Patents

Literature

40results about How to "Guaranteed catalytic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Immobilized enzyme carrier as well as preparation method and application thereof

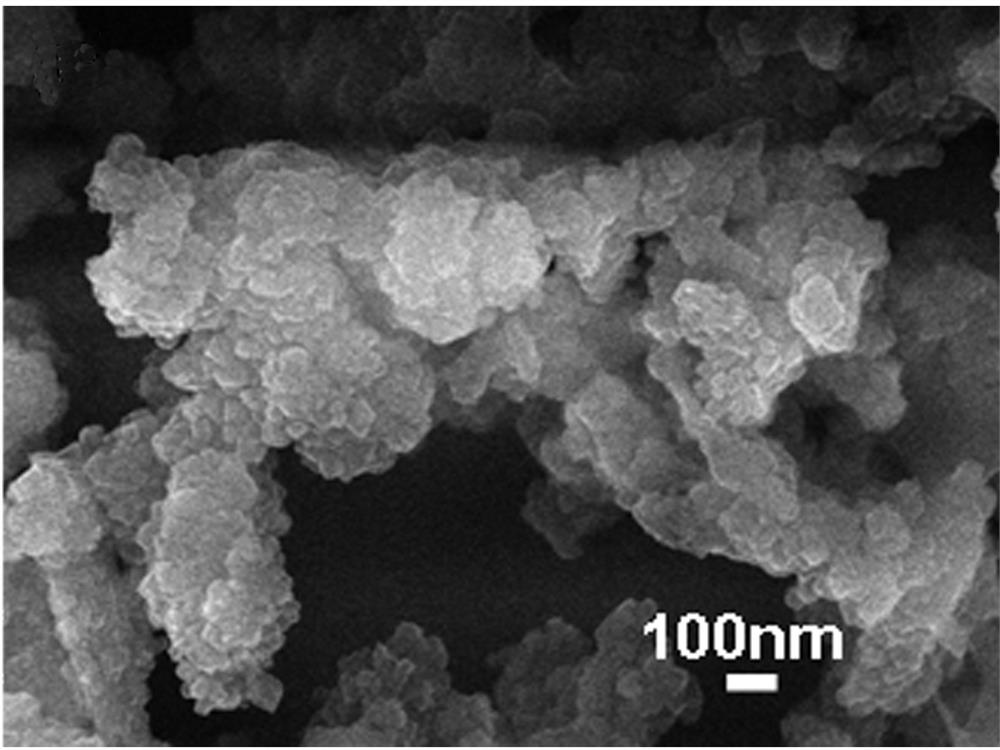

ActiveCN104531668ALow costSimple preparation processOn/in inorganic carrierCarbon nanotubeMagnetite Nanoparticles

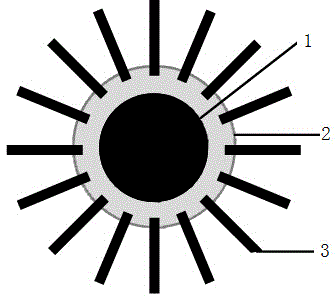

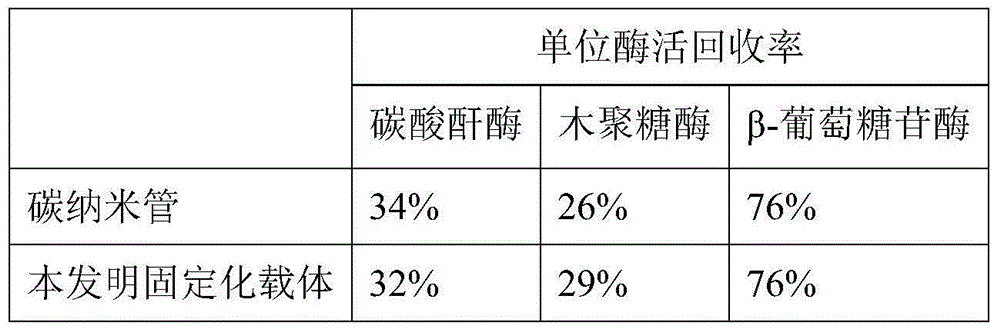

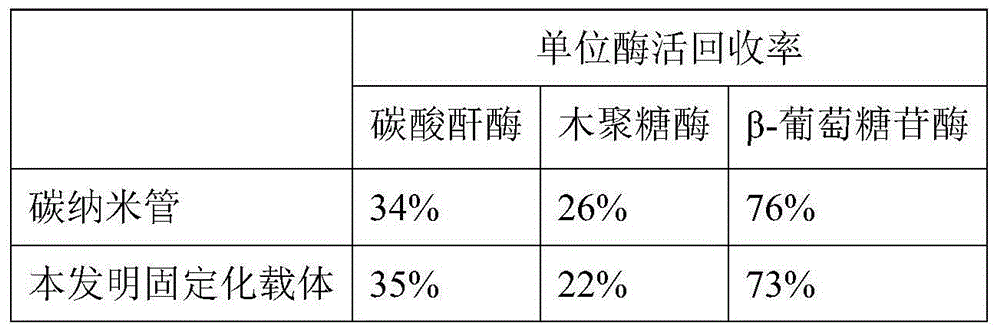

The invention discloses an immobilized enzyme carrier as well as a preparation method and an application thereof. The immobilized enzyme carrier comprises a magnetic nanoparticle, a hydrophilic sol-gel compound and a carbon nano tube, wherein the surface of the magnetic nanoparticle is wrapped by the hydrophilic sol-gel compound to form a hydroxyl-rich shell; one end of the carbon nano tube is wrapped by the hydroxyl-rich shell; and the carbon nano tube is grafted on the surface of the magnetic nanoparticle. The immobilized enzyme carrier and the biological enzyme are combined, so that catalytic efficiency is high; recycling of enzyme is facilitated; and the industrial production cost can be effectively reduced.

