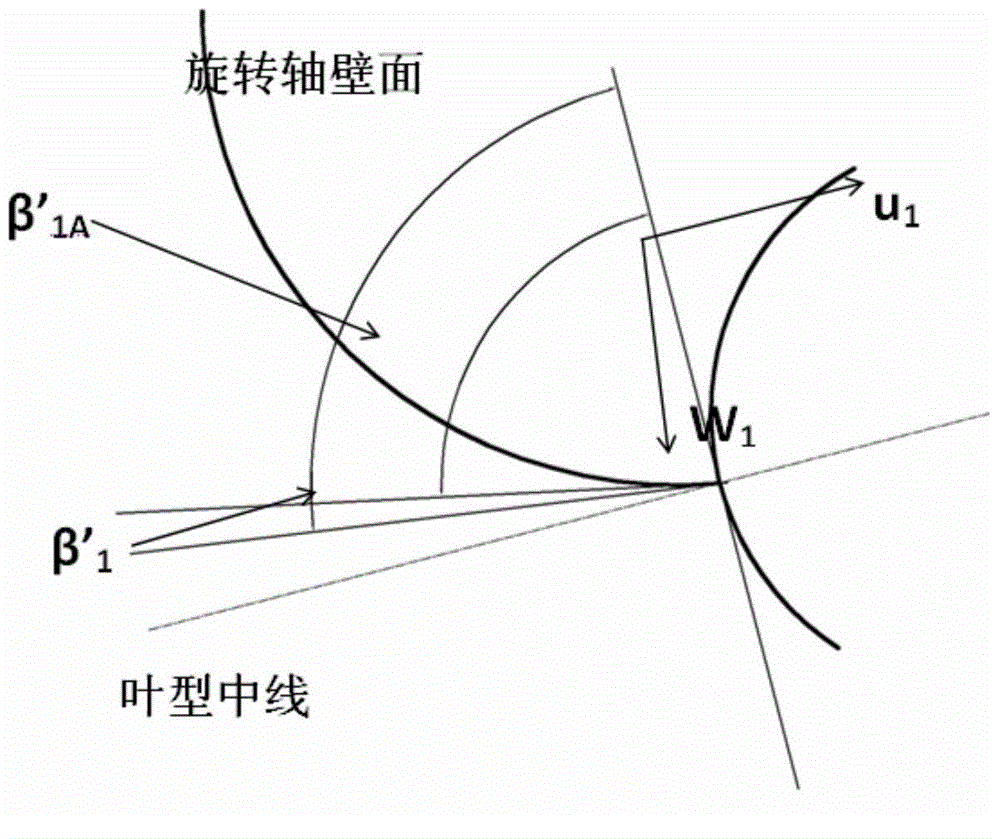

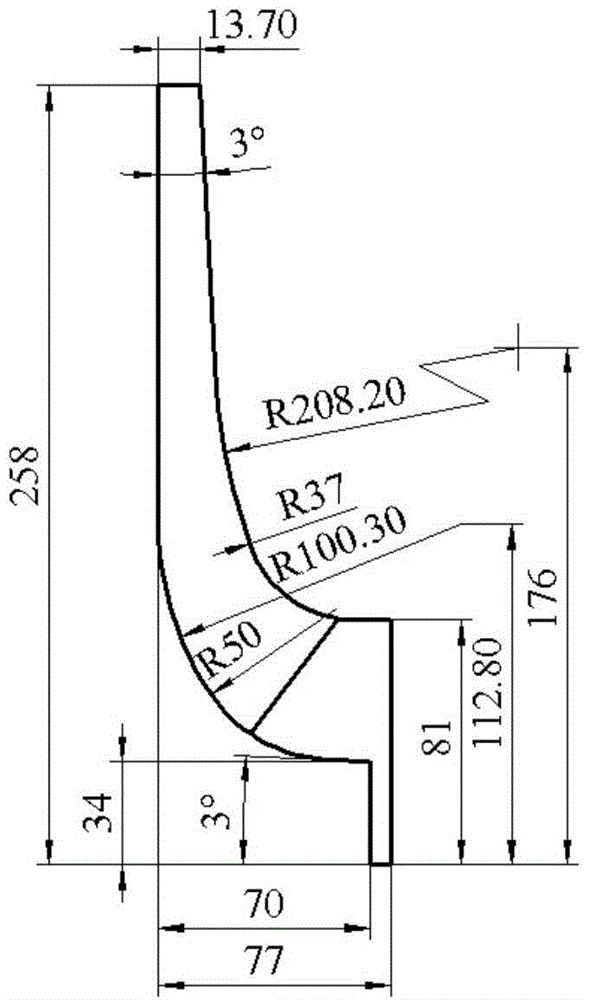

Method for improving cavitation-erosion performance of centrifugal pump

The invention relates to a method for improving the cavitation-erosion performance of a centrifugal pump. According to the method for improving the cavitation-erosion performance of the centrifugal pump, through the reducing of a blade head impact angle, the impact of a blade and incoming flow is reduced, the impact condition of impeller head liquid flow and the blade is improved, and the adaptation to the incoming flow can be better achieved. The width of an impeller channel is increased, the curves of a front cover plate and a back cover plate are adjusted, the impact loss due to the fact that the liquid flow is absorbed into the impeller from an outlet position is reduced, the effective working area of the centrifugal pump is improved, and the energy waste is reduced. Through the above improvement, the speed of fluid in the pump is more even, the phenomenon of over low local pressure is improved, and therefore the cavitation-erosion performance of the centrifugal pump is improved.

Owner:CHINA JILIANG UNIV

Reciprocating fluid energy device

ActiveUS9732724B1Significant turbulenceSmall surface areaWorking fluid for enginesHydro energy generationEngineeringEnergy device

A reciprocating fluid-energy device to be used in a flowing fluid, having a foil, an upstream support member, a downstream support member, and a frame, where the frame retains the device in place within the flowing fluid, the support members movably attach the foil to the frame, and the foil moves laterally back and forth across the direction of the flow of the fluid, with changes in direction of the movement of the foil occurring automatically and spontaneously without external intervention other than the force of the flowing fluid.

Owner:BURKE THOMAS J

Electric locomotive and city rail vehicle single-motor drive double-shaft way and bogie thereof

InactiveCN101104409AReduce angle of attackReduce wear and tearElectric locomotivesInterference fitBogie

Disclosed is a monomotor-driven double-shaft steering bogie for power cars and urban rail vehicles, comprising a truss, a brake shoe, a brake disc, an oscillating damper, wheels, wheel-countershafts, a drive motor, a shaft join, gear cases and a secondary spring. The invention is characterized in that the steering bogie has two shafts and is driven only by one motor, that means one motor drives the two shafts of the steering bogie synchronously. The drive motor is arranged at the middle part of the steering bogie and two gear cases are disposed at the two sides of the drive motor; two ends of the shaft of the drive motor are respectively connected with the two wheel-countershafts through