Method for improving cavitation-erosion performance of centrifugal pump

A centrifugal pump and cavitation technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, can solve unreasonable design of blade tail width, hump of centrifugal pump performance curve, and restricted effective working range, etc. problems, to achieve the effect of improving the phenomenon of low local pressure, improving cavitation performance, and improving the effective working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

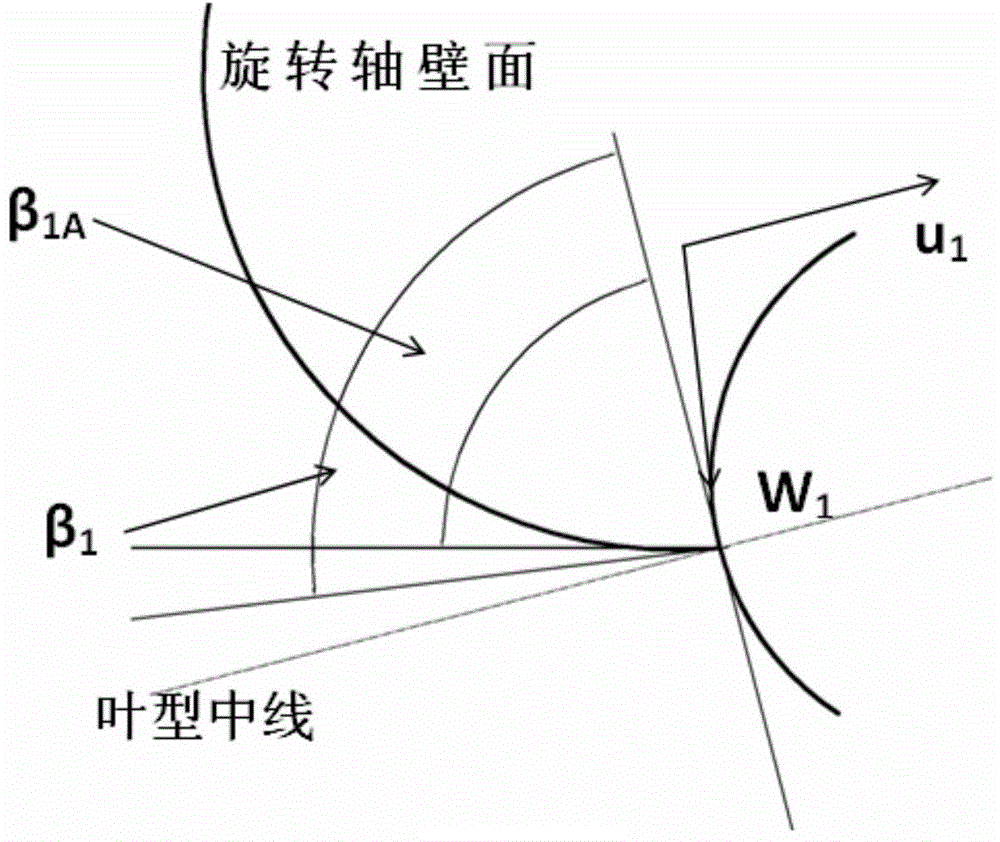

[0024] Such as figure 1 As shown, the prototype pump inlet installation angle relative flow angle are not equal, the difference between the two is the angle of attack , at this time there is a liquid flow impact on the blade head.