Owner:LIVINGZONE SHANGHAI BIO CHEM TECH CO LTD

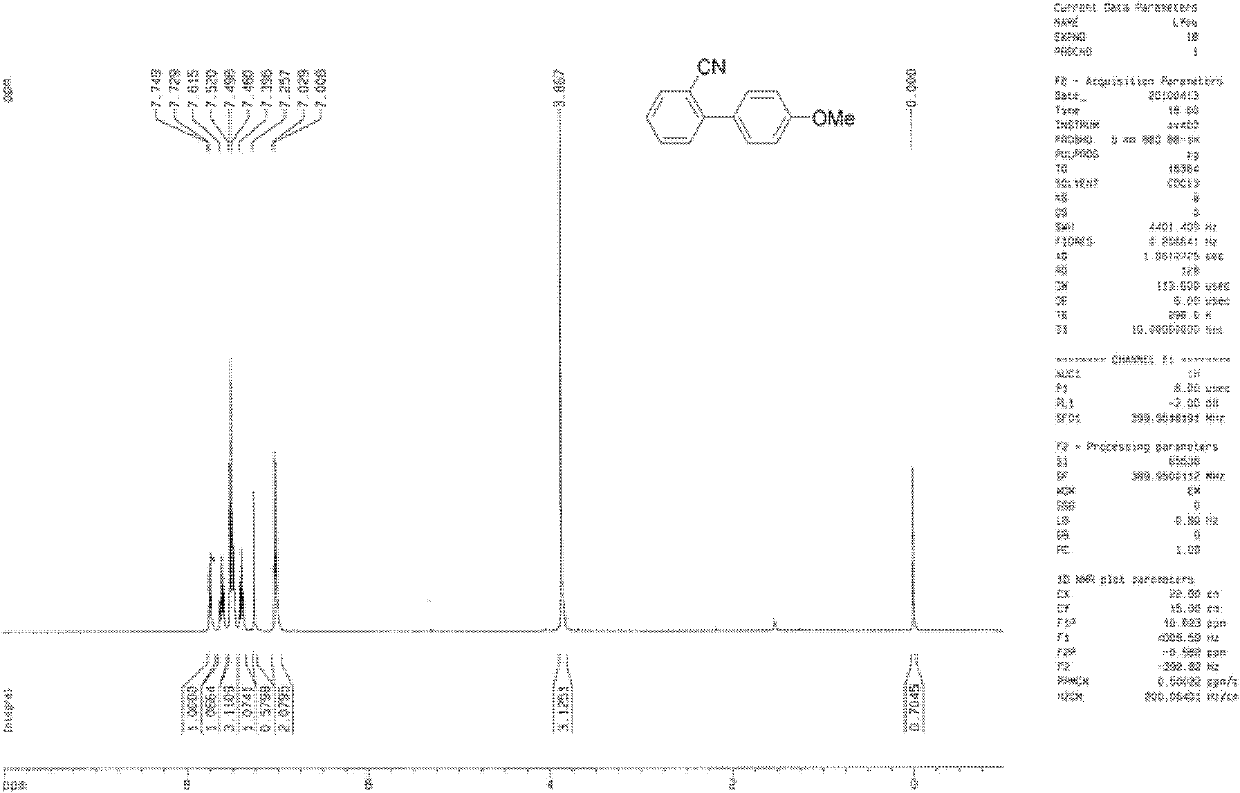

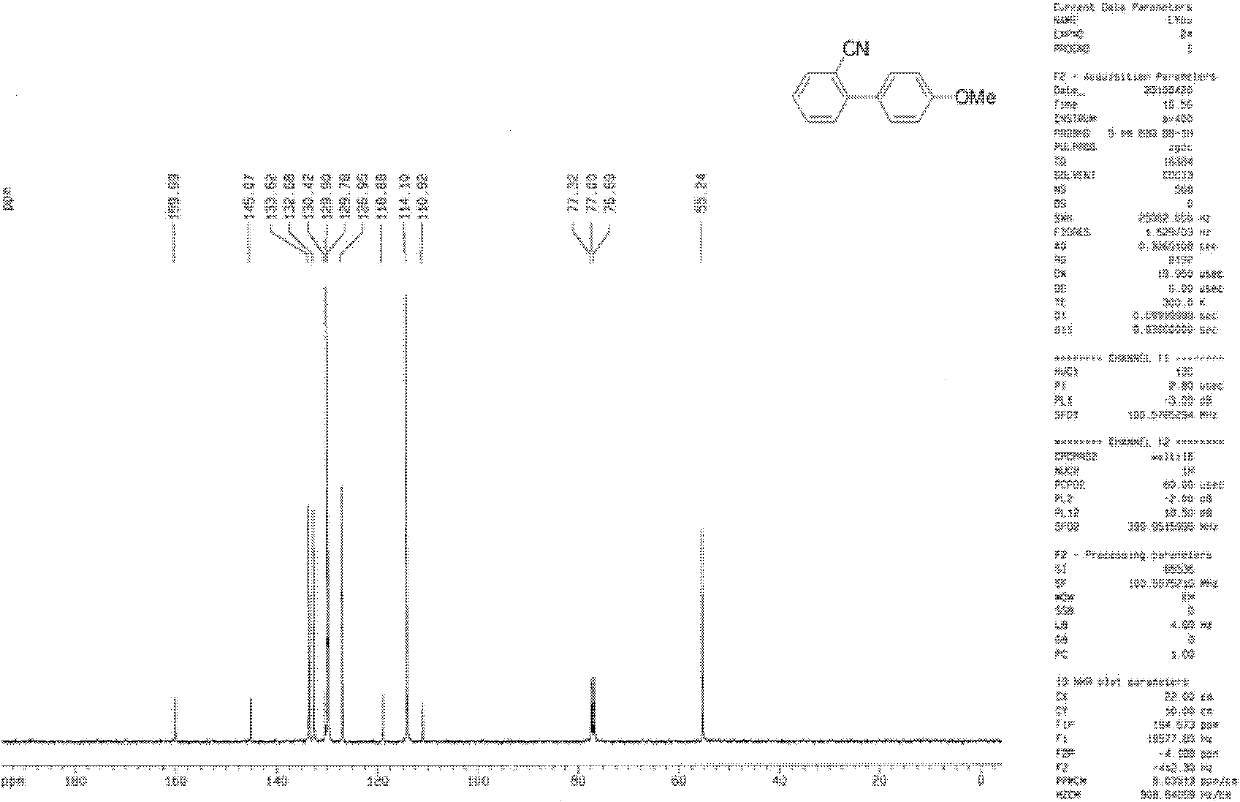

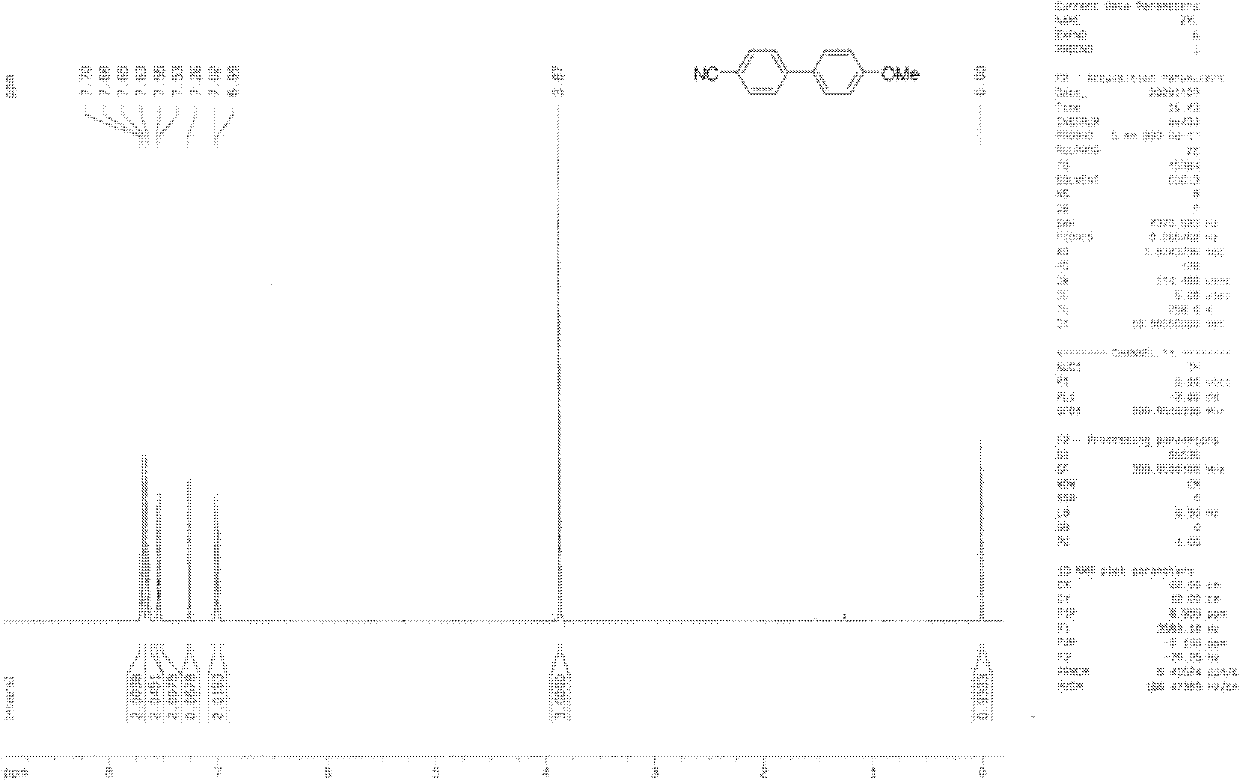

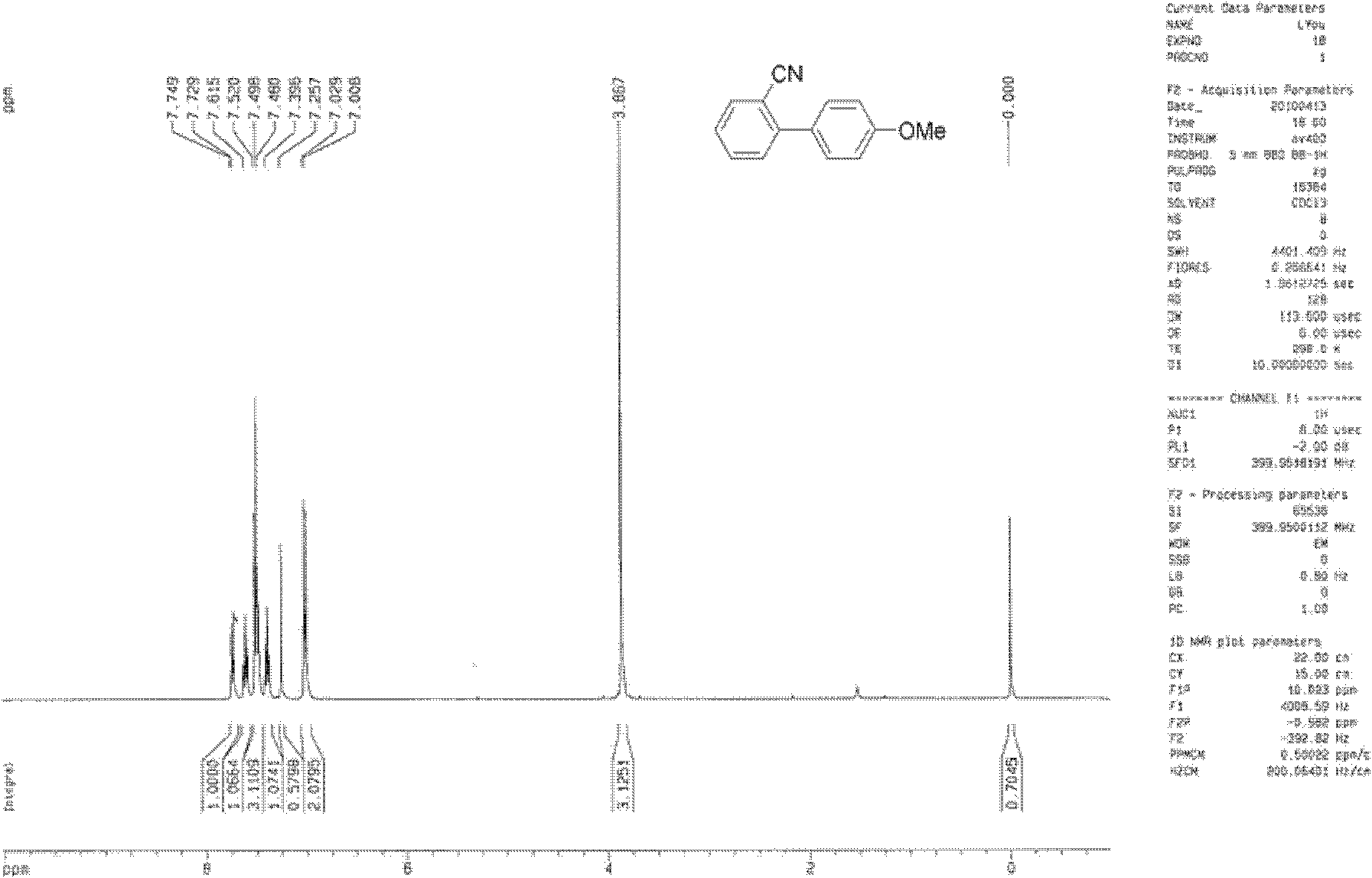

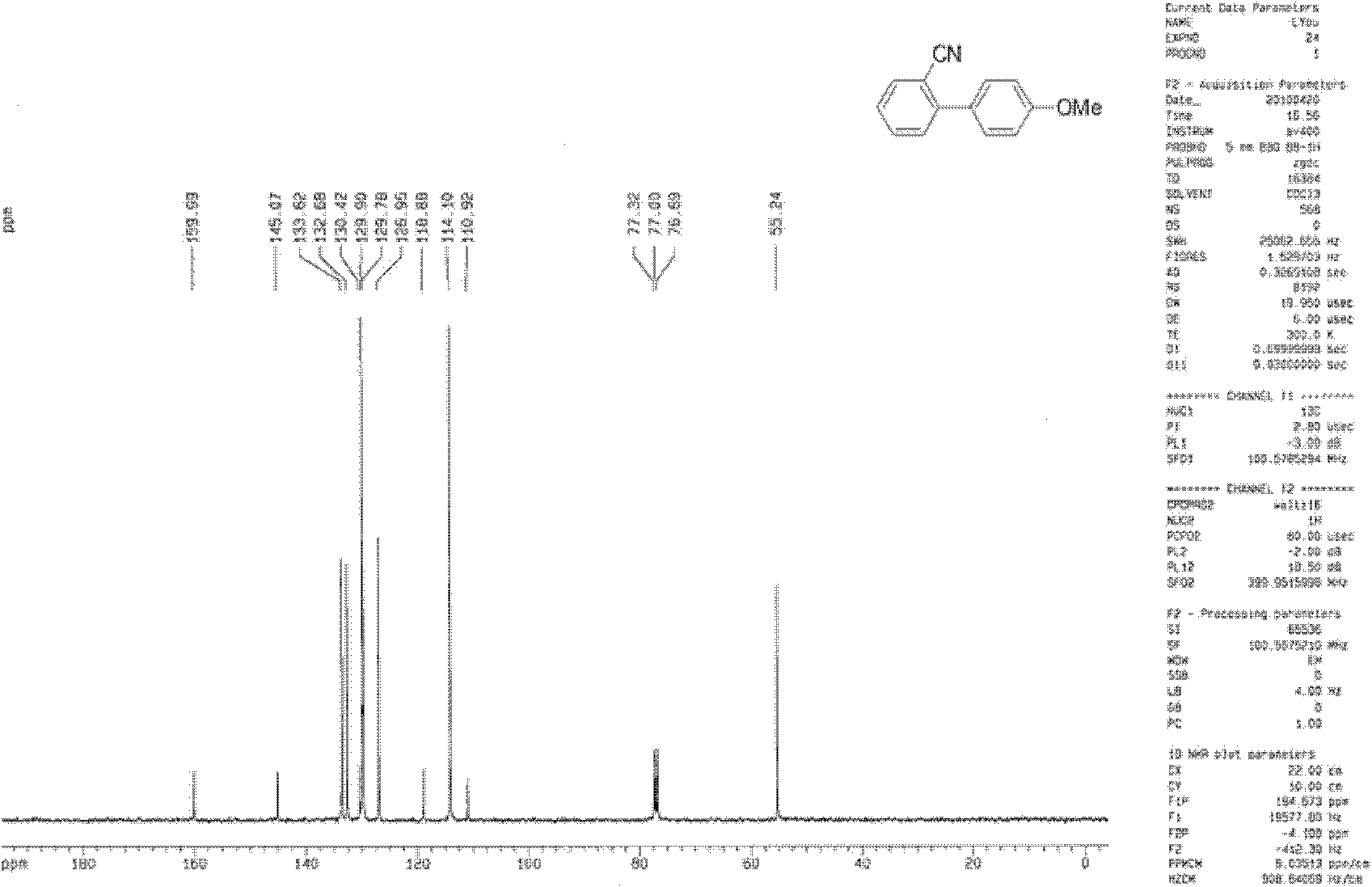

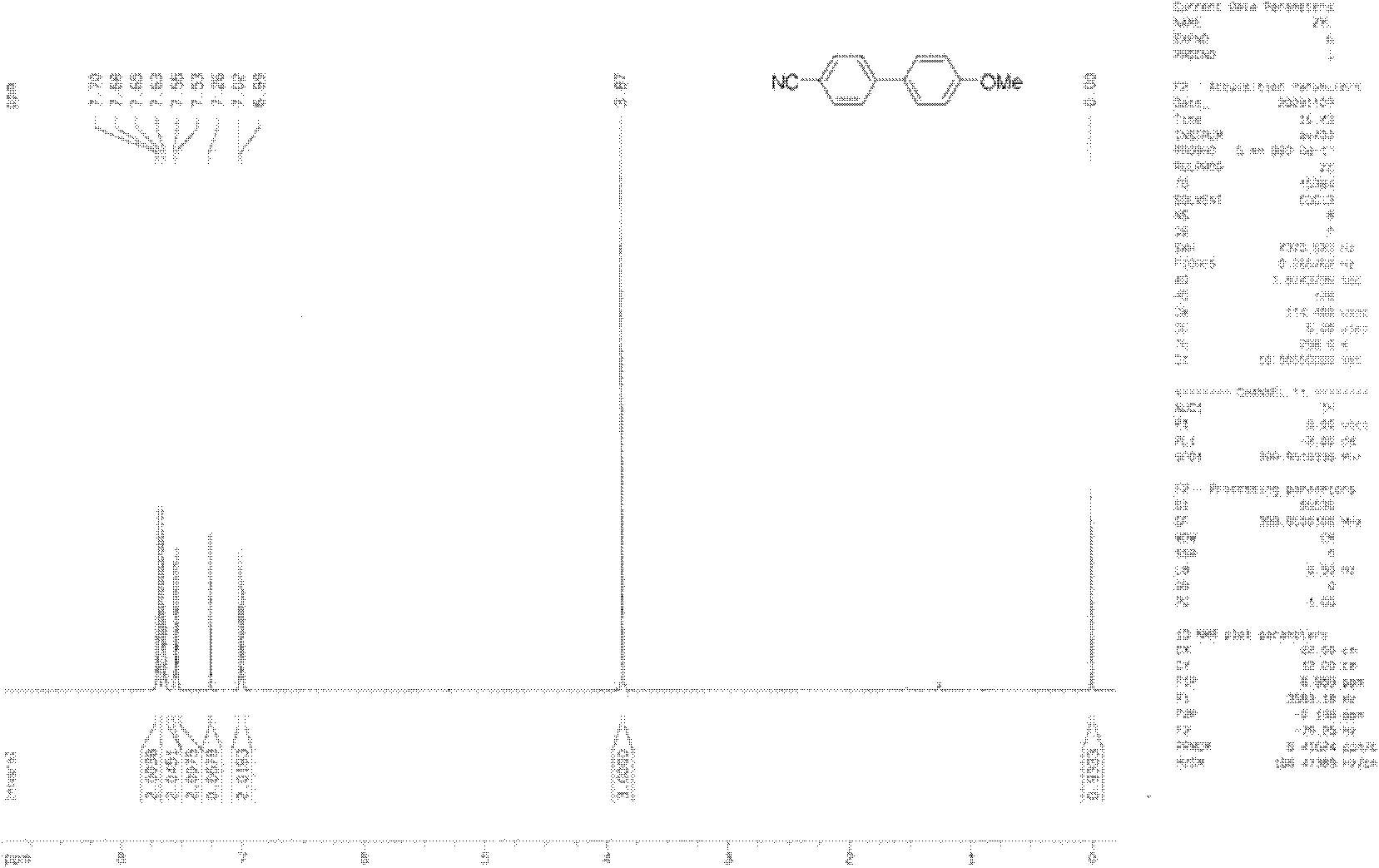

Method for preparing phenylaniline

ActiveCN102070465AGuaranteed catalytic efficiencyLow costPreparation by rearrangement reactionsNickel catalystHydrogen

The invention provides a method for preparing phenylaniline, which comprises the following steps: mixing cyanophenyl shown in the formula II, first alkaline compounds, nickel catalysts and borophenylic acid shown in the formula III or borophenylic esters shown in the formula VI to carry out suzuki coupling reaction for obtaining cyanobiphenyl shown in the formula IV; mixing the cyanobiphenyl, second alkaline compounds and oxyful, and hydrolyzing the cyanobiphenyl to obtain amido biphenyl shown in the formula V; and mixing the amido biphenyl, third alkaline compounds and sodium hypohalite to generate Hofmann degradation reaction for obtaining phenylaniline shown in the formula I, wherein R1 is chlorine, bromine, iodine, sulphonic acid ester radicals, carbonic ether radicals or alkyl ester radicals; R2 is alkyl, alkoxy, cyano, amido or hydrogen; R3 is chlorine, bromine or iodine; and R4 is alkyl, alkoxy, cyano, amido or hydrogen. The preparing method provided by the invention has the advantages of mild condition, low cost, cleanness and environment protection.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

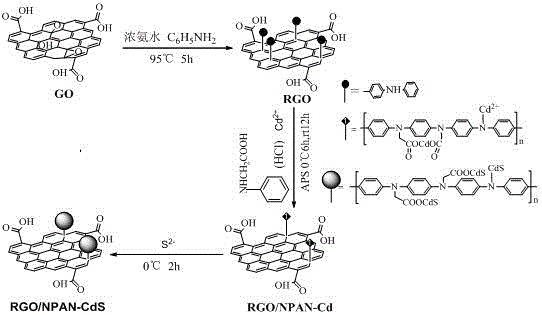

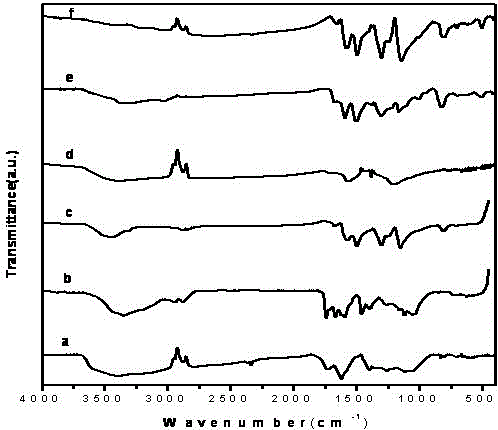

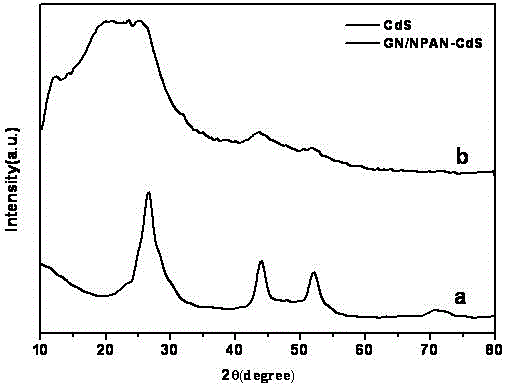

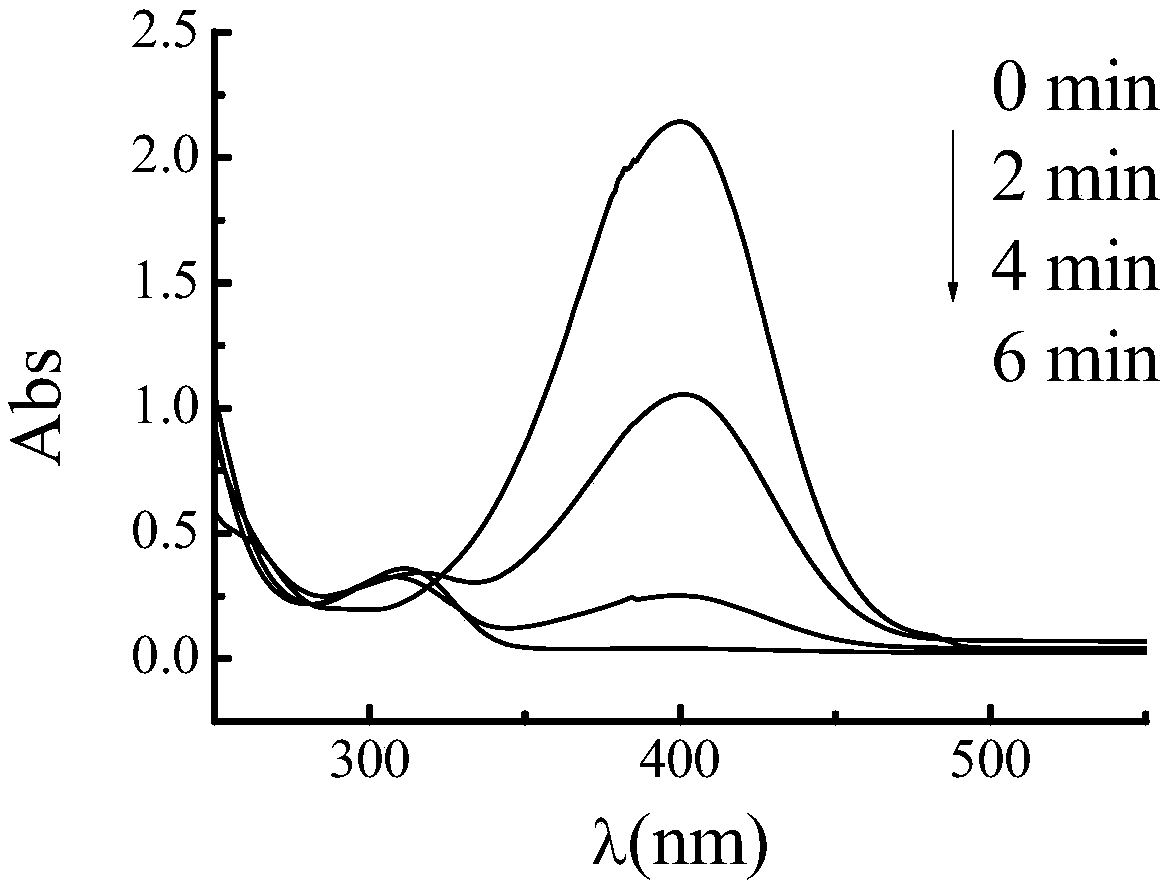

Method for preparing modified polyaniline grafted functionalized graphene composite cadmium sulfide quantum dots

InactiveCN106750278AGood dispersionAccelerated corrosionOrganic-compounds/hydrides/coordination-complexes catalystsIce waterUltrasonic dispersion

The invention relates to a method for preparing modified polyaniline grafted functionalized graphene composite cadmium sulfide quantum dots. The method comprises the steps of preparing graphene oxide (GO), carrying out ultrasonic dispersion to obtain a uniform solution, putting a certain volume of stronger ammonia water and aniline into the GO solution, carrying out a reaction at a certain temperature so as to obtain functionalized reduced graphene oxide (RGO), uniformly mixing a certain amount of RGO, N-phenylglycine and a cadmium source in an in-situ polymerization system with a weakly acidic atmosphere, adding a certain amount of ammonium persulfate into the mixture as an oxidant, carrying out a reaction so as to prepare a cadmium-containing composite material precursor, and finally, introducing a sulfur source under ice water bath conditions, thereby preparing an N-substituted polyaniline carboxylate grafted graphene cadmium sulfide quantum dot photoelectric material by using a mechanism of nucleation between sulfur and cadmium. According to the composite photoelectric material prepared by the method provided by the invention, the agglomeration of cadmium sulfide and graphene is inhibited through covalent grafting, the light corrosion resistance of cadmium sulfide is improved, the transfer speed of electrons is accelerated, and the efficiency of photoelectric conversion under visible light is increased.

