Electric locomotive and city rail vehicle single-motor drive double-shaft way and bogie thereof

A single-motor drive, urban rail vehicle technology, applied to electric locomotives, locomotive propulsion methods, locomotives, etc., can solve the problems of large distance between two axles, unfavorable bogies passing through curves, etc., to achieve critical speed increase and reduce wear. , the effect of reducing the destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

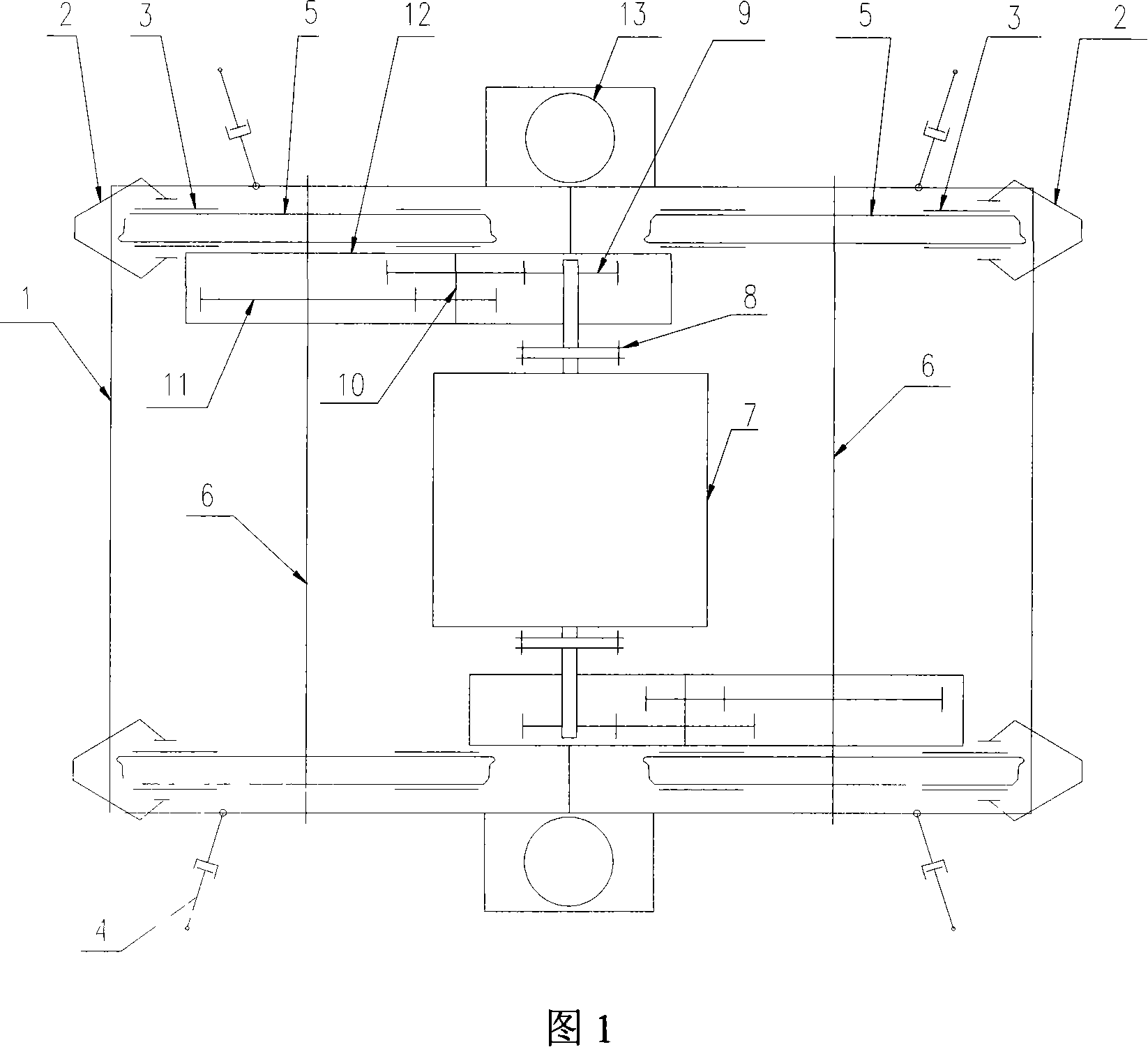

[0009] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0010] As can be seen from the accompanying drawings, the present invention is a bogie driven by a single motor with two axles (see the top view of the bogie 1) including a frame 1, a brake shoe 2, a brake disc 3, a shock absorber 4, and a wheel 5 , Wheel to shaft 6, drive motor 7, shaft coupling 8, driving gear 9, intermediate gear 10, bull gear 11, gear box 12, secondary spring 13 and other components. It is characterized in that the bogie adopts a single-motor-driven double-shaft mode, and one motor synchronously drives the two shafts of the bogie at the same time. The way of synchronous driving is to drive the gears of the two gearboxes respectively through the two ends of the drive motor shaft, and then drive the two wheels to the shafts respectively by the gears of the gearboxes. A drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com