the gears in the two gear cases; the drive motor is mounted on the beam of the truss and the shaft of the motor is parallel to the wheel-countershafts. The shaft of the motor is connected with the shafts of the drive gears in the gear cases; gear clusters are arranged inside the gear cases to shift gears. One gear cluster consists of a drive gear, an idle gear and a gearwheel; the gearwheels are fixed with the wheel-countershafts through interference fit and the wheel-countershafts are fixed with the wheels through interference fit. When the drive motor is galvanized, the shaft of the motor drives the drive gears to rotate and the drive gears drive the gearwheels to rotate through the idle gears; the interference fits between the gearwheels and the wheel-countershafts, and the interference fits between the wheel-countershafts and the wheels make the wheels to rotate, then the vehicle starts to move.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Multistage axial flow compressor with inter-static-blade self-circulating gas suction and injection functions

InactiveCN108661953AIncreased stability marginImprove efficiencyPump componentsAxial flow pumpsStability marginEngineering

The invention provides a multistage axial flow compressor with the inter-static-blade self-circulating gas suction and injection functions. The multistage axial flow compressor comprises a casing, a hub, N rows of static blades, a self-circulating gas suction and injection device and M rows of movable blades, wherein the hub is arranged at the center axis position of the casing, the N rows of static blades are arranged on the inner side of the casing in the axial direction of the casing, the self-circulating gas suction and injection device is arranged between one high-pressure-stage static blade and another low-pressure-stage static blade of the N rows of static blades, the M rows of movable blades are arranged on the outer side of the hub in the axial direction of the casing, the movableblades and the static blades are arranged in a staggered mode, N is greater than or equal to 2, M is greater than or equal to 1, and the self-circulating gas suction and injection device guides gas on suction surfaces of the high-pressure-stage static blades guided back to suction surfaces of the low-pressure-stage static blades for boundary-layer gas injection by utilizing the static pressure difference between the high-pressure stage and the low-pressure stage in the multistage axial flow compressor. According to the multistage axial flow compressor, the beneficial effects of boundary-layergas suction and injection technologies can both be achieved, so that the dual purposes of improving the stability margin and improving the efficiency can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com