Owner:EAST CHINA JIAOTONG UNIVERSITY

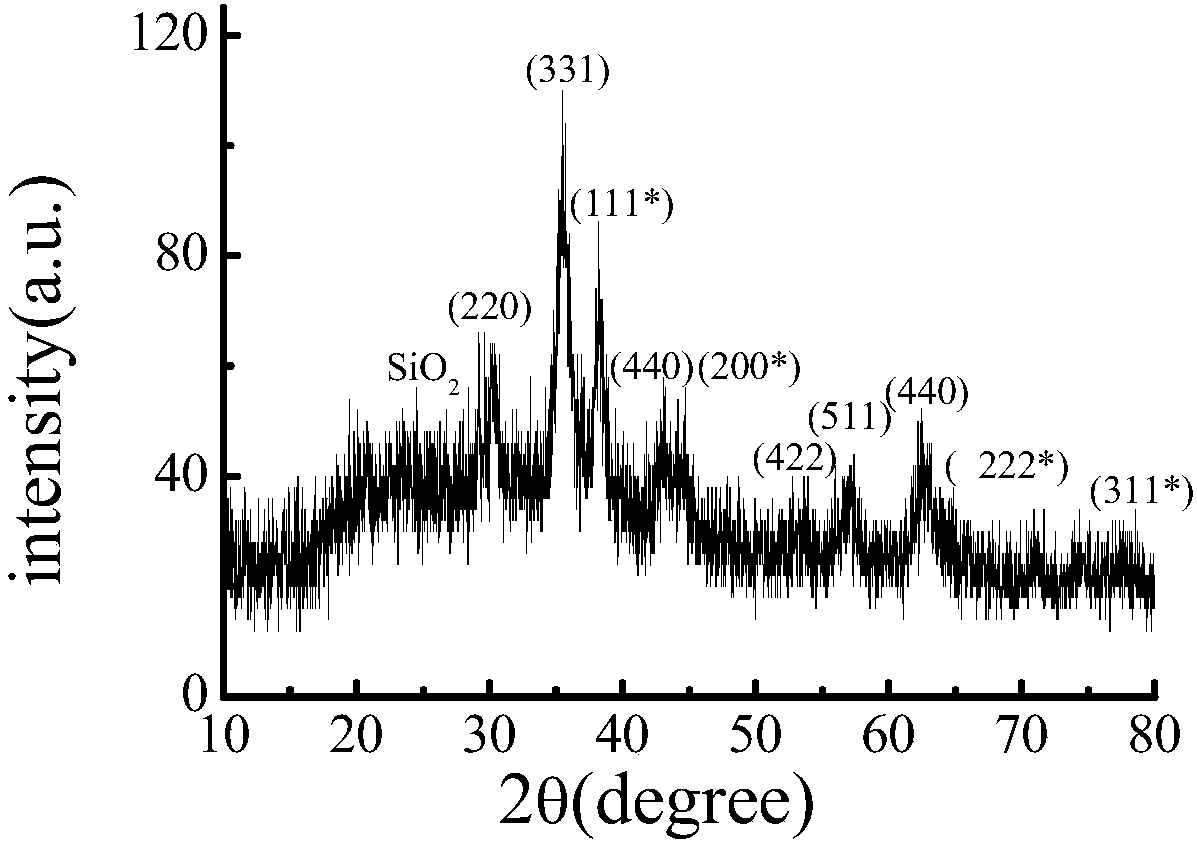

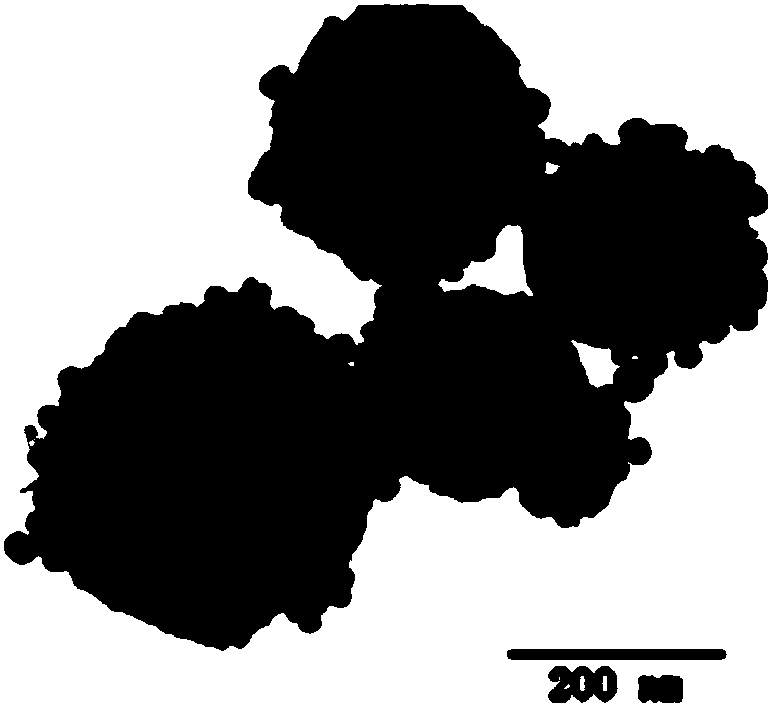

Preparation method of nanogold-loaded magnetic nanometer catalyst

InactiveCN108212211ASimple preparation protocolCatalytic reduction reactionOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystSilanes

The invention discloses a preparation method of a nanogold-loaded magnetic nanometer catalyst. The preparation method comprises the following steps of adopting a hydrothermal method for synthesizing to obtain a magnetic nanoparticle Fe3O4, and coating the magnetic nanoparticlewith silicon dioxide; modifying the silicon-coated magnetic nanoparticle through a sulfydrylsilane coupling agent: fully dispersing the silicon-coated magnetic nanoparticle into an ethanol solution, adding ammonium hydroxide and stirring, then dropwise adding a silane coupling agent solution with sulfydryl, stirring at the room temperature, magnetically separating a production, and washing; loading nanogold onto the sulfhydrylationmagnetic nanoparticle: after dispersing the sulfhydrylationmagnetic nanoparticle into deionized water, adding a nanogold solution, stirring at the room temperature, magnetically separating a production, and washing to obtain the nanogold-loaded magnetic nanometer catalyst. The preparation method provided by the invention is simple and practicable; experiment conditions are mild and easy to meet; the prepared nanogold-loaded magnetic nanometer catalyst can efficiently and quickly catalyze the reduction reaction of p-nitrophenol, and can be reutilized for not less than 8 times.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing maleic acid isopropyl ester

InactiveCN103304415AGuaranteed catalytic efficiencyHydrophilicity adjustableOrganic compound preparationCarboxylic acid esters preparationRefluxAlcohol

The invention discloses a method for preparing maleic acid isopropyl ester. The method comprises the following steps of: (1) preparing sulfonacid ionic liquid onium salt through sultone and nitrogen tertiary amine compounds; (2) dissolving the sulfonacid ionic liquid onium salt into water, slowly dropwise adding acid under ice bath so as to prepare a sulfonacid ionic liquid; and (3) carrying out condensation and reflux reaction on maleic anhydride, isopropanol, the sulfonacid ionic liquid and a water-carrying agent, separating a liquid, circularly catalyzing the sulfonacid ionic liquid at the lower layer, carrying out decompression distillation on an ester layer at the upper layer, then neutralizing with alkali, layering, and carrying out decompression distillation to obtain finished maleic acid isopropyl ester. The sulfonacid ionic liquid catalyst can be recycled and can absorb water, thus being beneficial to forwarding operation of the reaction, and realizing the recovery and recycling of excessive alcohol. The method is simple in procedures, pollution-free and non-corrosion, and has the advantages of being mild in conditions, environment-friendly and economic in benefits.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

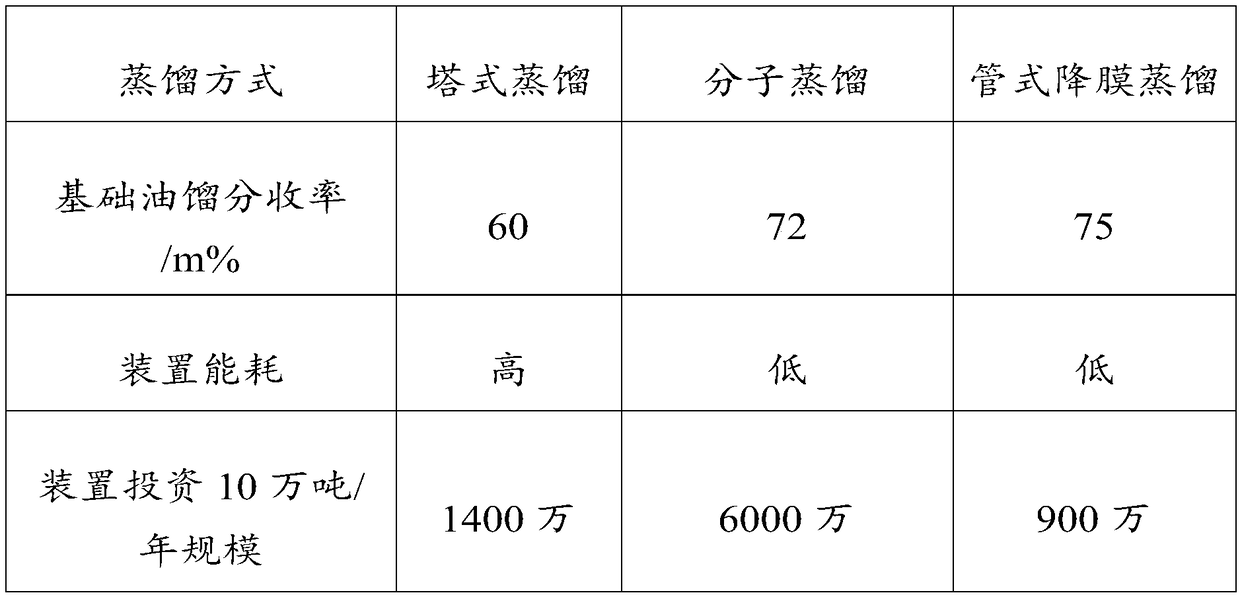

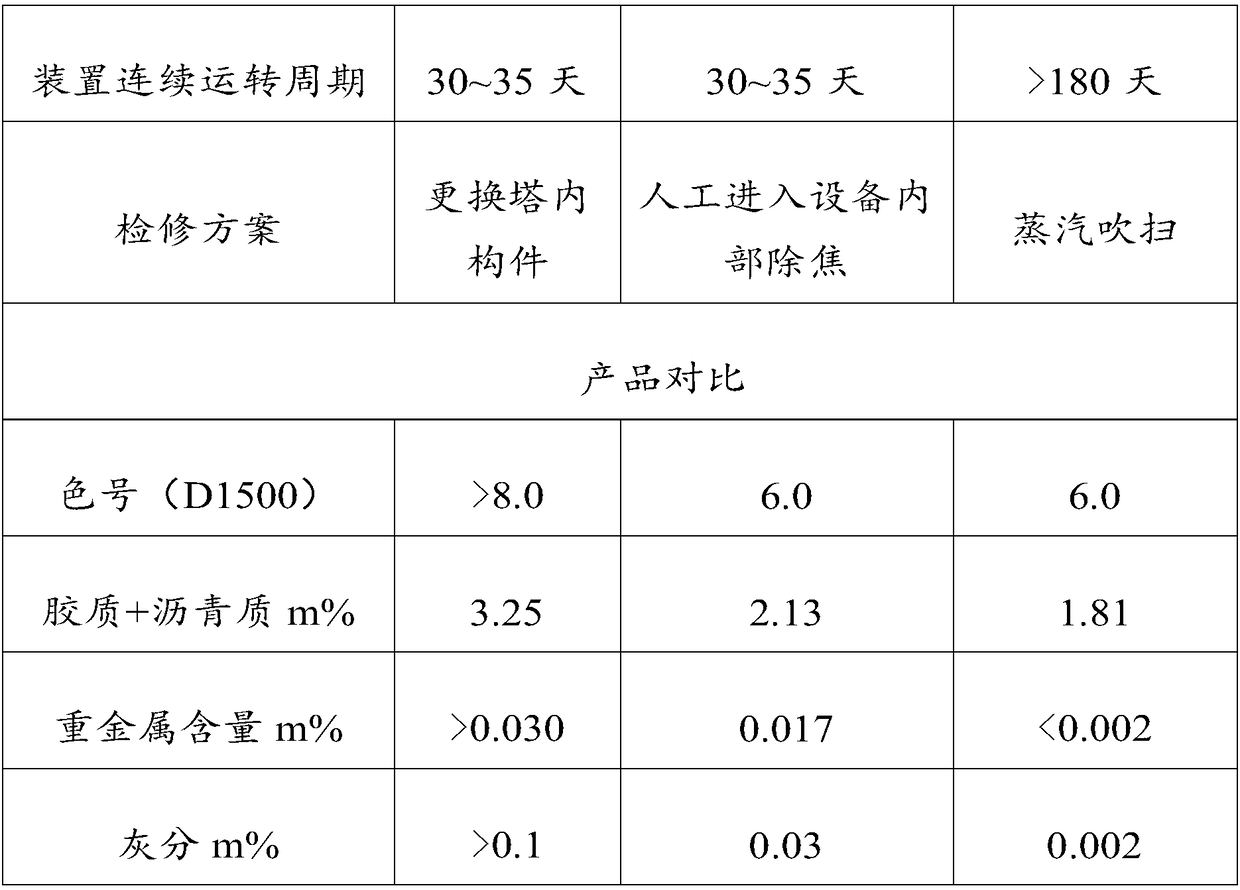

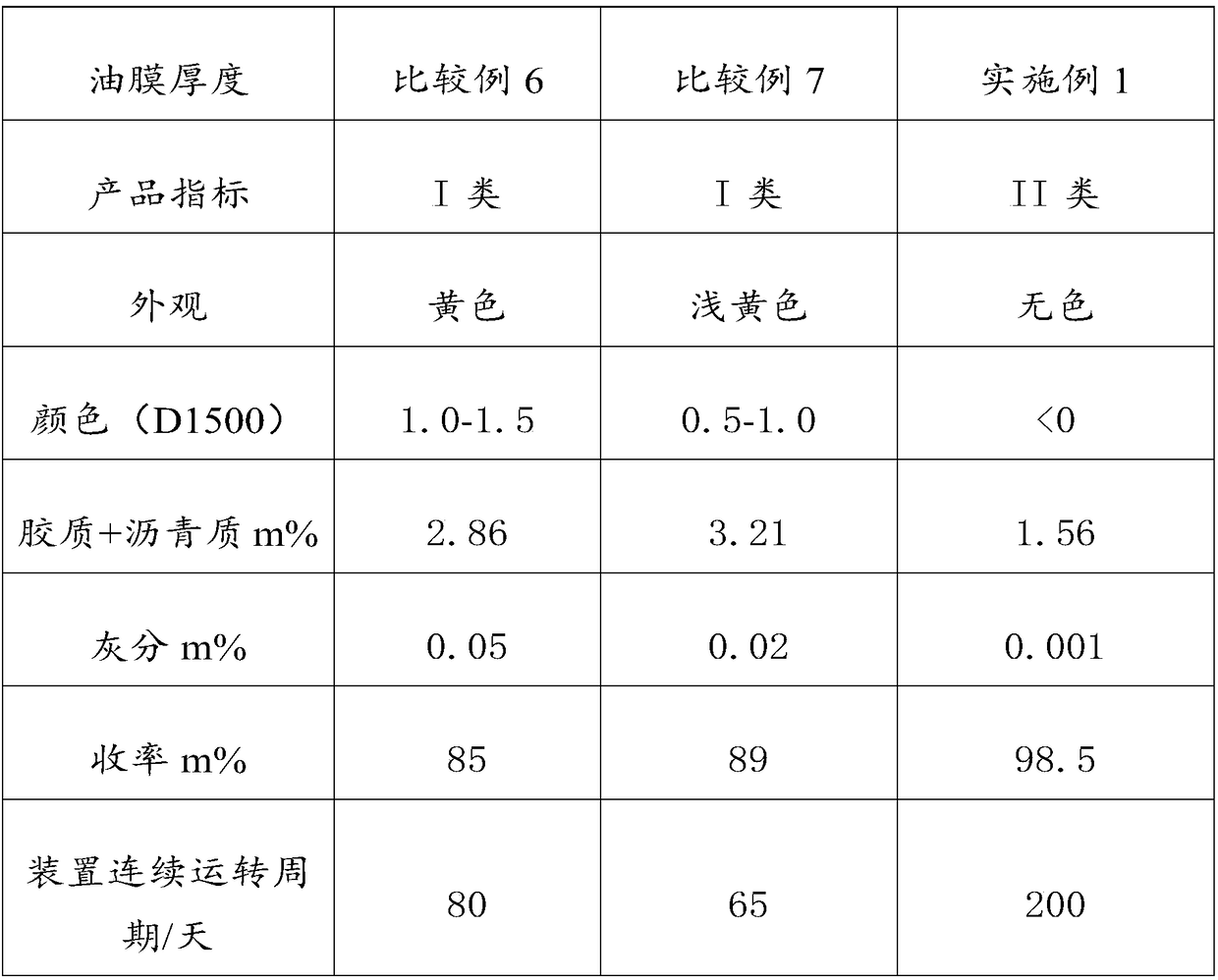

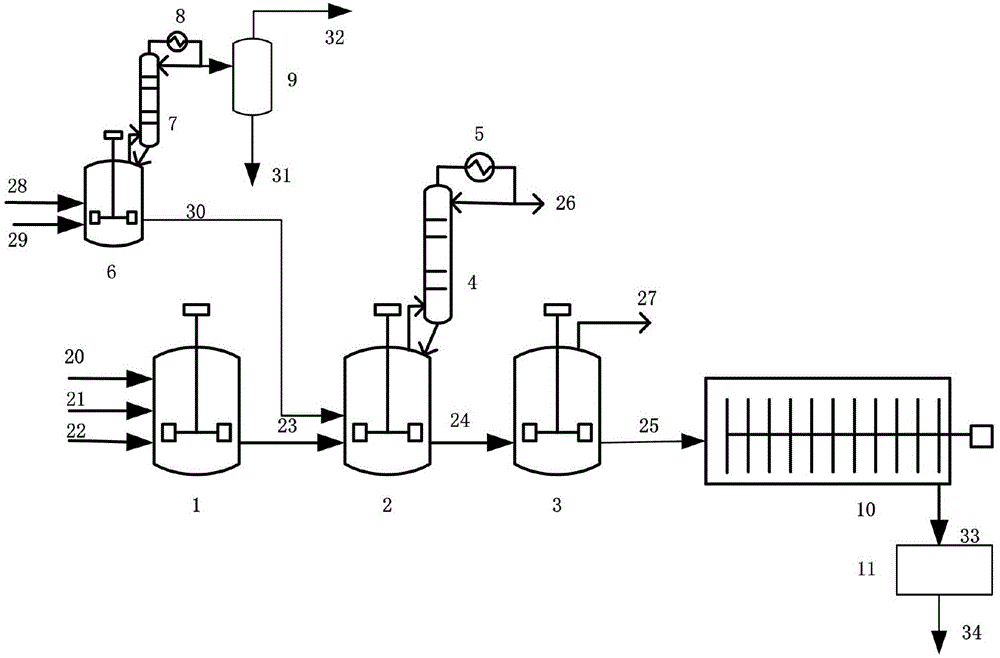

Method of hydrogenation recycling of waste mineral oil

ActiveCN109022032AAvoid cokingAvoid crackingTreatment with hydrotreatment processesBed hydrotreatment processes apparatusHeat carrierFiltration

The application provides a method of hydrogenation recycling of waste mineral oil, which includes the following steps: (a) removing impurities from the waste mineral oil through pressurized settlement, filtration and centrifugal separation; (b) heating the waste mineral oil after the impurity removal and performing oil-water separation to remove water from the waste mineral oil; (c) performing pressure-reduced flash to the dehydrated mineral oil to remove light components and emulsified water; (d) in a multiple-effect tubular falling-film evaporator, performing heat exchange with a heat carrier under a pressure reducing condition, collecting a volatile component from the top to obtain pre-hydrogenated oil; (e) blending the pre-hydrogenated oil with the light components and performing a hydrogenation reaction to obtain a hydrogenation product; (f) feeding the hydrogenation product into a normal pressure distillation column for treatment, and collecting the top products, naphtha and white oil, from the normal pressure distillation column; (g) feeding the bottom product of the normal pressure distillation column into a pressure-reduced distillation column to perform pressure-reduced distillation for producing basic oil. The method has simple processes, is great in raw material adaptability, is not liable to cause coking, and is high in product quality.

