Arable pitch mounting for aircraft gas turbine engine

A technology for aviation gas turbines and aeroengines, applied in the direction of gas turbine power units, arrangement/installation of power units, jet power units, etc., capable of solving problems such as high fuel consumption and/or weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

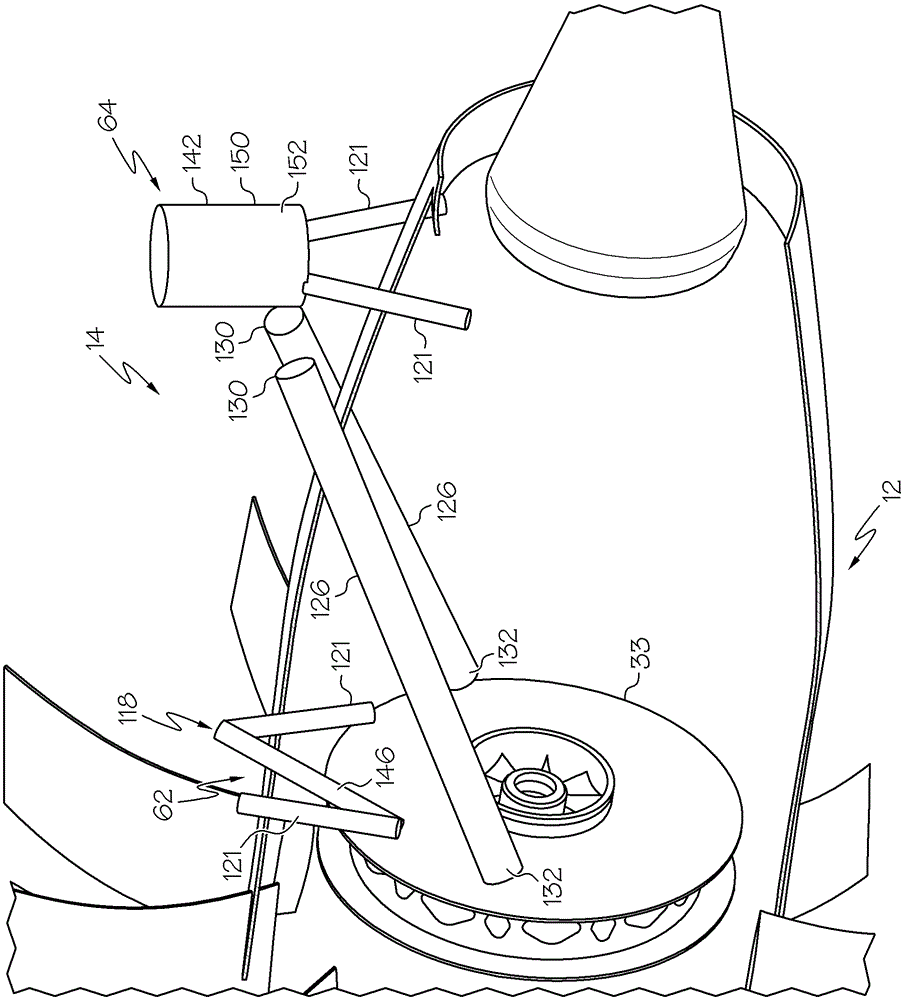

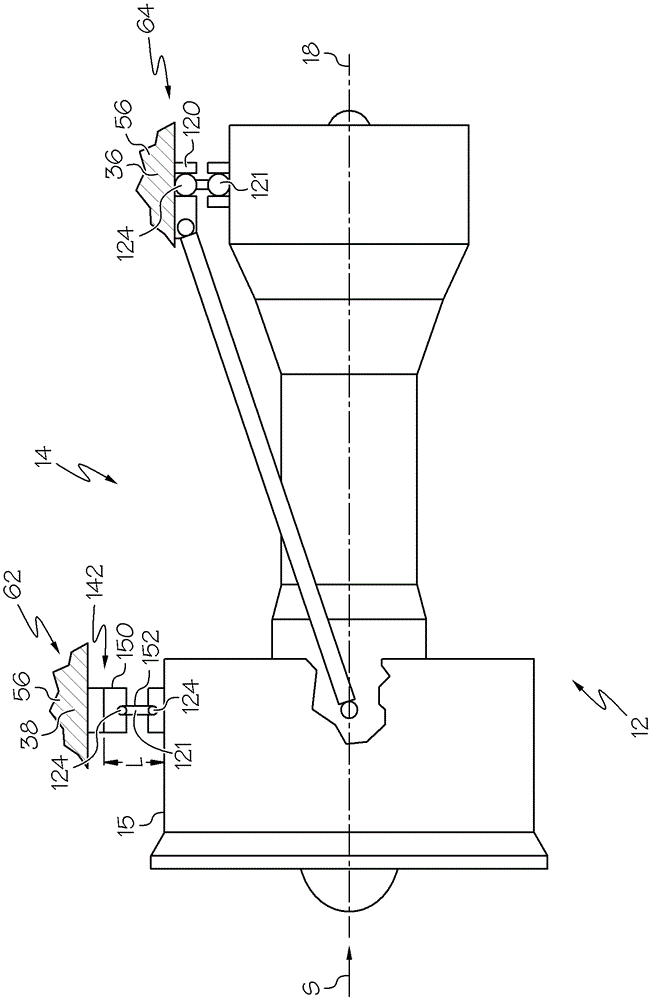

[0059] Embodiments described herein are described in connection with ducted fans and open rotor aviation gas turbine engines. Examples include ductless reverse rotatable front fan high bypass ratio engines, or UDFs.

[0060] exist figure 1 An exemplary aviation gas turbine engine 12 is shown in , and more particularly, a ductless reverse rotatable front fan high bypass ratio gas turbine engine 12 , also referred to herein as an open rotor gas turbine engine, is shown. Ductless and open rotor engines have open fan tips 13 that are not wrapped or surrounded radially outward by any fan casing or nacelle. Engine 12 is defined about engine centerline axis 18 and is suitably designed to be mounted by brackets 56 to a wing or fuselage (not shown) of an aircraft. The engine 12 extends rearward or downward from a front or upstream end 20 and a rear or downstream end 22 of the engine 12 . The engine 12 includes an outer casing 24 coaxially arranged about the centerline axis 18 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com