Hydraulic vane change device for wind-driven generator

A wind turbine and hydraulic technology, which is applied to wind turbines, wind turbine control, wind power generation and other directions, can solve the problems of complex structure, difficult maintenance and slow response of variable-pitch fans, and achieves simple structure, convenient maintenance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

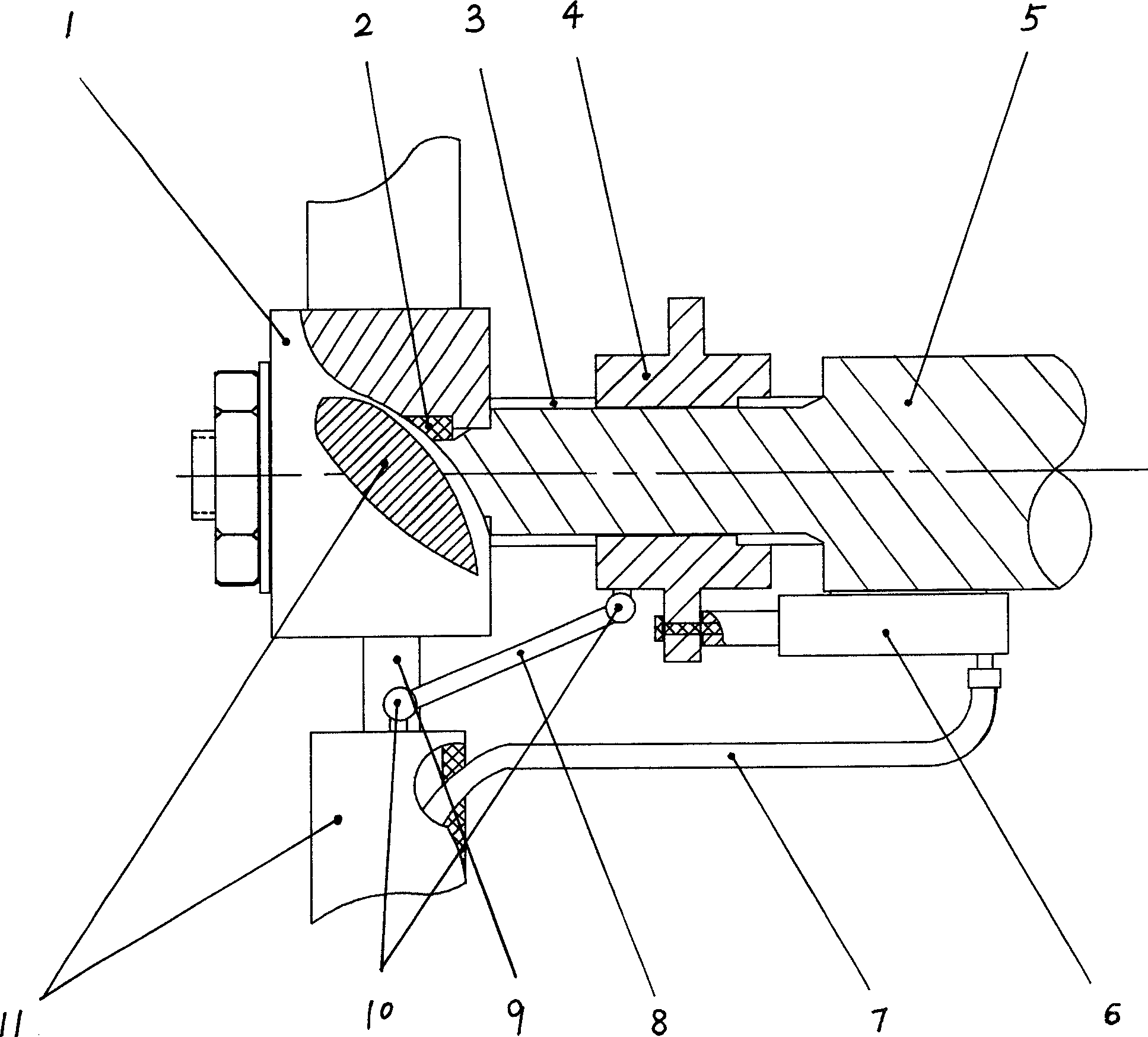

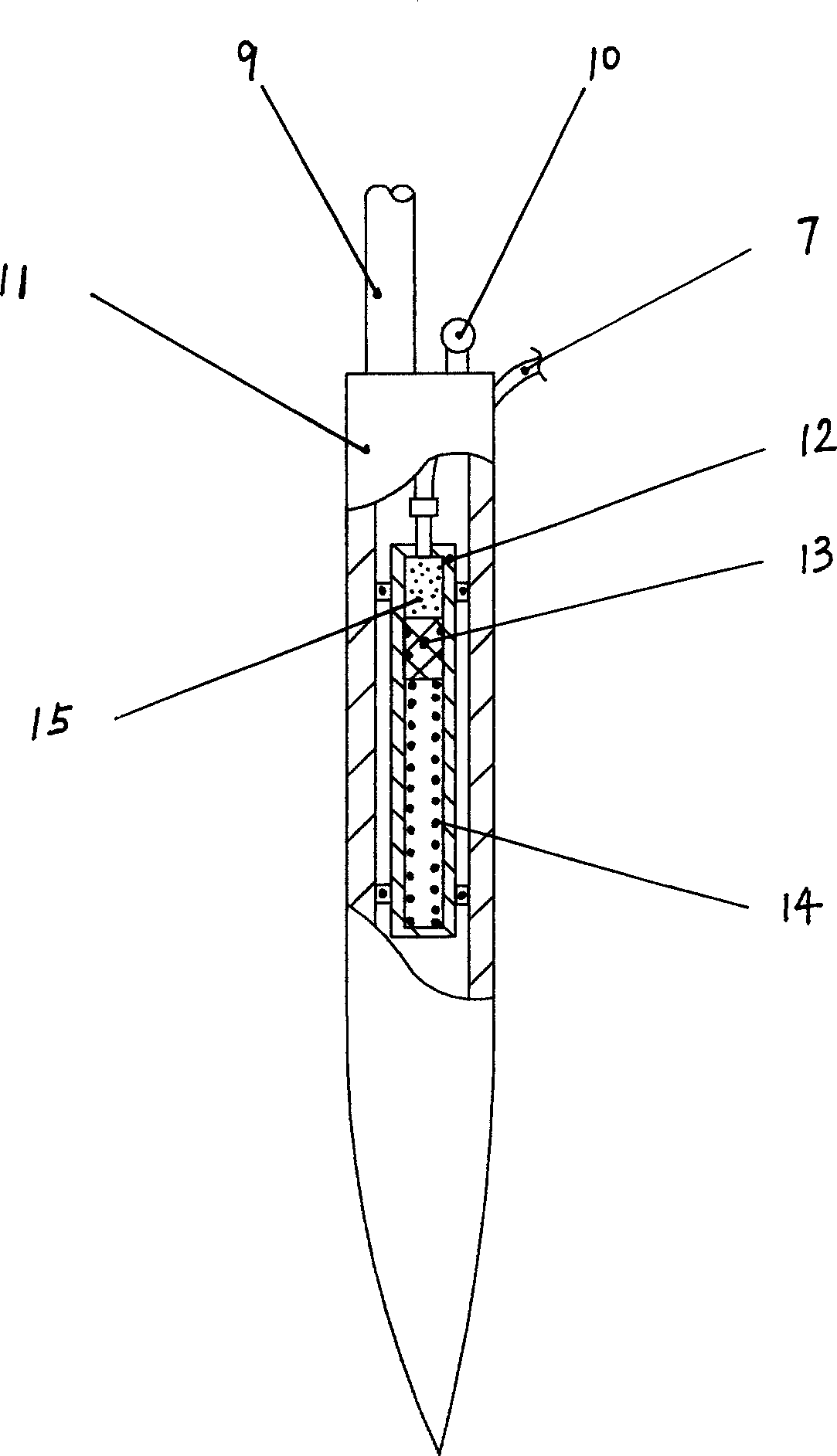

[0015] See figure 1 In the embodiment of the wind turbine hydraulic pitch device, the hub 1 is fixedly installed on the main shaft, and the hub 1 is provided with three propeller shafts 9 that are perpendicular to the main shaft and can rotate, and the blades 11 are installed one by one on each corresponding On the propeller shaft 9, the main shaft 5 is provided with a sliding sleeve 4, which is movably connected by a spline. The sliding sleeve 4 can slide along the axial direction of the main shaft 5, and the blade 11 is on the side of the propeller shaft 9 and on the sliding sleeve 4. The corresponding position is provided with a connecting head 10, the connecting heads 10 are connected by a connecting rod 8. The main shaft 5 is equipped with a hydraulic cylinder 6 with the same number of blades, the plunger of the hydraulic cylinder 6 is connected to the sliding sleeve 4, and the blade 11 A pressure storage tank is arranged inside, and the pressure storage tank is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com