Owner:FUSHUN XINRUI CATALYST

Continuous catalysis production method of PBT resin

InactiveCN105085873AImprove hydrolysis resistanceInhibition of hydrolytic scaling1,4-ButanediolAlcohol

The invention discloses a continuous catalysis production method of PBT resin, and pulping, esterification, pre-polycondensation and polycondensation are carried out in order. The invention is characterized in that a catalyst conversion step is carried out before the pulping step, that is a compound with a structural formula Ti(OR)4 and 1, 4-butylene glycol are mixed and added into a catalyst preparation pot, in a condition with absolute pressure of 1-95kPa and temperature of 60-210 DEG C, a reaction is carried out for 0.5-10 hours, by-products ROH are removed, and a catalyst is obtained for a catalysis esterification reaction. According to the invention, a reaction between traditional Ti(OR)4 alkoxy titanium catalyst and 1,4-butylene glycol is carried out, a continuous reaction of PBT resin with a dihydric alcohol titanium catalyst is carried out, and at least one of alkoxys of the dihydric alcohol titanium catalyst is replaced by 1,4-butylene glycol. Hydrolysis resistance of the catalyst is good and catalysis effectiveness of the catalyst is guaranteed, simultaneously partial alkyl alcohols are recycled, and thereby reducing accumulation of alkyl alcohols in subsequent reactors, reducing influences on esterification reaction and dehydration process, reducing alkyl alcohols in waste water, and reducing COD of waste water.

Owner:CHINA PETROCHEMICAL CORP

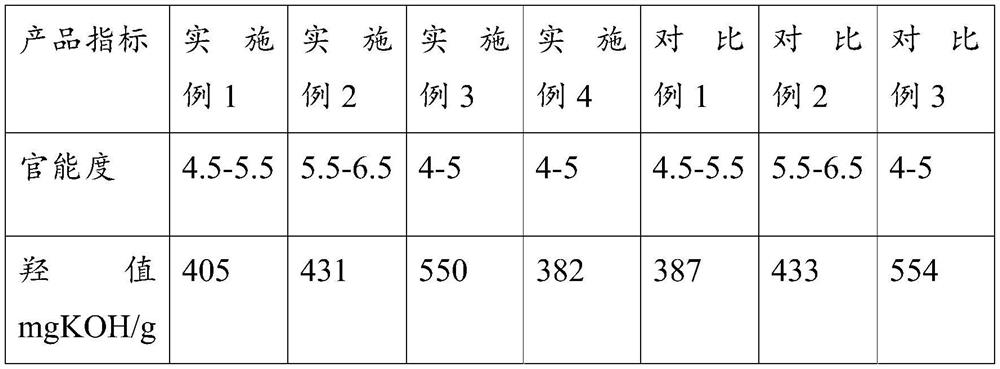

High-functionality polyether polyol and preparation method thereof

The invention provides high-functionality polyether polyol and a preparation method thereof, which are beneficial to reducing or eliminating the influence of a low-functionality initiator on product production based on the preparation method provided by the invention. The invention provides a preparation method of high-functionality polyether polyol, which comprises the following steps: adding a polyether polyol solvent and an initiator into a reaction vessel, adding alkylene oxide into the reaction vessel in the presence of a catalyst, and carrying out ring-opening polymerization reaction onthe alkylene oxide and the initiator in an inert gas atmosphere to generate the high-functionality polyether polyol, the initiators include a high functionality initiator and optionally a low functionality initiator.

Owner:WANHUA CHEMYANTAI RONGWEI POLYURETHANE CO LTD +1

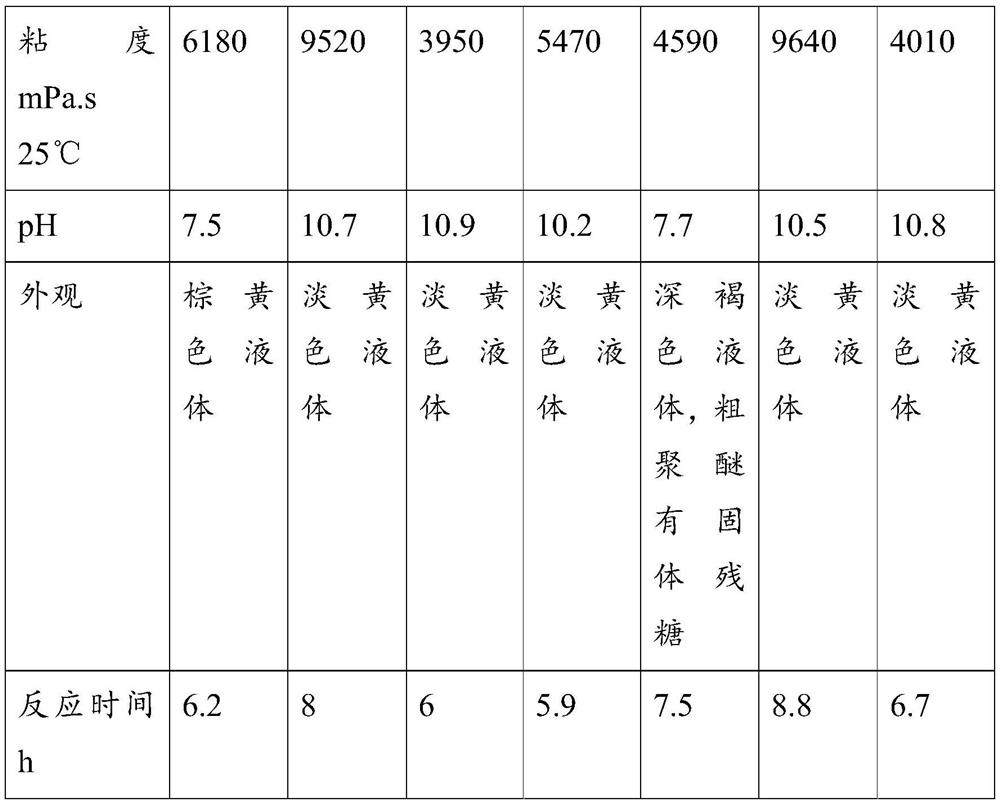

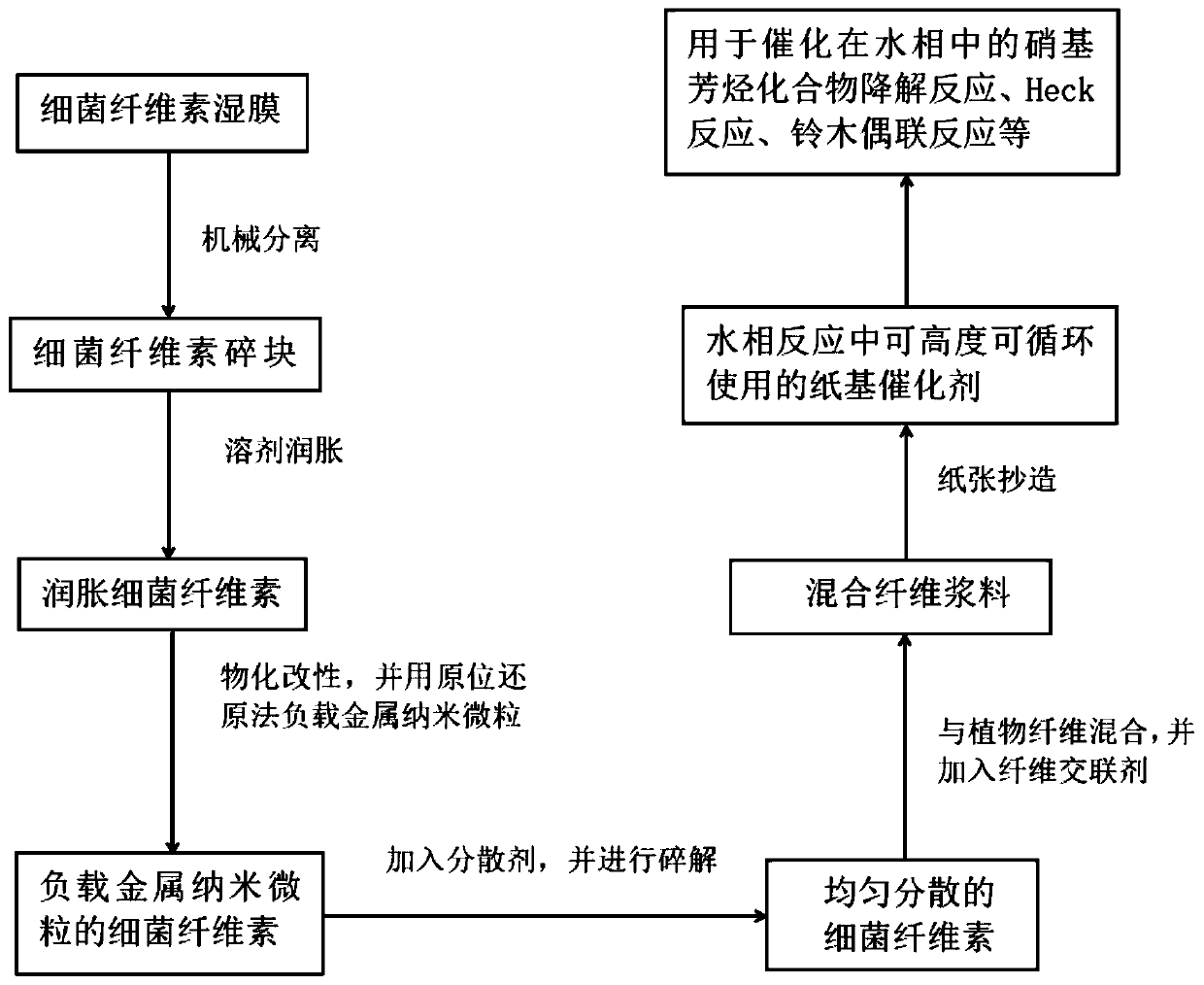

Method for improving water phase reaction recycling capability of bacterial cellulose-plant fiber composite paper-based catalyst

InactiveCN110090663AImprove binding stabilityGuaranteed catalytic efficiencyCatalyst carriersOrganic compound preparationPolyethylene oxidePolymer science

The invention discloses a method for improving the water phase reaction circulation capability of a bacterial cellulose-plant fiber composite paper-based catalyst. In the method, a dispersant and a fiber cross-linking agent are added in the process of preparing the paper-based catalyst by compounding bacterial cellulose loaded with metal nanoparticles and plant fibers, so that the water phase reaction recycling capability of the paper-based catalyst is improved. The bacterial cellulose is cellulose secreted and synthesized by bacterial microorganisms. The metals are gold, copper, silver, palladium, chromium, nickel and other metals with catalytic properties. The dispersant is carboxymethyl cellulose, xylan, glucomannan, cationic etherified starch, polyethylene oxide, and the like. The fiber crosslinking agent is polyethyleneimine, polyacrylamide, polyvinyl alcohol, polyamide epichlorohydrin, and the like. The paper-based catalyst prepared by the invention has the advantages of extremely convenient use and recovery, high water phase recycling capability, extremely low metal particle leaching rate, good catalytic efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

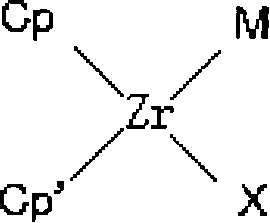

Boroxol titanocene metal catalyzer and preparation method and application thereof

The invention relates to a boroxol monotitanocene catalyst with high polymerization activity to alpha-olefin and high solubility in water, a relative preparation method and an application. The preparation method comprises synthesizing borate titanium trichloride from borate and titanium tetrachloride at the mol ratio of 1.00-1.05, reacting trimethylsilyl compound of cyclopentadienyl, lindenyl or relative derivative with borate titanium trichloride at the mol ratio of 1.05-1.10 to obtain borate titanium trichloride, reacting phenol or alcohol, pyrindine and borate dichloro monotitanocene at themol ratio of 1:1:1.05-1:1:1.1 to obtain boroxol monotitanocene catalyst. The invention uses borate group to lead into oxygen atoms, thereby stabilizing molecule structure and improving the solubilityand stability of the product in hexane with confirmed catalysis efficiency. The product is suitable for the homogeneous or slurry polymerization whose solvent is hexane. The synthesis method is simple. And the product can be used to synthesize the homopolymer or copolymer from ethylene or / and alpha olefin.

Owner:PETROCHINA CO LTD

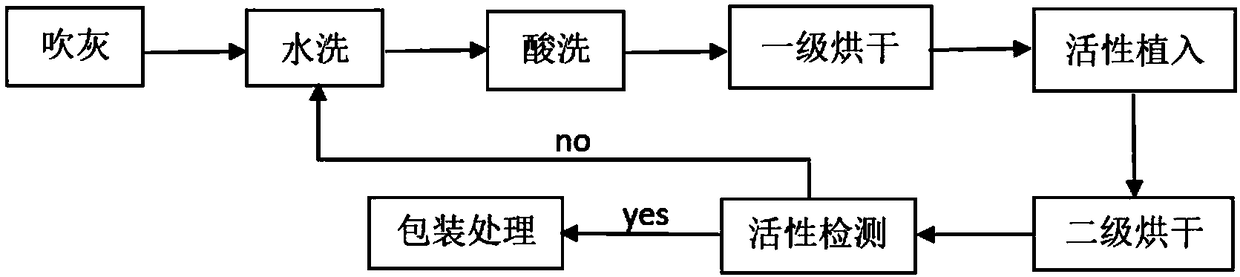

Denitration catalyst regeneration cyclic utilization method

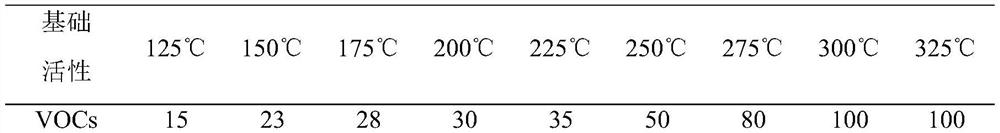

InactiveCN108097045AGuaranteed pass rateGuaranteed catalytic efficiencyDispersed particle separationCatalyst regeneration/reactivationCycle efficiencyCatalyst regeneration

The invention discloses a denitration catalyst regeneration cyclic utilization method. By using the method, the activity recovery of an inactivated denitration catalyst can be realized and the activity detection is performed on the denitration catalyst; the effective screening on unqualified and qualified catalysts is realized; the qualification rate of the finally obtained regenerated catalyst iseffectively ensured; the catalysis efficiency of the catalyst during the denitration catalysis for a next time is ensured; the regeneration cyclic utilization circulation efficiency of the whole denitration catalyst is improved.

Owner:GUANGZHOU DEV GRP CO LTD +2

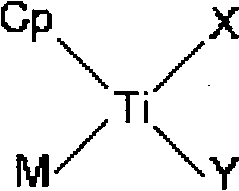

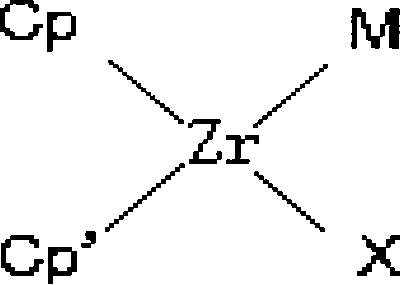

Single metallocene-titanium catalyst containing phosphate ester ligand and preparation method and application thereof

The invention relates to a single metallocene-titanium catalyst containing a phosphate ester ligand and a preparation method and application thereof. The preparation method comprises the following steps: performing reaction on 0.2 mol / L titanium tetrachloride hexane solution and 0.5 mol / L phosphate ester hexane solution for 2 hours according to the mol ratio of 1.00-1.05, and obtaining greenish yellow phosphate ester titanium trichloride; performing reaction on trimethyl silicane compounds of metallocene groups, indene groups or one derivative of the metallocene groups and the indene groups, and the phosphate ester titanium trichloride for 24 hours at a temperature of between 60 and 70 DEG C according to the mol ratio of between 1.05 and 1.10, and obtaining phosphate ester dichloro-singlemetallocene-titanium; and performing reaction on phenols or alcohols, pyridine and the phosphate ester dichloro-single metallocene-titanium according to the mol ratio of between 1:1:1.05-1:1:1.1, andobtaining phosphate ester single metallocene-titanium compounds. The catalyst has a stable molecular structure in hexane and is easy to dissolve, and the synthesis method is simple and convenient, suitable for homogeneous polymerization or slurry polymerization by adopting the hexane as a solvent, and used for synthesizing homopolymers or copolymers by adopting ethylene and alpha-olefin as raw materials.

