P-aminophenol imprinted polymer on surface of cadmium telluride quantum dot as well as preparation method and application thereof

A technology of cadmium telluride quantum dots and imprinted polymers is applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. The effect of improving efficiency and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

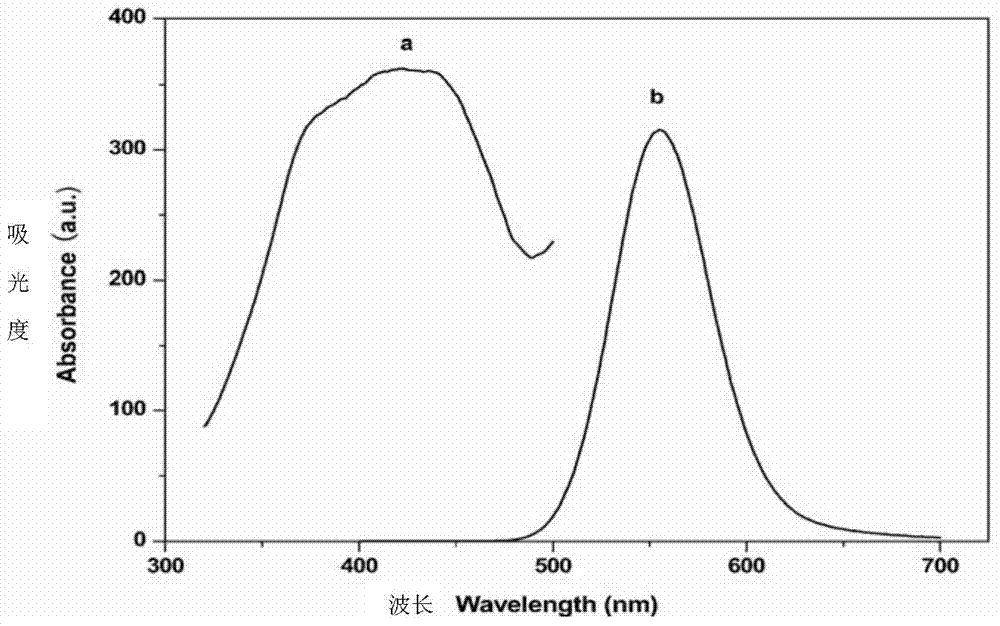

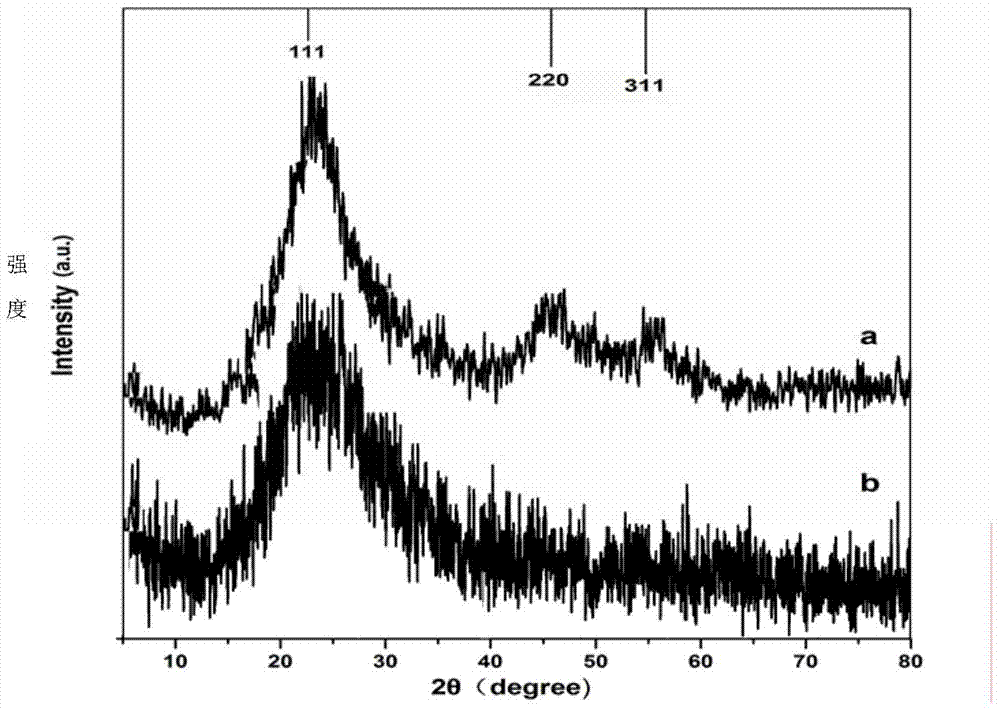

Embodiment 1

[0042] Accurately weigh 0.0327 g p-aminophenol, 0.2 g CdTeSiO 2 Add QDs to a 50 mL three-necked flask, add 10 mL of absolute ethanol, blow nitrogen, and stir for 20 min. Add 140 μL of 3-aminopropyltriethoxysilane (APTES), and stir for 30 min. Add 535 μL of TEOS, stir for 10 min and add 6.25 % wt NH 3 ·H 2 O 0.5 mL, stirred at room temperature for 20 h.