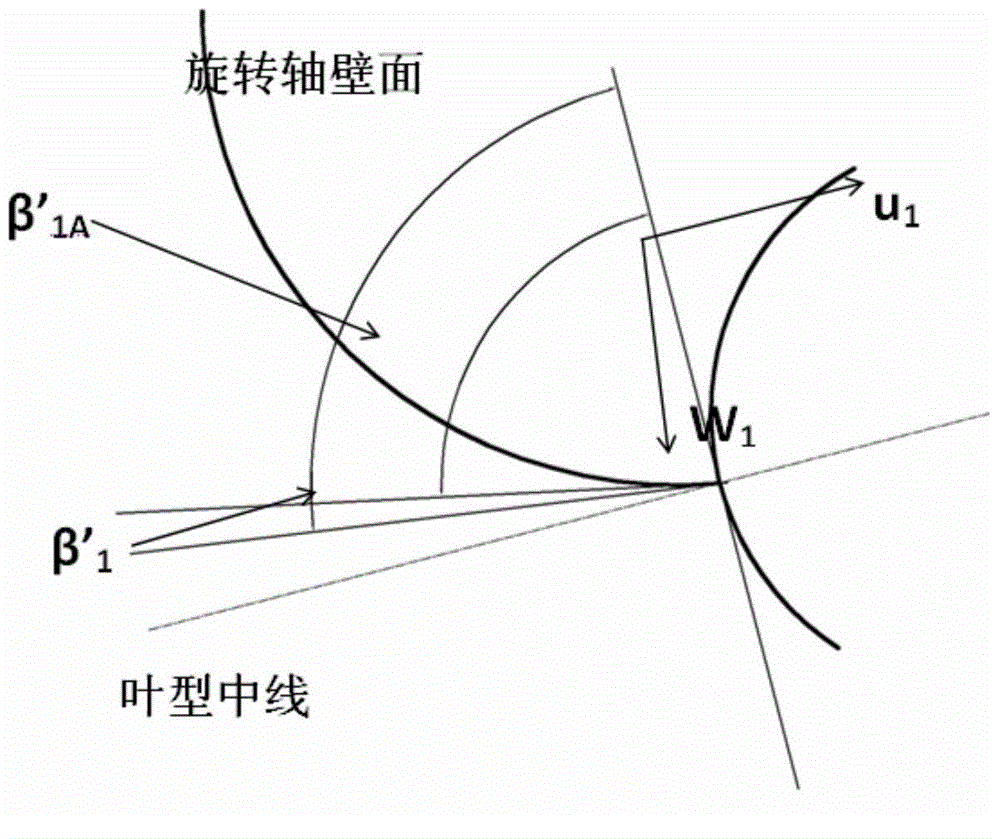

[0025] figure 2 Inlet mounting angle for modified pump shown relative flow angle The relationship between the two, we can see the difference between the two, both the angle of attack , to improve the impact of the blade head.

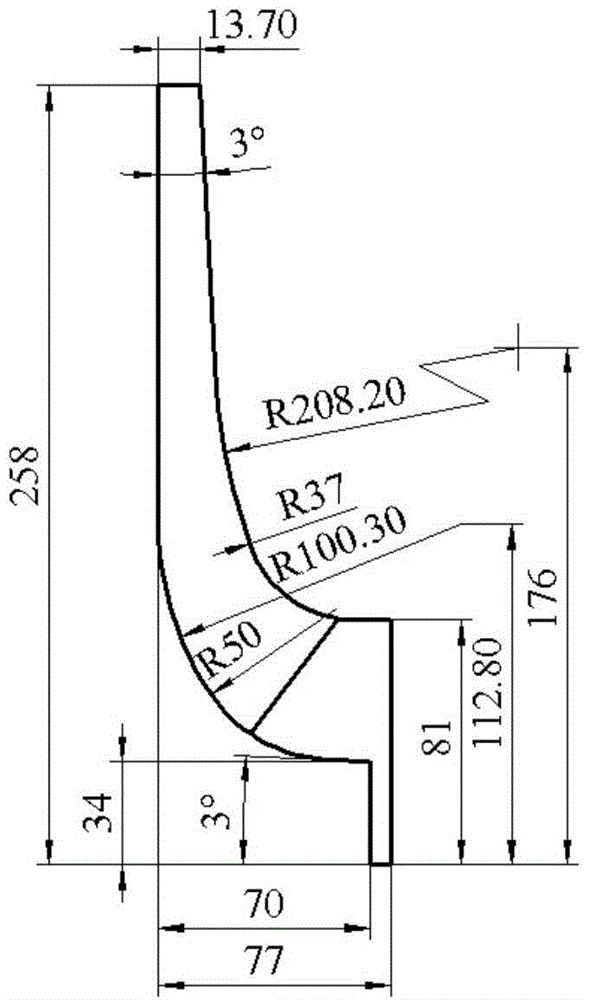

[0026] Depend on image 3 with Figure 4 It can be seen that the modification of the blade curve is mainly concentrated on the outlet width of the blade and on the front and rear cover curves, the modified blade outlet width Compared with the prototype pump vane outlet width increased by about 20%, and the area of the impeller flow path increased a lot compared to the same period last year.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com