Owner:PETROCHINA CO LTD

Preparation method and application of covalent organic framework compound and open-cage fullerene composite material

PendingCN113769712AImprove adsorptionSimple methodProductsGas treatmentComposite materialCovalent organic framework

The invention discloses a preparation method of a covalent organic framework compound and open-cage fullerene composite material. The method comprises the following steps of: performing chemical cage opening on fullerene, mixing the fullerene with a covalent organic framework, and performing ultrasonic treatment, stirring, washing, soaking and drying to obtain the covalent organic framework compound and open-cage fullerene composite material. The invention further provides application of the composite material, wherein the composite material can be used as an electrocatalyst for efficient hydrogen evolution, can solve the problem that the cost is too high due to the fact that a traditional electrocatalyst depends on precious metal, improves the catalytic activity of the electrocatalyst, can also be applied to adsorption of carbon dioxide, and has higher nitrogen doping rate and larger specific surface area and pore volume compared with traditional adsorbents, so that the material has better adsorbability, selectivity and repeatability. The method is suitable for preparing the covalent organic framework compound and open-cage fullerene composite material, and the prepared composite material can be further applied to carbon dioxide adsorption and can also be used as an electrocatalyst for efficient hydrogen evolution.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

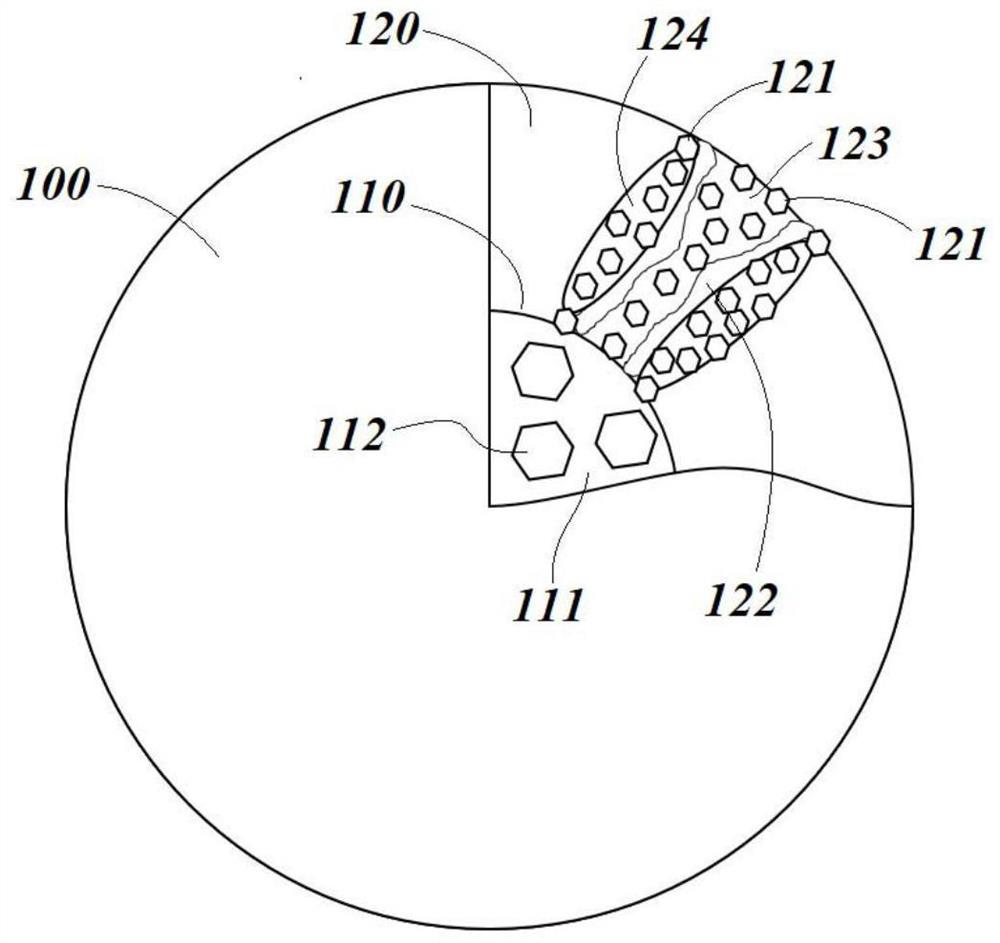

Boroxol cyclopentadienyl zirconium metal catalyzer and preparation method and application thereof

The invention relates to a boroxol cyclopentadienyl zirconium metal catalyst, a preparation method and an application. The preparation method comprises adding zirconium dichloride ethylene glycol dimethyl ether solution containing bis (cyclopentadienyl), bis (lindenyl) or relative derivative groups, whose density is 0.02mol / L, mixing and slowly adding boric acid dibasic ester compound and the ethylene glycol dimethyl ether solution of pyridine in 20min, while the pyridine density is 0.02mol / L and the density of boric acid dibasic ester is 0.02mol / L, wherein the mol ratio of boric acid dibasic ester compound, pyridine and the irconium dichloride containing bis (cyclopentadienyl), bis (lindenyl) or relative derivative groups is 1:1:1-1:1:1.05, reacting for 8h, and after the reaction, and evaporating the ethylene glycol dimethyl ether solution to obtain boroxol cyclopentadienyl zirconium metal catalyst. The synthesis materials are cheap, the process is simple, the yield is high, the catalystic polymerization activity is high, the product can be used for the homopolymerization or copolymerization of ethylene and alpha olefin and the synthesized copolymer has adjustable structure.

Owner:PETROCHINA CO LTD

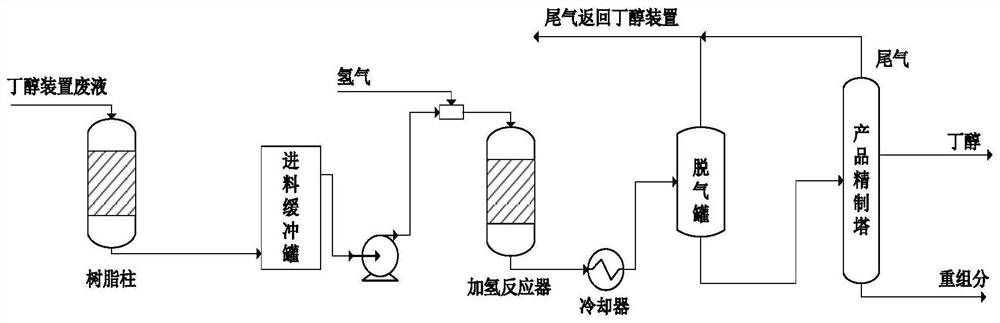

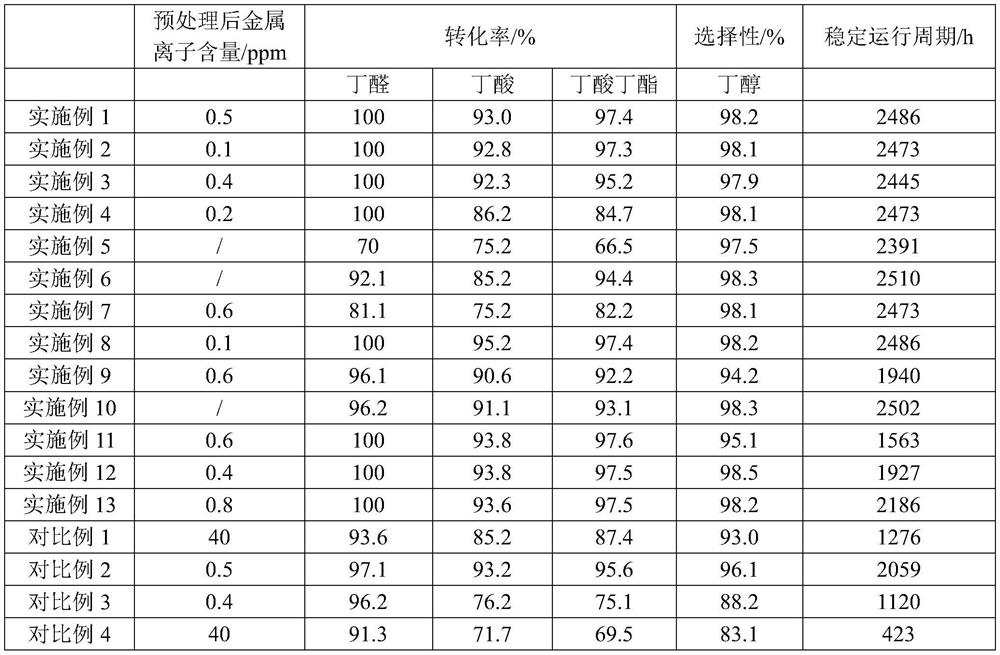

Method for recycling waste liquid from butanol device

ActiveCN113735688AImprove conversion rateHigh selectivityOrganic compound preparationHydroxy compound separation/purificationPtru catalystHydrogenation reaction

The invention discloses a method for recycling waste liquid from a butanol device. The method comprises the following steps: a, pretreating the waste liquid from the butanol device through ion exchange resin filled in a fixed bed; b, pressurizing the pretreated waste liquid, fully mixing the pretreated waste liquid with high-pressure hydrogen in a static mixer, and feeding the mixture into a fixed bed reactor for a hydrogenation reaction, wherein the fixed bed reactor is filled with a hydrogenation catalyst; c, after the reaction is finished, removing hydrogen and other light components dissolved in reaction liquid through a high-pressure degassing tank; and d, feeding the degassed reaction liquid to a product refining tower, and carrying out rectifying and separating to obtain butanol. The invention provides the resource recycling method aiming at the specific composition of the waste liquid from the butanol device, and has the advantages of high ester conversion rate, high product selectivity and long catalyst service life.

Owner:WANHUA CHEM GRP CO LTD

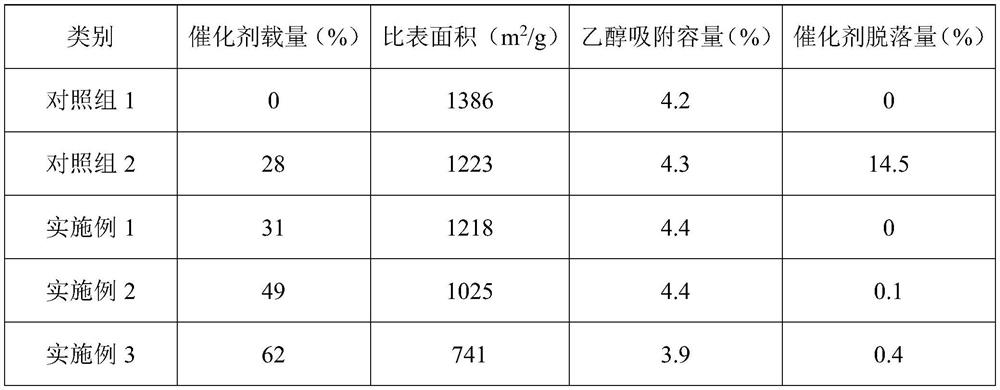

Efficient carbon fiber supported catalyst and preparation method thereof

ActiveCN113663729AMake full use of the effect of adsorption and concentrationIncrease loadOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberCarbon fibers

The invention discloses an efficient carbon fiber supported catalyst and a preparation method thereof. The preparation method comprises the following steps: step 1, dissolving manganese nitrate, copper nitrate and nickel nitrate in deionized water and alcohol, and forming a precursor alcohol solution of nitrate; heating and stirring the precursor alcohol solution until viscous thick gel is formed; and drying and calcining to obtain catalyst powder, wherein the catalyst mainly comprises a mixture of manganese oxide, copper oxide and nickel oxide; step 2, carrying out ball milling on the catalyst powder, and then mixing and stirring the catalyst powder with a prepolymer, a photoinitiator and silica sol for 10-60 minutes to form a mixed dipping solution; and step 3, completely immersing carbon fibers in the mixed dipping solution, carrying out ultrasonic treatment for 0.5-2 h, and then standing for 0.5-2 h; taking out the wet carbon fibers and placing the wet carbon fibers under a high-pressure mercury lamp or a xenon lamp for irradiation until drying; and dipping and loading the carbon fibers once or for multiple times. The catalyst has the advantages of high catalyst loading rate, difficult falling of the catalyst and the like.

Owner:南大恩洁优环境技术江苏股份公司

Process for catalytically synthesizing dimethyl carbonate

ActiveCN114213251AIncrease surface areaImprove effect efficiencyProductsReagentsPtru catalystPorous catalyst

The invention discloses a process for catalytically synthesizing dimethyl carbonate, which comprises the following steps: (1) carrying out complex breaking treatment on chemical nickel-plating wastewater, then adding a precipitator, separating out precipitate, and crushing into hydroxide powder; (2) uniformly mixing the hydroxide powder, silicon dioxide powder, calcium oxide powder and a binder, granulating, and calcining the obtained particles in an air atmosphere to obtain a catalyst precursor; and (3) soaking the catalyst precursor in clear water, cleaning, repeatedly executing the step until the pH value of the cleaning solution is constant, taking out a solid product, and drying to obtain the porous catalyst. And (4) taking the porous catalyst as a catalyst, preparing dimethyl carbonate by adopting a methanol-carbon dioxide direct method, inserting an ultrasonic vibration rod into the liquid level of methanol during preparation, and separating out dimethyl carbonate after completion. According to the process disclosed by the invention, the industrial waste liquid is used as a raw material and is modified to prepare the catalyst, so that the cost of the catalyst is reduced, and the conversion rate of methanol is effectively improved.

Owner:SHANDONG DEPU CHEM IND SCI & TECH

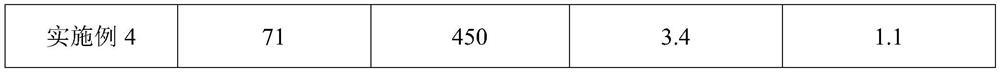

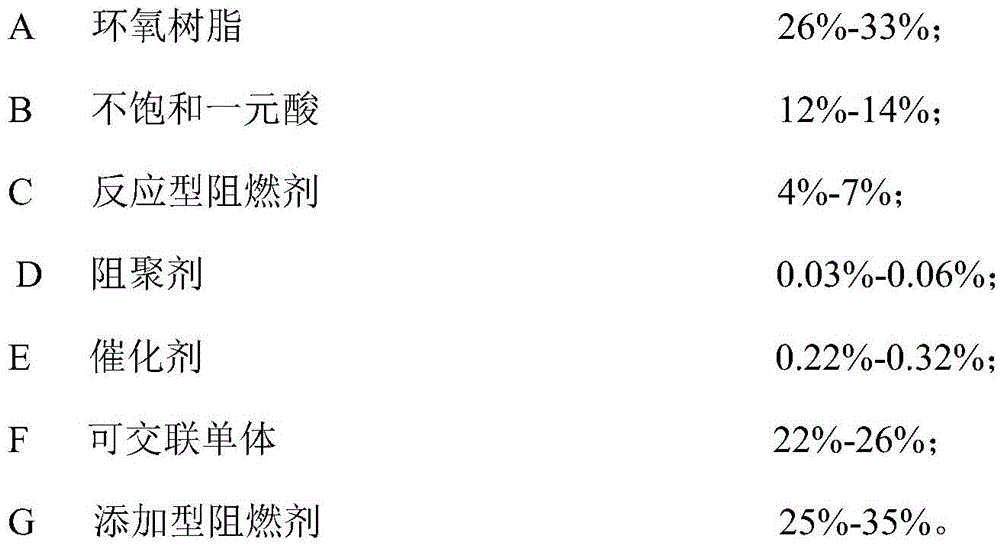

A low-smoke, halogen-free, high-temperature flame-resistant vinyl ester resin and its preparation method

ActiveCN104031213BHigh catalytic efficiencyGuaranteed catalytic efficiencyEnvironmental resistanceEpoxy

The invention relates to a low-smoke, halogen-free, high-temperature-resistant flame-retardant vinyl ester resin and a preparation method thereof, belonging to the technical field of flame-retardant vinyl ester resins. It is prepared from epoxy resin, unsaturated monobasic acid, reactive flame retardant, additive flame retardant, catalyst, polymerization inhibitor and crosslinkable monomer through a series of reactions. The invention is composed of raw materials with low price, low preparation cost, combined with the comprehensive effect of two kinds of flame retardants, reactive type and additive type, and the flame retardant effect is better than similar products on the market; the flame retardant resin is low-smoke and halogen-free, and can replace existing Brominated flame retardant chemically modified vinyl resin with halogen environmental protection issues; moderate viscosity, good construction performance, good anti-settling performance, outstanding corrosion resistance and high temperature resistance, can be used for building materials, automotive parts, etc., especially for FRP products that require low-smoke, halogen-free and flame-retardant requirements such as hand lay-up railway passenger car parts.

