Method for producing hydrogen with high yield and high purity by reforming and transforming dry refinery gas

A refinery dry gas, high-purity technology, used in chemical instruments and methods, hydrogen and hydrogen separation, etc., can solve the problems of low hydrogen yield and low purity, and achieve catalytic efficiency, high yield, and improved yield. The effect of rate and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

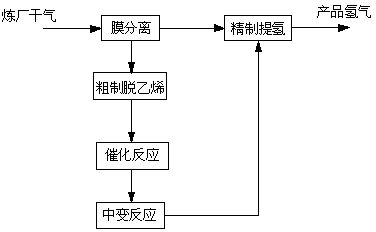

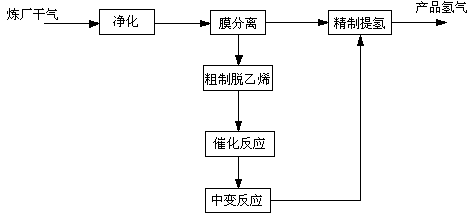

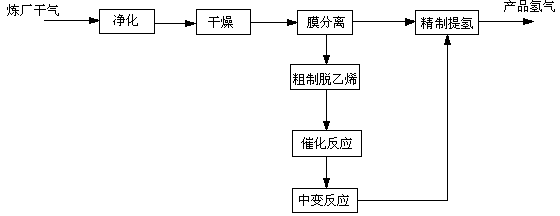

[0039] Such as figure 1 As shown, a method of high yield and high purity refinery dry gas reforming conversion hydrogen production described in this embodiment comprises the following steps:

[0040] (1) Membrane separation: the hydrogen concentration is 25% (volume ratio), the methane concentration is 50% (volume ratio), the nitrogen concentration is 21% (volume ratio), and the concentration of C2 and above fractions is 4% (volume ratio) The dry gas of the refinery is separated by membrane, the permeate side is enriched with hydrogen, the non-permeate side is enriched with methane, ethylene, ethane and fractions above C2, and the non-permeate side also includes some other gases, such as a small amount of hydrogen, nitrogen, etc.;

[0041](2) Refining hydrogen extraction: the hydrogen enriched on the permeate side in step (1) is subjected to pressure swing adsorption at a pressure of 1 MPa and a temperature of 20°C to obtain product hydrogen, at which point the purity of hydro...

Embodiment 2

[0048] Such as figure 1 As shown, a method of high yield and high purity refinery dry gas reforming conversion hydrogen production described in this embodiment comprises the following steps:

[0049] (1) Membrane separation: the hydrogen concentration is 40% (volume ratio), the methane concentration is 35% (volume ratio), the nitrogen concentration is 22.5% (volume ratio), and the concentration of C2 and above fractions is 2.5% (volume ratio) The dry gas of the refinery is separated by membrane, the permeate side is enriched with hydrogen, the non-permeate side is enriched with methane, ethylene, ethane and fractions above C2, and the non-permeate side also includes some other gases, such as a small amount of hydrogen, nitrogen, etc.;

[0050] (2) Refining hydrogen extraction: The hydrogen enriched on the permeate side in step (1) is subjected to pressure swing adsorption under the conditions of a pressure of 1.5MPa and a temperature of 30°C to obtain product hydrogen, at whic...

Embodiment 3

[0057] Such as figure 1 As shown, a high-yield, high-purity refinery dry gas reforming method for hydrogen production described in this example includes the following steps: the concentration of hydrogen is 40% (volume ratio), and the concentration of methane is 30% ( Refinery dry gas with a nitrogen concentration of 27% (volume ratio) and a fraction concentration of C2 and above 3% (volume ratio) is separated through membranes, the permeate side is enriched with hydrogen, and the non-permeate side is enriched with methane and ethylene Ethane and fractions above C2, the non-permeate side also includes some other gases, such as a small amount of hydrogen, nitrogen, etc.;

[0058] (2) Refining hydrogen extraction: the hydrogen enriched on the permeate side in step (1) is subjected to pressure swing adsorption at a pressure of 2 MPa and a temperature of 40°C to obtain product hydrogen;

[0059] (3) Crude deethylene: The mixed gas on the non-permeation side in step (1) is subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com