Stall detection of wind turbine blades

A wind turbine and detector technology, which is applied in the control of wind turbines, monitoring of wind turbines, wind turbines, etc., can solve problems such as reducing the power output of wind turbines, and achieve the effect of reducing stall and improving power production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

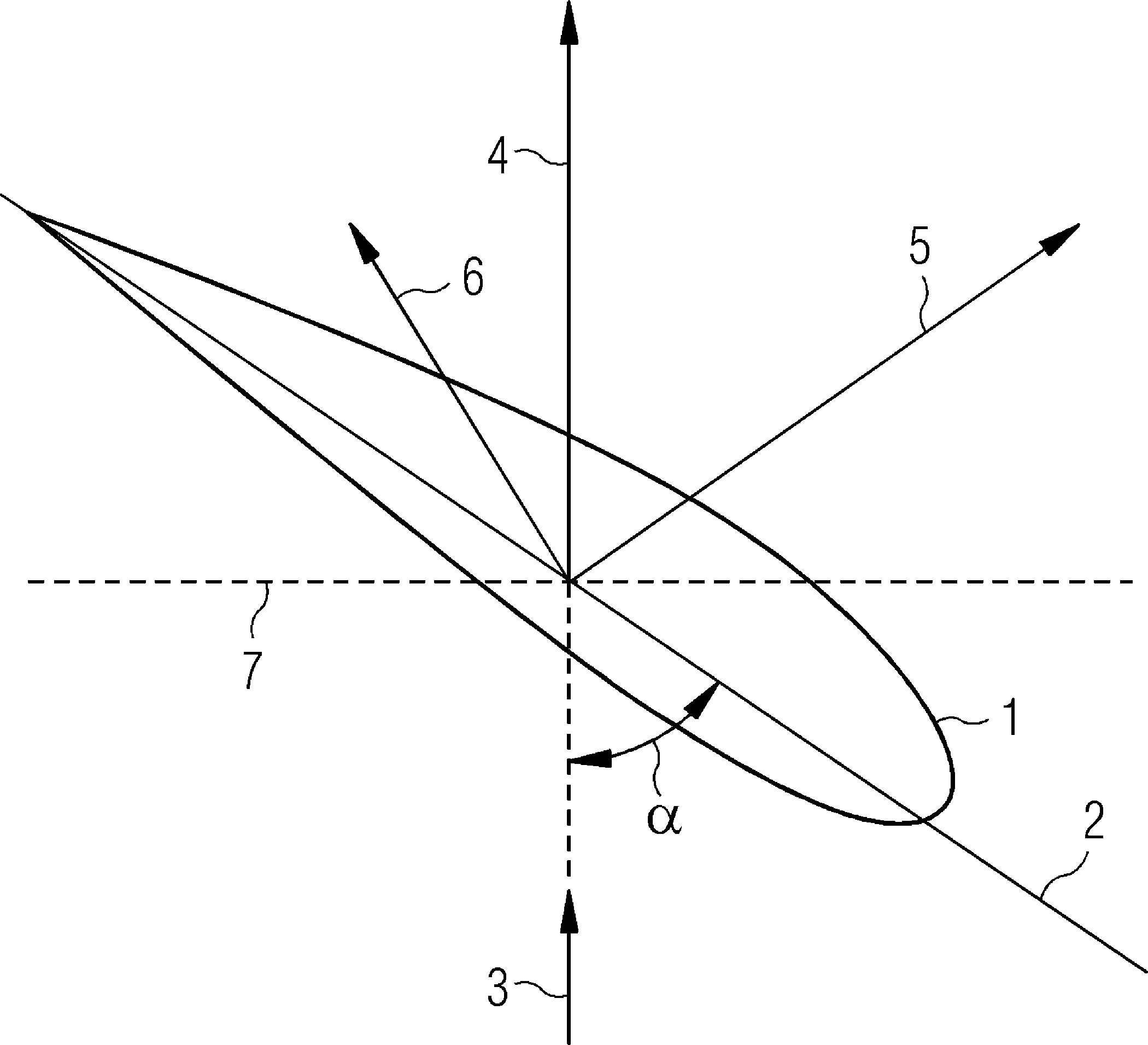

[0022] figure 1 An exemplary airfoil 1 of a rotor blade of a wind turbine is shown. The angle of attack α is measured between the chord line 2 of the airfoil 1 and the wind direction 3 . The corresponding pitch angle measured between the chord line 2 and the plane 7 of rotation can be used to describe the orientation of the rotor blade 1 . The chord line 2 intersects the leading and trailing edges of the airfoil 1 . Wind 3 acting on the airfoil 1 moves the rotor blade along the plane 7 of rotation. As the rotor blades rotate due to the rotor effective wind speed, the rotor blades experience an additional wind speed component opposite the direction of rotation. Thus, the blade experiences a wind speed as a result of the wind direction as seen by the rotating rotor blade.

[0023] Due to the profile of the rotor blade, a pressure drop is generated on the upper surface of the rotor blade, which pressure drop generates a lift force 5 perpendicular to the resulting wind speed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com