Owner:CHANGZHOU HUAKE POLYMERS

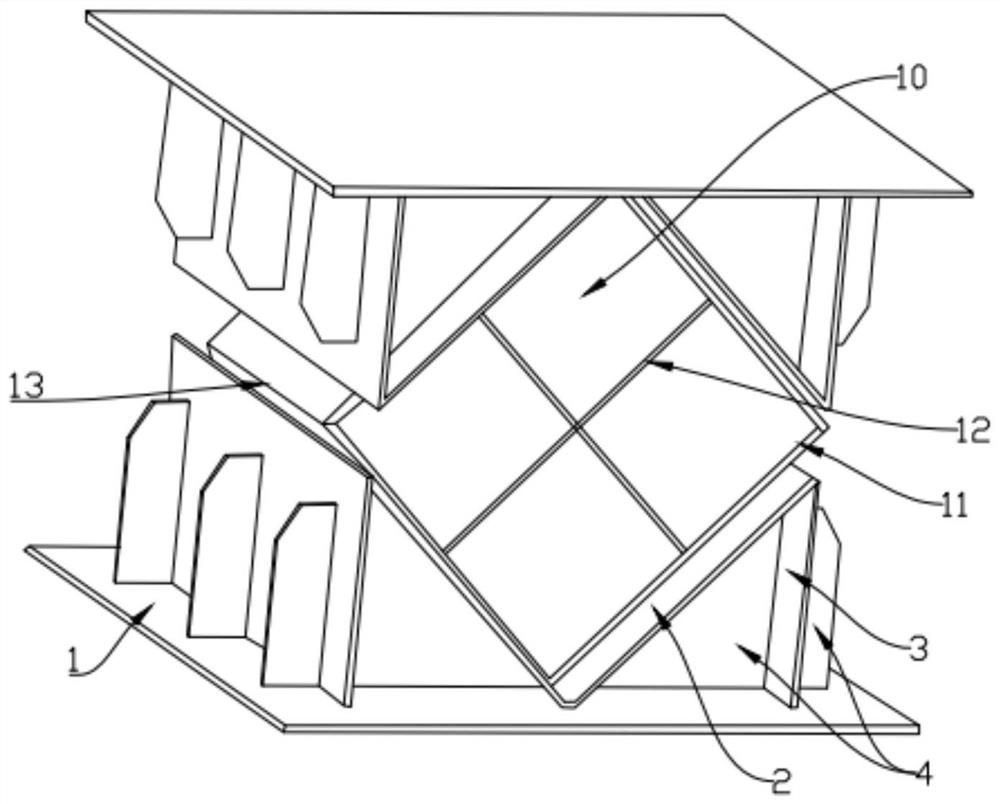

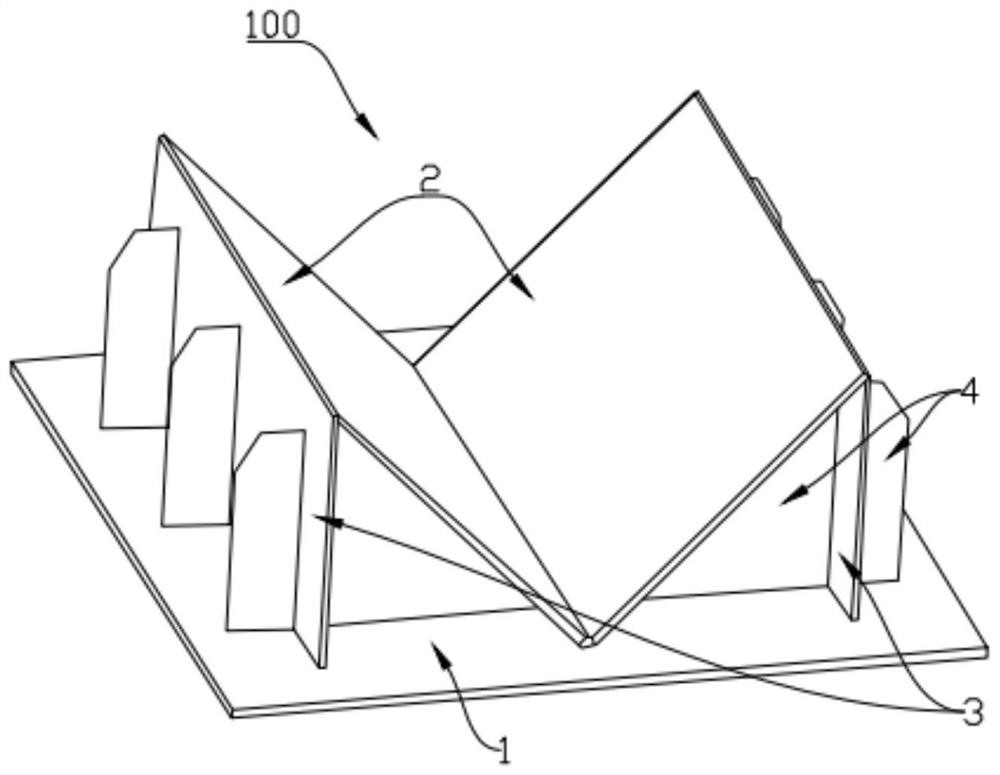

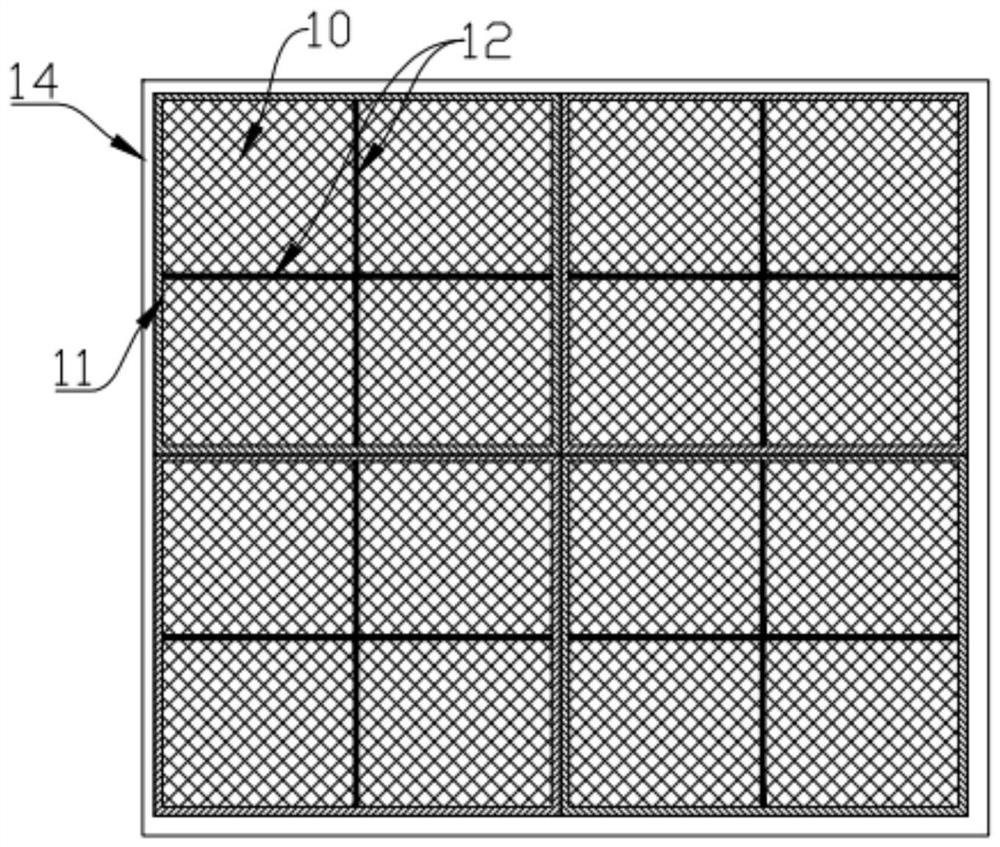

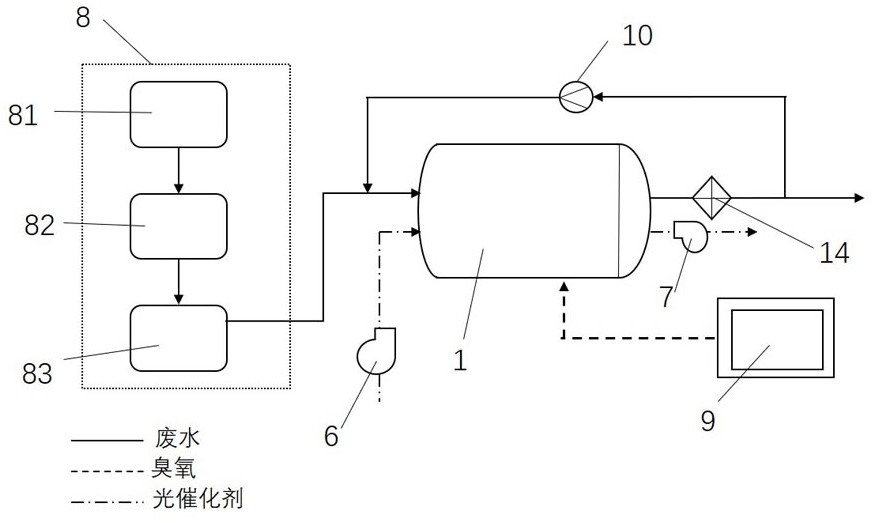

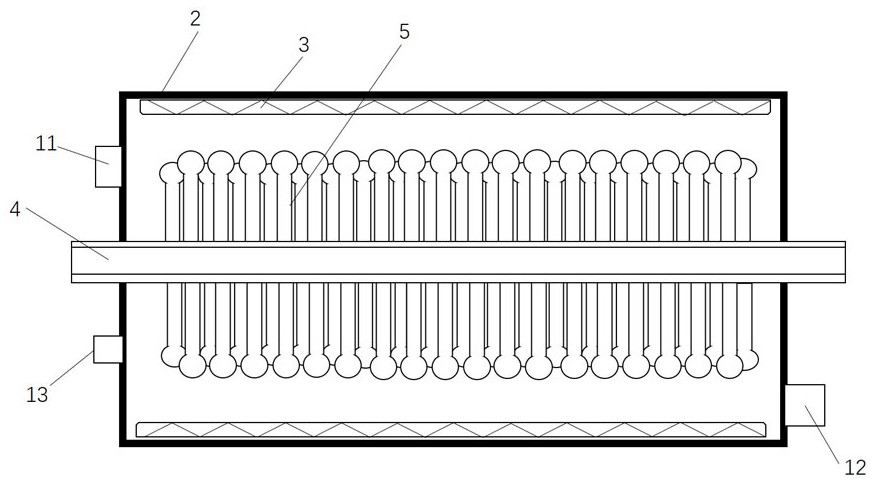

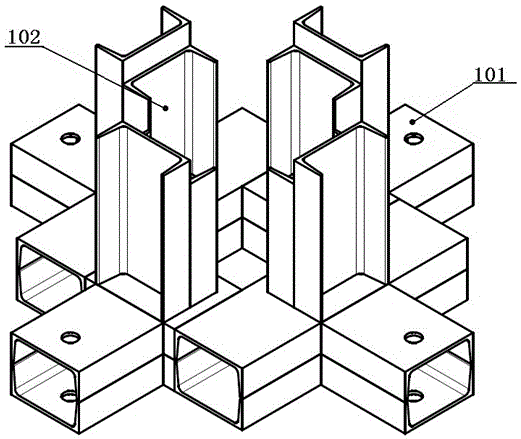

Welding tool for packaging marine catalyst module

PendingCN113996995APrecise positioningEasy dockingWelding/cutting auxillary devicesAuxillary welding devicesPtru catalystStructural engineering

The invention discloses a welding tool for packaging a marine catalyst module, which comprises two oppositely arranged positioning mechanisms, wherein the catalyst module is positioned by the two positioning mechanisms; and each positioning mechanism comprises a fixed base and a positioning frame fixedly arranged on the fixed base, each positioning frame comprises two supporting inclined plates which are obliquely fixed on the fixed base, a supporting area with an included angle of 90 degrees is defined by the two supporting inclined plates, the catalyst module is placed in the supporting area, and the supporting areas of the two positioning mechanisms are oppositely arranged to realize positioning of the catalyst module. According to the welding tool for packaging the marine catalyst module, a shell of the catalyst module is fixed and welded, so that the integrity of a catalyst is ensured, arrangement and placement of the catalyst in a reaction chamber are facilitated, and meanwhile, a catalyst carrier is prevented from being broken and the like.

Owner:合肥中海蓝航科技有限公司

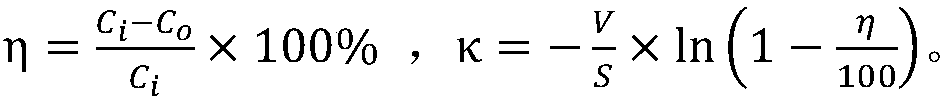

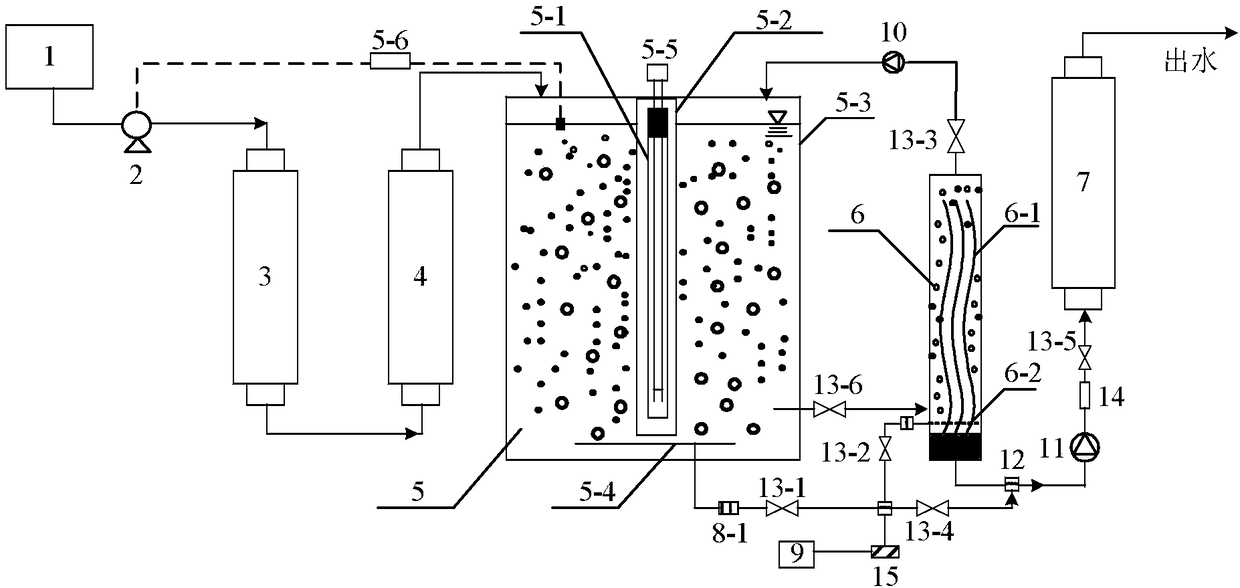

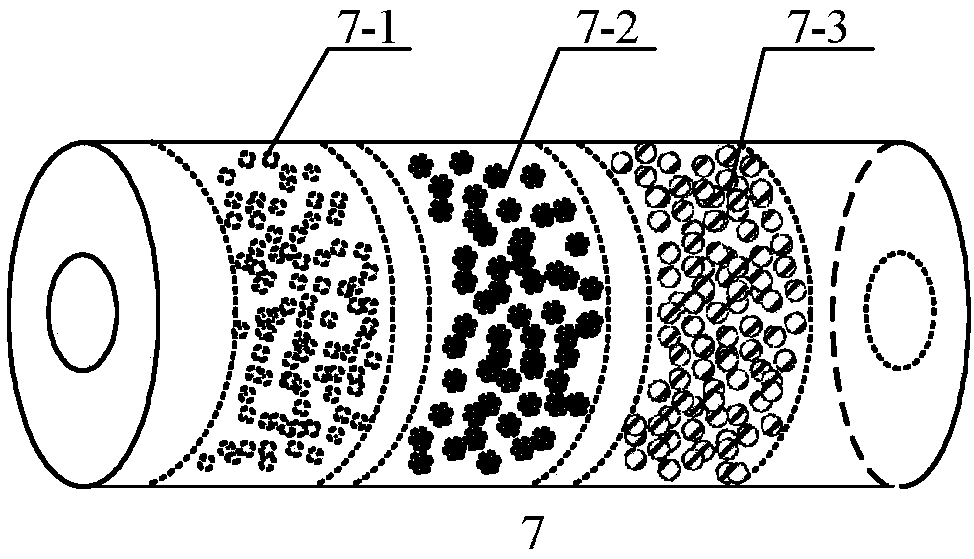

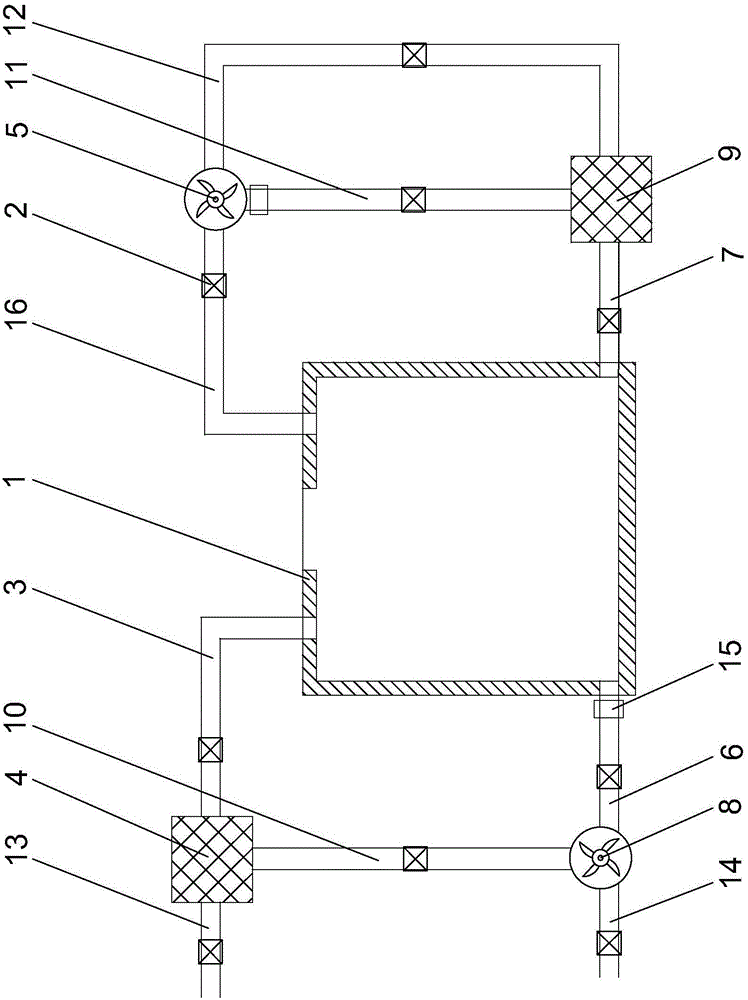

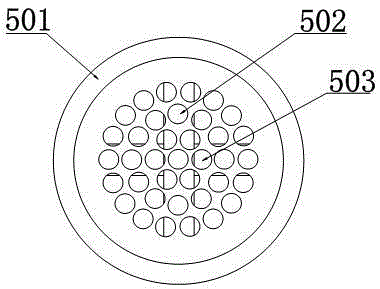

Novel external suspension photocatalysis membrane water purifier

PendingCN109179820AImprove throughputReduce pollutionWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionSolenoid valve

The invention discloses a novel external suspension photocatalysis membrane water purifier. The novel external suspension photocatalysis membrane water purifier comprises a water inlet tank, a water pump, a first filter, an active carbon filter, a photocatalysis reactor, a membrane separation system, an activation mineralization device, a reflux pump, a suction pump, solenoid valves 1-6, and an air compressor; the water inlet tank is connected with the water pump, the first filter, and the active carbon filter successively; the active carbon filter is connected with the photocatalysis reactor;the photocatalysis reactor is connected with the 6th solenoid valve, and then is connected with the membrane separation system; a first water outlet is connected with a three-way valve, and the suction pump; a water suction pump is connected with the 5th solenoid valve, and is connected with the activation mineralization device; a second water outlet is connected with the 3th solenoid valve, andis connected with the photocatalysis reactor; an aeration pipe is arranged in the photocatalysis reactor; a micropore aeration mechanism is arranged in the membrane separation system, and is connectedwith the air compressor through a pipeline. The novel external suspension photocatalysis membrane water purifier is capable of enhancing catalytic efficiency and membrane anti-pollution capacity, reducing operation energy consumption, is large in water processing amount, and possesses water activation and mineralization functions.

Owner:ZHEJIANG TONGJI VOCATIONAL COLLEGE OF SCI & TECH

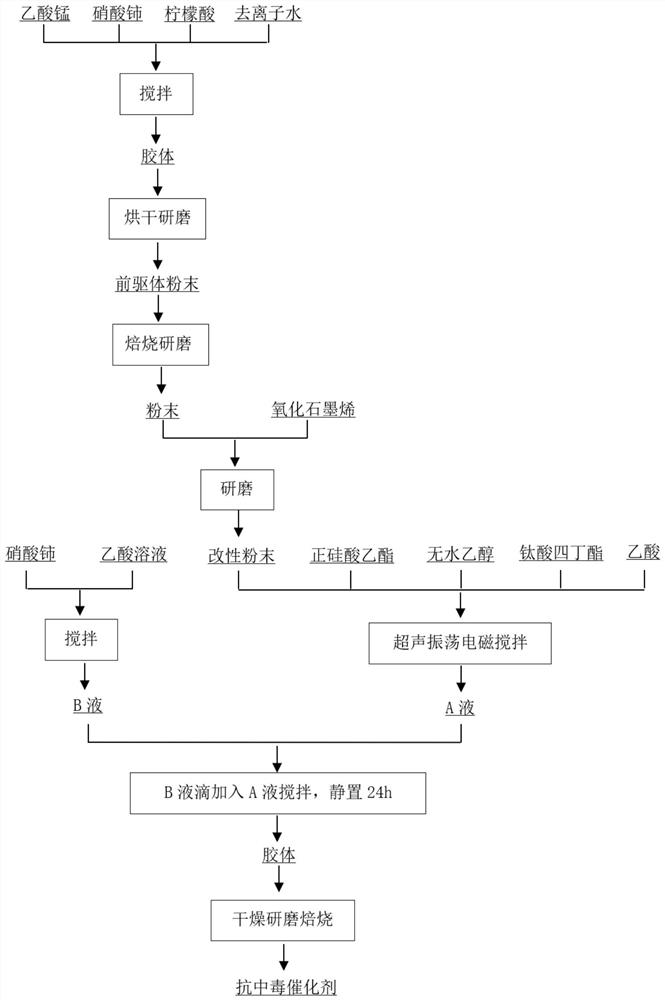

Layered perovskite type catalyst compounding method and composite catalyst

InactiveCN113893849AImprove poisoning situationGuaranteed catalytic efficiencyCatalyst protectionHeterogenous catalyst chemical elementsPtru catalystSilicic acid

The invention discloses a layered perovskite type catalyst compounding method and a composite catalyst, and relates to the technical field of catalysts. According to the invention, perovskite type composite oxide powder is coated as a catalyst core with a mixed solution of ethyl orthosilicate and tetrabutyl titanate, and a coating layer containing pores is formed on the outer layer of the catalyst core of the prepared layered perovskite type catalyst, so that the catalytic efficiency of the catalyst is ensured, and the catalyst has good SO2, H2O and alkali metal poisoning resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Boroxol cyclopentadienyl zirconium metal catalyzer and preparation method and application thereof

The invention relates to a boroxol cyclopentadienyl zirconium metal catalyst, a preparation method and an application. The preparation method comprises adding zirconium dichloride ethylene glycol dimethyl ether solution containing bis (cyclopentadienyl), bis (lindenyl) or relative derivative groups, whose density is 0.02mol / L, mixing and slowly adding boric acid dibasic ester compound and the ethylene glycol dimethyl ether solution of pyridine in 20min, while the pyridine density is 0.02mol / L and the density of boric acid dibasic ester is 0.02mol / L, wherein the mol ratio of boric acid dibasicester compound, pyridine and the irconium dichloride containing bis (cyclopentadienyl), bis (lindenyl) or relative derivative groups is 1:1:1-1:1:1.05, reacting for 8h, and after the reaction, and evaporating the ethylene glycol dimethyl ether solution to obtain boroxol cyclopentadienyl zirconium metal catalyst. The synthesis materials are cheap, the process is simple, the yield is high, the catalystic polymerization activity is high, the product can be used for the homopolymerization or copolymerization of ethylene and alpha olefin and the synthesized copolymer has adjustable structure.

