Container end closure with pull tab

a technology of pull tabs and end closures, applied in the field of container and pull tab openers, can solve the problems of not being able to achieve the desired free lift, and achieve the effect of lessening the free lift for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

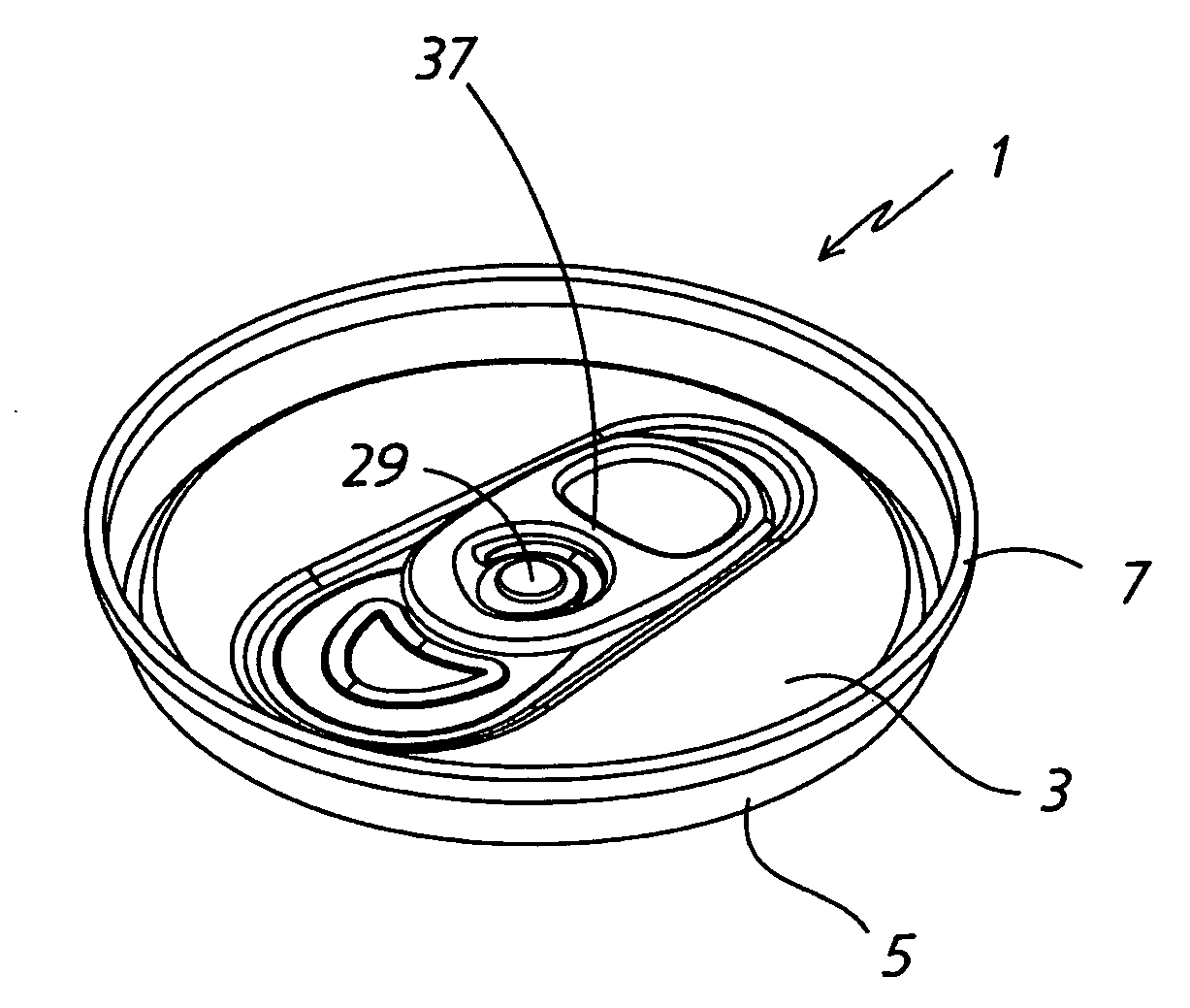

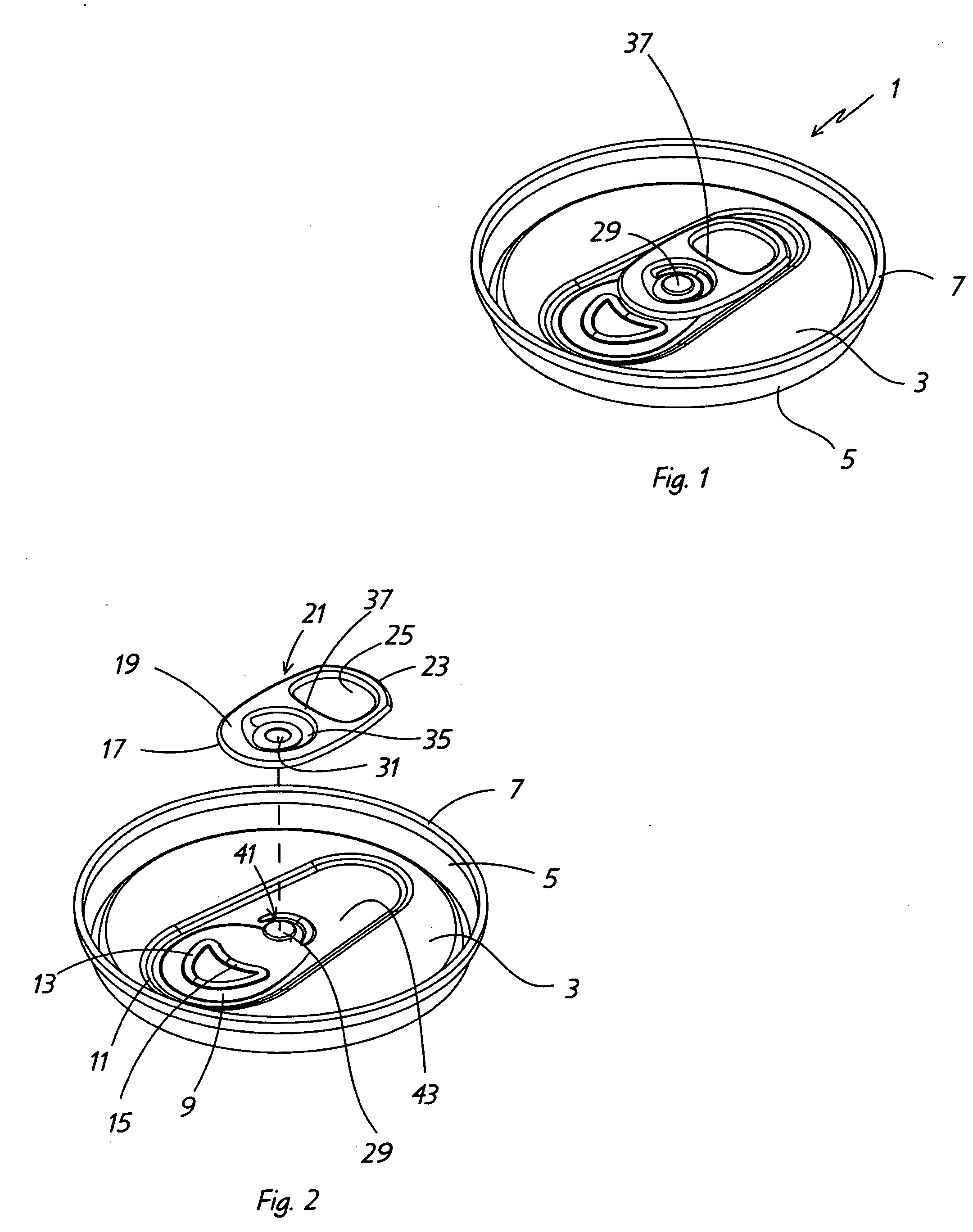

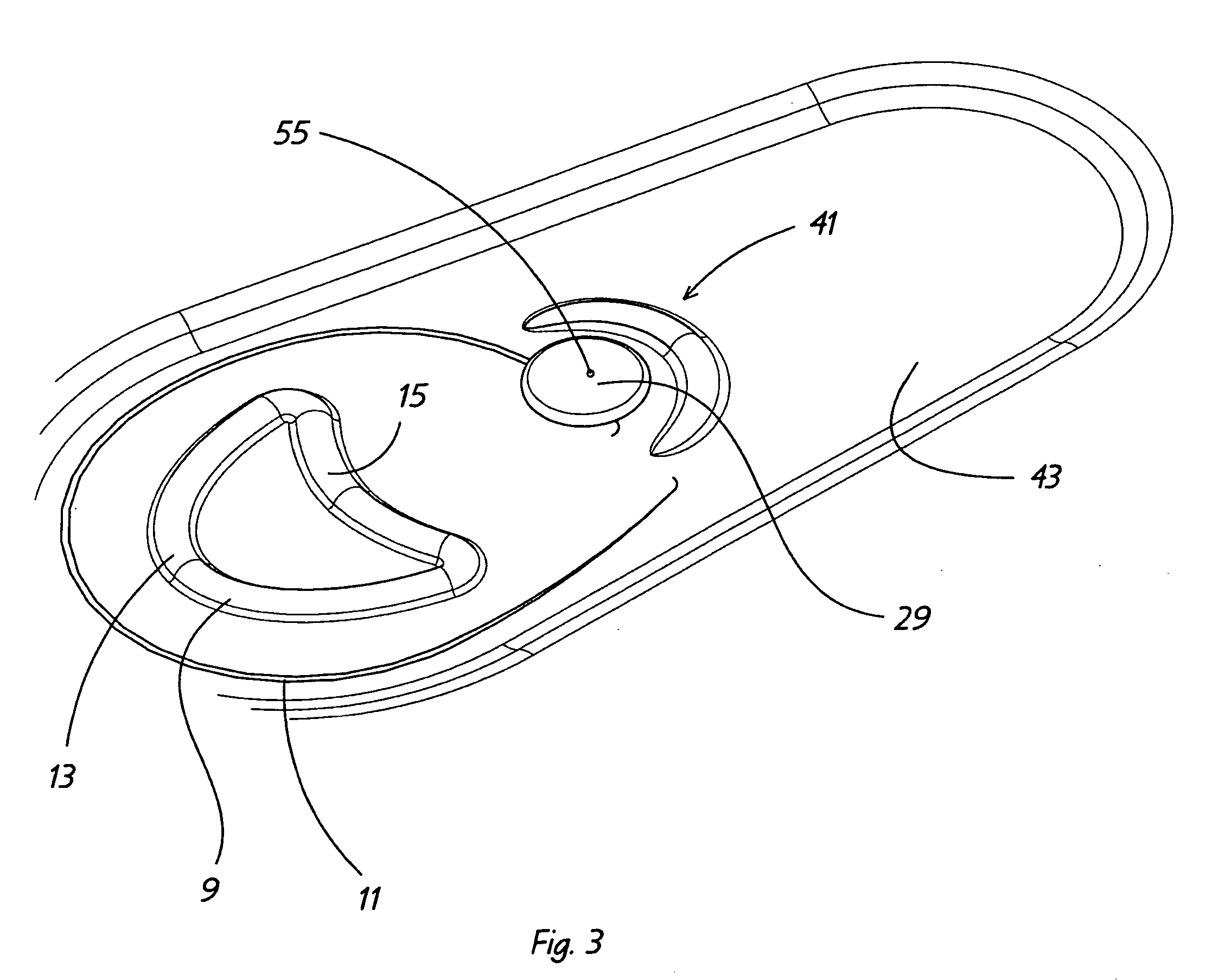

[0028] A first embodiment of the improved container end closure of the present invention is indicated generally at 1, and is shown in FIGS. 1-7 and 11. End closure 1 includes a central panel 3 having a generally circular shape which includes a circumferentially extending raised side wall 5 having an edge 7 for attaching end closure 1 to a suitable cylindrical container (not shown) in a manner well-known in the art.

[0029] In a preferred embodiment, end closure 1 will be formed of aluminum with central panel 3 having a thickness of approximately 0.007 inches. A usual tear panel 9 is formed in central panel 3 and defined by a frangible score line 11. Tear panel 9 includes a usual curved D-shaped protrusion 13 having an inner curved portion 15 which closely aligns with the curved outer end 17 of tab nose 19 of a usual pull tab, indicated generally at 21. Tab 21 is of a usual construction well-known in the beverage can art, having nose 17 and a rear curved lift end 23. Lift end 23 is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com