[0043] The reaction mixture was centrifuged at 10,000 r / min for 5 min, and the lower solid was washed with methanol and double-distilled water in order to obtain CdTeSiO 2 MIPs QDs. Blank polymers (NIPs) were prepared and treated the same except without the addition of p-aminophenol.

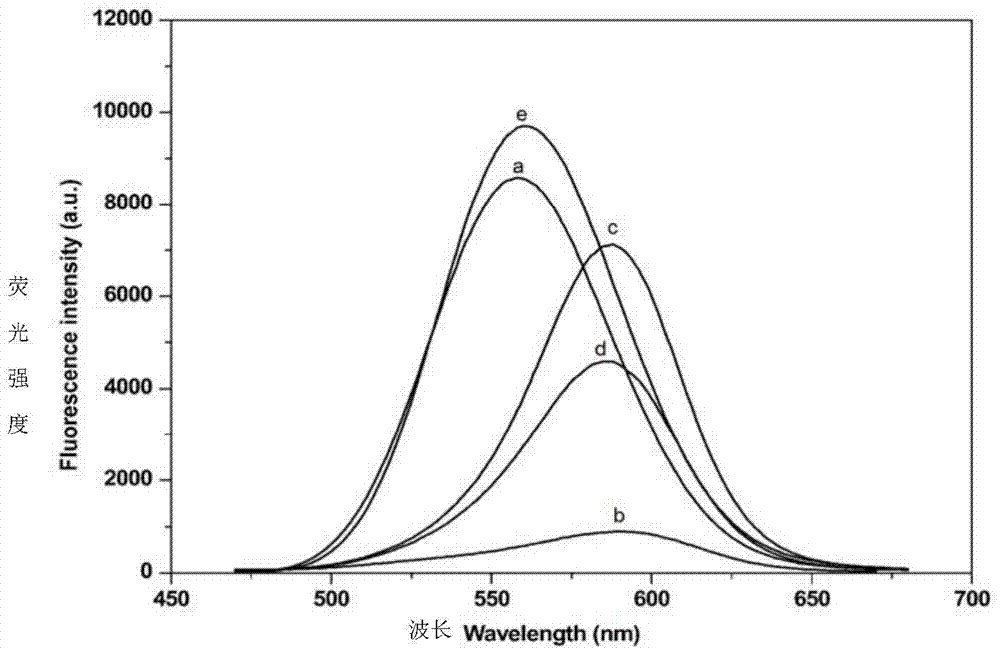

[0044] CdTeSiO that elutes p-aminophenol 2 MIPs QDs were dispersed in 10 mL of double-distilled water, and 0.2 mL of LCdTeSiO was added to a 5 mL EP tube 2 MIPs QDs, 1.0 mL Tris-HCl buffer solution (0.1 mol / L), different concentrations of p-aminophenol solution, sonicated for 10 min, allowed to stand at room temperature, and detected by ...

Embodiment 2

[0046] Accurately weigh 0.0218 g p-aminophenol, 0.2 g CdTeSiO 2 Add QDs to a 50 mL three-necked flask, add 10 mL of absolute ethanol, blow nitrogen, and stir for 20 min. Add 140 μL of APTES and stir for 30 min. Add 535 μL of TEOS, stir for 10 min and add 6.25% wt NH 3 ·H 2 O 0.5 mL, stirred at room temperature for 20 h.

[0047] The reaction mixture was centrifuged at 10,000 r / min for 5 min, and the lower solid was washed with methanol and double-distilled water in order to obtain CdTeSiO 2 MIPs QDs. Blank polymers (NIPs) were prepared and treated the same except without the addition of p-aminophenol.

[0048] CdTeSiO that elutes p-aminophenol 2 MIPs QDs were dispersed in 10 mL of double-distilled water, and 0.2 mL of LCdTeSiO was added to a 5 mL EP tube 2 MIPs QDs, 1.0 mL Tris-HCl buffer solution (0.1 mol / L), different concentrations of p-aminophenol solution, sonicated for 10 min, allowed to stand at room temperature, and detected by fluorescence. (see attached Fi...

Embodiment 3

[0050] Accurately weigh 0.0436 g p-aminophenol, 0.2 g CdTeSiO 2 Add QDs to a 50 mL three-necked flask, add 10 mL of absolute ethanol, blow nitrogen, and stir for 20 min. Add 140 μL of APTES and stir for 30 min. Add 535 μL of TEOS, stir for 10 min and add 6.25% wt NH 3 ·H 2 O 0.5 mL, stirred at room temperature for 20 h.

[0051] The reaction mixture was centrifuged at 10,000 r / min for 5 min, and the lower solid was washed with methanol and double-distilled water in order to obtain CdTeSiO 2 MIPs QDs. Blank polymers (NIPs) were prepared and treated the same except without the addition of p-aminophenol.

[0052] CdTeSiO that elutes p-aminophenol 2 MIPs QDs were dispersed in 10 mL of double-distilled water, and 0.2 mL of LCdTeSiO was added to a 5 mL EP tube 2 MIPs QDs, 1.0 mL Tris-HCl buffer solution (0.1 mol / L), different concentrations of p-aminophenol solution, sonicated for 10 min, allowed to stand at room temperature, and detected by fluorescence. (see attached Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com