Owner:PETROCHINA CO LTD

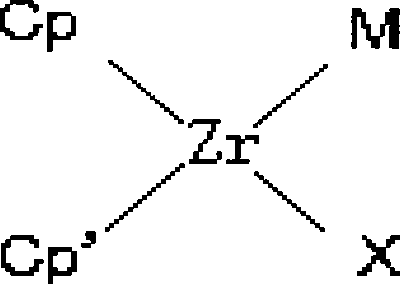

an o 3 / Photocatalytic advanced oxidation reaction system and method for high concentration wastewater

ActiveCN111573929BReduce deliveryReduce usageWater/sewage treatment by irradiationWater treatment compoundsUltraviolet lightsPhoto catalysis

Owner:北京中矿科技集团有限公司

Method for preparing phenylaniline

ActiveCN102070465BGuaranteed catalytic efficiencyLow costPreparation by rearrangement reactionsNickel catalystHydrogen

The invention provides a method for preparing phenylaniline, which comprises the following steps: mixing cyanophenyl shown in the formula II, first alkaline compounds, nickel catalysts and borophenylic acid shown in the formula III or borophenylic esters shown in the formula VI to carry out suzuki coupling reaction for obtaining cyanobiphenyl shown in the formula IV; mixing the cyanobiphenyl, second alkaline compounds and oxyful, and hydrolyzing the cyanobiphenyl to obtain amido biphenyl shown in the formula V; and mixing the amido biphenyl, third alkaline compounds and sodium hypohalite to generate Hofmann degradation reaction for obtaining phenylaniline shown in the formula I, wherein R1 is chlorine, bromine, iodine, sulphonic acid ester radicals, carbonic ether radicals or alkyl ester radicals; R2 is alkyl, alkoxy, cyano, amido or hydrogen; R3 is chlorine, bromine or iodine; and R4 is alkyl, alkoxy, cyano, amido or hydrogen. The preparing method provided by the invention has the advantages of mild condition, low cost, cleanness and environment protection.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

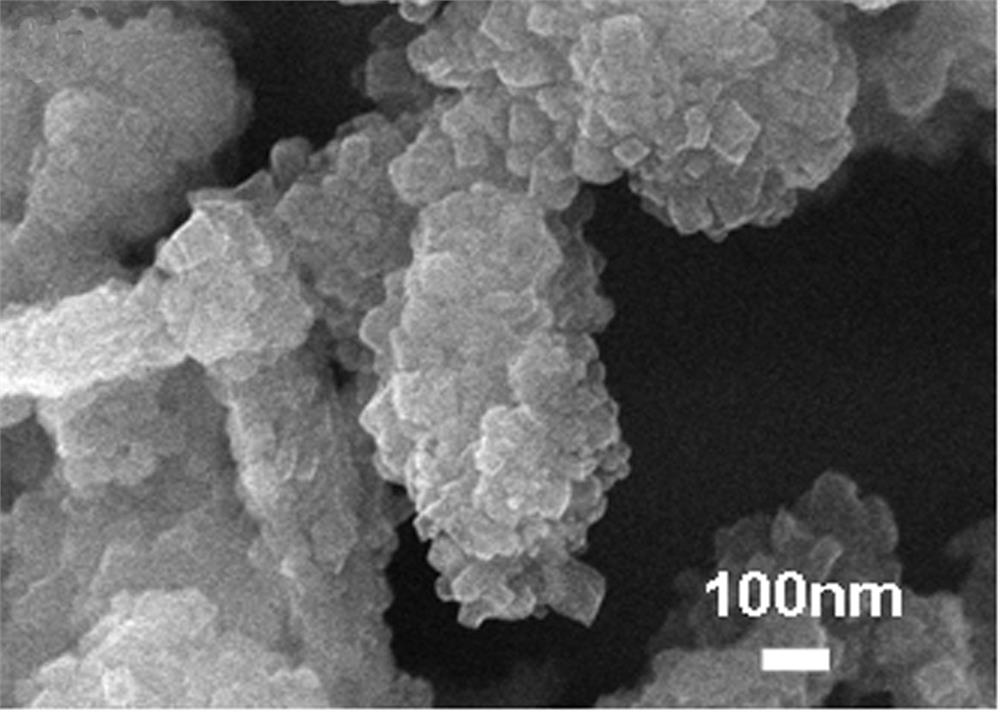

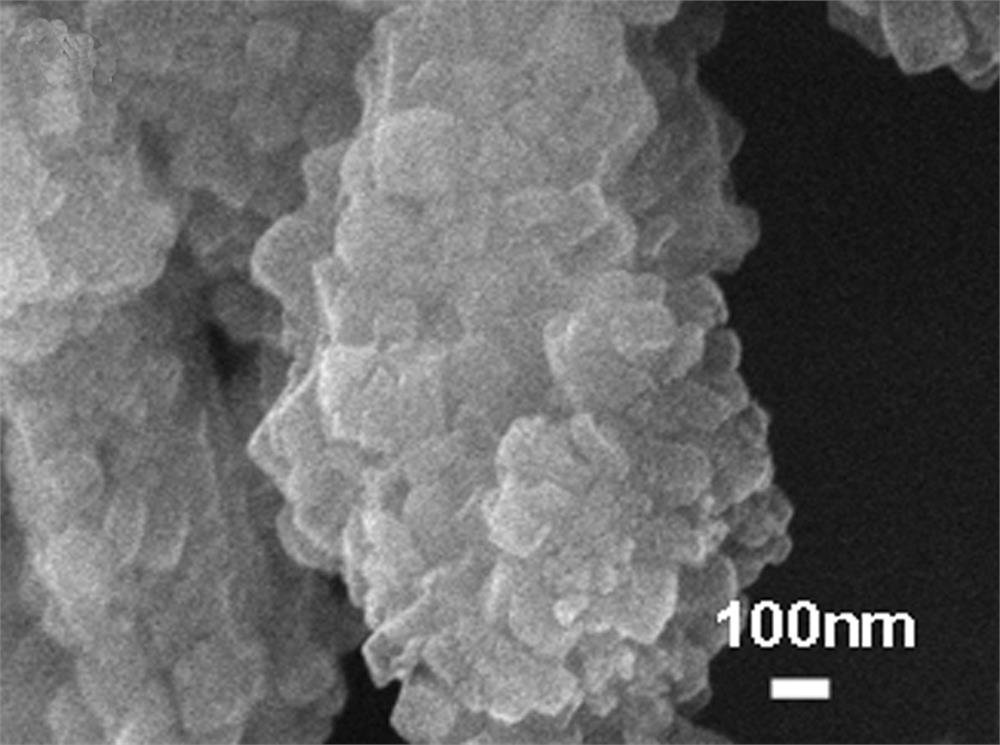

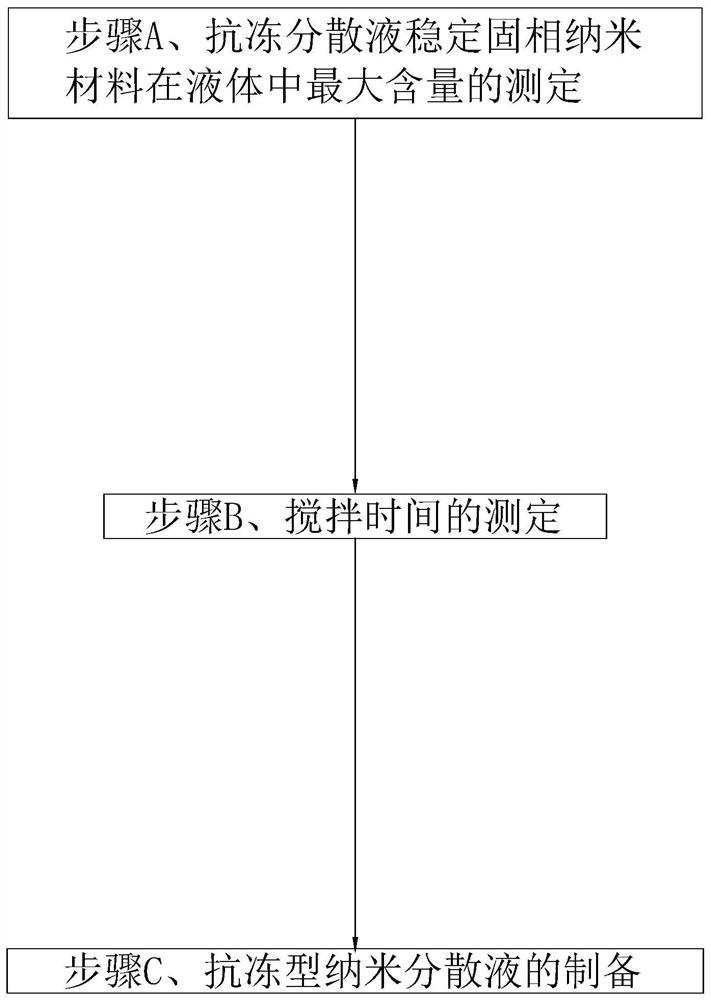

A kind of antifreeze type nano material dispersion liquid and preparation method thereof

ActiveCN108722385BGuaranteed catalytic efficiencyGuaranteed catalytic effectMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsAlcoholKetone

The invention discloses an antifreeze nanomaterial dispersion liquid and a preparation method thereof, which belongs to the technical field of nanomaterial dispersion liquid. Its technical points are: an antifreeze nanomaterial dispersion liquid, including nanomaterials and single-phase liquid. In terms of parts by weight of components, the ratio of the nanomaterial to the single-phase liquid is 1: (1-3). The single-phase liquid includes one of pure water, alcoholic liquid, or ketone liquid. The preparation method includes three steps: determination of the maximum content of the antifreeze dispersion-stabilized solid-phase nanomaterial in the liquid, determination of the stirring time, and preparation of the antifreeze type nanodispersion. After the freeze-thaw cycle, the present invention effectively reduces the impact on its original performance, thereby ensuring the catalytic efficiency and performance of the above-mentioned nanomaterial dispersion from the source; its preparation method is not only simple and convenient to operate, but also can Improve the dispersion, stability and anti-freeze properties of nanomaterial dispersions.

Owner:众联晟通(苏州)科技有限公司

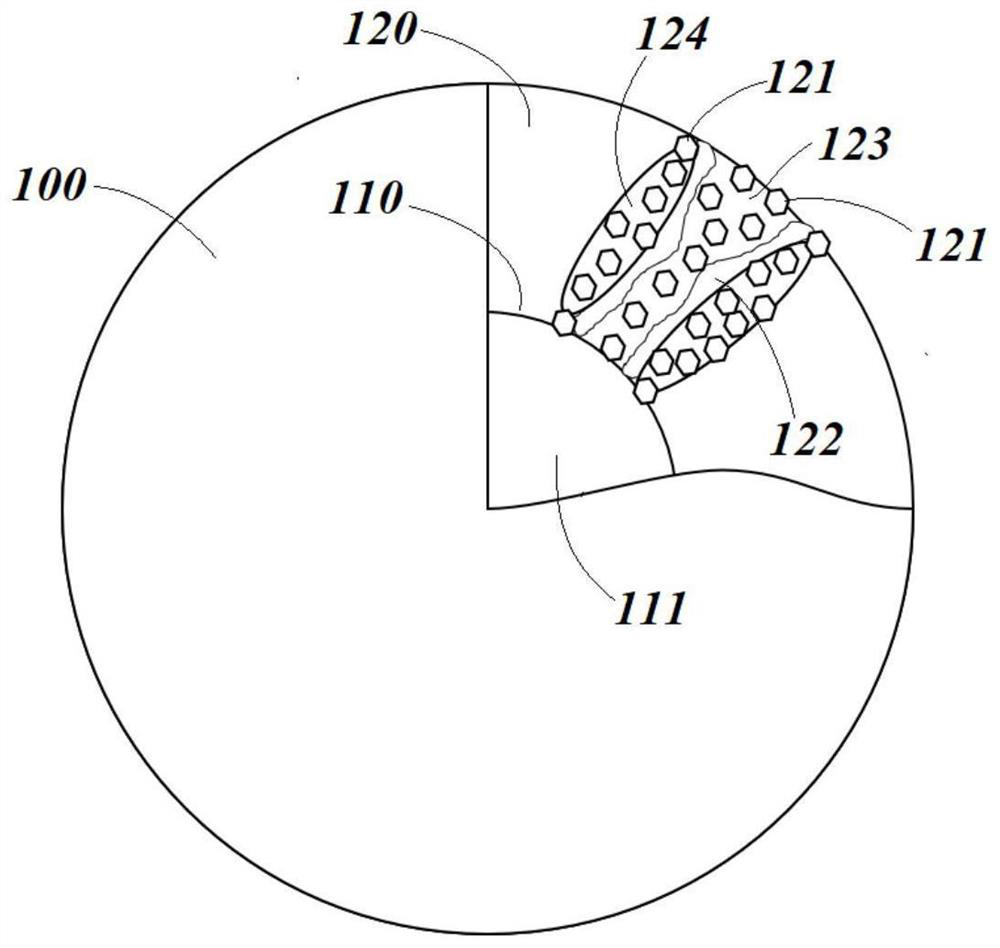

Poison-resistant layered granular catalyst and preparation method thereof

PendingCN113893848AImprove poisoning situationGuaranteed catalytic efficiencyGas treatmentCatalyst protectionCatalytic efficiencyPtru catalyst

The invention discloses a poison-resistant layered granular catalyst and a preparation method thereof, and relates to the technical field of catalysts. The catalytic efficiency of the poison-resistant layered granular catalyst is ensured by forming a coating layer containing pores on the outer layer of a catalyst core containing catalytic active components. Poisoning substances such as SO2, H2O and alkali metal can be prevented from being in direct contact with active substances. The catalyst has good SO2, H2O and alkali metal poisoning resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Device for removing dioxin through catalytic oxidation for waste gas treatment and using method of device

ActiveCN113499677ALow running costImprove oxidation capacityDispersed particle filtrationAir quality improvementPtru catalystFlue gas

The invention discloses a device for removing dioxin through catalytic oxidation for waste gas treatment and a using method of the device, and belongs to the technical field of waste gas treatment. The device for removing dioxin through catalytic oxidation for waste gas treatment comprises a mixing container, an inlet flue and an outlet flue which are used for conveying flue gas are arranged at the two sides of the outer wall of the mixing container respectively, the outer wall of the mixing container is further connected with an ozone conveying pipe, adjusting valves are fixedly arranged on the outer wall of the inlet flue and the outer wall of the ozone conveying pipe, a gas mixing mechanism is arranged in the mixing container, the bottom of the mixing container is connected with a shell, the shell is communicated with the mixing container, a secondary mixing mechanism matched with the gas mixing mechanism is arranged in the shell, and a catalyst layer is arranged in the outlet flue. The flue gas and the ozone are mixed for multiple times, so that dioxin in the flue gas is efficiently oxidized by the ozone, the oxidation effect of the ozone is improved, the situation that the ozone is discharged before reacting with the dioxin is avoided, and the comprehensive operation cost of waste gas treatment is reduced.

Owner:江苏百茂源环保科技有限公司 +1

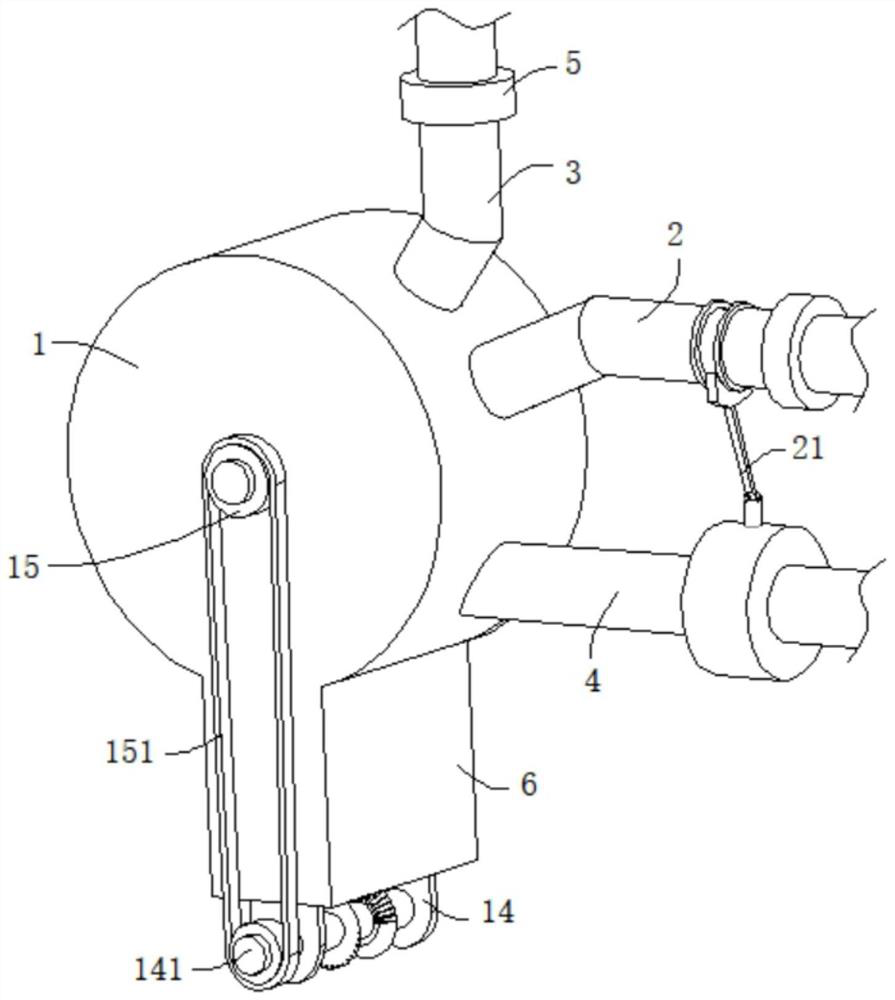

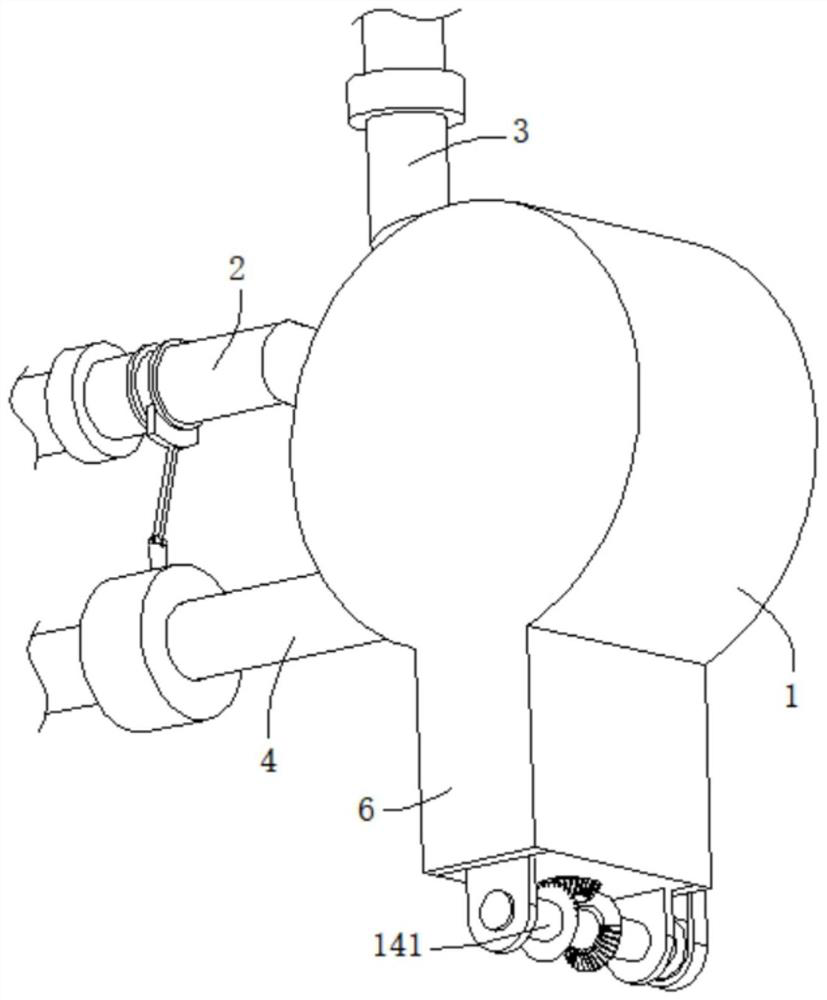

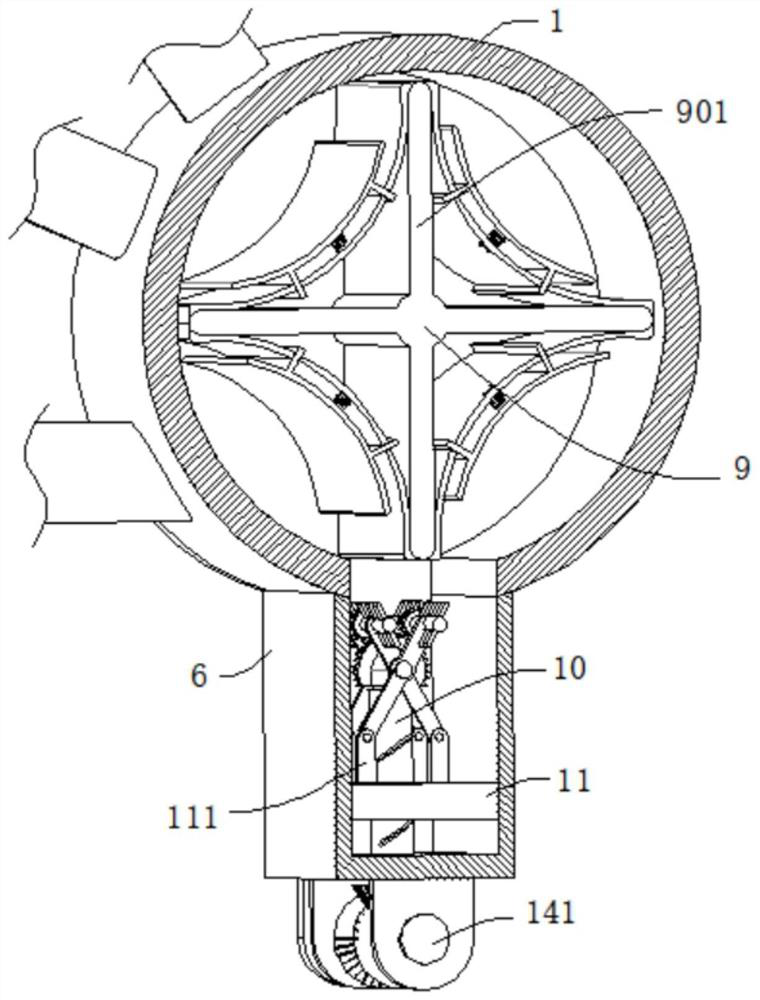

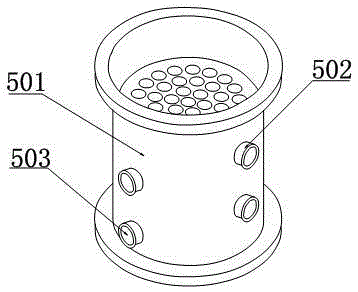

Rapid water temperature balance adjusting device

InactiveCN104312900AFast heatingGuaranteed catalytic efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringThermal water

The invention discloses a rapid water temperature balance adjusting device which comprises a tank body, heat exchangers, water pumps and electromagnetic valves, wherein a heat exchanger I and a water pump II are respectively connected to two sides of the top of the tank body by virtue of a bent tube I and a bent tube II; a water pump I and a heat exchanger II are connected to two sides of the bottom of the tank body by virtue of a connecting tube I and a connecting tube II; the heat exchanger I and the water pump I are connected by virtue of a middle tube I; the heat exchanger II and the water pump II are respectively connected with a backflow tube by virtue of a middle tube II; the heat exchanger I is further connected with a water inlet tube; the water pump I is connected with a water outlet tube; one electromagnetic valve is arranged on each tube; the connecting part of the middle tube II and the water pump II and the connecting part of the connecting tube I and the tank body are respectively provided with one temperature sensor. As two groups of heat exchangers are adopted to heat simultaneously, the speed in heating water inside the tank body is increased, the temperature of output hot water is kept in a constant state, and the catalysis efficiency of enzyme in corn starch is well ensured.

Owner:诸城兴贸玉米开发有限公司

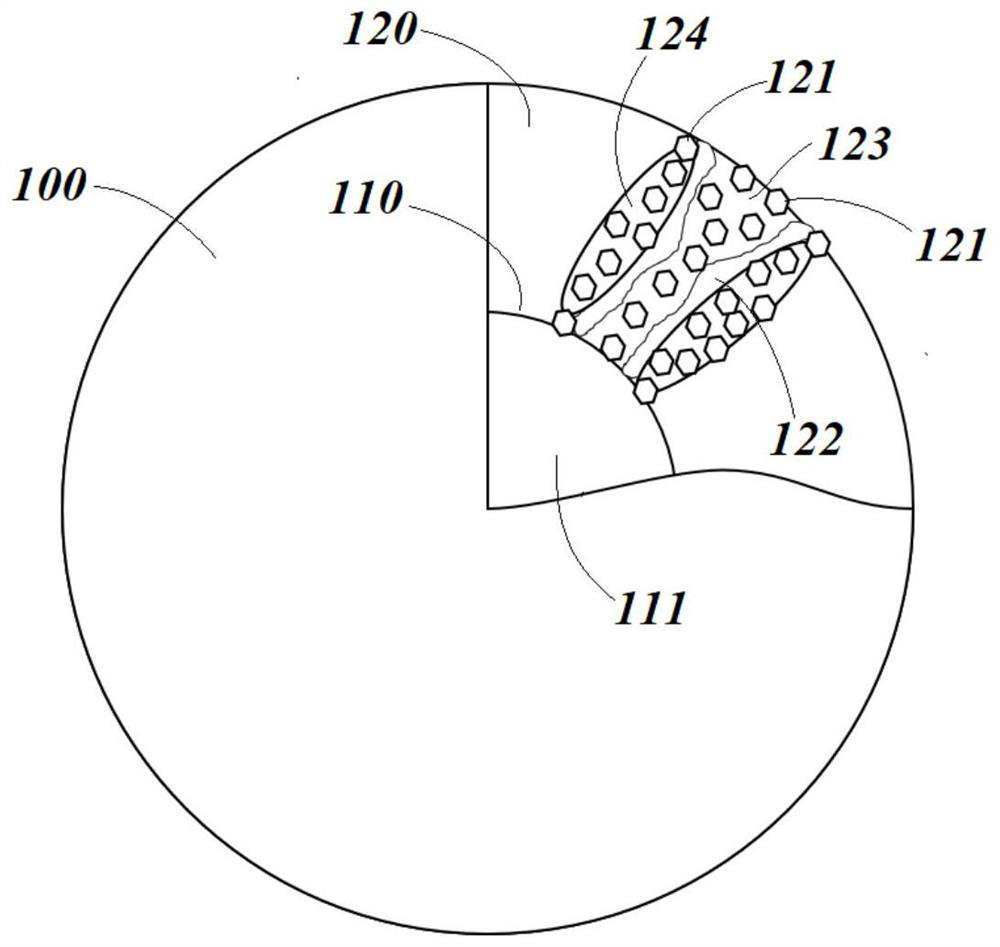

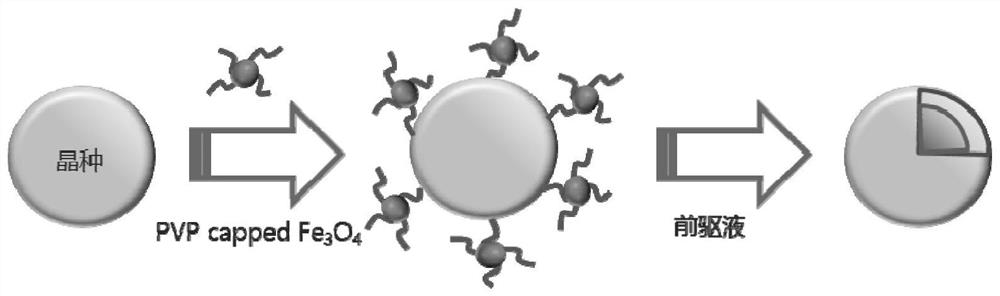

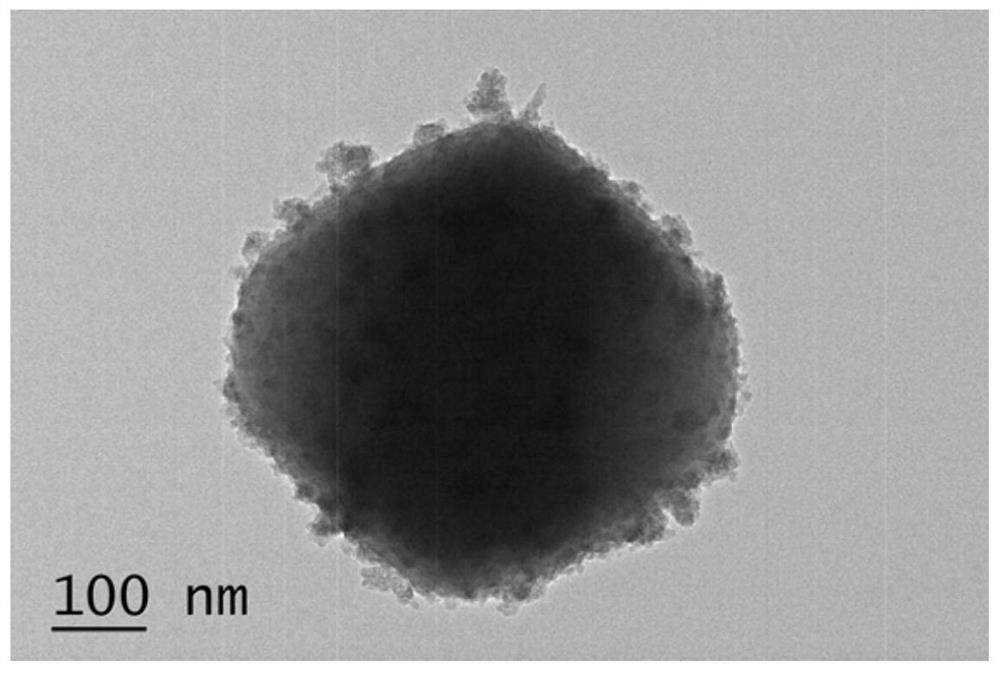

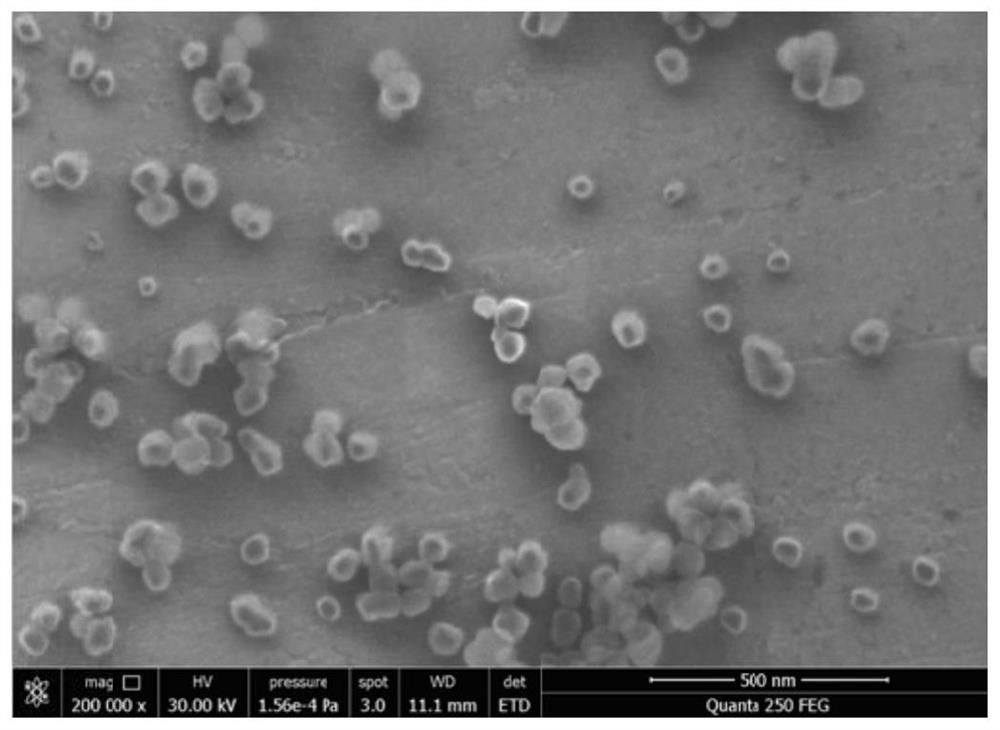

A kind of magnetic sandwich structure metal-organic framework material and its preparation method

ActiveCN109503858BImprove adsorption capacityEasy to fixOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMaterial synthesisNanoparticle

The invention discloses a magnetic sandwich structure metal-organic framework material and a preparation method, and belongs to the field of material synthesis. The material core of the present invention is MOFs, and the MOFs core is coated with a layer of nanometer Fe 3 O 4 particles, and nano Fe 3 O 4 There is a thin layer of MOFs outside the particles. The preparation method of the material of the present invention includes the following steps: MOF particles are placed in MOF precursor liquid and dispersed ultrasonically to obtain suspension A; 3 O 4 The particles and polyvinylpyrrolidone are dispersed in a polar solvent and dispersed ultrasonically to obtain suspension B; suspension A and suspension B are mixed and dispersed ultrasonically, and then heated with vibration in a water bath to obtain the prepared sandwich structure particles, which are separated by magnetic The desired granules are obtained, washed and dried. The material of the present invention can simultaneously ensure excellent adsorption and catalytic performance, and the adsorbed material can obtain better regeneration performance.

Owner:NANJING UNIV

A device for detritating tritiated water and its realization method

InactiveCN103936219BIngenious designReasonable structureMultistage water/sewage treatmentWater vaporProcess engineering

The invention discloses a device for tritiation removal of tritium-containing water and an implementation method thereof. The problems that a tritium-containing water tritiation removal device is complicated in process and high in energy consumption are solved by adopting the device. The device comprises a first liquefaction system, a steam heating device, a catalytic reaction section, a second liquefaction system and a product water collecting tank which are connected with one another from top to bottom in sequence, a steam generator connected with the steam heating device, and a raw water storage tank connected with the steam generator, wherein a hydrophilic catalyst is filled in the catalytic reaction section. The device disclosed by the invention is reasonable in structure, convenient and rapid in operation and high in tritiation removal efficiency, and can be used for transferring tritium into hydrogen from tritium-containing steam by virtue of a manner that the tritium-containing water and hydrogen flow reversely, thus realizing the tritiation removal of the tritium-containing water, and purifying the tritium-containing water; the device greatly reduces the energy consumption and cost, thus having very high application values.

Owner:SICHUAN INST OF MATERIALS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com